Page 1

PROFILO 500

PROFILO 500

Z 20° - 40°

Z 20° - 40°

User’s manual eng ver. 1.1

Page 2

2

Le informazioni contenute in questo documento sono state attentamente redatte e controllate.

Tuttavia non è assunta alcuna responsabilità per eventuali inesattezze. Tutti i diritti sono riservati e

questo documento non può essere copiato, fotocopiato, riprodotto per intero o in parte senza previo

consenso scritto della DTS .

DTS si riserva il diritto di apportare senza preavviso cambiamenti e modifiche estetiche , funzionali o di

design a ciascun proprio prodotto. DTS non assume alcuna responsabilità sull'uso o sull'applicazione

dei prodotti o dei circuiti descritti.

PROFILO 500

The information contained in this publication has been carefully prepared and checked. However, no

responsibility will be taken for any errors. All rights are reserved and this document cannot be copied,

photocopied or reproduced, in part or completely, without prior written consent from DTS.

DTS reserves the right to make any aesthetic, functional or design modifications to any of its products

without prior notice. DTS assumes no responsibility for the use or application of the products or

circuits described herein.

Les informations contenues dans le présent manuel ont été rédigées et contrôlées avec le plus grand

soin. Nous déclinons toutefois toute responsabilité en cas d'éventuelles inexactitudes. Tous droits

réservés. Ce document ne peut être copié, photocopié ou reproduit, dans sa totalité ou partiellement,

sans le consentement préalable de DTS.

DTS se réserve le droit d'apporter toutes modifications et améliorations esthétiques, fonctionnelles ou

de design, sans préavis, à chacun de ses produits. DTS décline toute responsabilité sur l'utilisation ou

sur l'application des produits ou des circuits décrits.

Las informaciones contenidas en este documento han sido cuidadosamenteredactadas y controladas.

Con todo, no se asume ninguna responsabilidad por eventuales inexactitudes. Todos los derechos han

sido reservados y este documento no puede ser copiado, fotocopiado o reproducido, total o

parcialmente, sin previa autorizaciónescrita de DTS.

DTS se reserva el derecho a aportar sin previo aviso cambios y modificaciones de carácter estético,

funcional o de diseño a cada producto suyo. DTS no se asume responsabilidad de ningún tipo sobre la

utilización o sobre la aplicació

n de los productos o de los circuitos descritos.

Page 3

3

INDICE

Technical features pag 3

Important Safety informations pag 4

Mounting the lamp pag 4

Voltage and frequency pag 5

Installation pag 5

Mains connection pag 6

Projector use pag 7

Open the unit pag 8

Cleaning and periodic controls pag 9

PROFILO 500

MADE IN ITALY

Page 4

4

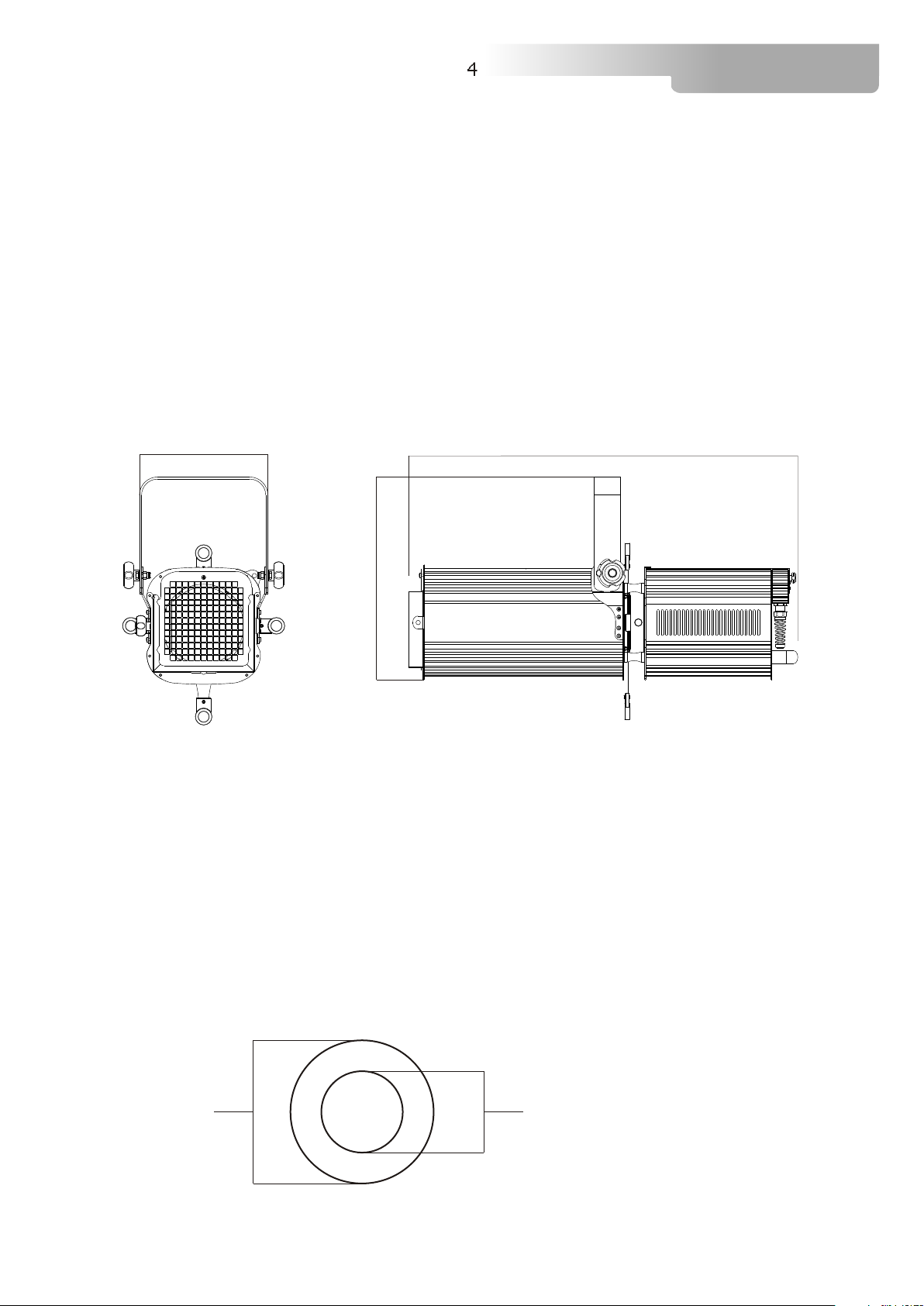

1- TECHNICAL FEATURES

Voltage: 230V 50/60 Hz

Lamp socket:GY9,5 500 W Lamp

IP grade protection: IP20

Steel boby with aluminium parts

2 lenses optic condenser

Linear Focus

Linear Zoom: 20°- 40 °

Metal Filter Holder: 150mm * 150mm

Metal protection grid

No internal Fans

Internal rotating profiler built up with four indipendent steel blades

Two internal microswitch for automatic unit switch during lamp substitution procedure

Weight : 11 Kg

Dimensions:

mm 205 mm 498

PROFILO 500

mm 290

PROFILO 500 BLACK COLOR D.T.S. COD.: 03.TP001

ACCESSORIES

Iris (cod. 03.TA2001)

Gobo holder (cod. 03.TA202) type “B”

Safety cable mm 3*600mm (cod. 0521A010)

Filters

C clamp G60 black (cod. 0521A004).

C clamp G60 chrome( 0521A004.20)

Gobo dimension

External diameter

86 mm max

Projected image diameter

48 mm max

Page 5

5

2- IMPORTANT SAFETY INFORMATIONS

2.1 Fire prevention:

- PROFILO 500 uses a GY9,5 500W lamp.

-Never locate the fixture on any flammable surface.

-Minimum distance from flammable materials: 1 MT.

-Minimum distance from the closest illuminable surface: 1 MT.

-Connect the projector to mains power via a thermal magnetic circuit breaker.

2.2 Prevention of electric shock:

-High voltage is present inside the unit. Unplug the unit prior to performing any function which

involves touching the inside of the projector, including lamp replacement.

-The level of technology present in the PROFILO 500 requires the assistance of specialised personnel

for all servicing. Please refer to an authorised DTS service centre.

-A good earth connection is essential for proper functioning of the projector.

-Never connect the unit without proper earth connection.

-The fixture should be located in places with a good air ventilation.

Never look directly into the lamp when it is on.

PROFILO 500

2.4 Safety:

-The projector should always be installed with bolts, clamps and other tools that are capable of

supporting the weight of the unit.

-Always use a second safety cable to sustain the weight of the unit in case of the failure of the main

fixing point.

-The external surface of the unit, at various points, may exceed 150°C. Never handle the unit until at

least 15 minutes have elapsed since the lamp was turned off.

-Always replace the lamp if any physical damage is evident.

-Never install the fixture in an enclosed area lacking sufficient air flow. The ambient temperature

should not exceed 35°C.

-A hot lamp may explode, so always wait for at least 15 minutes prior to attempting to replace the

lamp.

-Always wear suitable hand protection when handling the lamp.

2.5 Level of protection against the penetration of solid and liquid matter:

-The projector is classified as an ordinary appliance and its protection level against the penetration of

solid and liquid matter is IP 20.

3- MOUNTING THE LAMP

Warning: Switch off the unit before replacing the lamp.

Lamp:

CP82 GY9.5 500W 230/240V 12500 LM 3200 °K Life time 360 hours

T18 GY9.5500W 230/240V 11000 LM 3000 °K Life time 360 hours

T25 GY9.5500W 230/240V 11000 LM 3000 °K Life time 300 hours

Page 6

6

1): Loose the screw located on the rear side of the unit.

2)Open the top rear cover and insert the lamp.

The lamp used is manufactured from quartz glass and should be handled with care. Always adhere to

the instructions supplied in the lamp's packaging. Never touch the glass directly but use the tissue

provided in the lamp's packaging. The GX 9.5 lampbase is symmetrical.

DO NOT USE UNDUE FORCE ON THE GLASS. In case of difficulty, re-read the instructions and

repeat the procedure.

PROFILO 500

Pull

Close the cover and replace the screw. No lamp allignment needed

4- VOLTAGE AND FREQUENCY:

Profilo 500 can operate at 230V 50 - 60 Hz.

5- INSTALLATION:

PROFILO 500

For ceiling mounted installations, we reccomend the use of appropriate clamps to fix the unit to the

mounting surface.A safety cable must always be present

may be either floor or ceiling mounted.

Page 7

7

5.1 Ceiling installation

5.2 Floor installation

By Using a screw driver, remove the three screws fixing the bracket on both side of the unit.

Rotate the bracket by 180 ° and replace it on the opposite side of the unit.

Replace the screws.

PROFILO 500

5.3 Risk of fire:

Each fixture produces heat and must be installed in a well-ventilated place. The minimum

recommended distance from flammable material is 1 MT. Minimum distance from the object being

illuminated is 1,5 MT. Heat dispertion is done by natural ventilation

WARNING: The rear side of the unit,can reach very high temperature,

Handle the projector with extreme caution

5.5 Ambient temperature:

The projector should never be installed in places that lack a constant air flow. The ambient

temperature should NOT exceed 35°C.

6- MAINS CONNECTION

PROFILO 500 can operate at 230 VOLT 50-60 Hz.Prior to connecting the unit to your mains supply,

ensure that the model in your possession correctly matches the mains supply available. For

connection purposes, ensure that your plug is capable of supporting 6 amps at 230V,

Strict adherence to regulatory norms is strongly recommended.

6.1 Protection:

The use of a thermal magnetic circuit breaker is recommended for each PROFILO 500.

A good earth connection is essential for the correct operation of the projector.

,no fans installed inside the unit.

.

Page 8

8

PROFILO 500

7) PROJECTOR USE

7.1 Focus and Zoom adjustment.

In the front side of the unit are located the lenses for Focus and zoom adjustment.

Place the projector on the object to illuminate,loose the fixing lenses screws, adjust the lens position

till the projection is whell focused on the object.Thighten the screws The aluminiun external label with

.

the numers 0-9,indicates the actual position of the lenses ,the numbers are not indicatind the beam

opening angle in degree.

Zoom and Focus movement

7.2 Blades

Prifilo 500 is provided with four indipendent steel blades.Blades holder can rotate 90° left-right.

The blades let you create geometrical figures with the light.

Blade

Light beam with no blades inserted

Light beam with blades inserted

7.3 Blades insertion

To insert the blades in the holder,proceed as follow:

ocate the blades holder,place one side of the blade within the two parallel surfaces,push and tilt it on

the guideL.

Blades holder

Parallel surfaces

Blade inserted

Page 9

9

7.4 Accessories use (iris and gobo holder)

Profilo 500 can be provided also with iris and type B gobo holder

7.5 Iris insertion

Insert the iris in the support and lock it with the screw located on the left side.

Iris blades toward the lamp

PROFILO 500

Rear side PROFILO 500

Iris/Gobo holder lock screw

7.6 Gobo holder insertion

Insert the gobo in the support and lock it with the screw located on the left side.

8) APERTURA DEL PROIETTORE:

L'apparecchio consente di eseguire una completa ispezione delle parti interne del corpo proiettore,

rimuovendo i carter come di seguito indicato.

Attenzione: benchè il proiettore sia dotato di microinterruttori di corrente a sgancio automatico

all’apertura del cofano posteriore si consiglia vivamente di TOGLIERE TENSIONE PRIMA DI APRIRE

L'APPARECCHIO

PARTE POSTERIORE - ALIMENTAZIONE

Per eseguire l’ispezione della parte posteriore (parte di alimentazione ) del proiettore procedere

come indicato. Togliere la tensione elettrica, svitare ed estrarre il pomello posto nella parte posteriore

del proiettore; fare scorrere il cofano come indicato in fotografia.

Apertura

Page 10

10

PROFILO 500

PARTE ANTERIORE (GRUPPO LENTI FOCUS-ZOOM)

Per procedere all’ispezione della parte anteriore (dove sono posizionati il gruppo lenti focus e zoom)

è sufficiente far scorrere i coperchi superiori (vedi foto)

Apertura

Apertura

9) PULIZIA E CONTROLLI PERIODICI

9.1 Pulizia delle lenti

La polvere può ridurre in modo sostanziale la resa luminosa ed alterare la compattezza del fascio:

pulite dunque regolarmente le lenti, utilizzando un panno morbido o del cotone, inumiditi con un

liquido detergente specifico per la pulizia del vetro.

9.2 Controlli periodici:

Parti meccaniche:

Controllate che il proiettore non sia meccanicamente danneggiato. Se necessario, sostituite le parti

deteriorate.

Parti elettriche:

Controllate i collegamenti elettrici, in particolare la messa a terra ed il corretto funzionamento dei

microinterruttori.

ATTENZIONE :Togliete tensione prima di aprire l'apparecchio.

Microinterruttori; controllarne

periodicamente il corretto

funzionamento

Page 11

NOTE:NOTE:

11

PROFILO 500

Page 12

The information contained in this publication has been carefully prepared and checked.

However, no responsibility will be taken for any errors. All rights are reserved and this document

cannot be copied, photocopied or reproduced, in part or completely, without prior written consent

from D.T.S.

D.T.S. reserves the right to make any aesthetic, functional or design modifications to any of its

products without prior notice. D.T.S. assumes no responsibility for the use or application of the

products or circuits described herein.

MADE IN ITALY

*0517I124*

*0517I124*

D.T.S. Illuminazione s.r.l - Via Fagnano Selve 10-12-14 47843 - Misano Adriatico (RN) Italy

Tel. +39 0541 611131 Fax +39 0541 611111 info@dts-lighting.it www.dts-lighting.it

Loading...

Loading...