SLIM II photocell

MOUNTING INSTRUCTION

1. Principle of operation

Photocell includes transmitter and receiver (fig.1). The transmitter emit a coded Irfrared (IR) signal

invisible to the naked eye. Obstacle appearance (e.g. car) on photocell working area produces a

detection signal on receiver output. Receiver has NC and NO type output contacts, the circuit is protected

by additional relay. Photocell is destined to work in gate automation system as external element.

2. Technical data.

4 Guaranteed range 1-15 m

4 Angle of view adjustment horizontally 200° in receiver and transmitter

4 Power suplly of transmitter and receiver 12-24V AC/DC

(synchronization option requires AC supply)

4 Current consumption of transmitter max. 25 mA

4 Current consumption of receiver max. 25 mA

4 Working temperature (min. / max.) -20°C / +55°C

4 Outside dimensions (WxDxH) 35 x 30 x 110 mm

4 Mounting surface mounted splash proof case - Ip54

4 Output contacts NO and NC

v.1.4

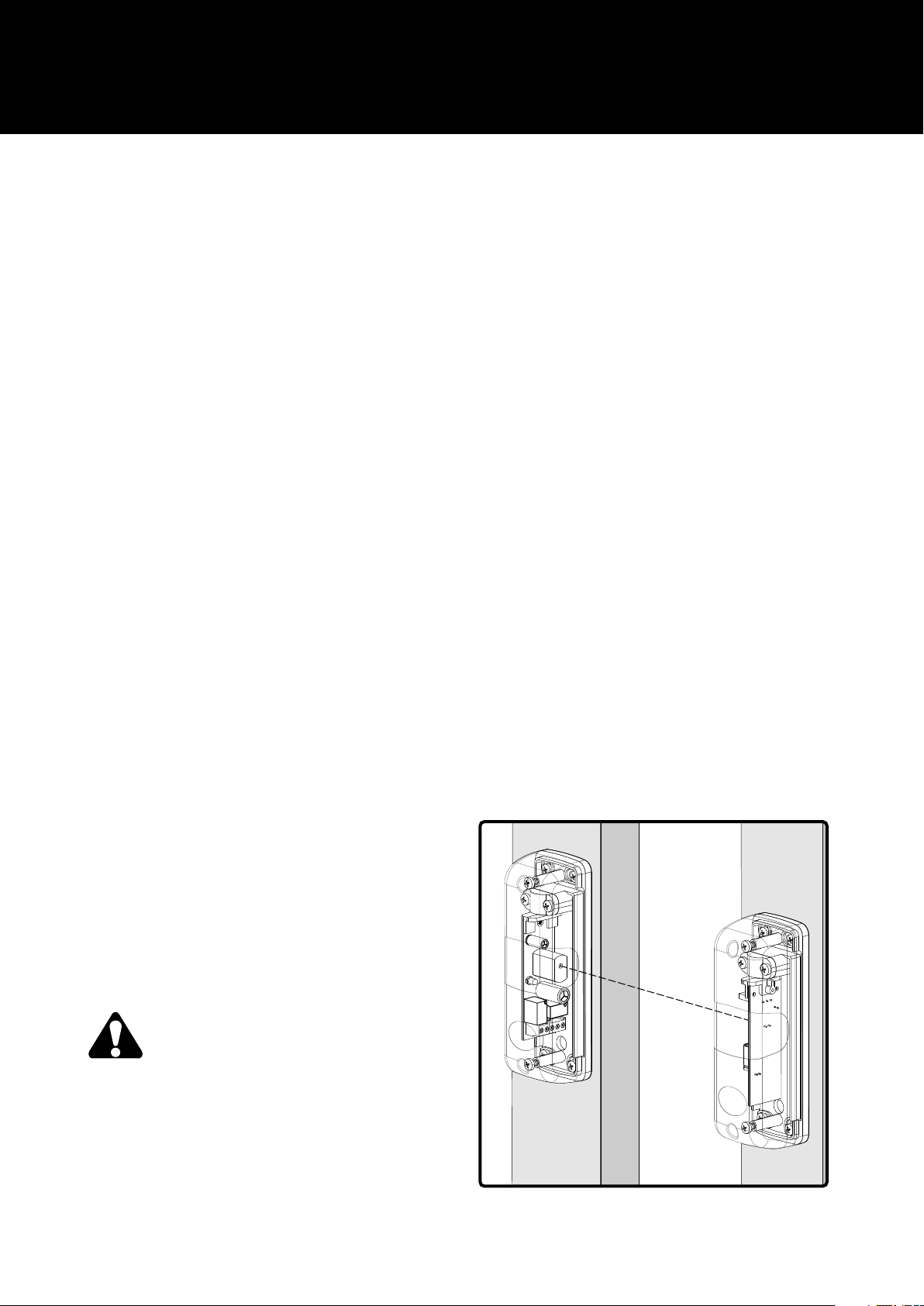

3. Photocell mounting.

For proper funcionality photocell must be mounted 40-60 cm off the ground, receiver and

transmitter distance not less than 1 m. Photocell has angle of view adjustment in receiver and transmitter.

Coaxial mounting is unnecessary. Give consideration to electric boards maximum angle of rotation inside

transmitter and receiver enclosure. Because of photosensitive elements it is recommended to mount

receiver on less sun exposure side. Both receiver and transmitter must be mounted vertically. Terminal

blocks and humidity carrying openings should be in the bottom part of enclosure. Proper receiver and

transmitter adjustment is facilitated by receiver's green diode RX. RX diode lights when transmitter ray

reaches receiver. Both enclosures should be mounted by 2 (diagonal mounting) or 4 screws available in

set.

Transmitter

TX

max 15 m

min 1m

Do not mount mirrors or reflection

screens in photocell's working area, if

possible mount the receiver on the less

exposed to the sun side, do not mount the photocell

receiver in a location exposed to strong light source

of stray light, especially fluorescent light, it can

inter f e r e t h e b a r rier. B e w are of o p tical

receiver/tra nsmit ter elements soiling wh ile

mounting.

Receiver

RX

Fig.1. Exemplary receiver - transmitter location

SLIM II photocell

MOUNTING INSTRUCTION

4. Photocell connection

Photocell cooporates with most of gate controllers available on market.

It is recommended to do electrical installation and photocell mounting by qualified person.

Connect photocell according to Fig. 3 scheme

and description below.

Without synchronization function

4Make sure the ZW jumper on the transmitter and

receiver are mounted.

4Connect the power supply 12-24V AC/DC to

photocell transmitter and receiver. POWER LEDs

on the transmitter and the receiver, and RX LED on

the receiver should light up.

4If you use the AC power supply to power the

transmitter and receiver use the same phase (with

one power supply)

4Connect the output signal of photocell (usually NC

and C) to proper inputs on the control unit. Pay

particular attention to the type of control (NC or NO)

required in the control panel. The standard solution

for gate automation is to work with optical sensors in

the NC.

2

1

With the use of synchronization function

Using synchronization function, you can

install two pairs of photocells with the

overlapping area of the optical range.

To use the synchronization function, you

must cut the ZW jumper in photocell transmitter and

receiver, and supply them with alternating voltage

(12-24V AC).

Connect the same wire to the terminal marked "1" on

the transmitter and the receiver of the first pair of

photocells. If swap wires only on the transmitter side

or only on the receiver side, will result in no action of

photocells. The second pair of photocells must be

powered by the same phase as the first, but wires in

the supply line of transmitter and receiver must be

swap. (the power wire connected to the terminal

marked "1" in the first pair of photocells, must be

swap with the next wire in the second pair of

photocells).

o

200

18 mm

93 mm

8 mm

USE THIS FIGURE AS A TEMPLATE

Description:

1. splash-proof cover

2. hole for wires =7mm

Fig. 2 Distance of the mounting holes

on a scale of 1:1, with the assembly drawing.

Power supply: 12-24V AC/DC Working Temp.: -20°C / +55°C

Current consumption: max. 25mA Cover IP: 54

Range: 1 - 15m Dimensions: 35x30x110mm

In case of problems with identifying the AC power cable, you can use the following

procedure, in order to connect two pairs of photocells located in one area of the optical range:

4make sure the jumper labeled 'ZW' in transmitters and receivers of both pairs of photocells are cut

(open),

4Connect the power supply 12-24V AC (alternating) to the transmitter and the receiver of the first pair of

photocells. POWER diode should light on the transmitter and receiver, as well as the RX diode on the

receiver. If the RX diode is off, swap wire only on the transmitter side or only on the receiver side. If the

RX diode still not light, it means that the receiver can not "see" the ray of the transmitter - adjust the

position of the transmitter or receiver and, if necessary, repeat this step.

4supply power to the receiver of the second pair of photocells. The result should be to light only the

POWER diode on the receiver. RX diode should remain off (meaning no reaction of the receiver of the

second pair of photocells on the ray from the transmitter of the first pair of photocells). If the RX diode is

light, swap the receiver supply wire.

4Supply power to the transmitter of the second pair of photocells. The POWER diode on the transmitter

should light, the RX diode on the receiver of second pair of photocells should also light up. If the RX diode

is off, swap the transmitter supply wire.

4Connect the photocell receiver signal terminals (usually NC and C) to the proper input of the control

unit. Pay particular attention to the type of control (NC or NO) required in the control panel. The standard

solution for gate automation is the work in optical sensors in the NC.

5. Receiving tests.

After photocell connection is done, it is recommended to check receiver (RX) reaction on Irfarared

signal breaks. Gate automation systems must be tested conformity to EN 12445 standard.

Photocell test:

4Supply power to receiver only and check if RX diode out.

4Supply power to transmitter and check if RX diode light.

4Displace roller of 5 cm diameter and 30 cm length, to break perpendiculary optical axis between

receiver and transmitter. First in the vacinity of transmitter TX, next in the vacinity of receiver RX,

next in the middle of distance between them. In all cases photocell should switch from standby to

alarm mode, which is signalized by RX diode wane.

6. Warranty.

DTM System checks all the devices before shipping. The warranty time is 24 months from the

selling date. This time is counted according to the warranty label. The manufacturer will fix all the

problems which come because of his fault. Non functionaing device should be delivered back to the

distributor with short problem description. The cost of mount/dismount is covered by user. The warranty

do not cover: batteries in the remotes, faults caused by improper usage, user self reairs and adaptations,

lightning strikes, over voltages or short circuits in the mains supply. Appropriate legal acts regulates

details of the warranty.

The intention of the WEEE Directive (Directive 2002/96/EC on waste electrical and electronic

equipment) is to reduce the amount of hazardous substances in waste.

The underlying purpose is to promote the avoidance, recovery and risk-free disposal of waste.

DTM System spółka z ograniczoną odpowiedzialnością spółka komandytowa

ul. Brzeska 7, 85-145 Bydgoszcz

tel./fax. (52) 340-15-83, 340-15-84

www.dtm.pl, dtm@dtm.pl

Transmitter - TX

jumper

**

LO POWER

terminal

numer “1”

*jumper ZW

ZW

1

1

AC/DC

12-24V

transmitter - TX

1

1

AC/DC

12-24V

Pair 2

Receiver - RX

*jumper ZW

terminal

**

LO POWER

Sygnalization:

POWER

ZW

terminal

terminal

no. “1”

ZW

no. “1”

1

*jumper ZW

1

receiver - RX

1

1

NC C NO

terminal description

* wires swap in the supply line

between two pair of photocell

Transmitter - TX

Pair 1

CONNECTION SCHEME

ZW

1

Receiver - RX

RX

POWER

Terminal

sygnalization:

For the synchronation function, use only the power supply voltage alternating current (AC) and cut the ZW jumper in transmitter and receiver of both pairs of photocells.

*

To do this, cut the LO POWER jumper in transmitter.

When using photocells in a place where interfere due to reflections from walls or other items reduce the power of the transmitter.

Swap wires in the supply line in one pair of photocell.

**

Control board

*jumper ZW

numer “1”

*

1

CONTROL SIGNAL 2

CONTROL SIGNAL 1

photocell 2 (NC)

signal INPUT 2

photocell 1 (NC)

singal INPUT 1

12-24V AC/DC

accessories supply OUTPUT

POWER SUPPLY, polarity irrelevant

Fig. 3 Wiring diagram to connect the photocell without synchronization (1 pair)

and using the synchronization function (two pairs of photocells).

Loading...

Loading...