Page 1

phoyocell FOCUS / FOCUS FLASH

MOUNTING INSTRUCTION

1. Principleofoperation.

Photocell includestransmitter and receiver(fig.1).Thetransmitter emit acoded Irfrared

(IR) signal ,invisible to thenakedeye.Obstacle appearance (e.g. car)on photocell workingarea

produces a detection signal on receiver output. Receiver has NC and NO type output contacts.

Photocell is destined to work in gate automation system as external element. Built-in signal

lampsinboth,receiverandtransmitter,suppliedwith24V,fulfillsignalfunctioningatesystem.

2.Technical data.

•Guaranteed range 1-15m

•Powersupply oftransmitter and receiver 24VAC/DC

•Current consumptionof transmitter 2x25mA

• Powersupply ofsignal lamp 24VAC/DC

•Current consumtionof signalization lamp 2x40mA

•Workingtemperature (min./ max.) -20°C / +55°C

• dimensions(szer.x głęb.x wys.) 62x28x100mm

• Mounting surfacemounted,IP54

• Output contacts typuNOi NC

v.3.0

3. Photocellmounting.

For proper funcionality photocell must be mounted coaxial, 40-60 cm off the ground,

receiver and transmitter distance not less than 1 m . Because of photosensitive elements it is

recommended to mountreceiver onless sun exposure side.Both receiverand transmitter must

be mounted vertically. Terminal blocks and humidity carrying openings should be in the

bottom part of enclosure. Proper receiver and

transmitter adjustment is facilitated by

receiver's diode RX. RX diode lights when

transmitter ray reaches receiver. Both

enclosures should be mounted by 2 (diagonal

receiver - RX

LED signalling

LED signalling

RX

POWER

POWER

transmitter - TX

mounting) or 4 screws available in set. To scale

down photocell sensitivity (minor receiver and

Terminal blocks

transmitter distance) it is recommended to

dismounttransmitter'slens.

RX TXmax 15 m.

min 1 m.

Fig. 1 Receiver - transmitter location

DTM System spółka z ograniczoną odpowiedzialnością spółka komandytowa

ul. Brzeska 7, 85-145 Bydgoszcz, POLAND

tel./fax. (52) 340-15-83, 340-15-84

www.dtm.pl, dtm@dtm.pl

Page 2

phoyocell FOCUS / FOCUS FLASH

MOUNTING INSTRUCTION

Do not mount mirrors or reflection screens in photocell's working area

Bewareofopticalreceiver/transmitterelementsstaining whilemounting.

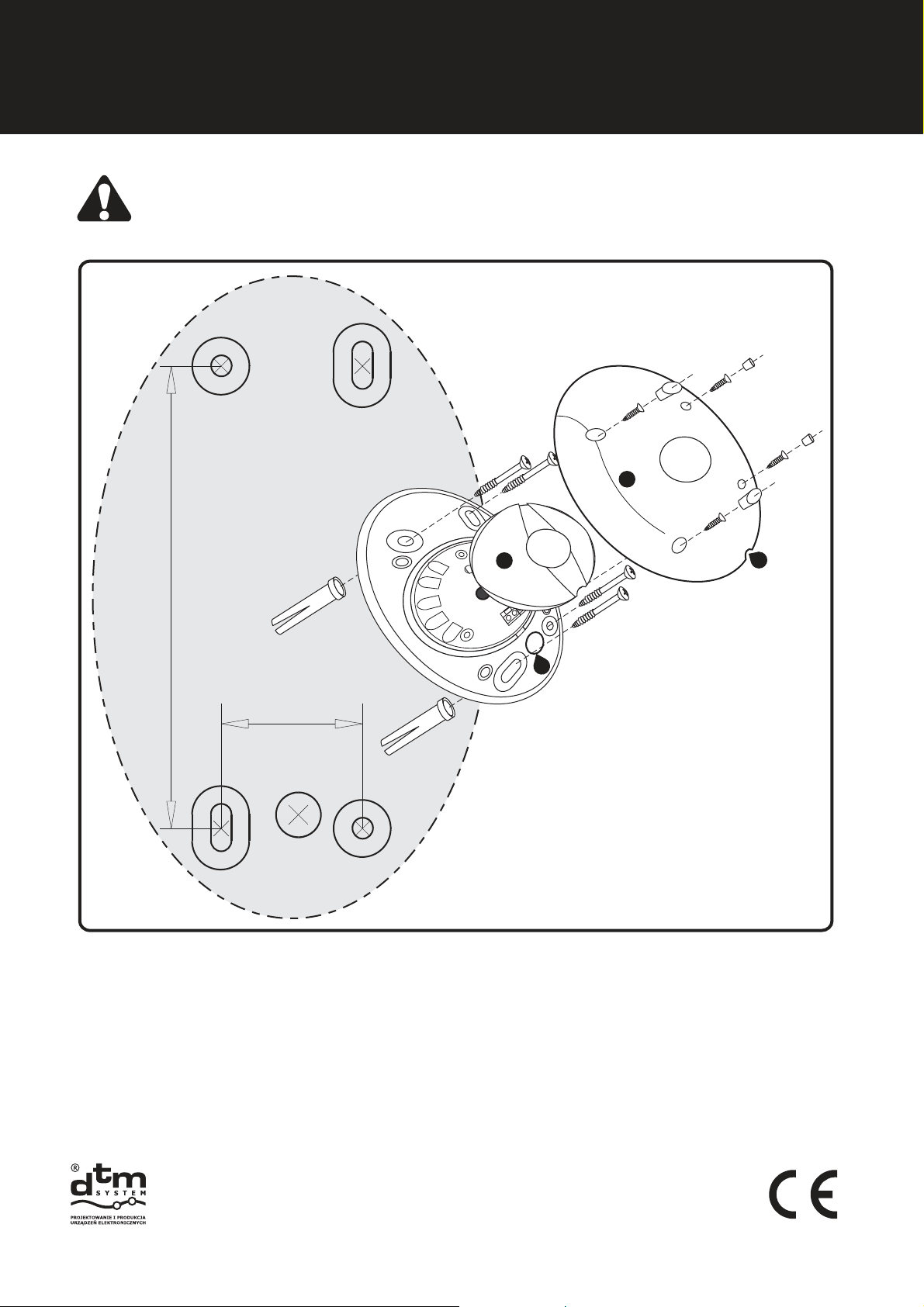

1

3

2

72 mm

4

22 mm

Legend:

1. Cover

2. Humidity carrying opening

3. Splash proof internal bowl

4. Signal conduits opening =6mmf

USE THIS FIGURE

AS A TEMPLATE

Fig. 2 Assembly dimentions - scale 1:1, transmitter (receiver) assembly drawing

4. Photocellconnection

Photocell cooperates with most of gate controllers available on market. It is

recommended to do electrical installation and photocell mounting by qualified person.

Connect photocell according to fig. 3 scheme. First find 24V AC/DC clips (polarity is not

important!) intended to power supply, in gate controller. Connect power supply to receiver

and transmitter.When power is on red LED’s (POWER) in receiver and transmitter light. Next

connect gate controllerinput to photocell'sreceiver output (RX pins: 1,2or 2,3). Payattention

DTM System spółka z ograniczoną odpowiedzialnością spółka komandytowa

ul. Brzeska 7, 85-145 Bydgoszcz, POLAND

tel./fax. (52) 340-15-83, 340-15-84

www.dtm.pl, dtm@dtm.pl

Page 3

CONNECTION SCHEME

to controller's input type(NC orNO). Photocells usually workswith NCmode ingate automatic.

It is recommended to connect signal lamps parallely, supplied with 24V AC/DC, current

consumptionab.80mA.

5.Receivingtests

After photocell connection isdone, itis recommendedto checkreceiver(RX) reaction on

Inrfarared signal breaks. Gate automation systems must be tested conformity to EN 12445

standard. Photocell test: 1. Supply power to receiver only and check if RX diode out. 2. Supply

power totransmitter andchceck ifRX diodelight. 3. Displace roller of 5 cm diameter and 30 cm

length, to break perpendicularly optical axis between receiver and transmitter. First in the

vacinity of transmitter TX, next in the vacinity of receiver RX, next in the middle of distance

between them. In all cases photocell should switch from standby to alarm mode, which is

signalizedbyRXdiodewane.

transmitter - TXreceiver - RX

Gate controller

Peripherial supply OUTPUT

Signal lamp OUTPUT

24V AC/DC (min.80 mA)

- max. external diameter of conduits - 6mm,

- recommended twisted pair 4 x 2 x 0,5

in case of underground electrical installation use

gel-filled cable!

24V AC/DC

signal INPUT

photocell (NC)

COMMAND SIGNAL

POWER SUPPLY, polarity is not important

SIGNAL LAMP, polarity is not important

POWER SUPPLY

SIGNAL LAMP

1 2 3 4 5 6 7

LAMP

C NO

24V

AC/DC

24V

AC/DC

NC

transmitter - TXreceiver - RX

2 3 4

1

24V

LAMP

AC/DC

24V

AC/DC

Fig. 3. Photocell connection electric scheme

DTM System spółka z ograniczoną odpowiedzialnością spółka komandytowa

ul. Brzeska 7, 85-145 Bydgoszcz, POLAND

tel./fax. (52) 340-15-83, 340-15-84

www.dtm.pl, dtm@dtm.pl

Page 4

phoyocell FOCUS / FOCUS FLASH

MOUNTING INSTRUCTION

6.Warranty.

DTM System checks all the devices before shipping. The warranty time is 24 months

from the selling date. This time is counted according to the warranty label. The manufacturer

will fix all the problems which come because of his fault. Non functionaling device should be

delivered back to thedistributor withshortproblem description.The costof mount/dismountis

covered by user.The warrantydo not cover:batteries inthe remotes, faults causedby improper

usage, user self repairs and adaptations, lightning strikes, over voltages or short circuits in the

mainssupply.Appropriate legalacts regulates details of the warranty.

The intention of the WEEE Directive (Directive 2002/96/EC on waste electrical and electronic

equipment) is to reduce the amount of hazardous substances in waste.

The underlying purpose is to promote the avoidance, recovery and risk-free disposal of waste.

DTM System spółka z ograniczoną odpowiedzialnością spółka komandytowa

ul. Brzeska 7, 85-145 Bydgoszcz, POLAND

tel./fax. (52) 340-15-83, 340-15-84

www.dtm.pl, dtm@dtm.pl

Loading...

Loading...