DTM Print LX910e Service Manual

User's Manual

© 2018 All rights reserved

Notices: The information in this document is subject to change without notice. NO WARRANTY OF ANY

KIND IS MADE WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. No liability is assumed for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material. This document

contains proprietary information that is protected by copyright. All rights are reserved. No part of

this document may be photocopied, reproduced, or translated into another language without prior written

consent.

Trademark Acknowledgments: Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

Printing History

Edition 1.0, 061318, Copyright 2018, All rights reserved.

FCC Compliance Statement: This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

For Users in the United States: This product is intended to be supplied by a UL listed Direct Plug-In Power

Supply marked "Class 2"or a UL listed ITE Power Supply marked "LPS" with output rated 12VDC, 5A or

higher. This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. In a domestic environment this product may

cause radio interference, in which case the user may be required to take adequate measures. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Use of shielded cables is required to comply with the Class B limits of Part 15 of the FCC Rules.

You are cautioned that any changes or modifications not expressly approved in this manual could

void your authority to operate and/or obtain warranty service for this equipment.

For Users in Canada: This digital apparatus does not exceed the Class B limits for radio noise for

digital apparatus set out on the Radio Interference Regulations of the Canadian Department of

Communications. Le present appareil numerique n'emet pas de bruits radioelectriques depassant

les limites applicables aux appareils numeriques de la class B prescrites dans le Reglement sur le brouillage

radioelectrique edicte par le ministere des Communications du Canada.

Product Disposal

Do not dispose of the printer or supplies in the same manner as normal household waste. Consult your local

authorities for disposal and recycling options.

Battery Notice

This product contains Perchlorate material. Special handling may apply. For more information, go to http://

www.dtsc.ca.gov/hazardouswaste/perchlorate/

WARNING

THE PRINT AREA CONTAINS HAZARDOUS MOVING PARTS. KEEP FINGERS AND OTHER BODY

PARTS AWAY.

CAUTION!

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THE UNIT TO RAIN OR

MOISTURE. TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE EXTERIOR PANELS.

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL. OPERATE THE UNIT WITH ONLY THE PROPER ELECTRICAL

SPECIFICATIONS AS LABELED ON THE PRINTER AND AC ADAPTER.

CAUTION!

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION.

CAUTION!

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

ii

Provided by:

©2019, DTM Print GmbH

More information: http: //dtm-print.eu

DTM Print GmbH

Mainzer Strasse 131

65187 Wiesbaden/Germany

Tel.: +49 (0) 611 92777-0

Fax: +49 (0) 611 92777-50

Email: sales@dtm-print.eu

Web: http://dtm-print.eu

iii

Table of Contents

Section 1: Getting Started ...............................................................................1

A. Choosing a Good Location ................................................................1

B. Unpacking and Inspection ................................................................2

C. Identifying the Parts ...........................................................................3

Section 2: Label Stock .....................................................................................6

A. Label and Roll Specifications ............................................................6

B. Installing Label Stock ......................................................................... 9

C. Adjusting Gap Sensor Position........................................................ 12

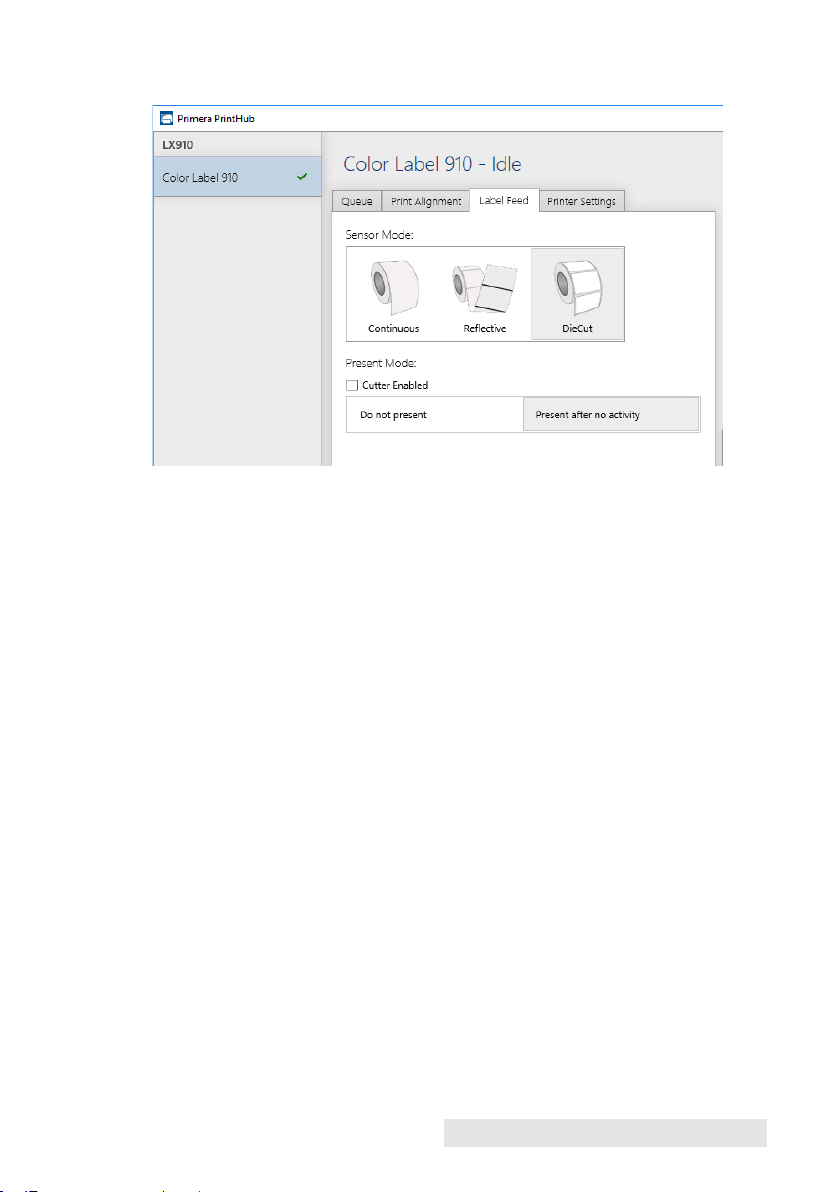

D. Set the Stock Sensor Mode ..............................................................13

E. Set the Present/Cut Mode...............................................................15

Section 3: Primera PrintHub ........................................................................18

A. Monitoring Ink Levels .....................................................................19

B. Using the Cost Estimator .................................................................19

C. Replacing Ink Cartridges/Low Ink Warning............................... 20

Section 4: Printing from a PC ......................................................................23

A. Using BarTender

B. Add Text, Barcodes and Graphics to a BarTender Label ...........29

C. Printing from BarTender .................................................................30

D. Printing from Other Programs .......................................................31

E. Adjusting Print Alignment ............................................................. 32

F. Creating a Full Bleed Print .............................................................. 34

G. Printer Driver Settings .....................................................................35

Section 5: Printing from a Mac ....................................................................39

A. Printer Utility Settings (LX910eConfig) ........................................39

B. Adjusting Print Alignment/Label Offsets .................................... 41

C. Set the Stock Sensor Mode ..............................................................43

D. Set the Output Mode ........................................................................ 44

E. Printing from Belight Labels and Addresses ...............................46

F. Create a Custom Label Size/Print from other Programs ........... 53

G. Creating a Full Bleed Print ..............................................................54

H. Printer Driver Settings ..................................................................... 55

Section 6: Troubleshooting and Maintenance .........................................57

A. Solving Print Alignment Problems ................................................57

B. Solving Print Quality Problems......................................................60

C. Color Matching and Design Tips ................................................... 62

D. Poor Print Quality – Cleaning the Cartridge ...............................64

E. Interpreting the Printer’s Indicator Lights ...................................67

F. Technical Support ............................................................................. 68

Section 7: Technical Specifications ............................................................69

Index ................................................................................................................. 70

iv

...........................................................................23

Section 1: Getting Started

THANK YOU…

... for choosing an LX910e Color Label Printer. The LX910e Printer

will print razor-sharp text and barcodes, vibrant colors, and even

stunning photo-realistic photographs directly onto rolls

of labels, card stock and a variety of other approved media.

This User's Manual is your complete step-by-step guide to quickly

and easily setting up and printing with your new Color Label

Printer!

A. CHOOSING A GOOD LOCATION

• Place the printer on a flat surface in a location with

adequate air circulation to prevent internal heat build up.

• Do not place the printer near heat sources such as radiators or

air ducts, or in a place subject to direct sun light,

excessive dust, mechanical vibration or shock.

• Allow for adequate clearance in front of the printer to

accommodate the printed label stock as it is leaving the printer

to avoid the possibility of binding or jamming of the label stock.

• Allow for adequate overhead and left side clearance for opening

the top cover to allow easy access to the label stock and ink

cartridge. The printer will require 24 cm (9.5 inches) of

additional space on the left side to completely open the cover

(Total = 68 cm or 26.75"). The printer will require an additional

40.4 cm (15.9 inches) of overhead space to open the cover (Total

= 63.5 cm or 25").

Getting Started 1

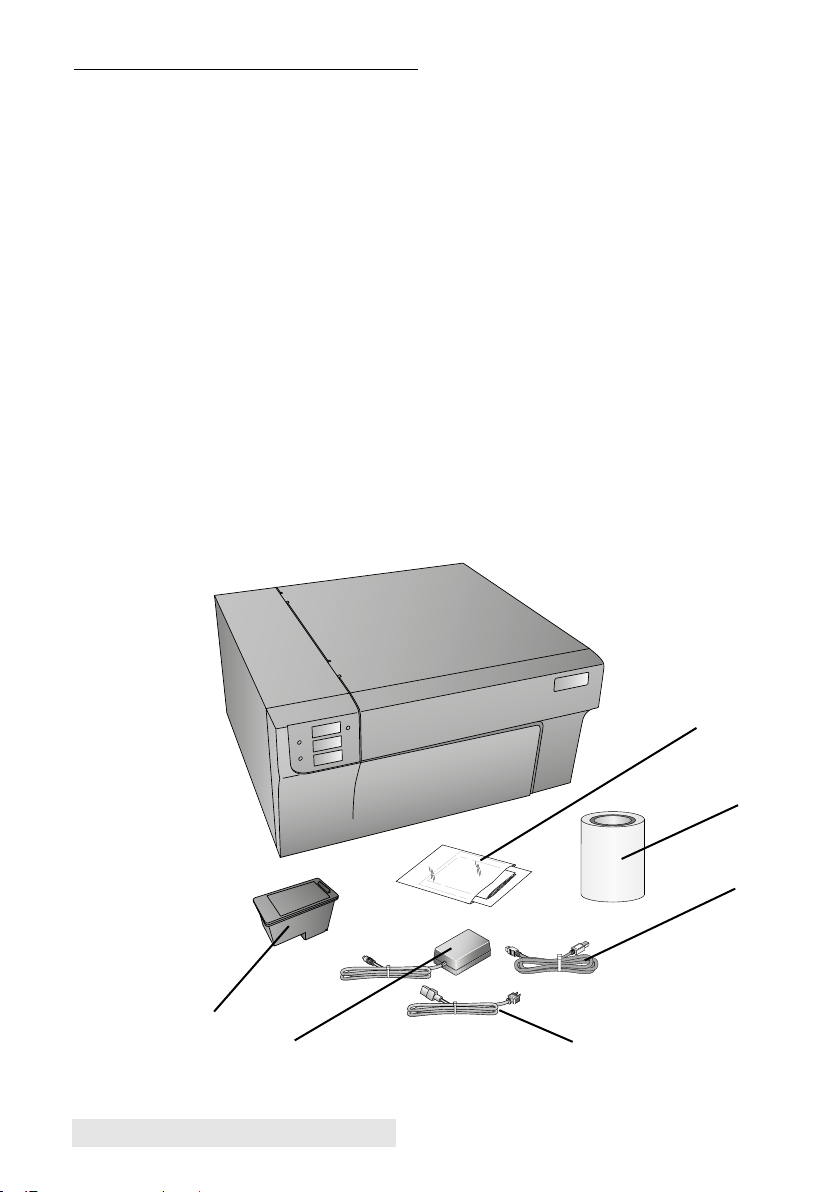

B. UNPACKING AND INSPECTION

While unpacking your printer, inspect the carton to ensure

that no damage has occurred during shipping. Make sure

that all supplied accessories are included with your unit.

The following items are included in the supply box:

1. Power Adapter

2. Separate Power Cord

3. 2 m USB Cable (If other USB cable is used, it must be 2 m (6")

or less.)

4. Color Dye Ink Cartridge Part Number 53492

5. Warranty Statement and Registration Card

The following items are inside the printer supply roll area:

6. Starter Roll of Primera Paper High Gloss Label Stock

Save the carton and packing materials. They will come in handy

when transporting the printer.

4

Also available sold separately: Pigment Ink Cartridge Part Number 53493

2 Getting Started

5

6

3

1

2

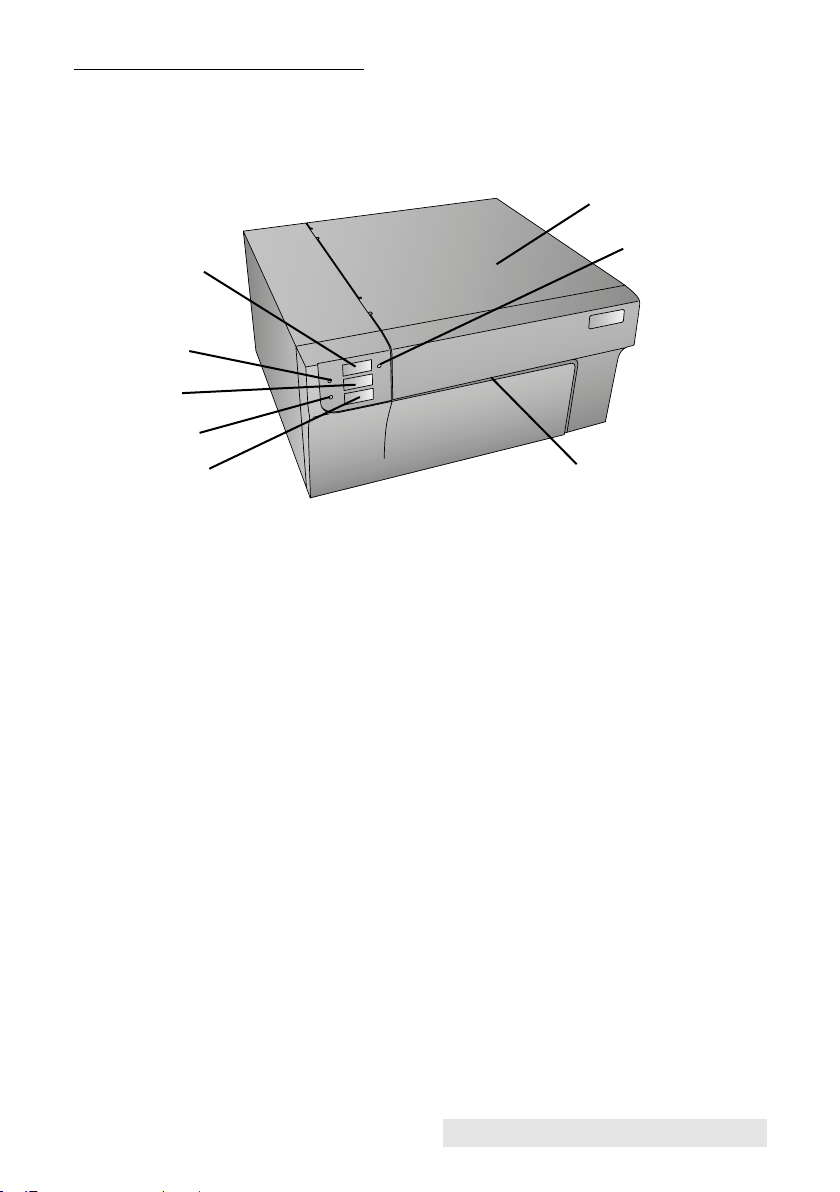

C. IDENTIFYING THE PARTS

This illustration shows the front of the printer with its control

buttons and LED indicator lights.

Top Cover

Pause Button

Power LED

Load/Feed

Button

Ink Low LED

Unload Button

The Pause Button is pressed to pause a job to allow for loading of

label stock and ink cartridges. The printer pauses after the printing

of the current label has finished. The Pause LED will illuminate

when the printer is paused.

The Power LED indicates that the printer is on and ready to receive

print jobs.

The Load/Feed Button is pressed in order to load label stock if the

printer does not automatically detect the stock. When stock is

loaded each press of the button will cause one label to be fed

through the printer.

The Ink Low LED will illuminate when a cartridge has 10% or less

of its ink remaining.

The Unload Button will unload the installed label stock by reversing

it through the printer. Make sure to tear off the

printed labels before pressing the Unload Button.

The Label Tear Bar is a serrated edge for conveniently tearing your

finished labels from the printer. The printer comes with a white tear

bar guard. For smoother label feeding, leave the guard in place

during printing. When you are ready to tear off a label, remove the

guard, tear off the label and replace the guard.

Pause LED

Label Tear Bar

Getting Started 3

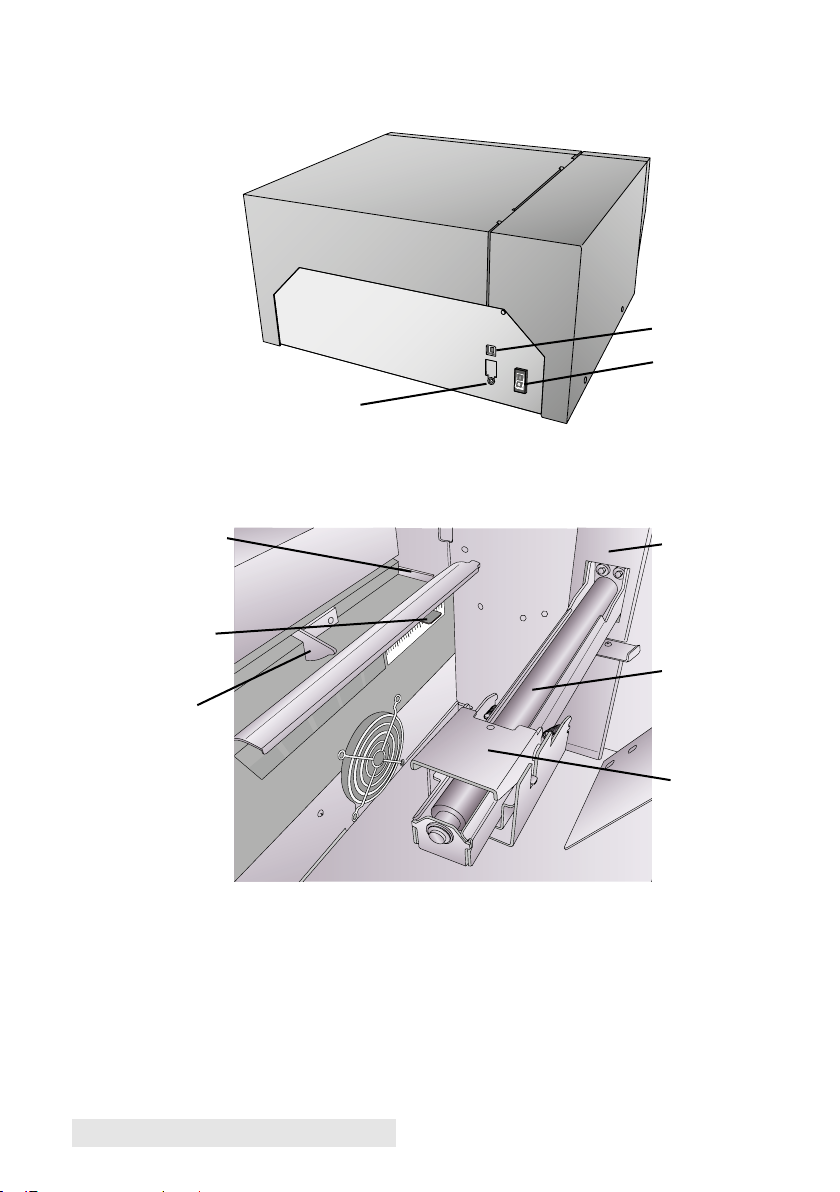

This illustration shows the input ports and power switch found

on the rear panel of the printer.

USB Port

Power Switch

Power Input Port

The next two illustrations show the interior of the printer.

Fixed Throat

Guide

Sensor

Adjustment

Movable

Throat Guide

Roll Stop

1.0

1.5

2.0

2.5

Roll Arm

Roll Guide

4 Getting Started

Grit Roller

Cutter Track

Removable Panel to

clear label jams

Cartridge

Carrier

Pressure Rollers

Cutter Wheel Replacement

Access Port

Getting Started 5

Section 2: Label Stock

A. LABEL AND ROLL SPECIFICATIONS

A wide variety of label stock can be used in the printer. Refer

to the specifications and settings in the following sections

before ordering custom stock from Primera or any stock from

another company.

Important! Test all custom made label stock with the intended printer

before ordering large quantities! Primera will only assume responsibility for custom label stock ordered from Primera.

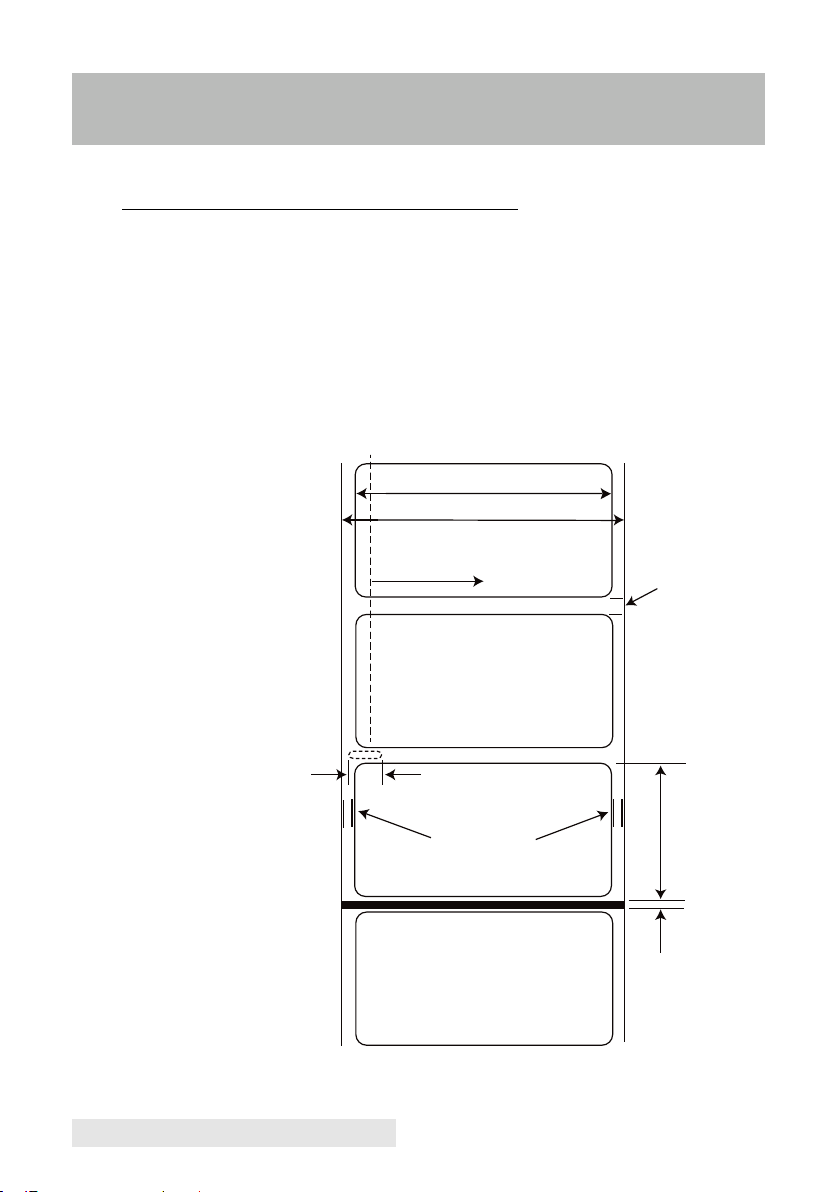

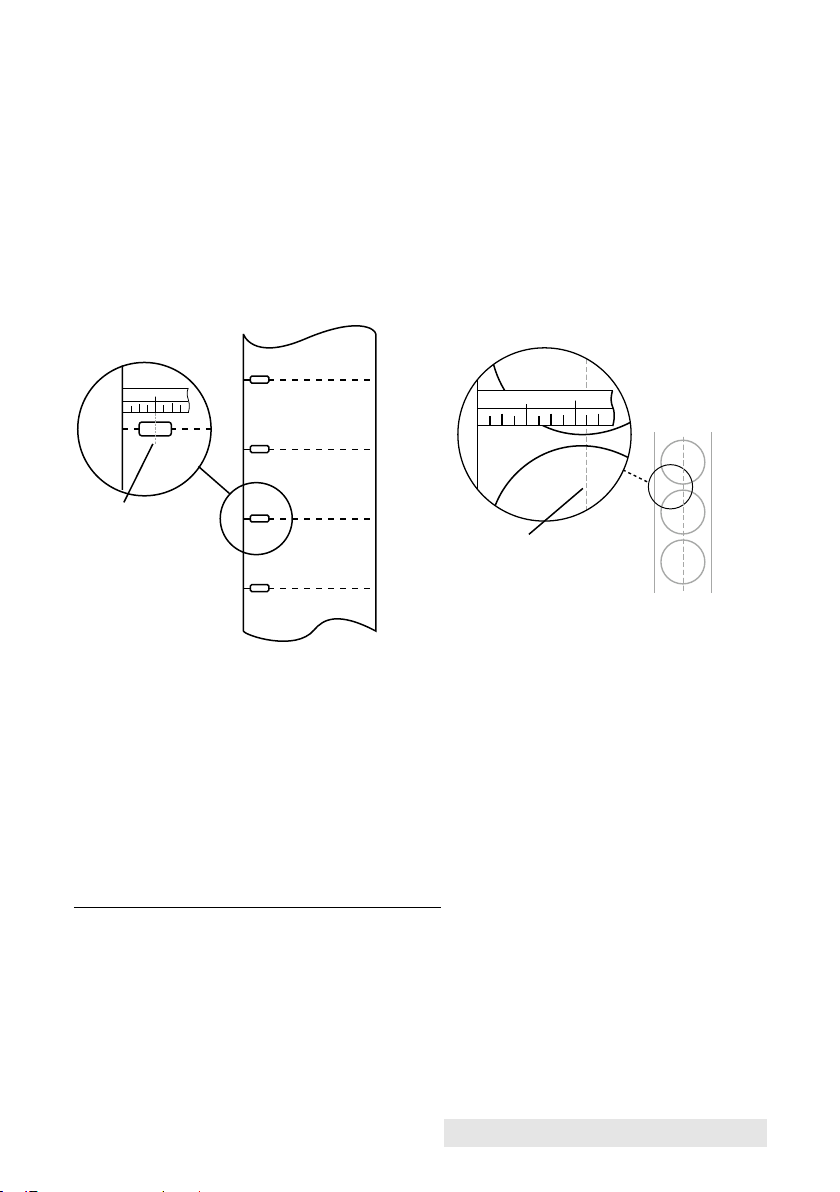

Label Sensing Methods

Method 1: Label

Gap Sensing

Method 2: Through-Hole

Sensing

Method 3: Reflective/Black

Mark Sensing

(Black Mark must be printed

on back side of label stock)

Label Width

Liner Width

Gap Sensor Adjustment Range

Width of Opening

Distance from

edge of Media

to edge of Label

Gap Between

Labels

Label Height

Black Mark

Width

Note: See table below for Max and Min values in inches and mm.

6 Label Stock

Max Min

Label width 209 mm (8.25") 13 mm (0.5")

Liner/media width 212 mm (8.375") 38 mm (1.5")

Label height/length 609 mm (24") 13 mm (0.5")

Gap between labels 253 mm (10") 2.5 mm (0.10")

Width of through-hole 12.65 mm (0.5") 6.325mm (0.25")

opening

Gap Sensor Adjustment 48 mm (1.9") 5.06 mm (0.20")

Range (from left edge)

Reflective/Black N/A 2.54 mm (0.1")

Mark Width*

Max Outer Diameter (OD) 152.4 mm (6.0") N/A

Inner Core Diameter (ID) 76.2 mm (3.0") 76.2 mm (3.0")

Total Thickness

254 µm/.254 mm)

N/A

(Liner + Label)** (10 mil/.0010”)

Distance from edge of Printer driver assumes 2 mm gap.

media to edge of label However, this is adjustable via the

left margin offset.

* The Reflective/Black Mark should be opaque to infrared light. The

mark should be between the labels. The end of the mark should

correspond with the beginning of the label.

** This is the recommended maximum. There are two factors that

determine whether the printer will accept any particular stock

thickness.

1. The ability for the printer to pull the paper through the print area.

2. The ability for the sensor to read through the backing if the

sensor is set to die-cut.

If you are printing in continuous or reflective label sensing mode

number 2 does not apply. The fact that the printer must read through

the backing in die-cut mode will limit the thickness much more than

the printer's ability to pull the paper through the print area. However,

if you adjust opacity level of the liner enough to allow the label to be

seen by the stock sensor, the thickness will only be limited by the

printer's ability to pull it through the printer area. For these reasons

the weight or thickness of the liner is a variable that can not easily be

defined. Primera recommends and uses 40# liner with all label stock.

It is important to test all label stock with the intended printer before

ordering large quantities!

Label Stock 7

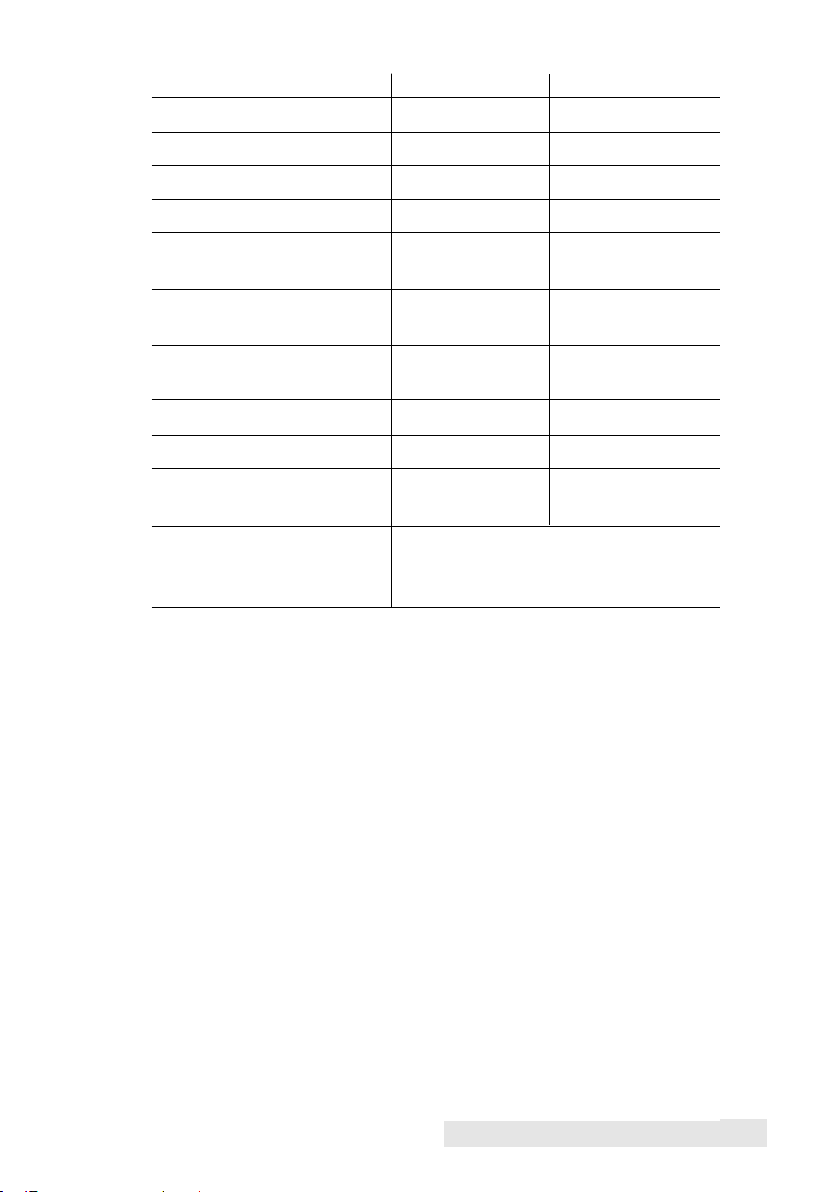

Roll Specifications

Label Side Out

Roll O.D.

Core I.D.

Core O.D.

Note on Label Orientation: If you are using an applicator

to apply your labels, be sure to order label stock with the correct

orientation for your applicator. For example most applicators will

apply the side of the label first, so you will want to print the labels

sideways.

Label Stock

3” 6”

(Max)

8 Label Stock

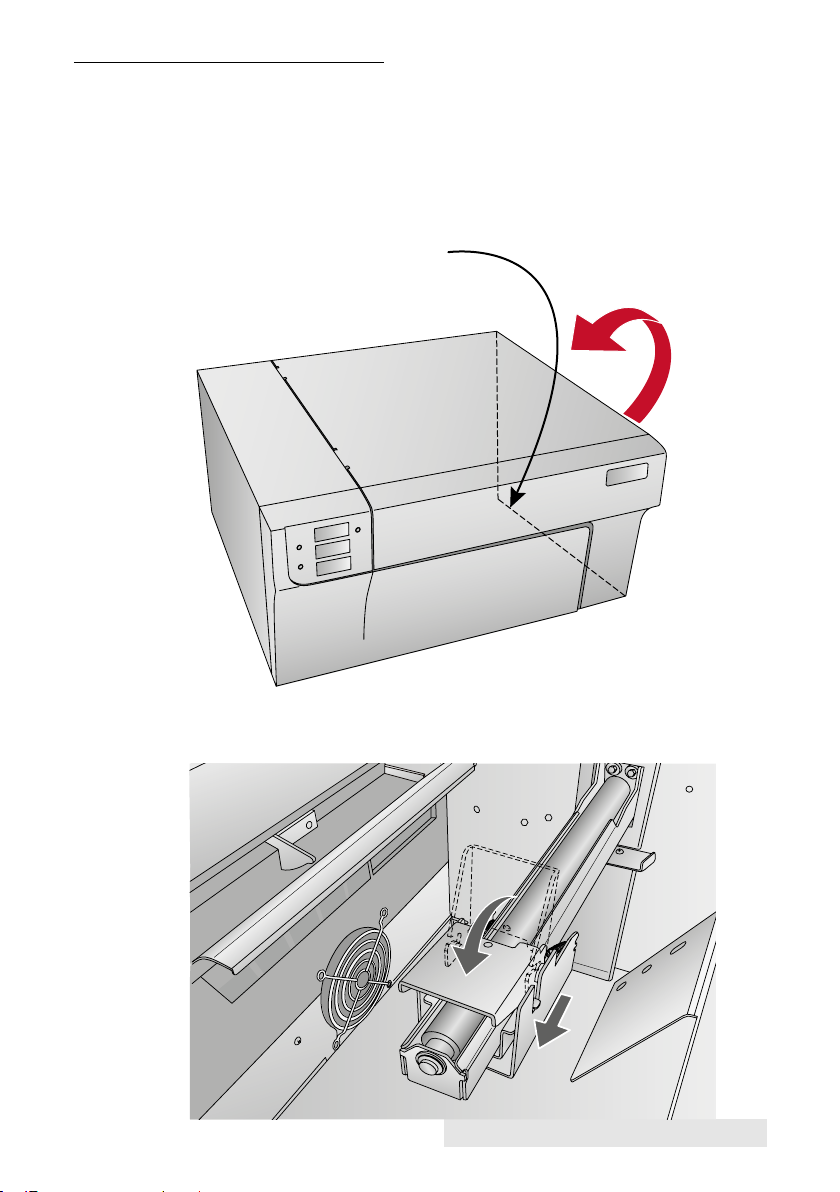

B. INSTALLING LABEL STOCK

Lift from back

The following steps will guide you through loading label stock

into your printer:

Make sure power is connected and printer is on.

1. Open the Top Cover.

corner of Cover

2. Lower the Roll Guide and pull it outward to make room

for your label stock.

Label Stock 9

3. Remove any shipping tape from your label stock roll to

ensure that it can unroll freely, making certain that no

adhesive portion is exposed. It is important to note that

any exposed adhesive surface can attach itself to the inner

workings of the print mechanism and cause a media jam.

4. Place your roll of label stock on the Roll Arm and push it

inward until it touches the Roll Stop.

Roll Stop

Do Not Pinch!

Roll Guide

Roll Arm

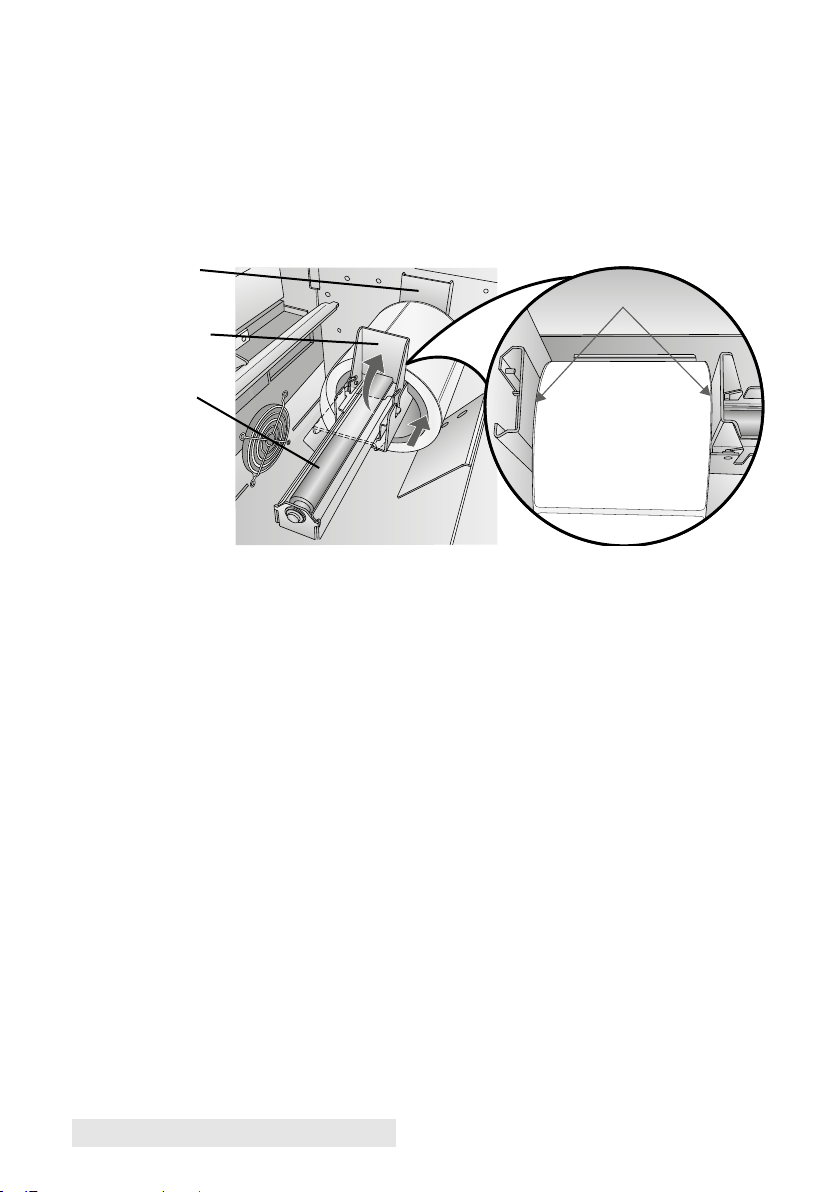

5. Flip up the Roll Guide and slide it inward until it touches

the label stock. The Roll Guide will automatically pull back

slightly to the correct position. There should be

approximately a 1mm gap between the Roll Guide and the

roll.

Important Note: Be aware that some label stock may have a core that

is slightly too large for the roll or the labels may have wrapped

unevenly causing some to stick out beyond the edge of the core.

Both of these issues can cause feeding problems.

10 Label Stock

6. Pull the Movable Throat Guide outward to make room for

the label stock.

7. Place the leading edge of the label stock under

Label Stock

the "label stock" symbols on the Throat Guides.

The label stock should be placed far enough into the throat

of the printer to correctly position the Movable Throat

Guide but not yet into the printer itself.

Movable Throat Guide

Fixed Throat Guide

Do Not Pinch!

8. Slide the Movable Throat Guide inward until it almost

touches the label stock.

Important Note: The label stock should be close enough to the Fixed and

Movable Thoat Guides to provide proper guidance but not close

enough to pinch the label stock. (0-1 mm gap on either side)

If the label stock is pinched by the guides, poor print quality or

feeding problems could result.

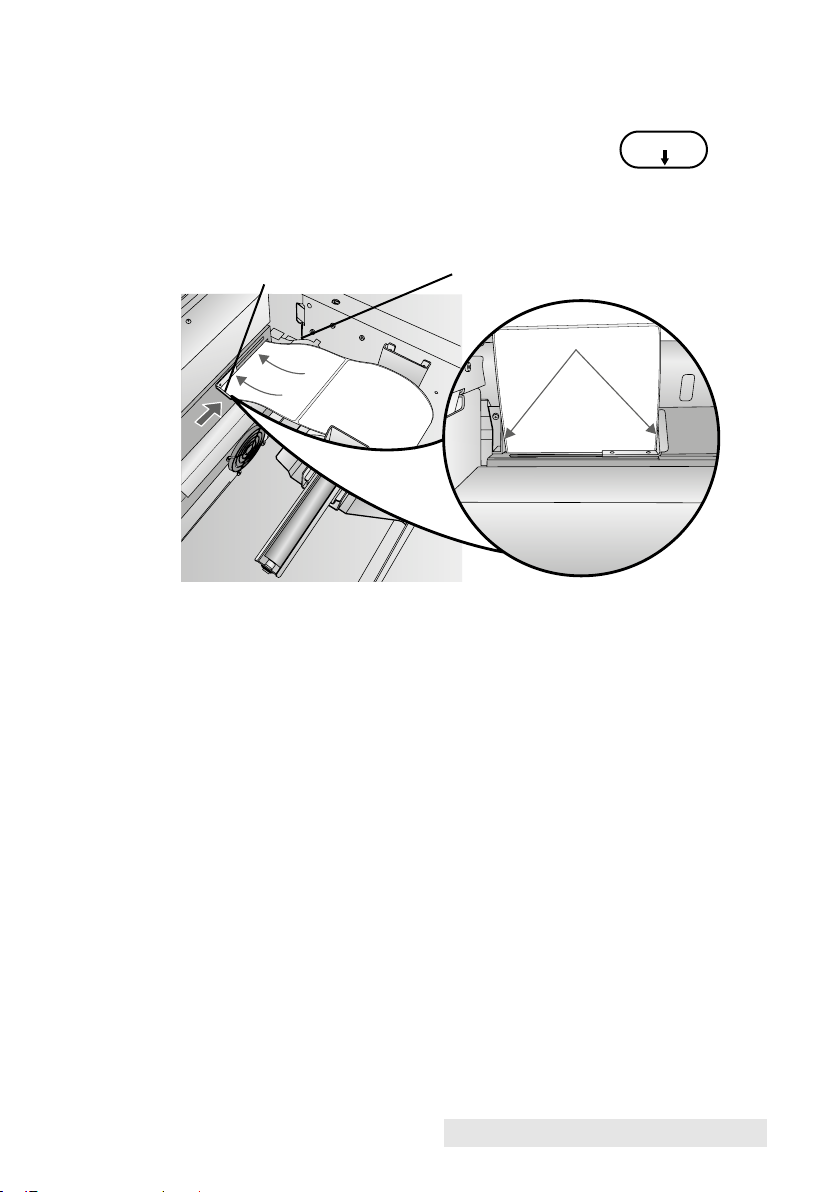

9. Feed the label stock further into the printer until it senses

the label and automatically feeds it through the printer. If

the printer fails to feed the label stock, press the Load/

Feed button on the front panel while continuing to guide

the label stock into the printer. If the printer does not

automatically grab and feed the stock or continues to feed

the stock without stopping check the Gap Sensor position

or mode (Section 2C or 2D).

Label Stock 11

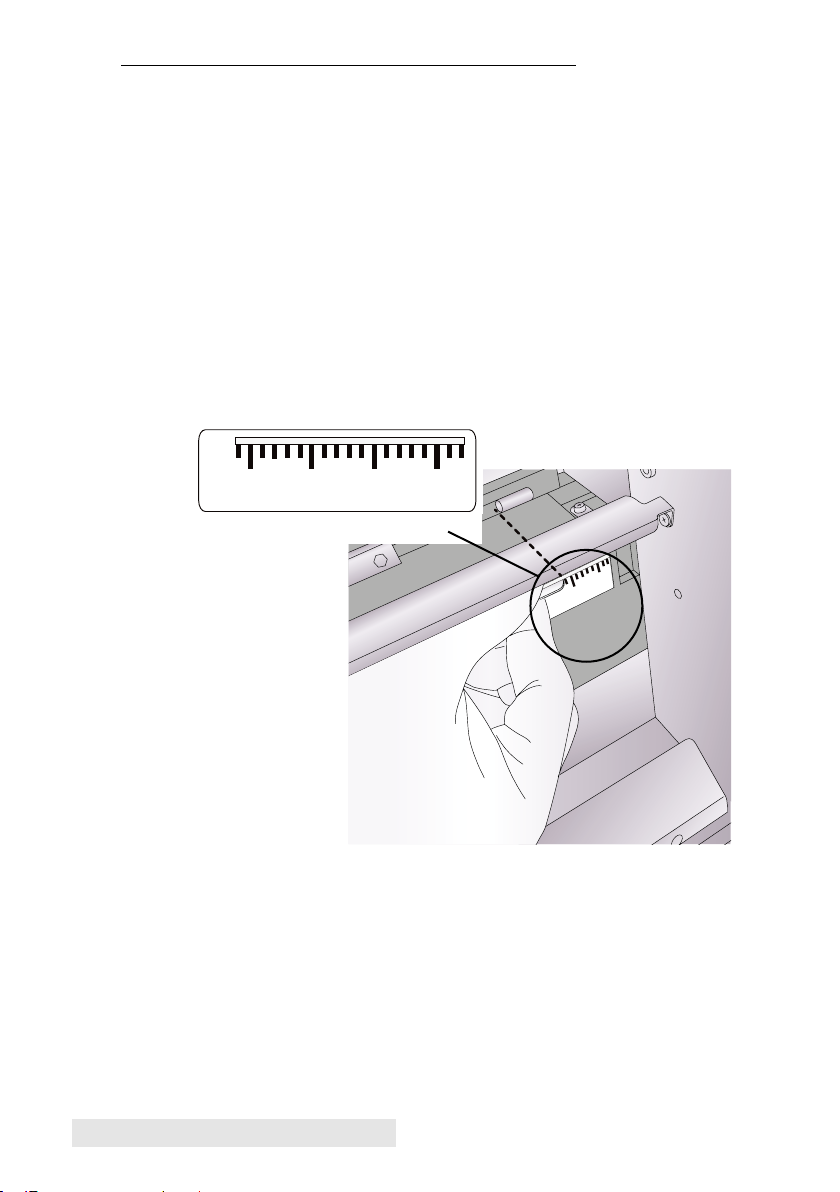

C. ADJUSTING THE GAP SENSOR POSITION

If you are using label stock other than standard square /

rectangular die-cut labels such as circular die-cut labels or

through-hole stock use the instructions below to adjust the

position of the label stock gap sensor. The sensor can be

adjusted using the slide bar on the inside of the printer. Below

the slide bar is a measurement which represents the distance

between the edge of the label stock and the sensor. Measure

the distance from the edge of the label stock to the correct

position on the stock. Set the sensor so the side of the slide bar

lines up to this measurement. See dashed line in the

illustration below.

Important Note: You must adjust the stock sensor before loading

nonstandard label stock.

in.

mm

2.0

50.8

1.5 1.0

Label Stock Sensor Slide

12.725.438.1

0.5

0.5

12.7

1.0

25.4

1.5

38.1

0.5

12.7

in.

mm

12 Label Stock

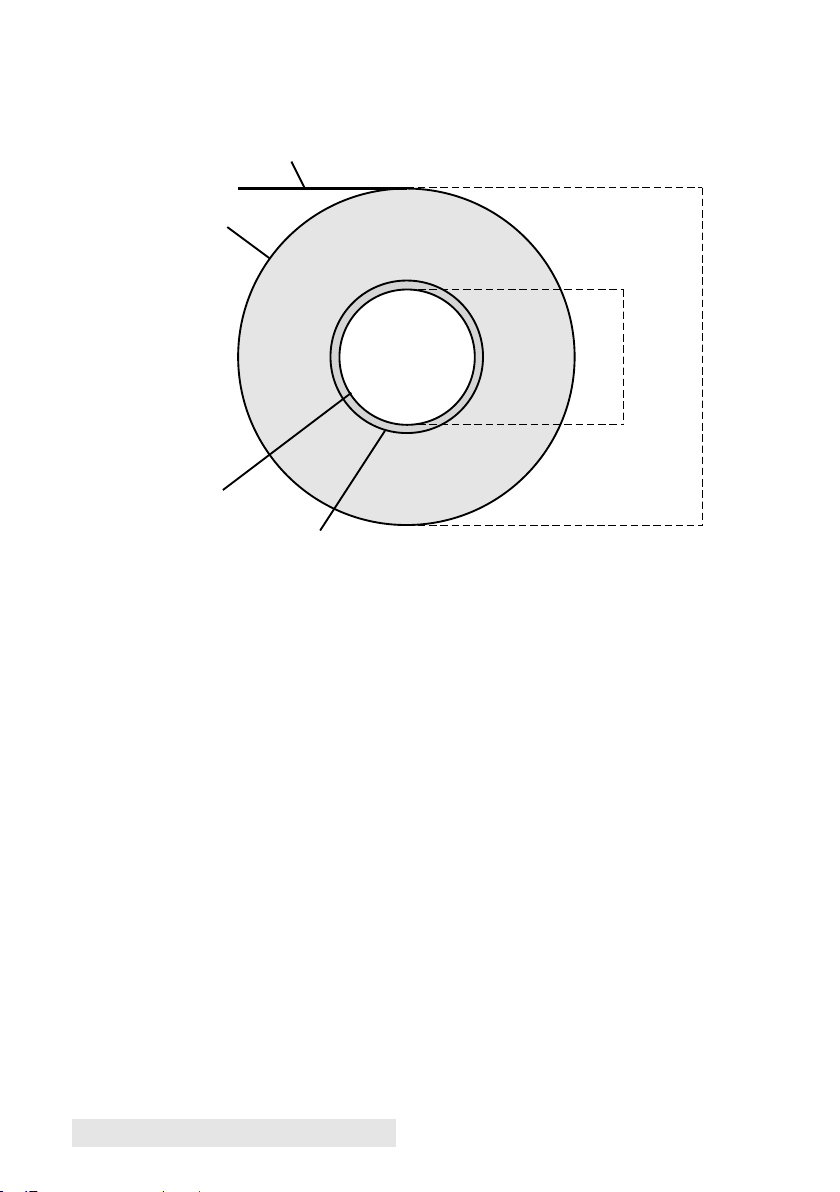

Circular Labels

If you are using Circular Labels you must adjust the stock

sensor to correspond with the very top of the label where the

circles are closest together. If the sensor is too far to the right or

the left the printer will still sense the label but the image may

be offset downward because the printer will start printing at

the wrong position. If you are using stock that has multiple

labels across make sure the sensor corresponds to a place on

the stock that has a label and not a vertical gap.

The sensor can only be moved a maximum of 2 inches

from the left side of the printable area. This means that the

maximum diameter circular label that can be printed is 4

inches. For circular labels larger than 4 inches in diameter, you

must have a black mark printed on the back of the label stock.

This means that you must change the Stock Sensor Mode to

Reflective. The printer will now look for the black mark

representing the beginning of the next label instead of the

die-cut. For more information on changing the Stock Sensor

Mode see Section 2D.

1/2”

Center

of Hole

Through-Hole Labels Circular Labels

Set Sensor Bar to 28.4 mm (1 1/8") for 50.8 mm (2") circular label (3 mm (1/8")

liner edge gap).

Center

of Circle

1 1/8”

Through-Hole Labels

If you are using card stock or label stock that has a hole punch

or a notch to identify a transition from backing to label, you

can adjust the Stock Sensor to position it over the identifying

mark.

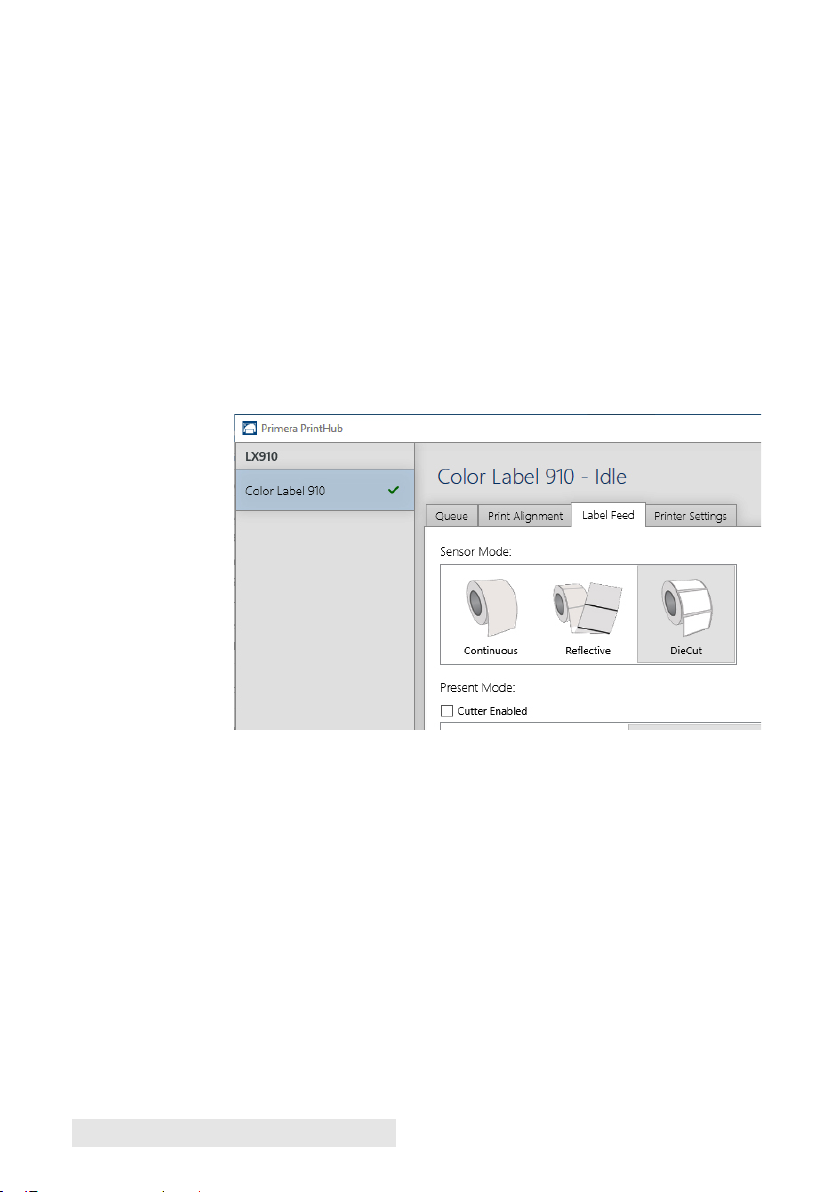

D. SET THE STOCK SENSOR MODE

The stock sensor mode refers to the method the printer will use

to detect the print starting position for each label. To adjust the

stock sensor mode, open the PrintHub. In most cases you will

NOT need to change this setting. By default it is set to sense

standard die-cut labels. It is only necessary to change this

setting if you are using clear labels or any label with a black

sensing mark on the back.

Label Stock 13

1. Connect the printer via USB and turn on the power. The

Stock Sensor Mode setting is stored in the printer's internal

memory so you will not be able to access it unless the

printer is turned on and properly communicating with the

computer.

2. Go to Start - Programs - Primera Technology - Primera

PrintHub.

3. Click on the Label Feed (3rd tab from left).

4. Select the Stock Sensor Mode by clicking on the graphic

that most closely corresponds to the stock you intend to

install.

5. Load the label stock after you have set the sensor mode.

14 Label Stock

There are three sensor modes:

Die-Cut (Default). If you are using standard die-cut labels that

look similar to the graphic, use this setting regardless of the

size of the label. Also, use this setting for Through-hole label

material where a hole is punched through each label or a notch

is cut in the side.

Reflective. Use Reflective for label material where a black

pre-printed line (black mark) on the back of the label stock

indicates the break between labels. Black marks are required

on clear label stock rolls, or label where the label waste matrix

(waste) is left on the liner. Black marks can also be used for

irregular shaped labels, circles larger than 4 inches or on any

stock where the print starting position can not be sensed using

the label itself.

Continuous. (Sensor off) If you have continuous stock with no

die-cut, reflective mark or holes, set the sensor type to

Continuous. This will turn off the stock sensor. In this mode

there is no way to set the print starting position. The printer

will simply start printing the first label and print each

subsequent label immediately after that previous one. To

produce a gap between prints simply add the desired amount

of white space to the end of the label being printed.

Important Note: You must also set the Stock Sensor Position (Section 2C)

so that the sensor is sensing the correct point on the label stock.

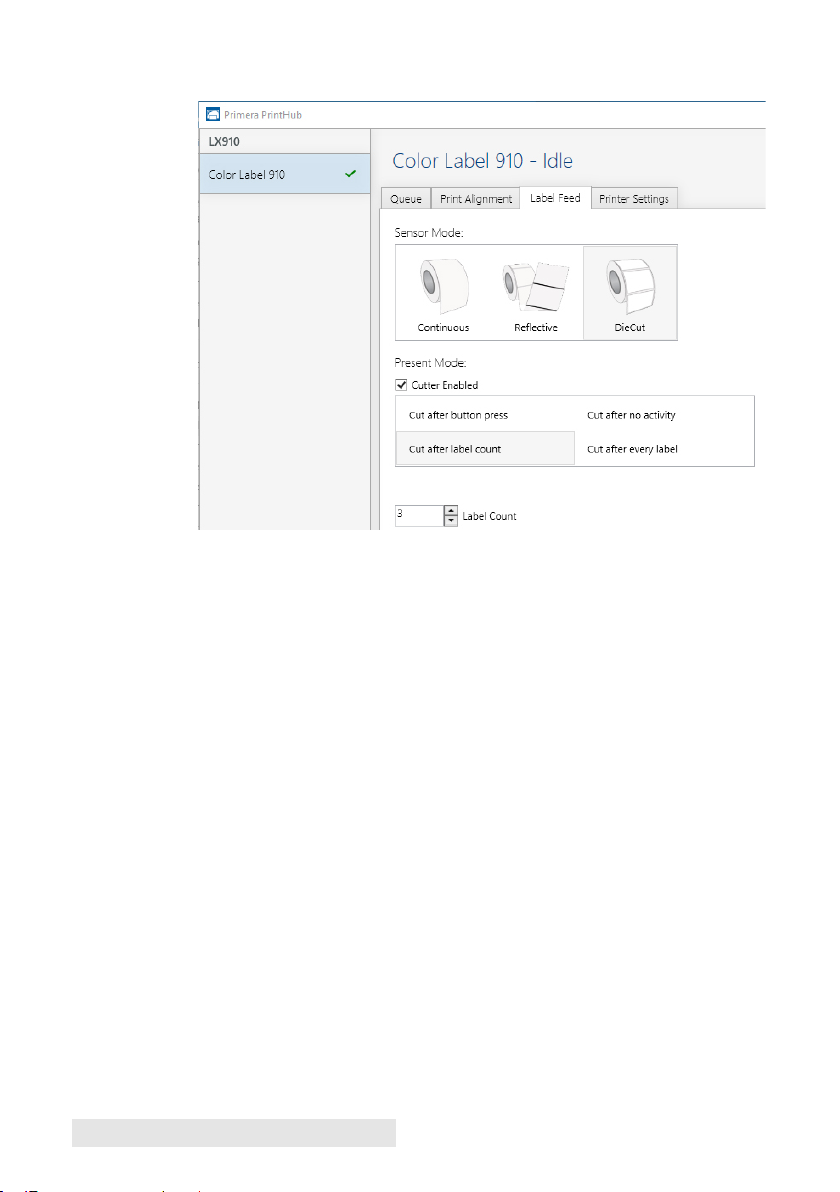

E: SET THE PRESENT/CUT MODE

Use the Present/Cut Mode to adjust how the printer presents

labels after they are printed or if/when they are cut after

printing. To adjust the Present/Cut Mode, open the PrintHub

program.

1. Connect the printer via USB and turn on the power. The

Output/Cut Mode Setting is stored on the printer main

board so you will not be able to access it unless the printer

is turned on and properly communicating with the computer.

2. Go to Start - Programs - Primera Technology - Primera

PrintHub.

3. Click on the Label Feed Tab.

4. Click on the Output/Cut Mode button.

There are different options available which change if the Cutter

is enabled or disabled. If the Cutter is disabled the label

present options will be available. If the Cutter is enabled the

present options are are no longer available but cut options

become available.

Label Stock 15

Cutter Options:

Cut after button press. This setting will cut after you press the

Load/Feed button on the printer. This can be used after one

label or an entire job. This feature is useful if you will not be

present at the end of the print to catch the cut label.

Cut after label count. This option will cut after the number of

labels specified in the toggle box that appears when this option

is selected. This is useful if you have front/back labels or sets

of labels.

Cut after no activity. This setting will cut at the end of a print

job if the printer does not receive another print job within one

second of the last print job in the queue. You can usethis

feature to cut at the end of multi-copy job, multi-page job or

multiple individual jobs in the queue.

Cut every label. This setting will cut after every label.

16 Label Stock

Present Options:

Do not present. In this mode the label stock does not move

after the last label is printed. This means that part of the last

label printed is still in the printer. This should be used only if

you have a label rewinder attached.

Present after no activity. This setting will present (feed all

printed labels past the tear off point) at the end of a print job if

the printer does not receive another print job within one second

of the last print job in the queue. You can use this feature to

present at the end of a multi-copy job, a multi-page job or

multiple individual jobs in the queue.

Label Stock 17

Section 3: Primera PrintHub

Primera PrintHub is used to interact with the printer for gathering

ink levels, maintenance, alignment, cost calculation and several

other functions. You can use it to manage these functions on

multiple LX910e printers and other Primera label printer models.

PrintHub automatically installs with your printer driver and can be

accessed through the printer driver preferences or as a program on

your Windows start menu.

1. Connect the printer via USB and turn on the power. The

PrintHub accesses most of the information it uses from the

printer itself so the printer must be turned on and

communicating for the program to be useful.

2. Go to Start - Programs - Primera Technology - Primera

PrintHub.

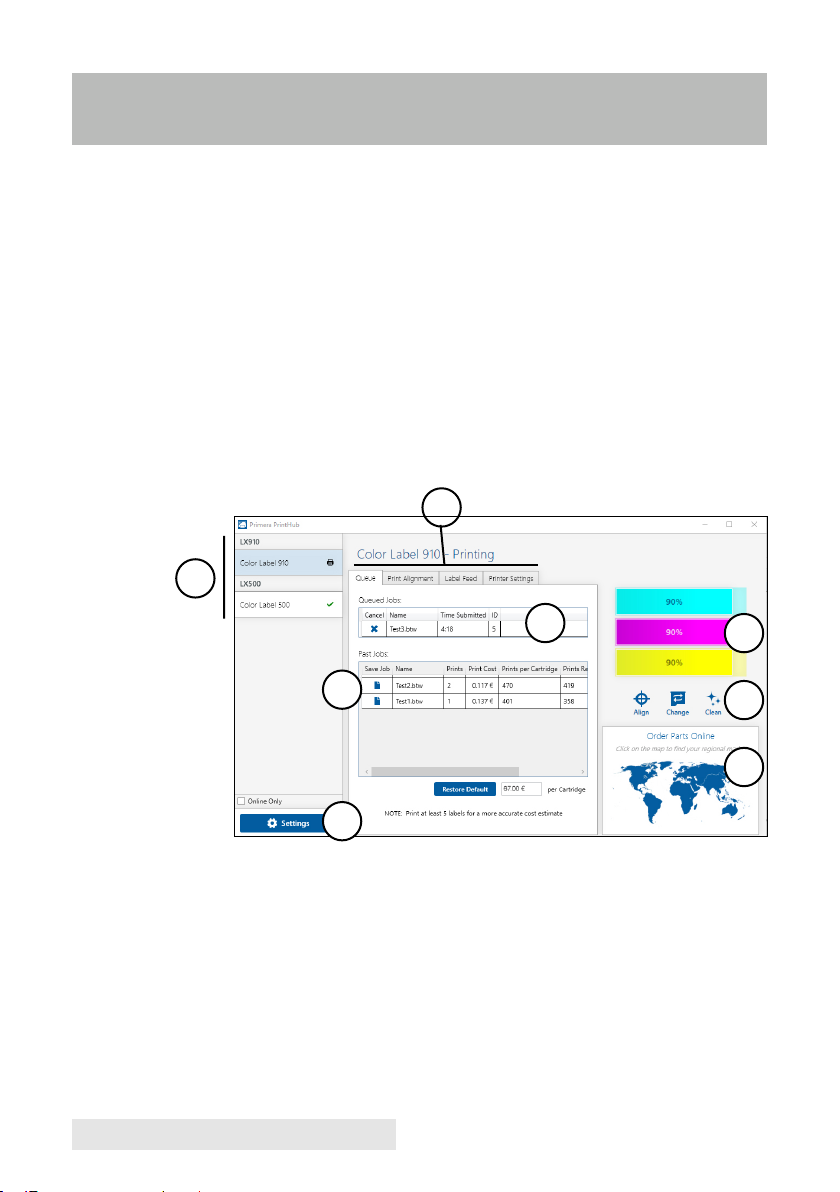

A

B

18 PrintHub

E

C

D

A. Adjust alignment, sensor mode, output mode and advanced

settings.

B. If you have multiple Primera printers connected, they will be

listed here.

C. Past jobs will show the last 5 jobs along with cost information.

Click the document icon to view a cost report.

D. Application Settings

E. Print Queue shows the currently printing job.

F. Order Link

G. Frequent Activities

H. Current Ink Levels

H

G

F

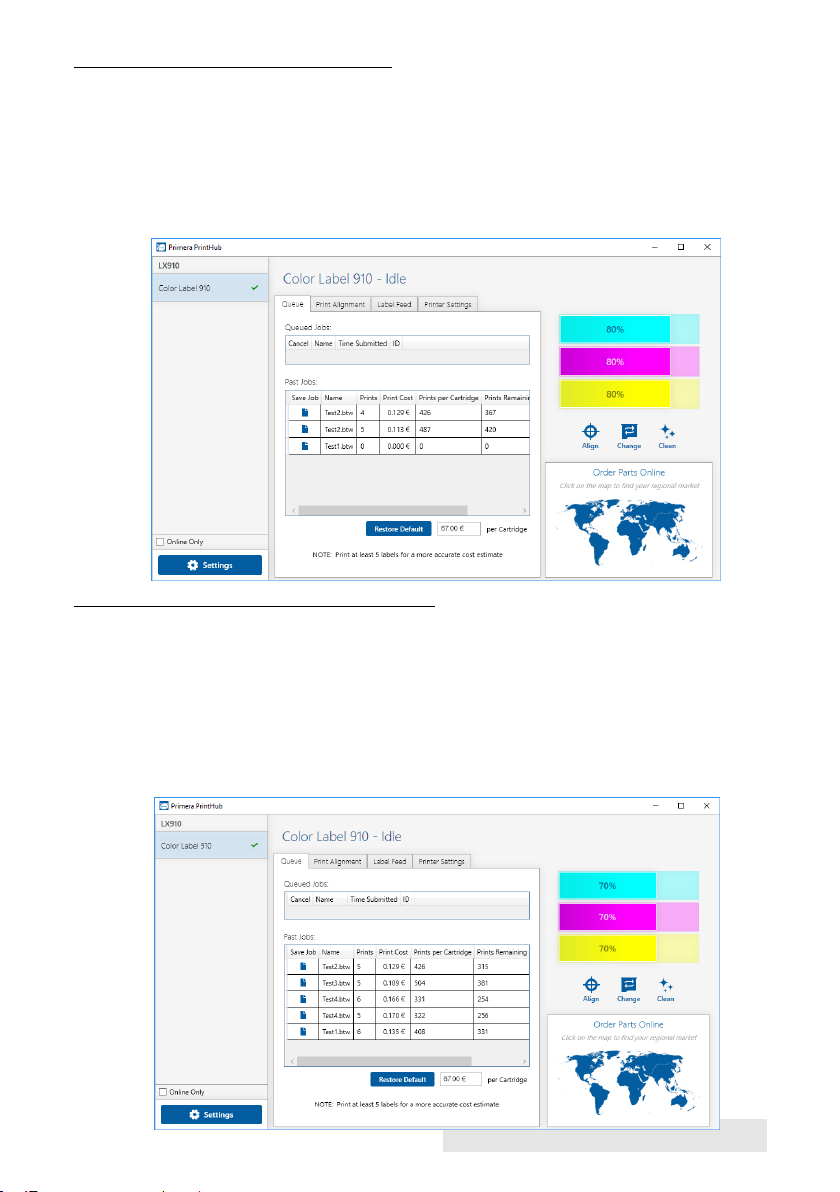

A: MONITORING INK LEVELS

Ink levels can be monitored at any time by using the PrintHub.

Immediately after printing starts the PrintHub will display the

ink levels in the upper right corner of the application. Ink is

displayed in 10% increments. Example 100% to 90% to 80%

etc.

B. USING THE COST ESTIMATOR

The cost estimator is found under the queue section on the first

tab of the PrintHub. The last five job costs are stored in the list.

Each job will show the cost per label based on the cost per

cartridge entered below the list. Enter the actual cost of the

cartridge you paid. Prints remaining on the currently installed

cartridge and total prints on new cartridge are both displayed.

PrintHub 19

Loading...

Loading...