DTM Print LX610e Service Manual

User’s Manual

©2020, DTM Print GmbH. All rights reserved

For the most recent version of this manual please visit dtm-print.eu/manuals

Notices: The information in this document is subject to change without notice. NO WARRANTY OF ANY KIND IS MADE

WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. No liability is assumed for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. This document contains

proprietary information that is protected by copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated into another language without prior written consent.

Trademark Acknowledgments: Primera and Primera LX610e are registered trademarks of Primera Technology, Inc. Windows is a

registered trademark of Microsoft Corporation. All other trademarks are the property of their respective owners.

Revision History

Edition 1.0, Copyright 2020, All rights reserved.

2 |

Table of Contents

Section 1: Getting Started ..........................................................................................................................................................................................................5

1A Choosing a Good Location ...................................................................................................................................................................................5

1B Unpacking and Inspection ...................................................................................................................................................................................6

1C Installing the Roll Holders ....................................................................................................................................................................................7

1D Identifying the Parts ........................................................................................................................................................................................... 11

Section 2: Media, Cartridges and Knives .........................................................................................................................................................................14

2A Label and Roll Specications ............................................................................................................................................................................14

2B Installing Digital Die-Cutting Label Stock ....................................................................................................................................................17

2C Installing Pre Die-Cut Label Stock ................................................................................................................................................................... 20

2D Replacing the Digital Die Cutting Knife holder ..........................................................................................................................................24

2E Replacing the Cutting Knife ...............................................................................................................................................................................26

2F Replacing Ink Cartridges .................................................................................................................................................................................... 27

2G Adjusting the Gap Sensor Position (Pre Die-Cut Labels Only) ..............................................................................................................29

Section 3: Primera PrintHub ................................................................................................................................................................................................... 31

3A Adjusting Knife Pressure and Stretch Factor ............................................................................................................................................... 32

3B Using the Cost Estimator ....................................................................................................................................................................................34

3C Set the Gap Sensor Mode (Pre Die-Cut Labels Only) ...............................................................................................................................35

3D Set the Present/Cut Mode .................................................................................................................................................................................37

3E Adjusting Print Alignment ................................................................................................................................................................................. 39

3F PrintHub Settings ..................................................................................................................................................................................................41

3G PrintHub Printer Settings ................................................................................................................................................................................... 43

3G1. Multiple Printer Support .........................................................................................................................................................................44

Section 4: Printing and Cutting with PTCreate ...............................................................................................................................................................46

4A Overview ..................................................................................................................................................................................................................46

4B PTCreate Software Activation .......................................................................................................................................................................... 50

4C Software Deactivation ......................................................................................................................................................................................... 52

4D: Tutorial: How to Setup a Print and Cut using PTCreate Pro – Vector File Cut ................................................................................ 53

4D.1 Choosing a Label Size (Page Layout) ................................................................................................................................................54

4D.2 Import a at Image (JPG, BMP, PNG, TIF, GIF) ..................................................................................................................................55

4D.3 Working with Layers in an Imported Vector File ........................................................................................................................... 57

4E Tutorial: How to Setup a Print and Cut using PTCreate Pro – Contour Cut ......................................................................................59

4E.1 Choosing a Label Size (Page Layout) ................................................................................................................................................. 59

4E.2 Import an Image .......................................................................................................................................................................................60

4E.3 Trace Image and create Cut Line .........................................................................................................................................................64

4E.4 Oset a Cut Path ........................................................................................................................................................................................67

4F Setup multiple identical cuts (Duplicate and Array) ................................................................................................................................69

4G Print Preview ..........................................................................................................................................................................................................74

4H Vector File Specications for Designer ..........................................................................................................................................................75

| 3

4I Tutorial How to setup a Print and Cut in PTCreate Standard ................................................................................................................. 76

4I.1 Choosing a Label Size (Page Layout) ..................................................................................................................................................76

4I.2 Import a at Image (JPG, BMP, PNG, TIF, GIF) ...................................................................................................................................77

4I.3 Add a Cut le ...............................................................................................................................................................................................80

4I.4 Print .................................................................................................................................................................................................................. 83

Section 5: Printing only to Pre Die-Cut labels ................................................................................................................................................................ 84

5A Using NiceLabel for Pre Die-Cut Printing ....................................................................................................................................................84

5A.1 Printing from NiceLabel ......................................................................................................................................................................... 87

5B Using BarTender for Pre Die-Cut Printing .................................................................................................................................................... 87

5C Add Text, Barcodes and Graphics to a BarTender Label ..........................................................................................................................95

5D Printing from Other Programs .........................................................................................................................................................................96

5E Creating a Full Bleed Print ..................................................................................................................................................................................98

5F Printer Driver Settings ........................................................................................................................................................................................100

Section 6: Troubleshooting ...................................................................................................................................................................................................103

6A Solving Pre Die-Cut Print Alignment Problems .......................................................................................................................................103

6B Maintenance .........................................................................................................................................................................................................105

6C Poor Print Quality – Cleaning the Cartridge ..............................................................................................................................................107

6D Technical Support ...............................................................................................................................................................................................111

Section 7: Technical Specications ....................................................................................................................................................................................112

4 |

Section 1: Getting Started

THANK YOU…

...for choosing an LX610e Color Label Printer. The LX610e Printer will print razor-sharp text and barcodes, vibrant colors, and even

stunning photo-realistic photographs directly onto rolls of labels, card stock and a variety of other approved media. AND with the

built in digital die cutter you can cut and create your labels in any size or shape you choose.

This User’s Manual is your complete step-by-step guide to quickly and easily setting up and printing with your new Color Label

Printer!

1A Choosing a Good Location

Place the printer on a at surface in a location with adequate air circulation to prevent internal heat buildup.

Do not place the printer near heat sources such as radiators or air ducts, or in a place subject to direct sun

light, excessive dust, mechanical vibration or shock.

Allow for adequate clearance in front of the printer to accommodate the printed label stock as it is leaving

the printer to avoid the possibility of binding or jamming of the label stock.

Allow for 6” of clearance behind the printer to accommodate loop creation during cutting operations. The

area directly behind the printer must also not be obstructed by USB or power cables connected to the

printer.

Allow for adequate overhead clearance for opening the top cover to allow easy access to the labels tock

and ink cartridge. The printer will require 7 inches (17.78 cm) of additional space on the top side to completely

open the cover (Total = 16.5” or 41.91 cm).

| 5

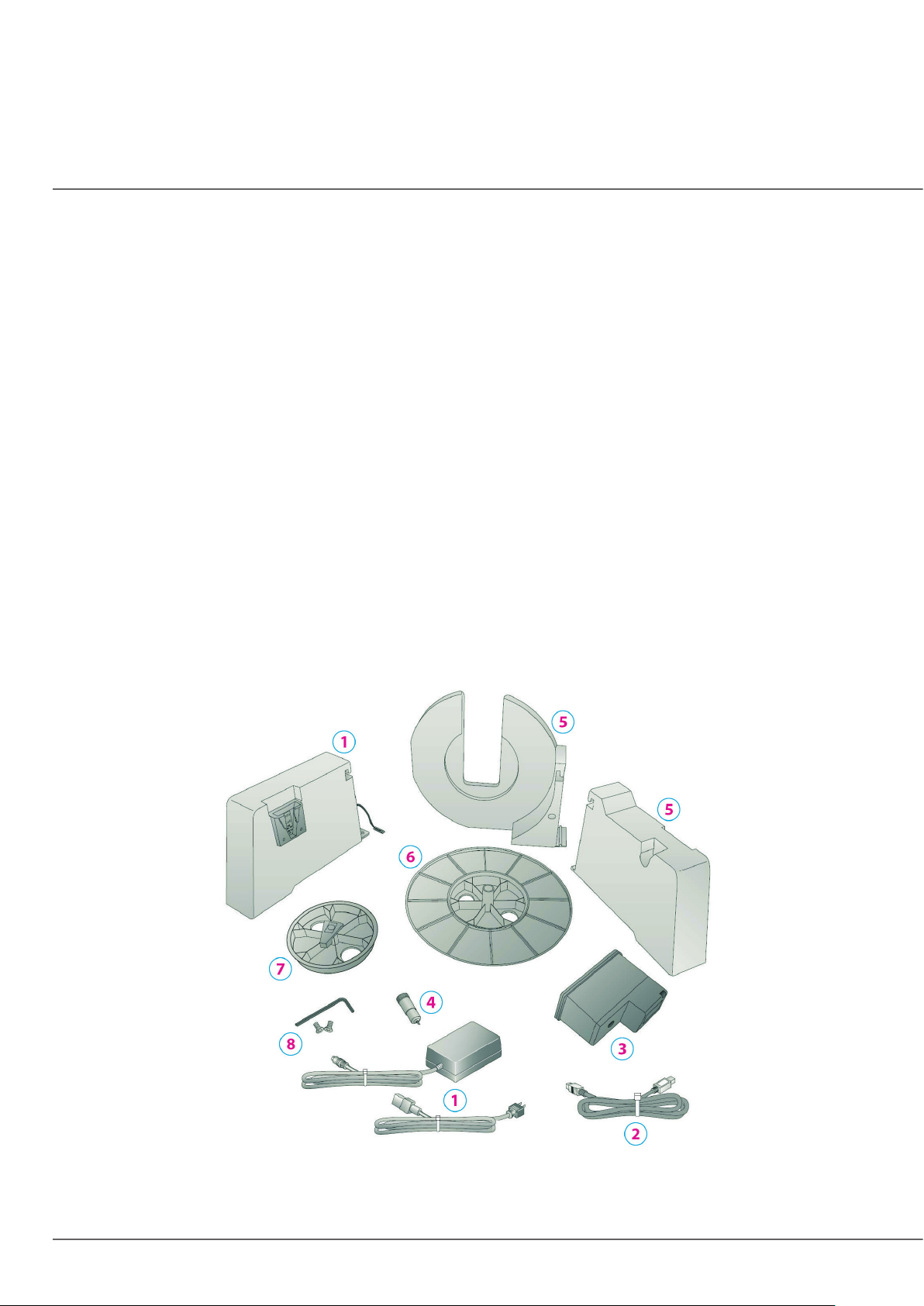

1B Unpacking and Inspection

While unpacking your printer, inspect the carton to ensure that no damage has occurred during shipping.

Make sure that all supplied accessories are included with your unit. The following items are included in the

supply box:

1. Power Adapter and Cord

2. 6’ USB Cable (If other USB cable is used, it must be 6’ (2 M) or less)

3. Color Dye Ink Cartridge Part Number 53496 (Pigment is also available – Part Number: 53491)

4. Die Cutting Knife Holder with knife preinstalled

5. Label roll holders (Assembly required – section 1C)

6. Large Roll Hub

7. Small Roll Hub

8. T8 Allen Key and two screws

9. Printed documentation

6 |

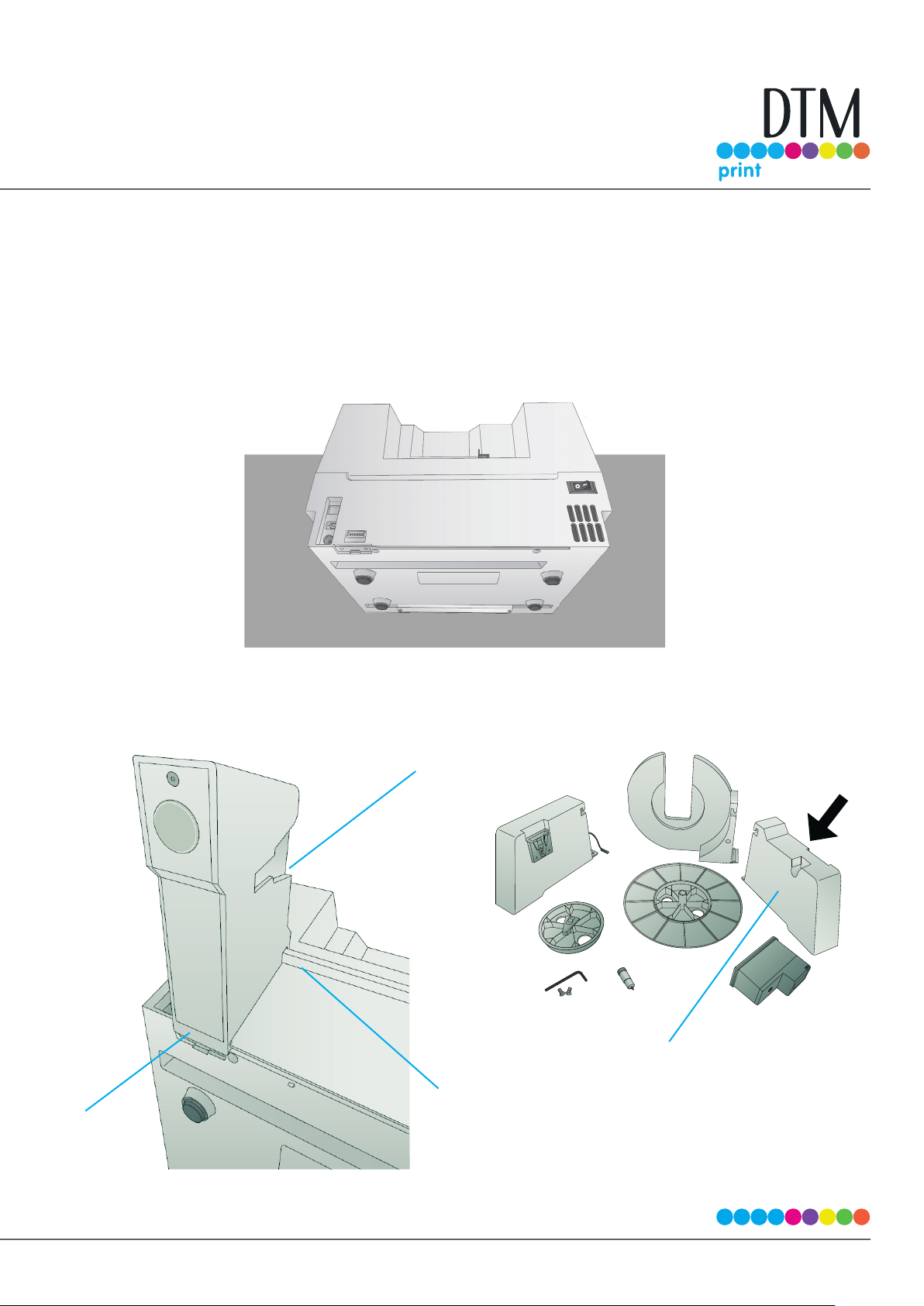

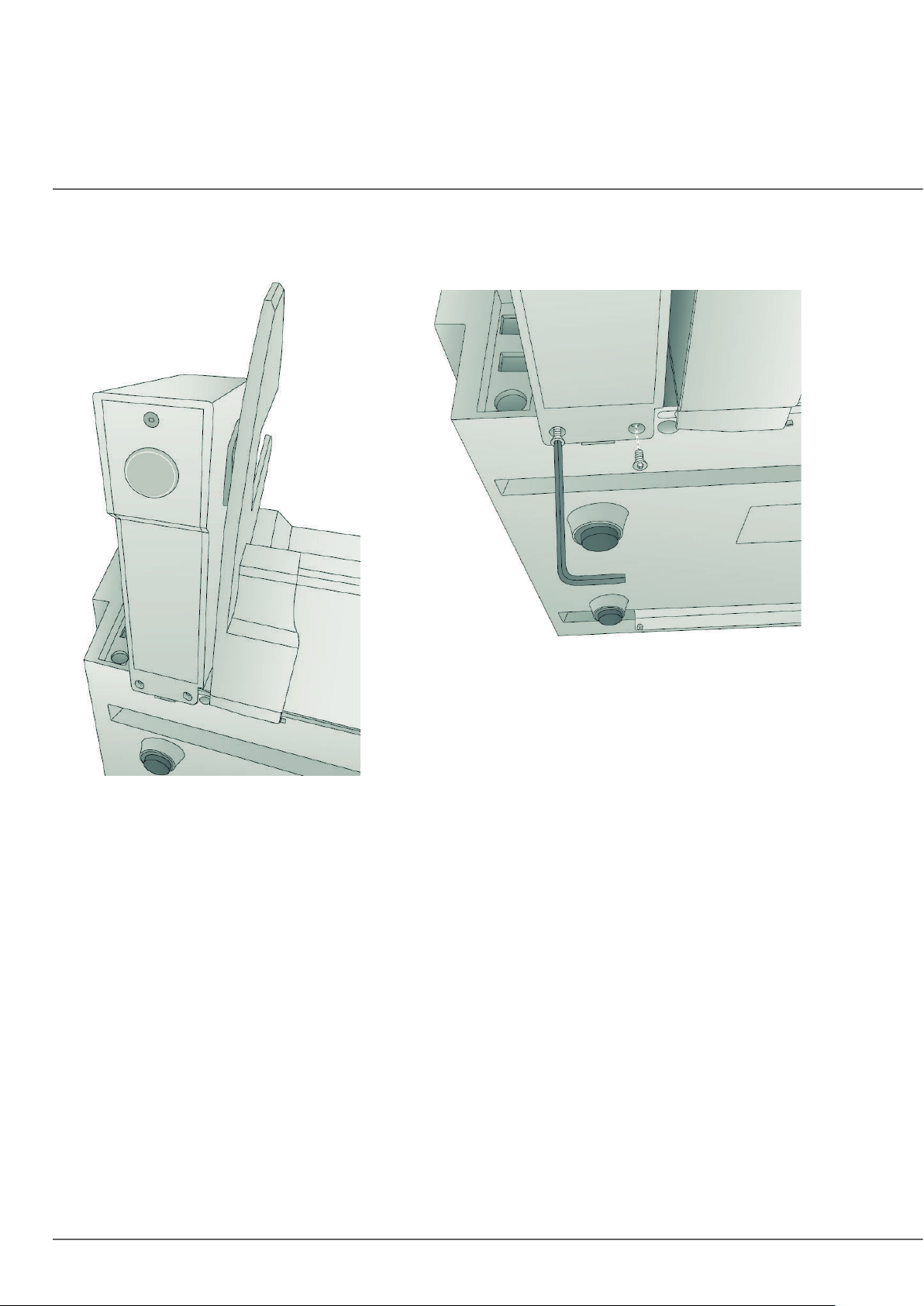

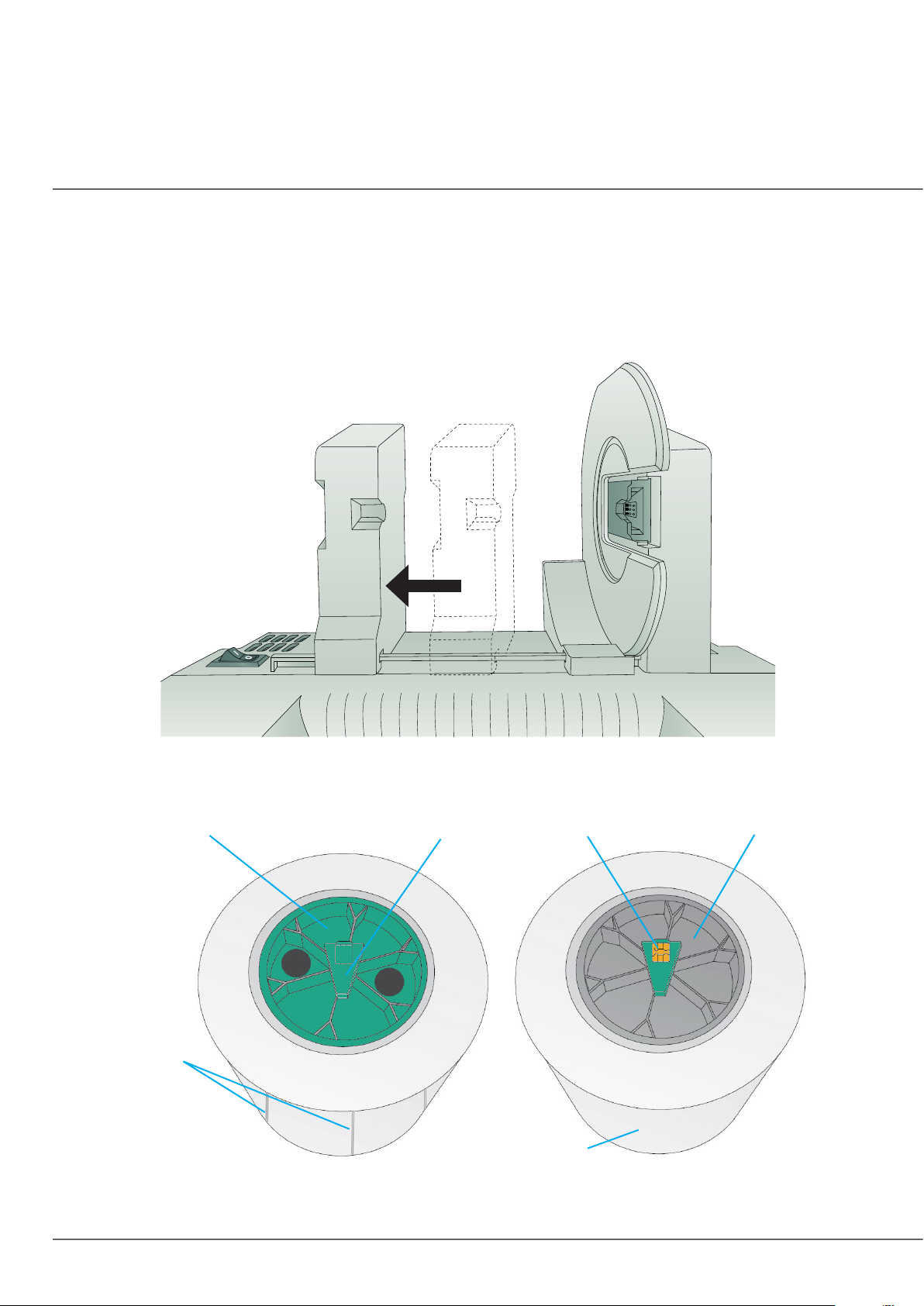

1C Installing the Roll Holders

Some light assembly is required before operating the printer.Follow these instructions to install the roll

holders.

1. Set the printer on its front so the bottom is facing you

2. Install the movable label roll holder by attaching the hooked end on the rail. The bottom of

the holder will t in the notch on the printer.

Movable Roll Holder

Tab

Movable Roll Holder

Rail

| 7

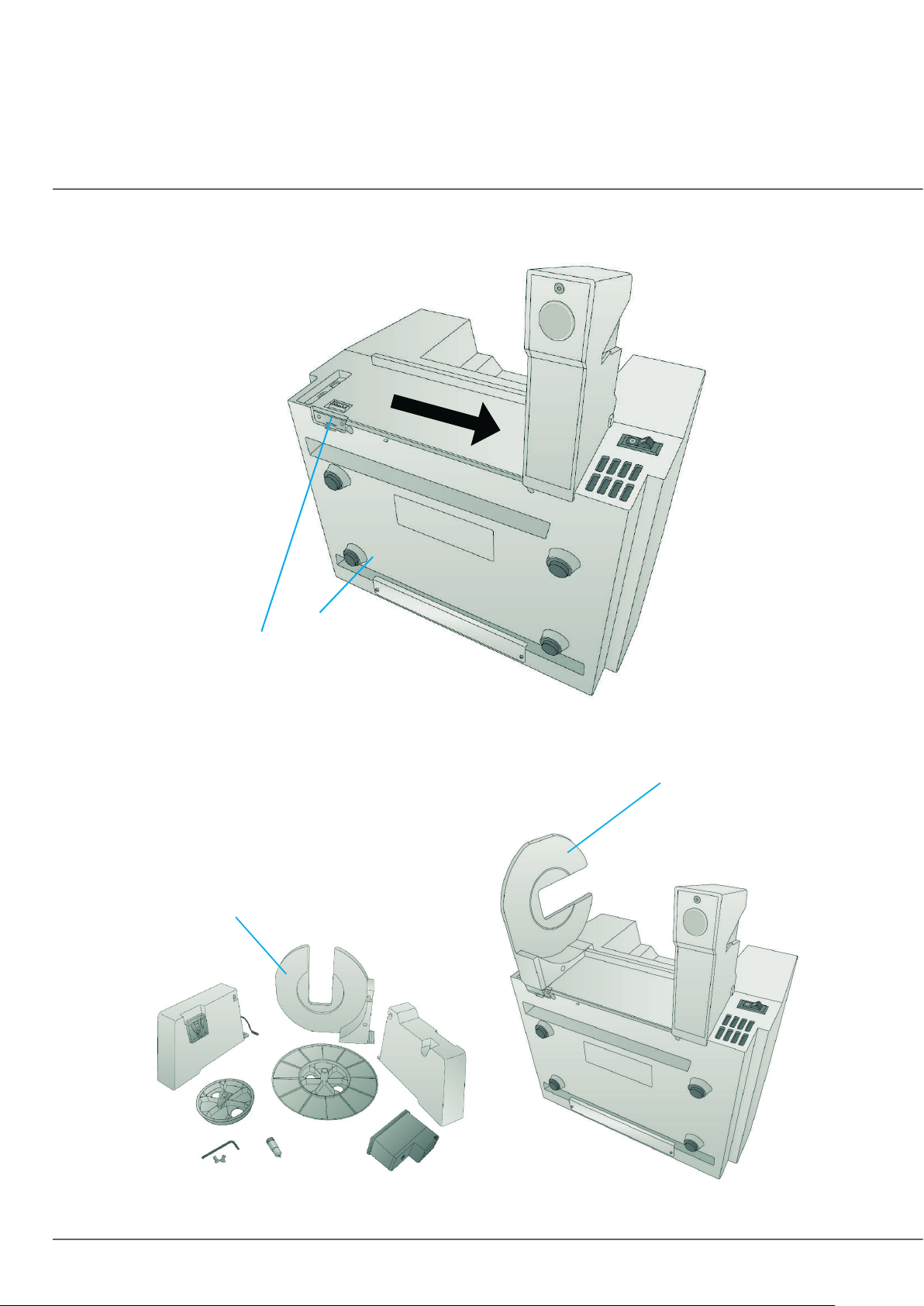

3. Slide the Roll Holder to the far right.

Notch

Notch

4. Install the roll guide by attaching the hookedend on the rail. The bottom of the holder will t in the

notch on the printer.

Roll Guide

Roll Guide

8 |

Stop

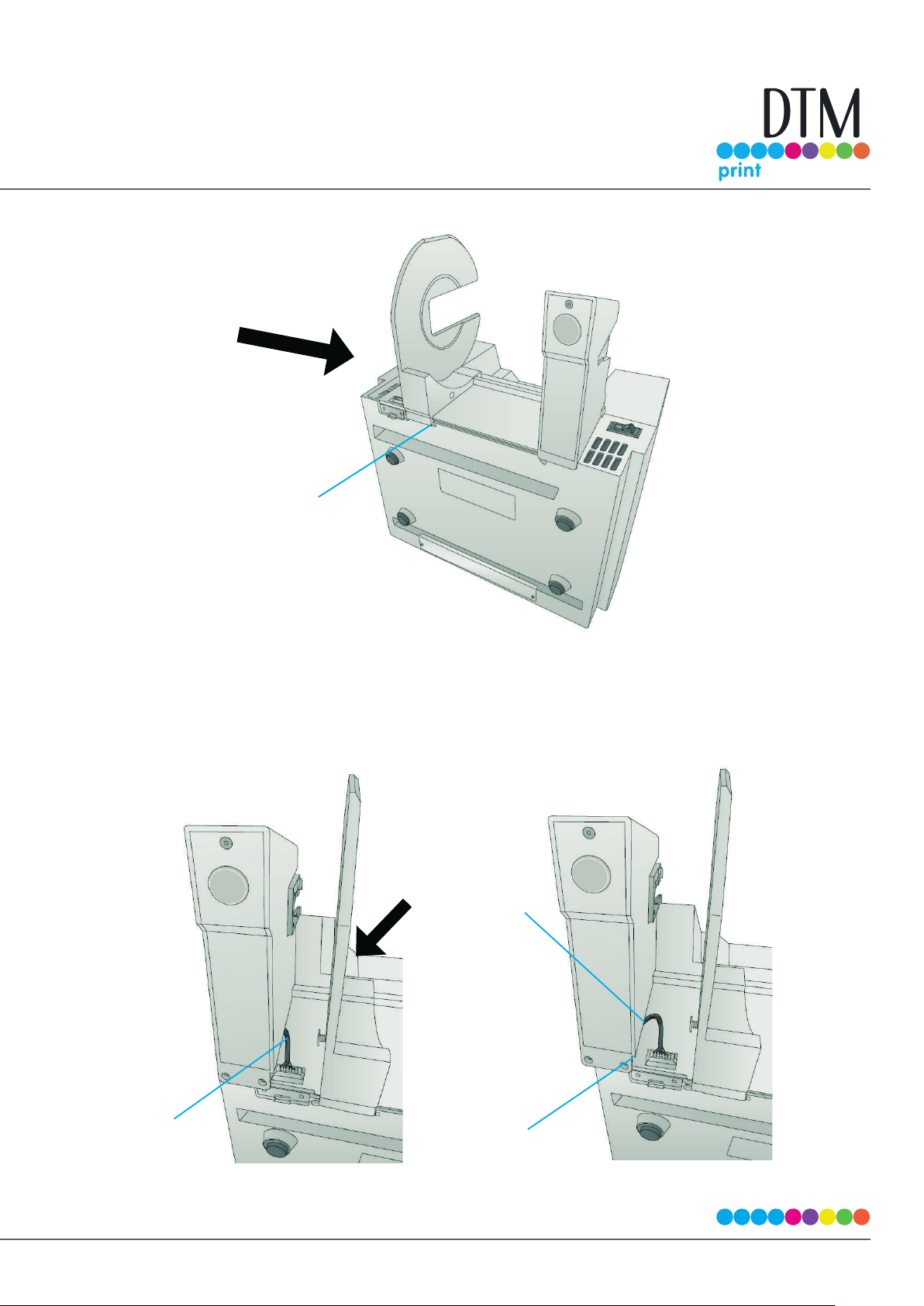

5. Slide the Roll Holder to the far right.

6. Locate the remaining roll holder with the protruding wire. Connect the wire to the port on the

printer.Tuck the wire inside the cavity.

Push the wire into

the cavity as you

move the holder

closer to the

notch

Wire

Notch

| 9

7. Snap the holder in place so the two screw holes line up with the holes on the printer.

8. Install the T8 screws using the INCLUDED Allen key or a Torx T8 screwdriver.

9. Rotate the printer back on its feet.

10 |

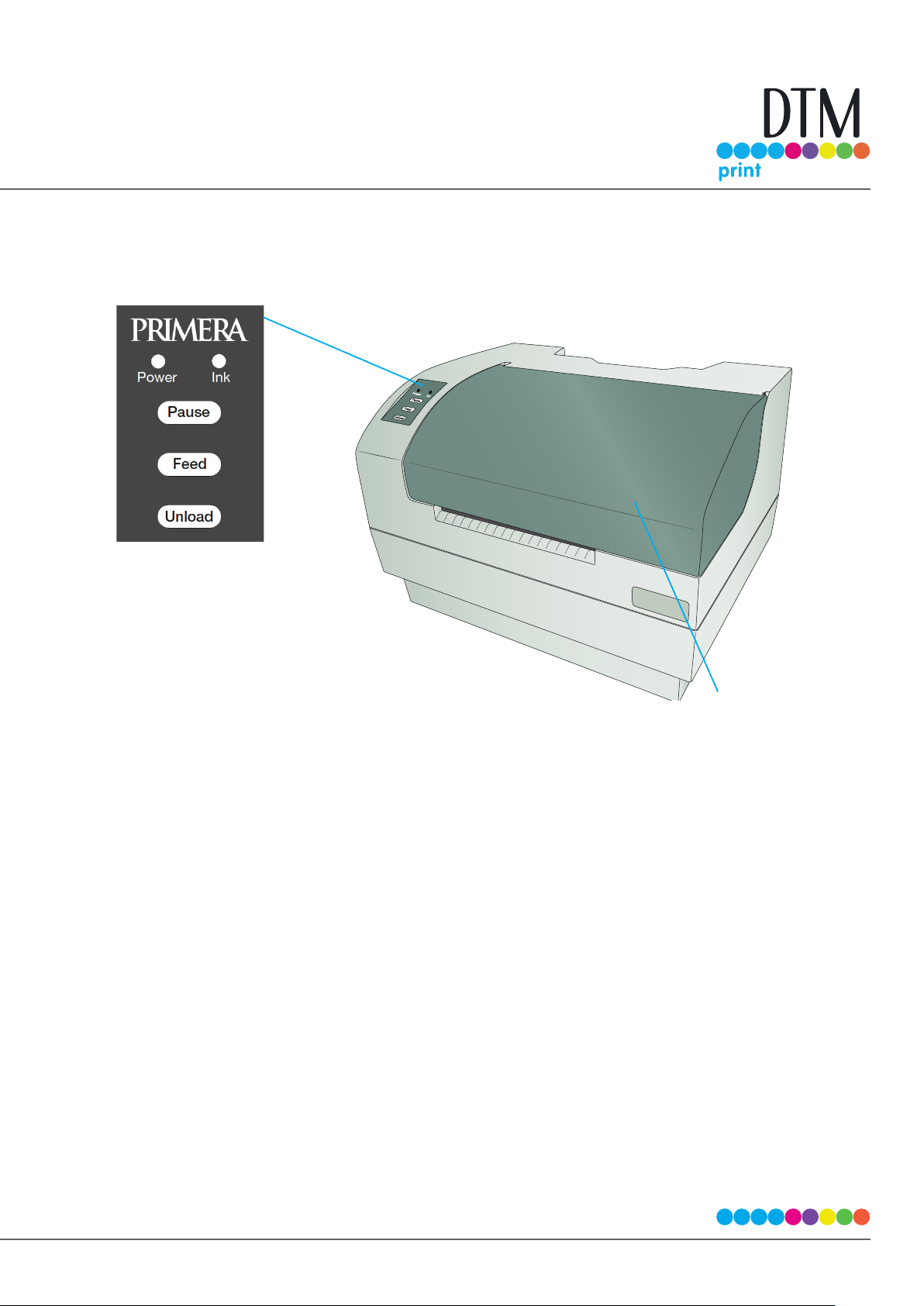

1D Identifying the Parts

These illustration shows the printer from various angles so all important parts can be identied.

Control Panel

Front Cover

The Power LED indicates that the printer is on and ready to receive print jobs.

The Ink LED will illuminate when a cartridge has 10% or less of its ink remaining.

The Pause Button is pressed to pause a job to allow for loading of label stock and ink cartridges. The print-

er pauses after the printing of the current label has nished.

The Feed Button is pressed in order to load label stock if the printer does not automatically detect the

stock. When stock is loaded each press of the button will cause one label or a few inches to be fed through

the printer.

The Unload Button is pressed to unload label stock after you receive an End of Roll message in PrintHub.

The printer will reverse the label stock through the feed area.

| 11

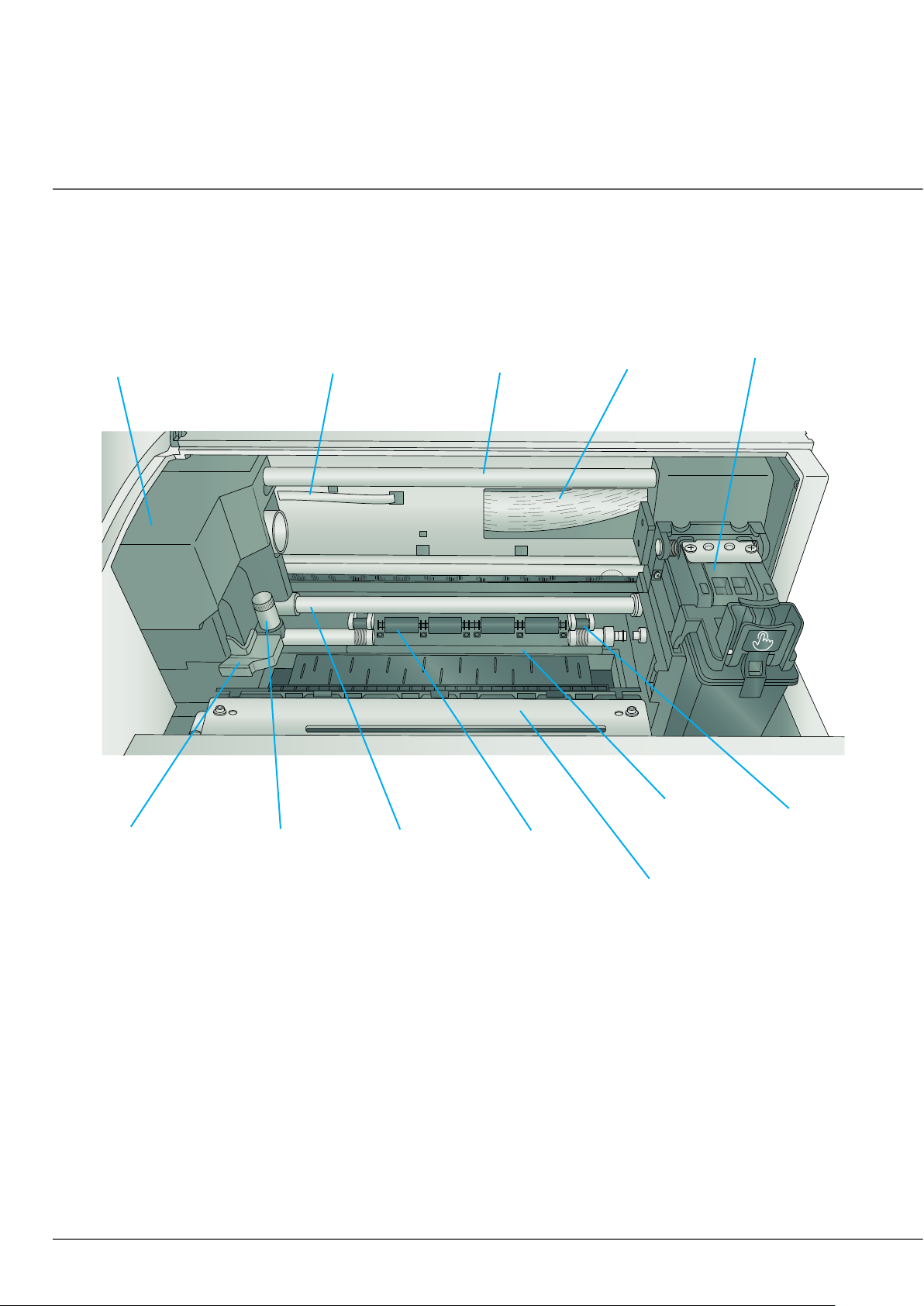

Interior

Die Cutting

Carriage

Die Cutter

Ribbon Cable

Upper Guide

Shaft

Print Carrier

Ribbon Cable

Print Carrier

Knife Collar

Handle

12 |

Die Cutting

Knife

Lower Guide

Shaft

Pre die-cut

rollers

Wear Strip

Die Cutting

Pinch Rollers

Cutter Wheel

Mechanism

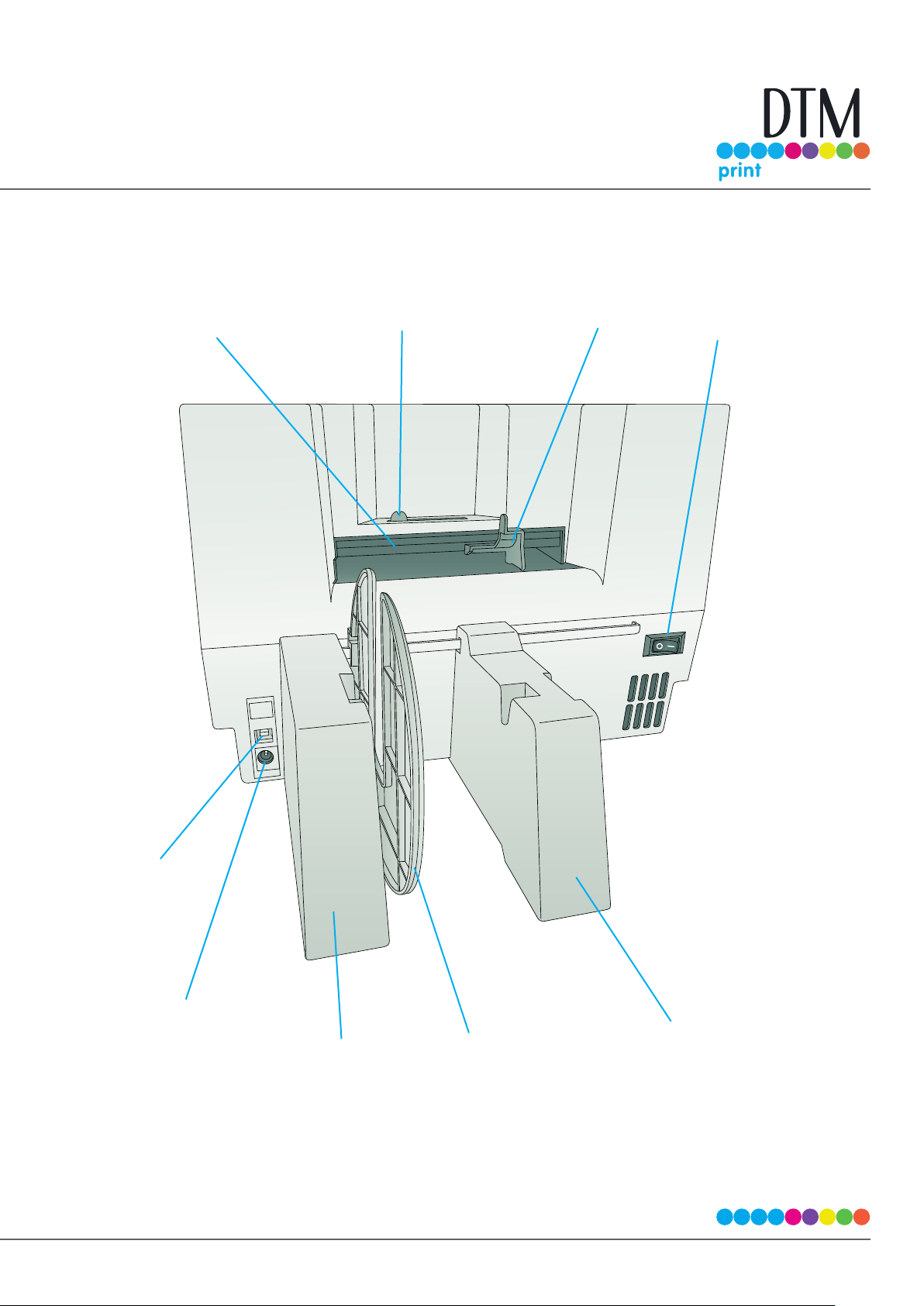

Back

Infeed Area

Gap Sensor

Adjustment

Movable

Throat Guide

Power Switch

USB

Power

Fixed Roller

Holder w/

Chip Reader

Fixed Guide

Movable Roll

Holder

| 13

Section 2: Media, Cartridges and Knives

2A Label and Roll Specifications

Pre Die-Cut Labels. A wide variety of pre die-cut label stock can be used in the printer. Refer to the

specications and settings in the following sections before ordering custom stock from Primera or any

stock from another company.

Digital Die-Cut Labels. If you are using the printer to digitally die-cut your own shapes and sizes only

DTM/Primera or Primera ASIA label stock can be used.

Important! Test all custom made label stock with the intended printer before ordering large quantities!

Primera will only assume responsibility for custom label stock ordered from DTM/Primera or Primera ASIA.

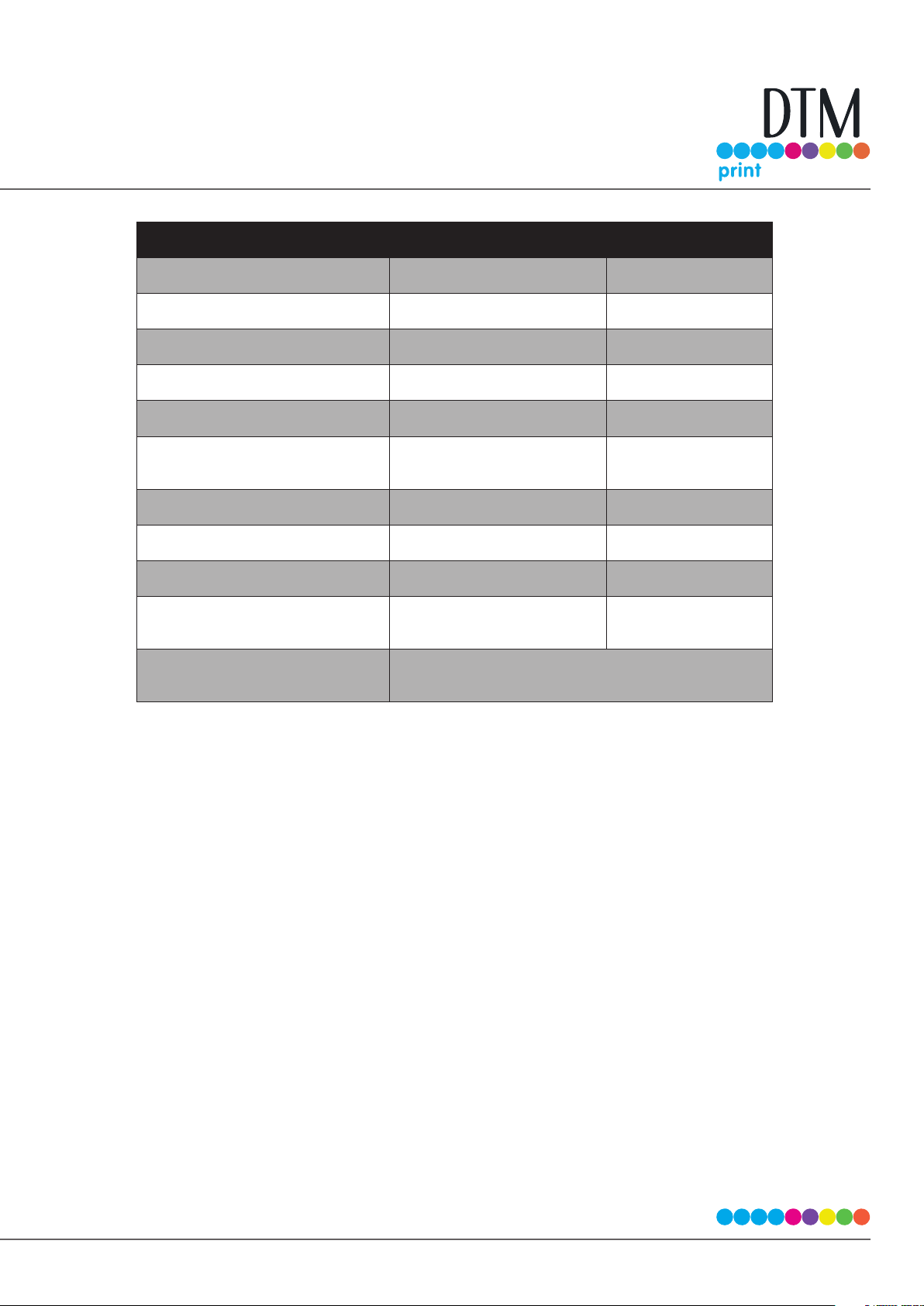

Label Sensing Methods

Label Width

Method 1: Label

Gap Sensing

Method 2: Through-Hole

Sensing

Method 3: Reective/Black

Mark Sensing

(Black Mark must be printed

on back side of label stock)

Label Width

Gap Sensor Adjustment Range

Width of Opening

Distance from

edge of Media

to edge of Label

Gap Between

Labels

Label Height

Black Mark

Width

14 |

Note: See table below for Max and Min values in inches and mm.

Max Min

Label width 127 mm (5”) 13 mm (0.5”)

Liner/media width 130.17 mm (5.125”) 54 mm (2.125”)

Label height/length 305 mm (12”) 13 mm (0.5”)

Gap between labels 253 mm (10”) 2.5 mm (0.10”)

Width of through-hole 12.65 mm (0.5”) 6.325 mm (0.25”)

Gap Sensor Adjustment

Range (from left edge)

Reective/Black Mark Width* N/A 2.54 mm (0.1”)

Max Outer Diameter (OD) 152.4 mm(6.0”) N/A

Inner Core Diameter (ID) 76.2 mm (3.0”) 76.2 mm (3.0”)

Recommended Total Thickness

(Liner + Label)**

Distance from edge of media to

edge of label

52 mm (2.05”) 10.16 mm (0.40”)

10 mil (.0010”)

Printer assumes 2 mm (1/16”) gap. However, this is adjustable

via the left margin oset.

* The Reective/Black Mark should be opaque to infrared light. The mark should be between the labels. The

end of the mark should correspond with the beginning of the label.

** This is the recommended maximum. There are two factors that determine whether the printer will accept

any particular stock thickness.

1. The ability for the printer to pull the paper through the print area.

2. The ability for the sensor to read through the backing if the sensor is set to die-cut.

If you are printing in continuous or reective label sensing mode number 2 does not apply. The fact that the

printer must read through the backing in die-cut mode will limit the thickness much more than the

printer’s ability to pull the paper through the print area. However, if you adjust opacity level of the liner

enough to allow the label to be seen by the stock sensor, the thickness will only be limited by the printer’s

ability to pull it through the printer area. For these reasons the weight or thickness of the liner is a variable

that cannot easily be dened. Primera recommends and uses 40# liner with all Pre Die-Cut label stock.

It is important to test all label stock with the intended printer before ordering large quantities!

| 15

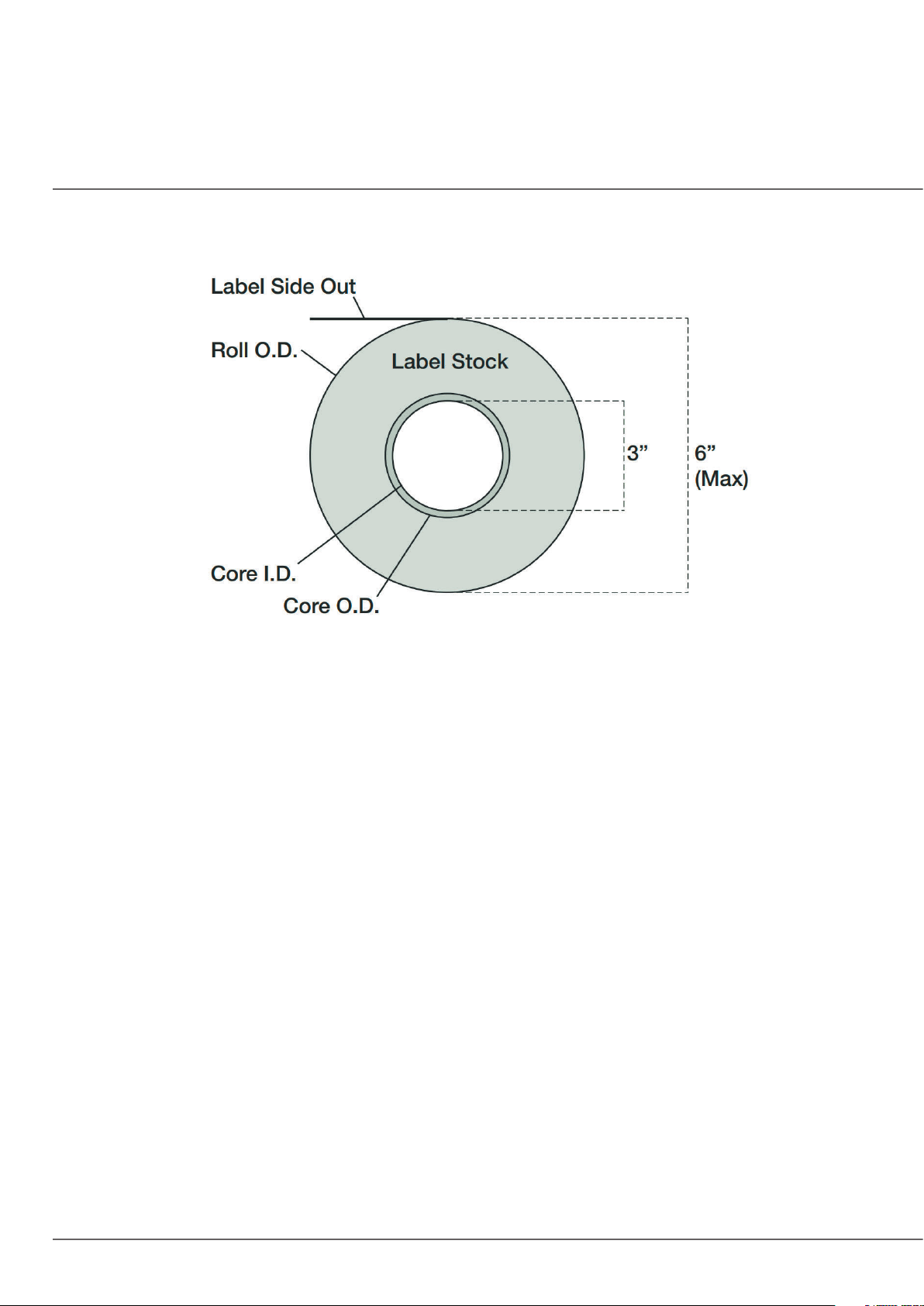

Roll specifications:

Note on Label Orientation: If you are using an applicator to apply your labels, be sure to order label stock with the correct

orientation for your applicator. For example, most applicators will apply the side of the label rst, so you will want to print the

labels sideways.

16 |

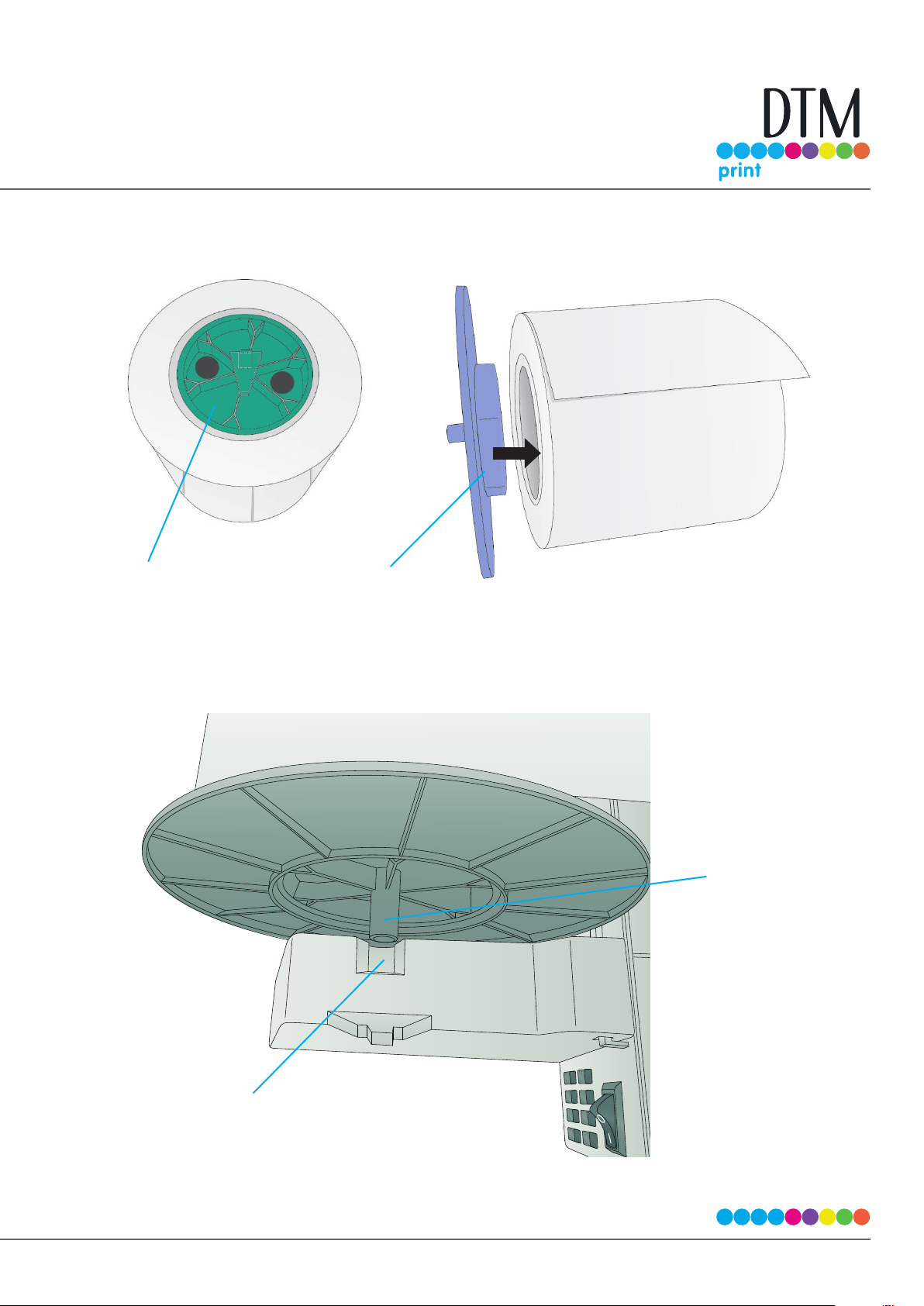

2B Installing Digital Die-Cutting Label Stock

1. Move the roll holder to the preset position for on demand digital die-cutting

(3rd mark from the left – 1.25”)

Move to third

mark from Left

2. Install the Blue Hub on the open side of the digital die-cutting media.

Note: The green hub is not needed for

digital die-cutting and can be stored in

the notch on the movable holder.

Digital Die Cutting

Media comes with

black hub with green

chip.

Blue Hub

| 17

3. Set the roll in place so that the blue pin sits in the notch on the roll holder.

Notch

Blue Pin

4. Make sure the green chip holder ts in the corresponding green slot on the roll holder.

Green Chip

Holder

Notch

18 |

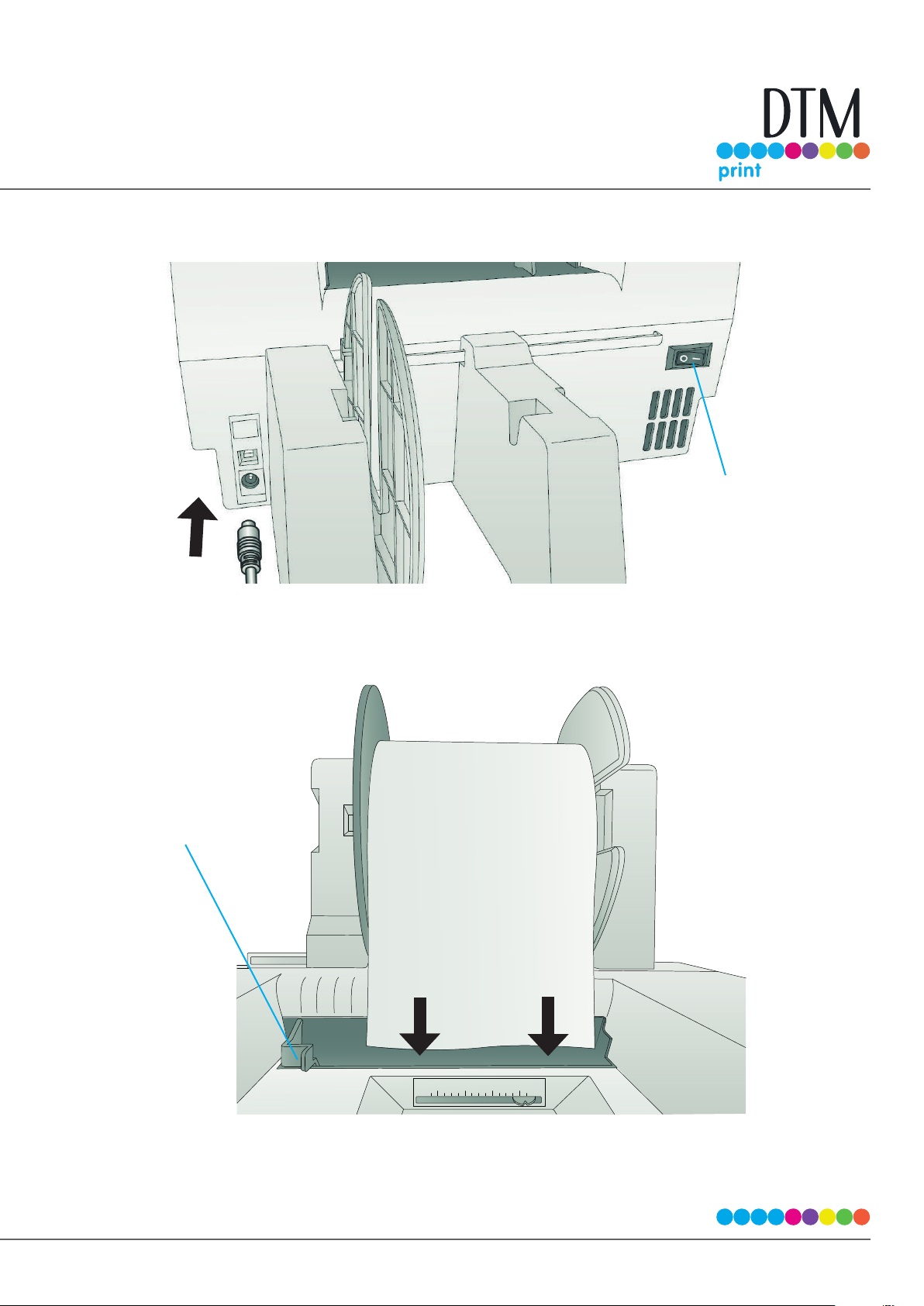

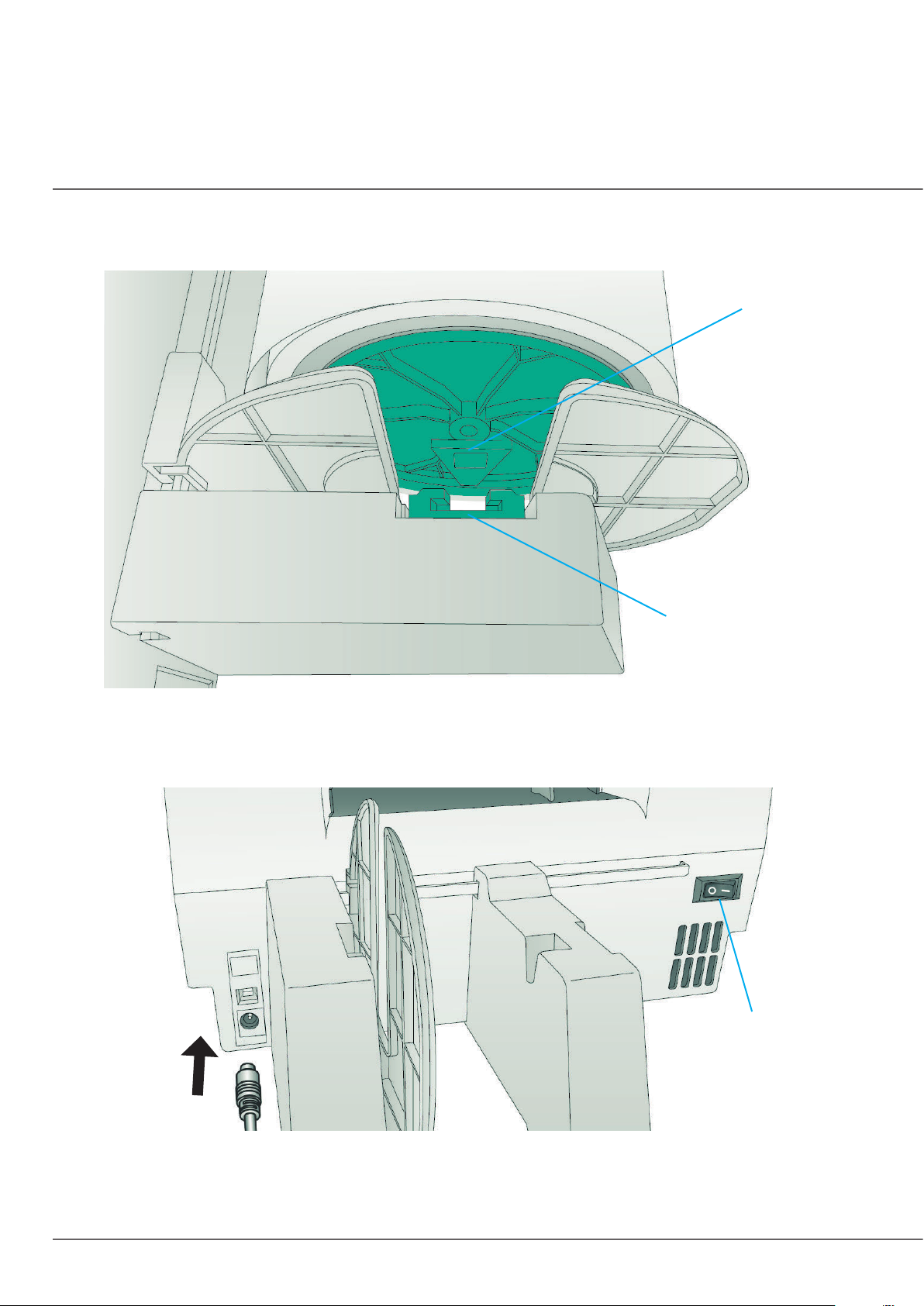

5. Before feeding the stock you must plug in power and switch on the printer.

Power Switch

Power Cable

6. Guide the leading edge of the roll into the feed area. Move the blue guide to the far side.

Blue Guide

50.8 38.1 25.4 12.7

2.0 1.5 1.0 0.5

mm

in

7. Push until the printer detects the stock, grabs it and pulls it through the printer.

| 19

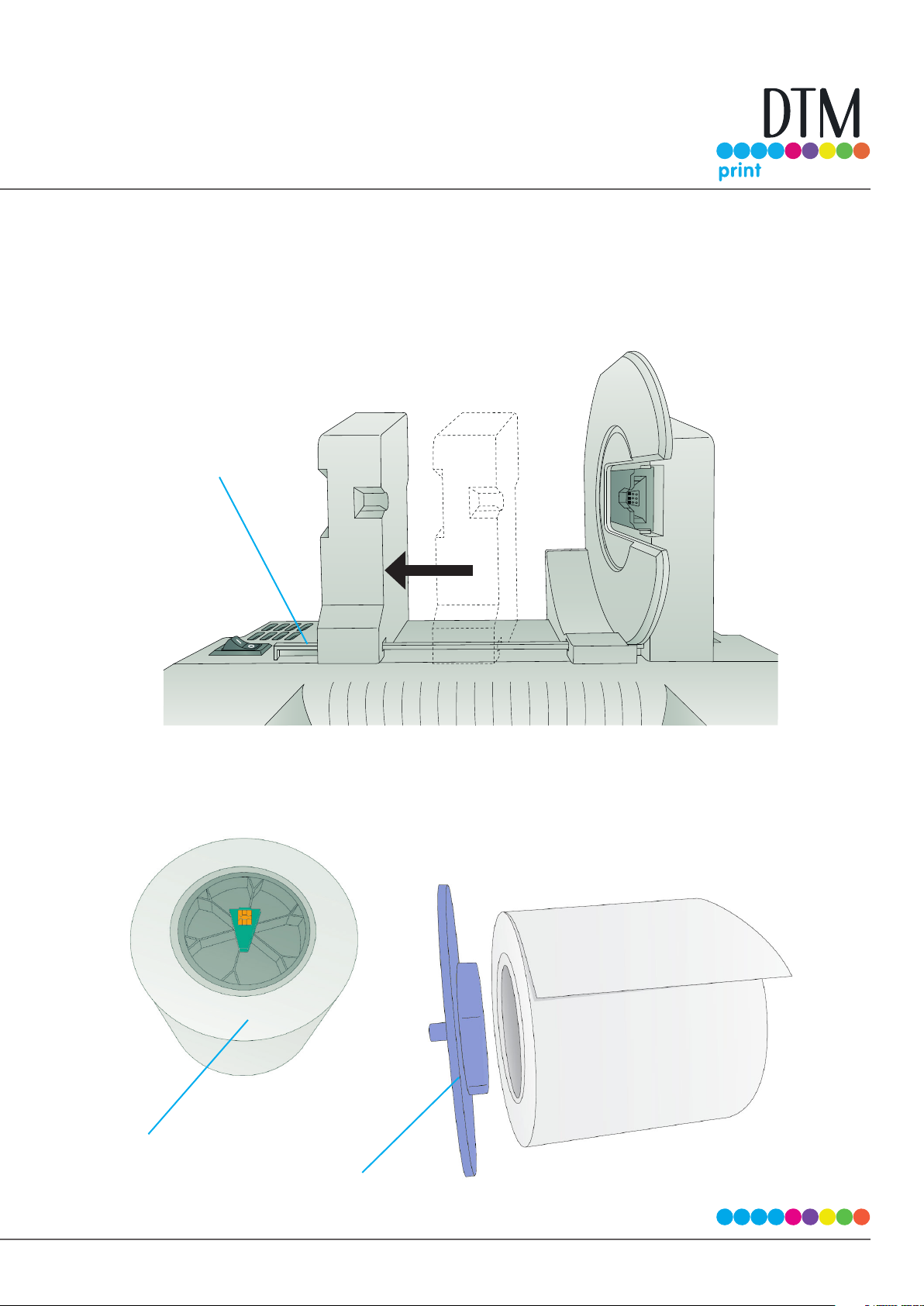

2C Installing Pre Die-Cut Label Stock

1. Move the roll holder to the approximate position which matches the width of the stock you are

installing. You can always ne tune this later.

2. Install the Green Hub on the right side of the pre die-cut media.

Die Cuts

Green Hub

Blank Chip Holder

Continuous Media

Pre Die-Cut Roll

(User must install Green Hub)

Smart Chip

(Hub/Chip comes preinstalled)

Black Hub

Digital Die-Cut Roll

20 |

3. Install the Blue Hub on the left side of the digital die cutting media.

Pre Die-Cut Media

Blue Hub

4. Set the roll in place so that the blue pin sits in the notch on the roll holder.

Blue Pin

Notch

| 21

5. Make sure the green blank chip holder ts in the corresponding green slot on the roll holder.

Green Chip

Holder

Notch

Before feeding the stock you must plug in power and switch on the printer.

Power Cable

Power Switch

22 |

6. Guide the leading edge of the roll into the feed area. Move the blue guide so that it touches the

label stock.

Gap sensor should

intersect the gap

between labels

Blue Guide

50.8 38.1 25.4 12.7

2.0 1.5 1.0 0.5

mm

in

Note: the positon of the label sensor. Slide

the sensor position indicator so that it

intersects with the gaps between your labels.

Gap Sensor Position

Indicator from right

edge of media

For most label stock you will not need to

move this.

7. Push until the printer detects the stock, grabs it and pulls it through the printer.

| 23

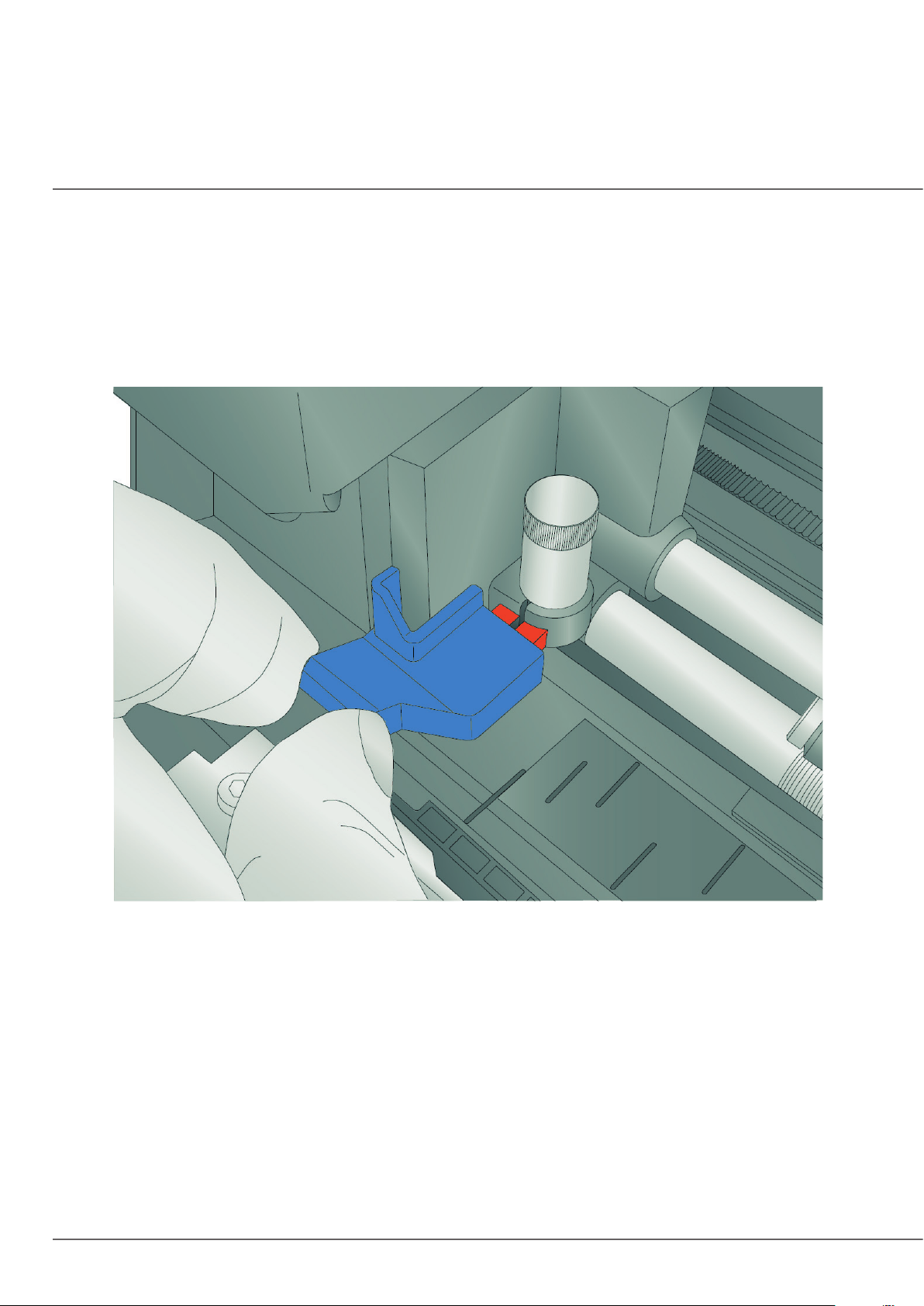

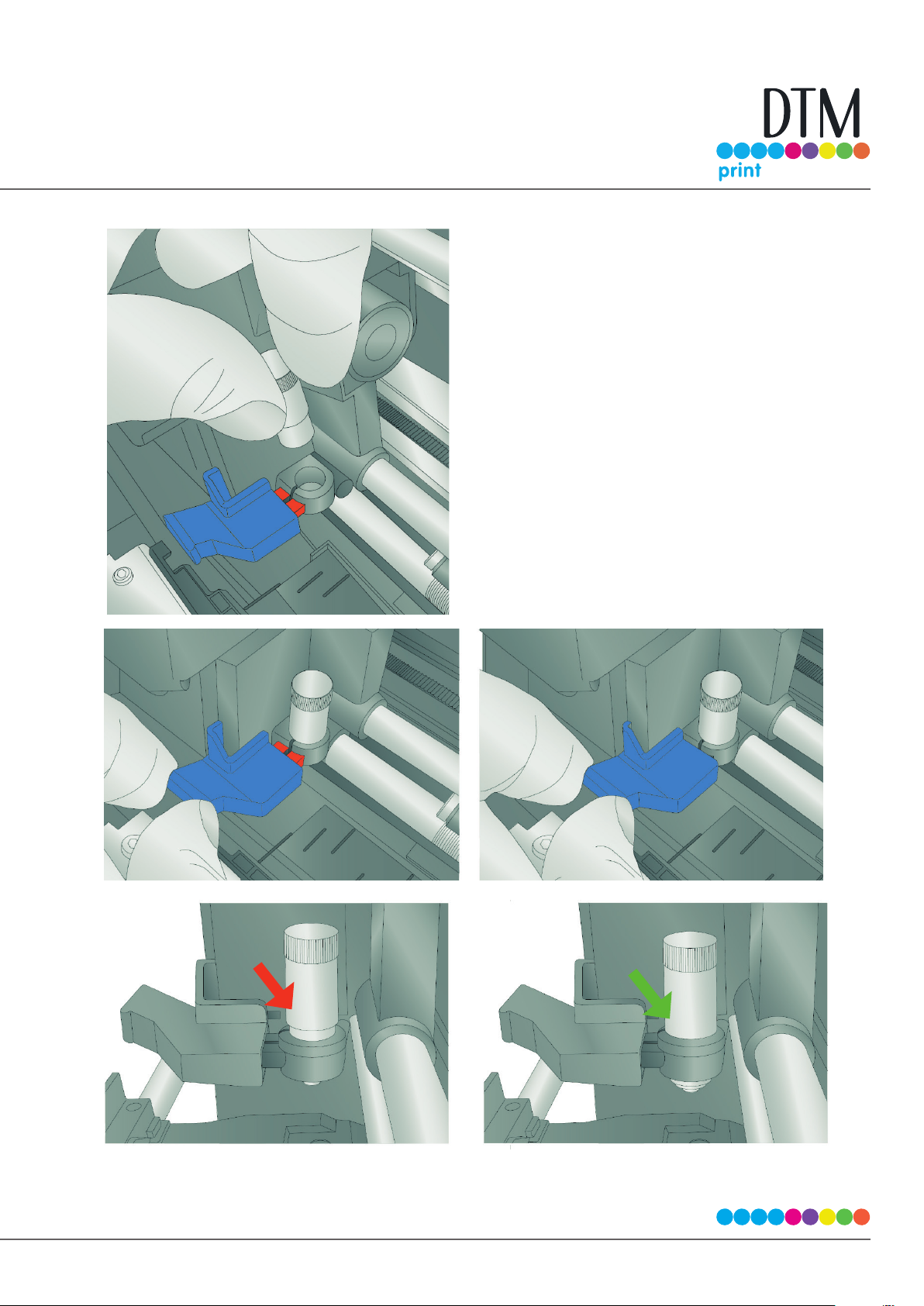

2D Replacing the Digital Die Cutting Knife holder

Install the included die cutting knife shown here.

1. Open the Cover

2. Pull out on the blue handle to loosen the knife collar.

24 |

3. Install the knife holder.

4. Push on the knife so it goes all the way

down before pushing the collar in.

5. Push the collar to tighten the knife holder

and allow it to cut.

Wrong !

RIGHT

| 25

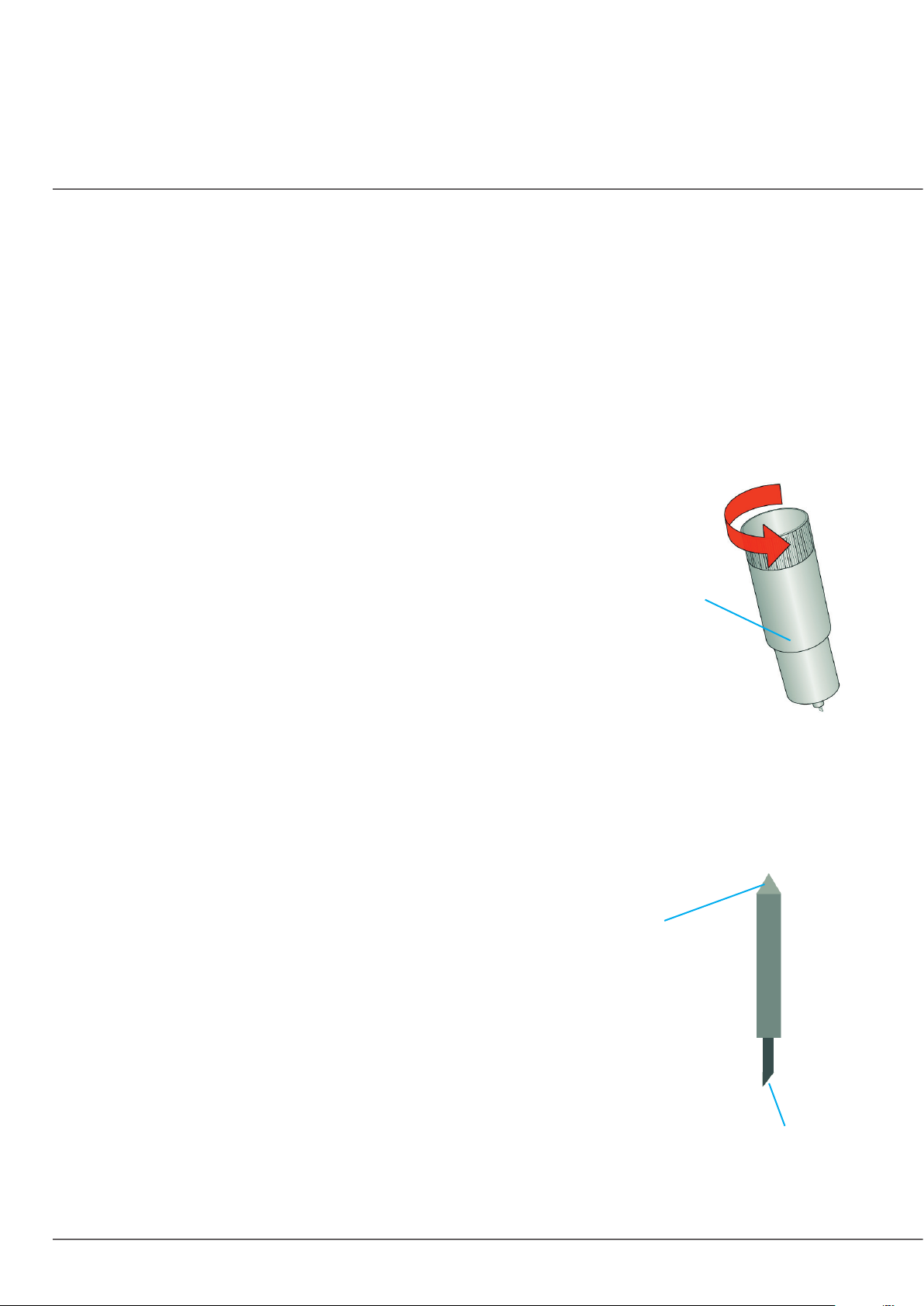

2E Replacing the Cutting Knife

When a knife is dull it will no longer cut through the label at maximum pressure. You will start to see ragged

cuts or cuts that do not cut all the way through the label material. You can attempt to increase the pressure

but you’ll probably need to replace the knife.

If a knife cuts through the liner and contacts the wear strip it may break the tip of the knife. This can be seen

under 10x magnication using a loupe or magnifying glass. If the tip is broken the knife must be replaced.

If your knife needs replacement, follow this procedure:

1. Remove the knife holder from the carrier using the instructions from

section 2D.

Knife Holder

2. Rotate the cap of the knife holder counter clockwise.

3. Remove the knife from the holder. You can tap the holder on a hard

surface to free the knife from the holder.

4. Locate a new knife. Remove the molded plastic cover from the knife. The plastic cap covers

the cutting end of the knife. However, both sides are sharp! The cutting end has an angled carbide

tip. The top end comes to a point so it can be easily centered in the receiving divot on the knife

holder cap.

5. Insert the cutting end into the knife holder.

Centering

Point

6. Using the knife holder cover center the back end of the knife in the

holder. You may need to screw down the cover and reverse it

several times until the knife has been centered. Do not force the

cap on the holder. The carbide tip will brea

Carbide Tip

Replacement Cutter Knife 5 pack Part Number: 074332

(Cutting End)

Replacement Knife Holder Part Number: 074548

26 |

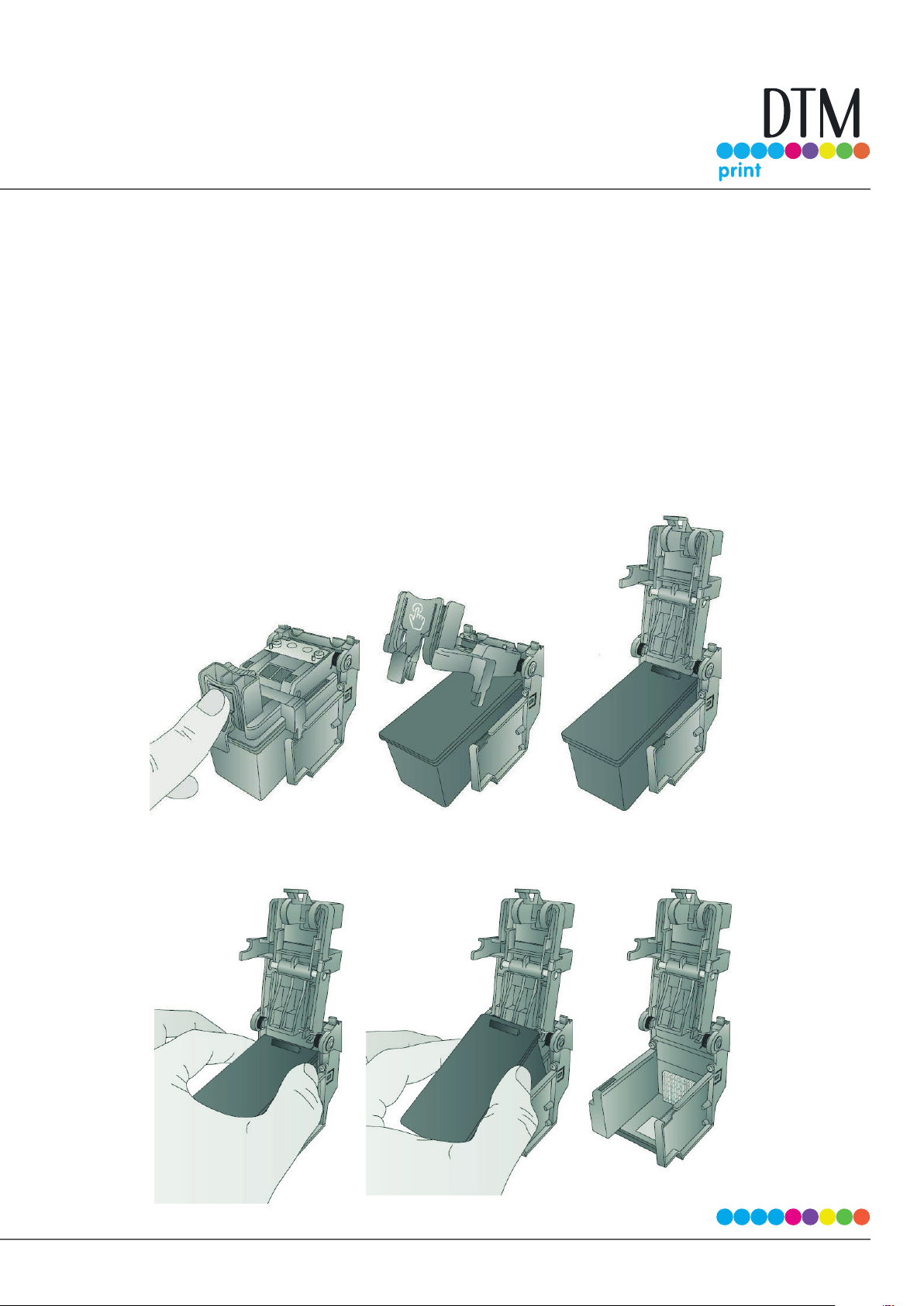

2F Replacing Ink Cartridges

You can replace cartridges at any time or wait for the Low Ink Warning to prompt you to replace

cartridges. You will receive low ink warnings at 10% and 0%. Press the Load/Feed button to continue

printing after you receive this warning.

To change a cartridge, follow this procedure:

1. Open the front cover. That cartridge will automatically move to the right side if it is not

already there.

2. Press or pinch the tab on the front of the cartridge holder.

3. Remove the cartridge.

| 27

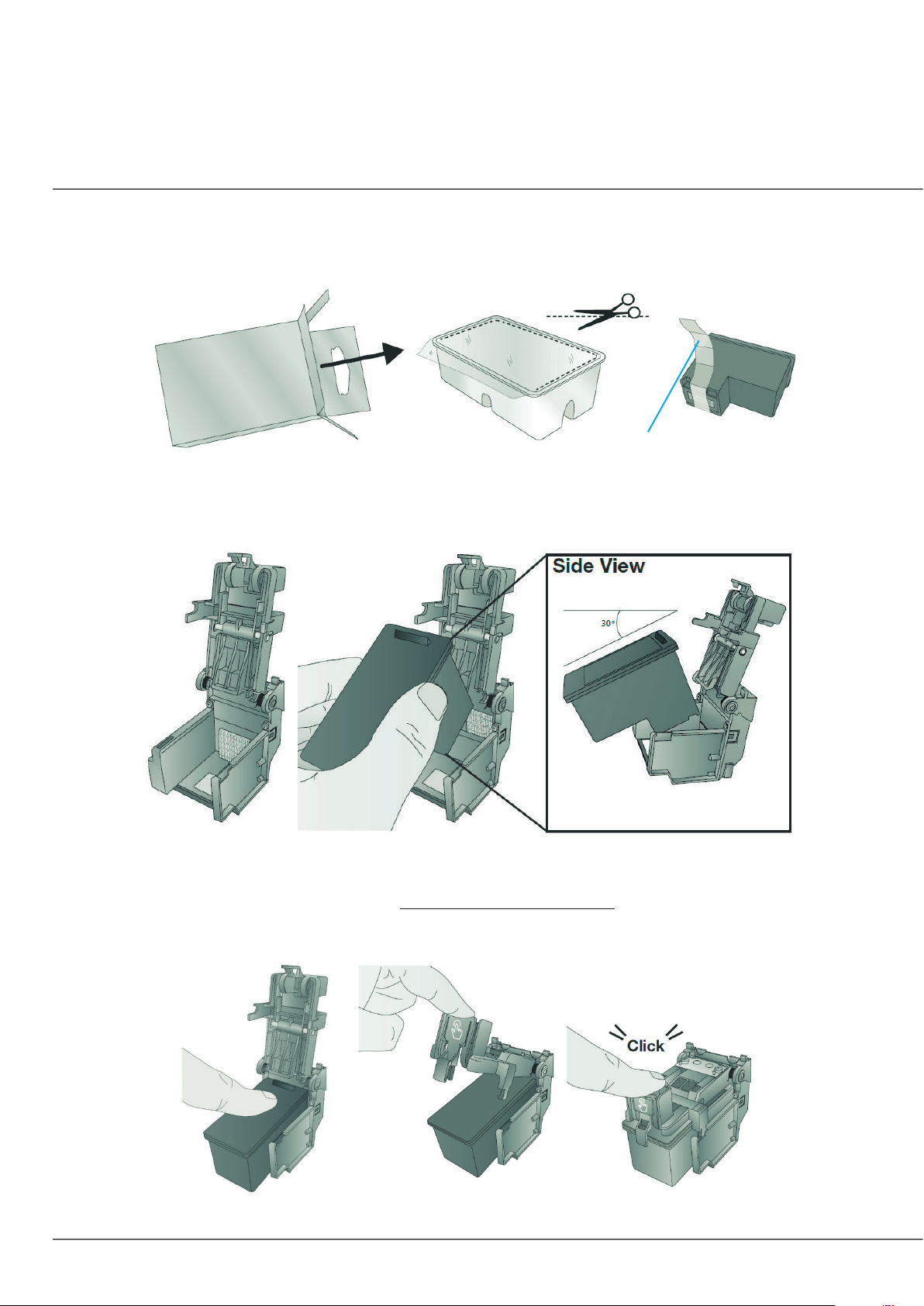

4. Locate a new cartridge and remove it from its packaging. Remove the foil outer package and

the tape covering the nozzles.

Remove Tape

5.

Place the new cartridge into the empty carriage. Note: When installing the cartridge, tilt the

cartridge at a slight backward angle of approximately 30 degrees.

6. Make sure the cartridge is pushed back far enough so the ridge on the cartridge is behind

the spring-loaded pusher on the lid. Push down on the cartridge. Close the lid on the cartridge by

lightly pressing down from the top until you hear a click.

PUSH DOWN

28 |

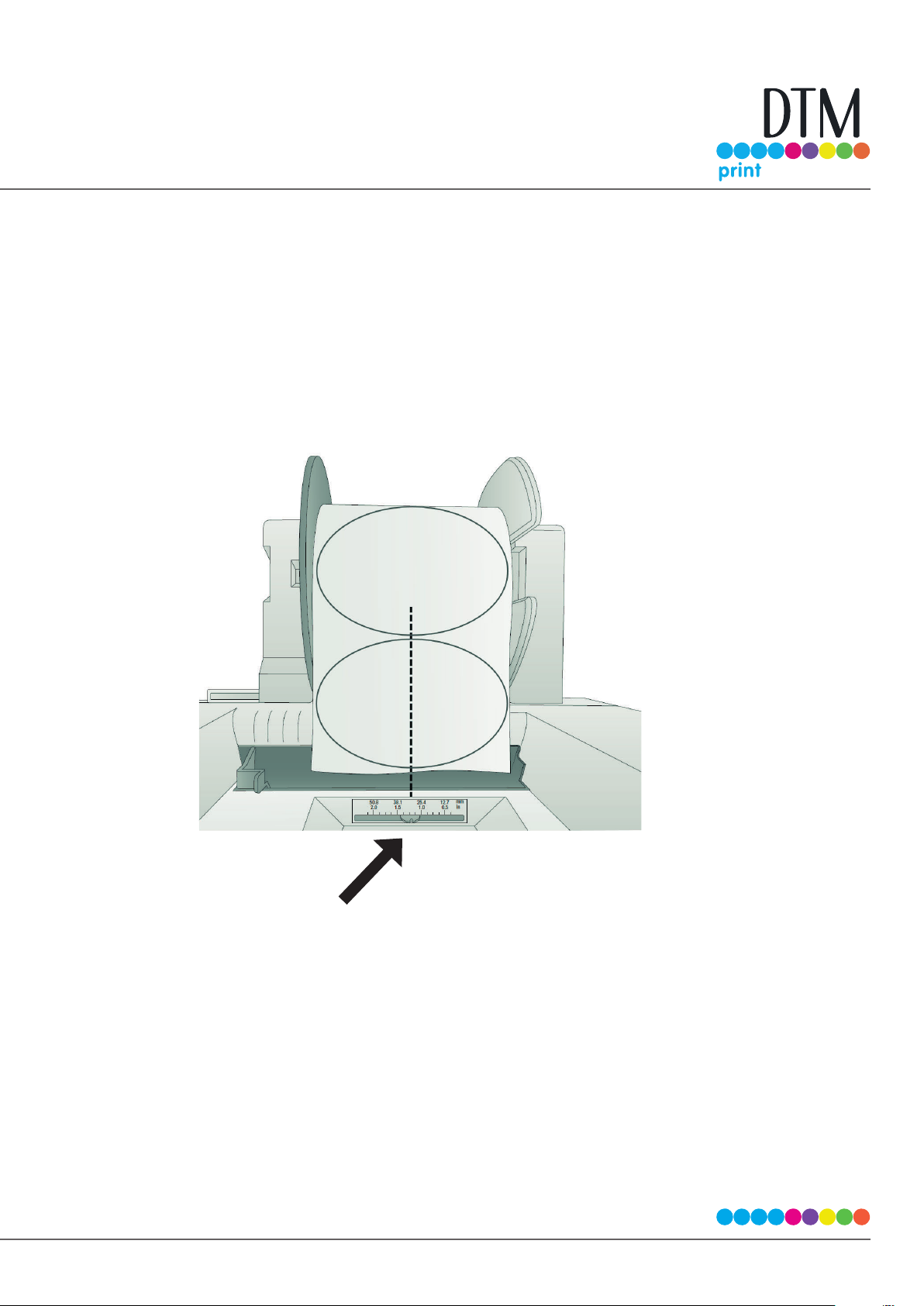

2G Adjusting the Gap Sensor Position (Pre Die-Cut Labels Only)

If you are using label stock other than standard square / rectangular die-cut labels such as circular die-cut

labels or through-hole stock use the instructions below to adjust the position of the label stock gap sensor.

The sensor can be adjusted using the slide bar on the back of the printer. Below the slide bar is a

measurement which represents the distance between the edge of the label stock and the sensor. Measure

the distance from the edge of the label stock to the correct position on the stock. Set the sensor so the side

of the slide bar lines up to this measurement. See dashed line in the illustration below.

Important Note: You must adjust the stock

sensor before loading nonstandard label

stock.

| 29

Circular Labels

If you are using Circular Labels you must adjust the stock sensor to correspond with the very top of the

label where the circles are closest together. If the sensor is too far to the right or the left the printer will still

sense the label but the image may be oset downward because the printer will start printing at the wrong

position. If you are using stock that has multiple labels across, make sure the sensor corresponds to a place

on the stock that has a label and not a vertical gap Important Note: You must adjust the stock sensor before

loading nonstandard label stock.31The sensor can only be moved a maximum of 2 inches from the left side

of the printable area. This means that the maximum diameter circular label that can be printed is 4 inches.

For circular labels larger than 4 inches in diameter, you must have a black mark printed on the back of the

label stock.This means that you must change the Stock Sensor Mode to Reective. The printer will now look

for the black mark representing the beginning of the next label instead of the die-cut. For moreinformation

on changing the Stock Sensor Mode see section 3C.

30 |

Loading...

Loading...