DTI DCLDD1 0 Series Manual

Manual

1 SAFETY INSTRUCTIONS

A)Keep these Operating Instructions in a place where they can always be easily consulted by the operator or by

maintenance personnel.

B)Before making an intervention or connection of any kind, make sure that the mains are disconnected both from

the instrument and from any device connected to it.

C)Caution, there may be hot components inside the plastic instrument container.

D)No user-serviceable parts are inside the plastic instrument container.

E)DTI products and any other device connected to them must be installed in compliance with the safety

regulations in force.

F)Make sure that, whenever a transformer for instrument power supply is required, it complies with the safety

regulations in force.

G)DTI products are designed and manufactured in compliance with the safety regulations in force. Nevertheless, if

our products are not installed in accordance with the Safety Instructions, as well as the indications given in these

Operating Instructions, then this may cause a reduction of the safety level of our products. Furthermore, the

ambient operating conditions given in our technical data must be complied by, and in any case absolutely avoid:

water condensation or excessive humidity; exposure to steam, corrosive - or toxic gases, contact with any type of

liquid, and exposure to shocks or to extreme vibrations. Not respecting the above indications could cause

malfunctioning and unpredictable consequences, e.g., in the worst cases malfunctions that could cause dangerous

electrical discharges on probes or other parts.

H)DTI products are guaranteed for a specific level of immunity against electromagnetic disturbances in

compliance with EC regulations. We would like to call to mind that electromagnetic disturbances can be either

irradiated and/or conducted. By irradiated electromagnetic disturbances we recommend to screen the

instruments with a metallic screen connected to ground. To eliminate, or at least reduce conducted

electromagnetic disturbances, that do not only propagate through the power supply, but also through probes or

connected loads, we recommend to carry out the electrical wiring according to the indications given in these

Operating Instructions. lf necessary, use filters suitable for specific applications and for the type of disturbances

detected.

I)lf probes are to be used in contact with foodstuffs, make sure that the employed type of probe is in compliance

with the local sanitary / health regulations.

J)DTI products do not provide any type of protection for the connected loads against: short-circuits, overcurrent

or overvoltage, excessive temperature etc., that must therefore be protected by suitable means (such as fuses,

thermo-magnetic circuit breakers, thermal protections,etc.). At any rate the electrical power lines that (directly or

through a transformer) supply an DTI product and any other device connected to it, must be manufactured in

compliance with theregulations in force.

K)When incorporating an DTI product in other devices, where any malfunction whatsoever of the DTI product

could cause a form of risk to persons, animals or things, it is ABSOLUTELY MANDATORY to provide a suitable

safety device, other than the DTI product, that automatically starts operating in case of a failure.

L)DTI products cannot be used as critical components in life supportdevices or systems without an expressly

written approval of the Managing Director of DTI.

DCLDD1x0xx

1. SAFETY INSTRUCTIONS

2. GENERAL DESCRIPTION

3. TECHNICAL FEATURES

4. INSTALLATION AND SCHEMES

5. FUNCTIONS

6. MAINTENANCE

7. CALIBRATION

8. ABOUT THE OPERATING INSTRUCTIONS

2 GENERAL DESCRIPTION

revision 1.0 30.10.2013

1

Manuale d’uso

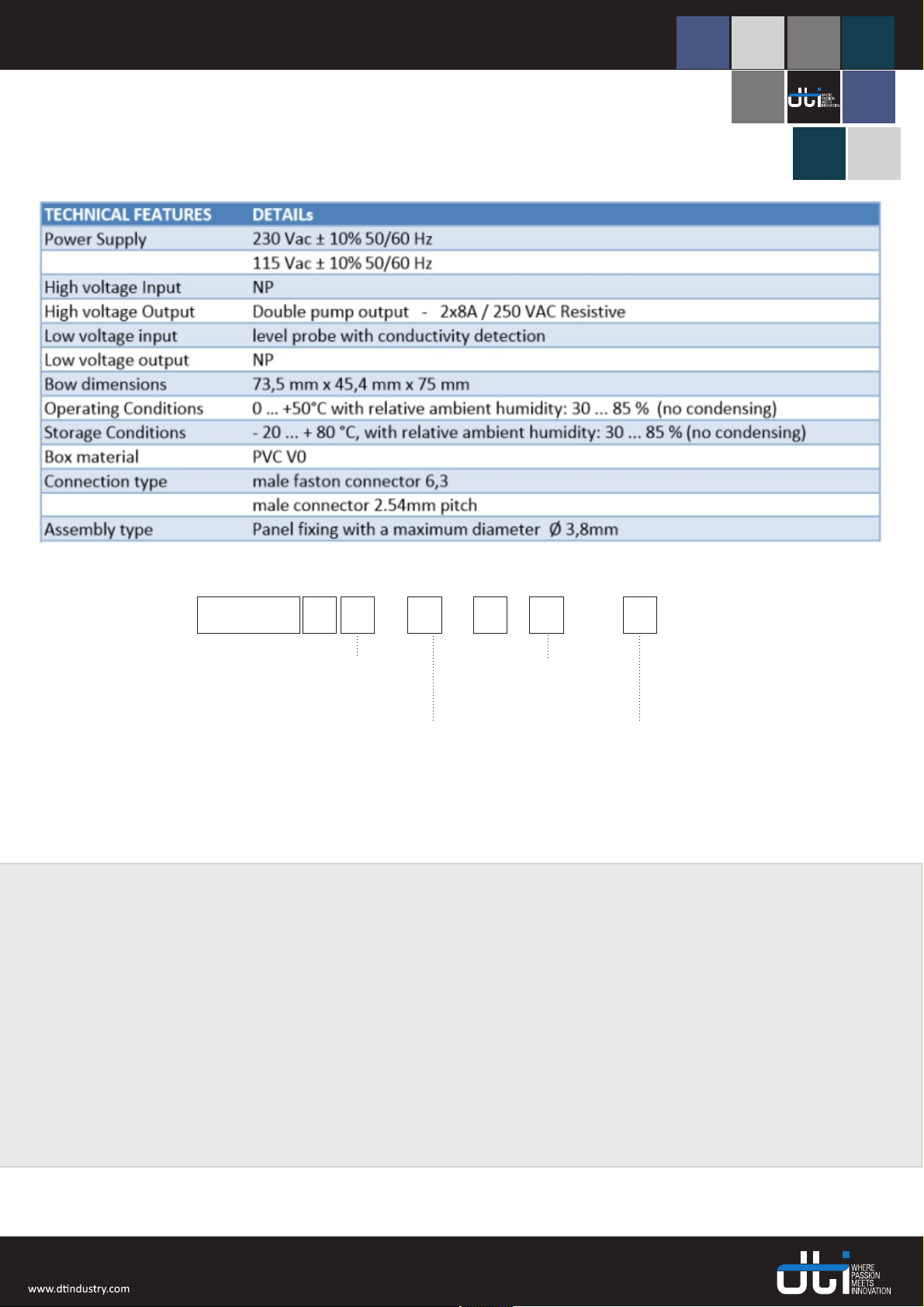

3. TECHNICAL FEATURES

DCLDD1x0xx

CONFIGURATION

DCLD

TYPES OF OUTPUTS

0= 1 Relè 16 A 250 Vac Resistive

1= 1 Relè 2x8A 250 Vac Resistive

D

1 1

POWER SUPPLY

1= 230 Vac 50/60Hz

2= 115 Vac 50/60Hz

0 0 0

TYPE OF CONNECTIONS

0= Male Faston 6.3

1= Male connector

TIME OUT

0= not present

1= 150seconds

5 FUNCTIONS

Loading cycle of a boiler with one level probe:

The loading function regulates and controls the correct level of water in the boiler.

If the level probe in not covered by water, then the pump and solenoid valveoutput are simultaneously activated. When the

probe is reached by water, the pump and solenoidvalveoutputare deactivated and remain switched off until the status of the

probechanges again.

revision 1.0 30.10.2013

2

Loading...

Loading...