Page 1

1

DYNertia3 user manual

Manual version 8.1 (≥ V3.3.0)

DISCLAIMER: This software and hardware is provided "as is" without warranty of any kind, either express or implied, including, without limitation, any warranty of merchantability and fitness for a

particular purpose. In no event shall the creators of this software be liable for any direct, special, incidental or consequential damages arising out of the use or inability to use the software. The creators

and distributors of this software shall not be liable for any loss, damages or costs, arising out of, but not limited to, lost profits or revenue, loss of use of the software, loss of data or equipment, the costs

WARNING: This hardware and software is protected by law and international treaties. Unauthorized reproduction or distribution of DYNertia3, or any portion of it, may result in severe civil and criminal

of recovering software, data or equipment or claims by third parties, damage to equipment, or other similar costs.

For continuous product improvement and due to ongoing development, we reserve the right to alter specifications without notice.

penalties and will be prosecuted to the maximum extent possible under law.

DYNertia3 software is copyright- Ross Mclean 2017

DYNertia3 hardware & firmware is copyright- Darren Todd 2017

www.dtec.net.au

Page 2

2

DYNertia3 user manual

STOP !!!

Please read the appropriate ‘Quick Start’ guide for your dyno

type (Chassis or Engine & Inertia or Brake) first.

Actual testing is outlined there!!!

This ‘full’ manual contains much detail; by reading the ‘Quick Start’

guide first you will gain a basic understanding of the concepts and

key points required.

There are sample files installed along with DYNertia3 software so you can connect

the hardware and learn to use many of the features without needing to perform actual

tests. It is much easier to study without the noise of a screaming engine!

All examples in this manual use ‘Metric’ units such as kph/Kw/Nm etc. DYNertia3 can

be set in the software to ‘Imperial’ if you prefer mph/Hp/Ft Lb etc!

www.dtec.net.au

Page 3

3

DYNertia3 user manual

Table of Contents

Chapter 1: Introduction .............................................................................................................................. 10

Introduction .......................................................................................................................................................... 11

Features ................................................................................................................................................................ 12

Overview- ......................................................................................................................................................... 12

Analysing Test Results-.................................................................................................................................. 12

Data Acquisition- ............................................................................................................................................. 13

File Management- ............................................................................................................................................ 14

Printing- ............................................................................................................................................................ 14

Additional Functions- ..................................................................................................................................... 14

Load Control Options (EC and PC units)- ..................................................................................................... 15

Chapter 2: Hardware Installation ............................................................................................................... 16

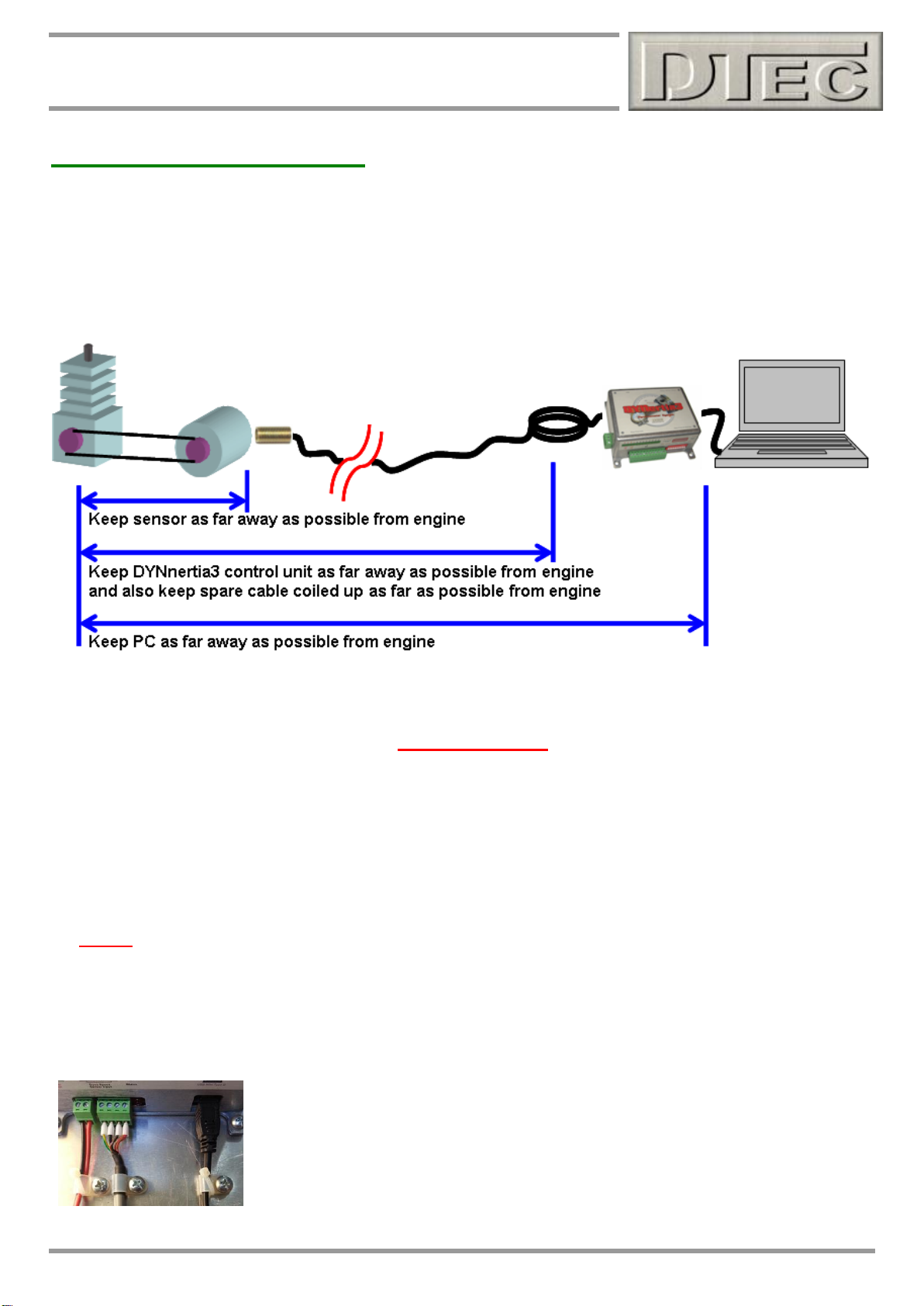

Hardware Mounting .............................................................................................................................................. 17

Mounting the DYNertia3 Sensor and Magnet ............................................................................................... 17

Alternate Sensors to the supplied one ......................................................................................................... 18

Mounting the Electronic Control Unit ........................................................................................................... 19

Hardware Wiring ................................................................................................................................................... 20

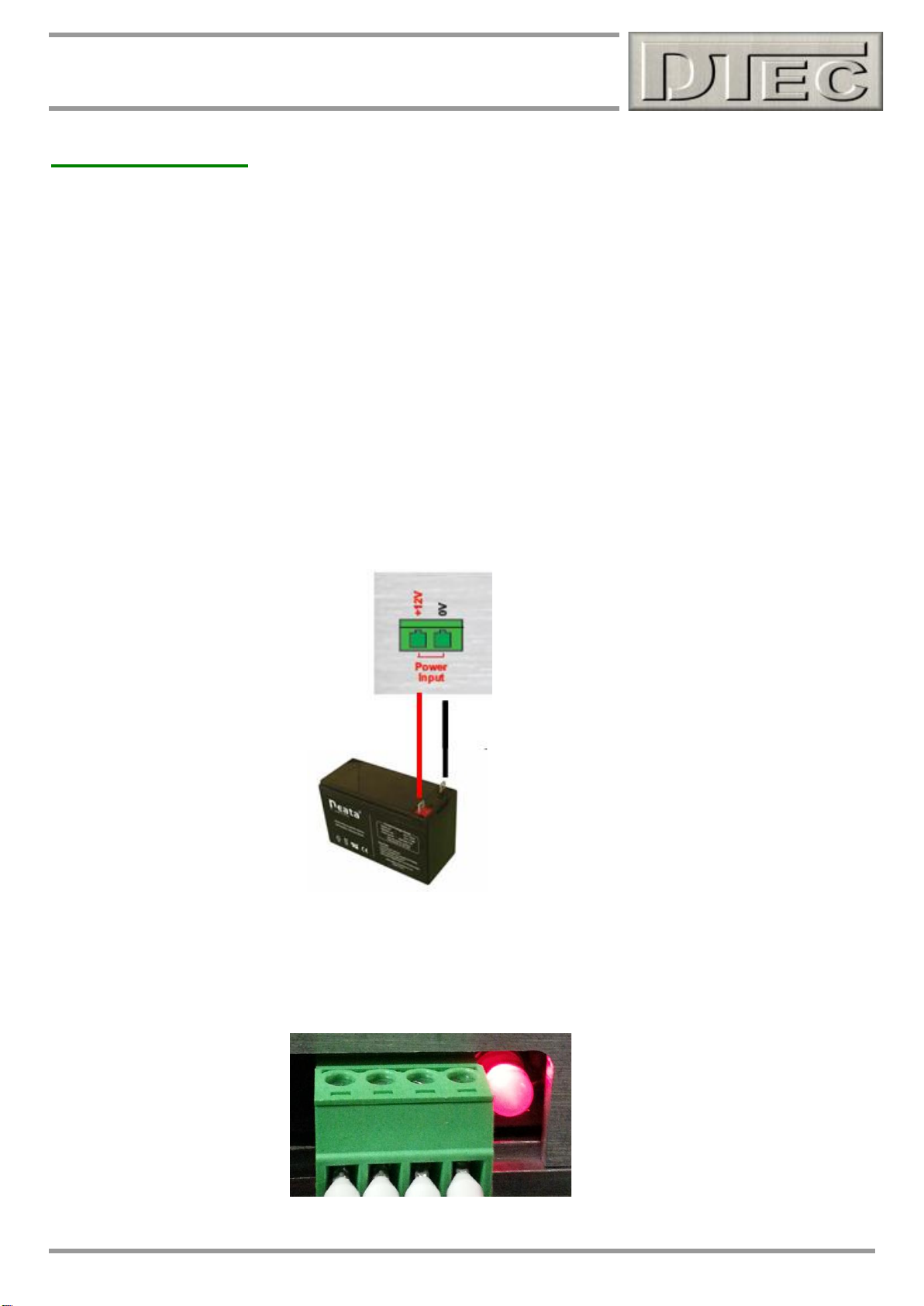

Power supply connection ............................................................................................................................... 20

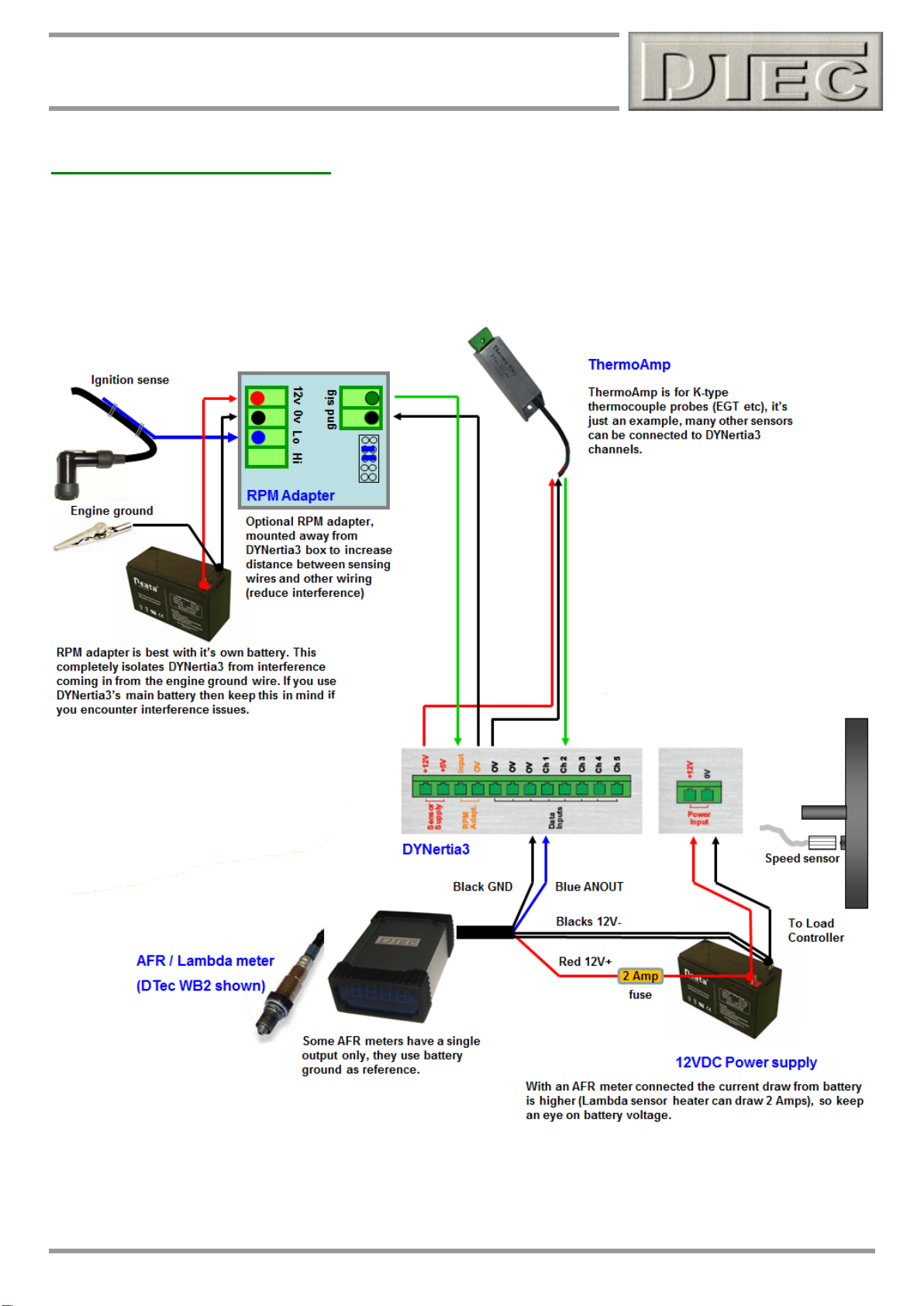

Example of typical wiring (additional devices shown) ................................................................................ 21

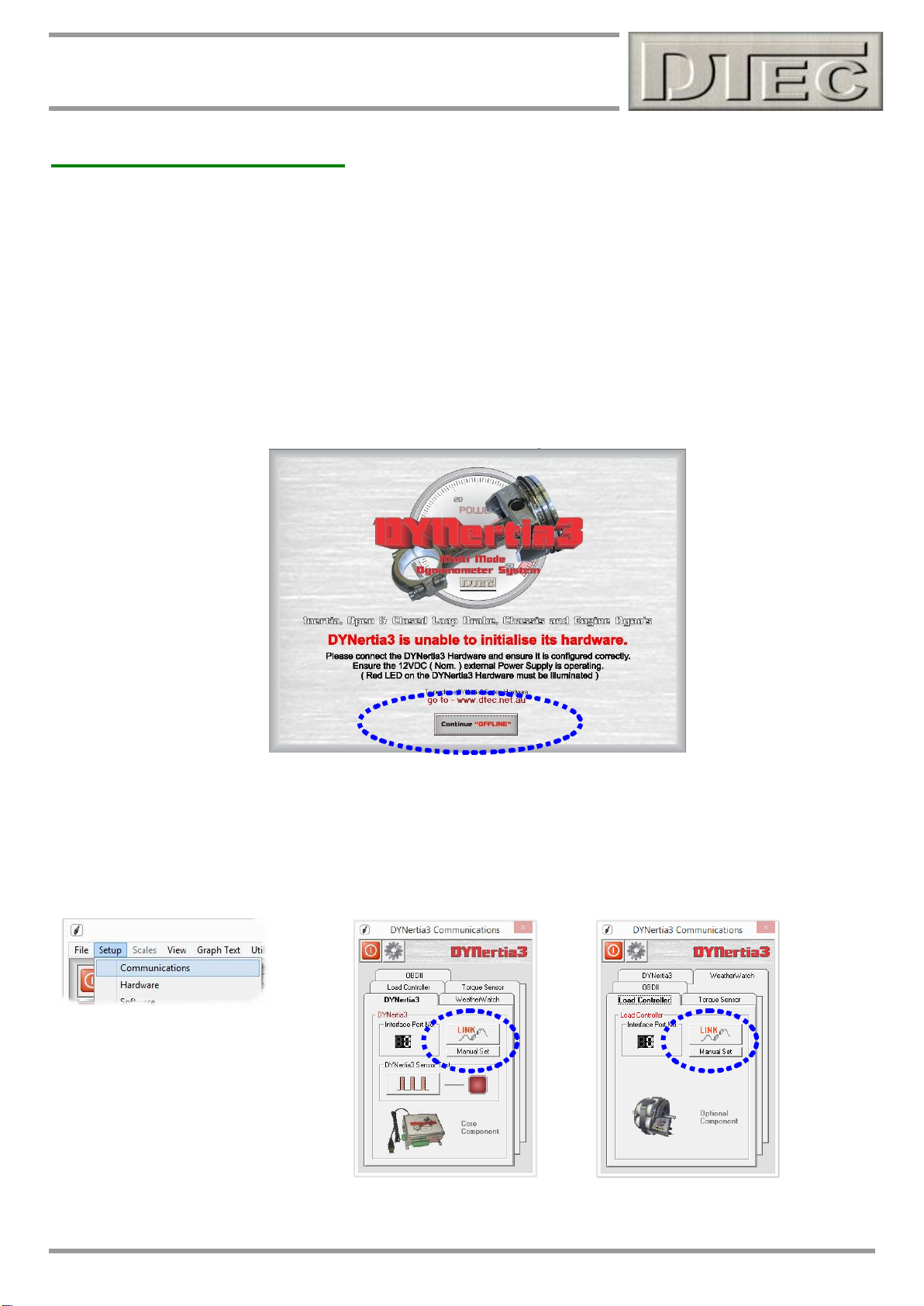

‘Linking’ Hardware to PC ..................................................................................................................................... 22

Chapter 3: ‘Brake’ Style Dyno Setup ......................................................................................................... 23

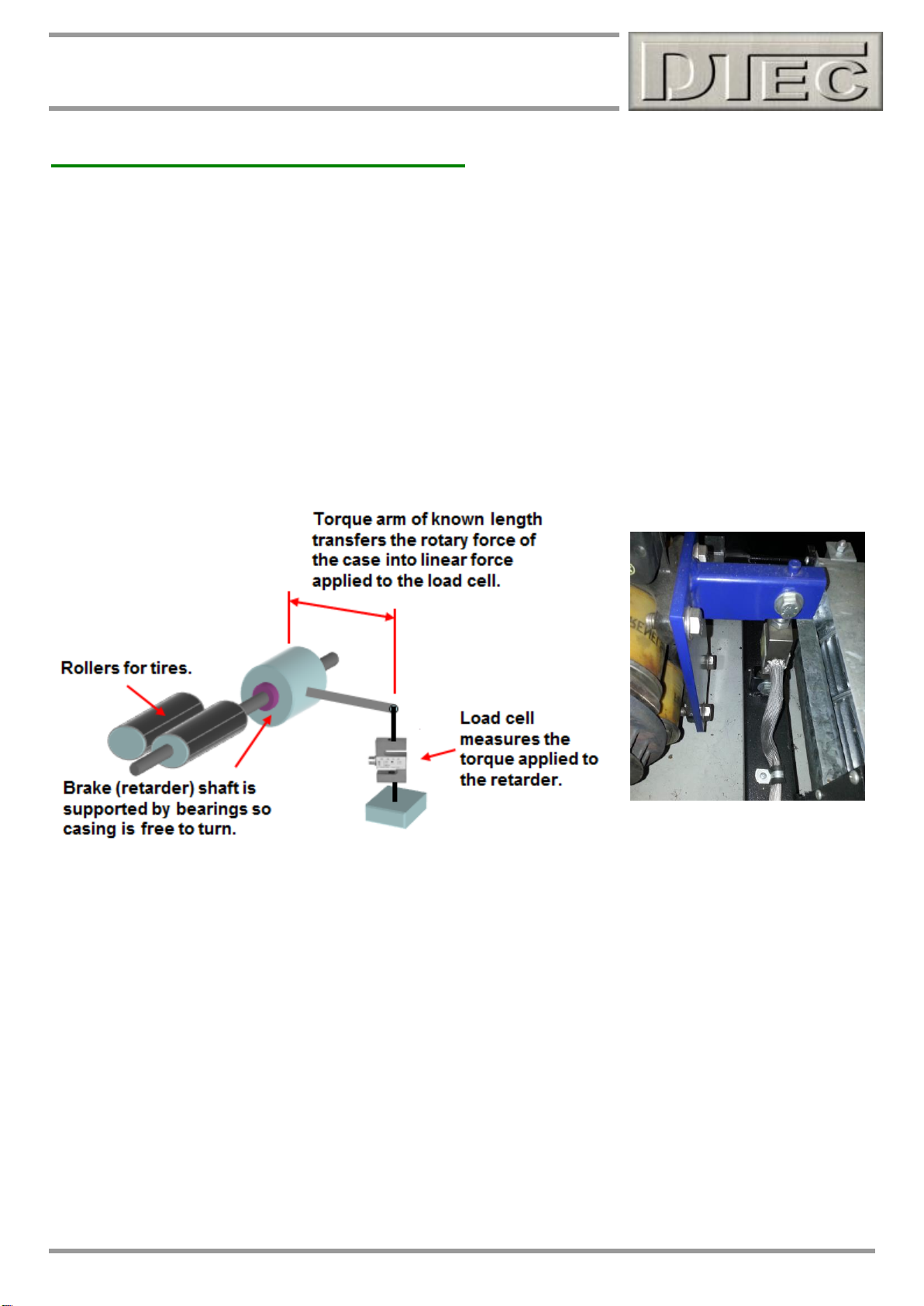

Brake (Absorber) Style Dyno Setup ................................................................................................................... 24

Basic concept .................................................................................................................................................. 24

Variations ......................................................................................................................................................... 25

Types of testing used with brake (retarder/absorber) style dyno’s ........................................................... 25

Load cell calibration and wiring for Brake type ........................................................................................... 25

Chapter 4: ‘Setup’ Menu Options .............................................................................................................. 26

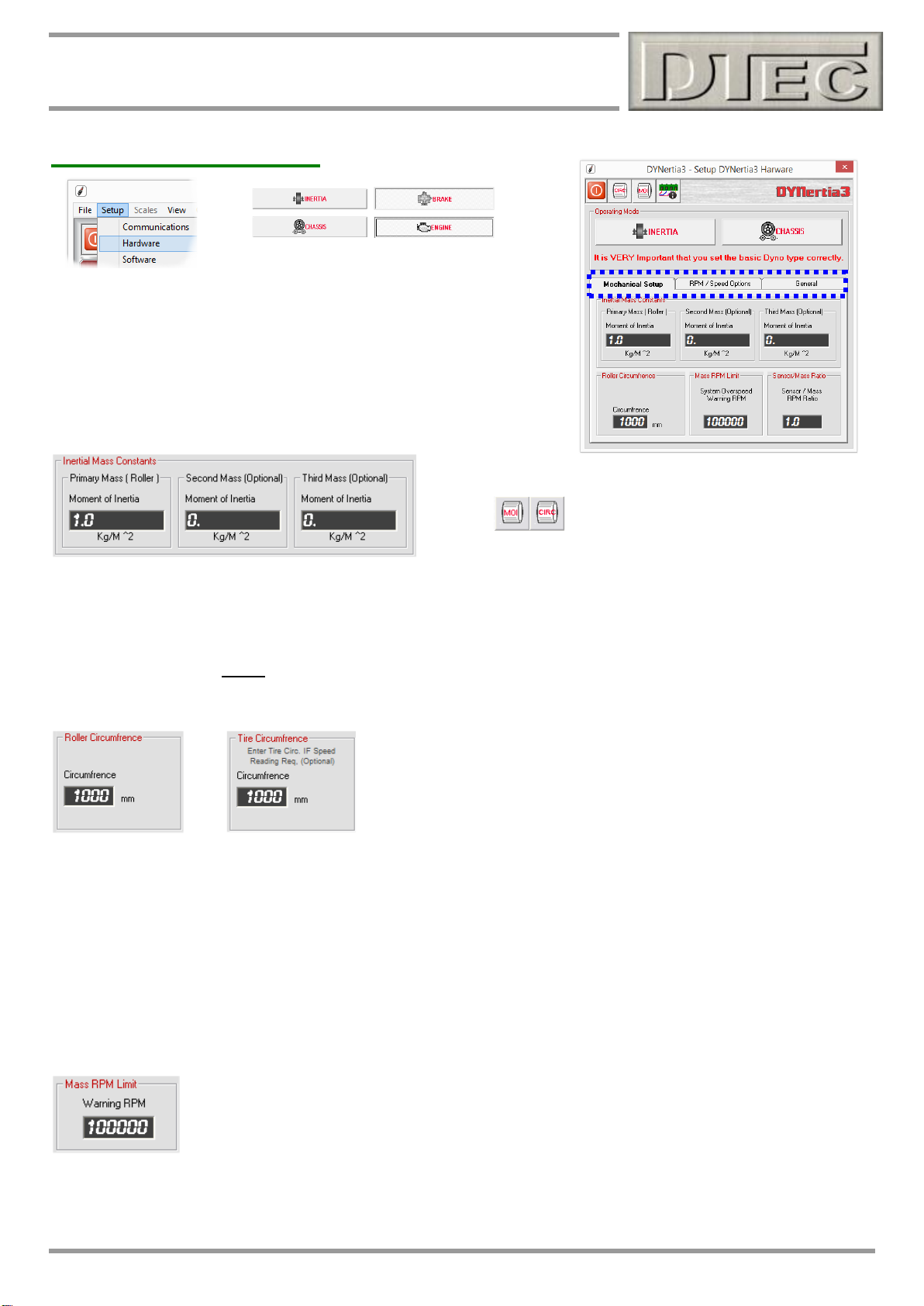

Hardware- Setup Menu ........................................................................................................................................ 27

Brake / Inertia Button ................................................................................................................................ 27

Chassis / Engine Button ........................................................................................................................... 27

Inertia Mass Constants ............................................................................................................................. 27

Roller Circumference ................................................................................................................................ 27

Tire Circumference .................................................................................................................................... 27

Mass RPM Limit ......................................................................................................................................... 27

Sensor/Mass Ratio .................................................................................................................................... 28

Pulse Generator ......................................................................................................................................... 28

Tacho / Speedometer ................................................................................................................................ 28

OBDII Adapter input for Engine RPM and vehicle speed ...................................................................... 28

RPM Adapter input for Engine RPM ........................................................................................................ 28

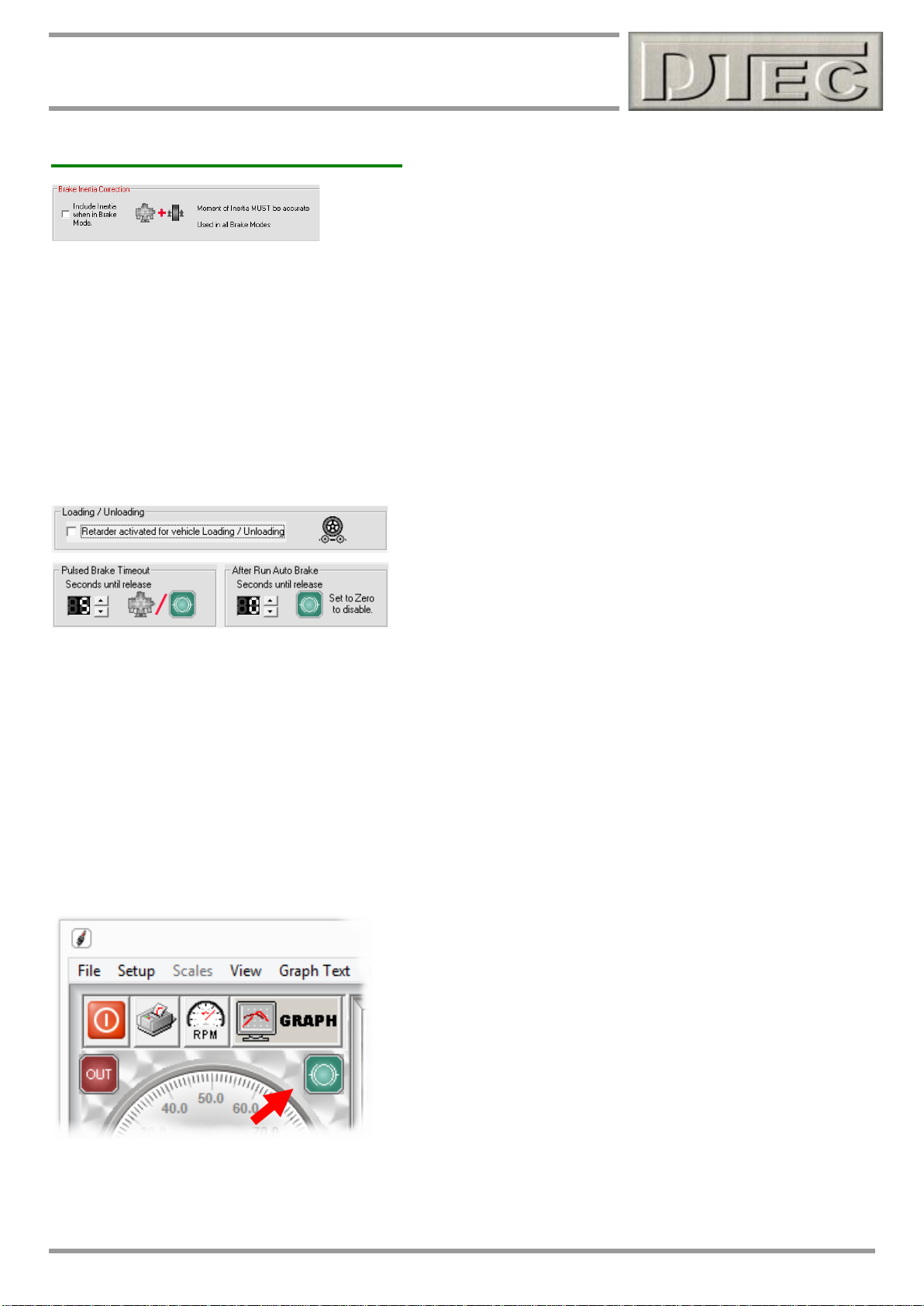

Brake Inertia Correction (Only in ‘BRAKE’ mode) ................................................................................. 29

After Run Auto Braking/Vehicle Loading ................................................................................................ 29

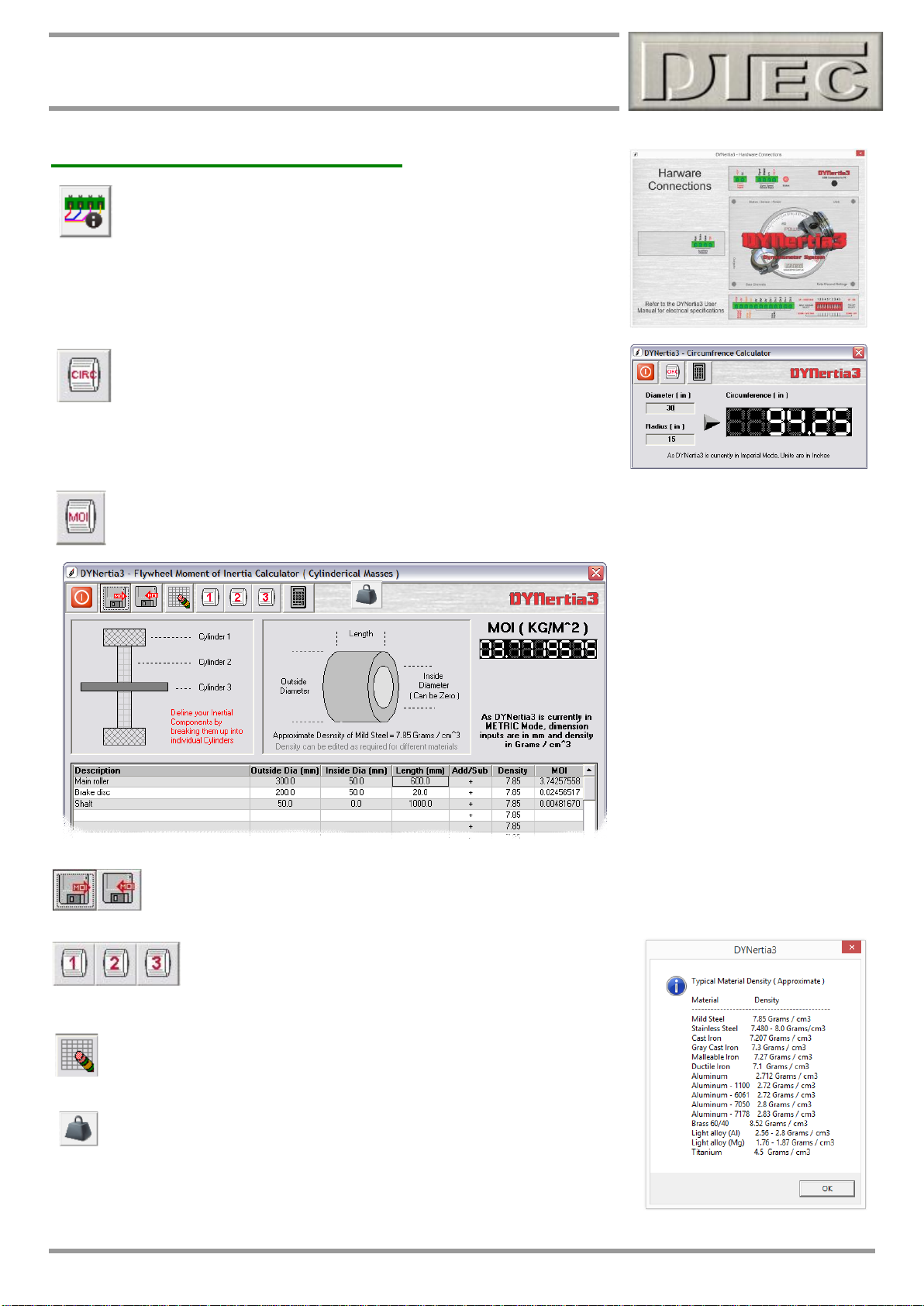

Hardware Connections ............................................................................................................................. 30

Circumference Calculator ......................................................................................................................... 30

Moment Of Inertia Calculator ................................................................................................................... 30

Software- Setup Menu ......................................................................................................................................... 31

Graph Smoothness ......................................................................................................................................... 31

Point by Point (Open Loop Brake Mode) ................................................................................................ 31

Inertia Mode Graph Smoothness ............................................................................................................. 31

Passwords ....................................................................................................................................................... 31

Password (Program & Setup)................................................................................................................... 31

Lambda / AFR .................................................................................................................................................. 31

Preferred Lambda/AFR Channel .............................................................................................................. 31

Custom Fuel – Stoic/AFR and Name ....................................................................................................... 31

Graph ................................................................................................................................................................ 32

Auto Display of Last Run .......................................................................................................................... 32

www.dtec.net.au

Page 4

4

DYNertia3 user manual

Graph Torque Traces ................................................................................................................................ 32

Graph Trace ID’s ........................................................................................................................................ 32

Auto Shift Traces Right ............................................................................................................................ 32

RPM / Speed Scales .................................................................................................................................. 32

Power / Torque Scales .............................................................................................................................. 32

Run .................................................................................................................................................................... 32

Run Screens – Chart Reorders ................................................................................................................ 32

Run Duration .............................................................................................................................................. 32

Use Actual run Min RPM ........................................................................................................................... 32

Run Summary ............................................................................................................................................ 32

Live Slip Monitor ....................................................................................................................................... 32

Display .............................................................................................................................................................. 33

Multiple Monitor Support .......................................................................................................................... 33

Hide Windows Desktop ............................................................................................................................. 33

Data Window Transparency ..................................................................................................................... 33

Screensaver: .............................................................................................................................................. 33

About ................................................................................................................................................................ 33

Display of System Details ......................................................................................................................... 33

System .............................................................................................................................................................. 34

End of Each Run ........................................................................................................................................ 34

DYNO Correction Systems ....................................................................................................................... 34

Run D3 Snapshot ...................................................................................................................................... 34

Configuration Reset .................................................................................................................................. 34

General ............................................................................................................................................................. 35

Metric / Imperial ......................................................................................................................................... 35

Media (Audio) ............................................................................................................................................. 35

Remote ‘Page Turner’ Actions ................................................................................................................. 35

Data Consistency ...................................................................................................................................... 35

Point by Point (Brake Mode) .................................................................................................................... 36

Ratios................................................................................................................................................................ 37

Last Ratio Set ............................................................................................................................................ 37

Low Speed / RPM Operation .................................................................................................................... 37

Set Ratio- Change Increment ................................................................................................................... 37

Run Comments ................................................................................................................................................ 37

Comment Editing ....................................................................................................................................... 37

Comments added to each new Run ........................................................................................................ 37

Company Name ......................................................................................................................................... 37

Outputs ............................................................................................................................................................. 37

All Outputs (DYNertia3 and accessories) ............................................................................................... 37

Auxiliary Outputs (DYNertia3) .................................................................................................................. 37

File Storage Paths (Icon) ................................................................................................................................ 38

Set DYNertia3 base file storage path ...................................................................................................... 38

User Details (Icon) ........................................................................................................................................... 38

Set User Details ......................................................................................................................................... 38

Archive Storage Paths (Icon) ......................................................................................................................... 39

Set DYNertia3 archive storage path ........................................................................................................ 39

Load Control- Setup Menu .................................................................................................................................. 39

Communications- Setup Menu ........................................................................................................................... 40

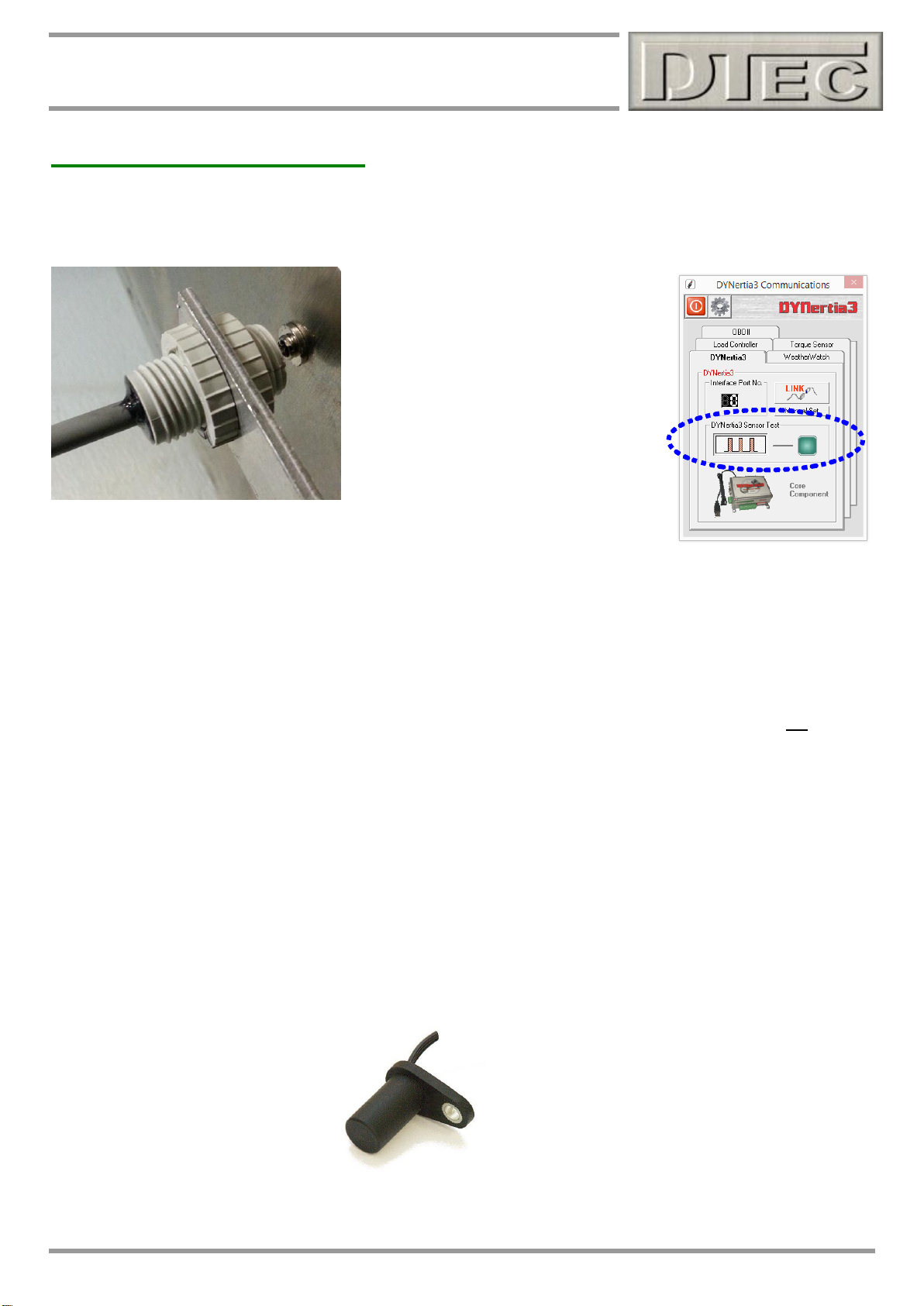

Interface Port No. ...................................................................................................................................... 40

Link Button................................................................................................................................................. 40

Manual Set Button ..................................................................................................................................... 40

DYNertia3 ......................................................................................................................................................... 40

DYNertia Sensor Test ................................................................................................................................ 40

Weather Watch ................................................................................................................................................ 40

Update Interval .......................................................................................................................................... 40

Load Controller ................................................................................................................................................ 41

Torque Sensor ................................................................................................................................................. 41

OBDII................................................................................................................................................................. 41

Device Manager ............................................................................................................................................... 41

Open Windows Device Manager .............................................................................................................. 41

Printer .................................................................................................................................................................... 42

www.dtec.net.au

Page 5

5

DYNertia3 user manual

PRM/Speed Source .............................................................................................................................................. 42

Sensor Configuration .......................................................................................................................................... 42

Data Limits / Alarms ............................................................................................................................................. 42

Losses Systems ................................................................................................................................................... 42

Main Graph Trace Colour (Visible only from ‘Graph’ screen) ......................................................................... 42

Grid ........................................................................................................................................................................ 42

Operator ................................................................................................................................................................ 42

Chapter 5: RPM Input Options ................................................................................................................... 43

Engine RPM, Purpose and Options .................................................................................................................... 44

Why we may need engine RPM ...................................................................................................................... 44

Windows used for RPM setup (referred to in this chapter) ........................................................................ 44

RPM input Options (7 Available!) .................................................................................................................. 45

RPM Adapter input .......................................................................................................................................... 47

Summary of your RPM options ...................................................................................................................... 49

General RPM input information ..................................................................................................................... 49

Chapter 6: Overview- 2 Main Windows ..................................................................................................... 50

Two Main DYNertia3 Windows (DYNO / GRAPH) .............................................................................................. 51

DYNO Window ...................................................................................................................................................... 52

Record Settings ............................................................................................................................................... 52

Minimum Run RPM .................................................................................................................................... 52

Maximum Run RPM ................................................................................................................................... 52

Current Ratio.............................................................................................................................................. 52

Mode ........................................................................................................................................................... 53

Status .......................................................................................................................................................... 53

DYNertia3 Hardware Lamps (DYN) .......................................................................................................... 53

Run Control ...................................................................................................................................................... 54

Start Run Button ........................................................................................................................................ 54

Correction Factors .......................................................................................................................................... 55

User Comments Field ..................................................................................................................................... 55

Output controls and Status ............................................................................................................................ 55

Dial Gauge Displays ........................................................................................................................................ 56

Power & Torque dials ................................................................................................................................ 56

RPM/Speed dial ......................................................................................................................................... 56

Gauges Mode ................................................................................................................................................... 56

Data Gauges ON Button ........................................................................................................................... 56

Speed to RPM (ratio setting) .......................................................................................................................... 56

Strip Charts ................................................................................................................................................ 56

Data Dial Gauges ....................................................................................................................................... 56

GRAPH Window.................................................................................................................................................... 57

Tool Bar Button Functions ............................................................................................................................. 57

Exit .............................................................................................................................................................. 57

Print ............................................................................................................................................................ 57

RPM/Speed Mode ...................................................................................................................................... 57

GRAPH/DYNO ............................................................................................................................................ 57

Selecting Trace to Analyze ............................................................................................................................. 57

Selecting Trace to Display.............................................................................................................................. 57

Graph controls ................................................................................................................................................. 58

Data displays ................................................................................................................................................... 59

Run Time Gauges/Charts (Visible only from ‘DYNO’ Window) ....................................................................... 60

RPM and Speed Scales ................................................................................................................................... 60

Chapter 7: Weather Corrections ................................................................................................................ 61

Correction Factors .......................................................................................................................................... 62

Viewing Weather Data ..................................................................................................................................... 63

Chapter 8: Loading/Viewing Files.............................................................................................................. 64

Loading of files into ‘GRAPH’ Window .............................................................................................................. 65

Previewing (DYNertia3 File Explorer) and Selecting Files .......................................................................... 65

www.dtec.net.au

Page 6

6

DYNertia3 user manual

DYNertia3 file Explorer ................................................................................................................................... 66

Creating / Deleting folders for tests .............................................................................................................. 68

Reviewing Audio Files .................................................................................................................................... 69

Secondary GRAPH Window ................................................................................................................................ 70

Viewing Files (‘GRAPH’ Window) ....................................................................................................................... 71

Adjusting Graph appearance ......................................................................................................................... 71

Zooming ........................................................................................................................................................... 71

Clear Graph Trims ........................................................................................................................................... 71

Clear Graph ...................................................................................................................................................... 71

Trace Visibility ................................................................................................................................................. 71

Grid ................................................................................................................................................................... 71

Chapter 9: Trim, Merge & Join Runs ......................................................................................................... 72

Trim a Run ............................................................................................................................................................. 73

Merge Runs ........................................................................................................................................................... 74

Join Runs .............................................................................................................................................................. 75

Chapter 10: Test Notes- Add/Save ............................................................................................................ 76

Adding Test Notes................................................................................................................................................ 77

‘User’ comments field ..................................................................................................................................... 77

Accessing User Comments ...................................................................................................................... 77

Templates .............................................................................................................................................................. 78

Saving notes and applying to other tests ..................................................................................................... 78

Chapter 11: Printing & Exporting .............................................................................................................. 79

Printing .................................................................................................................................................................. 80

General Printing .............................................................................................................................................. 80

Print ............................................................................................................................................................ 80

Setup Printer .............................................................................................................................................. 80

Offset Correction ....................................................................................................................................... 80

Printing main Graph screens ......................................................................................................................... 81

Dyno Operator ........................................................................................................................................... 81

Information for Printed Output................................................................................................................. 81

Print ............................................................................................................................................................ 81

Select Page ................................................................................................................................................ 81

Customising your printout ............................................................................................................................. 82

User Details and Company Logo ............................................................................................................. 82

Customer Disclaimer ................................................................................................................................ 82

Notes to print ........................................................................................................................................................ 83

General comments for printing ...................................................................................................................... 83

Produce comments on the main graph for printing .................................................................................... 83

Exporting data ...................................................................................................................................................... 84

Select a Trace to export ............................................................................................................................ 84

Chapter 12: Live Data Viewing ................................................................................................................... 85

Gauge Screens ..................................................................................................................................................... 86

Observing the engine data ............................................................................................................................. 86

Observing the Data Channels ............................................................................................................................. 88

Display Current AFR/Lambda ............................................................................................................................. 89

Chapter 13: Analysing Data (‘View’ Menu) ................................................................................................ 90

Trace Info .............................................................................................................................................................. 91

Secondary Graph ................................................................................................................................................. 91

Individual Trace Set ............................................................................................................................................. 92

Compare ................................................................................................................................................................ 93

Torque Analysis ................................................................................................................................................... 94

Losses ................................................................................................................................................................... 95

Lambda / AFR Deviation ...................................................................................................................................... 96

Distance / Speed / Time / RPM Analysis ............................................................................................................ 97

Slip / Tyre Growth................................................................................................................................................. 98

www.dtec.net.au

Page 7

7

DYNertia3 user manual

Run Duration Info ................................................................................................................................................. 99

Point to Point Times .......................................................................................................................................... 100

XY Graph ............................................................................................................................................................. 101

Run Data vs Time ............................................................................................................................................... 102

Chapter 14: Inputs- Using ........................................................................................................................ 103

Pin Allocations ................................................................................................................................................... 104

General Input Notes ........................................................................................................................................... 105

Important general information ..................................................................................................................... 105

Wiring inputs for best results ...................................................................................................................... 105

Connecting Sensors .......................................................................................................................................... 106

General sensor connection (0-5V input shown) ........................................................................................ 106

Resistive sensor connection ....................................................................................................................... 107

Connection of DTec’s ‘Thermo-Amp’ thermocouple amplifier (for K-type sensors) ............................. 107

Air/fuel ratio meter connection (DTec ‘WB2’ unit as example)................................................................. 108

Connection of load cell for brake (absorber) style dyno’s ....................................................................... 108

RPM Adapter Input ............................................................................................................................................. 109

General notes on wiring the RPM adapter input (secondary way of measuring RPM) .......................... 109

Using a DTec ‘RPM adapter’ for the RPM adapter input ........................................................................... 109

Basic connections for a DTec ‘RPM adapter’ to DYNertia3’s RPM Adapter input ................................. 110

Connections for a DTec ‘RPM adapter’ to suit spark plug wire sensing ................................................. 110

Connections for a DTec ‘RPM adapter’ to suit coil ‘switching’ signals .................................................. 110

Connections for a DTec ‘RPM adapter’ to suit coil ‘drive’ signals .......................................................... 111

Connections for a DTec ‘RPM adapter’ to suit ‘VR’ (inductive) sensors ................................................. 111

Sensor Configuration ........................................................................................................................................ 112

Configuring an input channel using pre-settings ...................................................................................... 112

Creating your own linear (2 points, straight line) sensor calibrations .................................................... 113

Naming and calibrating of Lambda / AFR meter inputs ............................................................................ 114

Creating your own non-linear sensor calibrations .................................................................................... 114

Testing sensor configurations ..................................................................................................................... 116

Getting the best data ..................................................................................................................................... 117

Channel Filtering ..................................................................................................................................... 117

Reference Voltage Correction ................................................................................................................ 117

Sensor Alarm Points .......................................................................................................................................... 118

Sensor On / Off (Recording) .............................................................................................................................. 118

Data Consistency ............................................................................................................................................... 119

Chapter 15: Outputs- Using ..................................................................................................................... 120

Auxiliary Connections ....................................................................................................................................... 121

Connecting outputs if required .................................................................................................................... 121

Output functions ........................................................................................................................................... 121

‘Run’ Output ............................................................................................................................................. 121

‘User’ Output ............................................................................................................................................ 121

‘Brake’ Output .......................................................................................................................................... 122

Chapter 16: Load Controllers .................................................................................................................. 123

Hardware Mounting & Basic Wiring ................................................................................................................. 124

Mounting the speed sensor................................................................................. Error! Bookmark not defined.

Mounting electrical components ........................................................................ Error! Bookmark not defined.

Eddy Current Load Controller Wiring .............................................................................................................. 125

Eddy controller wiring (basic- no accessories) ......................................................................................... 125

Eddy current controller wiring harness connections ................................................................................ 126

PWM Current Load Controller Wiring .............................................................................................................. 127

Wiring PWM controller wiring (basic- no accessories) ............................................................................. 127

PWM current controller wiring harness connections ................................................................................ 128

Load Cell Connection ........................................................................................................................................ 129

Wiring of the load cell (including pressure sensor style) ......................................................................... 129

Load Cell Setup & Calibration ........................................................................................................................... 130

Sensor Calibration ........................................................................................................................................ 130

Manual Sensor Calibration ........................................................................................................................... 132

Automatic Sensor Drift Cancellation ........................................................................................................... 132

www.dtec.net.au

Page 8

8

DYNertia3 user manual

Brake ‘Closed Loop’ PID Tuning ...................................................................................................................... 133

Load control system commissioning .......................................................................................................... 133

Load Unit- Current Limitation ................................................................................................................ 133

Load Control Output ............................................................................................................................... 133

Throttle Servo Speed .............................................................................................................................. 133

Sudden RPM/Speed Drop Warning ....................................................................................................... 134

PID Test Settings ..................................................................................................................................... 134

Setup procedure ...................................................................................................................................... 135

Proportional value ................................................................................................................................... 135

Integral value ........................................................................................................................................... 135

Derivative value ....................................................................................................................................... 135

Upload Settings ....................................................................................................................................... 136

Saving and Loading Configurations ..................................................................................................... 136

Last Runs PID Power .............................................................................................................................. 136

PID Settings History ................................................................................................................................ 136

Over Temperature Load Thermostat ..................................................................................................... 136

‘Closed Loop’ Windows ..................................................................................................................................... 137

Load control window .................................................................................................................................... 137

Manual testing load control.......................................................................................................................... 137

Manual Load Control ............................................................................................................................... 137

Manual Target Fast Setting .................................................................................................................... 137

Ramp testing load control ............................................................................................................................ 138

Ramp Load Control ................................................................................................................................. 138

Ramp Mode Editor ................................................................................................................................... 138

Saving and Loading Timelines............................................................................................................... 138

Step testing load control .............................................................................................................................. 139

Step Load Control ................................................................................................................................... 139

Step Mode Editor ..................................................................................................................................... 139

Saving and Loading Timelines............................................................................................................... 139

User testing load control .............................................................................................................................. 140

User Load Control ................................................................................................................................... 140

User Mode Editor ..................................................................................................................................... 140

Saving and Loading Timelines............................................................................................................... 140

Run Options, Files and Information ............................................................................................................ 141

Timeline Preview and Selection ............................................................................................................. 141

Throttle Trims .......................................................................................................................................... 141

Manual Min RPM ...................................................................................................................................... 141

Manual Mode Load Response ................................................................................................................ 142

Load Control Keyboard Steps................................................................................................................ 142

Run Min/Max ............................................................................................................................................ 142

Auxiliary Outputs .................................................................................................................................... 142

Run Throttle ............................................................................................................................................. 142

Record Run .............................................................................................................................................. 142

Load Controller Auxiliary Options.................................................................................................................... 143

Expansion port overview .............................................................................................................................. 143

Expansion port connection details ............................................................................................................. 143

Expansion port functions ............................................................................................................................. 144

Throttle Output ........................................................................................................................................ 144

Throttle Input ........................................................................................................................................... 144

Auxiliary Outputs 1 and 2 ....................................................................................................................... 145

Over Temperature Alarm Input .............................................................................................................. 145

Chapter 17: Losses Correction ................................................................................................................ 146

’Losses’ System ................................................................................................................................................. 147

What are the effects of Mechanical Losses?.............................................................................................. 147

What does Measured Mechanical Loss Correction do? ........................................................................... 147

Are these “Losses” worth worrying about? ............................................................................................... 147

Configuration Window .................................................................................................................................. 148

USER ESTIMATED Mechanical Loss Correction ....................................................................................... 150

MEASURED Mechanical Loss Correction ................................................................................................... 151

General setup for DYNO Loss testing ......................................................................................................... 152

www.dtec.net.au

Page 9

9

DYNertia3 user manual

How often should I run DYNO losses correction? ..................................................................................... 152

Observing effect of Losses Correction ....................................................................................................... 153

Chapter 18: Maths Channels .................................................................................................................... 154

Concept .......................................................................................................................................................... 155

Sample expressions, simple ........................................................................................................................ 157

Testing an expression .................................................................................................................................. 157

Variables in detail .......................................................................................................................................... 157

Creating and saving a math’s expression .................................................................................................. 158

Applying an expression to a dyno file ........................................................................................................ 158

‘Exception’ notifications ............................................................................................................................... 159

Chapter 19: ‘Utilities’ Menu ...................................................................................................................... 160

Send an email ................................................................................................................................................ 161

Lambda AFR Converter ....................................................................................................................... 161

RPM / Torque / Power Calculator ................................................................................................................. 162

Metric / Imperial convertor for Torque / Power .......................................................................................... 162

Display current Weather Data ...................................................................................................................... 162

Display Current AFR/Lambda ...................................................................................................................... 163

RPM/Speed Stability ...................................................................................................................................... 163

Data Diagnostics ........................................................................................................................................... 164

Chapter 20: Trouble Shooting & FAQ’s................................................................................................... 165

Trouble Shooting- Common Issues ................................................................................................................. 166

Frequently Asked Questions (FAQ’s) .............................................................................................................. 169

Chapter 21: Specifications ....................................................................................................................... 170

Specifications ..................................................................................................................................................... 171

Notes ................................................................................................................................................................... 172

Chapter 22: Additions & Changes ........................................................................................................... 173

Software V3.4.x Changes & Errata ................................................................................................................... 174

www.dtec.net.au

Page 10

10

Chapter 1: Introduction

Chapter 1: Introduction

Overview and features!

www.dtec.net.au

Page 11

11

Chapter 1: Introduction

Introduction

The DYNertia3 Dynamometer package allows for simple and inexpensive "Do It Yourself" construction / upgrade of an

Inertia or Brake Dyno.

Perfect for any one interested in engine / vehicle tuning, testing and modification whether it be car, bike or even model

sized engines.

For those requiring ‘Closed Loop’ Brake control, please refer to our chapter on the optional ‘Load Controller’ systems,

this is an additional unit that interfaces to the DYNertia3 box.

An Inertia type Dyno operates on the principle of calculating the Power required to accelerate a known mass, which is

simply an additional 'flywheel' coupled to the engine or vehicle. The controller senses the velocity of the rotating mass

and outputs this and other data to the DYNertia3 software. No expensive Load Cell is required and repeatability is

excellent.

Brake type Dyno’s use an absorber system (Hydraulic, Friction, Eddy Current etc) to load the engine and the resultant

Torque is measured by a ‘Load Cell’. In ‘Brake’ mode DYNertia3 uses this Torque input and RPM to calculate Power.

The DYNertia3 software package handles all of the functions required for Dyno control: configuration, saving Runs,

correcting for atmospheric conditions, filtering, displaying data, printing, overlaying and analyzing multiple Runs.

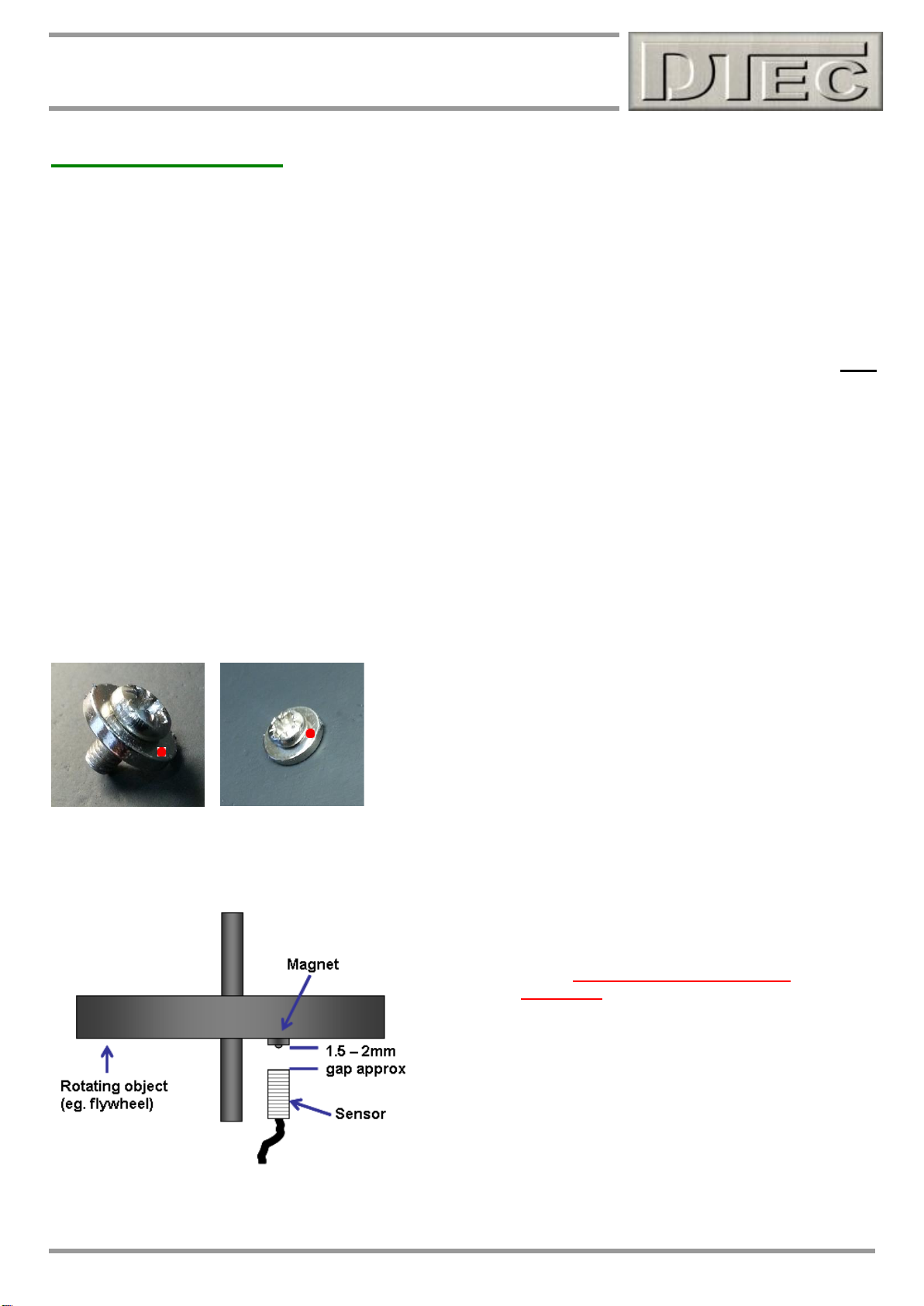

A rotation sensor is included with the DYNertia3 Controller; you simply attach a magnet (supplied) to the Inertial Mass /

Brake or drive system. Optionally, we can supply a Hall sensor designed to sense a metal ‘target’ rather than a

magnet, allowing a metal protrusion or tooth to be used as the Sensor "target".

The closed loop Load Controller systems use an alternative sensor system (sensor is still provided by us) as it is

triggered by a target wheel with multiple teeth.

For Engine or Chassis Inertia Dyno's we also provide a comprehensive guide to assist in the design and construction of

the Inertia Assembly. All you need in addition to this is the DYNerta3 package and a PC with a USB port.

Five analogue data channels and one digital input (secondary RPM input) are available for displayed and recording these are completely flexible and can be used for sensors such as Air Fuel ratio, Exhaust Temperature, Pressure, Load

Cell, secondary RPM etc. Two ‘Math’s’ channels can be created from any of the existing data (create your own

formulas), just think of the tuning possibilities!

www.dtec.net.au

Page 12

12

Chapter 1: Introduction

Features

Overview-

Suitable for chassis and engine dyno designs, either direct or indirect drive to the inertia flywheel. Power measurement

can also be taken from a ‘load cell’ for use on brake style dynos (e.g. water, eddy current, hydraulic, friction). DYNertia3

does not control the actual load on a brake style dyno, the load must be controlled manually (i.e. it’s not closed loop).

For closed loop control of a load please see our optional ‘Load controller’ unit and related chapter.

Software provided handles all data management, analyzing and graphing required for your dyno project with powerful

features yet a ‘clean’ interface. Both Metric and Imperial modes are provided, Power, Torque and setup parameters are

changed from kph/Kw/Nm/ºC to mph/Hp/Ft Lb/ ºF etc.

Comprehensive Manual provided, also design & construction information is available for the mechanical dyno system,

including an Excel spread sheet to assist with choosing and calculating the moment of inertia for your requirements.

Included magnetic sensor (hall effect) has an indicator for diagnostics. Integrated ‘optical isolation’ circuitry in the data

acquisition systems helps limit ignition interference and provides PC protection.

As an inertia dyno, accuracy is only limited by mechanical system variation, internally each rotation is timed to 1μs (1

millionth of a second). Dual microprocessors share the data acquisition and precision timing tasks.

Ideal for portable applications (track days & exhibitions). Power supply can be from a simple 12VDC battery, 7 to18VDC

is required, e.g. a cordless drill or bike battery is ideal! We recommend a battery as resistance to interference and data

acquisition signals is far better than with a ‘plug pack’!

Compact, approximately 110L x 83W x 45H (mm) with a small remote sensor for easy adaptation to your design.

No ignition system adapters are needed for RPM sensing. It can determine engine RPM from shaft RPM by ‘learning’

their relationship (ratio). Up to 8 gears can be learnt and later selected for quick testing in any gear; the ratio can also be

manually entered if no tachometer, simply based on number of sprocket teeth (e.g. for chain drive kart engine dynos).

If an engine RPM input (not otherwise required) from the engine is available, then this can not only be used as engine

RPM but also means the difference between engine and shaft/flywheel RPM can be plotted to show clutch engagement

RPM or reveal wheel slip on a chassis dyno.

Inertia value for up to 3 Inertia mass flywheels can be stored and easily selected for designs with adjustable Inertia mass

to tailor to engine characteristics.

Compensation for Dyno Inertia during ‘brake’ testing is easily applied. Great if you have an inertia dyno, but wish to add

an additional load (brake/retarder) for ‘running in’ engines or ‘steady state’ testing.

Analysing Test Results-

Supports multiple monitors, if a second monitor is available then key Windows can be viewed separately to allow clear

analysis, even if viewing and comparing many test results.

Overlay up to 10 Power and Torque graphs simultaneously, including the ‘Last Run’ which automatically appears after

your Run is completed. Run trace color sets are user selectable, however ‘Last Run’ always graphed in red for quick

identification.

Analyse and compare test results by easily ‘hiding’ any particular Run trace or quickly replacing with other saved Runs

for comparison.

A reference Run trace can be locked so that it always stays on the screen for comparisons against other tests.

Up to 4 sets of Runs can be merged to create a brand new 'averaged' Run. Perfect for getting the most from

analysis. The new generated file appears just like any other in DYNertia3. Comments are automatically attached that

reveal the individual runs that it was generated from for future reference.

All 5 analogue channels are recorded with each Run for analysis and their value at the cursor are shown in a floating

'data box' (which can also be saved to ‘clipboard’). DYNertia3 can overlay 2 chosen data channels with the existing

Power and Torque traces for display or all of the data for any trace can be shown in a separate single Window for

detailed analysis.

Select a graph trace; an onscreen cursor makes the dials (power, torque and RPM/speed) display exactly what was

happening at that point in the test Run.

Advanced torque analysis is provided to graphically display ‘area under the curve’ and related statistics for comparing

multiple traces.

www.dtec.net.au

Page 13

13

Chapter 1: Introduction

Analysing Test Results (cont.)-

The percentage difference between a reference trace and the remaining traces can be shown graphically, for all data.

Instantly see where each modification either improves or degrades performance compared to other runs. Great tool!

Lambda / AFR deviation is shown in a special Window that allows you to set a target value, it shows you where and by

how much the real test results varied (essential for quick mixture tuning). Obviously an AFR meter must be connected!

Select any RPM/speed points and the time between them is shown for all Runs (up to 10), clearly reveals ‘real world’

acceleration improvements after modifications. Best performing Runs between all points are highlighted.

Full data table display of ‘point by point’ Power, Torque, RPM and Speed are produced for detailed study and can be

exported directly into Microsoft Excel (with field headings included) or a text file (comma delimited ASCII, CSV.) can be

generated, even the main graph view can be exported as a bitmap image (‘.bmp’) for further analysis and file sharing.

The relationship between distance traveled, time elapsed, Speed and RPM can be studied in a graphical analysis

screen.

XY graph, choose any data to plot against another and display values at the cursor.

Math’s ‘Expressions’ (formula) can be applied to any existing data to generate an additional 2 data channels. A powerful

tool is provided to easily write, test and apply your concepts.

Click on the Run of interest to show all the data that relates to it. The test conditions, max readings, set up details or any

of your personal notes that are saved along with each run can all be reviewed.

Full manual ‘zoom’ available on Power, Torque and RPM displays to display selected graph regions of interest.

Runs can be ‘trimmed’, the lower and upper speed section of graphs can removed if visually required (e.g. if tests start

and finish RPM were inappropriately set) and the Run re-saved.

User selectable ‘Trace Shift’, the last 10 trace sets are always displayed (each new test trace ‘shifts’ the oldest one out

of selection) - great when performing comparisons.

‘Auto Load’ your graph after a Run – can be selected to automatically switch to the graph display after each test Run or

you can opt to do as many Runs as you like in quick succession and analyse as a graph later. A brief test summary is

also immediately available after each test Run is completed.

Onscreen graph legend to rapidly identify Run trace set colors and filenames and a run summary is available to give the

key data for all the selected runs in one concise table.

Data corrected for weather conditions with world standards (SAEJ607, SAEJ1349, DIN70020 or uncorrected). The

environmental conditions and resultant correction factor are stored with each Run. Data can be manually entered or

‘Weather Watch’, automatic updating weather station is available as an option (USB to PC).

Data Acquisition-

Data acquisition of 5 analogue input voltages is incorporated (‘common’ ground). This allows the monitoring of variables

such as air fuel ratio, exhaust temperature etc.

Inputs can be 0-5V or 0-15V (each channel has a range selection switch)

Resistive sensors, such as standard automotive temperature sensors, can be easily connected as each channel has a

selection switch that enables an internal ‘pull up’ resistor (just connect the sensors 2 wires directly to DYNertia3!).

A data logging function is provided allowing the 5 input channels (plus the digital RPM input) to be logged to the PC. The

logging rate can be set and the data is saved (with field headings included) as a text file (.CSV) for later analysis in

Microsoft Excel etc.

Input data can be viewed separately (can even be displayed on separate screen if dual monitors used) or is available

whilst performing testing. Minimum and maximum alarms can be set to alert if sensors detect anything outside an

acceptable level (lean mixtures, engine temperature overheat or oil pressure loss as examples).

The input channels are fully scalable, even for non-linear sensors. Many sensor choices are already pre-calibrated and

DYNertia3 software doesn't just display the input voltage measured, a table for each input allows it to be calibrated and

displayed in any units you choose (eg Lambda, air/fuel ratio, degrees, PSI etc).

For configuring non-linear sensors, such as automotive style temperature sensors, there is a tool provided that just

requires 3 test points to be entered and it creates a full calibration table.

www.dtec.net.au

Page 14

14

Chapter 1: Introduction

Data Acquisition (cont.)-

Simple screw type terminals on a removable terminal plug allow for quick and easy sensor wiring. Both a 5 Volt and 12

Volt output to power auxiliary sensors is also present if required.

An additional digital channel is provided if you wish to have engine RPM directly measured (via a Hall sensor or DTec’s

‘RPM adapter’). This option can help reveal tyre slip/growth on a chassis dyno or centrifugal clutch engagement RPM.

There is a dedicated analysis screen to examine slip/tyre growth.

File Management-

Designed to perform testing quickly- common user settings are saved to reduce set up times and any personal notes

you’ve entered in the provided form (general, vehicle, owner details etc) can be saved as a ‘template’ and applied to

other runs to save re-entering the details, even copies the Run’s set up details. Files can also be set to ‘auto name’, the

file name simply increments with each test (and can carry over any personal notes), no need to even re-enter a name.

Advanced previewing function (‘DYNertia3 File Explorer’) shows graphs, summary details and the data table of all saved

runs, this allows quick selection for loading into the main graph screen or for file management purposes. A cursor is

even available to highlight points of interest on the graph and indicate that same location in the data table- no more

browsing through cryptic file names!

User configurable directories- have as many separate directories to store your runs in as required and file protection can

be applied to prevent individual files from being accidentally changed or overwritten if required.

Printing-

Color print outs of your chosen graph or overlaid graphs (up to 5 printed on same graph) is only a mouse click away,

complete with preview. A report page is also generated that has a summary of all the important test conditions, max

readings, date, time, company logo, graph notes etc.

Printouts includes Run trace sets legends, colors and filenames, the graphs ‘grid lines’ can even be turned off!

Comments can be placed on the graphs to appear on the printouts.

Printing of specific areas of interest can be performed using the manual ‘zoom’ function.

Additional Functions-

‘Point by Point’ testing mode for brake style dyno’s allows recording of individual data points at the press of a button.

These individual data sets are then combined to construct a conventional Run trace for easy analysis and comparisons.

For dyno competition entertainment, after a run maximum Power and Torque can be displayed in large format for crowds

to easily see (result in both imperial and metric units).

Graphs are fully auto-scaled, Power, Torque and RPM scales are automatically configured for optimal display.

Flexible options for performing a test; a Run can be from ‘start’ command to ‘stop’ command or from ‘start’ command to

zero power. A minimum speed can also be specified and data below this will be discarded, this eliminates any different

start points of tests due to operator error.

All dial gauges have digital displays incorporated.

Gauges display ‘real time’ data during monitoring or setup. Ideal for steady state tuning with a brake type dyno! (only

RPM is displayed 'real time' in Inertia mode)

Data ‘Smoothing’ that is applied to the Power traces is adjustable to ensure you don’t miss out any detail but still end up

with optimal appearing graphs.

There is a “Losses” function that can be used to measure and apply a correction to data for mechanical losses in your

dyno system like friction and windage (typically very small) even or/and for driveline losses due to friction.

DYNertia3 is fully isolated (optically) from the PC, this helps prevent any damage to the PC from incorrect connections

(power DYNertia3 from a battery source for this full isolation!). DYNertia3 is also protected from reversed polarity supply

connection.

A ‘system in motion’ (“Run”) output is available that is active as long as the flywheel is rotating, or a function is used that

may result in rotation. This can directly control a relay to operate safety control systems/warnings if required or for

automatic fan controls etc.

www.dtec.net.au

Page 15

15

Chapter 1: Introduction

Additional Functions (cont.)-

An ‘Auto Brake’ output is available that can directly operate a relay for an automatic brake for slowing the flywheel down

if you wish, or an automatic cooling fan for cooling friction style brakes. The time it’s active for after a test Run is

adjustable in the software. The output can alternatively be operated manually in the software and will be active for either

a short time or continuously.

A ‘user controlled’ output is available can directly operate a relay, it is manually turned on or off from the software and

can be used for any general purpose function e.g. remotely turning on a cooling fan, pumps wheel clamps etc.

Tools to work out the moment of inertia of your dyno system, calibrate non linear sensors, convert air:fuel ratios to

Lambda and for analysing relationships between Power / Torque / RPM are incorporated.

Keyboard ‘shortcuts’ assist with easy operation and an inexpensive and commercially available wireless keyboard or