Switch SelectableSwitch Selectable

Switch Selectable

Switch SelectableSwitch Selectable

Switch SelectableSwitch Selectable

Switch Selectable

Switch SelectableSwitch Selectable

5W - 2W5W - 2W

5W - 2W

5W - 2W5W - 2W

5W - 2W5W - 2W

5W - 2W

5W - 2W5W - 2W

VV

ideo Tideo T

V

ideo T

VV

ideo Tideo T

VV

ideo Tideo T

V

ideo T

VV

ideo Tideo T

VMS-5000 Frequency 2450-2500 MHz

ransmitterransmitter

ransmitter

ransmitterransmitter

ransmitterransmitter

ransmitter

ransmitterransmitter

DTC COMMUNICATIONS INCORPORATED

How to contact DTC

For operator and troubleshooting

information, customers are encouraged to refer to

the details in this manual. For additional

clarification or instruction, or to order parts,

contact DTC.

Customer Service is available Monday through

Friday between the hours of 9:00 AM and

5:00 PM EST at:

Tel: 603-880-4411

Fax: 603-880-6965

Website: www.dtccom.com

Email: info@dtccom.com

486 Amherst Street

Nashua, New Hampshire 03063

USA

Copyright Notice

Copyright © 2003

DTC Communications, Inc. All rights

reserved. No part of this document may be

reproduced, transmitted, transcribed, stored in a retrieval system or translated into any

language or computer language, in any form or by

any means, including but not limited to electronic,

magnetic, mechanical, optical, chemical, manual or

otherwise, without the prior written permission of

DTC Communications, Inc.

Disclaimer

The information in the document is subject to change

without notice. DTC makes no representations or

warranties with respect to the contents hereof, and

specifically disclaims any implied warranties of merchantability or fitness for a particular purpose. DTC

reserves the right to revise this publication and to

make changes from time to time in the content hereof

without obligation of DTC to notify any person of such

revision or changes.

Trademarks

Trademarks of DTC Communications, Inc. include:

• DTC

®

• MiniPIX

• DynaPIX

Other product names used in this manual are the

properties of their respective owners.

®

Warranty

DTC warrants its manufactured components against

defects in material and workmanship for a period of

two (2) years, commencing on the date of original

purchase.

Products manufactured by others that are approved

for use with DTC equipment are warranted for the

manufacturer’s warranty period, commencing from

the date of shipment from DTC.

FCC information

Forms can be obtained from the FCC on their website at:

www.fcc.gov

You can also contact the FCC using their FAX back

service at: (888) 418-3676

Additional instructions are available by telephone at:

(888) 225-5322

The filing fee form is returned to:

Federal Communications Commission

1270 Fairfield Road

Gettysburg, PA 17325-7245

OP1920187 Rev A

2

TABLE OF CONTENTS

Manual Conventions

NOTE Describes special issues you should be aware of

while using a particular function.

WARNING Calls out situations in which equipment could

be damaged or a process could be incorrectly implemented, but in which operator safety is not a factor.

TIP Describes application hints.

RF EXPOSURE STATEMENT

This product is NOT recommended for use in body-worn

applications. Refer to Appendix A in this manual for instruction in the proper use of antennas with this device. When in

use a seperation distance of at least 20 cm must be

maintained between the supplied antenna and the body of

the user or nearby persons. At this distance the field density

will be 1.61 mW/cm2, well below the maximum permissable

exposure level of 5. mW/cm

Note: This device is for occupational use only. Occupa-

tional users are those persons who are exposed as a

consequence of their employment, provided these

persons are fully aware of and exercise control over

their exposure. See Appendix A. Antenna Safety.

FCC ID# H25VMS5000

2

.

Kit Contents ......................................................................... 4

Quick Start............................................................................ 5

Encryption ............................................................................ 6

Heat Considerations ........................................................... 7

Mounting Options ................................................................ 8

Reinstalling Heatsink .......................................................... 9

Connectors........................................................................ 10

Connections ...................................................................... 11

Basic Video Transmitter .................................................... 12

Single Power Source ......................................................... 1 3

Components ................................................................14-16

Programming ............................................................... 17-20

Specifications ...............................................................21-23

Features ............................................................................ 24

Warranty............................................................................. 25

Appendix A. Antenna Safety................................................ 26

3

Programming

C

P

r

Screwdriver

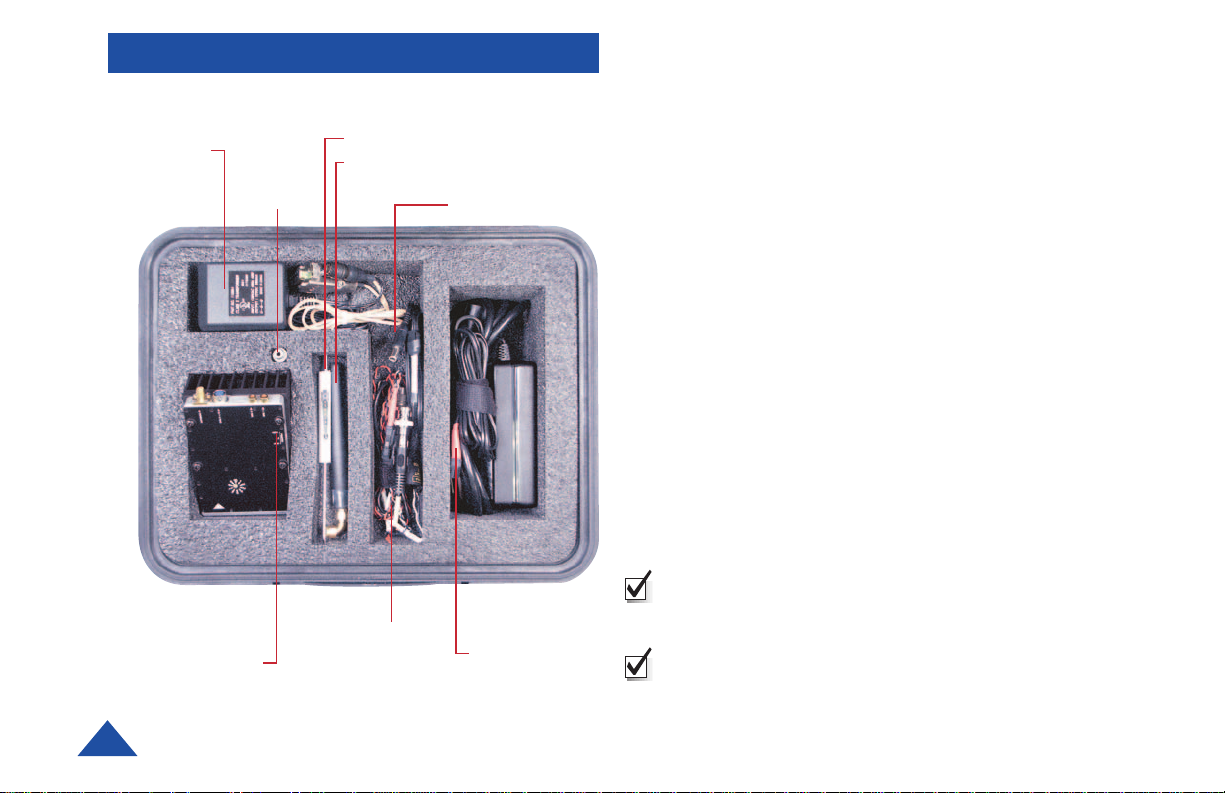

TYPICAL KIT

able with

4

ower Adapter

2W-5W Video

Transmitter

with Heatsink

RCA

RCA

Adapter

(F)

to

(F)

Antenna

(ANT-VIX)

Multi I/O Cable

for Transmitter

Power, Camera

Power and Video

Cable for

Camera Power

2.1mm to Molex

AC 100-240V

Power Adapter

with Molex Connecto

Included with your 5 Watt -2 Watt Transmitter:

• VMS-5000 Video Transmitter packaged in case with

heatsink attached

• Accessories kit containing:

• DTC programming software package

• DTC programming cable

• Camera Cable

• Dipole antenna with right angle SMA connector

• Video and Power In “Y” cable

• Four captive mounting screws

• Transmitter mounting bracket (optional)

NOTE: DTC has provided you with a “Y” cable (power

and video) terminated with an RCA connector and a

BNC adapter for your convenience.

NOTE: The dipole antenna included is not recom-

mended for normal use! This antenna enables you to

quickly set up your transmitter and ensure proper

operation. DTC highly recommends the use of

circularly polarized antennas for the best rejection of

multi-path.

QUICK START

1 Make sure that the external power source to the

transmitter is OFF.

2 Using a screwdriver, turn the channel selector to the

correct channel number.

3 Connect an antenna to the ANTENNA connector on the

module.

4 Select Hi or Lo Power using the recessed switch.

5 Connect the microphone or microphones to the MIC-1

and MIC-2 connectors on the module.

6 Connect a video source and external power (11 -16 VDC)

to the Video/Multi-I/O connector.

7 If you are using an (optional) Encryption model, choose

Encrypted (SCR) or Clear (CLR) as desired

8 Apply power to the transmitter.

Warning: Do not apply power to the transmitter until an

antenna has been connected in step 3.

7

5

6

3

4

2

5

ENCRYPTION OPTION

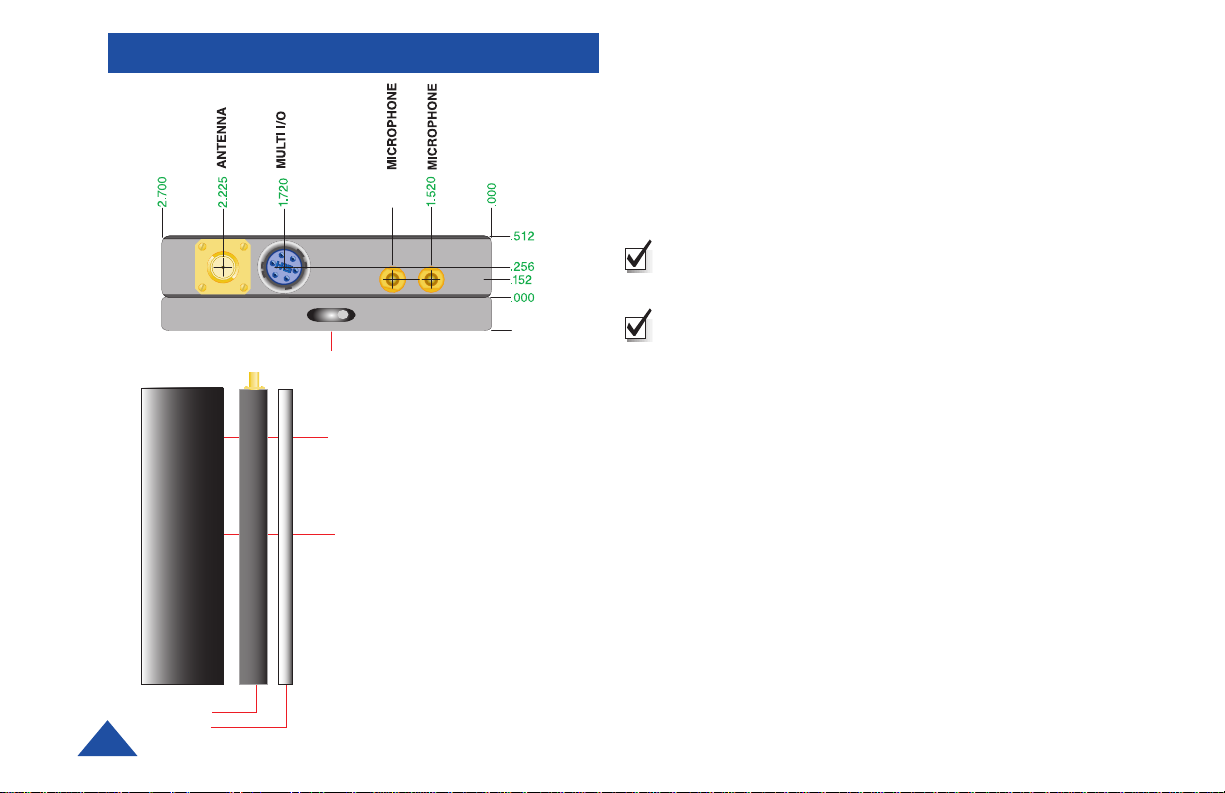

Top View

1.184

CLR SCR

SCRAMBLER

Screws

Screws

Side View

Heatsink,

Transmitter,

Heatsink

Transmitter

Encryption

6

and Encryption

As an option, the transmitter can be equipped with an

encryption module with a two position switch. In the CLR

(clear) mode, clear analog microwave video is transmitted. In

the SCR (scrambled) mode, the video will be scrambled

and capable of being decoded by a compatible receiver only.

Note: The scrambled transmission mode is recom-

mended. Casual scanners will not be able to decode the

signal and see what is being transmitted.

.

33

SCR position = ON, CLR position is OFF

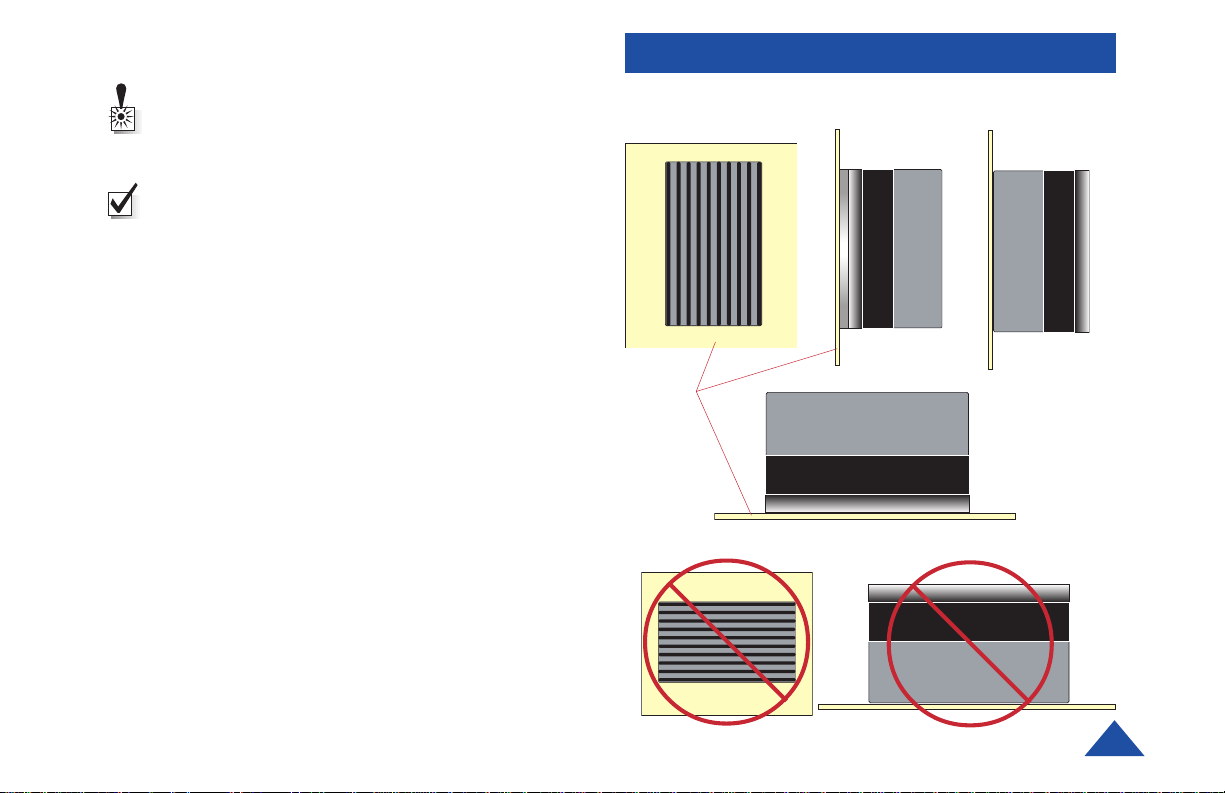

NOTE: NEVER remove the heatsink.

NOTE: HOT SURFACE MAY CAUSE BURNS. Ensure

that transmitter is properly ventilated and allow to cool

before touching.

Heat is an enemy of electronic components so it is imperative that the transmitter is not allowed to exceed 80 degrees

C. With the heatsink removed, the temperature would rise to

125 degrees C or more, which would be destructive to the

internal components. At 125 degrees C, the unit would also

deliver a serious burn if touched.

Much of the heat is given off by the final output transistor,

which is the most critical component when it comes to heat

considerations. The heatsink is shipped mounted to the

transmitter with four 6-32 screws, and has two additional 440 screws attached from the fin side of the heatsink to the

transmitter around the final output transistor. These screws

are critical for thermal conduction from the transmitter to the

heatsink. Removing these screws is not recommended.

If you plan to mount the transmitter, be sure to orient the

heatsink fins vertically for effective heat dissipation. Use one

of the recommended mounting procedures presented on

the next page.

HEAT CONSIDERATIONS

BEST: Fins V ertical Fins Vertical Fins V ertical

A way From Wall A way From Wall Against W all

Wall

NEVER: Fins Horizontal Fins Down

GOOD: Fins Up

7

MOUNTING OPTIONS

NOTE: ALWAYS mount the transmitter with the heatsink

fins oriented vertically for proper heat dissipation.

NOTE: Leave room for the antenna and/or connectors

when selecting a mounting surface. The supplied

antenna requires more than 5-inches of space.

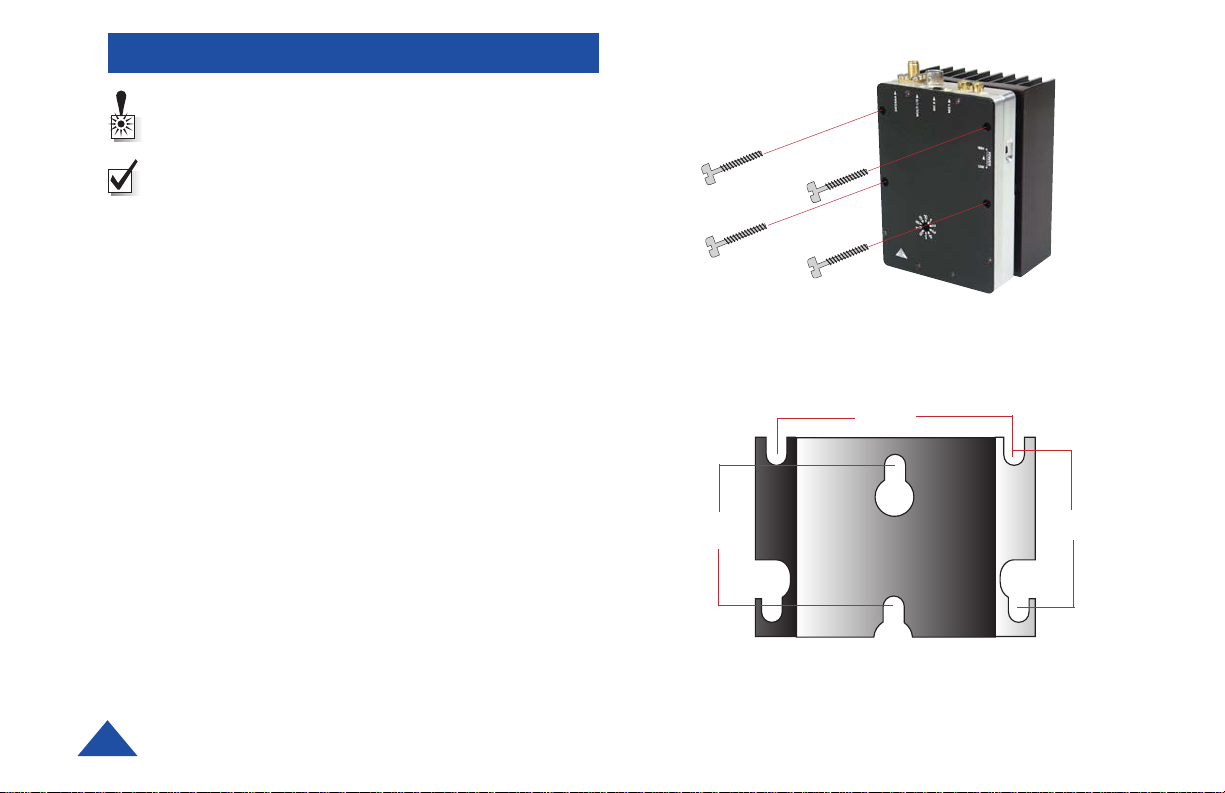

Option One

The transmitter and heat sink can be mounted (with cooling

fins vertical) against a heat-conductive metal surface. The

transmitter ships with four additional 6-32 pan head Phillips

mounting screws.

• Remove the four 6-32 Phillips screws from the front of the

transmitter.

• Install the four long 6-32 Phillips screws supplied. The

screws become captive.

• Pass the screws through the mounting surface and install

nuts to secure the assembly.

Option 1 Mounting Scheme

2.420

Option Two

An optional wall-mount bracket is available from DTC

Communications, which will allow simple mounting on a

variety of surfaces and enclosures.

• Loosen the four 6-32 Phillips screws from the front of the

transmitter.

• Install the bracket in the orientation shown. Retighten the

four Phillips screws. Hang bracket on wall using #10

screws.

8

1.125

1.475

Option 2 Mounting Scheme

NOTE: The transmitter’s baseplate operating tempera-

ture is -30° to + 80°C. The heatsink is always required.

Removing the heatsink is not recommended as

excessive heat can destroy the device

The transmitter is shipped with the heatsink attached.

Removing the heatsink is not recommended. If, due to your

particular situation, you find that you need to reinstall the

heatsink, refer to the steps provided here.

T o re-install the heat sink:

1 Ensure the chassis and heatsink surfaces are clean. If

needed, use rubbing alcohol to clean, then dry.

2 Align the transmitter and heatsink, with the back of the

transmitter mating with the front, flat surface of the

heatsink.

3 Secure the heatsink with four (4) 6-32 x 1” screws

(1-1/2” screws if using encryption model).

Install the screws from the transmitter side.

4 Make sure there is good contact between the transmitter

and the heat sink. They should be mounted flush to one

another.

5 IMPORTANT Two 4-40 screws must be installed on

the outside (fin side) of the heatsink to tighten the heat conductive surfaces nearest the final output power

transistor. These screws are essential for proper heat

dissipation. Do not operate the transmitter with these

screws removed. Screw must not exceed 0.125 depth

into transmitter or it will bottom-out and not provide

proper heat-conduction.

REINSTALLING HEATSINK

2.56

3.340

1.865

1.40

3.340

1.865

NOTE: Make sure to install all factory-provided hardware

to secure heatsink to transmitter for optimal thermal

conduction and heat dissipation. The temperature

must never exceed 80 Deg. C.

.000

.000

9

CONNECTORS

)

Antenna Connector

WARNING: Refer to Appendix A of

this manual for information on the

proper use of antennas.

10

Microphone Connectors

MA TING CONNECTORS

Lemo Male Part # (FFS.01.250.DLAE31

DTC Male Part # (8570003)

Hirose Part # HR10A-7P-6P (02)

DTC Part # 954020

Standard Male SMA Connector

MICROPHONE CONNECTORS

Two connectors accommodate two microphone inputs.

Each connector has two contacts and provides power to the

microphone as well as connecting the audio signal into the

transmitter. The audio sub-carriers are activated by the

presence of the microphone. If a microphone is removed,

that sub-carrier is removed from the transmit signal.

Turning off the unused sub-carrier saves power and

improves picture quality.

ANTENNAS

A standard SMA connector is used as the antenna connector

on both the VMS-5000. Refer to a list of DTC antennas

available on page 16.

TIP: You may use the VMS series transmitters with

other manufacturers antennas. Verify that they are

suited for the band you are operating in.

CONNECTIONS

CHANNEL SELECT SWITCH

Select a transmission channel by using the rotary switch

located on the front surface of the transmitter. Use a

screwdriver to rotate the switch to the desired channel

number.

HI/LOW OUTPUT POWER SWITCH

Select Hi or Low power by using the recessed power

switch. Switching to Hi power is equal to 5 Watt output

power. Switching to Low power is equal to 2 Watt output

power.

MUL TI I/O CONNECTOR

The multi I/O (6-pin Multi I/O) connector is mainly used as the

video and external power input connector. It also provides

access to many transmitter functions, such as:

• Programming the device

• Video in

• Power in

• Remote on

• Camera power

Channel Select

Switch

Multi I/O Connector

Pin 6:

Video in

Pin 5:

RS-232 in

Pin 4:

Remote on

switching to

ground

HI/LO Power

Switch

Pin 1: Ground

Pin 2: Ext power

input 11-16VDC

Pin 3: Camera

Power Output

11

BASIC VIDEO TRANSMITTER

Cable 4045171-024

AC Power Supply

9-16 V Power Source

For Transmitter Only

Stripped & T inned

Leads Standard

Camera

Antenna

Transmitter

+

Camera

Power

The basic VMS-5000 configuration consists of the video

transmitter, dipole antenna, and DTC cable part number

4045171-024. This cable is connected to the multi I/O port

of the transmitter.

It is configured to supply:

• The video signal to the transmitter

from the camera.

• Power to the transmitter through a

molex connector that can easily be

connected to DTC’s battery pack. It

also comes standard with stripped

and tinned leads for a customer

suppled power source. A recommended

DTC battery pack is listed below

and shown in the illustration:

• 4045177 (Optional D-Cell battery pack) Alkaline

The cable does not supply power to the camera. The

camera is powered separately with a customer-supplied

power source. DTC offers other cables that will supply

power to the camera as an option.

12

The VMS-5000 configuration, which uses the loop through

power source for the camera, consists of the video transmitter, dipole antenna, and DTC cable part number 405189-

024 . This cable is connected to the multi I/O port of the

transmitter.

It is configured to supply:

• The video signal to the transmitter

from the camera.

• Power to the transmitter through a

molex connector that can be easily

connected to DTC’s recommended battery pack.

• Power to the camera through a

molex connector that can easily be

connected to DTC’s optional

cameras.

SINGLE POWER SOURCE

Cable 405189-024

AC Power Supply

Camera

• 4045177 (Optional D-Cell battery pack) Alkaline

NOTE: You will need separate external camera power

compatible with the camera you use unless:

• Voltage requirements are compatible with the 11-16

VDC requirements of the transmitter

• Camera current requirements do not exceed 200 mA

Your main external power supply provides adequate

battery life

Stripped & Tinned

Leads Standard

Internal Loop

Camera Power

Loop Through Power

Source For Transmitter

& Camera 11-16 VDC

Antenna

Transmitter

13

COMPONENTS

Part Number Description

4045171-024 Video In/EXT Power/Cam. Power

cable, 24”standard.

Specifications

Video In: Multi I/O to RCA(M) with BNC adaptor

(YELLOW)

Ext. Power: 24 AWG wire with a molex connector

and stripped and tinned leads. (RED)

14

Part Number Description

4045189-024 Video In/EXT Power/Cam. Power

cable, 24”standard.

Specifications

Video In: Multi I/O to RCA(M) with BNC adaptor

(YELLOW)

Ext. Power: 24 AWG wire with a molex connector

and stripped and tinned leads. (RED)

Camera Power: 24 AWG wire with a molex connector

and stripped and tinned leads. (GRAY)

Part Number Description

4045174-006 Antenna Cable 6” standard

4045174-012 Antenna Cable 12” Option

Specifications

Connectors SMA to TNC

TO OPEN:

TO CLOSE:

Part Number Description

7011145-012 Microphone, 12” length

7011145-024 Microphone, 24” length

7011145-036 Microphone, 36” length

7011145-048 Microphone, 48” length

7011145-072 Microphone, 6’ length

7011145-144 Microphone 12’ length

7011145-360 Microphone 30’ length

Part Number Description

400023 12 Volt 2.5 AmpPower Supply

100-240 VAC input

Part Number Description

4045173 Programming cable (Connects from the

Multi I/O connector to the DB9 connector)

This cable plugs into COM1 or COM2,

serial ports of a PC. It allows for the

programming of the Video transmitter

with the DTC Programming software.

COMPONENTS

PUSH CONNECTORS TOGETHER UNTIL THE

MOLEX LOCKING MECHANISM CLICKS AND LOCKS

TO OPEN:

PUSH THIS TAB DOWN TO RELEASE THE MOLEX

LOCKING MECHANISM, THEN PULL CONNECTORS

APART.

Part Number Description

8590138 T erminal, Crimp, Female, micro-fit

8550104 Receptacle, 2 circuit, micro-fit (3.0)

Part Number Description

8590139 T erminal, Crimp, Male,

8550101 Plug, 2 circuit, Micro-fit (3.0)

(3.0) wire size 20-24 AWG plt

gold. Molex Part # 43030-0009

in line. Molex Part # 43645-0200

Micro-fit (3.0) wire size 20-24

AWG plt. gold.

Molex Part # 43031-0009

In line. Molex Part # 43640-0200

15

COMPONENTS

Part Number Description

ANT-VIS Dipole Antenna 2.4-2.5 GHz with

right angle SMA adaptor

The ANT-VIS is a 1/2 wave coaxial dipole portable duck

antenna. It can be mounted directly to the video transmitter, or

at a right angle using the adaptor provided.

Part Number Description

1088518 Optional Mounting Bracket

1087456 Captive Screw-No Encryption (4)

1087457 Captive Screw-With Encryption (4)

Part Number Description

VMS-5000-ENL The 5Watt - 2Watt Transmitter with

Encryption

VMS-5000 The 5Watt - 2Watt Transmitter

16

Part Number Description

1088307 The 5Watt - 2Watt Heatsink

PROGRAMMING

Introduction

DTC has built in a lot of flexibility in the programming options you have on the

VMS series transmitters. You can choose to use some, all or none of this

flexibility .

When you order a VMS transmitter, DTC will factory program your frequencies at

no additional charge to you. You may want to place a sticker over the rotary

switch on the chassis, so users in the field don’t attempt to change frequencies.

This is often the best path for state and local agencies with limited frequencies

available to them.

DTC will also provide you with free software and a free programming cable,

enabling you to change your video frequencies and their associated audio subcarriers. This is ideal if you often work with other agencies, or anticipate the

equipment being used by a multi-jurisdictional task force. You can program up to

ten channel settings per unit. In general, this allows you to program most variations you might encounter in the field at the depot level.

As a practical matter, your VMS transmitter’s video frequencies and audio subcarriers will be dictated by the frequency and sub-carriers(s) of your receiver and/

or repeater. In many cases, these devices are crystal controlled or have few

channel options.

TIP: Make sure that you program your transmitter to match the frequencies

and audio sub-carriers on your receiver, and test the components as a

system prior to going into the field!

17

PROGRAMMING

Installing DTC Universal Programming Software on your PC

NOTE: Uninstall any previous versions by going to Add/Remove Programs,

clicking on DTC Universal Programming, and clicking on uninstall.

1 Click on Start, click on run.

2 Click on the Browse button.

3 Click on or find your CD drive.

4 Install the JAVA Runtime Environment Application first (CD provided).

5 Follow the install wizard screens.

6 Install the Universal Programming software next (floppy provided).

7 Click on Start, click on run.

8 Click on the Browse Button.

9 Click on your floppy drive.

10 Double click on the setup.

11 The Mask References dialog box displays. Select

NO for normal installation. Select YES to hide

references to DTC (for covert operations).

12 Follow the install wizard screens.

Your programming software is inst alled.

18

1 Make sure that the power to the video transmitter is off.

2 Make sure the transmitter has an antenna installed into

the antenna connector prior to programming.

3 Install the programming cable into the Multi I/O connec-

tor on the transmitter.

4 Plug the serial cable of the programming cable into the

COM1 or COM2 port of your computer.

5 Connect the programming cable into a power source.

6 Select Start, programs, DTC communications on your

computer.

7 The system allows you to select device COM1 or COM2,

depending on which serial port you are connected to.

8 Follow the instructions on the DTC Universal Program-

ming screens to begin the download process.

PROGRAMMING

5

AC POWER

4

COM1 or COM2

Serial port of computer

3

2

6

7

8

19

PROGRAMMING

9 Click on the “Tx Channel” tab in the programmer screen.

10 Select a channel and click on the Edit Channel button to change settings.

11 Enter your new frequency and settings.

12 To change any of the MIC-2 or MIC-1 settings, click on the settings provided,

then click OK.

13 Click on the Upload button to upload your new settings to the transmitter.

Your new settings have been installed.

9

11

12

13

10

20

SPECIFICATIONS

General Specifications

Item Specification

Power Input Voltage External 11-16 Vdc

Power Consumption 18 Watts

Reverse Polarity

Protection YES

Chassis Dimensions 3.9 x 2.7 x 0.512”

Encryption Model 3.9 x 2.7 x 0.842”

HeatSink 2.88 x 1.825 x 4.375”

Available Camera Dependent upon voltage

Power supplied to the transmitter.

Current limited to 200 mA.

Controls 10 channel select rotary switch

Panel mounted, recessed slide

power selection switch

Connectors 2 pin Lemo: Mic 1

2 pin Lemo: Mic 2

SMA: Antenna

6 pin Multi I/O: Video in, Data in,

DC input 11-16 Vdc, camera

power, Remote ON/OFF,

Multiplexed Data out, Ground

Programmability 10 channels per

selected band

250 KHz resolution steps

Audio: User programmable from

6.0-7.5 MHz, in 10 kHz steps

Chassis notes Machined, solid aluminum with

rounded edges.

Environmental -30EC to +80EC T emperature

Factors 90% Humidity (non-condensing)

RF Specifications

Item Specification

Operating Frequency 2450-2500 MHz, 250 KHz

resolution steps

Power output 5.0 W max. @ nominal

supply voltage, 25 Deg. C.

-3db @ 7VDC ext. -2 dB

over temp.

Output Impedance 50 Ohms

Spurs and Harmonics

output -50 dBc

Load Pull Stability 8:1 VSWR

Frequency Stability +/- 0.003%, -30 to +50°C

Modulation Sensitivity 8 MHz/V nom.

Modulation Sensitivity

Variation +/- 5% across the band

Peak Carrier Deviation 4 MHz nom.

Number of channels 10 max. (user programmable)

Sub-carrier sideband level -28 dBc, +/- 2 dB

21

SPECIFICATIONS

Audio Specifications

Item Specification

General Mic level input (line level factory

opt.) 50-3000 Hz

Phased locked AGC on both

inputs. Sub-carrier auto sensing,

only active when microphone is

attached.

Number of sub-carriers 2

Sub-carrier frequencies 6.0-7.5 MHz , user programmable

Sub-carrier ON/OFF

Control Subcarriers are activated when

mic is connected.

Subcarrier Frequency

Stability +/- 0.003%, -30 to +70°C

Sub-Carrier Deviation 50 kHz peak

Audio S/N 45 dB min.

Frequency Response BW1.5dB = 50-3000 Hz

T otal Harmonic Distortion <2%

Input Level 8 mVpp@400 Hz for 50 kHz peak

dev.

Pre-Emphasis 75 µS

Input Impedance 10k Ω

Video Specifications

Item Specification

Video Frequency

Response BW1.5dB = 6 Hz - 5.0 MHz

Input Impedance 75 Ohms

Input Level 1Vp-p M

S/N 60 dB min.

Pre-Emphasis Per CCIR 405 525 line curve

Differential Gain 5%

22

SPECIFICATIONS

Approximate VMS-5000 Current vs. External Supply Voltage

1.8

1.7

1.6

1.5

1.4

1.3

1.2

Current Drain (A)

1.1

1.0

0.9

0.8

11 12 13 14 15 16

(Camera NOT included)

External Supply Voltage (Vdc)

Battery Type Part Number Transmitter Only Transmitter @ 5 W

& Camera 12 V @

180 mA

10 D Cell Alkaline 4045177 7 hours 6 hours

Pack

23

FEATURES

The VMS transmitters are small module transmitters designed for off-body applications. They are part of a family of video

transmitters from DTC that provide 250 mW, 2 Watts and 5 Watts output power.

Feature Description

Programmable User programmable video channels, selectable in 250 kHz steps. Two

Audio Sub-Carriers Audio sub carriers are OFF unless microphones are connected. The

Efficient Switching Power Supply They generate far less heat than traditional video transmitters.

External Power Loop Through The power applied to the Multi I/O pin is automatically looped through

Encryption Options The VMS series supports Ovation Micro ViewLock II™encryption,

24

user programmable audio sub carriers, selectable in 10 kHz steps

from 6 MHz to 7.5 MHz.

transmitter automatically senses when a microphone has been

connected.

The audio sub carriers are phase locked, and will not drift into the

video signal.

Automatic Gain Control is provided on each audio input, amplifying

soft sounds.

They operate significantly longer than traditional video transmitters on

the same power source.

the unit, and available on a second pin to power a remote device,

such as a camera. If you apply 12 Volts in, you will get 12 Volts out, with

a maximum current drain of 200mA

which adds approximately 0.35” to the thickness of the unit.

Appendix A

Antenna Safety

Using Antennas with the VMS-5000 Video Transmitter

Use an antenna suitable for 5-Watt operation, however to ensure safe

operation, it is

radiating surface of the antenna and any persons body. All RF category “Mobile”

equipment must by law use a separation distance of 20 cm. The antenna

supplied should not be placed closer than 20 cm (8in) to the body. To ensure

that proper spacing is maintained, locate the transmitter or arrange physical

barriers in such a way that people are prevented from approaching too closely.

Limit your exposure to the antenna when the unit is in operation.

imperative that proper spacing be maintained between the

25

486 Amherst Street • Nashua, New Hampshire 03063 • 603-880-4411

www.dtccom.com

Loading...

Loading...