DTC DTC-510B, DTC-520B, DTC-535BK User Manual

Data

Technology

Corporation

DTC

5008

Series

DISK CONTROLLERS

USER'S MANUAL

DATA

TECBIIlOLOGY

CORPORATION

DTC

588B

SERIES

DISK COIiTROLLERS

USER'S

MANUAL

DTC

part

number

89-88181.

Revision

88

Data

Technology

Corporation

Main

Office

2775

Northwestern

Parkway

Santa

Clara,

California

95851

(488)496

8434

Eastern

Region

Sales

Office

16

Wiggins

Avenue

Bedford,

HA

81738

(617)

275-4844

PREFACE

warranty

Data

Technology

corporation

(DTC)

maintains

a

complete

Repair

Department

for

the

sole

purpose

of

providing

efficient,

reliable

service.

All

DTC

products

are

warranted

against

defects

in

material

and

workmanship.

The

period

of

coverage

and

other

warranty

details

are

clearly

specified

in

the

DTC

purchase

agreement.

Check

this

agreement

for

exact

warranty

details.

Accuracy

All

information

in

this

manual

is

based

on

the

latest

product

information

available

at

the

time

of

printing.

DTC

has

reviewed

the

accuracy

of

the

technical

specifications,

but

DTC

cannot

be

held

responsible

for

any

omissions

or

errors

that

may

appear

in

this

manual.

Change

Information

The

DTC

product

line

is

constantly

being

reviewed

and

improvements

are

implemented

when

appropriate.

From

time

to

time

DTC

will

distribute

Field

Change

Orders

and

Technical

Bulletins

to

inform

users

of

enhancements

or

improvements

to

their

products.

Trademarks

LSI-II

is

a

trademark

of

Digital

Equipment

Corporation

VERSAbus

is

a

trademark

of

Motorola

Corporation

SASI

is

a

trademark

of

Shugart

Associates

IBM

Personal

Computer

is

a

trademark

of

International

Business

Machines

Corporation.

Multibus

is

a

trademark

of

Intel

Corporation

Reproduction

Information

in

this

manual

must

not

be

reproduced

by

any

means

without

the

prior

written

approval

of

DTC.

--i--

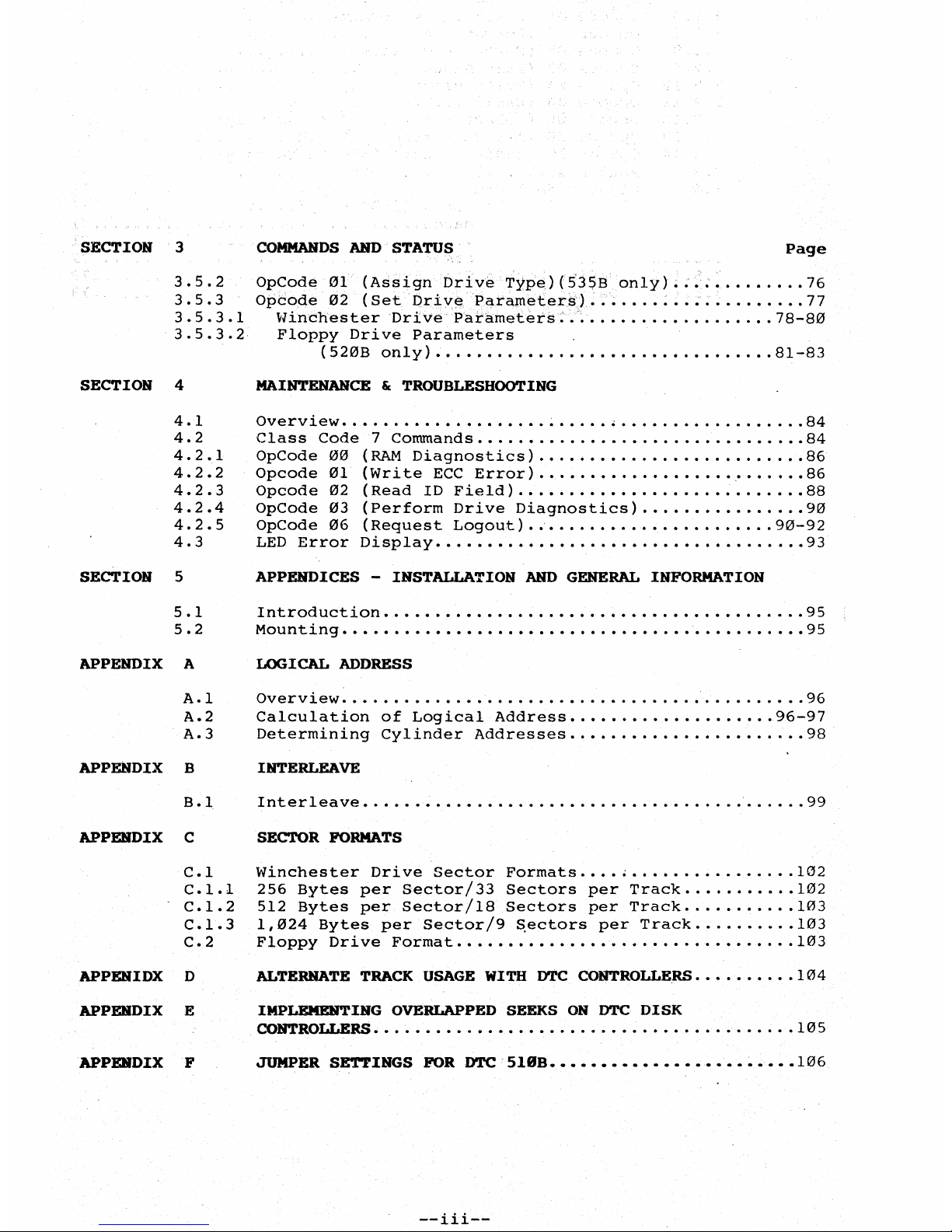

SECTION

3

3.5.2

3.5.3

3.5.3.1

3.5.3.2

SECTION 4

4.1

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.3

SECTION 5

5.1

5.2

APPENDIX

A

A.l

A.2

A.3

APPENDIX B

B.l

APPENDIX C

C.l

c.l.l

C.l.2

C.l.3

C.2

APPENIDX D

APPENDIX E

APPENDIX

F

COMMANDS

AND

STATUS

Page

OpCode

01

(Assign

Drive

Type)

(535B

only);

.......••••.

76

Opcode

02

(Set

Drive.

Parameters)

.•..••••.••...•.••...

77

~linchester

Drive

Parameters

.•••••.•••...•..•..••

78-80

Floppy

Drive

Parameters

(520B

only)

•••••••..••....•......•..••.....•

81-83

MAINTENANCE & TROUBLESHOOTING

Overv

iew

.••.•..•••••••....•..•....•....•..•....••...•

84

Class

Code

7

Commands

••..••••..•.••.••••.••••.••..•..

84

OpCode

00

(RAM

Diagnostics)

....•.••....••.••••.••.•..

86

Opcode

01

(Write

ECC

Error)

.••.•..•••..•.•..•.

,

•...••

86

Opcode

02

(Read

ID

Field)

••.••.•..•••.•........•....•

88

OpCode

03

(Perform

Drive

Diagnostics)

.•.•..••..•.....

90

OpCode

06

(Request

Logout)

..••••.••..••.•..••.••..

90-92

LED

Error

Display

.••.•••.••.••.•.••••..••.••.•..•.•.•

93

APPENDICES - INSTALLATION

AND

GENERAL

INFORMATION

Introduction

.........•..•.....•..••......•••.•.•.....

95

Mounting

•••.•....•.•••...••.•..•.••.•........•..••.•.

95

LOGICAL

ADDRESS

Overview

...•••...•..•...........•.••..•.•...•.....•..

96

Calculation

of

Logical

Address

•.••..•••.••....•

,

..

96-97

Determining

Cylinder

Addresses

•.•••.•..•..•..•.......

98

INTERLEAVE

Interleave

•..••••..••..•.......•..••.••.••••...•..•..

99

SECTOR

FORMATS

Winchester

Drive

Sector

Formats

..•.•.••..•..........

102

256

Bytes

per

Sector/33

Sectors

per

Track

•.•..••..•.

102

512

Bytes

per

Sector/18

Sectors

per

Track

....•.....•

103

1,024

Bytes

per

Sector

/9

S,ectors

per

Track

•••.••••.•

103

Floppy

Drive

Format

.•••.•.••...•.•.•.••.••.•••••..•.

103

ALTERNATE

TRACK

USAGE

WITH

DTC

CONTROLLERS

.........

.

104

IMPLEMENTING

OVERLAPPED

SEEKS

ON

DTC

DISK

CONTROLLERS .........................................

105

JUMPER

SETTINGS

FOR

DTC

518B

•....•.•....•..•........

106

--iii--

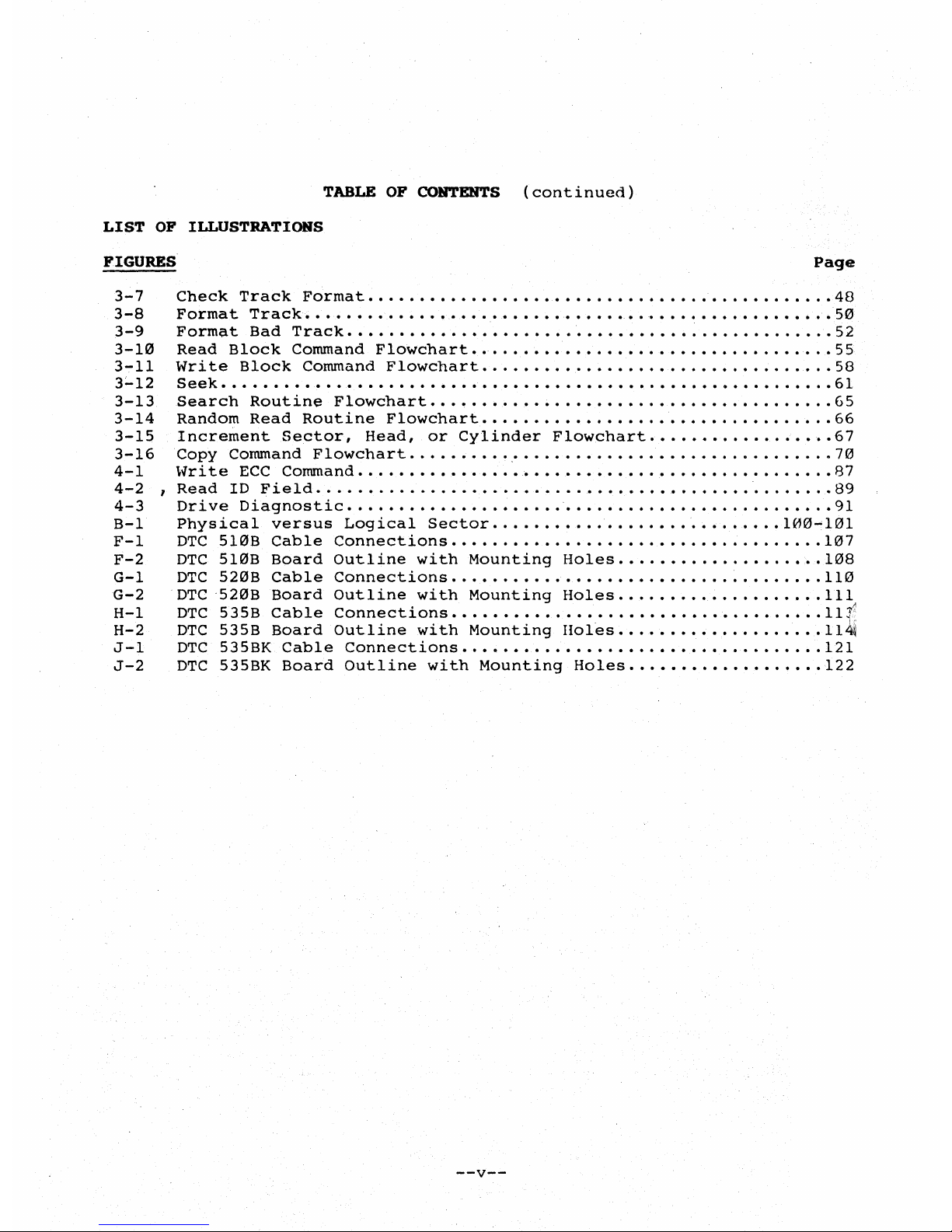

TABLE

OF

CONTENTS

(continued)

APPENDICES

Page

APPENDIX G

SWITCH SETTINGS

AND

JUMPER CONFIGURATION

FOR

52BB

•••

109

APPENDIX H

SWITCH SETTINGS

AND

JUMPER CONFIGURATIOIil

FOR

535B

•••

112

H-l

Jumper

Settings

for

SA800/80l

.......................

115

H-2

Jumper

Settings

for

SA850/SA85l

.....................

116

H-3

Jumper

Settings

for

TAN

DON

TA848-l/2

...............

116

H-4

Jumper

Settings

for

AMLYN

5850

......................

117

APPENDIX J

SWITCH SETTINGS

AND

JUMPER CONFIGURATION

FOR

535BK

..

118

J-l

DTC-5358K

Factory

Settings

..........................

120

J-2

Switch

Settings

for

KODAK

3.3

.......................

120

LIST

OF

TABLES

TABLE

1-1

Controller

Features

...........................................

2-4

1-2

Specifications

..................................................

4

2-1

Interpretaion

of

Request

.......................................

11

3-1

Summary

of

Class

Code'"

OpCodes

....................

:

........

35-37

3-2

Sense

Byte

Error

Codes

.......•.............................•...

44

3-3

Floppy

Drive

Track

Format

(Byte

5

Class.

Code

6)

............

72-73

4-1

Class

Code

7 Commands

..........................................

85

4-2

LED

Error

Displays

.............................................

94

LIST

OF

ILLUSTRATIONS

FIGURES

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

3-1

3-2

3-3

3-4

3-5

3-6

Typical

System

Configuration

............................

,

.......

7

500B

Series

Host

Interface

Signals

and

Pin

Designation.

'"

......

8

Controller

to

Winchester

Drive

Control

Interface

...............

12

Controller

to

Winchester

Drive

Data

Interface

..................

13

520B

Controller

to

Floppy

Disk

Drive

Interface

.................

14

535B

Controller

to

Floppy

Drive

Interface

......................

15

5358

Controller

to

Amlyn

Drive

Interface

.•.....................

16

535BK

Controller

to

KODAK

Disk

Drive

Interface

..............•..

17

Timing

Diagrams

.............•...............................

20-25

Flowcharts

..................................................

26-29

Typical

Command

Discriptor

Block

(CDB)

.........................

32

Test

Drive

Ready

...............................................

38

Recalibrate

Drive

..............................................

39

Request

ECC

Syndrome

.....................•..................•..

40

Request

Sense

..................................................

41

Format

Drive

..............................................••...

46

--iv--

TABLE

OF

CONTENTS

(continued)

LIST

OF

ILLUSTRATIONS

FIGURES

Page

3-7

3-8

3-9

3-10

3-11

3-12

3-l3

3-14

3-15

3-16

4-1

4-2

4-3

B-1

F-l

F-2

G-l

G-2

H-l

H-2

J-l

J-2

Check

Track

Format

..................•..........................

48

Format

Track

.....•.............•..............•................

50

Format

Bad

Track

.•..................•.................•........

52

Read

Block

Command

Flowchart

...................................

55

Write

Block

Command

Flowchart

..................................

58

Seek

•........•.................................................

61

Search

Routine

Flowchart

.......................................

65

Random

Read

Routine

Flowchart

..................................

66

Increment

Sector,

Head,

or

Cylinder

Flowchart

..................

67

Copy

Command

Flowchart

.........................................

70

h'ri

te

ECC

Command

..............................................

87

,

Read

ID

Field

..................................................

89

Drive

Diagnostic

...............................................

91

Physical

versus

Logical

Sector

................•......•....

100-101

DTC

510B

Cable

Connections

....................................

107

DTC

510B

Board

Outline

with

Mounting

Holes

....................

108

DTC

520B

Cable

Connections

............•.......................

110

DTC

520B

Board

Outline

with

Mounting

Holes

....................

111

DTC

535B

Cable

Connections

....................................

1Ll'

DTC

535B

Board

Outline

with

Mounting

Holes

....................

11~

DTC

535BK

Cable

Connections

.....•...•.........................

121

DTC

535BK

Board

Outline

with

Mounting

Holes

...•...............

122

--v--

SECTION 1

1.1

Scope

of

Guide

This

guide,

for

Data

Technology

Corporation's

500B

Series

Disk

Drive

Controllers,

provides:

Equipment

Information

and

Specifications

Interface

and

Configuration

Information

Command

and

Programming

Information

Installation

and

Testing

Instructions

Maintenance

and

Troubleshooting

Hints

This

guide

is

intended

to

satisfy

the

information

requirements

of

OEM

Engineers;

Engineering

and

Production

Technicians;

Personal

Computer

Enthusiasts;

and

others

with

a

need

to

know

about

these

disk

Controllers.

1.2

Overview

of

Equipment

The

DTC-5l0B

is

designed

to

control

two

industry

standard

ST506/406

or

compatible

5.25

Winchester

Disk

Drives.

The

DTC-520B

is

designed

to

control

a maximum

of

four

disk

drives.

It

supports

up

to

two

ST506/406

or

compatible

5.25

inch

Winchester

Disk

Drives

plus

two

industry

standard

SA4XX,

or

equivalent,

(48

or

96TPI)

Floppy

Disk

drives.

The

DTC-535B

is

designed

to

control

a maximum

of

four

drives

in

any

combination

of

up

to

two

industry

standard

5.25

inch

Winchester

Disk

Drives,

and

any

combination

of

two

industry

standard

SA8XX

type

interface

8

inch

Floppy

Disk

Drives.

Alternately,

it

can

be

strapped

tor

a

combination

of

two

hard

disk

drives

and

two

AMLYN

5850

drives

or

one

SA8XX

and

one

AMLYN

5850.

The

DTC-535BK

is

designed

to

control

a maximum

of

four

drives

in

any

combination

of

up

to

two

industry

standard

ST506

5.25

inch

Winchester

Disk

Drives,

or

equivalent,

or

up

to

four

5.25

inch

KODAK

3.3

Floppy

Disk

Drives.

Currently

supported

disk

drives

are

produced

by:

KODAK

IMI

SEAGATE

COGITO

BASF

MPI

SHUGART

QUANTUM

Cii-HB

OPE

TAN

DON

MICROPOLIS

CMI

RODIME

TI

TULIN

FUJITSU

MINI SCRIBE MICROSCIENCE

MAXTOR

The

interface

to

the

!lost

Computer

is

via

the

industry

standard

SASI

bus

and

is

easily

accomplished

by a standard

DTC

Host

Adapter.

DTC

is

a

major

supplier

of

SASI

compatible

Host

Adapters

for

most

computer

system

buses.

--1--

1.2

OVerview

of

Equipment

(continued)

Contact

your

DTC

sales

representative

for

information

on

available

Host

Adapters.

Proprietary

LSI

Circuits,

based

on

DTC's

field-proven

design,

allow

for

enhanced

performance,

small

size

and

economy.

Reliability

and

maintainability

have

been

proven

by

statistical

information

from

field

installation.

The

Mean

Time

between

Failures

(MTBF)

for

these

Controllers

is

20,000

hours.

The

Mean

Time

to

Repair

(MTTR)

is

0.1

hour.

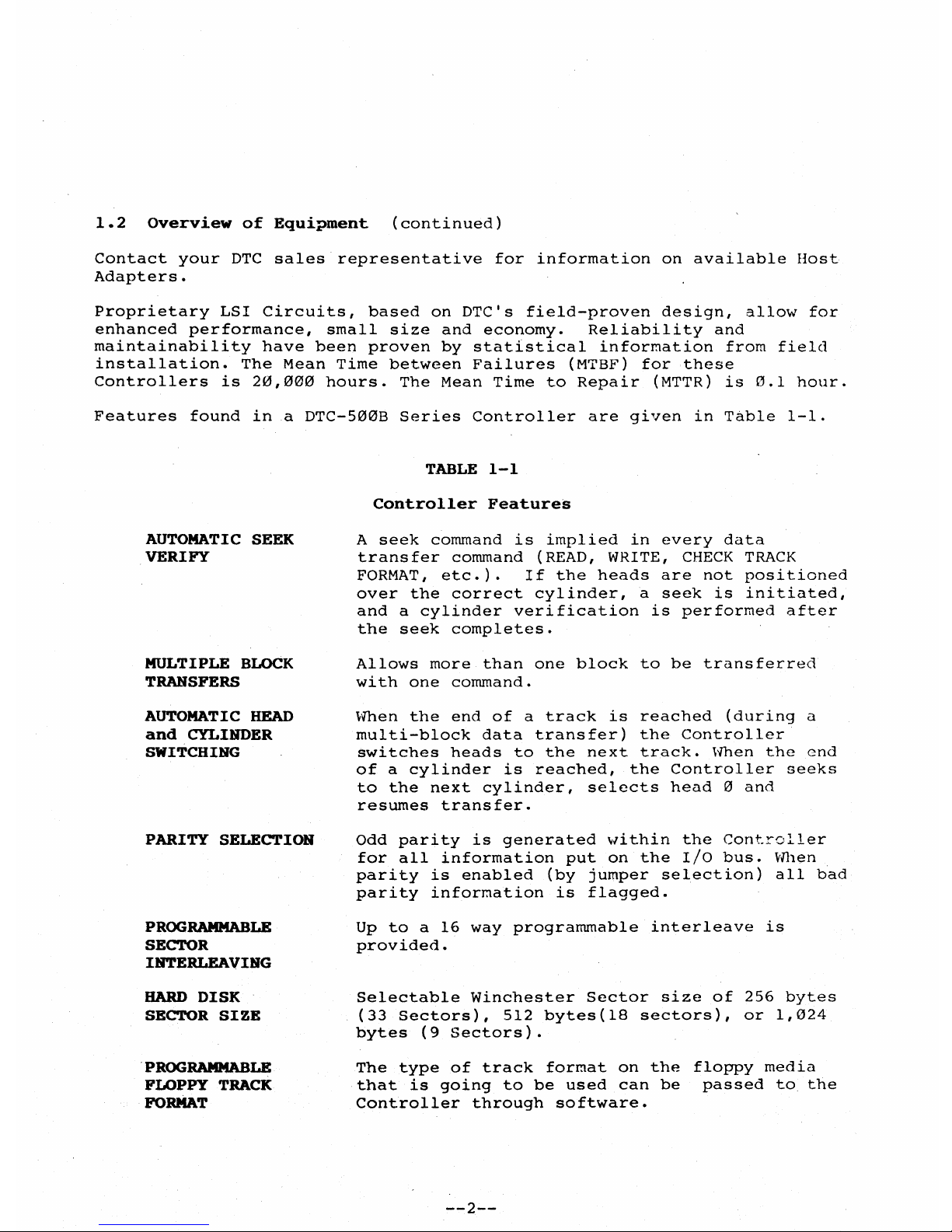

Features

found

in

a

DTC-500B

Series

Controller

are

given

in

Table

1-1.

AUTOMATIC SEEK

VERIFY

MULTIPLE

BLOCK

TRANSFERS

AUTOMATIC HEAD

and

CYLIII1DER

SWITCHIHG

PARITY

SELECTIOH

PROGRAMMABLE

SECTOR

IBTERLEAVIHG

BARD

DISK

SECTOR

SIZE

·PROGRAMMABLE

FLOPPY

TRACK

FORMAT

TABLE

1-1

Controller

Features

A

seek

command

is

implied

in

every

data

transfer

command

(READ, WRITE,

CHECK

TRACK

FORMAT,

etc.).

If

the

heads

are

not

positioned

over

the

correct

cylinder,

a

seek

is

initiated,

and

a

cylinder

verification

is

performed

after

the

seek

completes.

Allows

more

than

one

block

to

be

transferred

with

one

command.

~ilien

the

end

of

a

track

is

reached

(during

a

multi-block

data

transfer)

the

Controller

switches

heads

to

the

next

track.

lilien

the

end

of

a

cylinder

is

reached,

the

Controller

seeks

to

the

next

cylinder,

selects

head

0

and

resumes

transfer.

Odd

parity

is

generated

within

the

Controller

for

all

information

put

on

the

I/O

bus.

~fuen

parity

is

enabled

(by

jumper

selection)

all

bad

parity

information

is

flagged.

Up

to

a

16

way

programmable

interleave

is

provided.

Selectable

Winchester

Sector

size

of

256

bytes

(33

Sectors),

512

bytes(18

sectors),

or

1,024

bytes

(9

Sectors).

The

type

of

track

format

on

the

floppy

media

that

is

going

to

be

used

can

be

passed

to

the

Controller

through

software.

--2--

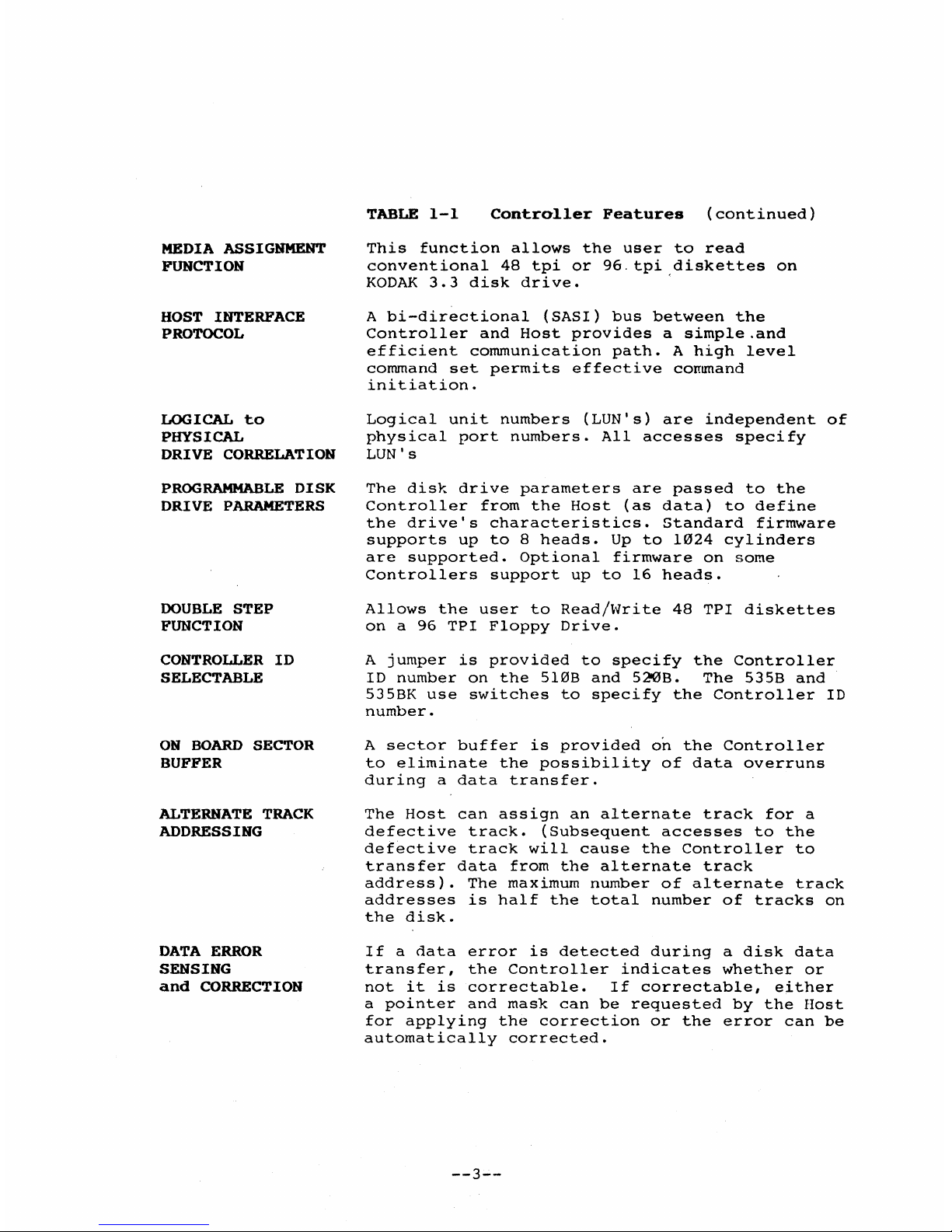

MEDIA

ASSIGNMENT

FUNCTION

HOST

INTERFACE

PROTOCOL

LOGICAL

to

PHYSICAL

DRIVE

CORRELATION

PROGRAMMABLE

DISK

DRIVE

PARAMETERS

DOUBLE

STEP

FUNCTION

CONTROLLER

10

SELECTABLE

ON

BOARD

SECTOR

BUFFER

ALTERNATE

TRACK

ADDRESSING

DATA

ERROR

SENSING

and

CORRECTION

TABLE

1-1

Contro11er

Features

(continued)

This

function

allows

the

user

to

read

conventional

48

tpi

or

96.tpi

diskettes

on

KODAK

3.3

disk

drive.

A

bi-directional

(SASI)

bus

between

the

Controller

and

Host

provides

a

simple.and

efficient

communication

path.

A

high

level

command

set

permits

effective

con~and

initiation.

Logical

unit

numbers

(LUN's)

are

independent

of

physical

port

numbers.

All

accesses

specify

LUN's

The

disk

drive

parameters

are

passed

to

the

Controller

from

the

Host

(as

data)

to

define

the

drive's

characteristics.

Standard

firmware

supports

up

to 8 heads.

Up

to

1024

cylinders

are

supported.

Optional

firmware

on

some

Controllers

support

up

to

16

heads.

Allows

the

user

to

Read/Hrite

48

TPI

diskettes

on a 96

TPI

Floppy

Drive.

A

jumper

is

provided

to

specify

the

Controller

ID

number

on

the

5l0B

and

520B.

The

535B

and

535BK

use

switches

to

specify

the

Controller

ID

number.

A

sector

buffer

is

provided

on

the

Controller

to

eliminate

the

possibility

of

data

overruns

during

a

data

transfer.

The

Host

can

assign

an

alternate

track

for

a

defective

track.

(Subsequent

accesses

to

the

defective

track

will

cause

the

Controller

to

transfer

data

from

the

alternate

track

address).

The

maximum

number

of

alternate

track

addresses

is

half

the

total

number

of

tracks

on

the

disk.

If

a

data

error

is

detected

during

a

disk

data

transfer,

the

Controller

indicates

whether

or

not

it

is

correctable.

If

correctable,

either

a

pointer

and

mask

can

be

requested

by

the

Host

for

applying

the

correction

or

the

error

can

be

automatically

corrected.

--3--

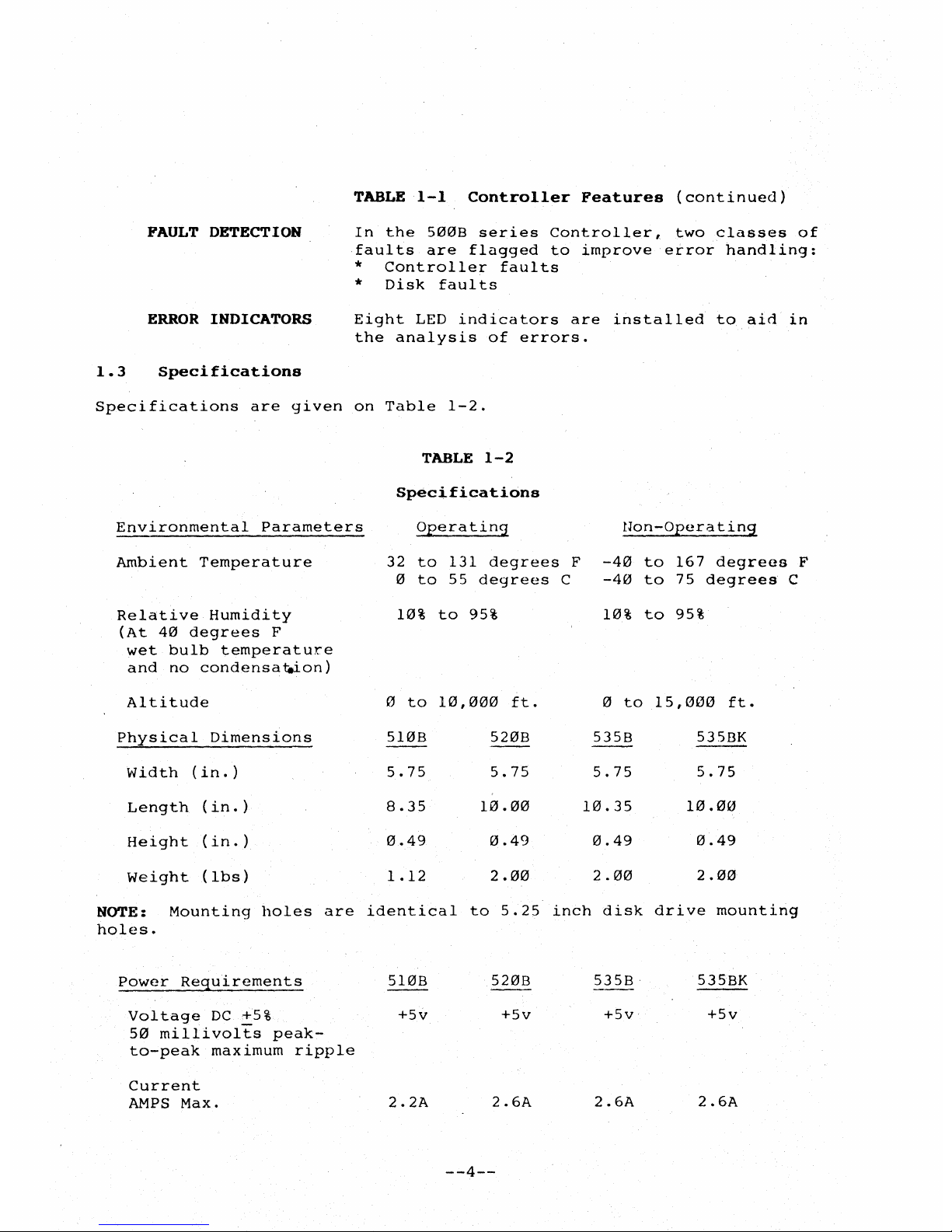

FAULT

DETECTION

ERROR

INDICATORS

1.3

Specifications

TABLE

1-1

Controller

Features

(continued)

In

the

5008

series

Controller,

two

classes

of

faults

are

flagged

to

improve

error

handling:

*

Controller

faults

*

Disk

faults

Eight

LED

indicators

are

installed

to

aid

in

the

analysis

of

errors.

Specifications

are

given

on

Table

1-2.

Environmental

Parameters

Ambient

Temperature

Relative

Humidity

(At

40

degrees

F

wet

bulb

temperature

and

no

condensaQJon)

Altitude

Physical

Dimensions

Width

(in.)

Length

(in.)

Height

(in.)

Weight

(lbs)

TABLE

1-2

Specifications

Operating

32

to

131

degrees

F

o

to

55

degrees

C

10%

to

95%

0

to

10,000

ft.

5108 5208

5.75 5.75

8.35

HJ.00

0.49

0.49

1.12

2.00

lion-Operating

-40

to

167

degrees

F

-40

to

75

degrees

C

10%

to

95%

0

to

15,000

ft.

5358

5358K

5.75 5.75

10.35 10.00

0.49

0.49

2.00 2.00

NOTE:

Mounting

holes

are

identical

to

5.25

inch

disk

drive

mounting

holes.

Power

Reguirements

51<l8

5208

5358

5358K

Voltage

DC

+5%

+5v

+5v +5v

+5v

50

millivolts

peak-

to-peak

maximum

ripple

Current

AMPS

Max.

2.2A

2.6A

2.6A

2.6A

--4--

1.4

Maintenance

Philosophy

The

error

detection

capability

of

these

Controllers

allows

isolation

of

a

fault

to

a

defective

disk

drive

or

Controller.

If

the

disk

drive

is

faulty,

the

manufacturer's

documentation

should

be

reviewed

to

determine

disposition.

A

two

level

maintenance

philosophy

is

recommended

for

the

DTC-500B

Series

Controller

and

associated

Host

Adapter.

Level

-

Replacement

of

the

defective

module

at

the

user's

site.

Level

2 -

Replacement

of

defective

component

at

DTC's

manufacturing

facility.

Section

4

of

this

manual

provides

maintenance

and

troubleshooting

data

that

should

be

reviewed

for

additional

information.

Contact

DTC

prior

to

returning

any

material.

1.5

Related

Documents

Related

documents

include:

-

Host

CPU

documentation

-

Disk

Drive

Manufacturer's

documentation

-

Host

Adapter

Installation

and

Software

Instructions

1.6

Inquiries

Contact

your

Data

Technology

Corporation

Sales

Representative

or:

DATA

TECHNOLOGY

CORPORATION

2775

Northwestern

Parkway

Santa

Clara,

CA

95051

(408)

496-0434

TWX

910-338-2044

DATA

TECHNOLOGY

CORPORATION

15

Wiggins

Avenue

Bedford,

MA

01730

(617

275-4044)

--5--

SECTION 2

HOST

AND

DISK

DRIVE

INTERFACES

2.1

Interface

Connections

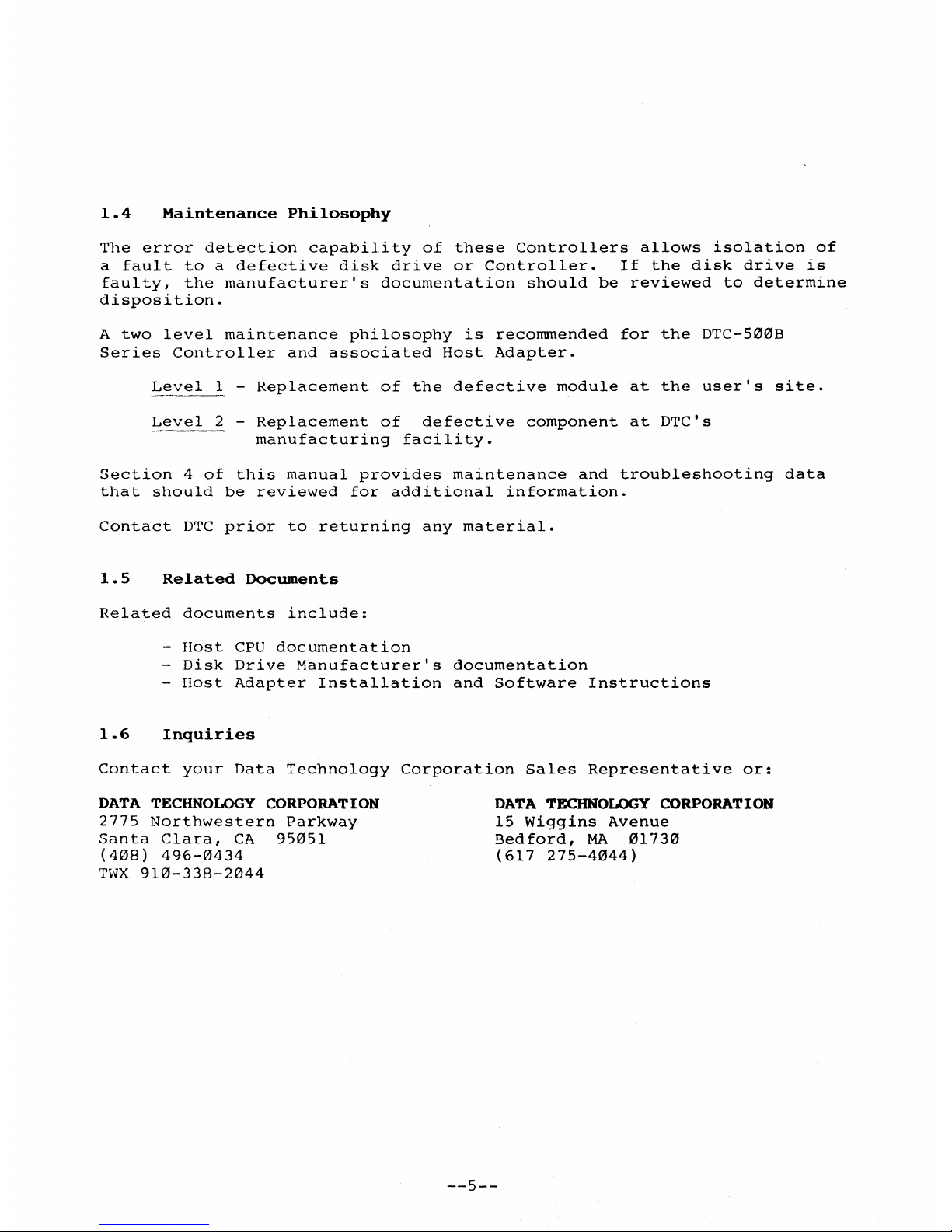

Figure

2-1

is

a

block

diagram

of

a

typical

system

configuration.

(See

the

Appendices

in

back

of

this

manual

for

the

location

of

the

Controller's

Cable

and

Power

Connectors).

The

Host

Computer's

I/O

Bus

is

attached

to

the

Controller

with

the

appropriate

Host

Adapter.

The

Host

Adapter

ensures

signal

compatibility

between

the

Host

Computer

and

the

Controller.

The

Host

Adapter

translates

the

signals

transferred

between

the

Host

Computer's

I/O

Bus

and

the

Controller's

SASI

Interface.

This

includes

directing

signals,

with

the

correct

polarity,

level

and

timing

to

the

corresponding

connector

pin.

The

Winchester

Disk

Drive

Control

Interface

exchanges

status

and

control

information

between

the

Controller

and

the

Disk

Drive(s).'

It

is

daisy-

chained

to

each

Disk

Drive

attached

to

the

Controller,

and

a

terminator

is

installed

in

the

last

physical

Disk

Drive

connected

to

the

chain.

Disk

Drive

parameters,

such

as

the

maximum

number

of

cylinders

and

number

of

heads,

are

passed

to

the

Controller

from

the

Host

Computer.

This

allows

Disk

Drives

with

different

parameters

and

characateristics

to

be

attached

concurrently

to

the

Controller

with

no

special

requirements.

The

Winchester

Disk

Drive's

Data

Interface

has

a

separate

cable

for

each

Disk

Drive.

It

exchanges

serial

MFM

Data

between

the

Controller

and

the

Selected

Disk

Drive.

The

Controller's

D.C.

Power

Interface

requirements

are

given

in

Table

1-2.

2.2

Host

Interface

The

ContrOller's

Host

Interface

is

attached,

via

the

appropriate

Host

Adapter,

to

the

I/O

Bus

of

the

Host

Computer.

Each

computer

manufacturer

specifies

the

signal

names

and

timing

considerations

for

their

I/O

Bus.

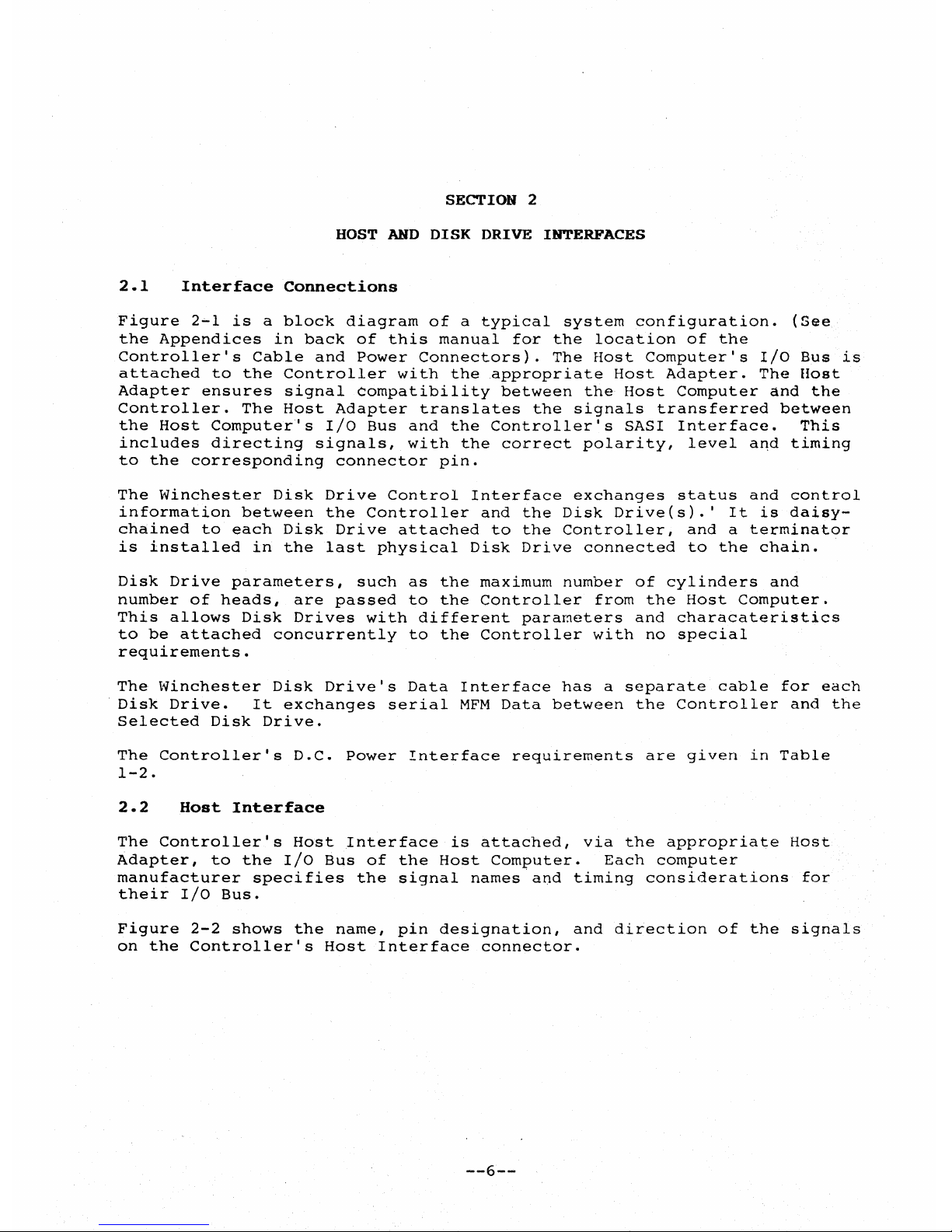

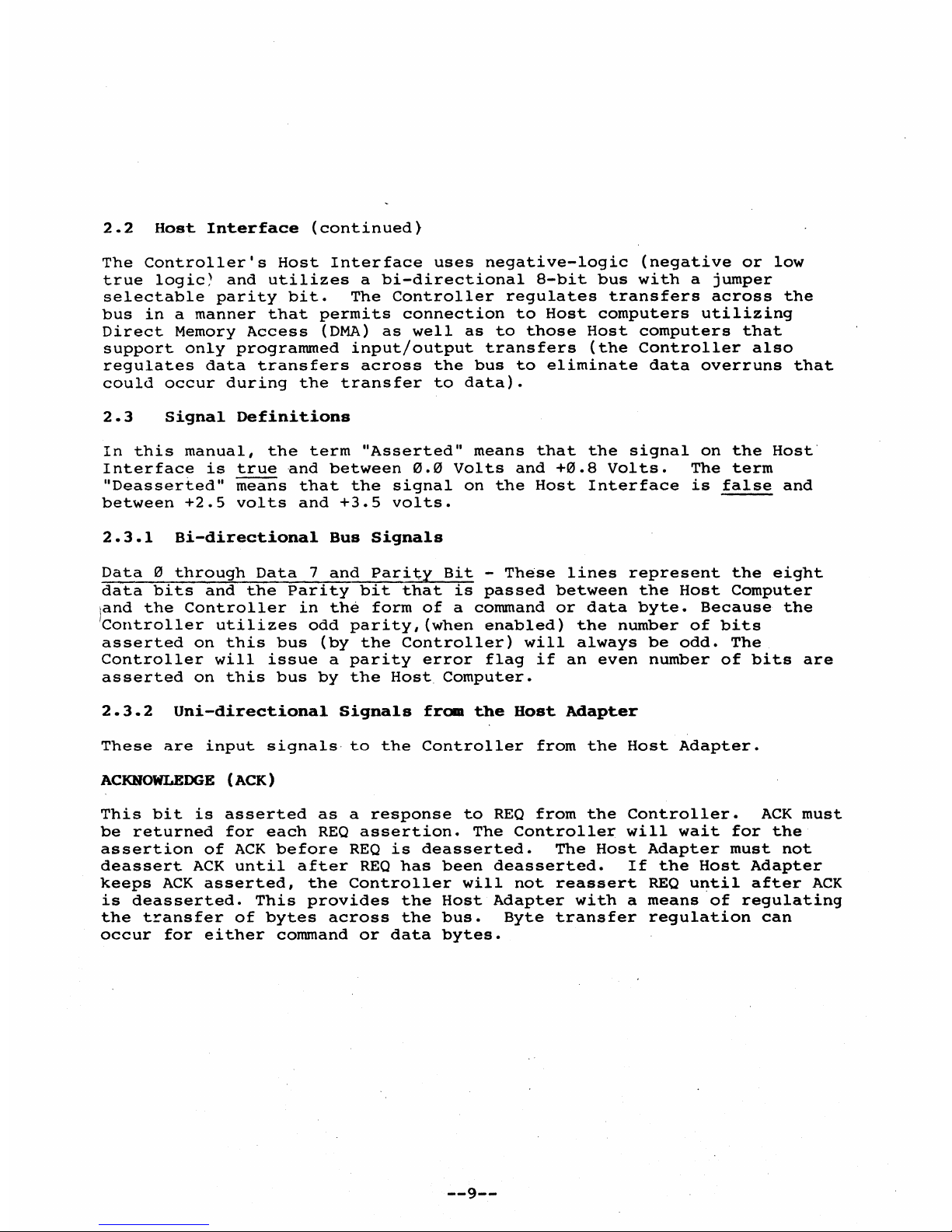

Figure

2-2

shows

the

name,

pin

designation,

and

direction

of

the

signals

on

the

Controller's

Host

Interface

connector.

--6--

/

HOST

COMPUTER I/O BUS

/

I

U

HOST

ADAPTER

SASI BUS

USA"

BUS

DISK

DRIVE

CONTROLLER

--------

--------

---

-

--l

1

I

I

DISK

DRIVE

I

I

I

(ST-506/406 Comp.)

1

I

I

1

I

I

T

I

DISK

DRIVE

2

I

I

(ST-506/1f06

Comp.)

I

I

I

--

I

5

114'

Winchester Drives I

_________________

-

__

I

T = Terminator

I

1-

-------------

--

1

1

1

-

I

FLOPPY DRIVE I

I

I

I

I

1

I

I

1

L--..-

T

1

FLOPPY

DRIVE

2

I

I

I

1

.

I

I

I 5

1/4

Floppy

Dnves

:

L

JUJI

!O..!

~i~

~

!!'

!'~~~.J

Figure

2-1

Typical System Configuration

--7--

HOST

ADAPTER

INTERFACE

LINES

DTC-SeeB

SERIES

DATA

0 (DB0)

<---------------------------->

2

DATA

l

(DB1)

<---------------------------->

4

DATA

2 (DB2)

<---------------------------->

6

DATA

3

(DB3)

<---------------------------->

8

DATA

4

(DB4)

<---------------------------->

10

DATA

5

(DB5)

<---------------------------->

12

DATA

6

(DB6)

<---------------------------->

14

DATA

7 (DB7)

<---------------------------->

16

PARITY

BIT

(PAR)

<---------------------------->

18

GND

20

GND

22

GND

24

NC

26

GND

28

GND

30

__________

~GN~D~----------------t32

GND

34

BUSY

<---------------------------->

36

ACKNOWKLEDGE

(ACK)

<---------------------------->

38

RESET

(RST)

<---------------------------->

40

MESSAGE

(MSG)

<---------------------------->

42

SELECT

(SEL)

<---------------------------->

44

COMMAND/DATA

(C/D

<---------------------------->

46

REQUEST

(REQ)

<---------------------------->

48

INPUT/OUTPUT

(I/O

<---------------------------->

50

NOTE:

All

signals

are

negative

true

and

all

odd

pins

are

connected

to

ground

(except

for

pin

25).

The

signal

lines

are

terminated

with

220

ohms

to

5V

and

330

ohms

to

ground.

Pin

25

and

26

can

be

used

for

terminator

power

so

they

are

left

unconnected.

FIGURE

2-2

HOST

INTERFACE

SIGNALS

and

PIN DESIGNATION

--8--

2.2

Host

Interface

(continued}

The

Controller's

Host

Interface

uses

negative-logic

(negative

or

low

true

logic~

and

utilizes

a

bi-directional

8-bit

bus

with

a

jumper

selectable

parity

bit.

The

Controller

regulates

transfers

across

the

bus

in a manner

that

permits

connection

to

Host

computers

utilizing

Direct

Memory

Access

(DMA)

as

well

as

to

those

Host

computers

that

support

only

programmed

input/output

transfers

(the

Controller

also

regulates

data

transfers

across

the

bus

to

eliminate

data

overruns

that

could

occur

during

the

transfer

to

data).

2.3

Signal

Definitions

In

this

manual,

the

term

"Asserted"

means

that

the

signal

on

the

Host

Interface

is

true

and

between

0.0

Volts

and

+0.8

Volts.

The

term

"Deasserted"

means

that

the

signal

on

the

Host

Interface

is

false

and

between

+2.5

volts

and

+3.5

volts.

-----

2.3.1

Bi-directional

Bus

Signals

Data

0

through

Data

7

and

Parity

Bit

-

These

lines

represent

the

eight

data

bits

and

the

Parity

bit

that

is

passed

between

the

Host

Computer

land

the

Controller

in

the

form

of

a

command

or

data

byte.

Because

the

'Controller

utilizes

odd

parity,

(when

enabled)

the

number

of

bits

asserted

on

this

bus

(by

the

Controller)

will

always

be

odd.

The

Controller

will

issue

a

parity

error

flag

if

an

even

number

of

bits

are

asserted

on

this

bus

by

the

Host

Computer.

2.3.2

Un

i-directional

Signals

from

the

Host

Adapter

These

are

input

signals

to

the

Controller

from

the

Host

Adapter.

ACKNOWLEDGE

(ACK)

This

bit

is

asserted

as

a

response

to

REO

from

the

Controller.

ACK

must

be

returned

for

each

REO

assertion.

The

Controller

will

wait

for

the

assertion

of

ACK

before

REO

is

deasserted.

The

Host

Adapter

must

not

deassert

ACK

until

after

REO

has

been

deasserted.

If

the

Host

Adapter

keeps

ACK

asserted,

the

Controller

will

not

reassert

REO

until

after

ACK

is

deasserted.

This

provides

the

Host

Adapter

with

a

means

of

regulating

the

transfer

of

bytes

across

the

bus.

Byte

transfer

regulation

can

occur

for

either

command

or

data

bytes.

--9--

2.3.2

Uni-directional

Signals

from

the

Host

Adapter

(continued)

RESET

(RST)

When

asserted,

this

bit

will

force

the

Controller

to

the

beginning

of

its

microcode

program

and

set

all

drive

parameters

to

their

default

value.

Reset

immediately

terminates

any

pending

command

without

the

transmission

of

the

status

or

message

bytes.

Any

error

status

request

(after

RST

has

been

asserted)

will

result

in

invalid

status

information

being

transferred.

All

Disk

Drive

interface

lines

are

deasserted.

Reset

must

be

asserted

for

a

minimum

of

250

nanoseconds

and

a maximum

of

10

seconds.

The

Controller

monitors

its

Host

Interface

and

waits

for

an

asserted

Select

(SEL)

signal

and

the

asserted

ID

bit

corresponding

to

the

Controller

after

Reset.

SELECT

(SEL)

When

asserted,

indicates

~he

beginning

of

the

command

transaction.

The

Host

Adapter

asserts

SEL

to

gain

the

attention

of

the

Controller.

A

Data

bit

on

the

bus

must

also

be

asserted

during

SEL

time

to

select

a .

Controller.

The

Controller

will

return

BUSY

as

acknowledgement

for

SEL.

After

the

assertion

of

BUSY,

the

Host

Adapter

will

deassert

SEL

and

the

data

bit

(ID

bit).

The

Controller

will

wait

until

SEL

is

deasserted

before

it

asserts

REQ. SEL

can

be

asserted

immediately

following

a

Reset.

--10--

2.3.3

Uni-directional

Signals

from

the

Controller

These

are

the

output

signals

from

the

Controller

to

the

Host

Adapter:

Input/Output

(I/O)

- When

asserted,

the

information

on

the

bi-

d~rectional

Bus

~s

driven

by

the

Controller.

When

deasserted,

the

information

on

the

bi-directional

Bus

is

driven

by

the

Host.

The

Host

may

use

this

signal

to

enable

its

Data

Bus

line

drivers.

Command/Data

(C/D)

- When

asserted,

the

information

bytes

transmitted

across

the

b~-d~rectional

Bus

are

command,

status,

or

message

bytes.

Ilhen

deasserted,

the

bytes

transmitted

across

the

bi-directional

Bus

are

data

bytes.

Busy

(BUSY) -

This

bit

is

asserted

in

response

to

the

Select

signal

and

ID

b~t

be~ng

asserted

from

the

Host

to

indicate

that

the

Controller's

Host

Interface

is

currently

in

use.

Busy

remains

asserted

through

the

message

phase.

Hessage

(MSG)

- When

asserted,

this

line

indicates

that

the

command

is

completed.

This

bit

is

always

followed

with

the

assertion

of

the

Tnput/Output

and

Request

signals.

Request

(REQ) -

This

bit

operates

in

conjunction

with

the

Input/Output,

Command/Data,

and

Message

signals.

See

Table

2-1

for

an

interpretation

of

these

signal

lines.

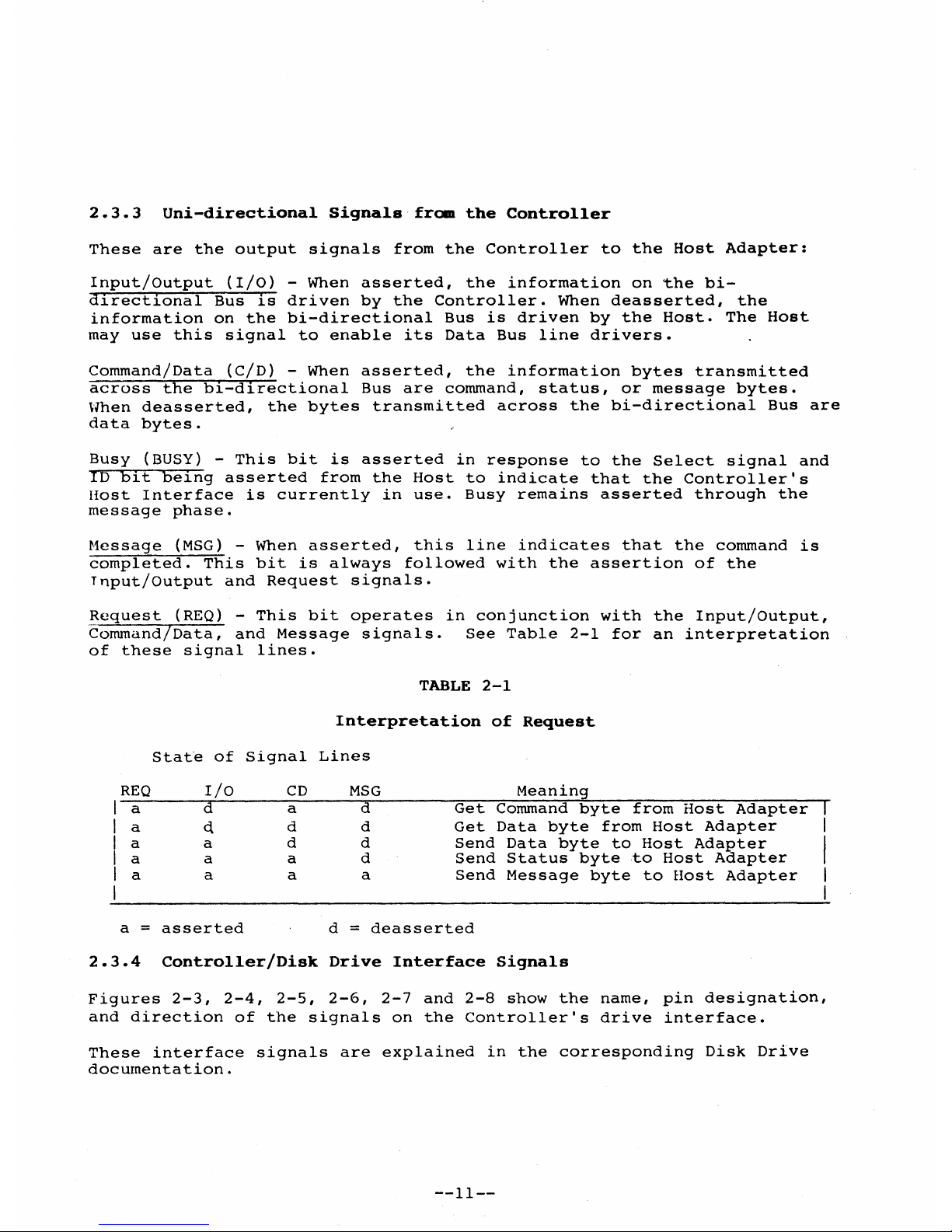

TABLE

2-1

Interpretation

of

Request

State

of

Signal

Lines

REQ

I/O

CD

MSG

Meaning

I

a d a d

Get

Command

byte

from

Host

Adapter

I

a

cl.

d d

Get

Data

byte

from

Host

Adapter

I

a a

d d

Send

Data

byte

to

Host

Adapter

I

a

a a d

Send

Status

byte

to

Host

Adapter

I

a a a a

Send

Message

byte

to

Host

Adapter

I

a =

asserted

d =

deasserted

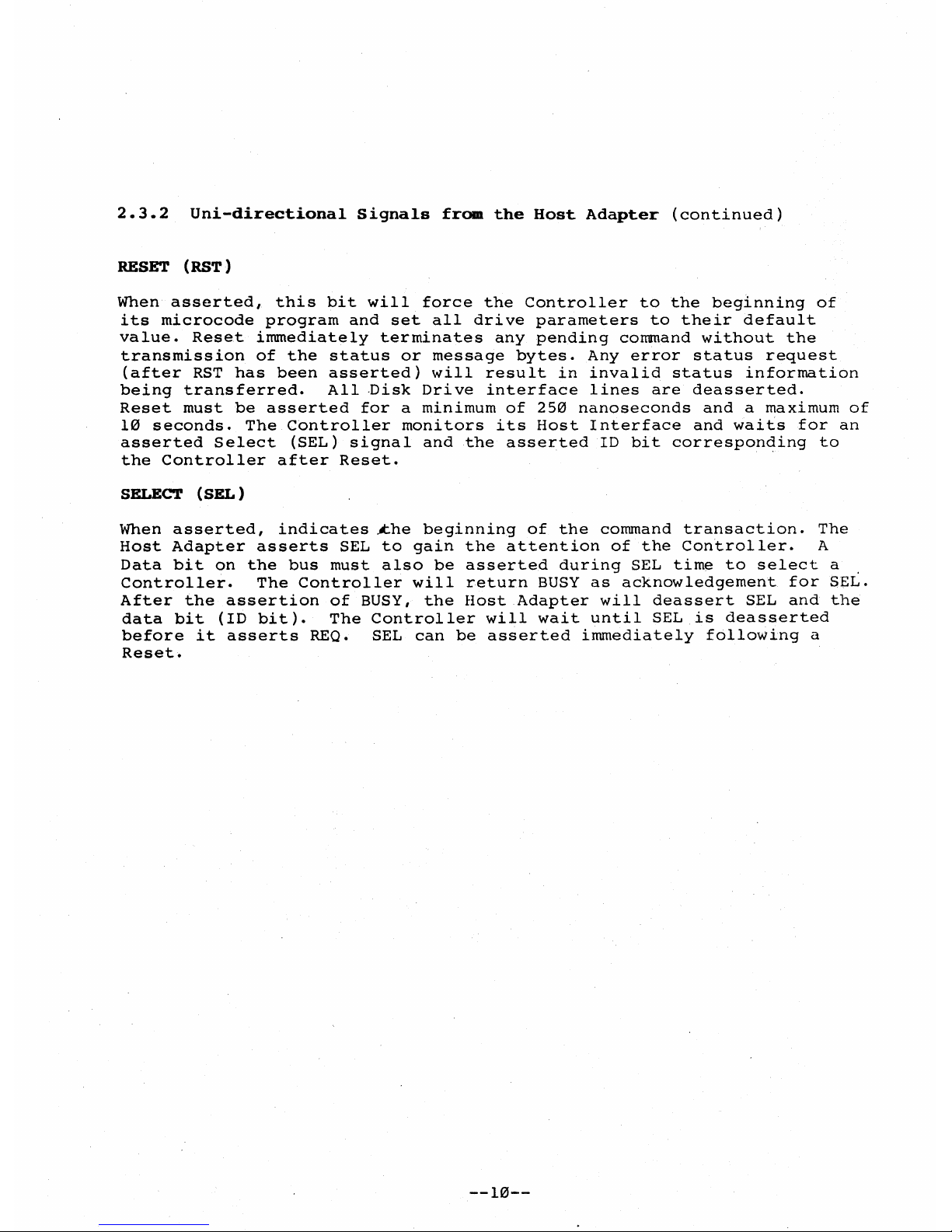

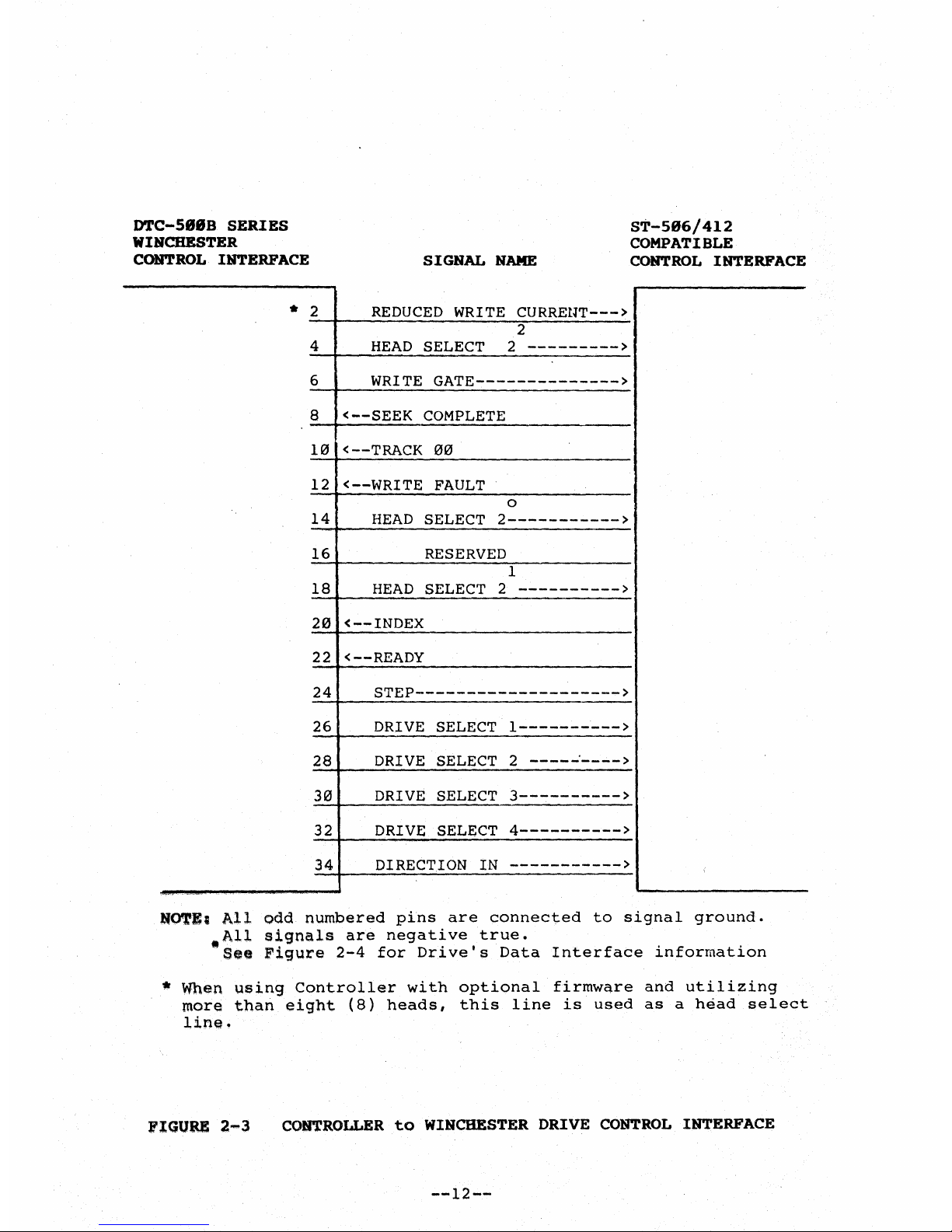

2.3.4

Controller/Disk

Drive

Interface

Signals

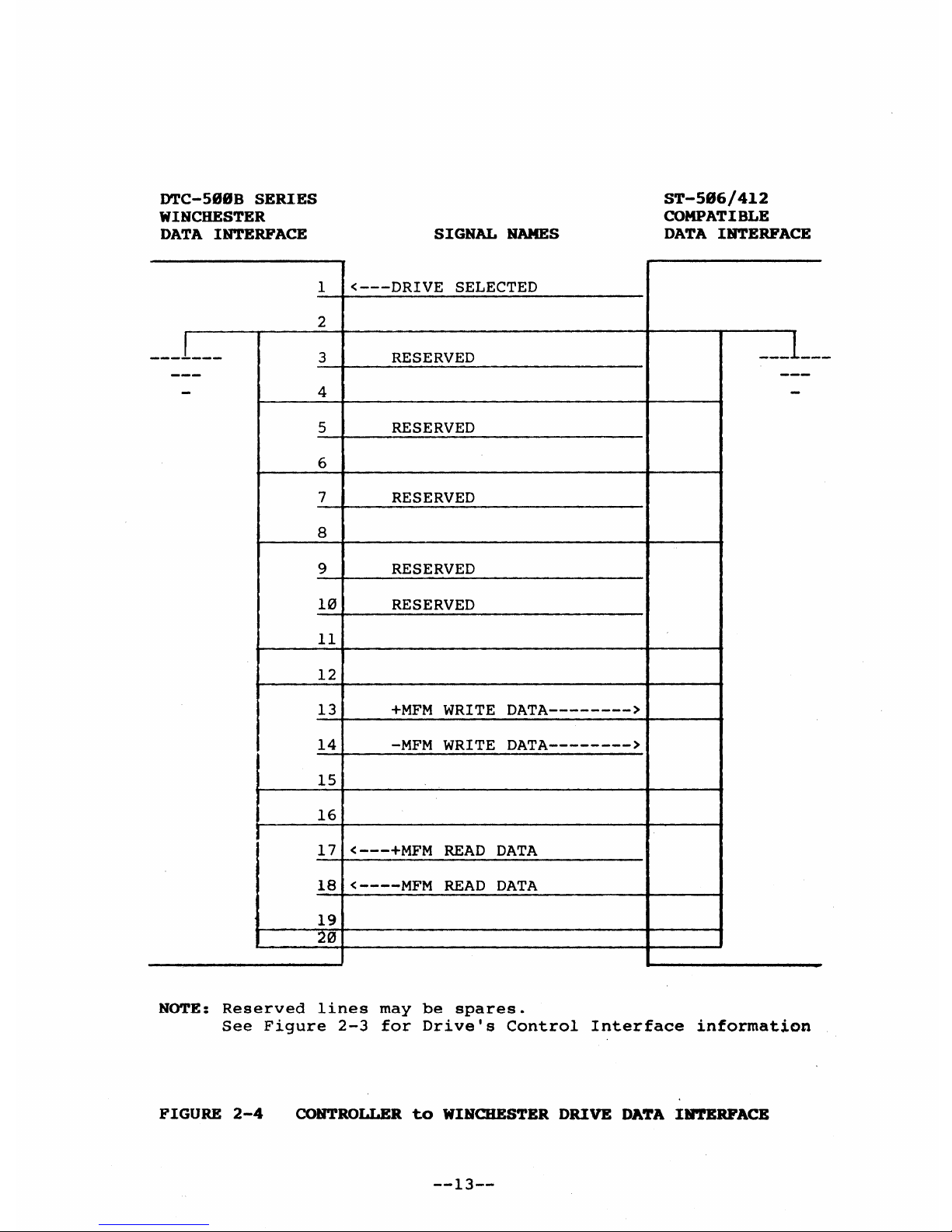

Figures

2-3,

2-4,

2-5,

2-6,

2-7

and

2-8

show

the

name,

pin

designation,

and

direction

of

the

signals

on

the

Controller's

drive

interface.

These

interface

signals

are

explained

in

the

corresponding

Disk

Drive

documentation.

--11--

D'l'C-588B

SERIES

WINCHESTER

CONTROL

INTERFACE

*

2

4

6

8

113

12

14

16

18

213

22

24

26

28

313

32

34

SIGNAL

NAME

REDUCED

WRITE

CURREUT--->

2

HEAD

SELECT 2

--------->

WRITE

GATE-------------->

<--SEEK

COMPLETE

<--TRACK

1313

<--WRITE

FAULT

0

HEAD

SELECT

2----------->

RESERVED

1

HEAD

SELECT 2

---------->

<--INDEX

<--READY

STEP-------------------->

DRIVE SELECT

1---------->

DRIVE SELECT 2

-----'---->

DRIVE SELECT

3---------->

DRIVE

SELECT

4---------->

DIRECTION IN

----------->

ST-586/412

COMPATIBLE

CONTROL

INTERFACE

NOTE;

All

odd

numbered

pins

are

connected

to

signal

ground

.

• AII

signals

are

negative

true.

See

Figure

2-4

for

Drive's

Data

Interface

information

* When

using

Controller

with

optional

firmware

and

utilizing

more

than

eight

(8)

heads,

this

line

is

used

as a head

select

lina.

li'IGUM

2-3

CONTROLLER

to

WINCHESTER DRIVE

CONTROL

INTERFACE

--12--

DTC-51iJ1iJB

SERIES

WINCHESTER

DATA

INTERFACE

___

L

__

---

-

1

2

3

4

5

6

7

8

9

HI

11

12

13

14

15

16

17

18

19

_20

SIGI!IAL

NAMES

<---DRIVE

SELECTED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

+MFM

WRITE

DATA-------->

-MFM

WRITE

DATA-------->

<---+MFM

READ

DATA

<----MFM

READ

DATA

NOTE:

Reserved

lines

may

be

spares.

ST-51iJ6/412

COMPATIBLE

DATA

INTERFACE

__

L _

---

-

See

Figure

2-3

for

Drive's

Control

Interface

information

FIGURE

2-4

COII1TROLLER

to

WINCBES'rER

DRIVE

DATA

1II1TERPACE

--13--

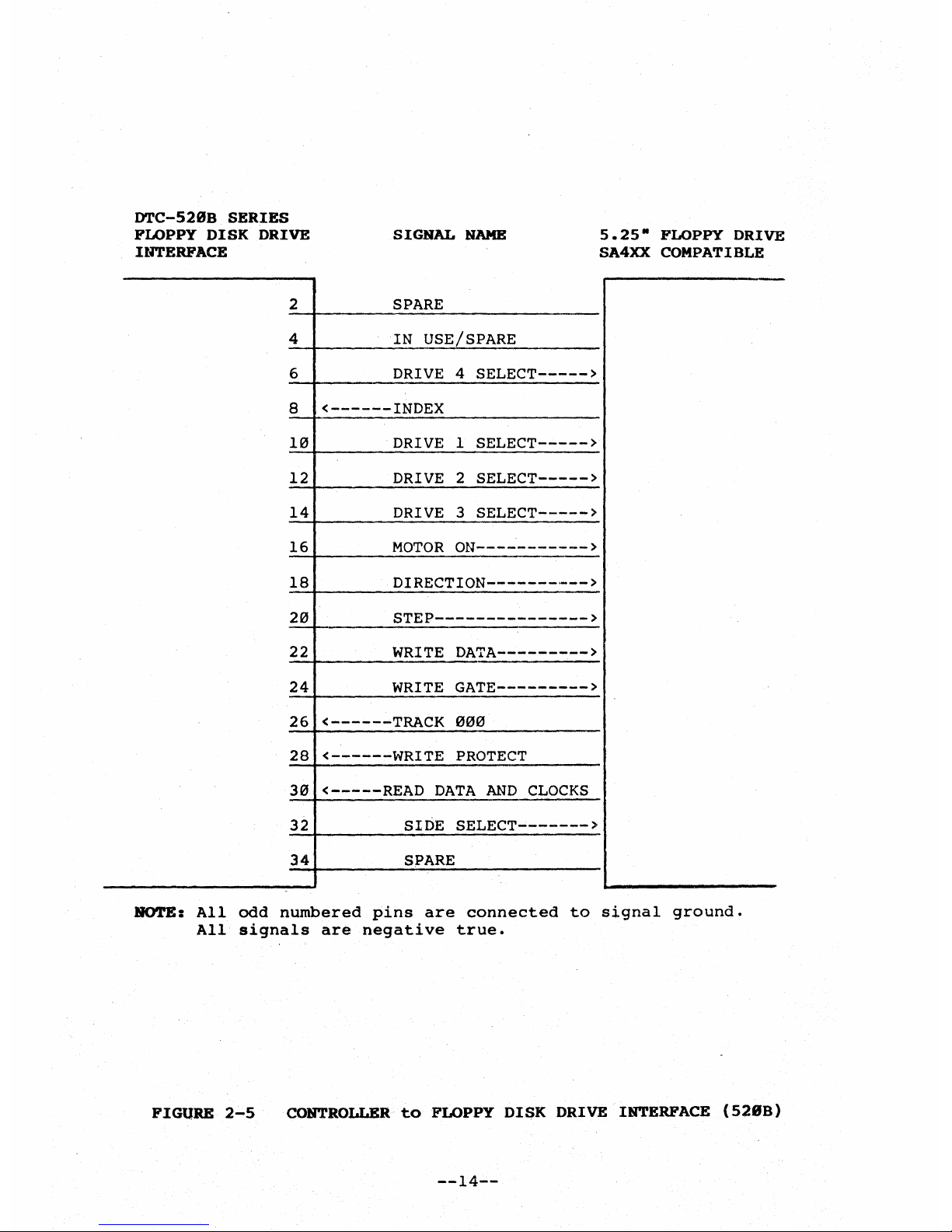

DTC-52i1B

SERIES

FLOPPY

DISK

DRIVE

IlITERFACE

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

SIGNAL

NAME

SPARE

IN

USE/SPARE

DRIVE 4

SELECT----->

<------INDEX

DRIVE 1

SELECT----->

DRIVE 2

SELECT----->

DRIVE 3

SELECT----->

MOTOR

ON----------->

DIRECTION---------->

STEP--------------->

WRITE

DATA--------->

WRITE

GATE--------->

<------TRACK

000

<------WRITE

PROTECT

<-----READ

DATA

AND

CLOCKS

SIDE

SELECT------->

SPARE

5 •

25·

FLOPPY DRIVE

SA4XX COMPATIBLE

NOTE:

All

odd

numbered

pins

are

connected

to

signal

ground.

All

signals

are

negative

true.

FIGURE

2-5

CONTROLLER

to

FLOPPY

DISK

DRIVE INTERFACE

(528B)

--14--

535B

CONTROLLER

SA8XX

INTERFACE

EXTERNAL

\~RITE

CURRENT

SWITCHING---->

2

<----TRUE

READY

*

8

<----TWO

SIDED

*

+

10

<----DISK

CHANGE

*

12

SIDE

SELECT

*

+

---------------->

14

IN

USE * ----------------------->

16

110TOR

ON * (HEAD

LOAD)---------->

18

<----INDEX

20

<----READY

22

<----SECTOR

24

DRIVE SELECT 1

(SIDE

SELECT

OPT)+

--->

26

DRIVE SELECT

2

(SIDE

SELECT

OPT)+

--->

28

DRIVE SELECT 3

(SIDE

SELECT

OPT)+

--->

30

DRIVE

SELECT 4

(SIDE

SELECT

OPT)+

--->

32

DIRECTION SELECT

(SIDE

SELECT

OPT)+-->

34

STEP---------------------------->

36

WRl'rE

DATA

--------------------->

38

WRITE

GATE---------------------->

40

<----TRACK

00

42

<----WRITE

PROJECT

44

<----READ

DATA

46

<----SEP

DATA

48

<----SEP

CLOCK

50

NOTE:

All

odd

numbered

pins

are

connected

to

signal

ground.

All

signals

are

negative

true.

*

Jumper

enabled

alternate

I/O

lines.

+

SA860

only.

FIGURE

2-6

CONTROLLER

to

FLOPPPY

DISK

DRIVE

INTERFACE(535B)

--15--

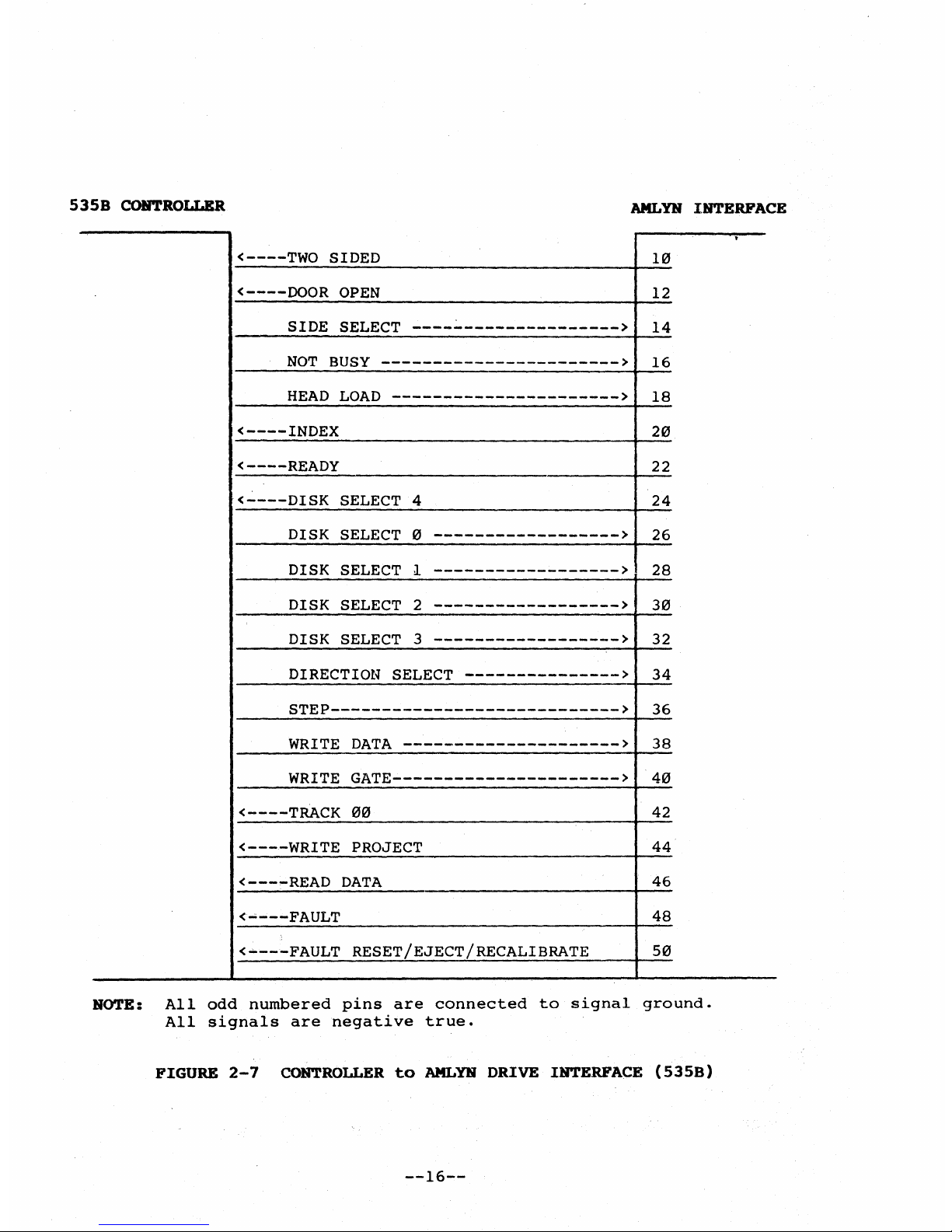

535B

CONTROLLER

AMLYH

INTERFACE

<----TWO

SIDED

1~

<----DOOR

OPEN

12

SIDE

SELECT

-------------------->

14

NOT

BUSY

----------------------->

16

HEAD

LOAD

---------------------->

18

<----INDEX

20

<----READY

22

<----DISK

SELECT 4

24

DISK SELECT 0

------------------>

26

DISK SELECT 1

------------------>

28

DISK SELECT 2

------------------>

30

DISK SELECT 3

------------------>

32

DIRECTION SELECT

--------------->

34

STEP---------------------------->

36

WRITE

DATA

--------------------->

38

WRITE

GATE---------------------->

40

<----TRACK

00

42

<----WRITE

PROJECT

44

<----READ

DATA

46

<----FAULT

48

<----FAULT

RESET/EJECT/RECALIBRATE

50

NOTE:

All

odd

numbered

pins

are

connected

to

signal

ground.

All

signals

are

negative

true.

FIGURE

2-7

CONTROLLER

to

AMLYH

DRIVE

INTERFACE

(535B)

--16--

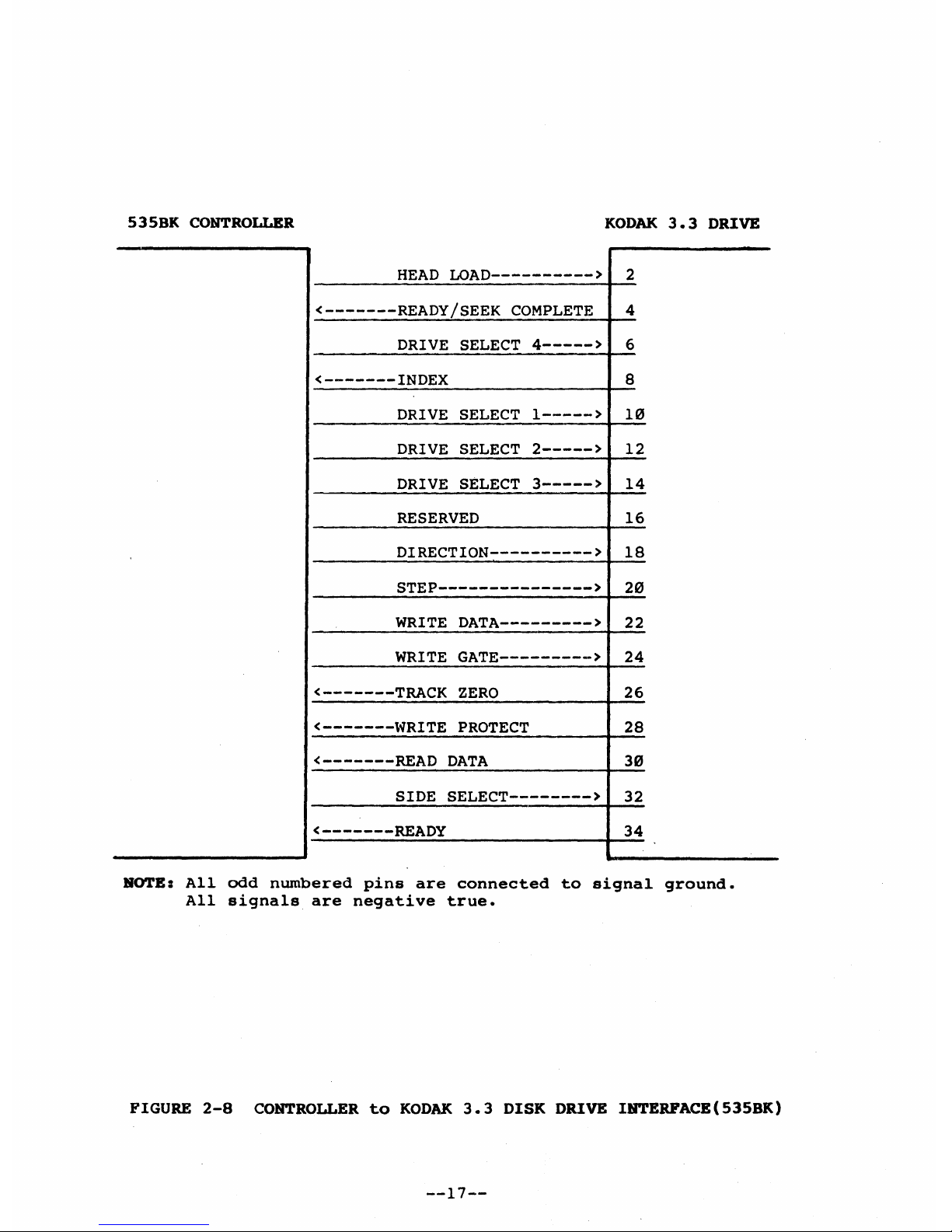

535BK

CONTROLLER

KODAK

3.3

DRIVE

HEAD

LOAD---------->

2

<-------READy/SEEK

COMPLETE

4

DRIVE

SELECT

4----->

6

<-------INDEX

8

DRIVE SELECT

1----->

1'"

DRIVE

SELECT

2----->

12

DRIVE

SELECT

3----->

14

RESERVED

16

DIRECTION---------->

18

STEP--------------->

2'"

WRITE

DATA--------->

22

WRITE

GATE--------->

24

<-------TRACK

ZERO

26

<

-------\~RITE

PROTECT

28

<-------READ

DATA

3'"

SIDE

SELECT-------->

32

<-------READy

34

NOTE:

All

odd

numbered

pins

are

connected

to

signal

ground.

All

signals

are

negative

true.

FIGURE

2-8

CONTROLLER

to

KODAK

3.3

DISK

DRIVE INTERFACE{535BK)

--17--

2.4

Sequence

of

Operation

The

Controller

performs

an

internal

RAM

test

upon

power-up.

If

there

is

a

RAM

failure,

the

Controller

will

display

an

error

code

18

(hex)

and

will

not

respond

to

the

Host.

Commands

are

issued

to

the

DTC-500B

Series

Controller

via

the

Host

Adapter

following

a

defined

protocol

(SASI).

The

Host

initiates

a

command

sequence

by

selecting

the

Controller

on

the

bus.

If

the

Controller

is

not

busy,

it

requests

command

bytes

from

the

Host

for

task

execution.

(Command

structure

is

described

in

Section

3.0).

Upon

reception

of

the

last

command

byte,

the

Controller

begins

execution

of

the

command.

For

the

data

transfer

commands,

a

check

is

performed

on

the

disk

address

and

status

is

flagged

if

it

exceeds

the

drive

limits.

The

data

is

stored

in

a

sector

buffer

before

any

transfer

to

the

Host

or

disk

drive

takes

place.

This

buffer

eliminates

any

possibility

of

data

overruns

between

the

Host

and

the

disk.

Upon

completion

of

the

command,

the

Controller

will

send

the

completion

status

and

the

message

byte

to

the

Host.

If

an

error

is

indicated,

further

delineation

of

the

completion

status

r:Iay

be

requested

by

the

Host

issuing

the

appropriate

sense

commands.

Request

Sense

Command

will

clear

the

error

in

the

LED's.

Parity

must

be

enabled

or

disabled

on

both

the

Host

and

Controller.

If

parity

is

enabled,

the

Controller

will

generate

ODD

parity

for

all

data

it

puts

on

the

Host

Bus

and

it

will

check

for

ODD

parity

for

all

data

it

receives

from

the

Host

Bus.

If

parity

is

disabled,

the

Controller

does

not

generate

or

check

parity.

2.4.1

Select

Phase

Following

a

Reset,

and/or

upon

completion

of

a

command,

the

Controller

monitors

the

bi-directional

Bus

for

the

assertion

of

Select.

The

Host

Adapter

asserts

SEL

and

the

Controller's

Address

Bit

on

the

bi-

directional

Data

Bus

to

indicate

that

a

command

is

ready

for

the

Controller.

The

Host

then

waits

for

the

Controller

to

respond

with

BUSY.

Upon

reception

of

BUSY,

the

Host

deasserts

Select

and

the

Controller's

Address

Bit.

The

Controller

now

has

control

of

the

bi-directional

bus.

HOTE:

The

Host

may

keep

Select

and

the

Controller's

Address

Bit

asserteo

until

it

is

ready

to

enter

the

Command

Fetch

Phase.

--18--

2.4.2

Command

Phase

After

the

Host

deasserts

Select

and

the

Controller's

Address

Bit,

the

Controller

asserts

the

Command/Data

(C/D)

bit

to

indicate

a Command

transfer,

and

deasserts

r/o

to

indicate

an

output

from

the

Host.

The

command

bytes

are

transferred

OVer

the

bi-directional

bus

one

byte

with

each

REO/ACK

handshake

protocol,

until

all

command

bytes

are

transferred

to

the

Controller.

The

Command

Phase

ends

after

the

last

REO

pulse

from

the

Controller

is

deasserted.

NOTE:

The

Host

must

not

assert

ACK

until

after

REO

is

asserted

and

must

not

deassert

ACK

until

after

REO

is

deasserted.

The

Controller

waits

until

ACK

from

the

previous

byte

transfer

is

deasserted

before

it

reasserts

REO

to

transfer

the

next

byte.

This

provides

a

means

for

the

Host

to

regulate

the

byte

transfer

across

the

bi-directional

bus.

2.4.3

Data

Phase

This

phase

is

skipped

when

the

command

does

not

require

a

transfer

of

data.

If

a

Read

or

Write

data

transfer

is

required

for

the

command,

the

following

occurs:

a.

The

Controller

deasserts

the

Command/Data

(C/o)

line

to

indicate

a

Data

transfer.

b.

Depending

on

the

command

type

(read

or

write)

the

I/O

line

(for

the

bi-directional

bus)

is

asserted

or

deasserted

by

the

Controller.

c.

The

data

is

transferred

(one

byte

at

a

time)

with

the

same

REO/ACK

handshake

protocol

used

in

the

Command

Phase.

d.

After

all

data

bytes

are

transferred,

the

Controller

exits

this

phase

and

enters

the

Status

phase.

2.4.4

Status

and

Message

Phase

After

all

the

Command

and

Data

bytes

have

been

transferred,

a

Status

byte

is

placed

on

the

bi-directional

bus

by

the

Controller.

(REO,C/D,

and

I/O

are

asserted,

MSG

is

deasserted).

The

Controller

waits

for

ACK

from

the

!lost.

Upon

receipt

of

ACK,

the

status

byte

is

transferred.

The

Controller

asserts

REO,

C/O,

I/O

and

MSG

to

indicate

to

the

Host

that

the

command

is

complete.

This

action

can

be

used

to

generate

an

interrupt

in

the

Host.

After

the

Host

responds

with

ACK,

the

Controller

will

deassert

BUSY, REO,

C/O,

I/O,

and

MSG.

This

completes

the

normal

command

sequence

and

the

Controller

is

ready

to

be

Selected

by

the

Host

Adapter

for

the

next

command

sequence.

--19--

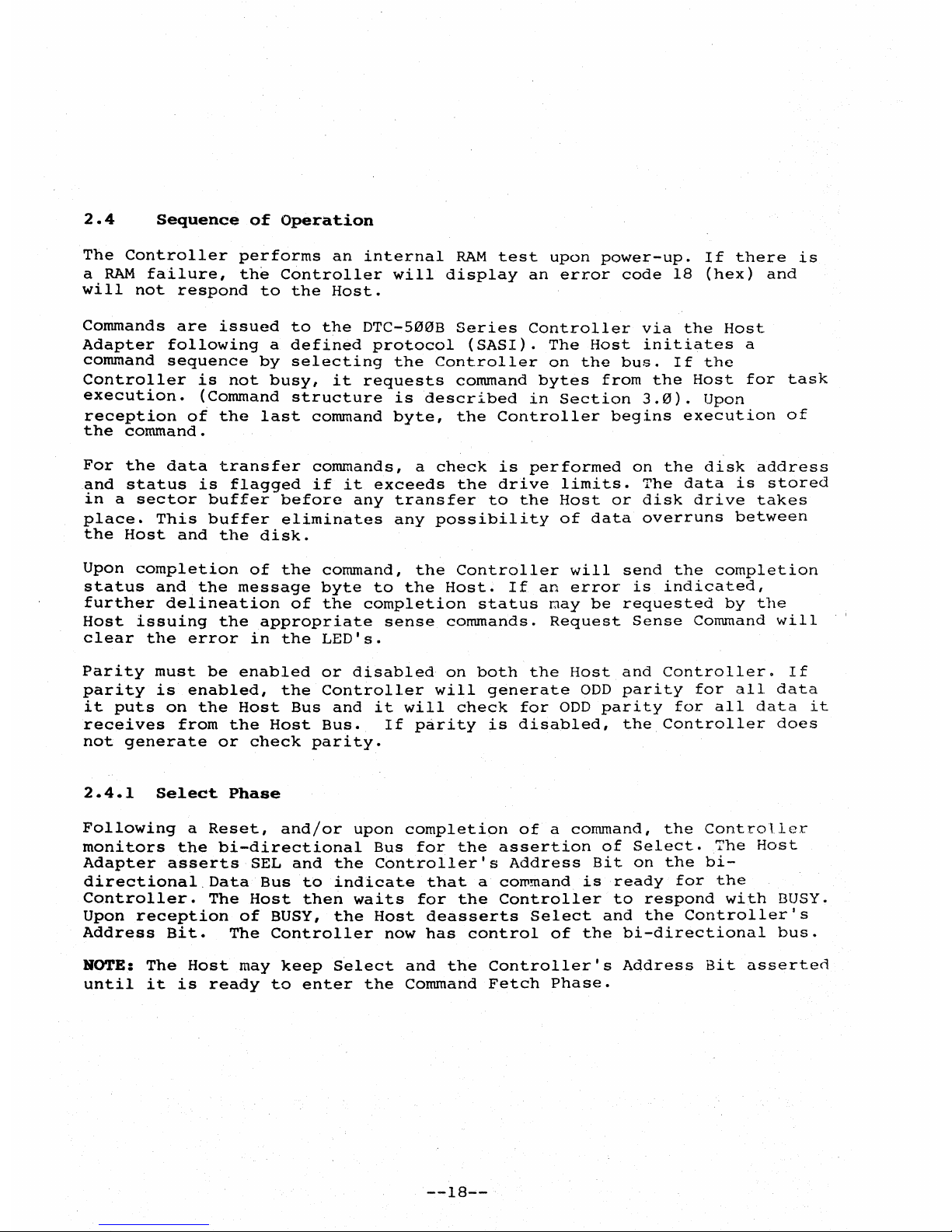

SEL

D~

BSY

NOTES:

TIMING

DIAGRAMS

Timing

Requirementa

for

Controller

Selection

,-----------------

,

,

1<---

>~I----------~

I lOOnal

1 1

1

1

, ,-------r----------------------

1<------->1<------->

I 4 ms 1

no

time

1

max

1

limit

1.

SEL

must

be

deasserted

before

the

Controller

will

assert

RBQ.

·2.

After

Power

On

or

Reset,

when

the

first

command

is

issued,

it

may

take

the

Controller

a maximum

of

4 ms

to

respond

with

BUSY.

The

BUSY

response

time

for

all

successive

commands

will

be

within

50

us.

FIGURE

2-9

TIMING

DIAGRAMS

(sheet

I

of

6)

--20--

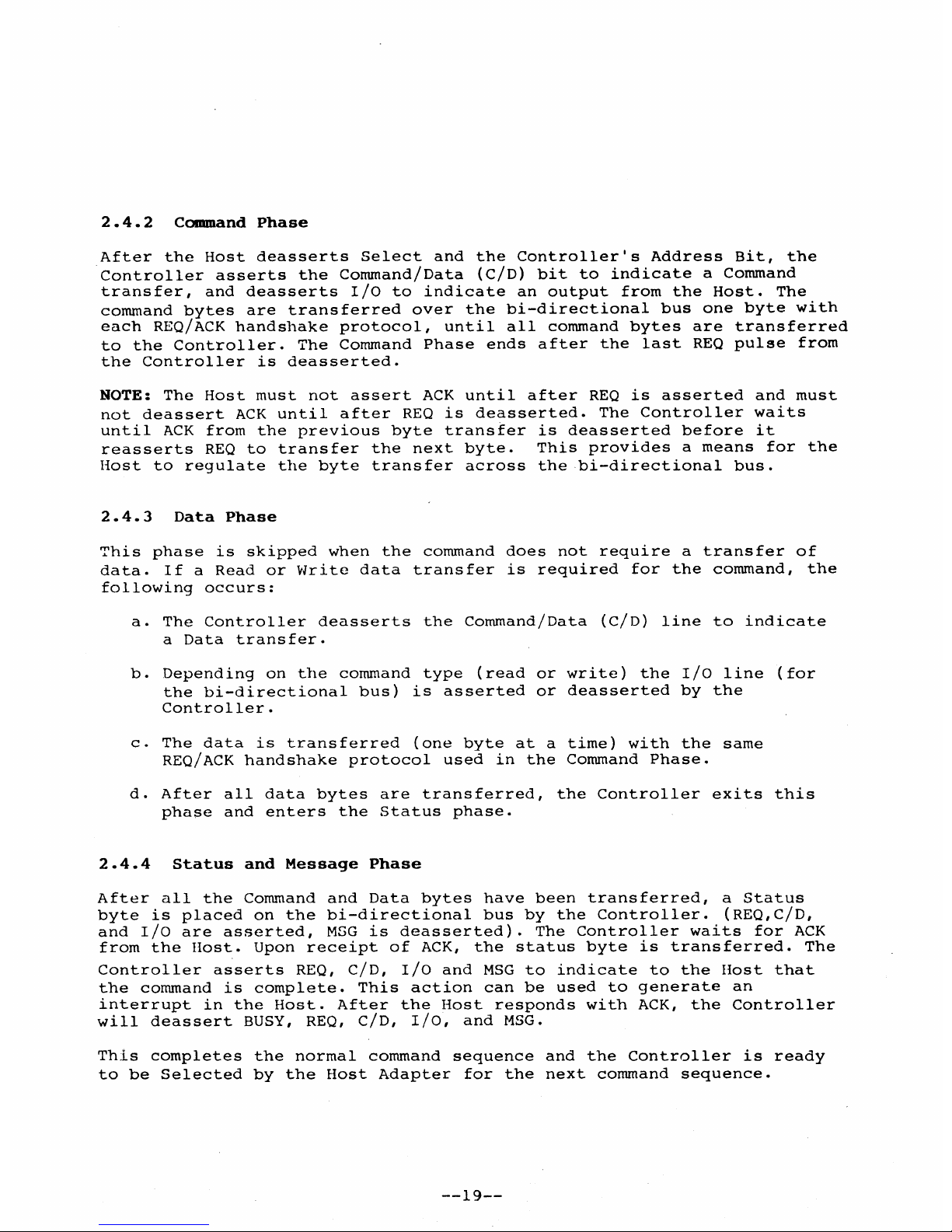

TIMING

DIAGRAMS

Timing

Requir~nts

for

Command

Transfer

Phase

(from

Host

Adapter.

one

byte)

1/0

____

x

1

___

I

CID f'--------------------------------------

___

1,-------------------------------------

MSG

X

REO

ACK

DB

NOTES:

1

1

1<

->1

_______________________________

_

I

588nsl

I

min

I

I 1

1

I 1 1 1

1<----->1<------>1<------>1

Ino

time I 588

ns

lno

time

I

I

limit

1

typ

I

limit

I

I I I

Data

driven

by

_______________________

~-----.X-----X

Host

Adapter

I

I---r-I'"'-----'

1

<--->

1 1

<->

I

1188nsl

18nsl

1

max

1

1.

I/O*,

C/D*,

MSG*

changes

500

ns

min

before

the

1st

REO

for

the

phase

and

remain

unchanged

until

the

Controller

goes

into

the

next

phase.

2.

Data

driven

by

the

Controller

is

stable

100ns

min

at

the

Host

Adapter

end

before

REO*

is

asserted

and

0ns

min

after

REO*

is

deasserted.

3.

Data

driven

by

the

Host

Adapter

is

stable

100ns

max

(at

the

Host

Adapter

end)

after

ACK*

is

asserted

and

0ns

min

after

REO*

is

deasserted.

FIGURE

2-9

TIMING

DIAGRAMS

(sheet

2

of

6)

--21--

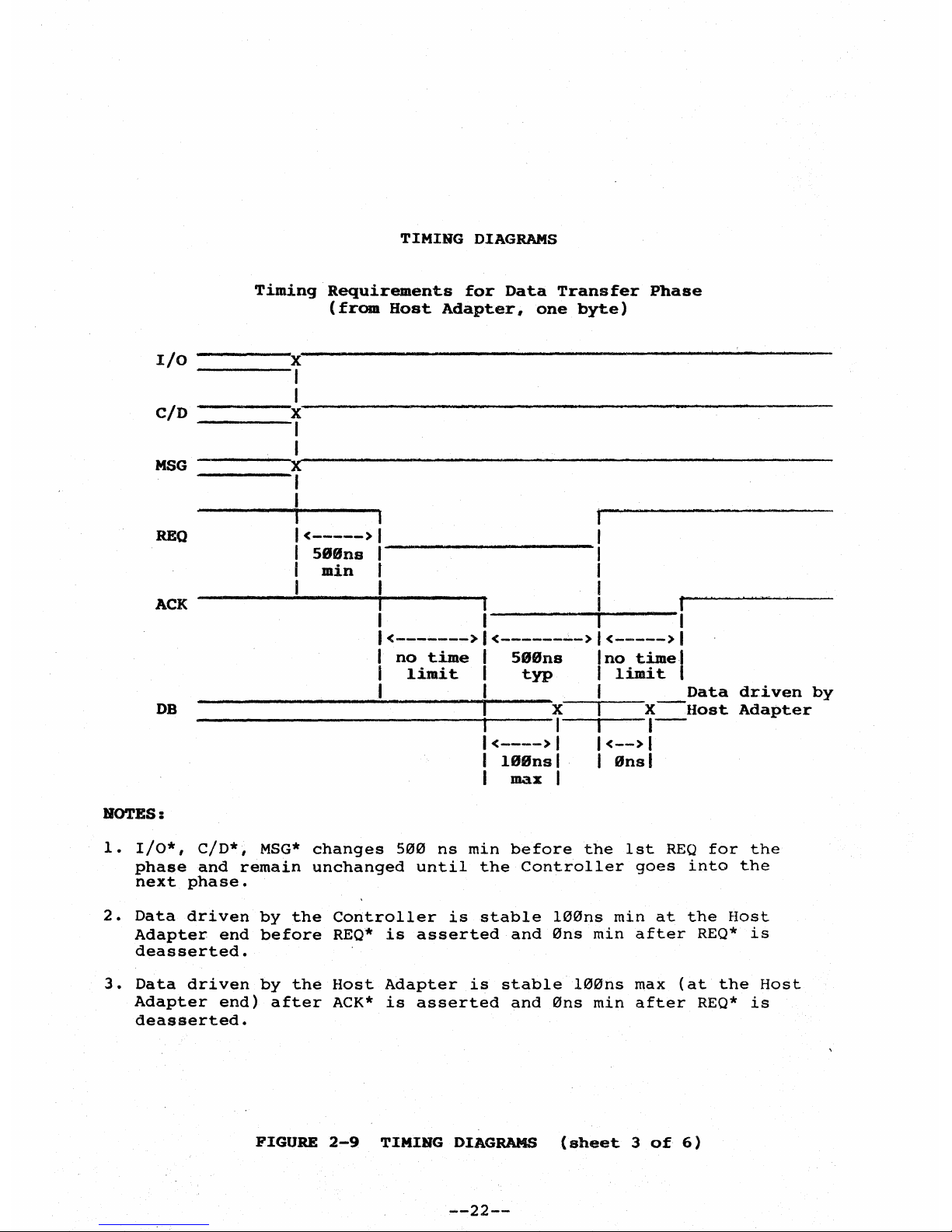

I/O

C/D

MSG

REO

ACK

DB

1!if00ES:

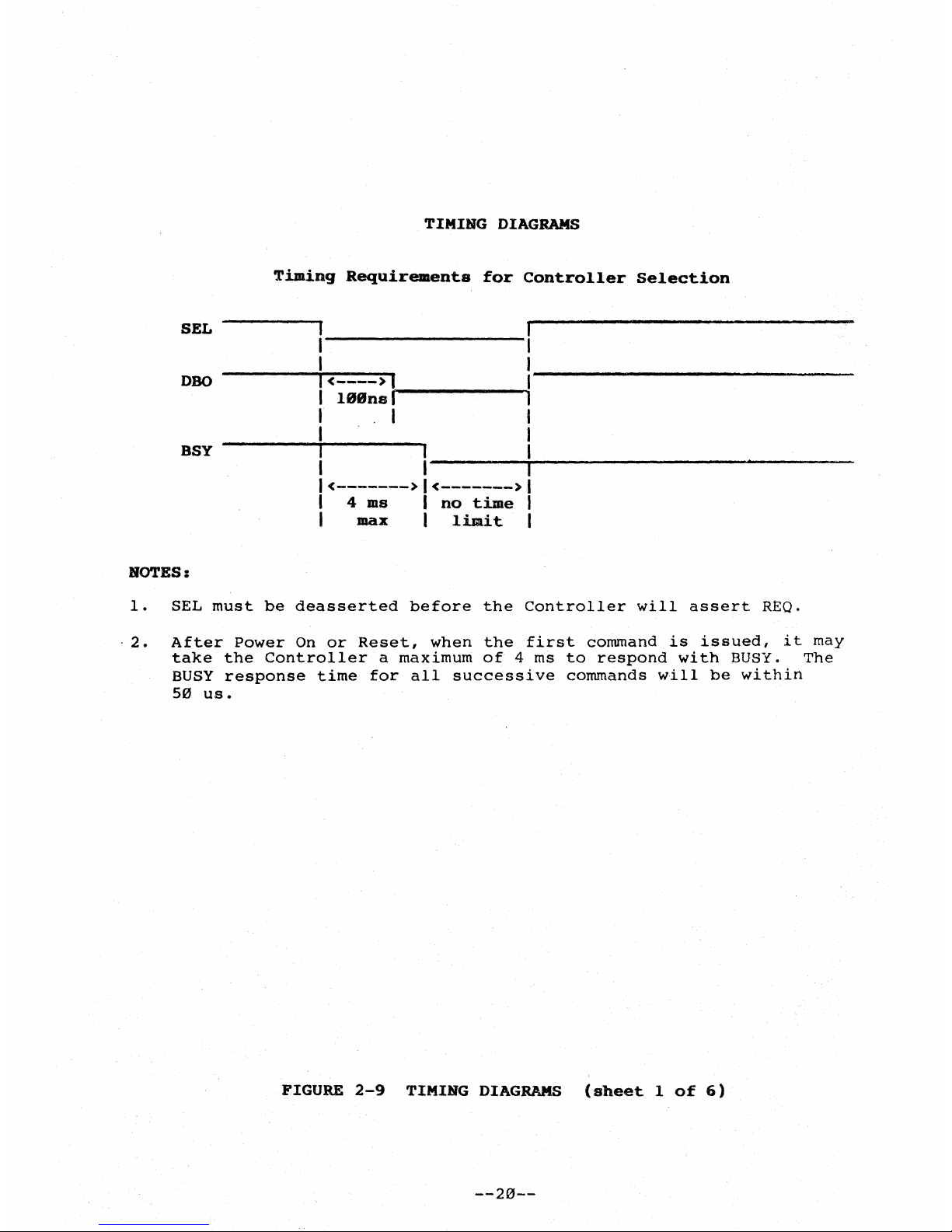

TIMING

DIAGRAMS

Timing

Requirements

for

Data

Transfer

Phase

(from

Host

Adapter,

one

byte)

X

I

I

X

I

I

x:

I

I

I

1<----->

I

51Ulns

I

min

I

I

---------------,

I

f

I

I

I

I I

<------->1<-------->1<----->1

no

time

I 5BI'lns I

no

time

I

limit

I

typ

I

limit

I I

Data

driven

by

------------------~--------~l~----~x

I

X---Host

Adapter

-----------+1--1

I

I-

I

<---->

I I

<-->

I

I

II'lBnsl

I

I'lnsl

I

max

I

1.

1/0*,

C/D*,

MSG*

changes

SI'lI'l

ns

min

before

the

1st

REO

for

the

phase

and

remain

unchanged

until

the

Controller

goes

into

the

next

phase.

2.

Data

driven

by

the

Controller

is

stable

ll'll'lns

min

at

the

Host

Adapter

end

before

REO*

is

asserted

and

I'Ins

min

after

REO*

is

deasserted.

3.

Data

driven

by

the

Host

Adapter

is

stable

11'11'1ns

max

(at

the

Host

Adapter

end)

after

ACK*

is

asserted

and

I'Ins

min

after

REO*

is

deasserted.

FIGURE

2-9

TIMING

DIAGRAMS

(sheet

3

of

6)

--22--

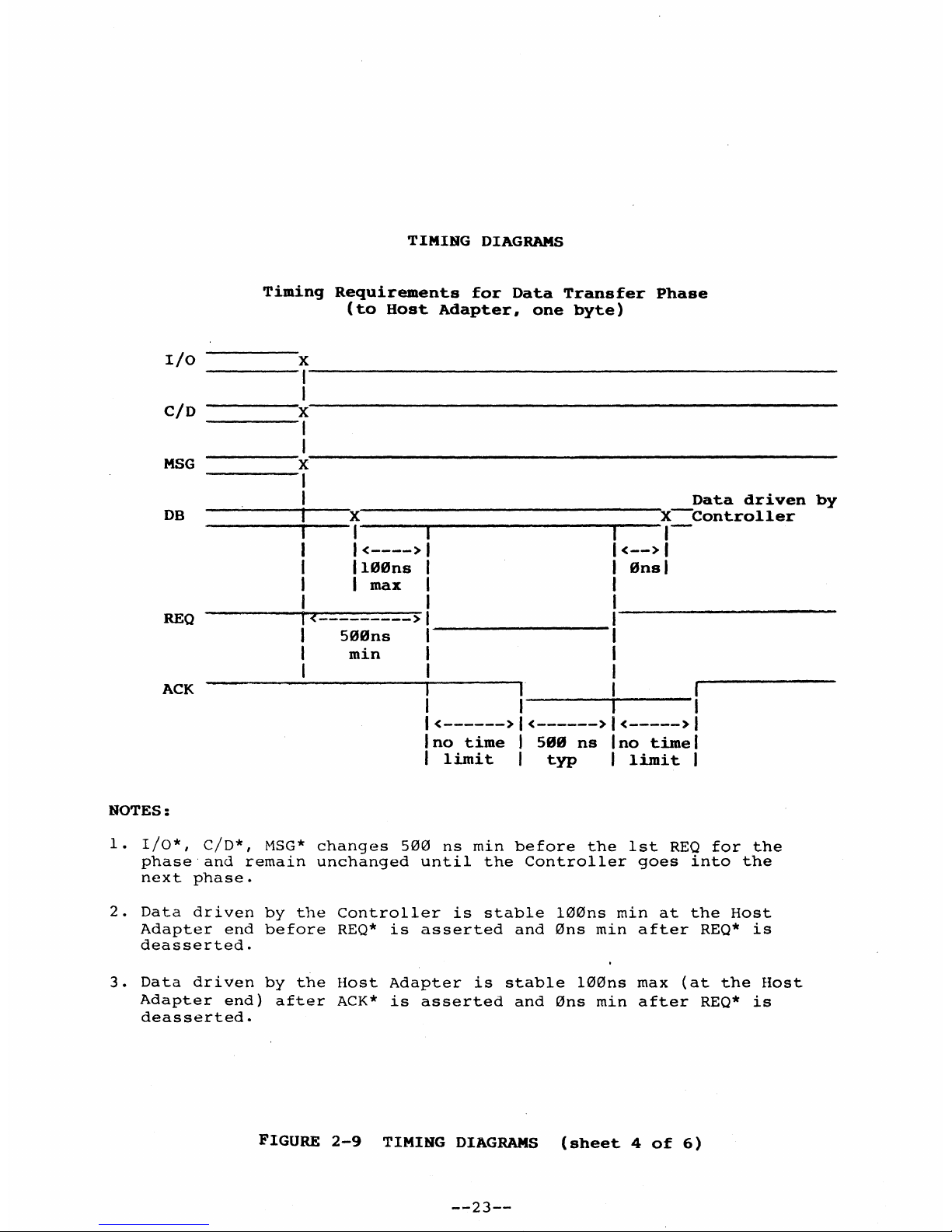

I/O

C/D

MSG

DB

REO

ACK

NOTES:

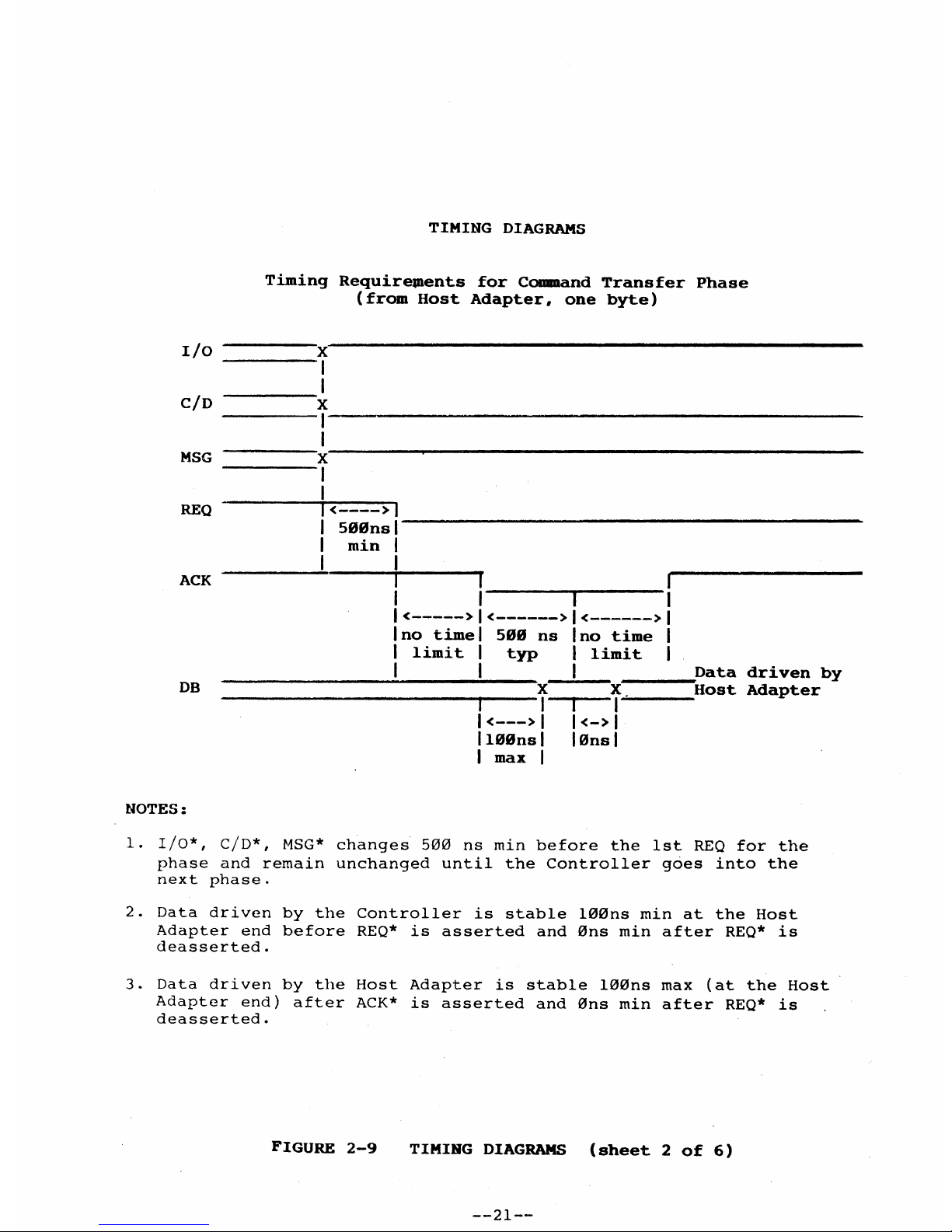

TIMING

DIAGRAMS

Timing

Requirements

for

Data

Transfer

Phase

(to

Host

Adapter,

one

byte)

_________ x ________________________________________________ _

I

------_1---------------------------------------

______

...:X

I

------_1------------------------------------------

_____

x

I

I

Data

driven

by

_

________

~I~---x.

_____

-r

________________

~~--x--Controller

I

1-

I

1--

I

1<---->

<-->1

I

1100ns

0nsl

I I

max

I

1<--

-->

I

500ns

I

I

min

___

+-

__

1

I

<------>1<------>

<----->1

no

time

580

ns

Ino

time

I

limit

typ

I

limit

I

1.

1/0*,

C/D*,

HSG*

changes

500

ns

min

before

the

1st

REO

for

the

phase

and

remain

unchanged

until

the

Controller

goes

into

the

next

phase.

2.

Data

driven

by

the

Controller

is

stable

100ns

min

at

the

Host

Adapter

end

before

REQ*

is

asserted

and

0ns

min

after

REQ*

is

deasserted.

3.

Data

driven

by

the

Host

Adapter

is

stable

100ns

max

(at

the

Host

Adapter

end)

after

ACK*

is

asserted

and

0ns

min

after

REQ*

is

deasserted.

FIGURE

2-9

TIMING

DIAGRAMS

(sheet

4

of

6)

--23--

Loading...

Loading...