DSE DSE331 Operator's Manual

DSE331 Operator Manual ISSUE 3

DEEP SEA ELECTRONICS PLC

DSE331 ATS Controller Operators Manual

Document Number 057-146

Author: Allan Jones

DSE331 Operators Manual

2

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

ENGLAND

Sales Tel: +44 (0) 1723 890099

Sales Fax: +44 (0) 1723 893303

E-mail: sales@deepseaplc.com

Website:

www.deepseaplc.com

DSE 331 ATS controller Operators Manual

© Deep Sea Electronics Plc

All rights reserved. No part of this publication may be reproduced in any material form (including photocopying or storing in

any medium by electronic means or other) without the written permission of the copyright holder except in accordance with the

provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to

Deep Sea Electronics Plc at the address above.

The DSE logo is a UK registered trademarks of Deep Sea Electronics PLC.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Deep Sea Electronics Plc reserves the right to change the contents of this document without prior notice.

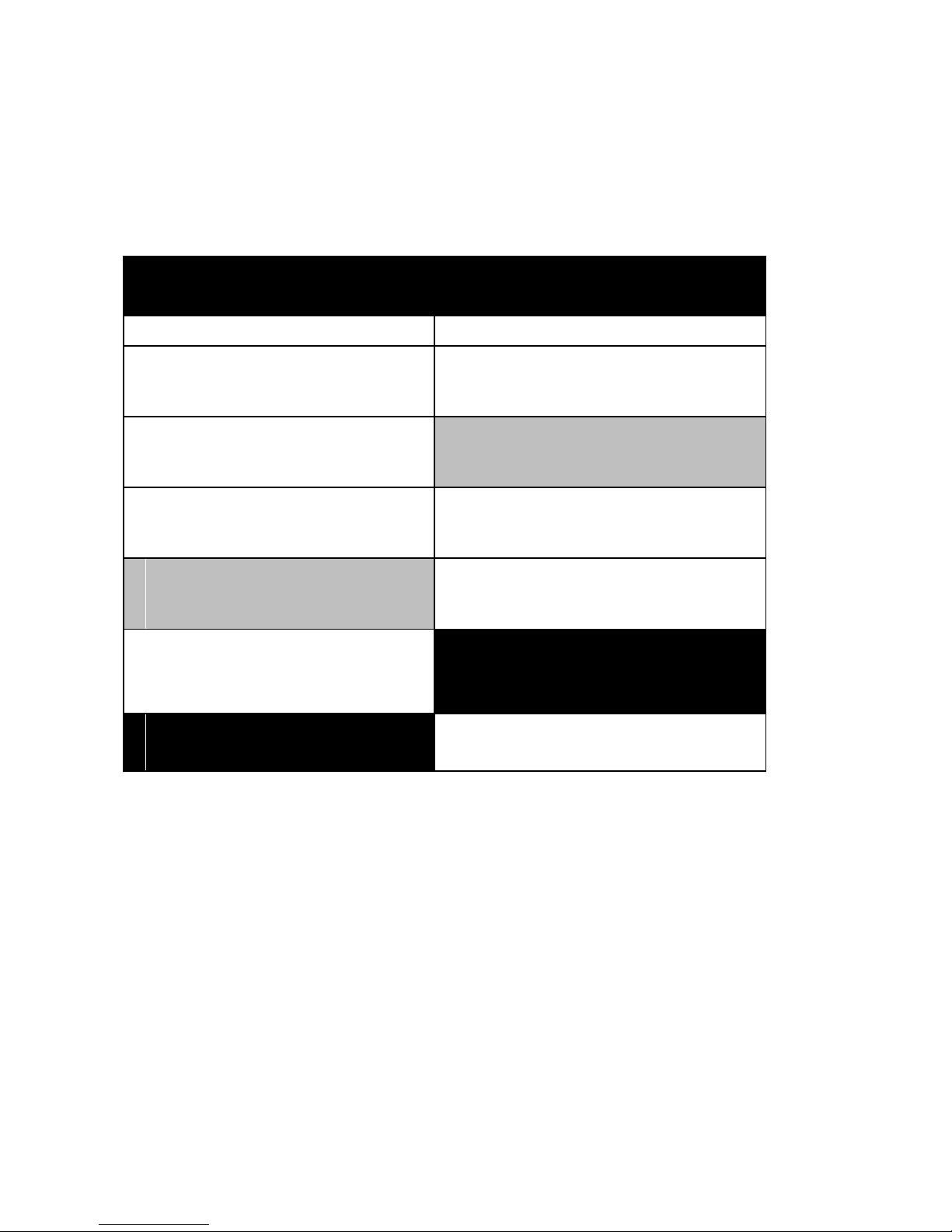

Amendments List

Issue Comments Minimum

Module version

required

Minimum

Configuration Suite

Version required

1 Initial release 1 5.10.13.0

2 Ammended Gasket part number 1 5.10.13.0

3 Ammended FPE Ac topology List 1 5.10.13.0

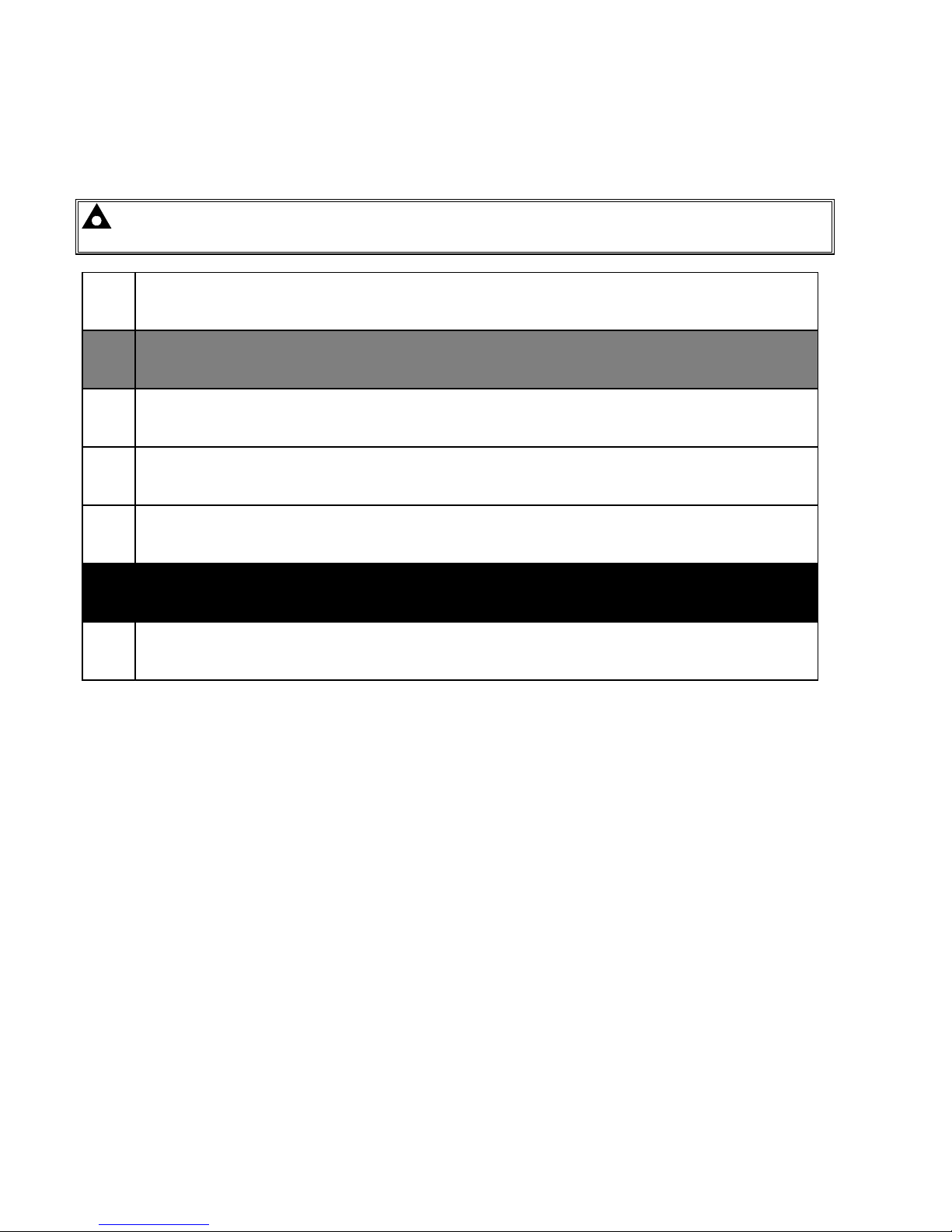

Typeface: The typeface used in this document is Arial. Care should be taken not to mistake the upper case letter I with the numeral 1. The numeral 1 has a top serif

to avoid this confusion.

NOTE:

Highlights an essential element of a procedure to ensure correctness.

CAUTION!:

Indicates a procedure or practice which, if not strictly observed, could result in damage or destruction of

equipment.

WARNING!:

Indicates a procedure or practice which could result in injury to personnel or loss of life if not followed

correctly.

Deep Sea Electronics Plc owns the copyright to this manual, which cannot be copied, reproduced or disclosed

to a third party without prior written permission.

SAE Society of Automotive Engineers (USA)

DSE331 Operators Manual

3

TABLE OF CONTENTS

1 BIBLIOGRAPHY .............................................................................. 5

2 INTRODUCTION .............................................................................. 5

3 SPECIFICATIONS ........................................................................... 6

3.1 PART NUMBERING ................................................................................... 6

3.1 POWER SUPPLY REQUIREMENTS ......................................................... 7

3.2 TERMINAL SPECIFICATION ..................................................................... 7

3.3 S1/S2 VOLTAGE / FREQUENCY SENSING ............................................. 7

3.4 INPUTS ....................................................................................................... 8

3.4.1 DIGITAL INPUTS .....................................................................................................8

3.5 OUTPUTS................................................................................................... 8

3.5.1 CONFIGURABLE NORMALLY OPEN RELAY OUTPUTS A & B ............................8

3.5.2 CONFIGURABLE CHANGEOVER RELAY OUTPUTS C & D ..................................8

3.5.3 CONFIGURABLE OUTPUTS E - H ..........................................................................8

3.6 COMMUNICATION PORTS ....................................................................... 8

3.7 DIMENSIONS AND MOUNTING ................................................................ 9

3.7.1 DIMENSIONS ...........................................................................................................9

3.7.2 PANEL CUTOUT......................................................................................................9

3.7.3 WEIGHT ...................................................................................................................9

3.7.4 FIXING CLIPS ..........................................................................................................9

3.7.5 OPTIONAL SILICON SEALING GASKET................................................................9

3.8 APPLICABLE STANDARDS .................................................................... 10

3.9 ENCLOSURE CLASSIFICATIONS .......................................................... 11

3.9.1 IP CLASSIFICATIONS ........................................................................................... 11

3.9.2 NEMA CLASSIFICATIONS .................................................................................... 12

4 INSTALLATION ............................................................................. 13

4.1 TERMINAL DESCRIPTION ...................................................................... 13

4.1.1 DC SUPPLY & DC OUTPUTS. ............................................................................... 13

4.1.2 DIGITAL INPUTS. .................................................................................................. 13

4.1.3 VOLT FREE OUTPUTS. ........................................................................................ 13

4.1.4 S1 SENSING .......................................................................................................... 14

4.1.5 S2 SENSING ............................................................................................................ 14

4.1.6 PC CONFIGURATION INTERFACE CONNECTOR ............................................... 14

4.2 TYPICAL WIRING DIAGRAM ................................................................... 15

5 DESCRIPTION OF CONTROLS ................................................... 16

QUICKSTART GUIDE ....................................................................................... 17

5.1.1 MODE SELECTION OPERATION.......................................................................... 17

5.2 GRAPHICAL DISPLAY ............................................................................ 18

5.2.1 DISPLAY PAGES ................................................................................................... 18

5.2.1.1 STATUS ......................................................................................................................... 18

5.2.1.2 INSTRUMENTATION ..................................................................................................... 18

5.2.1.3 ALARMS .......................................................................................................................... 19

5.2.1.4 SCHEDULER. ................................................................................................................... 19

5.2.2 ALARM ICONS....................................................................................................... 19

5.3 CONTROLS .............................................................................................. 20

5.3.1 MODE SELECTION ............................................................................................... 20

5.3.2 DISPLAY ................................................................................................................ 20

5.3.3 LOAD SWITCHING CONTROL .............................................................................. 20

6 OPERATION .................................................................................. 21

6.1 AUTOMATIC MODE OF OPERATION ..................................................... 21

DSE331 Operators Manual

4

6.1.1 WAITING IN AUTO MODE ..................................................................................... 21

6.1.2 STARTING SEQUENCE ........................................................................................ 21

6.1.3 S1 / S2 ON LOAD .................................................................................................. 21

6.1.4 STOPPING SEQUENCE ........................................................................................ 21

6.2 MANUAL OPERATION ............................................................................ 22

6.2.1 STARTING SEQUENCE ........................................................................................ 22

6.2.2 S1 OFF LOAD ........................................................................................................ 22

6.2.3 S2 ON LOAD.......................................................................................................... 22

6.2.4 TRANSFER BUTTONS OPERATION .................................................................... 22

6.2.5 STOPPING SEQUENCE ........................................................................................ 22

6.3 TEST ON OPERATION ........................................................................... 23

6.3.1 STARTING SEQUENCE ........................................................................................ 23

6.3.2 S2 ON LOAD.......................................................................................................... 23

6.3.3 STOPPING SEQUENCE ........................................................................................ 23

6.4 LOAD SWITCHING CONTROL ............................................................... 24

6.4.1 BREAKER SCHEME A .......................................................................................... 24

6.4.2 S1 / S2 LOAD INHIBIT ........................................................................................... 24

6.4.3 LOAD SHEDDING .................................................................................................. 24

6.4.4 TIMING DIAGRAM ................................................................................................. 24

6.4.5 BREAKER SCHEME B .......................................................................................... 25

6.4.5.1 CHECK SYNCHRONISING IS DISABLED ......................................................................25

6.4.5.1.1 TRANSFERRING TO S2........................................................................................................................ 25

6.4.5.1.2 TRANSFERRING TO S1........................................................................................................................ 25

6.4.5.1.3 LOAD SHED INPUT ............................................................................................................................... 25

6.4.5.1.4 TIMING DIAGRAM ................................................................................................................................. 25

6.4.5.2 CHECK SYNCHRONISING IS ENABLED .......................................................................26

6.4.5.2.1 TRANSFER TO S2 ................................................................................................................................. 26

6.4.5.2.2 TRANSFER TO S1 ................................................................................................................................. 26

6.4.5.2.3 LOAD SHED INPUT ............................................................................................................................... 26

6.4.5.2.4 TIMING DIAGRAM ................................................................................................................................. 26

7 PROTECTIONS .............................................................................. 27

7.1 S2 ............................................................................................................. 27

7.2 S1 ............................................................................................................. 27

7.3 PLANT BATTERY ................................................................................... 27

8 FRONT PANEL CONFIGURATION ............................................... 28

8.1 ACCESSING THE FRONT PANEL EDITOR (FPE) ................................. 29

8.1.1 EDITING A PARAMETER ...................................................................................... 29

8.2 ADJUSTABLE PARAMETERS (CONFIGURATION EDITOR) ............... 29

9 MAINTENANCE, SPARES, REPAIR AND SERVICING ............... 34

9.1 PURCHASING ADDITIONAL CONNECTOR PLUGS FROM DSE ......... 34

9.2 PURCHASING ADDITIONAL FIXING CLIPS FROM DSE....................... 34

9.3 PURCHASING SEALING GASKET FROM DSE ..................................... 34

10 WARRANTY ................................................................................ 35

11 DISPOSAL ................................................................................... 35

11.1 WEEE (WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT) ..... 35

11.2 ROHS (RESTRICTION OF HAZARDOUS SUBSTANCES) ................. 35

12 APPENDIX ................................................................................... 36

12.1 COMMUNICATIONS OPTION CONNECTIONS ................................... 36

12.1.1 DESCRIPTION ....................................................................................................... 36

12.1.2 PC TO CONTROLLER (DIRECT) CONNECTION .................................................. 36

Bibliography / Introduction

5

1 BIBLIOGRAPHY

This document refers to and is referred to by the following DSE publications which can be obtained from the DSE

website www.deepseaplc.com

DSE PART DESCRIPTION

053-131 DSE331 installation instructions

057-149 DSE331 Configuration Suite manual

2 INTRODUCTION

This document details the installation and operation requirements of the DSE331 Series modules, part of the

DSEAts ® range of products.

The manual forms part of the product and should be kept for the entire life of the product. If the product is passed

or supplied to another party, ensure that this document is passed to them for reference purposes.

This is not a controlled document. You will not be automatically informed of updates. Any future updates of this

document will be included on the DSE website at www.deepseaplc.com

The DSE 331 module has been designed to allow the operator to control the transfer of the load from one supply

to another, typically the mains supply and a standby generator or two mains supplies.

The user also has the facility to view the system operating parameters via the LCD display.

The DSE 331 module monitors the supplies, indicating the operational status and fault conditions, automatically

transferring the load to the backup supply in case of mains supply failure. The LCD display indicates the status.

The powerful microprocessor contained within the module allows for incorporation of a range of enhanced

features:

• Text & Icon based LCD display (selectable in the software)

• True RMS Voltage monitoring.

• Supply parameter monitoring.

• Fully configurable inputs for use as alarms or a range of different functions.

Using a PC and the DSE Configuration Suite software allows alteration of selected operational sequences, timers

and alarm trips.

Additionally, the module’s integral fascia configuration editor allows adjustment of this information.

A robust plastic case designed for front panel mounting houses the module. Connections are via locking plug and

sockets.

Specifications

6

3 SPECIFICATIONS

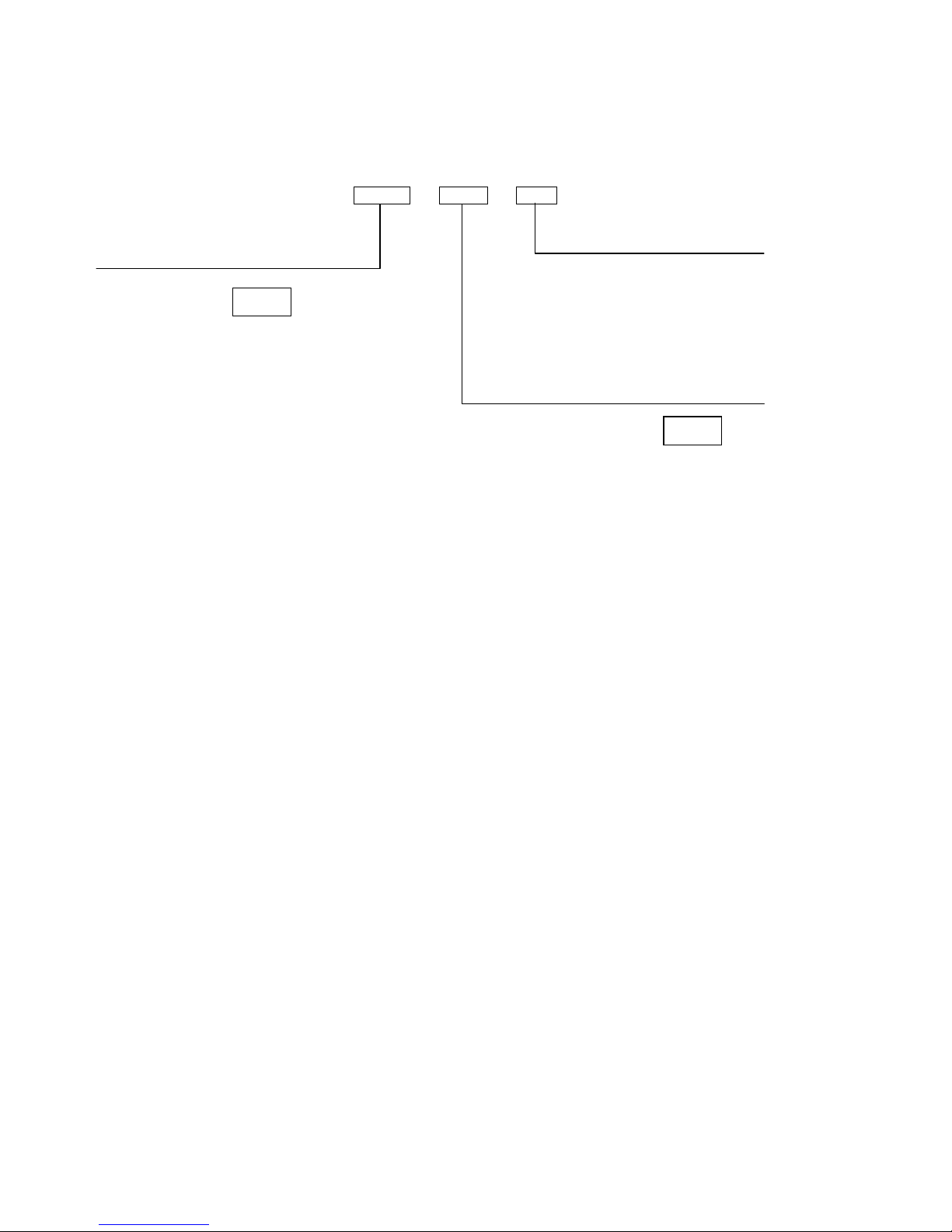

3.1 PART NUMBERING

0331 - 001 - 01

At the time of this document production, there have been no revisions to the module hardware.

Product type

Variant

Hardware revision

Revision 1

001

DSE 331 Auto

Transfer Switch

(ATS) Module

331

Specifications

7

3.1 POWER SUPPLY REQUIREMENTS

Minimum supply voltage 8V continuous, 5V for up to one minute.

Cranking dropouts

Able to survive 0V for 50mS providing the supply was at least

10V before the dropout and recovers to 5V afterwards.

Maximum supply voltage 35V continuous (60V protection for one minute)

Reverse polarity protection -35V continuous

Maximum operating current

Auto mode will all inputs active and

all LEDs illuminated

168mA at 12V, 80mA at 24V

Maximum standby current

(Stop mode with no active inputs)

39mA at 12V, 20mA at 24V

Plant supply instrumentation display

Range 0V-35V DC (note Maximum continuous operating voltage of 35V

DC)

Resolution 0.1V

Accuracy 1% of full scale

3.2 TERMINAL SPECIFICATION

Connection type Screw terminal, rising clamp, no internal spring

Min cable size 0.5mm² (AWG 24)

Max cable size 2.5mm² (AWG 10)

3.3 S1/S2 VOLTAGE / FREQUENCY SENSING

Measurement type True RMS conversion

Sample Rate 5KHz or better

Harmonics Up to 11th or better

Input Impedance

300K Ω ph-N

Phase to Neutral 15V

(minimum required for sensing frequency

)

to 333V AC

(absolute maximum)

Suitable for 110V to 277V nominal

(±20% for under/overvoltage detection)

Phase to Phase 25V

(minimum required for sensing frequency

)

to 576V AC

(absolute maximum)

Suitable for 190V ph-ph to 479V ph-ph nominal

(±20% for under/overvoltage detection)

Common mode offset

from Earth

100V AC (max)

Resolution 1V AC phase to neutral

2V AC phase to phase

Accuracy ±1% of full scale phase to neutral

±2% of full scale phase to phase

Minimum frequency 3.5Hz

Maximum frequency 75.0Hz

Frequency resolution 0.1Hz

Frequency accuracy ±0.2Hz

Specifications

8

3.4 INPUTS

3.4.1 DIGITAL INPUTS

Number 4

Arrangement Contact between input terminal and the module’s plant supply negative terminal

Low level threshold 3.0V minimum

High level threshold 4.1V maximum

Maximum input voltage +60V DC with respect to module’s plant supply negative terminal

Minimum input voltage -2V DC with respect to module’s plant supply negative terminal

Contact wetting current 6mA ±1mA

Open circuit voltage 12V ±1V

3.5 OUTPUTS

3.5.1 CONFIGURABLE NORMALLY OPEN RELAY OUTPUTS A & B

Number 2 (Configurable outputs A & B)

Type Volts free normally open contacts

Rating 8A @ 35VDC

3.5.2 CONFIGURABLE CHANGEOVER RELAY OUTPUTS C & D

Number 2 (Configurable output C)

Type Volts free change over contacts.

Rating 8A @ 35VDC

3.5.3 CONFIGURABLE OUTPUTS E - H

Number 4

Type Fully configurable, DC outputs rated at DC voltage

Rating 8A @ 35VDC

Protection Protected against over current & over temperature. Built in load dump feature.

3.6 COMMUNICATION PORTS

USB Port USB2.0 Device for connection to PC running DSE configuration suite only

Specifications

9

3.7 DIMENSIONS AND MOUNTING

3.7.1 DIMENSIONS

180mm x 116mm x 42mm

(7.1” x 4.6” x 1.7”)

3.7.2 PANEL CUTOUT

154mm x 98mm

(6” x 3.9”)

3.7.3 WEIGHT

400g (0.4kg)

3.7.4 FIXING CLIPS

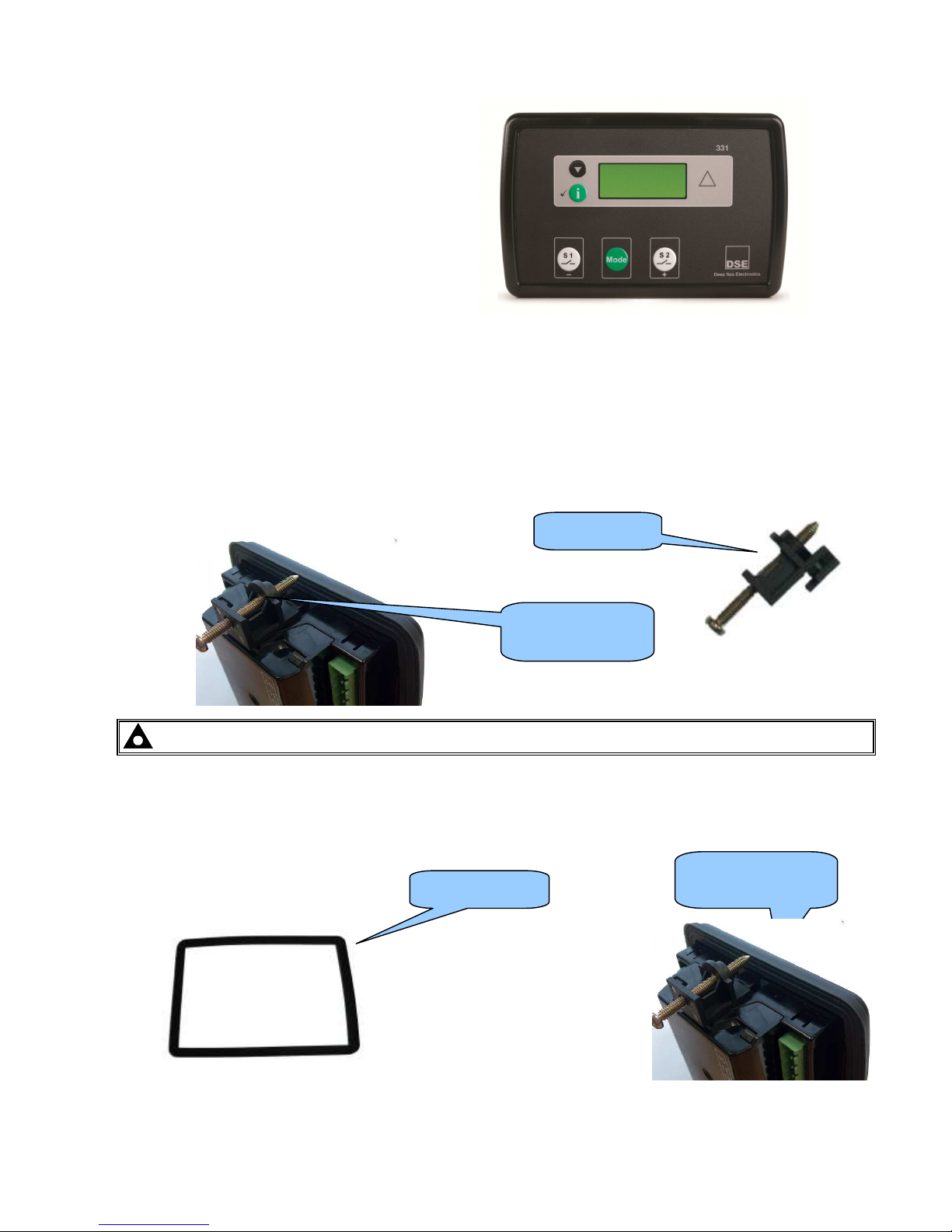

The module is held into the panel fascia using the supplied fixing clips.

• Withdraw the fixing clip screw (turn anticlockwise) until only the pointed end is protruding from the clip.

• Insert the three ‘prongs’ of the fixing clip into the slots in the side of the module case.

• Pull the fixing clip backwards (towards the back of the module) ensuring all three prongs of the clip are

inside their allotted slots.

• Turn the fixing clip screws clockwise until they make contact with the panel fascia.

• Turn the screws a little more to secure the module into the panel fascia. Care should be taken not to over

tighten the fixing clip screws.

NOTE:- In conditions of excessive vibration, mount the panel on suitable anti-vibration mountings.

3.7.5 OPTIONAL SILICON SEALING GASKET

The optional silicon gasket provides improved sealing between the module and the panel fascia.

The gasket is fitted to the module before installation into the panel fascia.

Take care to ensure the gasket is correctly fitted to the module to maintain the integrity of the seal.

Fixing clip fitted to

module

Fixing clip

Gasket fitted to

module

Sealing gasket

Specifications

10

3.8 APPLICABLE STANDARDS

BS 4884-1

This document conforms to BS4884-1 1992 Specification for presentation of

essential information.

BS 4884-2 This document conforms to BS4884-2 1993 Guide to content

BS 4884-3 This document conforms to BS4884-3 1993 Guide to presentation

BS EN 60068-2-1

(Minimum temperature)

-30°C (-22°F)

BS EN 60068-2-2

(Maximum temperature)

+70°C (158°F)

BS EN 60950

Safety of information technology equipment, including electrical business equipment

BS EN 61000-6-2

EMC Generic Immunity Standard (Industrial)

BS EN 61000-6-4

EMC Generic Emission Standard (Industrial)

BS EN 60529

(Degrees of protection

provided by enclosures)

IP65 (front of module when installed into the control panel with the optional sealing

gasket)

IP42 (front of module when installed into the control panel WITHOUT being sealed

to the panel)

UL508

NEMA rating

(Approximate)

12 (Front of module when installed into the control panel with the optional sealing

gasket).

2 (Front of module when installed into the control panel WITHOUT being sealed to

the panel)

IEEE C37.2

(Standard Electrical Power

System Device Function

Numbers and Contact

Designations)

Under the scope of IEEE 37.2, function numbers can also be used to represent

functions in microprocessor devices and software programs.

The 331 controller is device number 11L-331 (Multifunction device protecting Line

(generator) – 331 series module).

As the module is configurable by the generator OEM, the functions covered by the

module will vary. Under the module’s factory configuration, the device numbers

included within the module are :

2 – Time delay starting or closing relay

30 – annunciator relay

42 – Running circuit breaker

62 – time delay stopping or opening relay

74– alarm relay

81 – frequency relay

86 – lockout relay

In line with our policy of continual development, Deep Sea Electronics, reserve the right to change specification without notice.

Specifications

11

3.9 ENCLOSURE CLASSIFICATIONS

3.9.1

IP CLASSIFICATIONS

3xx series specification under BS EN 60529 Degrees of protection provided by enclosures

IP65 (Front of module when module is installed into the control panel with the supplied sealing gasket).

IP42 (front of module when module is installed into the control panel WITHOUT being sealed to the panel)

First Digit Second Digit

Protection against contact and ingress of solid objects Protection against ingress of water

0 No protection 0 No protection

1 Protected against ingress solid objects with a diameter

of more than 50 mm. No protection against deliberate

access, e.g. with a hand, but large surfaces of the

body are prevented from approach.

1 Protection against dripping water falling vertically. No

harmful effect must be produced (vertically falling drops).

2 Protected against penetration by solid objects with a

diameter of more than 12 mm. Fingers or similar

objects prevented from approach.

2 Protection against dripping water falling vertically. There

must be no harmful effect when the equipment

(enclosure) is tilted at an angle up to 15° from its normal

position (drops falling at an angle).

3 Protected against ingress of solid objects with a

diameter of more than 2.5 mm. Tools, wires etc. with a

thickness of more than 2.5 mm are prevented from

approach.

3 Protection against water falling at any angle up to 60°

from the vertical. There must be no harmful effect (spray

water).

4 Protected against ingress of solid objects with a

diameter of more than 1 mm. Tools, wires etc. with a

thickness of more than 1 mm are prevented from

approach.

4 Protection against water splashed against the equipment

(enclosure) from any direction. There must be no harmful

effect (splashing water).

5 Protected against harmful dust deposits. Ingress of

dust is not totally prevented but the dust must not

enter in sufficient quantity to interface with satisfactory

operation of the equipment. Complete protection

against contact.

5 Protection against water projected from a nozzle against

the equipment (enclosure) from any direction. There must

be no harmful effect (water jet).

6 Protection against ingress of dust (dust tight).

Complete protection against contact.

6 Protection against heavy seas or powerful water jets.

Water must not enter the equipment (enclosure) in

harmful quantities (splashing over).

Specifications

12

3.9.2 NEMA CLASSIFICATIONS

3xx series NEMA Rating (Approximate)

12 (Front of module when module is installed into the control panel with the optional sealing gasket).

2 (front of module when module is installed into the control panel WITHOUT being sealed to the panel)

NOTE: - There is no direct equivalence between IP / NEMA ratings. IP figures shown are approximate

only.

1

IP30

Provides a degree of protection against contact with the enclosure equipment and against a limited amount of falling dirt.

2

IP31

Provides a degree of protection against limited amounts of falling water and dirt.

3

IP64

Provides a degree of protection against windblown dust, rain and sleet; undamaged by the formation of ice on the enclosure.

3R

IP32

Provides a degree of protection against rain and sleet:; undamaged by the formation of ice on the enclosure.

4 (X)

IP66

Provides a degree of protection against splashing water, windblown dust and rain, hose directed water; undamaged by the formation

of ice on the enclosure. (Resist corrosion).

12/12K

IP65

Provides a degree of protection against dust, falling dirt and dripping non corrosive liquids.

13

IP65

Provides a degree of protection against dust and spraying of water, oil and non corrosive coolants.

Loading...

Loading...