Page 1

053-060

ISSUE 1

DEEP S EA E L E CT R O NI C S

DSE6120 Installation Instructions

ACCESSING THE FRONT PANEL EDITOR (FPE)

The module must be in STOP mode with the engine at rest before configuration mode can be accessed.

To enter the ‘configuration mode’ press both the INFO and STOP buttons together.

ENTERING THE CONFIGURATION EDITOR PIN NUMBER

If the module PIN number has been set, the PIN number request is then shown. The configuration

cannot be viewed or changed until the PIN number is correctly entered.

• The first * is flashing. Press + or – buttons to adjust it to the correct value for the first digit of

the PIN number.

• Press when the first digit is correctly entered.

• The entered digit will turn back to a * to maintain security.

• Enter the remaining digits of the pin number using the same method.

If the Configuration PIN has been entered successfully (or the PIN number has not been set in the module) the first

configurable parameter is displayed.

NOTE:- When is pressed after editing the final PIN digit, the PIN is checked for validity. If the number is not

correct, the editor is automatically exited. To retry you must re-enter the editor as described above

.

EDITING A PARAMETER

Enter the editor as described above.

• Press to select the required ‘page’ as detailed below.

• Press (+) to select the next parameter or (-) to select the previous parameter within the current page.

• When viewing the parameter to be changed, press the () button. The value begins to flash.

• Press (+) or (-) to adjust the value to the required setting.

• Press () the save the current value, the value ceases flashing.

• Press and hold the () button to exit the editor.

.

NOTE: -

Values representing pressure will be displayed in Bar. Values representing temperature are displayed in

degrees Celsius

.

NOTE: - When the editor is visible, it is exited after 5 minutes of inactivity to ensure security.

NOTE:- To exit the front panel configuration editor at any time, press and hold the () button. Ensure you

have saved any changes you have made by pressing the button first.

NOTE:- The PIN number is automatically reset when the editor is exited (manually or automatically) to ensure

security.

Deep Sea Electronics Plc.

Tel:+44 (0)1723 890099

Fax: +44 (0)1723 893303

LO CALL (from UK BT landlines)

Telephone 0845 260 8933

Email: support@deepseaplc.com

Web: www.deepseaplc.com

Deep Sea Electronics inc.

Phone: +1 (815) 316-8706

Fax: +1 (815) 316- 8708

TOLL FREE (USA only) :

Tel: 1 866 636 9703

Email: dsesales@deepseausa.com

Web: www.deepseausa.com

Deep Sea Electronics Plc.

(Far East)

Tel:+66 2 670 6228

Fax: +66 2 678 3028

Email: support@deepseaplc.com

Web: www.deepseaplc.com

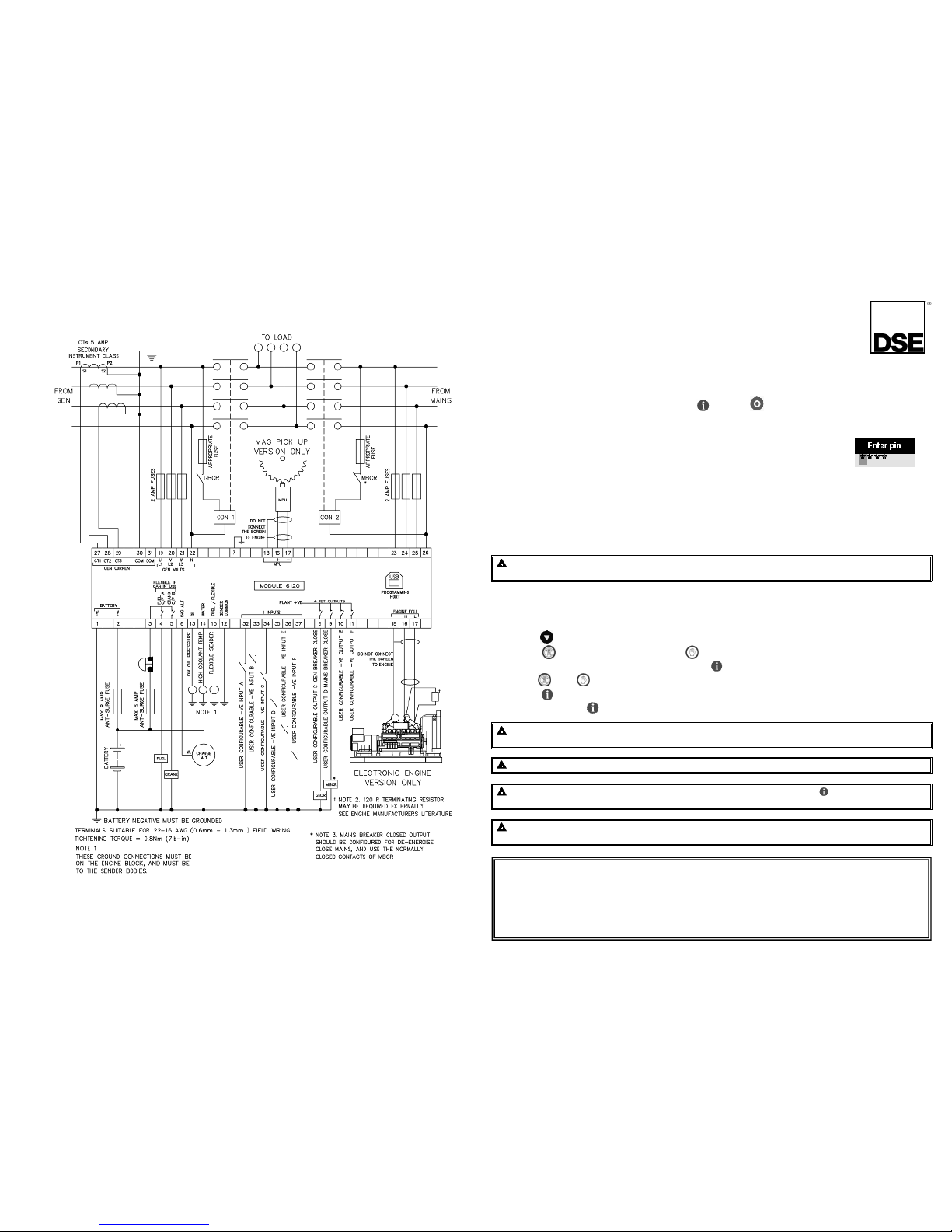

T

ypical Wiring Diagram

Page 2

ADJUSTABLE PARAMETERS (Configuration editor)

(Factory default settings are shown in bold italicised text)

Section

Parameter as shown on display

Values

PIN

Pin Entry

# # # #

DISPLAY

Contrast

0% - 100% (53%)

Language English - Others

LCD Page Timer

hh:mm:ss (5m)

Auto Scroll Delay

1s - 1hr (2s)

ALT CONFIG

Default Config

Default Config

ENGINE

Oil Pressure Low Shutdown

0bar - 9.97bar (1.03bar)

Coolant Temperature High Shutdown 2ºC - 140ºC (95ºC)

Start Delay Timer

0 - 10hr (5s)

Pre Heat Timer

0 - 5m (0s)

Crank Duration Timer

0 - 1m (10s)

Crank Rest Timer

0 - 1m (10s)

Safety On Delay 0 - 1m (10s)

Smoke Limiting

0 - 15m (0s)

Smoke Limiting Off

0 - 1m (0s)

Warm Up Timer

0 -1hr (0s)

Cool Down Timer

0 - 1hr (1m)

Speed Low Shutdown Active, Inactive

Speed Low Shutdown

0RPM - 6000RPM (1270RPM)

Speed High Shutdown

0RPM - 6000RPM (1740RPM)

Speed Overshoot Delay

0-10s (2s)

Speed Overshoot

0% - 10% (0s)

Fail To Stop Delay 0 - 2m (30s)

Battery Voltage Low Warning

Active, Inactive

Battery Low Voltage

0V – 40V (10V)

Battery voltage Low Warning Delay

0 - 24hr (1m)

Battery Voltage High Warning

Active, Inactive

Battery Voltage High Warning Delay 0V - 24hr (1m)

Battery Voltage High Warning

0V – 40V (30V)

Charge Alternator Failure Warning

Active, Inactive

Charge Alternator Failure Warning

0V – 39V (6V)

Charge Alternator Failure Warning Delay

0 - 24hr (5s)

Charge Alternator Failure Shutdown Active, Inactive

Charge Alternator Failure Shutdown

0V – 5.9V (4.0V)

Charge Alternator Failure Shutdown Delay

0 - 24hr (5s)

GENERATOR

Voltage Low Shutdown

50V – 360V (184V)

Voltage Nominal

50V – 276V (230V)

Voltage High Shutdown 231V – 360V (277V)

Frequency Low Shutdown

0Hz - 75Hz (43Hz)

Frequency Nominal

0Hz - 75Hz (50Hz)

Frequency High Shutdown

0Hz - 75Hz (58Hz)

Full Load Rating

5A – 6000A (500A)

Delayed Over Current Active, Inactive

Delayed Over Current

50% - 120% (100%)

AC System Single Phase, 2 Wire

3 Phase, 4 Wire

3 Phase, 4 Wire3 Phase, 4 Wire

3 Phase, 4 Wire

2 Phase, 3 Wire (L1 & L3)

3 Phase, 4 Wire (Delta)

2 Phase, 3 Wire (L1 & L2)

3 Phase, 3 Wire

CT Primary

5A - 6000A (600A)

Generator Transient Delay

0 - 10m (0.7s)

ront Panel Configuration Editor

(Factory default settings are shown in bold italicised text)

Section Parameter as shown on display

Values

MAINS Voltage Low Trip 50V – 360V (184V)

Voltage High Trip 50V – 360V (276V)

Frequency Low Trip 0Hz - 75Hz (45Hz)

Frequency High Trip 0Hz - 75Hz (55Hz)

Mains Transient Delay 0 - 30s (2s)

Return Delay 0 - 1hr (30s)

Mains Transfer Time 0 - 10m (0.7s)

TIMERS

LCD Page Timer

hh:mm:ss (5m)

Auto Scroll Delay

1s - 1hr (2s)

Pre Heat Timer 0 - 5m (0s)

Crank Duration Timer

0 - 1m (10s)

Crank Rest Timer

0 - 1m (10s)

Safety On Delay

0 - 1m (10s)

Smoke Limiting

0 - 15m (0s)

Smoke Limiting Off

0 - 1m (0s)

Warm Up Timer

0 -1hr (0s)

Cool Down Timer

0 - 1hr (1m)

Fail To Stop Delay

0 - 2m (30s)

Battery voltage Low Warning Delay

0 - 24hr (1m)

Battery Voltage High Warning Delay 0V - 24hr (1m)

Return Delay 0 - 5hr (30s)

Generator Transient Delay 0.1s - 2m (30s)

Mains Transient Delay 0 - 30s (2s)

Mains Transfer Time 0 - 10m (0.7s)

DIMENSIONS AND MOUNTING

DIMENSIONS

216mm x 158mm x 42mm

(8.5” x 6.2” x 1.6”)

PANEL CUTOUT

182mm x 137mm

(7.2” x 5.4”)

1.1.1 WEIGHT

510g (0.51kg)

1.1.2 FIXING CLIPS

The module is held into the panel fascia using the supplied fixing clips.

• Withdraw the fixing clip screw (turn anticlockwise) until only the pointed end is protruding from the clip.

• Insert the three ‘prongs’ of the fixing clip into the slots in the side of the 6000 series module case.

• Pull the fixing clip backwards (towards the back of the module) ensuring all three prongs of the clip are

inside their allotted slots.

• Turn the fixing clip screws clockwise until they make contact with the panel fascia.

• Turn the screws a little more to secure the module into the panel fascia. Care should be taken not to over

tighten the fixing clip screws.

NOTE:- In conditions of excessive vibration, mount the panel on suitable

anti-vibration mountings.

Loading...

Loading...