Page 1

COMPLEX SOLUTIONS

MADE SIMPLE.

DEEP SEA ELECTRONICS PLC

DSE4110

AUTOSTART CONTROL MODULE

OPERATING MANUAL

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 2

DSE Model 4110 AutoStart Operators Manual

2 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

ENGLAND

Sales Tel: +44 (0) 1723 890099

Sales Fax: +44 (0) 1723 893303

E-mail: sales@Deepseaplc.com

Website: www.deepseaplc.com

DSE Model 4110 Control System Operators Manual

© Deep Sea Electronics Plc

All rights reserved. No part of this publication may be reproduced in any material form (including photocopying or storing in any

medium by electronic means or other) without the written permission of the copyright holder except in accordance with the

provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to Deep

Sea Electronics Plc at the address above.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Deep Sea Electronics Plc reserves the right to change the contents of this document without prior notice.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 3

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 3

TABLE OF CONTENTS

Section Page

1 INTRODUCTION .............................................................................................. 4

2 CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION. ........ 4

3 OPERATION .................................................................................................... 5

3.1 AUTOMATIC MODE OF OPERATION ............................................................................... 5

3.2 MANUAL OPERATION ....................................................................................................... 6

3.3 EXERCISE SCHEDULER .................................................................................................... 7

4 PROTECTIONS ................................................................................................ 8

4.1 WARNINGS ......................................................................................................................... 8

4.2 SHUTDOWNS ...................................................................................................................... 8

5 DESCRIPTION OF CONTROLS ...................................................................... 9

6 FRONT PANEL CONFIGURATION ............................................................... 10

6.1 ACCESSING THE FRONT PANEL CONFIGURATION EDITOR .................................... 10

6.2 EDITING THE CONFIGURATION ..................................................................................... 10

7 CONFIGURATION TABLES .......................................................................... 11

8 INSTALLATION INSTRUCTIONS .................................................................. 15

8.1 PANEL CUT-OUT .............................................................................................................. 15

8.2 COOLING........................................................................................................................... 16

8.3 UNIT DIMENSIONS ........................................................................................................... 16

8.4 FRONT PANEL LAYOUT .................................................................................................. 18

8.5 REAR PANEL LAYOUT .................................................................................................... 18

9 ELECTRICAL CONNECTIONS ...................................................................... 19

9.1 CONNECTION DETAILS................................................................................................... 19

9.2 CONNECTOR FUNCTION DETAILS ................................................................................ 20

10 SPECIFICATION ......................................................................................... 21

11 COMMISSIONING ....................................................................................... 22

11.1 PRE-COMMISSIONING ................................................................................................. 22

12 FAULT FINDING ......................................................................................... 23

13 TYPICAL WIRING DIAGRAM ..................................................................... 24

14 APPENDIX .................................................................................................. 25

14.1 SOLID STATE OUTPUTS .............................................................................................. 25

14.2 PUSH BUTTONS ........................................................................................................... 26

14.3 ALARM / SHUTDOWN INDICATIONS .......................................................................... 26

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 4

DSE Model 4110 AutoStart Operators Manual

4 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

1 INTRODUCTION

The DSE 4110 automatic start module has been primarily designed to allow the user to start and stop the

generator, transferring the load automatically to the generator. If required the generator can be started and

stopped manually.

The DSE 4110 module has a built in LCD hours counter, which displays the number of hours that the generator

has run, to the nearest 1/10 hour.

The DSE 4110 module monitors the engine, utilising 8 LEDs to indicate fault conditions. When a fault is detected

the generator is automatically shut down, giving a true first up fault condition.

The customer, using the module’s front panel configuration editor, can alter selective operational sequences,

timers and alarm trips.

The module is housed in a fully enclosed robust plastic case for front panel mounting, offering a high rating of IP56

with the optional gasket. Connections to the module are via locking plug and sockets.

2 CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION.

NOTE:

Highlights an essential element of a procedure to ensure correctness.

CAUTION!

Indicates a procedure or practice which, if not strictly observed, could result

in damage or destruction of equipment.

WARNING!

Indicates a procedure or practice, which could result in injury to personnel

or loss of life if not followed correctly.

©

Deep Sea Electronics Plc owns the copyright to this manual, which cannot

be copied, reproduced or disclosed to a third party without prior written

permission.

Compliant with BS EN 60950 Low Voltage Directive

Compliant with BS EN 50081-2 EMC Directive

Compliant with BS EN 50082-2 EMC Directive

UL Registered Component for USA & Canada

Year 2000 Compliant

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 5

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 5

3 OPERATION

The following description details the sequences followed by a module containing the standard ‘factory

configuration’. Always refer to your configuration source for the exact sequences and timers observed by any

particular module in the field.

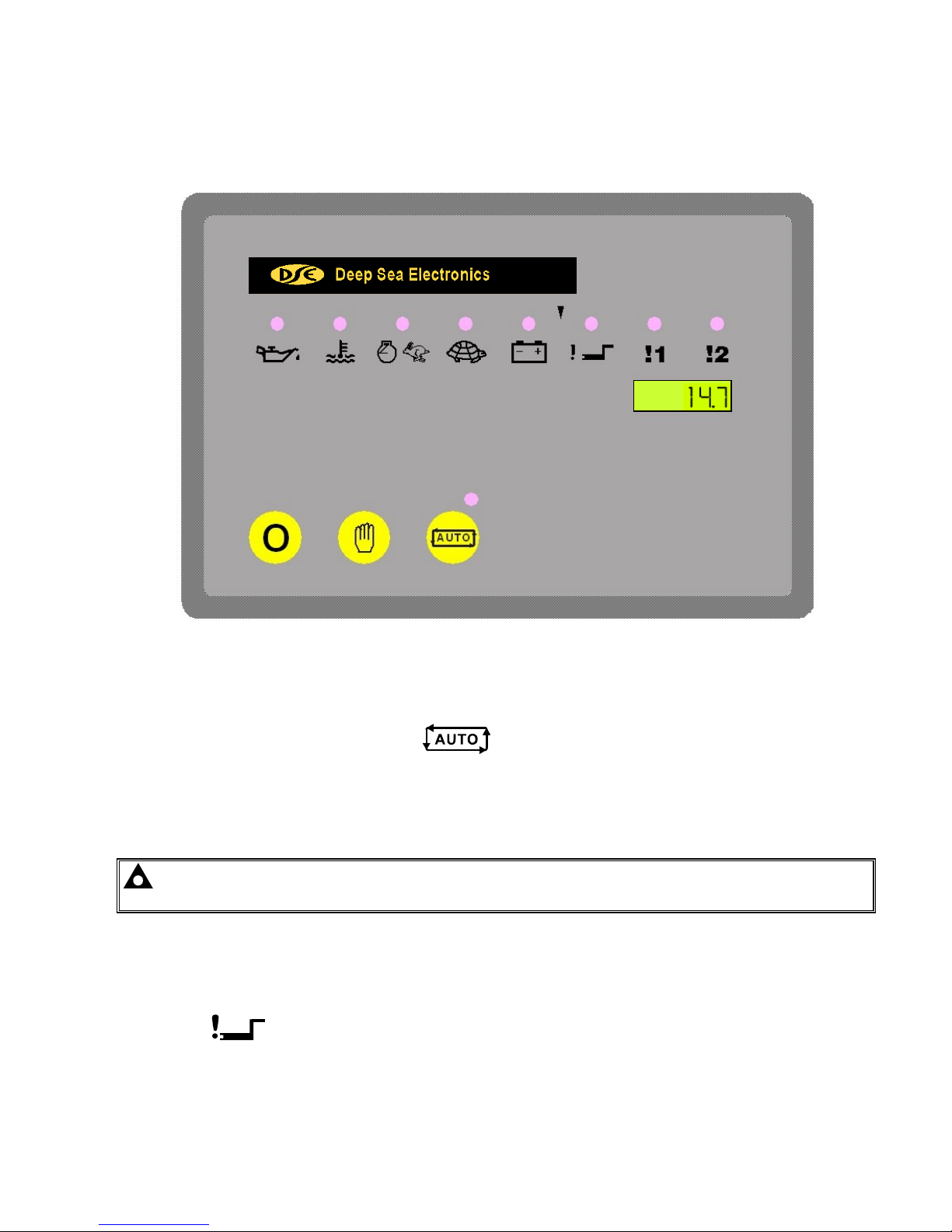

FIG 1

3.1 AUTOMATIC MODE OF OPERATION

This mode is activated by pressing the Auto

pushbutton. An LED indicator beside the button confirms

this action.

The start sequence is initiated when the remote start input is activated. To allow for false remote start signals, the

Start Delay timer is initiated. After this delay, if the pre-heat output option is selected then the pre-heat timer is

initiated and the corresponding auxiliary output (if configured) will energise.

NOTE:- If the Remote Start signal is removed during the Start Delay timer, the unit will return to a

stand-by state.

After the above delays, the Fuel Solenoid is energised, then one second later, the Starter Motor is engaged.

The engine is cranked for a 10-second period. If the engine fails to fire during this cranking attempt then the starter

motor is disengaged for a 10-second rest period. Should this sequence continue beyond the 3 starting attempts,

the start sequence will be terminated and

Fail to Start

fault will be illuminated.

When the engine fires, the starter motor is disengaged and locked out at 20 Hz measured from the Alternator

output. Rising oil pressure can also be used to disconnect the starter motor, however it cannot be used for

underspeed or overspeed detection.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 6

DSE Model 4110 AutoStart Operators Manual

6 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the

fault.

Once the engine is running, the Warm Up timer, if selected, is initiated, allowing the engine to stabilise before it

can be loaded.

Once the Warm Up timer has expired, the output Load Transfer is activated if it has been configured.

On removal of the Remote Start signal the Stop Delay timer is initiated. After which the Load Transfer output (if

configured) is deactivated and the Cool Down Period is initiated. After the Cool Down Period has elapsed, the

Fuel Solenoid is de-energised, bringing the generator to a stop.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can not be

changed.

NOTE:- The exercise scheduler can be used in AUTO mode, see the section entitled “Exercise

Scheduler” elsewhere in this manual for details.

3.2 MANUAL OPERATION

To initiate a start sequence in MANUAL, press the

pushbutton.

NOTE:- There is no Start Delay in this mode of operation.

If the pre-heat output option is selected this timer is then initiated and the auxiliary output selected is energised.

After the above delay the Fuel Solenoid is energised, then the Starter Motor is engaged.

The engine is cranked for a 10 second period. If the engine fails to fire during this cranking attempt then the starter

motor is disengaged for the 10 second rest period. Should this sequence continue beyond the 3 cranking attempts,

the start sequence will be terminated and Fail to Start

fault will be displayed.

When the engine fires, the starter motor is disengaged and locked out at 20 Hz measured from the Alternator

output. Rising oil pressure can also be used to disconnect the starter motor, however it cannot be used for

underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure, High Engine

Temperature, Under-speed and any delayed Auxiliary fault inputs to stabilise without triggering the fault.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can not be

changed.

Once the engine is running, the Warm Up timer, if selected, is initiated, allowing the engine to stabilise before it

can be loaded.

The generator will continue to run until the Auto mode is selected.

If Auto mode is selected and the automatic start not active, then the Remote Stop Delay Timer begins, after which

the Fuel Solenoid is de-energised, bringing the generator to a stop.

Selecting STOP (O) de-energises the FUEL SOLENOID, bringing the generator to a stop.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 7

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 7

3.3 EXERCISE SCHEDULER

Available in module versions V1.3 and higher.

The exercise scheduler is used to give a 30-minute test run every seven days. The starting time is configurable and

repeated every week, but the run duration is fixed at 30 minutes.

The scheduler is configured as follows:

• Press and hold the button. After 6½ seconds, the LED beside the Auto button will extinguish. This

sets the ‘exercise run time’ to the current time.

• Release the button, the LED beside the Auto button will illuminate to show that the module is in

Auto mode. The exercise period will begin.

• After 30minutes, the set will stop; the same 30 minute exercise period will be repeated on a 7 day cycle so long

as the module is in the Auto mode.

• When the exercise timer is set, the Auto LED will blink every 3½ seconds. To cancel the timer, press and hold

the

button for 6½ seconds, the Auto LED will extinguish to show the timer has been cancelled and

will return to steady operation once the Auto button is released. Removing DC power from the module will also

reset the exercise timer.

NOTE: - If an output is configured to “load transfer” the exercise run will be ON-LOAD.

NOTE: - If remote start input is active, the set will continue to run beyond the end of the exercise

time as the set is then under the control of the remote start input.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 8

DSE Model 4110 AutoStart Operators Manual

8 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

4 PROTECTIONS

The module will indicate that an alarm has occurred by illuminating the relevant LED.

4.1 WARNINGS

Warnings are used to warn the operator of an impending fault

BATTERY CHARGE FAILURE, if the module does not detect a voltage from the warning light terminal on the

auxiliary charge alternator, the

icon will illuminate. (Either 8 Volts or 16 Volts depending on the configuration

of Nominal DC Voltage).

Inputs 1 and 2 can be configured as warnings or shutdowns. The relevant icon will be illuminated when the input is

active

4.2 SHUTDOWNS

Shutdowns are latching and stop the generator. The alarm must be cleared and the fault removed to reset the

module. In the event of a shutdown the appropriate icon will be illuminated

NOTE:- The alarm condition must be rectified before a reset will take place. If the alarm condition

remains it will not be possible to reset the unit (The exception to this is the Low Oil Pressure alarm and

similar ‘delayed alarms’, as the oil pressure will be low with the engine at rest). Any subsequent

warnings or shutdowns that occur will be displayed steady, therefore only the first-up shutdown will

appear flashing.

NOTE:- The safety on time (used for delayed alarms) is pre set to 12 seconds and can not be

changed.

FAIL TO START, if the engine does not fire after the pre-set 3 attempts at starting, a shutdown will be initiated.

The

icon will illuminate.

LOW OIL PRESSURE, if the module detects that the engine oil pressure has fallen below the low oil pressure

switch after the Safety On timer has expired, a shutdown will occur.

The

icon will illuminate.

HIGH ENGINE TEMPERATURE, if the module detects that the engine coolant temperature has exceeded the high

engine temperature switch after the Safety On timer has expired, a shutdown will occur.

The

icon will illuminate.

OVERSPEED, if the engine speed exceeds the pre-set trip (14% above the nominal frequency) a shutdown is

initiated. Overspeed is not delayed, it is an immediate shutdown.

The

icon will illuminate.

NOTE:- During the start-up sequence the overspeed trip level is extended to 24% above the normal

frequency for the duration of the safety timer to allow an extra trip level margin. This is used to prevent

nuisance tripping on start-up.

UNDERSPEED, if the engine speed falls below the pre-set trip (20% of the nominal frequency) after the Safety On

timer has expired, a shutdown is initiated.

The

icon will illuminate.

Inputs 1 and 2 can be configured as warnings or shutdowns. The relevant icon will be illuminated when the input is

active

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 9

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 9

5 DESCRIPTION OF CONTROLS

The following section details the function and meaning of the various controls on the module.

Low Oil

Pressure

Shutdown

High Coolant

Temperature

Shutdown

Over Speed

Shutdown

Under

Speed

Shutdown

Charge Alt

Failure

Warning

Fail To

Start

Shutdown

Auxiliary

Input 1

Active

Warning /

Shutdown

Auxiliary

Input 2

Active

Warning /

Shutdown

Stop Mode Manual

Mode

Automatic

Mode And

Indicator LED

Tamperproof LCD Hours Counter.

Displaying Hours and Tenths of

Hours when fuel solenoid is

energised.

FIG 2

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 10

DSE Model 4110 AutoStart Operators Manual

10 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

6 FRONT PANEL CONFIGURATION

The DSE 4110 module is fully configurable from the front panel. There is no requirement for a PC / Laptop or

software.

6.1 ACCESSING THE FRONT PANEL CONFIGURATION EDITOR

♦ With the unit is in Stop mode, Configuration Mode is selected by operation of a small switch on the rear,

bottom edge of the PCB. This is partially hidden to prevent accidental operation.

Switch In Normal Mode Switch in Configuration Mode

♦ Once Configuration Mode is selected, the ‘Auto’ LED will commence rapid flashing and all normal operation is

suspended.

6.2 EDITING THE CONFIGURATION

♦ The Stop

pushbutton can be used to select the LED ‘code’ that corresponds to the required function. The 5

left-hand LED’s will form the code. See configuration table overleaf.

♦ The Manual

pushbutton will allow the user to change the associated value. The 3 right-hand LED’s inform

the user of the current setting for the chosen function. See configuration table overleaf.

♦ When the required parameters are displayed, pressing the Auto

button will save the new setting

and the process is repeated for each function change.

♦ When configuration is complete, the Configuration Mode Selector Switch should be returned to the ‘Normal’

position.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 11

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 11

7 CONFIGURATION TABLES

Function

! 1 ! 2

Value (Default in Bold)

Pre-heat Timer

{ { { {

O

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Used to pre-heat the engine prior to cranking. The output is active for the duration of the setting, prior to cranking.

Start Delay

{ { {

O

{

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Used to give a delay between activating the remote start input, or a mains failure and actually starting the engine.

Stop Delay

{ { {

O O

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Used to give a delay between deactivating the remote start input and actually stopping the engine.

Energise to Stop

Hold Timer

{ {

O

{ {

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Used for the control of the engine stop solenoid. When the engine is to be stopped, the Energise To Stop output

becomes active, closing the stop solenoid (fuel valve). When the engine comes to rest, the stop solenoid will remain

energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete stop.

Warm-up Timer

{ {

O

{

O

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Delay between the engine being available for use and the closure of the generator load-switching device to allow time

for the engine to warm before being loaded. This occurs after the 12 second safety on timer.

Cooling Timer

{ {

O O

{

{ { {

0 Seconds

{ {

O

5 Seconds

{

O

{

10 Seconds

{

O O

15 Seconds

O

{ {

20 Seconds

O

{

O

30 Seconds

O O

{

60 Seconds

O O O

180 Seconds

Delay between opening the generator load-switching device and stopping the engine to allow time for the engine to

cool down before being stopped. This is particularly useful when used in conjunction with turbo-charged engines.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 12

DSE Model 4110 AutoStart Operators Manual

12 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

Function

! 1 ! 2

Value (Default in Bold)

Nominal Frequency

{

O

{ { {

{ { {

50 Hz (O/S +14% /

Overshoot +24%)

{ {

O

60 Hz (O/S +14% /

Overshoot +24%)

The systems nominal frequency. Either 50 Hz or 60 Hz

Nominal DC Voltage

{

O

{ {

O

{ { {

12V DC (CF 8V)

{ {

O

24V DC (CF 16V)

The generator battery voltage. Either 12 Volts or 24 Volts. It is used for the charge alternator failure level.

LOP Switch Contact

{

O

{

O

{

{ { {

Close on Fault

{ {

O

Open on Fault

Configuration for the oil pressure switch. Either to close to battery negative on a fault, or open on a fault.

HET Switch Contact

{

O

{

O O

{ { {

Close on Fault

{ {

O

Open on Fault

Configuration for the coolant temperature switch. Either to close to battery negative on a fault, or open on a fault.

Crank disconnect on

Oil Pressure

{

O O

{ {

{ { {

Disabled

{ {

O

Enabled (2 Second

Delay)

If this is enabled, the starter motor will disconnect 2 seconds after the oil pressure switch detects oil pressure.

NOTE:- Not suitable for all generators, due to the different monitoring points on lubrication systems.

Underspeed

Detection

{

O O

{

O

{ { {

Disabled

{ {

O

Enabled (U/S –20%)

If this is enabled, the unit will shut down the generator if the frequency falls below 20% of the nominal frequency.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 13

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 13

Function

! 1 ! 2

Value (Default in Bold)

Auxiliary Input 1

Function

O

{ { { {

{ { {

Immediate Warning

Close on Fault

{ {

O

Immediate Warning

Open on Fault

{

O

{

Immediate Shutdown

Close on Fault

{

O O

Immediate Shutdown

Open on Fault

O

{ {

Delayed Warning

Close on Fault

O

{

O

Delayed Warning

Open on Fault

O O

{

Delayed Shutdown

Close on Fault

O O O

Delayed Shutdown

Open on Fault

Programmable input, can be configured to one of the following

♦ Immediate warning close on fault – If the input is activated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate warning open on fault – If the input is deactivated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate shutdown close on fault – If the input is activated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Immediate shutdown open on fault – If the input is deactivated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Delayed warning close on fault – If the input is activated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed warning open on fault – If the input is deactivated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed shutdown close on fault – If the input is activated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

♦ Delayed shutdown open on fault – If the input is deactivated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

Auxiliary Input 2

Function

O

{ { {

O

{ { {

Immediate Warning

Close on Fault

{ {

O

Immediate Warning

Open on Fault

{

O

{

Immediate Shutdown

Close on Fault

{

O O

Immediate Shutdown

Open on Fault

O

{ {

Delayed Warning

Close on Fault

O

{

O

Delayed Warning

Open on Fault

O O

{

Delayed Shutdown

Close on Fault

O O O

Delayed Shutdown

Open on Fault

Programmable input, can be configured to one of the following

♦ Immediate warning close on fault – If the input is activated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate warning open on fault – If the input is deactivated at any time the unit will alarm and energise the

common warning and common alarm output.

♦ Immediate shutdown close on fault – If the input is activated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Immediate shutdown open on fault – If the input is deactivated at any time the generator will be shutdown and

energise the common warning and common shutdown output. The generator can not be started.

♦ Delayed warning close on fault – If the input is activated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed warning open on fault – If the input is deactivated and the saftey time has elapsed the unit will alarm and

energise the common warning and common alarm output.

♦ Delayed shutdown close on fault – If the input is activated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

♦ Delayed shutdown open on fault – If the input is deactivated and the saftey time has elapsed the generator will be

shutdown and energise the common warning and common shutdown output.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 14

DSE Model 4110 AutoStart Operators Manual

14 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

Function

! 1 ! 2

Value (Default in Bold)

Auxiliary Output 1

Function

O

{ {

O

{

{ { {

Not used

{ {

O

Pre-heat

{

O

{

Load Transfer

{

O O

Common Warning

O

{ {

Common Shutdown

O

{

O

System in Auto

O O

{

Common Alarm

O O O

Energise to Stop

Programmable output can be configured to one of the following.

♦ Pre-heat. - The output is energised for the period of pre-heat time prior to cranking and between the cranking

attempts.

♦ Load Transfer. - The output is active after the saftey timer and warmup timer have elapsed.

♦ Common warning. - The output is active if there are any warning alarm active.

♦ Common shutdown - The output is active if there are any shutdown alarms active.

♦ System in auto. - The output is active when the system is in automatic mode.

♦ Common Alarm. - The output is active if there is any alarm condition.

♦ Energise to stop. - The output is energised when the engine is required to stop (normal or fault conditions) and will

remain energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete

stop.

Auxiliary Output 2

Function

O

{ {

O O

{ { {

Not used

{ {

O

Pre-heat

{

O

{

Load Transfer

{

O O

Common Warning

O

{ {

Common Shutdown

O

{

O

System in Auto

O O

{

Common Alarm

O O O

Energise to Stop

Programmable output can be configured to one of the following.

♦ Pre-heat. - The output is energised for the period of pre-heat time prior to cranking and between the cranking

attempts.

♦ Load Transfer. - The output is active after the saftey timer and warmup timer have elapsed.

♦ Common warning. - The output is active if there are any warning alarm active.

♦ Common shutdown - The output is active if there are any shutdown alarms active.

♦ System in auto. - The output is active when the system is in automatic mode.

♦ Common Alarm. - The output is active if there is any alarm condition.

♦ Energise to stop. - The output is energised when the engine is required to stop (normal or fault conditions) and will

remain energised for the period of the Energise To Stop Timer, to ensure the engine has come to a complete

stop.

NOTE: - All the outputs are solid state, rated at 1.2 Amps and switch to battery negative when

active.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 15

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 15

8 INSTALLATION INSTRUCTIONS

The model DSE 4110 Module has been designed for front panel mounting. Fixing is by 2 clips for easy assembly.

8.1 PANEL CUT-OUT

154 mm

(6.1”)

FIG 3

Maximum panel thickness – 8mm (0.3”)

In conditions of excessive vibration the module should be mounted on suitable anti-vibration mountings.

98 mm

(3.9”)

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 16

DSE Model 4110 AutoStart Operators Manual

16 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

8.2 COOLING

The module has been designed to operate over a wide temperature range -30 to +70º C. Allowances should be

made for the temperature rise within the control panel enclosure. Care should be taken NOT

to mount possible

heat sources near the module unless adequate ventilation is provided. The relative humidity inside the control

panel enclosure should not exceed 95%.

8.3 UNIT DIMENSIONS

FIG 4A

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 17

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 17

FIG 4B

FIG 4C

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 18

DSE Model 4110 AutoStart Operators Manual

18 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

8.4 FRONT PANEL LAYOUT

FIG 5

8.5 REAR PANEL LAYOUT

FIG 6

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 19

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 19

9 ELECTRICAL CONNECTIONS

Connections to the Module are via plug and sockets.

9.1 CONNECTION DETAILS

The following describes the connections and recommended cable sizes to the 2 plugs and sockets on the rear of

the Module. See rear panel layout FIG 6.

PIN

No

DESCRIPTION CABLE

SIZE

NOTES

1

DC Plant Supply Input

(-ve)

1.0mm

Connected to plant battery negative

2

DC Plant Supply Input

(+ve)

1.0mm

Connected to plant battery positive

(Recommended Fuse 2A)

3

Fuel Solid State Output

1.0mm

Used to operate the fuel relay.

4

Start Solid State Output

1.0mm

Used to operate the cranking relay.

5

Auxiliary Solid State Output 1

1.0mm

Configurable output.

6

Auxiliary Solid State Output 2

1.0mm

Configurable output.

7

Charge Fail Input/ Excitation

Output

1.0mm

Must NOT be connected to plant supply

negative if not used.

8

Low Oil Pressure Input

0.5mm

Switch to negative.

9

High Engine Temp Input

0.5mm

Switch to negative.

10

Auxiliary Input 1

0.5mm

Switch to negative.

11

Auxiliary Input 2

0.5mm

Switch to negative.

12

Automatic start Input

0.5mm

Switch to negative.

13

Not used

14

Not used

15

Functional Earth

1.0mm

Connect to a good clean earth point

16

Not used

17

Not used

18

Not used

19

Not used

20

Alternator Input L1

1.0mm

Do not connect if not used. (2A Fuse)

21

Alternator Input N

1.0mm

Do not connect if not used.

NOTE:- All the outputs are solid state, rated at 1.2 Amps and switch to battery negative when active.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 20

DSE Model 4110 AutoStart Operators Manual

20 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

9.2 CONNECTOR FUNCTION DETAILS

The following describes the functions of the 3 connectors on the rear of the module. See rear panel layout FIG 5.

PIN

No

DESCRIPTION

1 DC Supply -ve. System DC negative input. (Battery Negative).

2 DC Supply +ve. System DC positive input. (Battery Positive).

3 Fuel solid state output. Plant Supply negative from pin 1. Used to control the fuel

solenoid or engine fuel control system.

4 Starter solid state output. Plant Supply negative from pin 1. Used to control the

Starter Motor.

5 Auxiliary solid state output 1. Plant Supply negative from pin 1. Configurable

output, see configuration tables for options available.

6 Auxiliary solid state output 2. Plant Supply negative from pin 1. Configurable

output, see configuration tables for options available.

7 Charge Fail input / Excitation output. Supplies excitation to the Plant Battery

Charging Alternator, also an input for the Charge Fail detection circuitry.

8 Low Oil Pressure input. This is a negative switched input, it is possible to calibrate

the input to be a normally closed signal or a normally open signal. This input is

used to signal to the module that the oil pressure is low.

9 High Engine Temperature input. This is a negative switched input, it is possible to

calibrate the input to be a normally closed signal or a normally open signal. This

input is used to signal to the module that the engine temperature is high.

10 Auxiliary input 1. This is a negative switched configurable input, see configuration

tables for options available. It is possible to configure the input to be a normally

closed signal or a normally open signal.

11 Auxiliary input 2. This is a negative switched configurable input, see configuration

tables for options available. It is possible to configure the input to be a normally

closed signal or a normally open signal.

12 Automatic start input. This is a negative switched input, which will start the

generator when Auto is selected.

13 Not used

14 Not used

15 Functional Earth - Ensure connection to a good clean earth point.

16 Not used

17 Not used

18 Not used

19 Not used

20 Generator L1 sensing input. Connect to alternator L1 output.

21 Generator N sensing input. Connect to alternator N output.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 21

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 21

10 SPECIFICATION

DC Supply

8.0 to 35 V Continuous.

Cranking Dropouts

Able to survive 0 V for 50mS, providing supply was at least 10 V before

dropout and supply recovers to 5V. This is achieved without the need

for internal batteries.

Typical Standby Current

20A at 12 V. 20A at 24 V.

Max. Operating Current

150A at 12 V. 250A at 24V

Alternator Input Range

Single phase 2 wire system

15V AC - 277 V AC (ph-N) (+20%)

3Phase 4Wire System

15V AC - 277 V AC (ph-N) 3 Phase 4wire (+20%)

Alternator Input Frequency

50Hz - 60 Hz at rated engine speed

Start solid state Output

1.2 Amp DC at supply voltage. Switched to negative

Fuel solid state Output

1.2 Amp DC at supply voltage. Switched to negative

Auxiliary solid state Outputs

1.2 Amp DC at supply voltage. Switched to negative

Dimensions

Panel cutout

154mm x 98mm ( 6.1” x 3.9”) Maximum panel thickness 8mm (0.3”)

Charge Fail / Excitation Range

12 Volts = 8 Volts CF 24 Volts = 16 Volts CF

Operating Temperature Range

-30 to +70°C

Electromagnetic Compatibility

BS EN 50081-2 EMC Generic Emission Standard (Industrial)

BS EN 50082-2 EMC Generic Immunity Standard (Industrial)

Electrical Safety

BS EN 60950 Safety of I.T. equipment, including electrical business

equipment.

Cold Temperature

BS EN 60068-2-1 to -30

o

C

Hot Temperature

BS EN 60068-2-2 to +70

o

C

Humidity

BS2011-2-1 to 93% RH @ 40°C for 48 Hours

Vibration

BS EN60068-2-6

10 sweeps at 1 octave/minute in each of 3 major axes.

5Hz to 8Hz @ +/-7.5mm constant displacement

8Hz to 500Hz @ 2gn constant acceleration

Shock

BS EN 60068-2-27

3 Half sine shocks in each of 3 major axes

15gn amplitude, 11mS duration

Applicable Standards

Compliant with BS EN 60950 Low Voltage Directive

Compliant with BS EN 50081-2: 1992 EMC Directive

Compliant with BS EN 61000-6-4: 2000 EMC Directive

Compliance to European Legislation

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 22

DSE Model 4110 AutoStart Operators Manual

22 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

11 COMMISSIONING

11.1 PRE-COMMISSIONING

Before the system is started, it is recommended that the following checks are made:-

1) The unit is adequately cooled and all the wiring to the module is of a standard and rating compatible with the

system.

2) The unit DC supply is fused and connected to the battery and that it is of the correct polarity.

3) To check the start cycle operation take appropriate measures to prevent the engine from starting (disable the

operation of the fuel solenoid). After a visual inspection to ensure it is safe to proceed, connect the battery

supply. Select “MANUAL”, the unit start sequence will commence.

4) The starter will engage and operate for the pre-set crank period. After the starter motor has attempted to start

the engine for the pre-set number of attempts the LCD will display its icon indicating; ‘Failed to start’

.

Select the STOP/RESET position to reset the unit.

5) Restore the engine to operational status (reconnect the fuel solenoid), again select “MANUAL”, this time the

engine should start and the starter motor should disengage automatically. If not then check that the engine is

fully operational (fuel available, etc.) and that the fuel solenoid is operating. The engine should now run up to

operating speed. If not and an alarm is present, check the alarm condition for validity, then check input wiring.

The engine should continue to run for an indefinite period.

6) Select “AUTO” on the front panel, the engine will run for the pre-set stop delay, then stop. The generator

should stay in the standby mode. If not check that there is not a signal present on the Automatic start input.

7) Initiate an automatic start by supplying the automatic start signal. The start sequence will commence and the

engine will run up to operational speed. Once the generator is available the output Load Transfer is activated

if it has been configured.

8) Remove the automatic start signal the stop sequence will be initiated. After the pre-set time period, the

generator will shutdown into it’s standby mode.

9) If despite repeated checking of the connections between the 4110 and the customer’s system, satisfactory

operation cannot be achieved, then the customer is requested to contact the factory for further advice on:-

INTERNATIONAL TEL: +44 (0) 1723 890099

INTERNATIONAL FAX: +44 (0) 1723 893303

E-mail: Support@Deepseaplc.com

Website : www.deepseaplc.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 23

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 23

12 FAULT FINDING

SYMPTOM POSSIBLE REMEDY

Unit is inoperative Check the battery and wiring to the unit. Check the DC supply. Check the DC

fuse.

Unit shuts down Check DC supply voltage is not above 35 Volts or below 9 Volts

Check the operating temperature is not above 70 °C. Check the DC fuse.

Low oil Pressure fault operates

after engine has fired

Check engine oil pressure. Check oil pressure switch and wiring. Check

switch polarity is correct (i.e. Normally Open or Normally Closed).

High engine temperature fault

operates after engine has fired.

Check engine temperature. Check switch and wiring. Check switch polarity is

correct (i.e. Normally Open or Normally Closed).

Shutdown fault operates Check relevant switch and wiring of fault indicated by the illuminated LED.

Check configuration of input.

Warning fault operates Check relevant switch and wiring of fault indicated by the illuminated LED.

Check configuration of input.

Fail to Start is activated after preset number of attempts to start

Check wiring of fuel solenoid. Check fuel. Check battery supply. Check battery

supply is present on the Fuel output of the module. Refer to engine manual.

Continuous starting of generator

when in AUTO

Check that there is no signal present on the “Automatic start” input.

Generator fails to start on receipt

of Automatic start signal

Check that there is a signal on the “Automatic start” input. Confirm that the

input is configured to be used as “Automatic start”.

Pre-heat inoperative Check wiring to engine heater plugs. Check battery supply. Check battery

supply is present on the Pre-heat output of module. Check pre-heat has been

selected in your configuration. NB all the outputs are negative switching.

Starter motor inoperative Check wiring to starter solenoid. Check battery supply. Check battery supply

is present on the Starter output of module. NB all the outputs are negative

switching.

Fuel solenoid inoperative Check wiring to fuel solenoid. Check battery supply. Check battery supply is

present on the fuel output of module. NB all the outputs are negative

switching.

NOTE:- The above fault finding is provided as a guide check-list only. As it is possible for the

module to be configured to provide a wide range of different features always refer to the source of your

module configuration if in doubt.

NOTE: - All the outputs are solid state, rated at 1.2 Amps and switch to battery negative when

active.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 24

DSE Model 4110 AutoStart Operators Manual

24 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

13 TYPICAL WIRING DIAGRAM

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 25

DSE Model 4110 AutoStart Operators Manual

057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR 25

14 APPENDIX

14.1 SOLID STATE OUTPUTS

DSE’s utilisation of Solid State Outputs gives many advantages, the main points being:

♦ No Moving Parts

♦ Fully Overload / Short Circuit Protected.

♦ Smaller dimensions hence lighter, thinner and more cost effective than conventional relays.

♦ Lower power consumption hence increased reliability.

The main difference from conventional outputs is that solid state outputs switch to negative (–ve) when active. This

type of output is normally used with an automotive or plug in relay.

Battery positive (+)

Solid state output from DS E module

eg. Terminal 3 of 4110 - FUEL

Fuel Solenoid

(+ terminal)

* Observe polarity when using

relays fitted with integral diodes!

*

A

D

B

C

A

B

C

D

Solid State Output

from DSE Module Pin

Automotive

relay Pin

8 Pin Plugin relay Function

3 86 7 Fuel Output

85 2 To Positive supply via fuse

30 1 To Positive supply via fuse

87 3 To Fuel Solenoid

Example of relay pins connected to DSE solid state output to drive a fuel solenoid.

See section on Typical Connections else where in this manual for overall typical wiring diagram

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Page 26

DSE Model 4110 AutoStart Operators Manual

26 057-022 4110 OPERATING MANUAL ISSUE 5.1 18/06/2007 JR

14.2 PUSH BUTTONS

Display Description

Stop/Reset

Manual mode

Auto mode

14.3 ALARM / SHUTDOWN INDICATIONS

Display Description

Low Oil Pressure

High Coolant Temperature

Overspeed

Underspeed

Fail to start (Over-crank)

Charge Fail

!1

Auxiliary Alarm input 1 (Warning or Shutdown)

!2

Auxiliary Alarm input 2 (Warning or Shutdown)

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

parts@genpowerusa.com

SHOP ONLINE

www.genpowerusa.com

Loading...

Loading...