Page 1

AUTOMATIC TRANSFER SWITCH

PANEL (ATS) DSE 333

1 Phase 230V

3 Phase 400V

OPERATION AND MAINTENANCE

Stephill Generators Ltd

Wallis close

Park Farm South

Wellingborough

Northants

NN8 6AG

Tel : +44 (0)1933 677911

Fax: +44 (0)1933 677916

E-mail : info@stephill-generators.co.uk

Web : www.stephill-generators.co.uk

Issue 2

Page 2

CONTENTS

Page

1.0

SAFETY

1

2.0

INSTALLATION

1

2.1

ELECTRICAL INSTALLATION

1

2.2

AC WIRING

1

2.3

DC WIRING

1

3.0

START GUIDE

1-2

3.1

DISPLAY PAGES

3

3.2

STATUS

3

3.2

INSTRUMENTATION

3

3.4

ALARMS

3

3.5

EVENT LOG

4

3.6

LCD INDICATORS

4

3.7

SCHEDULE

4

4.0

CONTROLS

4

4.1

MODE SELECTION

4

5.0

DISPLAY

5

5.1

LOAD SWITCHING CONTROL

5

6.0

OPERATION

5

6.1

AUTOMATIC MODE OF OPERATION

5

6.1.1

WAITING IN AUTO MODE

5

6.1.2

STARTING SEQUENCE

5

6.1.3

GENERATOR ON LOAD

5

6.1.4

STOPPING SEQUENCE

6

6.2

MANUAL OPERATION

6

6.2.1

STARTING SEQUENCE

6

6.2.2

GENERATOR OFF LOAD

6

6.2.3

GENERATOR ON LOAD

6

6.2.4

TRANSFER BUTTONS OPERATION

6

6.2.5

STOPPING SEQUENCE

6

6.3

TEST ON LOAD OPERATION

7

6.3.1

STARTING SEQUENCE

7

6.3.2

GENERATOR ON LOAD

7

6.3.3

STOPPING SEQUENCE

7

7.0

MODULE DISPLAY

7

7.1

BACKLIGHT

7

7.2

PROTECTIONS

7

7.2.1

GENERATOR

7

7.2.2

MAINS

8

7.3

PLANT BATTERY

8

8.0

SYSTEM TEST

8

9.0

FRONT PANEL CONFIGURATION

8

9.1

ACCESSING THE FRONT PANEL EDITOR (FPE)

9

9.2

EDITING A PARAMETER

9

9.3

ADJUSTABLE PARAMETERS (CONFIGURATION EDITOR)

9

9.4

SCHEDULER SETTING

10

10

CHECK LIST FOR AUTOMATIC OPERATION

10

11

WARRANTY

10

1 PHASE ATS WIRING (STEPHILL)

11

1 PHASE ATS WIRING 100A+ (ATS)

12

3 PHASE ATS WIRING DSE 333 (ATS)

13

3 PHASE ATS WIRING DSE 333 (STEPHILL)

14

ATS – GENERATOR – MAINS INTERCONNECTION WIRING DSE 333

15

Issue 2

Page 3

1 SAFETY

Warning

ATS Panel should only be installed, maintained or serviced by a qualified electrician.

The generator set may start without warning whilst in AUTO mode.

Before undertaking any service or maintenance work, ensure the mains and generator supply are

isolated and generator is switched to off.

The generator is supplied with the battery disconnected/isolated for safety reasons and should not

be re-connected until all connections have been made.

Because of the nature of the equipment and the permanent mains connection, the terminals within

the generator may be LIVE even if the generator itself is not running.

2 INSTALLATION

Make sure that the Generator is at least one metre away from any building during operation.

Operate in a well ventilated unconfined area, so that fumes can be properly dispersed.

Silencer outlet should be facing an open area to prevent fumes being recirculated.

Consideration will also need to be made for refuelling and maintenance.

If installing in a confined area please consult manufacturer.

2.1 ELECTRICAL INSTALLATION

2.2 AC Wiring

Please ensure the correct cross sectional area of cable between the Alternator/Panel and

Distribution board used is adequate to carry the full rated continuous output of the generator,

allowing for de-rating in high ambient temperatures. Please consult IEE regulations as per the

correct sizing of cable and other issues regarding wiring. Flexible cable is recommended for

alternator connections allowing for a generous loop before the cable enters the alternator terminal

box because of the vibration caused by the set starting. If this is not possible a terminal box can be

fitted nearby and flex fitted between this and the generator terminal box. These precautions will not

be needed when fixing to a control box which is not attached to the Alternator. Please refer to

Wiring diagram.

2.3 DC WIRING

For the DC wiring we recommend 1.5mm if the generator is more than 10Meters away please

consult manufacturer for cable sizing. Please refer to Wiring diagram.

3 START GUIDE

Note For full instructions download handbook on DSE website http://www.deepseaplc.com/home/

This section provides a quick start guide to the module’s operation.

Issue 1 1

Page 4

Issue 1 2

Page 5

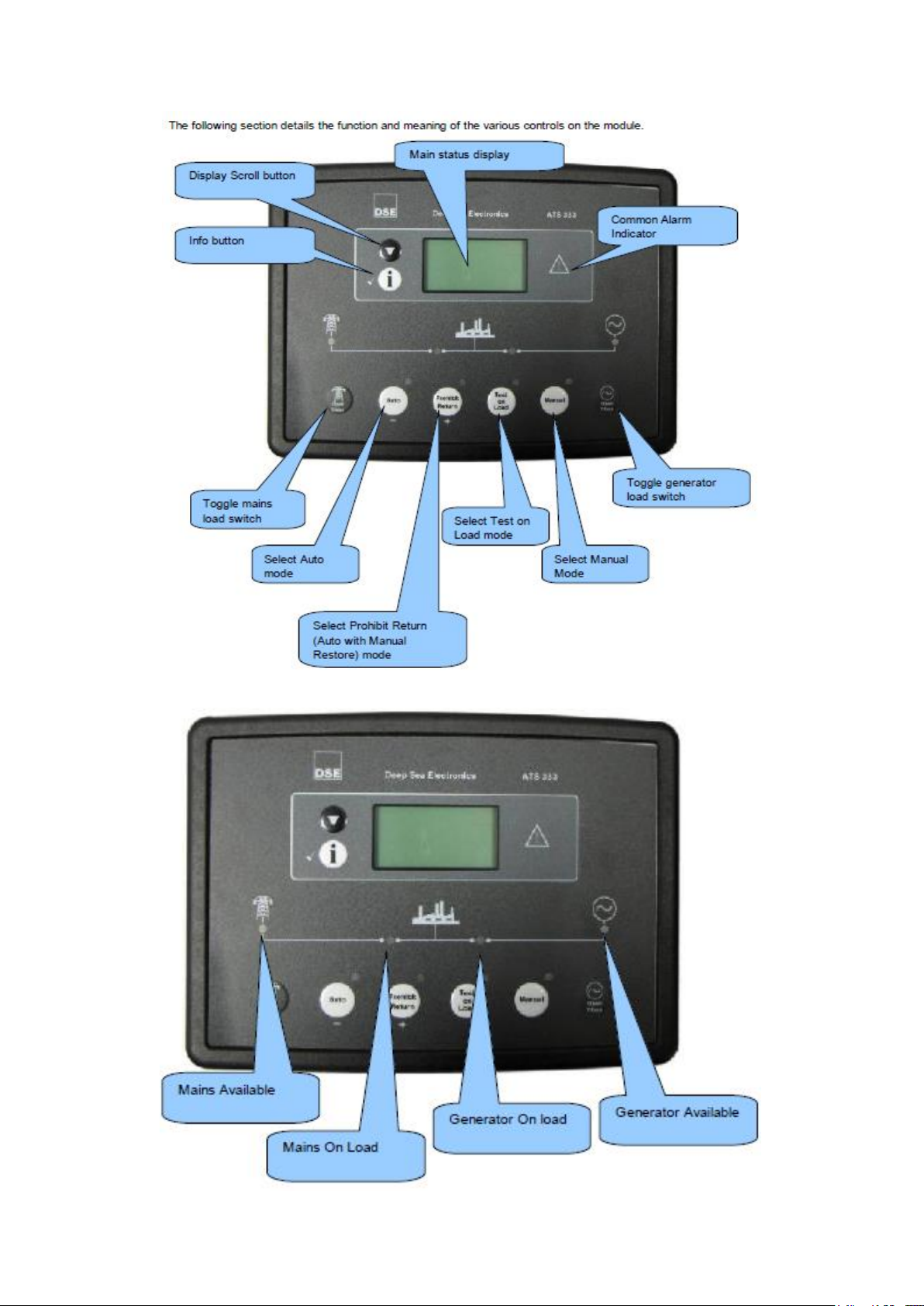

3.1 DISPLAY PAGES

It is possible to scroll to display the different pages of information by repeatedly operating the scroll

button

Once selected the page will remain on the LCD display until the user selects a different page or after

an extended period of inactivity, the module will revert to the status display.

When scrolling manually, the display will automatically return to the Status page if no buttons are

pressed for the duration of the configurable LCD Page Timer.

If an alarm becomes active while viewing the status page, the display shows the Alarms page to draw

the operator’s attention to the alarm condition.

At power up, the display will show the software version, and then display the default display screen,

which will display Mains instrumentation.

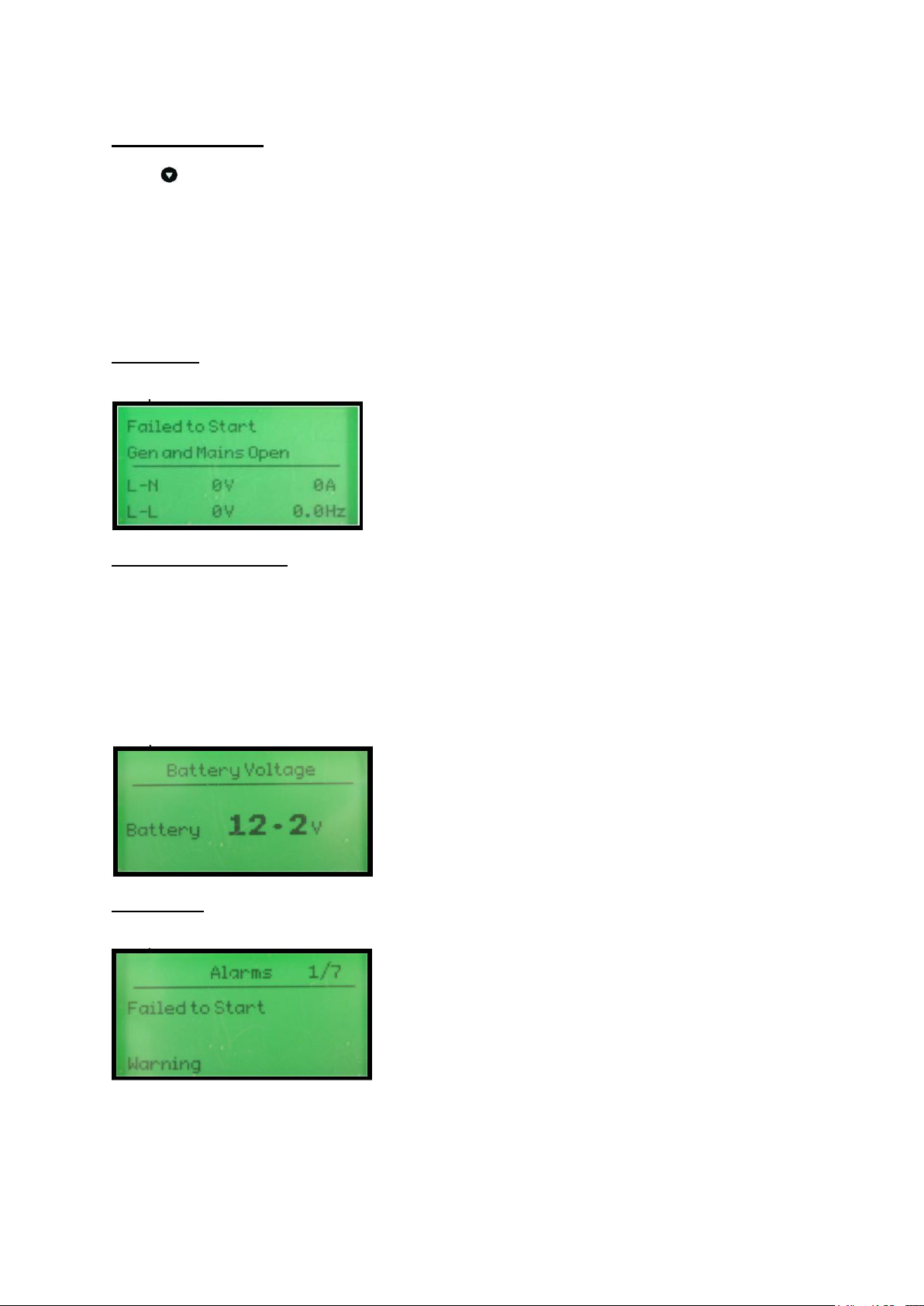

3.2 STATUS

Displays voltage operational status information

Example:

3.3 INSTRUMENTATION

The instrumentation page contains the following information

Generator Voltage L1-N

Generator Voltage L-L

Generator Frequency

Mains Voltage L1-N

Mains Voltage L-L

Mains Frequency

Load current (A)

Battery Voltage Example:

3.4 ALARMS

Lists any current alarms

Example

Issue 1 3

Page 6

This button places the module into its ‘Automatic’ mode. This mode allows the module to

control the function of the load switching completely automatically. The module will

monitor the remote start input and mains supply status and once a start request is

made, the set will be placed on load.

Upon removal of the starting signal (or the mains supply returns), the module will

automatically transfer the load from the generator to the mains and remove the genset

starting instruction.

For further details, please see the more detailed description of ‘Auto operation’

elsewhere in this manual.

Operation is as AUTO MODE above but the load is not transferred back to the mains

supply when it is reinstated. This function is sometimes called “MANUAL RESTORE”

Once in Test on load mode the module will send a start request to the generator and

place the set on load. The set will remain on load when in this mode.

This mode allows manual control of the ATS functions. Once in Manual mode the

module will send a start request to the generator.

Breakers can be opened and closed using the transfer buttons detailed below.

3.5 EVENT LOG

Displays the entire event log

Example:

3.6 LCD INDICATORS

Shows the status of the configurable LCD indicators

Example:

3.7 SCHEDULE

Shows the settings of the exercise scheduler

Example:

4.0 CONTROLS

4.1 MODE SELECTION

Issue 1 4

Page 7

This button changes between the various pages About, Status, Instrumentation, Alarms,

Event Log, LCD Indicators

This buttons scrolls through the items in the currently displayed page.

Pressing this button when the mains is on load will open the mains load switch. Pressing

this button when the generator is on load and the mains is healthy, will open the

generator load switch, wait for the duration of the transfer delay, then close the mains

load switch.

Pressing this button when the generator is on load will open the generator load switch.

Pressing this button when the mains is on load and the generator is available, will open

the mains load switch, wait for the duration of the transfer delay, then close the

generator load switch.

5.0 DISPLAY

5.1 LOAD SWITCHING CONTROL

Two fascia mounted buttons are provided for load switching operation when in manual mode. These

buttons are enabled/disabled in the modules PC configuration Suite so refer to your configuration file

to ensure the configuration has enabled the buttons.

6 OPERATION

6.1 AUTOMATIC MODE OF OPERATION

Activate auto mode by pressing the Auto pushbutton.

Auto mode will allow the transfer system to operate fully automatically, starting and stopping the

generator as required with no user intervention.

6.1.1 WAITING IN AUTO MODE

If a starting request is made and there is no input present for Auto Start Inhibit, the starting sequence

will begin.

Starting requests can be from the following sources:

Mains failure

Activation of an auxiliary input that has been configured to remote start

Activation of the inbuilt exercise scheduler.

6.1.2 STARTING SEQUENCE

To allow for ‘false’ start requests, the start delay timer begins.

Should all start requests be removed during the start delay timer, the unit will return to a stand-by

state.

If a start request is still present at the end of the start delay timer, start signal is given to the generator

set by the start/run output.

If the generator fails to become available before the generator failure timer expires. This is indicated

on the LCD display, but the starting signal remains active.

6.1.3 GENERATOR ON LOAD

Once the generator is measured as being within limits (and the Auxiliary Generator Ready signal is

received, the mains is removed from the load, and after the transfer timer has expired, the generator

is placed on load.

If all start requests are removed and there is no input present for Auto Restore Inhibit, the stopping

sequence will begin.

Issue 1 5

Page 8

Pressing this button when the mains is on load will open the mains load switch.

Pressing this button when the generator is on load and the mains is healthy, will

open the generator load switch, wait for the duration of the transfer delay, then

close the mains load switch.

Pressing this button when the generator is on load will open the generator load

switch. Pressing this button when the mains is on load and the generator is

available, will open the mains load switch, wait for the duration of the transfer

delay, then close the generator load switch.

6.1.4 STOPPING SEQUENCE

The return delay timer operates to ensure that the starting request has been permanently removed

and isn’t just a short term removal.

After the return delay timer, the generator load switch is opened, then after the transfer timers, the

mains is placed back on load.

Should another start request be made during the cooling down period, the generator will be placed on

load.

The cooling timer allows the set to run off load and cool sufficiently before being stopped. This is

particularly important where turbo chargers are fitted to the engine.

After the cooling timer has expired, the set is stopped.

6.2 MANUAL OPERATION

Manual mode allows the operator to start and stop the set manually, and if required change the state

of the load switching devices. Manual off load mode is active when the Manual button is pressed.

6.2.1 STARTING SEQUENCE

The start request is sent to the generator via the start/run relay output.

If the generator fails to become available before the generator failure timer expires. This is indicated

on the LCD display, but the starting signal remains active.

6.2.2 GENERATOR OFF LOAD

The generator will continue run OFF LOAD in this mode unless:

The mains supply fails

An input is given for Auxiliary Mains Failure

An input is given for Transfer to Generator

The fascia mounted transfer buttons are pressed (when configured)

6.2.3 GENERATOR ON LOAD

Once on load, the generator will remain on load unless:

An input is given for Transfer to Mains

The fascia mounted transfer buttons are pressed (when configured)

The module mode is changed to STOP\RESET or AUTO mode. The system may then transfer back

to mains supply automatically if conditions are suitable.

6.2.4 TRANSFER BUTTONS OPERATION

Two fascia mounted buttons are provided for load switching operation when in manual mode.

6.2.5 STOPPING SEQUENCE

The set will not be stopped in this mode of operation.

To begin the stopping sequence, the module should be placed in the AUTO or PROHIBIT RETURN

mode.

Issue 1 6

Page 9

6.3 TEST ON LOAD OPERATION

Manual mode allows the operator to start and stop the set manually, and if required change the state

of the load switching devices. Manual off load mode is active when the Test on Load button is

pressed.

6.3.1 STARTING SEQUENCE

The start request is sent to the generator via a digital output configured to Start and Run S2.

If S2 fails to become available before S2 fail delay timer expires. This is indicated on the LCD display,

but the starting signal remains active.

6.3.2 GENERATOR ON LOAD

The Generator will continue to run ON LOAD in this mode unless:

The generator supply fails – The mains supply is placed back on load if available.

An input is given for Transfer to Mains

6.3.3 STOPPING SEQUENCE

The set will not be stopped in this mode of operation.

To begin the stopping sequence, the module should be placed in the AUTO or PROHIBIT RETURN

mode.

7 MODULE DISPLAY

7.1 BACKLIGHT

The backlight will be on if the unit has sufficient voltage on the power connection while the unit is

turned on.

7.2 PROTECTIONS

7.2.1 GENERATOR

The 333 ATS module monitors the generator supply to ensure that it remains within configured levels.

If the generator supply fails, it is taken off load and the start/run signal is to be removed.

Generator failure

The generator has not become available after the period of the Generator Failure timer has expired.

Generator Under Voltage shutdown

The generator supply is below the configured under voltage trip level

Generator Under Frequency shutdown

The generator supply is below the configured under frequency trip level

Failed to reach loading voltage

The generator is running and within under / over voltage trip points, but has failed to reach the

configured Loading Voltage, hence it is unfit to take load.

Failed to reach loading frequency

The generator is running and within under / over frequency trip points, but has failed to reach the

configured Loading Frequency, hence it is unfit to take load.

Issue 1 7

Page 10

7.2.2 MAINS

Mains alarms signal that the mains supply is out of limits. In AUTO mode, the generator is called to

start (if not already running) and will be placed on load when available.

If the mains supply fails while the generator is running in MANUAL mode, the 333 ATS module

transfers load to the generator supply.

Should an input configured to Simulate Mains Available be active, the mains failure detection is

inhibited.

Mains failure

Combined message to indicate the failure of the mains supply or activation of an input configured to

Auxiliary MainsFailure.

Mains Under Frequency trip

The mains supply is below the configured Under Frequency trip level.

Mains Under Voltage trip

The mains supply is below the configured Under Voltage trip level.

Mains Over Frequency trip

The mains supply is above the configured Over Frequency trip level.

Mains Over Voltage trip

The mains supply is above the configured Over Voltage trip level.

7.3 PLANT BATTERY

Plant battery alarms are Warning alarms only. The module displays the fault but no further action is

taken.

Under Voltage warning

The battery supply is below the configured Under Voltage warning level.

Under Voltage warning

The battery supply is above the configured Over Voltage warning level.

8 SYSTEM TEST

It is recommended that the generator is tested every week and run on load for 30 minutes.

9 FRONT PANEL CONFIGURATION

This configuration mode allows the operator limited customising of the way the module operates.

Use the module’s navigation buttons to traverse the menu and make value changes to the

parameters:

Issue 1 8

Page 11

Page

Parameter as shown on

Values

DISPLAY

Contrast 0% - 100%

(53%)

Language

English - Others

Current date and time

Date month year hh:mm:ss

GENERATOR

Under Voltage Trip

50V – 360V (208V)

Under Frequency Trip

0Hz - 75Hz (45Hz)

MAINS

Immediate mains dropout

Active,Inactive

Under Voltage Trip

50V – 360V (208V)

Over Voltage Trip

50V – 360V (260V)

Under Frequency Trip

0Hz - 75Hz (45Hz)

Over Frequency Trip

0Hz - 75Hz (55Hz)

TIMERS

Warm Up Time

0 -1hr (1s)

Start Delay

0 - 10hr (5s)

Mains Transient Delay

0 - 30s (2s)

Generator Failed Delay

0 - 1m (60s)

Elevator Delay

0 – 5m (0s)

Non sync Transfer Time

1 – 10m (0.7s)

Check-sync Transfer Time

1 – 10m (0.2s)

Return Delay

0 - 5hr (30s)

Cool Down Timer

0 - 1hr (3m)

Generator Transient Delay

0 - 30s (5s)

Fail to Stop Delay

0 – 2m (30s)

Scroll Delay

0 – 1hr (5s)

Page Timer

0 – 1hr (5m)

SCHEDULE

Schedule

Active, Inactive

Schedule On Load

Active, Inactive (only available

when Scheduler is active)

Schedule Period

Weekly, Monthly (only available

when Scheduler is active)

Schedule time and date selection

(1-16)

Press when editing to select

the different parameters within

the scheduler.

9.1 ACCESSING THE FRONT PANEL EDITOR (FPE)

To enter the ‘configuration mode’ press both the DOWN and INFO buttons together.

9.2 EDITING A PARAMETER

Enter the editor as described above.

Press to select the required ‘page’ as detailed below.

Press + to select the next parameter or - to select the previous parameter within the current page.

When viewing the parameter to be changed, press the button. The value begins to flash.

Press + or - to adjust the value to the required setting.

Press to save the current value, the value ceases flashing.

Press and hold the button to activate the changes you have made and exit the editor.

9.3 ADJUSTABLE PARAMETERS (CONFIGURATION EDITOR)

When viewing the configuration editor, Press to select the required ‘page’ as listed below.

Front Panel Configuration Editor (Factory default settings are shown in bold italicised text)

Parameter as shown on

Issue 1 9

Page 12

Enter the editor as described above and press the button to access

the Scheduler page.

Press to enter edit mode and use the + / i buttons to make the

Schedule function active.

Press to save your change.

Press + to move to the next item.

Review the current setting and choose if the Scheduler is to perform an

‘on load’ test (active) or ‘off load’ test (inactive)

Press + to move to the next item.

Review the current setting and choose if the Scheduler is to perform a

weekly schedule (repeats every 7 days) or monthly (repeats every 28

days)

Press + to move to the next item.

Press to select which schedule entry to edit (there are up to 16

entries indicated by the number in the tope left corner)

Press to edit the schedule. The item being edited flashes.

Press + / - to change the flashing item.

Press to move to the next editable value. (On, Day, Run Time etc)

Press to save your change

9.4 SCHEDULER SETTINGdi

spay

ues

10 CHECK LIST FOR AUTOMATIC OPERATION

1. Auto mode selected on DSE333.

2. Generator output MCB & RCD in on position.

3. Generator in auto mode.

3. Battery charger switched on.

11 WARRANTY

All equipment supplied by STEPHILL GENERATORS LTD carries a warranty

of 12 months from date of despatch.

During the warranty period, should the plant fail due to faulty design, materials or workmanship by

STEPHILL or its sub-contractors, we undertake to rectify the fault by replacement or repair at our

option.

STEPHILL will accept no responsibility whatsoever for equipment that has failed due to;

- Improper repair or use of parts not supplied by STEPHILL.

- Lack of, or incorrect maintenance.

- Fair wear and tear, misuse, negligence, accidental damage, improper

storage, incorrect starting / warm-up / run-in or shutdown.

No warranty claim will be considered by STEPHILL unless any defective parts are available for

inspection by us, or our nominees, to determine the reason or cause of failure, and STEPHILL is

given the option of repair or replacement.

STEPHILL are not responsible for incidental or consequential damages, downtime, or other costs due

to warrantable failure, and unauthorised alterations made to any product supplied by STEPHILL.

Issue 1 10

Page 13

CT COMMON MUST BE

CONNECTED TO THE SAME

GROUND AS BATTERY NEGATIVE

LOAD

N

L1

34

37

37

GENERATOR

S2

GENERATOR

29

29

GCC

29

29282726

NL3L2L1

CONTACTOR

38

29

MECHANICAL INTERLOCK

29

42

4224

MC

ELECTRICAL INTERLOCK

26

25 24

GENERATOR

LOADING RELAY

OUTPUT B

24

38

L

29

N

1.5mm Black

34

LOAD CURRENT

1.5mm Black

37

37363534

COMCT3CT2CT1

38

3826

F4 2A

26

26

GEN VOLTS

DSE 333 ATS

MAINS

CONTACTOR

MCC

41

GC

23 41

30

23

2223

MAINS

LOADING RELAY

OUTPUT A

33

33

NE L

39

33

F3 2A

3343

ON / OFF

43 44 3943 44

39

33

33

39

33

F5 2A

30 39

30

30

MAINS VOLTS

33

33

33

323130

NL3L2L1

39

L

33

MAINS

S1

N

BATTERY

CHARGER

+

OUTPUT D

OUTPUT C

-VE

+VE

2

1

1

4

OUTPUT E

A B C D E F G H I J

11 12 13 14 15 16 17 18 19 201 2 3 4 5 6 7 8 9 10

10 -VE INPUTS

21

-

1

3

LEGEND

= GENERATOR CONTACTOR

GC

= GENERATOR CONTACTOR COIL

GCC

= MAINS CONTACTOR

MC

= MAINS CONTACTOR COIL

MCC

STEPHILL GENERATORS

Phone 01933 677911

Fax 01933 677916

Drawing Number

SW180014

Drawn

R Golding

2

F1 2A

3

1

Description

1 Phase ATS Panel DSE 333

Last Number Used

45

MC

14

1

1

Issue

GC

1 15

4 REMOTE START

1

Revision

Date

A

03-04-14

B

05-02-16

New drawing

Fuse removed from battery charger.

1

3

1 BATTERY -VE

3 BATTERY +VE

Page 14

GENERATOR

SUPPLY

LOAD

NL

113

110

MCGC

L

101

201201

L

MAINS

SUPPLY

N

GENERATOR

D.C. CONTROL

REMOTE

START

BATTERY

-VE

-VE

+VE

104

F3

2A

105

113

110

35

34

CT2 CT336COM

CT1

LOAD CURRENT

OUTPUT

C

3

4

10

4

1

4

105

37

26

V W

U

GEN VOLTS

12

20

F4

2A

1

3

104

292827

N

CLOSE GEN

5 9 11 12

NOT USED

1

-VE

BATTERY

CHARGER

3

+VE

104

A2

109 209

MC

105

108

24

25

B

7 86

L

Mechanical Interlock

222117

MC GC

1

211

13 14 15 16 17 18 19 20

OFF/ON

SUPPLY ON

204

N

210

GC

NOT USED

F2

2A

204

A2

A1A1

205

208

22

23

A

CLOSE MAINS

201

F1

2A

205

205

30 31 32 33

MAINS VOLTS

204

204

NTSR

204

N

STEPHILL GENERATORS

Phone 01933 677911

Fax 01933 677916

Drawing Number

SW180017

Drawn

R Golding

Description

1 Phase ATS Panel DSE 333 100A +

Last Number Used

209

Issue

A

Date

20-11-15

Revision

New drawing

Page 15

LOAD

NL3L2L1

113

110

111

113

112

MCGC

L1

101

201

201

L1

GENERATOR

SUPPLY

BATTERY

L2

L3

GENERATOR

D.C. CONTROL

REMOTE

-VE

START

-VE

+VE

204

L2

MAINS

SUPPLY

L3

NN

102

103

104

F5

2A

105

112

111

110

35

34

CT2 CT336COM

CT1

LOAD CURRENT

OUTPUT

C

3

4

4

4

113

105

37

26

U

12

20

1

F8

2A

1

3

F7F6

2A

2A

107

106

104

107

106

292827

V W

GEN VOLTS

5 9 11 12

N

CLOSE GEN

7 8610

NOT USED NOT USED

1

-VE

BATTERY

CHARGER

3

+VE

104

A2

Mechanical Interlock

GC

109 209

MC

105

108

24

25

B

13 14 15 16 17 18 19 20

22211

MC GC

1

211

L

204

N

OFF/ON

SUPPLY ON

210

F4

2A

204

A2

MC

A1A1

GC

208

23

A

CLOSE MAINS

201

204

205

22

202

203

F1

F22AF3

2A

205

205

30 31 32 33

MAINS VOLTS

206

206

2A

207

207

204

204

NTSR

STEPHILL GENERATORS

Phone 01933 677911

Fax 01933 677916

Drawing Number

SW180016

Drawn

R Golding

Description

3 Phase ATS panel DSE 333

Last Number Used

209

Issue

A

Date

20-11-15

Revision

New drawing

Page 16

GENERATOR

S2

CT COMMON MUST BE

CONNECTED TO THE SAME

GROUND AS BATTERY NEGATIVE

37

37

37

48

L1

49 49

L2

50 50

L3

29

N

48

49

50

GENERATOR

CONTACTOR

48

29

29

LOAD

L1

L2

34

37

35

37

36

37

L3

N

MAINS

CONTACTOR

39

33

39

4646

4747

33

33

39

33

33

39

L1

46

L2

47

33

MAINS

S1

L3

N

LEGEND

= GENERATOR CONTACTOR

GC

= GENERATOR CONTACTOR COIL

GCC

= MAINS CONTACTOR

MC

= MAINS CONTACTOR COIL

MCC

STEPHILL GENERATORS

Phone 01933 677911

Fax 01933 677916

Drawing Number

SW180018

Drawn

R Golding

4826

492727

F4 2A

F4 2A

1.5mm Black

1.5mm Black

34

35

LOAD CURRENT

-VE

2

1

2

F1 2A

3

1.5mm Black

36

OUTPUT C

+VE

1

1

1.5mm Black

37

37363534

COMCT3CT2CT1

4

26

26

GEN VOLTS

OUTPUT D

Description

3 Phase ATS Panel DSE 333

502828

F4 2A

29

29

GCC

42

4224

MC

29

29282726

NL3L2L1

GENERATOR

LOADING RELAY

DSE 333 ATS

OUTPUT E

Last Number Used

50

MECHANICAL INTERLOCK

ELECTRICAL INTERLOCK

26

24

25 24

OUTPUT B

A B C D E F G H I J

11 12 13 14 15 16 17 18 19 201 2 3 4 5 6 7 8 9 10

LOADING RELAY

14

MC

1

41

23 41

30

23

2223

MAINS

OUTPUT A

10 -VE INPUTS

GC

1 15

1

1

Issue

A

33

MCC

GC

Date

01-02-16

F5 2A

F5 2A

30 39

31 46

30

30

31

MAINS VOLTS

Revision

New drawing

F5 2A

32 47

32

323130

F3 2A

3343

ON / OFF

33

33

NL3L2L1

33

43 44 3943 44

NE L

BATTERY

CHARGER

+

-

1

3

21

4 REMOTE START

1

3

1 BATTERY -VE

3 BATTERY +VE

Page 17

ATS PANEL DSE333

GENERATOR

Cable to be sized as per iee regulations.

3 PHASE

BROWN

BLUE

1 PHASE

GREEN/YELLOW

U BROWN

V BLACK

W GREY

N BLUE

EARTH

L1

L2

L3

N

Cable to be sized as per Iee regulations.

L1

N N

L1

L2

L3

N

L1

BROWN

BLUE

GREEN/YELLOW

U BROWN

V BLACK

W GREY

3 PHASE

N BLUE

EARTH

1 PHASE

REMOTE START -VE

BATTERY -VE

BATTERY +VE

DC CONTROL

STEPHILL GENERATORS

Phone 01933 677911

Fax 01933 677916

4

1

3

Drawing Number

SW18015

Drawn

R Golding

Description

ATS - GENERATOR - MAINS

INTERCONNECTION WIRING

DSE 333

1.5mm (MAX 10M)

Last Number Used

47

DEEP SEA 3110

DEEP SEA 6110

4

(13) (32) (61) REMOTE START -VE

1

(1) (1) (1) BATTERY -VE

3

(2) (2) (2) BATTERY +VE

DEEP SEA 7310

DC CONTROL

DateIssue

A

01-04-14

B

19-11-15

Revision

New drawing

7310 Wiring added.

Loading...

Loading...