Page 1

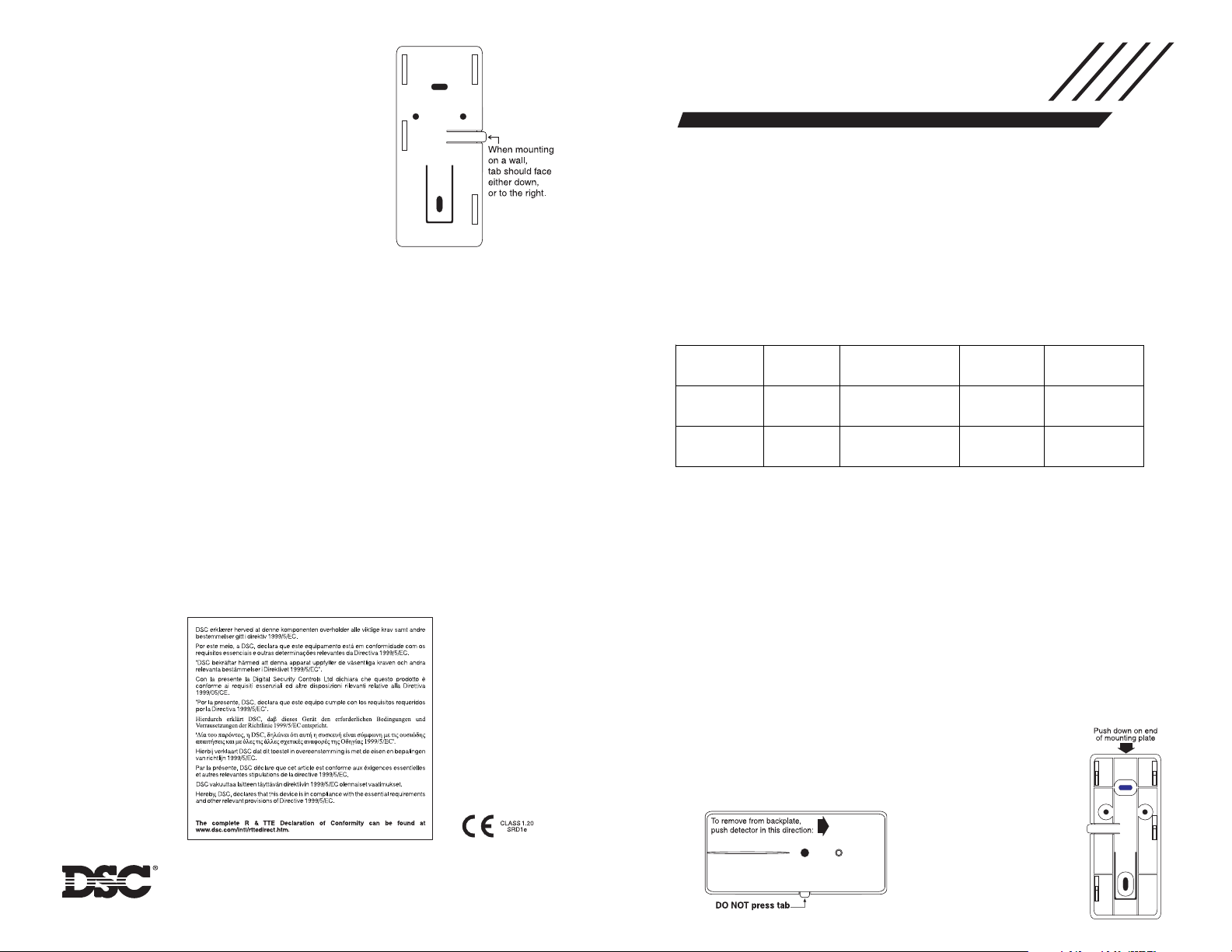

Mounting the Detector

Once you have found a location that is within range of

the receiver, you can mount the WLS912L.

1. Remove the mounting plate from the detector.

2. At the selected mounting location, place the

mounting plate on the wall (with the tab facing

down, or to the right), or on the ceiling. Mark the

screw locations. Wall anchors should be used for

all screw locations.

3. Secure the backplate to the wall.

4. Slide the detector onto its backplate.

5. Repeat the installation test using the AFT–100

tester to confirm proper operation.

FCC Compliance Statement

CAUTION: Changes or modifications not expressly approved by Digital Security Controls Ltd. could void your authority to use

this equipment.

This equipment generates and uses radio frequency energy and if not installed and used properly, in strict accordance with the

manufacturer’s instructions, may cause interference to radio and television reception. It has been type tested and found to comply

with the limits for Class B device in accordance with the specifications in Subpart “B” of Part 15 of FCC Rules, which are designed

to provide reasonable protection against such interference in any residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to television or radio reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

• Re-orient the receiving antenna

• Relocate the alarm control with respect to the receiver

• Move the alarm control away from the receiver

• Connect the alarm control into a different outlet so that alarm control and receiver are on different circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user

may find the following booklet prepared by the FCC helpful: “How to Identify and Resolve Radio/Television Interference Problems”. This booklet is available from the U.S. Government Printing Office, Washington, D.C. 20402, Stock # 004-000-00345-4.

Limited Warranty

Digital Security Controls Ltd. warrants that for a period of twelve months fr om the date of purchase, the product shall be free of defects

in material and workmanship under normal use and that in fulfilment of any breach of such warranty, Digital Security Controls Ltd.

shall, at its option, repair or replace the defective equipment upon return of the equipment to its repair depot. This warranty applies

only to defects in parts and workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond c ontrol

of Digital Security Controls Ltd. such as lightning, excessive voltage, mechanical shock, water damage, or damage arising out of abuse,

alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in lieu of any and all other warranties, whether express

or implied and of all other obligations or liabilities on the part of Digital Security Controls Ltd. This warranty contains the entire warranty. Digital Security Controls Ltd. neither assumes responsibility for, nor authorizes any other person purporting to act on its behalf

to modify or to change this warranty, nor to assume for it any other warranty or liability concerning this product.

In no event shall Digital Security Controls Ltd. be liable for any direct, indirect or consequential damages, loss of anticipated profits,

loss of time or any other losses incurred by the buyer in connection with the purchase, installation or operation or failure of this product.

©2002 Digital Security Controls Ltd.

Toronto, Canada • www.dsc.com

Technical Help Desk (Canada & US): 1-800-387-3630

Printed in Canada 29005723 R005

WLS912L

Glassbreak Detector

Available Models: WLS912L-433, WLS912L-900

Installation Instructions

The WLS912L is a battery-operated glassbreak sensor, designed to detect the sound

produced by the shattering of framed glass. Equipped with an RF transmitter, the

WLS912L establishes a supervised, one–way communications link with the system

controller. The WLS912L uses Dynamic Signal Processing* to provide accurate

detection of plate, laminated, wired and tempered glass types, while rejecting common false alarm sounds.

Specifications

Operating Voltage: 3.0V (two 3V Lithium batteries)

Operating Temperature: 0

Operating Humidity: 5% – 95% RH, non-condensing

o

C - 50oC (32o F - 122oF)

Maximum detection range

Glass Type Thickness Minimum Glass

Size (L X W)

Plate/

Tempered

Wired/

Laminated

1/8" – 1/4"

3 – 6mm

1/4"

6mm

12" X 12"

30cm X 30cm

18"X18"

46cmX46cm

Compatible control units/receivers: (P)NT9010-433, P(C)5132-433 or Envoy

Battery Guidelines and Installation

• Use fresh batteries. Most batteries have a “best before” date printed on their

packaging or on the batteries themselves. Buy batteries that have a “best

before” date of two years or more from your purchase date

• When disposing of used batteries, follow the instructions and precautions

printed on the batteries. Many cities and communities have collection sites or

services for used household batteries. Contact your municipal offices for

information on the disposal of used batteries

• Do not mix old and new batteries

• Dispose of any batteries promptly, keep away from children

NOTE: Use only Energizer Lithium EL123AP, Tekcell CR123A or Panasonic

CR123A lithium batteries. Use of any other battery may present a risk of fire or

explosion.

CAUTION: The cell used in this device may cause a fire or chemical burn hazard if

mistreated. Do not recharge, disassemble, heat above 100°C

(212°F) or incinerate.

To install batteries:

1. Remove the detector from its mounting plate:

If unmounted, hold the detector by its sides and push down on

the top end of the mounting plate, as shown at

right.

If mounted, press the

detector in the direction

shown below.

*Protected under US Patent 5,675,320

Level 1

Setting

20ft

6m

20ft

Level 2

Setting

10ft

3m

DO NOT USE

6m

Page 2

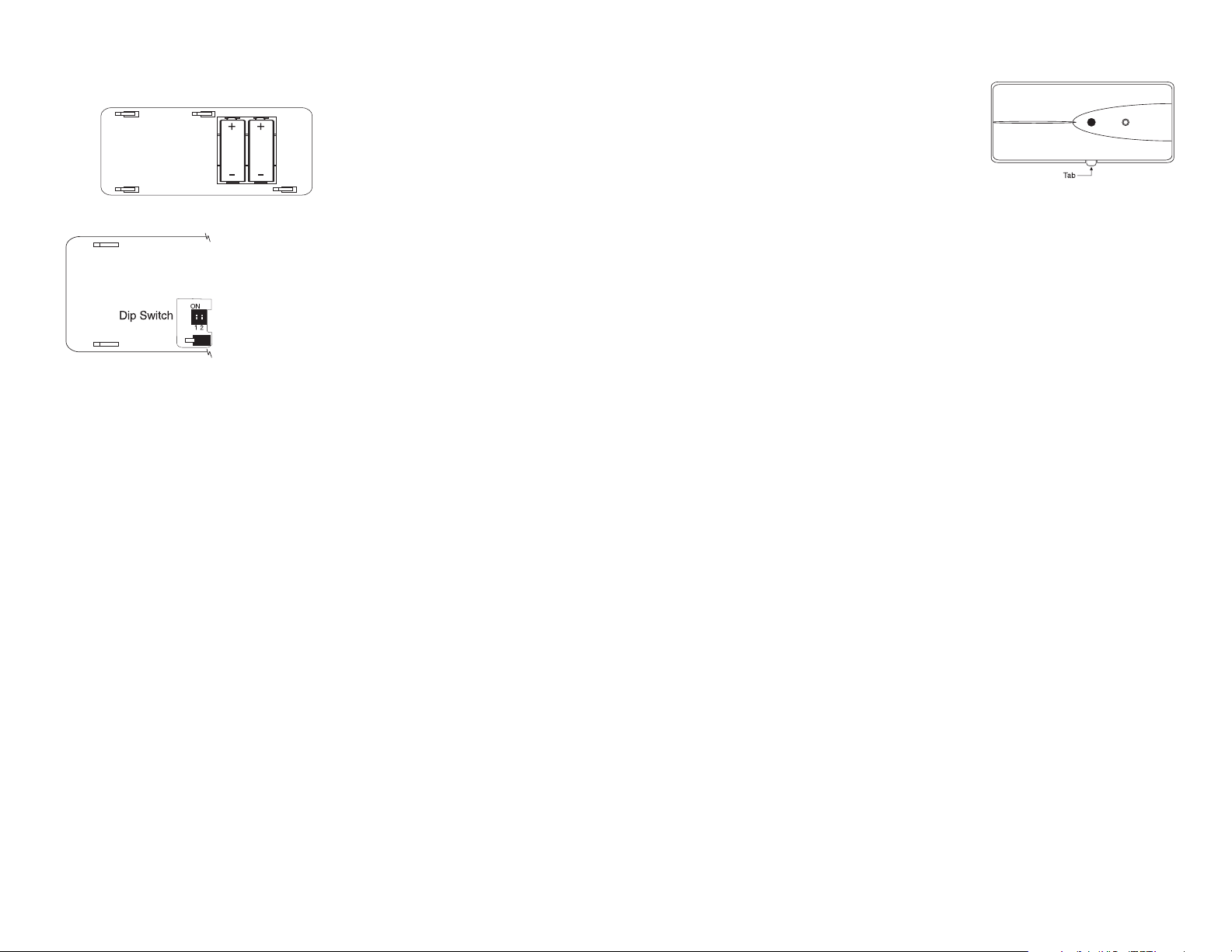

2. Install the batteries positive (+) side first, with the correct polarity, as shown

below.

Setting the Dip Switches

The detector has user-selectable dip switch settings as

shown.

Dip Switch 1– Not Used

Dip Switch 2– Level 1/Level 2 Detection

This is a sensitivity selection dip switch which may be

used to optimize false alarm immunity for certain acoustic environments.

The detector is factory set for Level 1 detection (Dip

Switch 2 = OFF). This is the highest sensitivity setting

for the detector, and will be suitable for most applications.

For rooms which are smaller, and contain a significant number of sound-reflective

surfaces (such as bathrooms, kitchens, entrances, etc.), Level 2 detection (Dip

Switch 2=ON) provides a reduced sensitivity setting which may be more appropriate.

Selecting a Mounting Location

The detector is omnidirectional, providing 360 degree coverage. Coverage is measured from the center of the detector to the point on the glass farthest from the detector.

Guidelines for optimizing detection and avoiding false alarms

• For optimum protection, the detector should have a direct line of sight to the

protected glass.

• Window coverings will absorb sound from the shattering glass. In these cases,

mount the detector as close as possible to the protected glass, either on an

adjacent wall, the ceiling, or behind the window covering if possible.

• The detector should be mounted at least 1.8m (6 feet) off the ground.

• Do not mount the detector on the same wall as the protected glass.

• Avoid installation near noise sources, such as speakers or other objects which

produce sounds continuously.

• Do not install the detector beyond the maximum recommended range, even if

the AFT–100 simulator shows additional range - future changes in room

acoustics could reduce the range.

• Application on 24 hour loops should be avoided unless the location is

unoccupied.

• Test false alarm immunity by creating any sounds in the room which will likely

occur when the alarm system is armed.

Note: Test the detector thoroughly for proper placement using the AFT-100

Glassbreak Simulator. Other simulators may trip the unit, but will not provide

accurate test results.

Testing the detector

Perform the following tests with each WLS912L detector to ensure that it is mounted

in the best possible location.

Detection Test:

1. Place the detector in test mode by

momentarily pressing down on the tab on

the base plate, as shown. The LED will blink

periodically to indicate that it is operating in

test mode. You can end the test mode by

momentarily pressing the tab on the base

plate. Test mode will end automatically after

10 minutes.

2. Use double-sided tape to temporarily mount the detector in the selected location

Note: The detector will not respond to the glassbreak simulator unless the test

mode operation has been enabled by momentarily pressing down on the test

mode tab on the base plate.

3. At the window to be protected, test the detector using the AFT–100 Glassbreak

Simulator. The AFT–100 Glassbreak Simulator generates plate or tempered

glass sounds. Use the plate glass setting if you are unsure of the glass type.

Observe the following when testing the detector:

• If the WLS912L detects the sound generated by the AFT-100 three times

in a row, the detector is in a good location. If the detector does not

respond each time, relocate the detector and repeat the test.

• If the windows in question are covered by drapes or blinds, place the

AFT-100 tester behind the closed window coverings, and then activate it.

If the drapes prevent reliable detection, we suggest that the detector be

mounted behind the drapes either on an adjacent wall or on the ceiling.

• If there are multiple windows, or one large window, activate the tester at

the furthest point on the glass from the detector.

Receiver Test:

You also need to perform a Module Placement Test to ensure that the selected location is in range of the wireless receiver (see the Placement Test instructions in the

installation instructions for your receiver).

1. Press and hold the test mode tab for 5 seconds

2. Release the test mode tab. The keypad will display the test result.

Enrolling the WLS912L

On the back of the detector, there will be two serial numbers: a five-digit number and

a six-digit number. Please refer to your receiver installation manual for information on

which serial number should be enrolled.

NOTE: If using a WLS900 system, you must use the five-digit serial number.

Loading...

Loading...