DSC T-LINK TL250, T-LINK TL350 Installation Manual

T-Link TL250/TL300

Network Internet

Alarm Communicator

Installation Manual

Software Version 1.20

WARNING Please Read Carefully

Note to Installers

This warning contains vital information. As the only individual

in contact with system users, it is your responsibility to bring

each item in this warning to the attention of the users of this system.

System Failures

This system has been carefully designed to be as effective as

possible. There are circumstances, however, involving fire, burglary, or other types of emergencies where it may not provide

protection. Any alarm system of any type may be compromised

deliberately or may fail to operate as expected for a variety of

reasons. Some but not all of these reasons may be:

Inadequate Installation

A security system must be installed properly in order to provide

adequate protection. Every installation should be evaluated by a

security professional to ensure that all access points and areas

are covered. Locks and latches on windows and doors must be

secure and operate as intended. Windows, doors, walls, ceilings

and other building materials must be of sufficient strength and

construction to provide the level of protection expected. A

reevaluation must be done during and after any construction

activity. An evaluation by the fire and/or police department is

highly recommended if this service is available.

Criminal Knowledge

This system contains security features which were known to be

effective at the time of manufacture. It is possible for persons

with criminal intent to develop techniques which reduce the

effectiveness of these features. It is important that a security system be reviewed periodically to ensure that its features remain

effective and that it be updated or replaced if it is found that it

does not provide the protection expected.

Access by Intruders

Intruders may enter through an unprotected access point, circumvent a sensing device, evade detection by moving through

an area of insufficient coverage, disconnect a warning device, or

interfere with or prevent the proper operation of the system.

Power Failure

Control units, intrusion detectors, smoke detectors and many

other security devices require an adequate power supply for

proper operation. If a device operates from batteries, it is possible for the batteries to fail. Even if the batteries have not failed,

they must be charged, in good condition and installed correctly.

If a device operates only by AC power, any interruption, however brief, will render that device inoperative while it does not

have power. Power interruptions of any length are often accompanied by voltage fluctuations which may damage electronic

equipment such as a security system. After a power interruption

has occurred, immediately conduct a complete system test to

ensure that the system operates as intended.

Failure of Replaceable Batteries

This system’s wireless transmitters have been designed to provide several years of battery life under normal conditions. The

expected battery life is a function of the device environment,

usage and type. Ambient conditions such as high humidity, high

or low temperatures, or large temperature fluctuations may

reduce the expected battery life. While each transmitting device

has a low battery monitor which identifies when the batteries

need to be replaced, this monitor may fail to operate as

expected. Regular testing and maintenance will keep the system

in good operating condition.

Compromise of Radio Frequency (Wireless) Devices

Signals may not reach the receiver under all circumstances

which could include metal objects placed on or near the radio

path or deliberate jamming or other inadvertent radio signal

interference.

System Users

A user may not be able to operate a panic or emergency switch

possibly due to permanent or temporary physical disability,

inability to reach the device in time, or unfamiliarity with the

correct operation. It is important that all system users be trained

in the correct operation of the alarm system and that they know

how to respond when the system indicates an alarm.

Smoke Detectors

Smoke detectors that are a part of this system may not properly

alert occupants of a fire for a number of reasons, some of which

follow. The smoke detectors may have been improperly

installed or positioned. Smoke may not be able to reach the

smoke detectors, such as when the fire is in a chimney, walls or

roofs, or on the other side of closed doors. Smoke detectors may

not detect smoke from fires on another level of the residence or

building.

Every fire is different in the amount of smoke produced and the

rate of burning. Smoke detectors cannot sense all types of fires

equally well. Smoke detectors may not provide timely warning

of fires caused by carelessness or safety hazards such as smoking in bed, violent explosions, escaping gas, improper storage of

flammable materials, overloaded electrical circuits, children

playing with matches or arson.

Even if the smoke detector operates as intended, there may be

circumstances when there is insufficient warning to allow all

occupants to escape in time to avoid injury or death.

Motion Detectors

Motion detectors can only detect motion within the designated

areas as shown in their respective installation instructions. They

cannot discriminate between intruders and intended occupants.

Motion detectors do not provide volumetric area protection.

They have multiple beams of detection and motion can only be

detected in unobstructed areas covered by these beams. They

cannot detect motion which occurs behind walls, ceilings, floor,

closed doors, glass partitions, glass doors or windows. Any type

of tampering whether intentional or unintentional such as masking, painting, or spraying of any material on the lenses, mirrors,

windows or any other part of the detection system will impair its

proper operation.

Passive infrared motion detectors operate by sensing changes in

temperature. However their effectiveness can be reduced when

the ambient temperature rises near or above body temperature or

if there are intentional or unintentional sources of heat in or near

the detection area. Some of these heat sources could be heaters,

radiators, stoves, barbeques, fireplaces, sunlight, steam vents,

lighting and so on.

Warning Devices

Warning devices such as sirens, bells, horns, or strobes may not

warn people or waken someone sleeping if there is an intervening wall or door. If warning devices are located on a different

level of the residence or premise, then it is less likely that the

occupants will be alerted or awakened. Audible warning devices

may be interfered with by other noise sources such as stereos,

radios, televisions, air conditioners or other appliances, or passing traffic. Audible warning devices, however loud, may not be

heard by a hearing-impaired person.

Telephone Lines

If telephone lines are used to transmit alarms, they may be out of

service or busy for certain periods of time. Also an intruder may

cut the telephone line or defeat its operation by more sophisticated means which may be difficult to detect.

Insufficient Time

There may be circumstances when the system will operate as

intended, yet the occupants will not be protected from the emergency due to their inability to respond to the warnings in a

timely manner. If the system is monitored, the response may not

occur in time to protect the occupants or their belongings.

Component Failure

Although every effort has been made to make this system as

reliable as possible, the system may fail to function as intended

due to the failure of a component.

Inadequate Testing

Most problems that would prevent an alarm system from operating as intended can be found by regular testing and maintenance. The complete system should be tested weekly and

immediately after a break-in, an attempted break-in, a fire, a

storm, an earthquake, an accident, or any kind of construction

activity inside or outside the premises. The testing should

include all sensing devices, keypads, consoles, alarm indicating

devices and any other operational devices that are part of the

system.

Security and Insurance

Regardless of its capabilities, an alarm system is not a substitute

for property or life insurance. An alarm system also is not a substitute for property owners, renters, or other occupants to act

prudently to prevent or minimize the harmful effects of an emergencysituation.

Table of Contents

Section 1: Introduction 1

1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2: Quick Start 3

2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Resetting to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 3: Bell Follower Installation (Mode 1) 5

Section 4: Stand alone Installation (Modes 2 & 3) 6

4.1 Stand alone Mode 2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Input Expander Mode 3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 5: Standard Installation (Mode 4) 7

5.1 Input Expander Mode 3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2 Standard connection with PC4020(CF)/PC5020(CF). . . . . . . . . . . . . . . . . . . . . . . . . 7

5.3 Wiring T-Link to a DSC compatible Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 UL Listed Commercial Fire Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 6: DVACS Installation (Mode 5) 9

6.1 DVACS Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 DVACS Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 7: TL300 Telephone Simulation 11

7.1 TL300 Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 T-Link TL300 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 8: T-Link Operation 12

8.1 Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.3 IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.4 Port Usage Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.5 Integrated Call Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.7 Test & Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 9: Programming Guide 15

9.1 Basic Programming (PC4020 Control Panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 Basic Programming (PC5020 Control Panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.3 T-Link DVACS Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.4 T-Link TL300 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 9: Programming Descriptions (Advanced) 18

Section 10: Programming Worksheets 26

Glossary 30

Appendix A: T-Link TL250 Compatibility Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Appendix B: T-Link TL300 Compatibility Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appendix C: T-Link Tl250/Tl300 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix D: Contact ID Reporting Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Appendix E: Network Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Section 1: Introduction

T-Link TL250/TL300

The T-Link TL250/300 modules are network internet communicators that send alarm system

information to a central station receiver. The module is pre-programmed with the most commonly used settings for quick installation. Default options can be custom programmed using TLink Console software if required.

T-Link TL300

The T-Link TL300 connects directly to the telephone output of a control panel and simulates a

telephone connection, providing a TCP/IP connection that sends predefined Contact ID codes

to the central station. The T-Link TL300 on-board zones can be used as in mode 2 (4-zone

stand-alone) and mode 3 (12-zone stand-alone). Modes 1 and 5 are not supported.

Software Version 1.0

• Supports TL250 and Modes 1, 2, 3 and 4 only.

Software Version 1.10

• Supports TL250, includes Version 1.0 options and Mode 5, TL250 DVACS panel conversion (Canada only). Corresponding version numbers for SG DRL3-IP and T-Link Console

are required to ensure compat ibility (i.e., SG DRL3-IP v1.10 and T-Link Console v1.10 are

required for corresponding T-Link TL250 v1.10).

NOTE: For DVACS mode an SG-DRL3-IP v1.10 receiver line card is required to communicate

with the T-Link TL250 v1.10 or higher.

• Account code extended from 6 to 10 digits.

Software Version 1.20

• Supports TL250 and TL300 and all Version 1.10 options.

• Supports new zone type ‘98’ Panel Absent.

• Supports basic programming from an LCD 5500 Keypad.

• Default Installer code has changed from CAFE to 5555 for this software version

1.1 Operating Modes

Mode 1: Bell Follower (TL250 only)

In Mode 1, the T-Link TL250 monitors the Bell Output of a control panel. The system identifies the Bell Output cadence and transmits the corresponding Fire or Burglar alarm reporting

code to the central station. Refer to section 3 for details

Refer to the appropriate control panel Installation Manual.

NOTE: Do not use Mode 1 for UL or ULC listed installations.

Mode 2: 4-Zone Panel (TL250 and TL300)

In Mode 2, the system is configured for 4-zone, stand alone oper atio n. Refer to section 4.1 fo r

details.

Mode 3: 12-Zone Panel (TL250 and TL300)

If the T-Link TL250 detects a PC5108 expander card on power up it will automatically configure

itself for 12-zone standalone operation with normally open loops. Refer to section 4.2 for details.

NOTE: In modes 2 & 3, the connections between the PC5108 inputs or T-Link TL250 inputs and

the alarm control unit outputs (relay contacts) shall be done in metal conduit, within 20 ft.

Stand-alone operation will still require the inputs to be programmed with the desired alarm

types.

Mode 4: Standard Mode (TL250 only)

In standard mode, the system is configured as a communicator with a compatible DSC alarm

panel: Models PC4020, PC4020CF, PC5020 or PC5020CF. Refer to section 5 for details.

1

Mode 5: DVACS®* Mode (V1.10 or later)(TL250 only)

In DVACS mode, the system is configured as a communicator with a compatible DVACS

alarm panel. Refer to section 6 for details. Refer to appendix C for a list of compatible

DVACS panels and modules.

NOTE: T-Link TL250 zone events are transmitted using the standard T-Link SIA protocol.

DVACS generated events are transmitted using the DVACS protocol.

NOTE: DVACS Mode 5 is used in ULC listed installations.

* DVACS is a registered trademark of Electro Arts Ltd. Scarborough Ontario, Canada

1.2 Specifications/Requirements

The maximum allowable current draw from a compatible DSC panel on the Aux terminal

Output is 500 mA @ 12V

DC. Operational current draw of the T-Link TL250 is 250 mA. The

T-Link TL250 module has 2 switched negative programmable outputs (50 mA @ 12 V

Specifications

Input Voltage:12 VDC

Input Current: T-LINK TL250 Max current draw: 275mA

Dimensions: 3.25” × 5.25” (8.3 cm × 13.3 cm)

Operating Temperature: 32°-122°F (0°-49°C)

Output Protocols: UDP/IP 10/100 BaseT half duplex, TCP/IP for Console and DLS commu-

nications

Input Protocols: PC-Link (SIA format), DVACS (V1.10 and higher), Contact ID protocol.

(TL300 Only)

Digital Inputs: 4-digital inputs (can be increased to 12 using the PC5108)

Connectors: 4-pin header for the PC-Link and RJ-45 for Ethernet, DVACS adaptor

(DVACS kit only)

Programming: Panel keypad, console on the RS232 or remote T-Link console.

Network: Ethernet LAN/WAN 10 BaseT or 10/100 BaseT

E-mail: sends alarm messages to maximum 2 E-mail addresses

(NOT available for DVACS installations)

Downloading Support for DSC Panels:DLS-3 and/or System Administrator software

Multiple Central Stations: primary and backup via phone line*

(NOT available for DVACS installations).

Call Direction Options: primary or backup communicator using panel call direction

(NOT available for DVACS installations).

Approval Listings: FCC, IC, CE

UL (Grade of Service AA, Encr ypted Line Security)

ULC (Signal Channel Security Level 4/5)

*NOTE:This manual shall be used with the Installation Manual of the associated Alarm Controller for installation.

NOTE: For UL Listed fire installations, shared on-premises communication equipment is

required to be UL Listed for Information Technology Equipment. The communication medium

between protected property and communications service provider must be for the exclusive

use of the protected property and not shared with other communications service provider

subscriber.

NOTE:When a hub or router/gateway is used on the premises with the T-Link TL250, 24-hr.

standby power is required for these devices (i.e., UL listed UPS, battery backup).

NOTE:This equipment (T-Link TL250) shall be installed and used within an environment that

provides the POLLUTION DEGREE MAX 2 and OVERVOLTAGES CATEGORY II NON-HAZARDOUS LOCATIONS, indoor only. The equipment must be FIXED and permanently connected,

and is intended to be installed by SERVICE PERSONS (i.e., having the appropriate technical

training and experience necessary to be aware of hazards which that person may be exposed

to in performing the task, and of measures to minimize the risks to that person or other persons).

T-LINK TL300 Max current draw: 360mA

CAUTION

Ethernet communication lines must be connected to an approved (acceptable to local authorities) type NID (Network Interface Device) before leaving the premises (e.g., UL installations,

UL60950 Listed NID).

DC).

2

Section 2: Quick Start

2.1 Installation

1. Determine the Operating Mode Required

The operating mode (Modes 1, 2, 3, Standard Mode, or DV ACS Mode) will determine how the

unit is to be wired.

2. Determine the Mounting Location

Select a mounting location in a dry, protected area at least 30 cm. away from physical contact

with any person. Refer to page 34, appendix C, for Network Protection details.

NOTE: Do not exceed the following recommendations for wire run distances

• Input wiring should must be minimum 22 gauge quad (0.5mm). Two pair twisted is preferred.

• PC5108, or zone wiring must not exceed 1,000' (305m) (in wire length) from the T-Link

module.

• Shielded wire is not necessary unless wires are run in an area that may present exce s si v e

RF noise or interference.

• Refer to section 9, Programming Descriptions, section [36] for zone wiring details.

3. Route Wiring to Mounting Location

Route wiring from the hard wired zones or control panel as required.

NOTE: Route wiring through conduit to a junction box if possible.

4. Mount the T-Link TL250/300 Panel

2.2 Testing

Mode 4, Standard Mode: Ensure the panel is programmed to use the T-Link TL250 in accordance with the settings outlined in section 8, Programming Guide. Simulate Burglar and Fire

Zone violation on the DSC alarm panel. Verify that the T-Link TL250 transmits the events to

the central station.

Mode 1: Ensure the T-Link is programmed in accordance with the settings outlined in Sections

9, Programming Descriptions. Simulate Burglar and Fire Zone violation on the alarm panel.

Verify that the T-Link TL250 transmits the events to the central station.

Modes 2, 3 and 5 (DVACS): Simulate Inputs violations in accordance with the settings outlined in Sections 9, Programming Descriptions. Verify that the T-Link TL250 transmits the

events to the central station.

TL300 Simulated Phone: Ensure the T-Link TL300 Input 1 is programmed in accordance

with the TL300 settings outlined in Sections 9, Programming Descriptions. Simulate Burglar

and Fire Zone violation on the alarm panel. Verify that the T-Link TL300 transmits the associated Contact ID code to the central station.

3

2.3 Resetting to Factory Defaults

Hardware Defaults (all modes)

• Remove Power from the T-Link TL250/TL300; disconnect battery and control panel if

applicable

• Disconnect all wiring from the PGM1 and IN1 terminals. Connect a jumper wire between

the PGM1 and IN1 terminals

• Apply power to the system

• Remove power from the T-LINK TL250/TL300 for approximately 20 seconds

• Reconnect all original wiring and reapply power to the T-Link TL250/TL300.

• Test System - refer to section 2.2

NOTE: A restart is required for the programming changes to take effect. Allow up to 15 seconds for a restart.

Mode 4:

In mode 4, the T-Link can be Defaulted through the panel keypad:

• Enter section 999 of the T-Link TL250

• Enter 00 to default the unit to factory settings

• Enter 55 to restart the unit.

2.4 LCD 5500 Programming

All Modes (Software version 1.2 only)

Local programming of basic options can be done through a standard DSC Power LCD keypad.

Connect the keypad on the T-Link Keybus terminals. Access to programming mode uses the

same code as the console (default is '5555').

NOTE:Programming mode access can be done only on power up for 30 seconds, and only

if the reset to factory default is not activated.

• Access the Installer mode using [*][8], followed by the installer code.

NOTE:The [*] and [#] keys are not supported to re-enter installer code in the event of an

incorrect entry. All keys will be ignored if the correct sequence following [*][8] is not

entered.

• Four Programming Sections are available and will be displayed in the sequence indicated

below. See section 9 for details

[001] T-Link IP Address:

|___|___|___|.|___|___|___|.|___|___|___|.|___|___|___|

[003] T-Link Account Code

|___|___|___|___|___|___|___|___|___|___|

[007] Primary Receiver IP Address

|___|___|___|.|___|___|___|.|___|___|___|.|___|___|___|

[007] Primary Receiver Gateway IP Address

|___|___|___|.|___|___|___|.|___|___|___|.|___|___|___|

When programming is completed, press the "#" key to save changes and exit programming

mode. A 2-minute timing delay begins when entering the programming mode. At the end of the

timing delay T-Link will exit program mode and save the changes made regardless of where

the programmer is in the programming sequence.

• Remove power from the system

• Reconnect all original wiring and reapply power to the system

• Test System - Refer to section 2.2

NOTE: A restart is required for the programming changes to take effect. Allow up to 15 seconds for a restart.

4

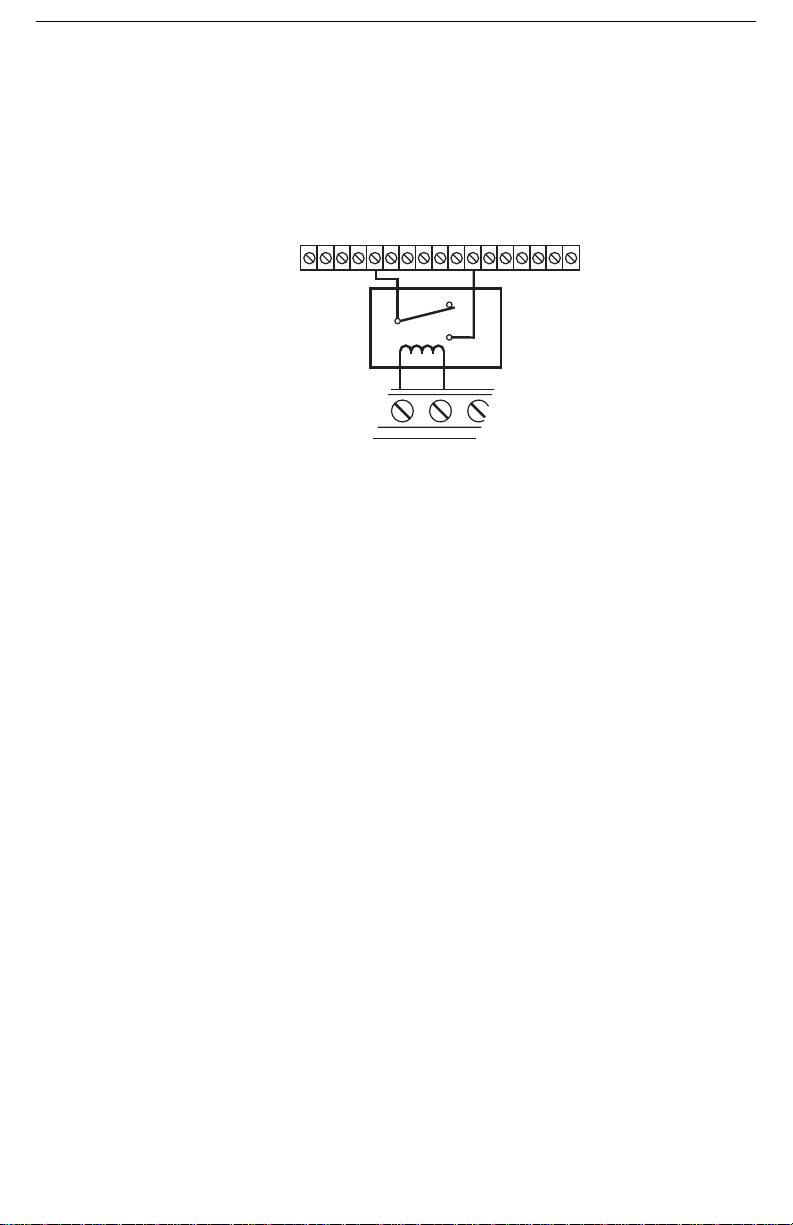

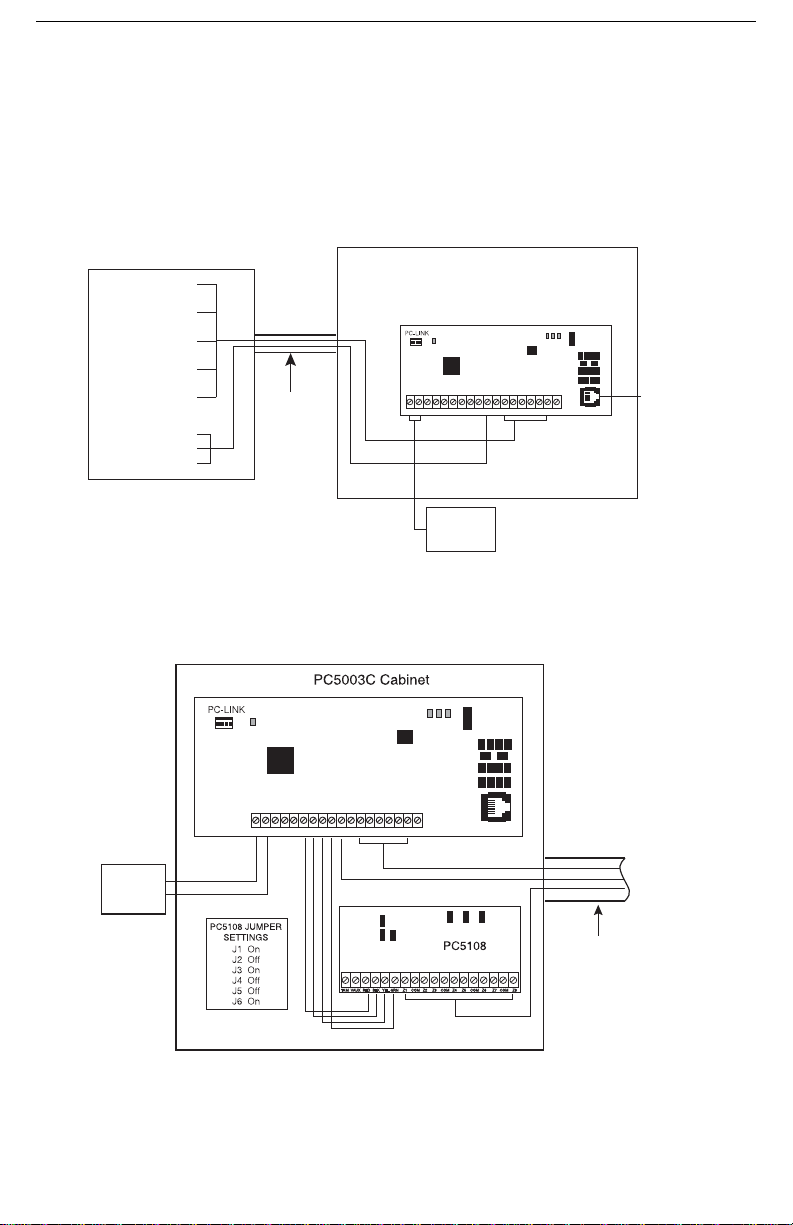

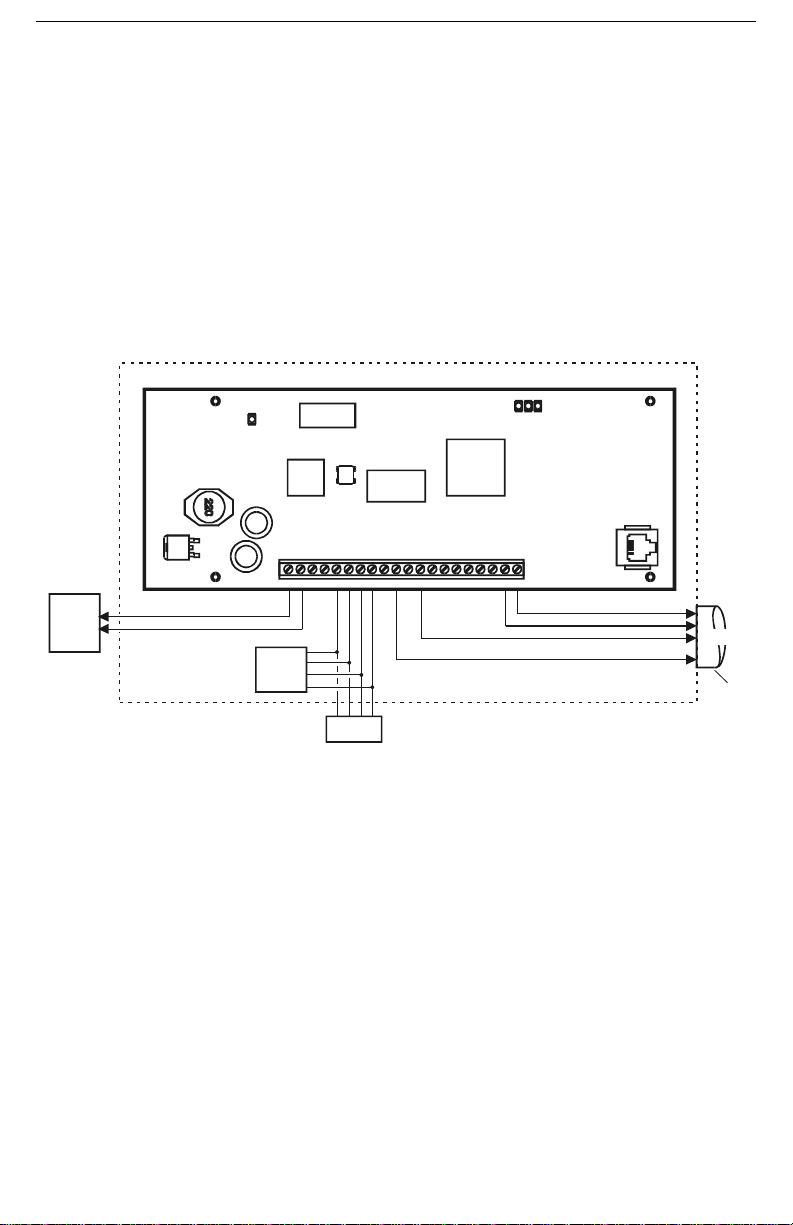

Section 3: Bell Follower Installation (Mode1)

BELL+ BELL-

Alternate connection for

Control Panels where Bell

switches High

Relay

Com

NC

NO

+12V GND YX RX GND RE D YE L G RN PGM1 PGM2 IN1 GND GNDIN2 IN3 IN4 EARTH

3.1 Setup and Installation

3.1.1 Bell Follower Installation (Mode 1)

Install the T-Link TL250 in a DSC enclosure (model PC5003C) when used in a Bell Follower

configuration. Refer to section [036][99].

Connect the 12V

NOTE: Bell Follower mode can not be used in UL or ULC listed installations.

Refer to options [062] through [065].

DC and GND terminals to the external 12V power source.

5

Section 4: Stand-alone Installation (Modes 2&3)

PC5003C Cabinet

Note: Wiring between the control panel and the T-Link

TL250 must be enclosed in metal conduit.

Outputs

Input

+12V GND TX RX GND RED BLK YEL GRN IN1 IN2 IN3 IN4 EARTHGND GND1 PGM 2

LK

ACT

SPD

STAT

T-LINK TL250

12V 275mA

UL Listed

Power Supply

CAT5 Cable

(shielded)

10/100 BaseT

Network

PGM1 Trouble Output

IN1 - IN4

Zone Inputs

(Not supervised)

Fire/Burglary

Alarm Panel

Metal Conduit

(20ft max.)

J6

J4

J5

J1

J2 J3

+12V

GND

GNDRED BLK

YEL

GRN GNDIN1 GND

EARTH

IN3 IN4IN21 PGM 2

TX RX

LK

ACT

SPD

STAT

Cat5

Network

10/100 BaseT

T-LINK TL250

12V 275mA

UL Listed

Power Supply

PGM1 Trouble Outputs

Metal

Conduit

(20ft max.)

Z1 - Z8 Inputs (NO/NC)

(Not supervised)

IN1 - IN4 Inputs (NO/NC)

(Not supervised)

Connect

to Fire/Burg.

Alarm

Panel

Install the T-Link TL250 in a DSC enclosure (model PC5003C) when used in a stand-alone configuration or with the PC5108 module.

Connect the 12V

NOTE: For UL Listed installations, the power supply used must be UL Listed for the application.

4.1 Stand alone Mode 2 Configuration

4.2 Input Expander (Mode 3 Configuration)

To expand from the 4-zone inputs a PC5108 must be connected to the T-Link. Connect the

Keybus from the PC5108 to the Keybus of the T-Link TL250. Any devices that require 12V

motion detectors, glass break detectors, etc., will require an external 12V

DC and GND terminals to the external 12V power source.

DC,

DC power supply .

6

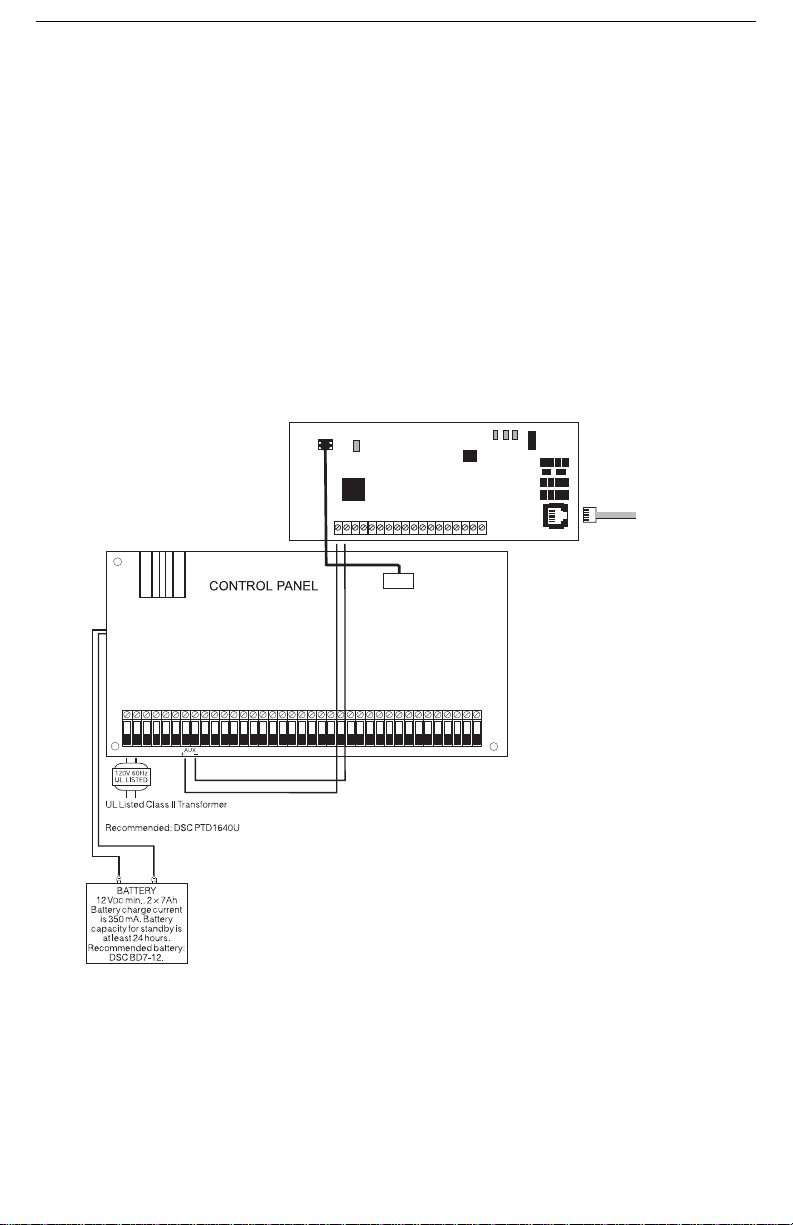

Section 5: Standard Installation (Mode 4)

+12V GND TX RX GND RED BLK YELGRN PGM1PGM2 IN1 GND IN2 IN3 GND IN4 EARTH

Network

PC-LINK

PC-LINK

SUPERVISED

SUPERVISED

STAT

Network Connection

Use only CAT5 cable

(300ft / 100m max.)

Supervised

WARNING!: Do not connect transformer

to receptacle controlled by a switch. The

transformer must be UL Listed and have

a restraining means.

V = 12VDC

I = 250mA (275mA with PGM or PC5108)

RED

BLK

+

-

LK

ACT

SPD

16.0V@40VA

5.1 Power864 and Maxsys Panel Setup and Installation

Refer to the PC4020(CF) or PC5020(CF) Installation Manuals for control panel installations.

Mount the T -Link on the side wall of the PC4050C or PC4050CR cabinet. Refer to appendix C

for Network Protection installation instructions.

Remove power from the control panel before any connections are made to the T-Link TL250.

Connect the 12V

plied cable from the T-Link TL250 white connector to the PC-Link header of the control panel.

The black wire of the PC-Link cable is pin 1 on the PC-Link header for the PC5020 v3.2 or

higher control panels. The PC-Link header is polarized on the PC4020 v3.31 or higher control

panel. Connect the e-ground to a proper earth-ground connection.

5.2 Standard Connection with PC4020(CF)/PC5020(CF)

CAUTION: All circuits are supervised and power limited. Refer to section 5.4, UL Listed Commercial Fire Systems diagram for wire routing. Do NOT route any wiring over the circuit

boards. Maintain at least 1” (25.4mm) separation between circuit board and wiring.

A minimum of 1/4” (7mm) separation must be maintained at all points between non power limited wiring and power limited wiring.

DC and GND terminals to the panel auxiliary power output. Connect the sup-

7

5.3 Wiring T-Link to a DSC Compatible Control Panel

• Secure the T-Link module to the side of the cabinet using the supplied standoffs.

• With AC power and battery disconnected removed from the DSC control panel, wire the T-Link to

the panel using 4 wires from the PC-Link of the panel to the “PANEL” connector on the T-Link.

• Wire the panel's AUX+ and - to 12V

DC and GND terminals of T-Link.

• Apply AC and DC to the main control panel. Both the T-Link and the panel should power up.

• Do the necessary programming that is required.

NOTE: If a Bell/Siren will not be used, wire the Bell/Siren terminals on the panel with a 1000

ohm resistor. For Commercial Fire installation, when a bell/siren is used in the application, it

should be connected to the DSC module PC4702BP. Refer to the PC4020 Installation manual.

The keypad or any other accessory connected to the Combus shall be connected within 3 feet

/ 0.9 m and in conduit.

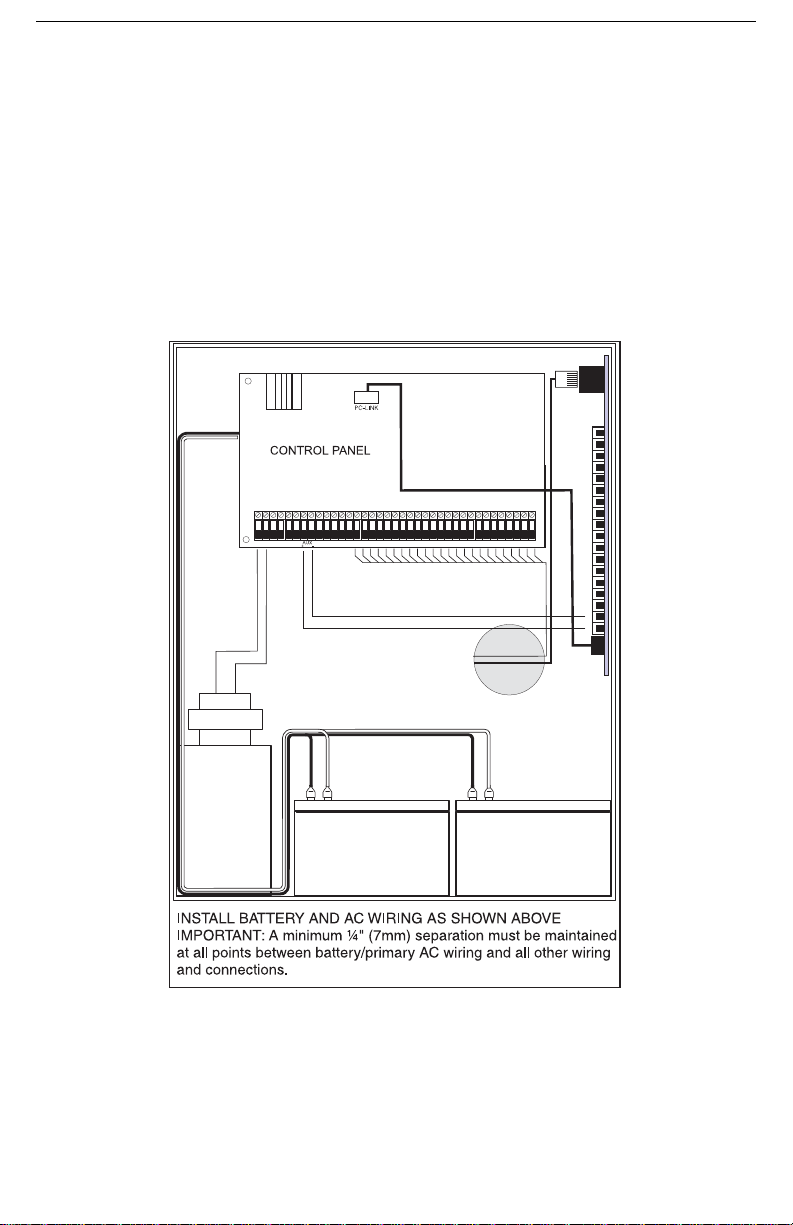

5.4 Battery and AC Power Lead Routing for

UL Listed Commercial Fire Systems

GND

+12V

T-Link board must be mounted on the side of the cabinet. Refer to

the mounting instructions in the associated Installation Manual.

8

Section 6: DVACS Installation (Mode 5)

DVACS Panel

Installed in Cabinet

ULC Listed Installation

DVACS RS-232

TX, RX, GND

12/24V

DC

Red, Blk

F1/F2

DVACS

Subset

MLR2

with DVL2A

DV1660

DVACS

Network

DVACS

Network

SG-DVL2A

Tx

Rx

ALARM

ACK./

TROUBLE

SELECT

WATCHDOG

WATCHDOG

SELECT

TROUBLE

ACK./

ALARM

Rx

Tx

CARRIERCARRIER

FUNCT. FUNCT.

BACKSPACE

Rx

ESCAPE

TROUBLE

OPTION

ACK.

ENTER

Tx

SG-CPM2

AC

F E D

7 8 9 C

650B

1 2 3 A

4

LAN/WAN/

Internet

LAN/WAN/

Internet

DVACS Panel

Alternate

Power Supply

Installed in Cabinet

ULC Listed Installation

DVACS cable must be run

in metal conduit & terminated

with an RJ-45 connector

RJ-45 to PC-Link Adaptor

12V Red, Blk

DC

T-Link TL250

PC 5003C Cabinet

CON5

CON2

CON1

CON1

CON3

CON3

PCLINKPCLINK

SPD ACT LNK

STAT

+12V GNDTX RX GND RED BLK YEL GRN PGM1 PGM2 IN1 GND IN2 IN3 GND IN4 EARTH+12V GNDTX RX GND RED BLKYEL GRN PGM1 PGM2 IN1 GND IN2 IN3 GND IN4 EARTH

220

System III Receiver

with DRL3-IP Line Card

RRLLL = 02345

IP Account = 010A000034

DVACS Automation Protocol

1 Digit 101A 034...

2 Digits 1010A 034...

3 Digits 10100A 034...

SIA Automation Protocol

1 Digit S025[#000034|...

2 Digits S0245[#000034|...

3 Digits S02345[#000034|...

ID=34

Account = 010A000034

RRLL = 010A

For Decimal Account#

Account = 010A000056

Typical T-Link TL250/DVACS Installation

ULC Listed Power Supply

with Battery Backup

DV1660

6.1 DVACS Panel Installation.

Remove power from the control panel before wiring connections to the T-Link TL250 module.

Connect the 12V

DVACS cable from the T-Link TL250 Adaptor on the PC-Link header to the DVACS connector on the control panel. Connect the e-ground to a proper earth-ground connection.

In a typical DVACS Installation, a DVACS panel is connected to an F1/F2 subset that communicates the alarm information to the central station comprising an SG MRL2 receiver with an

SG DVL2A module installed.

To send DVACS Alarm information over the internet, the T-Link TL250 performs the equivalent functions of the F1/F2 subset and the polling function of the SG DVL2A. DVACS alarm

information is sent to the T-Link TL250 by connecting the existing RJ-45 terminated cable to

the PC-Link Header on the TL250 module with an RJ-45 to PC-Link adaptor. The T-Link

transmits DVACS alarm information in the DVACS protocol and T-Link Alarm information in

the SIA protocol over the internet to a System III Receiver with SG-DRL3-IP line card

installed.

DC and GND terminals to the panel auxiliary power output. Connect the

6.2 DVACS Events

DVACS events generated on DVACS panels connected through the T-Link TL250 follow the

same protocols used on the SG-DVL2A module.

DVACS Alarms Examples

Example 1 (DVACS with receiver set as 1 digit line number)

Printer:

01 Nov 2004-11:38:22-01/02-SG -01-1-001--Burgl Alm Zn#02

Computer:

Example 2 (DVACS with receiver set as 3 digits line number)

1011 001 A 02

Printer:

01/02-SG -01-001-014--Burgl Alm Zn#13

Computer:

101001 014 A 13

9

SIA

DVACS Alarms Examples

Example 1 (DVACS with receiver set as 1 digit line number)

Printer:

01 Nov 2004-13:50:51-01/02-SG -01-1-0456--Fire Alm Zn999

Computer:

3011 0456FA 999

Example 2 (DVACS with receiver set as 3 digits line number)

Printer:

01 Nov 2004-13:51:03-01/02-SG -01-001-0456--Medical Alm Zn001

Computer:

3011 0456MA 001

Additional Events:

If the T -Link TL250 trans mitter does not receive polls (response) from the panel, the T-Link will generate the events previously generated by the SG-DVL2A for DVACS panel and restoral.

SIA

Printer:

01 Nov 2004-13:50:51-01/02-SG -01-1-001--Account Absent

Computer:

3011 0001YC 000

Printer:

01 Nov 2004-13:50:51-01/02-SG -01-1-001--Account Present

Computer:

3011 0001YK 000

Standard

Printer:

01 Nov 2004-13:50:51-01/02-SG -01-1-001--IDcde IncResp

Computer:

1011 001 A 0A

Printer:

01 Nov 2004-13:50:51-01/02-SG -01-1-001--IDcde Restore

Computer:

1011 001 R 0A

NOTE: The SG-DRL3-IP will use 10-digit account identifications in it's IP table for DVACS

transmitters. The first four digits represents the receiver and line number originally used on

the SG-DVL2A and are programmed as the first four digits of the T-Link account (refer to

appendix F of SG-DRL3-IP Installation Manual).

NOTE:If the automation protocol in the form of 1RRL, 3RRL is required when using the DRL3IP in the DVACS configuration, set DRL3-IP Option [11] =1 and CPM3 Options [10] & [11] = 03

10

Section 7: TL300 Telephone Simulation

CON5

SPD ACT LNK

STAT

+12V GND TX R X GND RED B LK YEL GRN PGM 1 PGM2 IN1 G ND IN2 IN3 GN D IN4 EARTH T1 R1

T-Link TL300

(Refer to al arm panel manu facturers doc umentation)

Note: Do NOT con nect the alarm panel or T-link TL300 to telep hone line

Temporary connection of Keypad for programming

of T-Link during fi rst 30 seconds of power up shown

Configure zone as zone definition 98 (see section [036]-[047] Option [98]

To Tip and Ring on Alarm Panel

12V 360mA

UL Listed

Power Supp ly

or

Pane l Aux

12VDC

PC5108

(optional)

LCD5500

Keypad

PC5003 Cabinet

7.1 TL300 Panel Installation.

• Secure the T -Link module to the side of the cabinet of the control panel or ins ta ll the T-Link TL300

in a DSC enclosure (model PC 5 0 03C). Refer to Appendix B: T-Link TL300 Compatibility Chart

for a list of panels supported

• With AC power and battery disconnected removed from the control panel, connect the T-L300 to

the RJ31 phone jack from the panel to the RJ31 connector on the T-Link.

• Wire the panel's 12V

Listed Power supply.

• Wire the panel's Ti p and Ring terminals to the T1 and R1 terminals of T-Link TL300.

• Apply AC and DC to the main control panel. Both the T-Link and the panel should power up.

• Do the necessary programming that is required.

DC and GND terminals of T-Link or Power unit with a 12VDC 225 mA UL

Connect PGM1 to panel zone to indicate network l oss configure as TLM or FTC

7.2 T-Link TL300 Operation

Communication events between the panel, T-Link and the Central Station receiver are as follows:

• When an alarm triggers, the panel goes off-hook

• The T-Link module sends a dial tone to the panel

• The Panel dials the telephone number of the central station

• The T-Link detects the DTMF dialing and stops sending the dial tone.

• The T-Link sends a request to the Receiver.

• The Receiver responds with the command to the T -Link to generate the corresponding handshake.

• After receiving the handshake, the Panel transmits the alarm message in DTMF Contact ID format

• The T-Link decodes and transforms DTMF digits into an IP packet and sends it to the Receiver

over IP.

• The Receiver acknowledges alarm and sends command to the T-Link to generate a corresponding

kiss-off signal.

• After the T-Link generates kiss-off, the Panel goes on-hook if no more alarms need to be sent.

11

Connect to

Alarm Panel

Metal Conduit

20 ft(6m) max

Loading...

Loading...