DSC The NEW FORCE 2 F2-210, The NEW FORCE 2 F2-211, The NEW FORCE 2 F2-212 Installation Instructions Manual

Page 1

PIR/MICROWAVE MOTION DETECTOR

F2-210 SERIES

INSTALLATION

INSTRUCTIONS

FEATURES

• Multi-level PIR signal processing

• Digital Microwave signal processing

• DRO microwave technology for low current and reliable

operation

• MOV transient / static protection

• High RF immunity with SMD construction

• Exceptional white light immunity

• Microprocessor low voltage protection

• Optional tamper switch

• Optional Form ‘C’ alarm contacts

*

SPECIFICATIONS

ELECTRICAL

Operating Voltage .................................................9.5 to 14.5 V

Ripple Tolerance ................................................. 3 VP-P at 12 VDC

Stand-by Current ................................................ 30 mA at 12 VDC

Alarm Current ..................................................... 30 mA at 12 VDC

Alarm Contacts ............................................. Form ‘A’ (standard)

Form ‘C’ (optional)

Tamper Contact .............................................................. Optional

Contact Ratings ............................................... 100 mA at 24 V

Alarm Contact Series Resistance ............................. 10W 0.25W

OPERATION

Coverage (max. length x max. width) ....... 30' × 40' (9m × 12m)

Alarm Duration ............................................................ 2 seconds

Walk Speed ......................... 0.5 ft/s to 10 ft/s (0.15m/s to 3.0m/s)

Nominal Mounting Height .......................................... 7.5' (2.3m)

Jumper .............................................................. Alarm LED on/off

IMMUNITY

RF Immunity ...................... 30 V/m over range 0.01 to 1200 MHz

Transients at Terminals .................................2.4 kV at 1.2 joules

Static Discharge Immunity .................................................. 10 kV

White Light ......................................... 20 000 Lux at the detector

Operating Temperature ..................... 32° to 122° F (0° to 50° C)

Humidity ................................ 5% to 95% RH non-condensing

DESCRIPTION

The Force 2 210 is a Short Range Dual Detector employing both

Microwave (MW) and Passive Infrared (PIR) motion sensors. The

sensors are combined through a microprocessor to provide

“intelligent” motion detection designed to eliminate “single

detector” false alarms.

Significant new technical features such as Multi-Level PIR signal

processing, a high reliability DRO microwave sensor and digital

MW signal analysis combine for a new level of detection sensitivity,

stability and false alarm immunity.

The PIR and MW systems are each designed as independent, high

quality motion detectors. When combined, the result is a detector

with unmatched performance.

The detector indicates an alarm when both sensors detect motion

within 10 seconds of each other. The first sensor, either the PIR

or MW, which detects motion will start the 10 second confirmation

period during which the other sensor must also detect motion. If

the first sensor’s detection is not confirmed within 10 seconds, the

unit disregards the alarm.

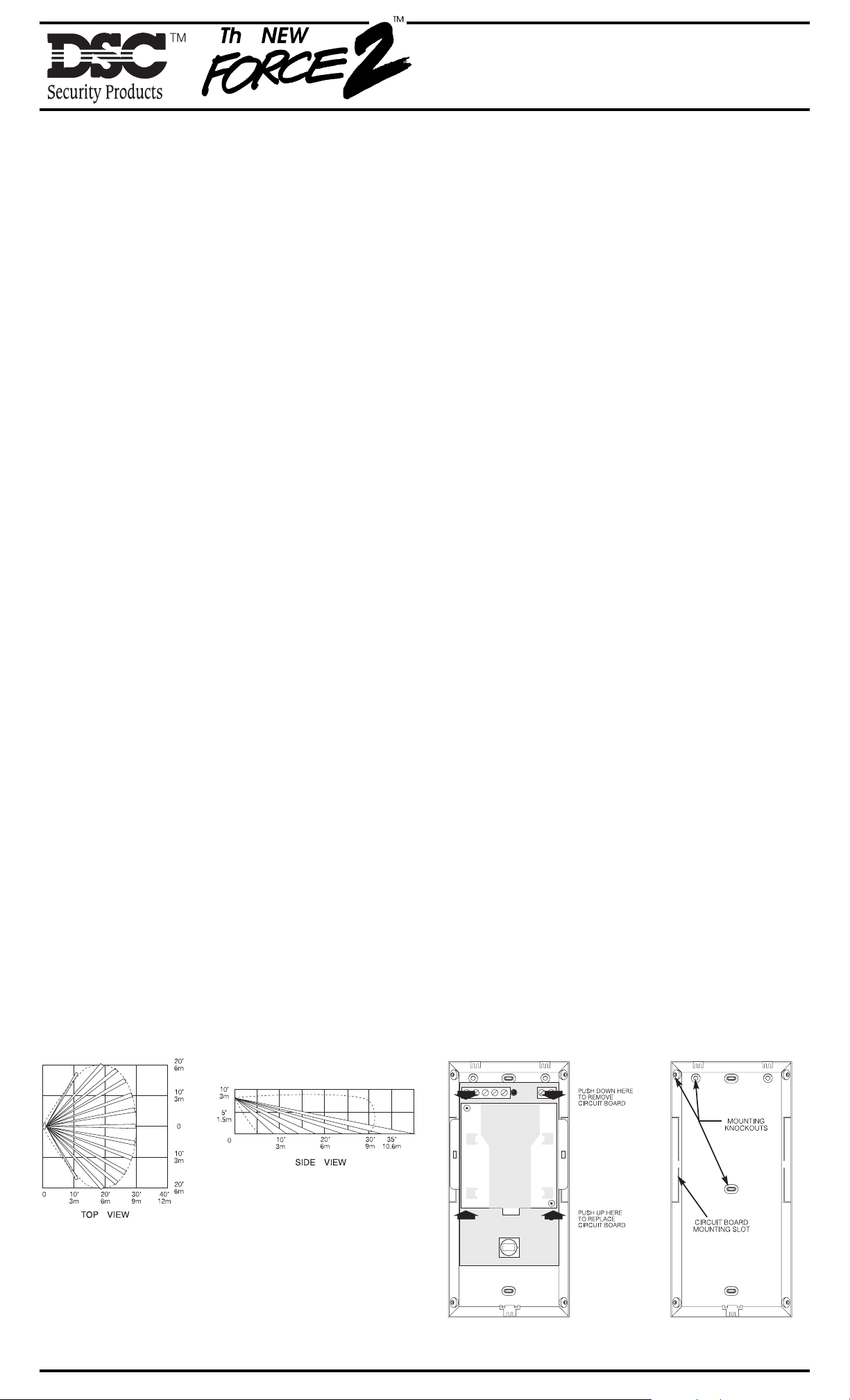

PIR / MW BEAM PATTERNS

LOCATING THE DETECTOR

Mount the detector in a dry indoor location which will allow the

intruder to walk perpendicular to the beam, and allows the beam

pattern to adequately cover the area being protected. Survey the

mounting location and the area being protected for the following

potential problems.

MOUNTING HEIGHT

The FORCE 2 is designed to provide optimum coverage when

mounted between 2.1m (7') to 2.4m (8’) from the floor. If the unit

is mounted above 2.4m (8’), the PIR will have a slightly longer

range, but the “dead” zone directly below the unit will be increased.

If the unit is mounted below 2.1m (7’) the PIR section will have a

shorter range and the “dead” zone directly below the detector will

be decreased.

REFLECTIVE/METALLIC SURFACES

DC

DC

**

Do not aim the detector at reflective surfaces or metallic surfaces

that could vibrate. Reflective surfaces could distort the PIR coverage

pattern; vibrating metallic surfaces or rotating fans could be seen

as motion by the MW sensor. Metallic surfaces close to the unit may

reduce MW sensitivity.

AIR FLOW

The FORCE 2 is protected against air flow and airborne

contamination. However, do not locate the detector where it will

be subject to direct high air flow such as fans, hot air vents or open

windows.

CONTAMINATION

Do not locate the detector near a source of oil or water vapour,

such as a steaming kettle or cooking area in a kitchen.

SUNSHINE

The FORCE 2 is resistant to white light but direct sunlight is a high

energy source. Do not locate the detector where it will receive

direct sunlight, particularly in the morning or evening when the sun

is low and may shine in through a window.

TEMPERATURE CHANGES

Do not aim the detector at objects that change temperature rapidly,

such as heaters or ovens.

OBSTRUCTIONS

Do not limit the desired area of protection with large objects such

as plants or filing cabinets.

PETS

Do not aim the detector where pets may trigger either the Microwave

or PIR motion sensors. If both sensors are tripped, an alarm will

result.

DISASSEMBLING THE DETECTOR

To open the detector, pull on the front of the detector while pressing

on the release at the bottom of the detector with a small screwdriver.

To remove the circuit board and sensor assembly from the detector

case, press gently on the top of the MW detector until the circuit

board unlocks and slides towards the bottom of the detector.

To replace the circuit board and sensor assembly, place the

circuit board assembly into the detector’s back so that the white

plastic frame fits into the two slots in the detector’s back. Press

gently on the bottom of the MW detector assembly to slide the

circuit board towards the top of the detector. The circuit board

assembly will snap firmly into place.

NOTE: To avoid damage to the detector, do not press against

any of the components on the circuit board when removing and

replacing the board.

With the circuit board removed, use a small screwdriver to punch

out the wiring and mounting knockouts located in the detector’s

back. Feed the wiring through the wiring knockout and secure the

detector to the wall.

*

Patented.

**

UL only verified up to 85% RH non-condensing.

J1

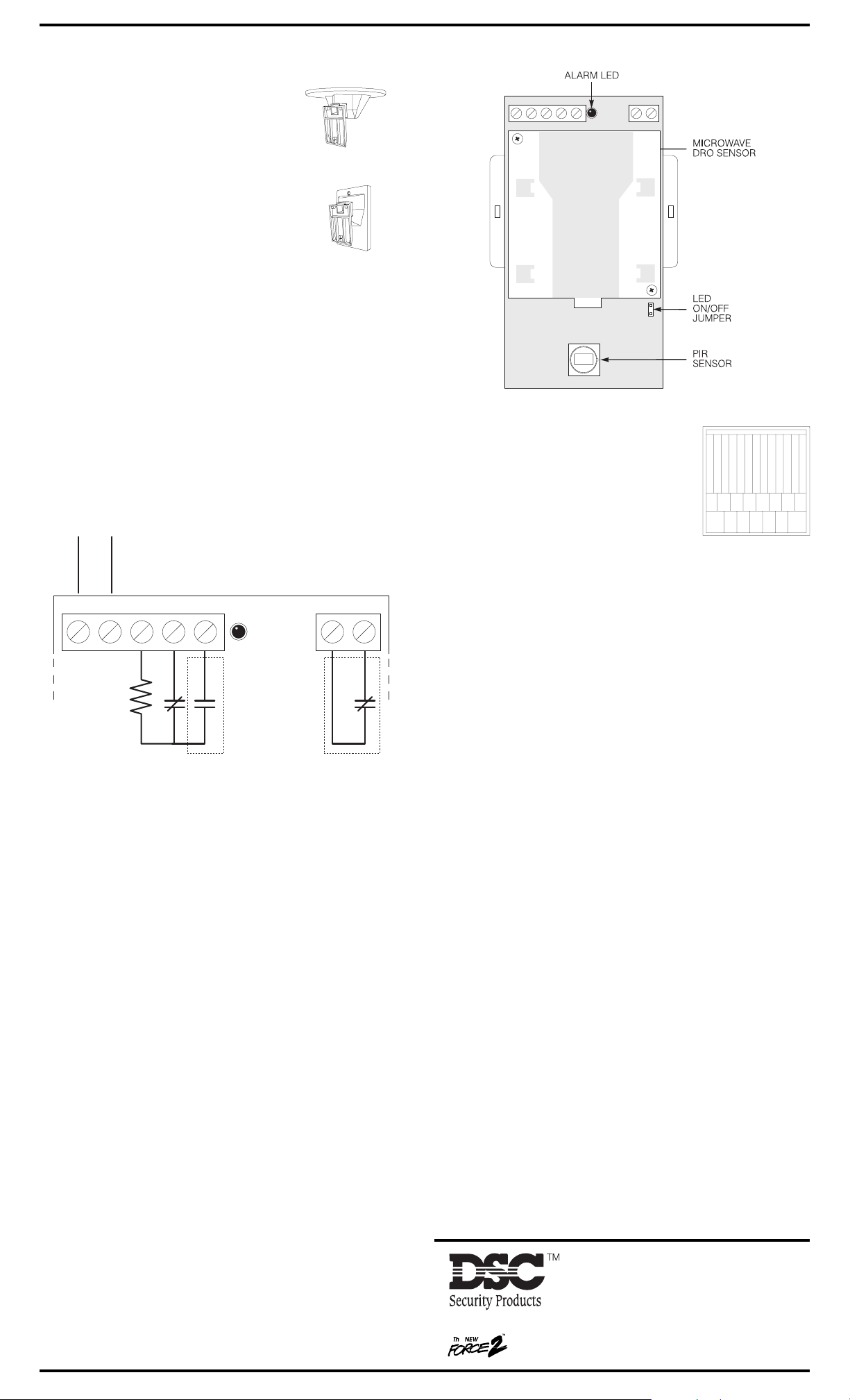

DM-C AND DM-W DETECTOR MOUNTING BRACKETS

Page 2

Use the optional DM-W Wall Mount and DM-C Ceiling Mount

brackets to solve difficult placement

problems. The DM-W and DM-C

DM-CDM-C

DM-C

DM-CDM-C

Ceiling Mounting BracketCeiling Mounting Bracket

Ceiling Mounting Bracket

Ceiling Mounting BracketCeiling Mounting Bracket

mount to either the wall or ceiling and

allow for full vertical and horizontal

positioning of the motion detector the detector can be tilted up or down

and rotated through 90° to obtain the

best position for optimal coverage.

The New Force 2 has been designed

to be fully compatible with the DM-W

DM-WDM-W

DM-W

DM-WDM-W

Wall Mounting BracketWall Mounting Bracket

Wall Mounting Bracket

Wall Mounting BracketWall Mounting Bracket

and DM-C brackets. Contact your

DSC distributor for more information.

IMPORTANT NOTE: Maximum

detection coverage occurs when the

FORCE 2 is mounted at the height

specified in the mounting instructions and the mounting surface

is vertical. If this cannot be achieved with a mounting bracket,

then detector coverage may be less than specified.

WIRING

Once the detector is mounted in the desired location, connect the

wiring as shown below. Note that various models have the

following optional features.

FORCE 2 - OPTIONS

F2-210F2-210

F2-210 ....................... ‘A’ Alarm contact only

F2-210F2-210

F2-211F2-211

F2-211 ....................... ‘A’ Alarm contact & Tamper switch

F2-211F2-211

F2-212F2-212

F2-212 ....................... ‘C’ Alarm contact & Tamper switch

F2-212F2-212

NOTE: Contacts are shown in the non-alarm state with power

applied to the detector.

POWER

12VDC30mA

ALARM

Contacts Rated

100mA @ 24V

DC

GND +12 C NC NO T1 T2

10Ω

NC NO

OPTION OPTION

TAMPER

Contacts Rated

100mA @ 24V

DC

POWER UP

Upon application of power, the alarm indicator will be illuminated

for 60 seconds to indicate the unit is warming up. During this

period, the alarm relay is held in its normal non-alarm state. After

the 60 second warm-up period, the alarm indicator will go out and

the unit will respond to motion in the protected area.

ALARM INDICATOR ON/OFF JUMPER J1

With Jumper J1 OFF, the alarm indicator will turn on each time the

unit goes into alarm. With J1 ON, the alarm indicator is disabled.

WALK TESTING

It is imperative that the unit be thoroughly walk tested after mounting

to ensure that coverage extends over the desired area.

Once coverage has been confirmed, Jumper J1 may be set to the

ON position to disable the alarm LED indicator.

IMPORTANT NOTE: Upon installation, the unit should be

thoroughly tested to verify proper operation. The end user should

be instructed on how to perform walk tests, and should perform a

walk test at least once per year.

COMPONENT LOCATIONS

J1

PIR LENS

TOP

The PIR lens is mounted with the textured

side facing in (smooth side facing out).

Note that the long lens elements are at the

top when the lens is properly positioned.

Ensure the lens is properly seated, and

that the lens holder is securely snapped

into place.

PIR LENS

LIMITED WARRANTY

Digital Security Controls Ltd. warrants that for a period of five years

from the date of purchase, the product shall be free of defects in

materials and workmanship under normal use and that in fulfilment

of any breach of such warranty, Digital Security Controls Ltd. shall,

at its option, repair or replace the defective equipment upon return

of the equipment to its repair depot. This warranty applies only to

defects in parts and workmanship and not to damage incurred in

shipping or handling, or damage due to causes beyond the control

of Digital Security Controls Ltd. such as lightning, excessive

voltage, mechanical shock, water damage, or damage arising out

of abuse, alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and

is and shall be in lieu of any and all other warranties, whether

expressed or implied and of all other obligations or liabilities on the

part of Digital Security Controls Ltd. Digital Security Controls Ltd.

neither assumes, nor authorizes any other person purporting to act

on its behalf to modify or to change this warranty, nor to assume

for it any other warranty or liability concerning this product.

In no event shall Digital Security Controls Ltd. be liable for any

direct, indirect or consequential damages, loss of anticipated

profits, loss of time or any other losses incurred by the buyer in

connection with the purchase, installation or operation or failure

of this product.

WARNING: Digital Security Controls Ltd. recommends that the

entire system be completely tested on a regular basis. However,

despite frequent testing, and due to, but not limited to, criminal

tampering or electrical disruption, it is possible for this product

to fail to perform as expected.

IMPORTANT INFORMATION

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY DIGITALCHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY DIGITAL

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY DIGITAL

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY DIGITALCHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY DIGITAL

SECURITY CONTROLS LTD. COULD VOID THE USER’S AUTHORITY TO OPERATESECURITY CONTROLS LTD. COULD VOID THE USER’S AUTHORITY TO OPERATE

SECURITY CONTROLS LTD. COULD VOID THE USER’S AUTHORITY TO OPERATE

SECURITY CONTROLS LTD. COULD VOID THE USER’S AUTHORITY TO OPERATESECURITY CONTROLS LTD. COULD VOID THE USER’S AUTHORITY TO OPERATE

THIS EQUIPMENT.THIS EQUIPMENT.

THIS EQUIPMENT.

THIS EQUIPMENT.THIS EQUIPMENT.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION ISTHIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION ISTHIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOTSUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOTSUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANYCAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANYCAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSEINTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSEINTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATION.UNDESIRED OPERATION.

UNDESIRED OPERATION.

UNDESIRED OPERATION.UNDESIRED OPERATION.

© Digital Security Controls Ltd.

Toronto, Canada

Tech Line: 1-800-387-3630

Web Site: www.dscgrp.com

is a trademark of Digital Security Controls Ltd.

29002410 R002

Loading...

Loading...