Page 1

PK5500/RFK5500/RFK5564 v1.3

Installation Instructions, Instructions d’Installation , Instrucciones de instalación

English, Français, Español

1 2 3

4 5 6

7 8

9

0

#

*

WARNING: Please refer to the System Installation Manual for information on limitations regarding product use and function and information on the limitations as to liability of the manufacturer.

NOTE: These instructions shall be used in conjunction with the system Installation Manual of the Control Panel with which this equipment is intended to be used.

ATTENTION: Ce manuel contient des informations sur les restrictions concernant le fonctionnement et l’utilisation du produit et des informations sur les restrictions en ce qui concerne la responsabilité du fabricant. La

totalité du manuel doit être lu attentivement.

NOTE: Ce manuel doit être utilisé en conjonction avec le Manuel d'installation du Panneau de contrôle.

ATENCIÓN: Consulte el Manual de instalación del sistema para obener información sobre las limitaciones del uso y funciones del producto, así como las limitaciones de la responsabilidad del fabricante.

NOTA: Estas instrucciones deberán utilizarse conjuntamente con el Manual de instalación del sistema del Panel de control con el que se vaya a utilizar este equipo.

Page 2

English

Installation Instructions

The PK55XX\RFK55XX keypads can be used on security systems with

up to 64 zones. These keypads are compatible with the latest version

of the folllowing DSC security systems:

•PC580 •PC585 •PC1555MX •PC1565

•PC1616 •PC1832 •PC1864 •PC5005

•PC5008 •PC5010 •PC5015 •PC5016

•PC5020

The RFK55XX keypads combine a wireless receiver with the respective

PK55XX keypad.

Specifications

• Temperature range: -10°C to +55°C (14°F to 131°F), Temperature

range for UL/ULC: 0°C to +49°C (32°F to 120°F)

• Humidity (MAX): 93%R.H.

• Plastic enclosure protection degree: IP30, IK04

• Voltage rating: 12VDC nominal

• Connects to control panel via 4-wire Keybus

• 1 keypad zone input/PGM output*

• PK55XX Current draw: 50mA (standby)/125mA (maximum)

• RFK55XX Current draw: 75mA (standby)/135mA (maximum)

• Wall mount tamper

• 5 programmable function keys

• Ready (Green LED), Armed (Red LED), Trouble (Yellow LED), AC

(Green LED)

• Low temperature sensor

• Frequency: 433.92MHz (RFK55XX-433)

• Up to 32 wireless zones (RFK5500 Only)

• Up to 64 wireless zones (RFK5564 and Power v4.6+Only)

*Zone not to be programmed as Fire type or 24h type.

Unpacking

The Power keypad package includes the following parts:

•One Power keypad •Keypad inner door labels

•Four mounting screws •1 tamper switch

•2 end-of-line resistors •Installation Instructions

Mounting

You should mount the keypad where it is accessible to designated

points of entry and exit. Once you have selected a dry and secure location, perform the following steps to mount the keypad.

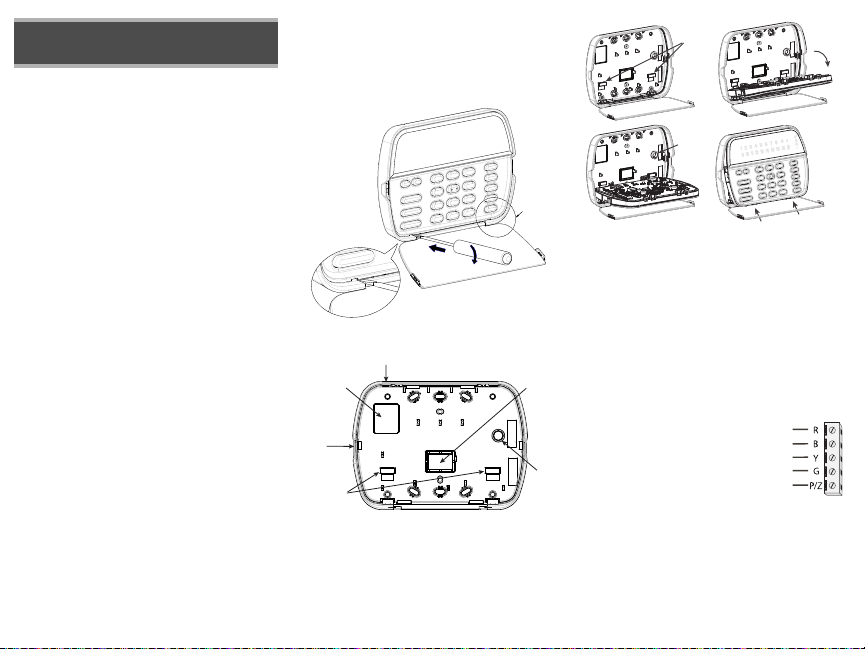

Disassemble Keypad

1. Insert a flat head screwdriver into the provided slot (first of two)

2. Move screwdriver toward the back plastic and lift as in the below diagram. This will unhook one side of the front plastic.

3. Repeat step # 1 and 2 on the second provided slot to disconnect the

front plastic and allow access for wiring.

3

1

2

Mount and Wire Keypad

Knock Out

Wiring Slot

Knock Out

Hooks

Knock Out

Tamper

1.

3.

1. Secure Keypad to wall using mounting holes. Use all 4 screws provided

unless mounting on a single gang box.

2. Place keypad into hooks on the backplate and swing down to engage.

3. Run wire through wiring slot or knockouts. Connect Keybus and PGM/Zone

wiring to keypad. Place tamper switch into tamper hole on backplate.

4. Remove keypad from hooks. Place keypad into backplate, ensure the wire

is pushed back into the wall as much as possible. Route the wire inside the

keypad ensuring high components are avoided. Snap the front assembly

closed, ensuring that there is no pressure to the keypad from the wire

below.

NOTE: If any tension found between the front keypad assembly and wiring,

please open the keypad reroute the wire and close again. Repeat these

steps until the keypad is closed properly.

Wiring

1. Before wiring the unit, ensure that all

power (AC transformer and battery) is disconnected from the control panel.

2. Connect the four Keybus wires from the control panel (red, black, yellow and green) to

the keypad terminals. Refer to diagram:

3. If programmed as an input, you can connect a device - such as a door contact - to

the ‘P/Z’ terminal of the keypad. This eliminates the need to run wires

back to the control panel for the device. To connect the zone, run one wire

from the device to the ‘P/Z’ terminal and the other wire from the device to

the B (black) terminal. For powered devices, run the red wire to the R

(positive) terminal and the black wire to the B (negative) terminal. When

using end of line supervision, connect the zone according to one of the

configurations outlined in your system’s Installation Manual.

4. If the ‘P/Z’ terminal is programmed as an output, the output follows the

PGM programmed in Section [080]. A small relay, buzzer or other DC

Hooks

Tamper

2.

4.

Press to Snap

PK55XX/RFK55XX

RED

BLK

YEL

GRN

To zone or

PGM output

Swing

to engage

Page 3

operated device may be connected between the positive supply voltage

and the ‘P/Z’ terminal (maximum load is 50mA).

NOTE: For UL Residential Fire Installations use at least one additional DSC

compatible keypad in conjunction with an RFK55XX keypad or install the

RFK55XX keypads within 3 feet from the control unit and mechanically protect the keybus wires

Applying Power

Once all wiring is complete, and the equipment is secured to the building

structure with at least two screws apply power to the control panel:

1. Connect the battery leads to the battery.

2. Connect the AC transformer.

For more information on control panel power specifications, see the control

panel Installation Manual.

Broadcasting LCD Labels

All LCD programming is done per keypad. If more than one LCD keypad is

present on the system, labels programmed at one keypad can be broadcast

to all other LCD keypads. Perform the following procedure in order to broadcast labels:

Step 1 - Program one LCD keypad completely.

Step 2 - Make sure all LCD keypads are connected to the Keybus.

Step 3 - Enter keypad programming by pressing [,][8][Installer

Code][,], then enter section [998] at the keypad that was programmed.

Press [,] to confirm the label broadcast. The keypad will now broadcast all

the information programmed to all the other LCD keypads on the system.

Step 4 - When the keypad is finished press the [#] key to exit.

NOTE: LCD Label broadcast from this keypad is only compatible

with PC1616/1832/1864 control panels and other PK5500/

RFK5500/RFK5564 keypads.

Language Programming

Hold (<>) keys for 2 seconds to enter language programming, scroll to

the desired language and Press [,] to select.

NOTE: If section [077] option 4 is OFF, language programming

can only be performed while in installers programming.

Enrolling the Keypad

The keypad will need to be assigned to a partition and slot if supervision or

keypad zones are being used. Keypad assignments and keypad option programming must be done at each keypad individually.

The 1st digit of keypad assignment is used to determine partition assignment (1 to 8). If partitioning is not used, enter [1]. For Global Keypads,

enter [0].

The 2nd digit of keypad assignment is used to determine slot assignment

for keypad supervision. Each keypad will be assigned a different slot number from 1 to 8. PK5500 and RFK5500/64 LCD keypads come defaulted in

slot 8. If LCD keypads are used one LCD keypad must remain in slot 8.

NOTE: The RFK55XX enrolls as two modules:

Keypad 8 = keypad section of the RFK55XX

PC5132 = receiver section of the RFK55XX

NOTE: Deleting all wireless devices from the RFK55XX or defaulting the

RFK55XX will cause a supervisory fault.

Enter the following at each keypad installed on the system:

1. Enter Installer Programming by pressing [,][8][Installer’s Code]

2. Press [000] for Keypad Programming

3. Press [0] for Partition and Slot Assignment

4. Enter the 1st digit (0 to 8 for partition assignment)

5. Enter the 2nd digit (1 to 8 for slot assignment supervision)

6. Press the [#] key twice to exit programming.

7. After assigning all keypads, perform a supervisory reset by entering

[,][8][Installer’s Code][902] and wait for 60 seconds.

8. Press the [#] key to exit programming after 60 seconds.

Programming Labels

1. Enter keypad programming by pressing [,][8][Installer Code][,]. Enter

the 3-digit section number for the label to be programmed.

2. Use the arrow keys (<>) to move the underline bar underneath the letter to be changed.

3. Press the number keys [1] to [9] corresponding to the letter you require.

The first time you press the number the first letter will appear. Pressing the

number key again will display the next letter

[1] - A, B, C, 1 [4] - J, K, L, 4 [7] - S, T, U, 7 [0] - Space

[2] - D, E, F, 2 [5] - M, N, O, 5 [8] - V, W, X, 8

[3] - G, H, I, 3 [6] - P, Q, R, 6 [9] - Y, Z, 9,0

4. When the required letter or number is displayed use the arrow keys

(<>) to scroll to the next letter.

5. When you are finished programming the Zone Label, press the [,] key,

scroll to “Save,” then press [,].

6. Continue from Step 2 until all Labels are programmed.

Label Library

The Label Library is a database of words commonly used when programming labels. Individual words can be combined as needed. e.g.,

Each line of the display supports a maximum of 14 characters. If a

Door.

word will not fit on a line, scroll right until the cursor appears at the first

character of the second line then add the word.

To program a custom label using the Label Library:

1. Enter keypad programming and select the label to change. e.g.,

[*][8][Installer Code][*][001] (to program the label for zone 01).

2. Press [*] to open the “Select Options” menu.

3. Press [*] again to select the “Words” option.

4. Enter the 3-digit number corresponding to a word (see Words Table

below) or use the scroll keys [<][>] to view words in the library.

5. Press [*] to select the word.

6. To add another word, repeat the above procedure from step 2.

7. To add a space, press the right scroll key [>].

.

Front +

8. To clear characters, select “Clear to End” or “Clear Display” from the

“Select Options” menu.

9. To save the current label, press [*] to access the “Select Options”

menu, scroll left [<] to “Save” then press [*] again.

Changing Brightness/Contrast

LCD Keypads

1. Press [,][6][Master code].

2. Use the [<][>] keys to scroll to either Brightness Control or Contrast Control.

3. Press [,] to select the setting you want to adjust.

4. a) ‘Brightness Control’: There are multiple backlighting levels. Use the [<][>]

keys to scroll to the desired level.

b) ‘Contrast Control’: There are 10 different display contrast levels. Use the

[<][>] keys to scroll to the desired contrast level.

5. To exit, press [#].

Changing the Buzzer Level

LCD Keypads

1. Press [,][6][Master Code].

2. Use the [<][>] keys to scroll to Buzzer Control.

3. Press [,]to select Buzzer Control.

4. There are 21 different levels. Use the [<][>] keys to scroll to the desired

level.

5. To exit, press [#].

Broadcasting Door Chime

All door chime programming is done per keypad. If more than one keypad is

present on the system, door chime programmed at one keypad can be broadcast to all other keypads. Perform the following procedure in order to broadcast

door chime:

Step 1 - Program one keypad completely.

Step 2 - Make sure all keypads are connected to the Keybus.

Step 3 - Enter keypad programming by pressing [,][8][Installer Code][,], then

enter section [994] at the keypad that was programmed. Press [,] to

confirm the chime programming broadcast. The keypad will now broadcast all the door chime information programmed to all the other keypads

on the system.

Step 4 - When the keypad is finished press the [#] key to exit.

Page 4

Keypad Enrollment

Enter keypad programming by pressing [,][8][Installer’s Code][000].

[0] Partition / Slot Assignment

Digit Option Valid Range Default

1st Partition Assignment (0=Global Keypad) 0 to 8 1 I_____I

2nd Slot Assignment 1 to 8 LED,ICON=1/LCD=8 I_____I

[1]-[5] Function Key Assignment

Function Key Button Valid Range Default Function

[1] Function Key 1 Assignment 00 to 32 03 Stay Arm I_____I_____I

[2] Function Key 2 Assignment 00 to 32 04 Away Arm I_____I_____I

[3] Function Key 3 Assignment 00 to 32 06 Chime On/Off I_____I_____I

[4] Function Key 4 Assignment 00 to 32 14 Sensor Reset I_____I_____I

[5] Function Key 5 Assignment 00 to 32 16 Quick Exit I_____I_____I

Keypad Function Keys

Refer to your system installation manual for a complete list of all function key options available for your system.

[00] - Null [08] - Bypass Mode [16] - Quick Exit [26] - Time & Date Program

[01] - Partition 1 Select [09] - Trouble Display [17] - Activate Stay/Away [27] - Partition 3 Select

[02] - Partition 2 Select [10] - Alarm Memory [18] - *Global Away Arm [28] - Partition 4 Select

[03] - Stay Arm [11] - User Programming [19] - Command Output 3 [29] - Partition 5 Select

[04] - Away Arm [12] - User Functions [21] - Command Output 4 [30] - Partition 6 Select

[05] - No Entry Arm [13] - Command Output 1 [22] - *Global Disarming [31] - Partition 7 Select

[06] - Chime On/Off [14] - Command Output 2 [23] - Bypass Recall [32] - Partition 8 Select

[07] - System Test [15] - *Global Stay Arm [24] - Bypass Group Recall [33] - Local PGM Activate

*Available only on the PC1616/PC1832/PC1864 version 4.2 or higher.

Keypad Programming

Enter keypad programming by pressing [,][8][Installer Code][,]

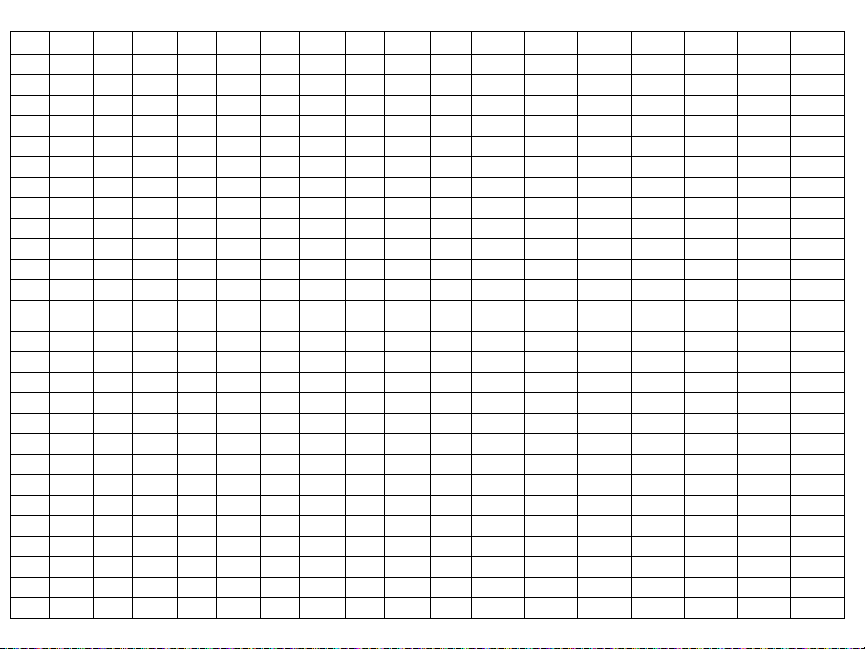

[001]-[064] Zone Label 1 to 64

ex. For Zone 1 enter section [001], for Zone 2 enter section [002] etc. Default: “Zone 1” - “Zone 64”

Section Zone Label

[001] to [064] 1 to 64

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[065] Fire Alarm Label (28 Characters)

Default:“Fire Zone”

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[065]

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[066] Fail to Arm Event Message

Default: “System Has Failed to Arm”

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[066]

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[067] Alarm When Armed Event Message

Default: “Alarm Occurred While Armed < >”

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[067]

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[071] First User Display Mask

Default Option ON OFF

ON I____I 1 Hold [P]anic Key prompt ON Hold [P]anic Key prompt OFF

ON I____I 2 Auto-arm Control/Time prompt ON Auto-arm Control/Time prompt OFF

ON I____I 3 Quick Arm prompt ON Quick Arm prompt OFF

ON I____I 4 Interior Arm prompt ON Interior Arm prompt OFF

OFF I____I 5 Quick Exit prompt ON Quick Exit prompt OFF

OFF I____I 6 Thermostat Control prompt ON Thermostat Control prompt OFF

OFF I____I 7 ACK All Trouble Prompt ON ACK All Trouble Prompt OFF

OFF I____I 8 Music Input prompt ON Music Input prompt OFF

[072] Second User Display Mask

Default Option ON OFF

ON I____I 1 User-initiated Call-up prompt ON User-initiated Call-up prompt OFF

OFF I____I 2 For Future Use

OFF I____I 3 Walk Test prompt ON Walk Test prompt OFF

ON I____I 4 Command Output#1 prompt ON Command Output#1 prompt OFF

ON I____I 5 Command Output#2 prompt ON Command Output#2 prompt OFF

OFF I____I 6 Command Output#3 prompt ON Command Output#3 prompt OFF

OFF I____I 7 Command Output#4 prompt ON Command Output#4 prompt OFF

OFF I____I 8 For Future Use

[073] Download LCD Message Duration

Default: 003 I_____I_____I_____I (Valid entries are 000-255), 000=Unlimited Message Disp.This

number represents the number of times the Downloaded message is cleared by pressing any key while the

message is up after timeout).

Page 5

[074] Key Options

Default Option ON OFF

ON I____I 1 [F]ire Key Enabled [F]ire Key Disabled

ON I____I 2 [A]uxiliary Key Enabled [A]uxiliary Key Disabled

ON I____I 3 [P]anic Key Enabled [P]anic Key Disabled

OFF I____I 4-8 For Future Use

[076] First Keypad Options

Default Option ON OFF

ON I____I 1 Display Code when Programming Display “Xs” when Programming

ON I____I 2 Local Clock Display ON Local Clock Display OFF

OFF I____I 3 Local Clock Displays 24-hr Time Local Clock Displays AM/PM

ON I____I 4 Auto Alarm Memory Scroll Enabled Auto Alarm Memory Scroll Disabled

OFF I____I 5 Local Display of Temperature ON Local Display of Temperature OFF

ON I____I 6 Bypass Options prompt ON Bypass Options prompt OFF

OFF I____I 7 For Future Use

OFF I____I 8 Auto-Scroll Open Zones ON Auto-Scroll Open Zones OFF

[077] Second Keypad Options

Default Option ON OFF

ON I____I 1 Chime Enabled for Zone Openings Chime Disabled for Zone Openings

ON I____I 2 Chime Enabled for Zone Closings Chime Disabled for Zone Closings

OFF I____I 3 5th Terminal is Keypad PGM Output 5th Terminal is Keypad Zone Input

ON I____I 4 Language Selection Enabled Language Selection Disabled

OFF I____I 5 Power LED Enabled Power LED Disabled

ON I____I 6 Power LED indicates AC present Power LED indicates AC absent

ON I____I 7 Alarms always Displayed When Armed Alarms not Displayed When Armed

OFF I____I 8 Low Temperature Warning Enabled Low Temperature Warning Disabled

[080] PGM Terminal 1

I_______I _______I 1-14 Follow PGM Output Number, 15 Local PGM Pulse , 16 Local PGM T oggle

Default: 01

[082] Local PGM Output Pulse Activation Time

Default: 00 I_______I _______I Minutes (Valid Range 00-99)

Default: 05 I_______I _______I Seconds (Valid Range 00-99)

[101]-[108] Partition Labels

ex. For Partition 1 enter section [101], for Partition 2 enter section [102] etc.

Section Partition Label

[101] to [108] 1 to 8

NOTE: Partition 1 Label is also used as the System Label

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

[120]-[151] Command Output Labels

Default: “Command_O/P_1” - “Command_O/P_4”

For Partition 1 Command O/P 1 to 4 enter [120] to [123] For Partition 5 Command O/P 1 to 4 enter [136] to [139]

For Partition 2 Command O/P 1 to 4 enter [124] to [127] For Partition 6 Command O/P 1 to 4 enter [140] to [143]

For Partition 3 Command O/P 1 to 4 enter [128] to [131] For Partition 7 Command O/P 1 to 4 enter [144] to [147]

For Partition 4 Command O/P 1 to 4 enter [132] to [135] For Partition 8 Command O/P 1 to 4 enter [148] to [151]

Section Part

[120]-[151] 1 to 8 1 to 4

[201]-[264] Door Chime Sound Programming

You can program the keypad to make up to four different door chime sounds for individual zones.

ex. For Zone 1 enter section [201], for Zone 2 enter section [202] etc.

Default Option ON OFF

ON I____I 1 6 Beeps Disabled

OFF I____I 2 “Bing-Bing” Sound Disabled

OFF I____I 3 “Ding-Dong” Sound Disabled

OFF I____I 4 Alarm Tone Disabled

OFF I____I 5-8 For Future Use

[994][,] Initiate Global Keypad Chime Broadcast

[995][,] Reset Keypad Options to Factory Default

[996][,] Label Default

[997] View Software Version

[998][,] Initiate Global Label Broadcast

[999][,] Reset Keypad EEPROM to Factory Defaults

Cmd.

Output

Label

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I

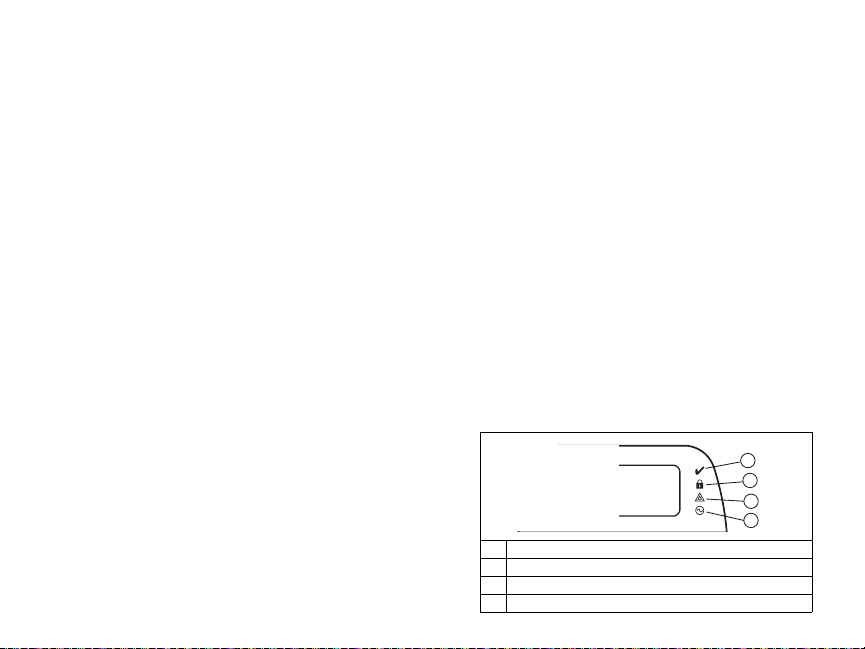

Keypad Display Symbols

1

2

3

4

1 Ready Light (green) – If the Ready light is on, the system is ready for arming.

2 Armed Light (red) – If the Armed light is on, the system has been armed successfully.

3 System Trouble – Indicates that a system trouble is active.

4 AC – Indicates that AC is present at the main panel.

Page 6

Wireless Integration (RFK55XX Only)

NOTE: Power v4.5 and lower uses 2 -digit subsections.

Compatible Wireless Devices

The RFK55XX can receive signals from the following devices:

• WLS912L-433 Glass Break Detector * • WS4945 Mini Door/Window Contact*

• WLS914-433 Pet Immune PIR* • WS4965*/WS8965 Tri-Zone Contact

• WS4904(P)*/8904(P) Pet Immune • WS4969 Wireless Keys

• WS4916*/8916 Smoke Detector • WS4975/8975 Door/Window Contact

• WS4926 Smoke Detector* • WS4985/8985 Flood Detector

• WS4938 Panic Button* • WS4913*/8913 CO Detector**

• WS4939*/8939 Wireless Key • WS4920 Wireless Repeater*

* Only these models are UL listed.

** CO Detector requires PC1616/1832/1864 v4.5 or higher.

Downloading

The RFK55XX product has an integrated wireless receiver. When downloading

to this keypad, please select the RF5132 v5.4 file. When using an RFK5564

keypad, please select the RFK5164 v5.4 file. DLS IV must be used in order to

have the capability of downloading to this keypad.

Testing Wireless Devices

1. Temporarily put the wireless devices in the places you want to mount them.

2. At a system keypad, enter [,][8][Installer Code].

3. Enter programming section [904], then enter the zone number.

NOTE: If global placement test is enabled (Section [900], option 8

ON) enter [001] to test all zones.

4. Activate the device being tested until a result is displayed on the keypad

or sounded by the keypad or bell.

Result LED/ICON Keypad LCD Keypad Bell/Buzzer

Good Light 1 ON Steady Good 1 Beep/Squawk

Bad Light 3 ON Steady Bad 3 Beeps/Squawks

While in placement test the Ready and Armed LEDs are used to indicate the

reception of a valid signal from a wireless device. The Green (Ready) LED

indicates that a transmission was received from a device that is enrolled on

the system. The Red (Armed) LED indicates that a transmission was received

from a device that is not enrolled on the system. The corresponding LED will

flash once per transmission.

Activate the device until you get 3 good results in a row. Wait 10 seconds

between each test on the same device. You may mount wireless devices

where results were good.

Devices indicating a bad result must be moved to another location. You may

only have to move the device a few inches to correct a bad result.

NOTE: Do not mount any device where a “bad” test result was indicated.

Testing Portable Device Reception

To test portable devices (e.g., WS49X9) press the button(s) at several different

points in the installation, to confirm the coverage area. If these devices do not

operate from all points in the installation, you will need to move the RFK55XX.

Receiver Placement Test

The RFK5500/RFK5564 performs best in locations where RF interference is

minimal. To find an optimal mounting location for the keypad, perform the

following placement test:

1. Temporarily connect the Keybus wires to the keypad (refer to wiring

instructions).

2. Hold the keypad in the intended mounting location.

3. Enter keypad programming mode by pressing [,][8][Installer Code],

then enter section [904].

4. If the yellow Trouble LED is on, interference levels are high and a new

mounting location should be found. If the LED is flashing or off, interference is low and the location is good.

Repeater Placement Test (in event of interference)

Power v4.6 and higher

If the “Receiver Placement Test” described above indicated the presence of

interference and you are unable to move the keypad from the interference

source, perform the following procedure while installing a WS4920 Repeater.

1. Temporarily mount the WS4920 in the desired location.

2. Use the WS4920 to test for signal noise. Refer to the WS4920 installation

manual for instructions.

3. If no noise is detected in the desired mounting location, test for adequate

signal strength through the interference at the RFK5500/RFK5564.

4. At the system keypad, enter [

5. Enter programming section [804][900] then set option 1 to “OFF”. This

option returns a “good” placement test result if the WS4920 signal

strength in the vicinity of the RFK5500/RFK5564 is within acceptable levels through the interference.

6. Exit section [804][900].

7. Enter programming section [904] and perform placement test as described

in “Testing Wireless Devices.”

8. If “bad” test results are returned, move the repeater closer to the

RFK5500/RFK5564.

9. Once “good” test results are achieved, set option 1 in section [804][900]

to “ON.”

NOTES

• All devices on the system should be enrolled on one of the WS4920

repeaters on the system.

• Perform a Repeater Placement Test only when installing the RFK5500/

5564 in areas of high interference. The preferred solution is to move the

receiver to another location. Please move the receiver as an alternate to

installing a WS4920 repeater.

Do not install both repeater and receiver in high noise areas.

•

,][8][Installer Code].

Replacing Wireless Device Batteries

1. Remove the cover of the device from its backplate. This creates a tamper

condition on the zone.

2. Refer to the battery installation instructions on the Installation Sheet of

each component. Be sure to note the proper orientation of the batteries

as you install them.

3. When the fresh batteries are in place, re-attach the cover to the backplate. The tamper is restored and the zone sends a battery trouble restoral signal to the receiver. The battery trouble is now clear and the device

should function normally.

NOTE: When batteries in one device need to be replaced, the batteries

in all devices should be replaced at the same time.

Troubleshooting

1. When I enter the zone number when adding a wireless device, the

keypad gives me a long beep.

•The keypad must be properly connected to the Keybus to enter ESNs.

2. I have entered the ESN for the device but when I violate the device,

the zone does not show open on the keypad.

Check the following:

•Ensure the ESN has been entered correctly.

•Ensure that the zone is enabled for the partition (if partition programming is used).

•Ensure that the wireless zone is not assigned to a zone used by

PC5108 modules, an on-board zone or a keypad zone.

•Ensure that the zone is programmed for something other than “Null

Operation” and that the wireless zone attribute is turned on.

3. When I try a module placement test I get no result or “Bad” results.

Check the following:

•Verify that you are testing the correct zone.

•Verify that the device is in range of the keypad. Try testing the device

in the same room as the receiver.

•Confirm that the keypad is properly connected to the Keybus.

•Check that you are testing the zone correctly. Refer to the instruc-

tions that came with the device.

•Check that the batteries are working and installed correctly.

•Look for large metal objects that may be preventing the signal from

reaching the keypad.

•The device must be located where consistent “Good” results are

obtained. If several devices show “Bad” results, or if panic pendants

and wireless keys operate inconsistently, move the receiver.

4. The LED on the motion detector does not turn on when I walk in front

of the unit.

•The LED is for walk test purposes only. See your WS4904P-433/

WS4904P(L)-433 instruction sheet for walk test instructions.

Page 7

Wireless Programming (Power v4.6 and higher)

[804] Wireless Receiver Programming (RFK55XX Only)

Enter Wireless programming by pressing [,][8][Installer’s Code][804]

[001]-[064] Wireless Device Serial Numbers

Default =000000 Zones 33-64 for RFK5564 only

[001] Zone 1 I_____I_____I_____I_____I_____I_____I [033] Zone 33 I_____I_____I_____I_____I_____I_____I

[002] Zone 2 I_____I_____I_____I_____I_____I_____I [034] Zone 34 I_____I_____I_____I_____I_____I_____I

[003] Zone 3 I_____I_____I_____I_____I_____I_____I [035] Zone 35 I_____I_____I_____I_____I_____I_____I

[004] Zone 4 I_____I_____I_____I_____I_____I_____I [036] Zone 36 I_____I_____I_____I_____I_____I_____I

[005] Zone 5 I_____I_____I_____I_____I_____I_____I [037] Zone 37 I_____I_____I_____I_____I_____I_____I

[006] Zone 6 I_____I_____I_____I_____I_____I_____I [038] Zone 38 I_____I_____I_____I_____I_____I_____I

[007] Zone 7 I_____I_____I_____I_____I_____I_____I [039] Zone 39 I_____I_____I_____I_____I_____I_____I

[008] Zone 8 I_____I_____I_____I_____I_____I_____I [040] Zone 40 I_____I_____I_____I_____I_____I_____I

[009] Zone 9 I_____I_____I_____I_____I_____I_____I [041] Zone 41 I_____I_____I_____I_____I_____I_____I

[010] Zone 10 I_____I_____I_____I_____I_____I_____I [042] Zone 42 I_____I_____I_____I_____I_____I_____I

[011] Zone 11 I_____I_____I_____I_____I_____I_____I [043] Zone 43 I_____I_____I_____I_____I_____I_____I

[012] Zone 12 I_____I_____I_____I_____I_____I_____I [044] Zone 44 I_____I_____I_____I_____I_____I_____I

[013] Zone 13 I_____I_____I_____I_____I_____I_____I [045] Zone 45 I_____I_____I_____I_____I_____I_____I

[014] Zone 14 I_____I_____I_____I_____I_____I_____I [046] Zone 46 I_____I_____I_____I_____I_____I_____I

[015] Zone 15 I_____I_____I_____I_____I_____I_____I [047] Zone 47 I_____I_____I_____I_____I_____I_____I

[016] Zone 16 I_____I_____I_____I_____I_____I_____I [048] Zone 48 I_____I_____I_____I_____I_____I_____I

[017] Zone 17 I_____I_____I_____I_____I_____I_____I [049] Zone 49 I_____I_____I_____I_____I_____I_____I

[018] Zone 18 I_____I_____I_____I_____I_____I_____I [050] Zone 50 I_____I_____I_____I_____I_____I_____I

[019] Zone 19 I_____I_____I_____I_____I_____I_____I [051] Zone 51 I_____I_____I_____I_____I_____I_____I

[020] Zone 20 I_____I_____I_____I_____I_____I_____I [052] Zone 52 I_____I_____I_____I_____I_____I_____I

[021] Zone 21 I_____I_____I_____I_____I_____I_____I [053] Zone 53 I_____I_____I_____I_____I_____I_____I

[022] Zone 22 I_____I_____I_____I_____I_____I_____I [054] Zone 54 I_____I_____I_____I_____I_____I_____I

[023] Zone 23 I_____I_____I_____I_____I_____I_____I [055] Zone 55 I_____I_____I_____I_____I_____I_____I

[024] Zone 24 I_____I_____I_____I_____I_____I_____I [056] Zone 56 I_____I_____I_____I_____I_____I_____I

[025] Zone 25 I_____I_____I_____I_____I_____I_____I [057] Zone 57 I_____I_____I_____I_____I_____I_____I

Zone 26 I_____I_____I_____I_____I_____I_____I [058] Zone 58 I_____I_____I_____I_____I_____I_____I

[026]

[027] Zone 27 I_____I_____I_____I_____I_____I_____I [059] Zone 59 I_____I_____I_____I_____I_____I_____I

[028] Zone 28 I_____I_____I_____I_____I_____I_____I [060] Zone 60 I_____I_____I_____I_____I_____I_____I

[029] Zone 29 I_____I_____I_____I_____I_____I_____I [061] Zone 61 I_____I_____I_____I_____I_____I_____I

[030] Zone 30 I_____I_____I_____I_____I_____I_____I [062] Zone 62 I_____I_____I_____I_____I_____I_____I

[031] Zone 31 I_____I_____I_____I_____I_____I_____I [063] Zone 63 I_____I_____I_____I_____I_____I_____I

[032] Zone 32 I_____I_____I_____I_____I_____I_____I [064] Zone 64 I_____I_____I_____I_____I_____I_____I

[081] Wireless Supervisory Window

Default One Way Wireless

008 for EU; 096 for NA I______I______I______I

NOTE: This entry is in minutes and when multiplied by 15 determines the length of the supervisory

window; valid entries are 004 to 096, which correlates to 1 to 24 hours.

[082]-[085] Zone Transmitter Supervision Options

Default ON

Option 1 1 I_____I 9 I_____I 17 I_____I 25 I_____I

Option 2 2 I_____I 10 I_____I 18 I_____I 26 I_____I

Option 3 3 I_____I 11 I_____I 19 I_____I 27 I_____I

Option 4 4 I_____I 12 I_____I 20 I_____I 28 I_____I

Option 5 5 I_____I 13 I_____I 21 I_____I 29 I_____I

Option 6 6 I_____I 14 I_____I 22 I_____I 30 I_____I

Option 7 7 I_____I 15 I_____I 23 I_____I 31 I_____I

Option 8 8 I_____I 16 I_____I 24 I_____I 32 I_____I

[082]

Zone

Supervision

ON/OFF

[083]

Zone

Supervision

ON/OFF

[084]

Zone

Supervision

ON/OFF

[085]

Zone

Supervision

ON/OFF

[086]-[089] Zone Transmitter Supervision Options (for RFK5564 only)

Supervision

[086]

Default ON

Zone

Option 1 33 I_____I 41 I_____I 49 I_____I 57 I_____I

Option 2 34 I_____I 42 I_____I 50 I_____I 58 I_____I

Option 3 35 I_____I 43 I_____I 51 I_____I 59 I_____I

Option 4 36 I_____I 44 I_____I 52 I_____I 60 I_____I

Option 5 37 I_____I 45 I_____I 53 I_____I 61 I_____I

Option 6 38 I_____I 46 I_____I 54 I_____I 62 I_____I

Option 7 39 I_____I 47 I_____I 55 I_____I 63 I_____I

Option 8 40 I_____I 48 I_____I 56 I_____I 64 I_____I

ON/OFF

[087]

Zone

Supervision

ON/OFF

[088]

Zone

Supervision

ON/OFF

[089]

Zone

Supervision

ON/OFF

Wireless Key Programming

[101]-[116] Wireless Key Serial Number Default = 000000

[101] Key 1 I_____I_____I_____I_____I_____I_____I [109] Key 9 I_____I_____I_____I_____I_____I_____I

[102] Key 2 I_____I_____I_____I_____I_____I_____I [110] Key 10 I_____I_____I_____I_____I_____I_____I

[103] Key 3 I_____I_____I_____I_____I_____I_____I [111] Key 11 I_____I_____I_____I_____I_____I_____I

[104] Key 4 I_____I_____I_____I_____I_____I_____I [112] Key 12 I_____I_____I_____I_____I_____I_____I

[105] Key 5 I_____I_____I_____I_____I_____I_____I [113] Key 13 I_____I_____I_____I_____I_____I_____I

[106] Key 6 I_____I_____I_____I_____I_____I_____I [114] Key 14 I_____I_____I_____I_____I_____I_____I

[107] Key 7 I_____I_____I_____I_____I_____I_____I [115] Key 15 I_____I_____I_____I_____I_____I_____I

[108] Key 8 I_____I_____I_____I_____I_____I_____I [116] Key 16 I_____I_____I_____I_____I_____I_____I

Page 8

Keypad Function Keys

Please see your system installation manual for a complete list of all the function key options available for your system.

[00] - Null [13] [03] - Stay Arm [14] [04] - Away Arm [16] -

- [,][9] No Entry Arm

[05]

- [,][4] Chime On/Off

[06]

[,][7][1]

Command Output 1 [27] - Disarm (Off)

[,][7][2]

Command Output 2 [29] - Auxiliary Alarm

[,][0]

Quick Exit [30] - Panic Alarm

[17] -

[,][1]

Activate Stay/Away [33] - Night Arm

[25] - Instant Stay Arm

[141]-[156] Wireless Function Key Programming

Function 1

[141] Key 1 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Default 03

Function 2

Default 04

Function 3

Default 27

Function 4

Default 30

[142] Key 2 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[143] Key 3 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[144] Key 4 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[145] Key 5 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[146] Key 6 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[147] Key 7 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[148] Key 8 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[149] Key 9 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Function 1

Default 03

Function 2

Default 04

Function 3

Default 27

Function 4

Default 30

[150] Key 10 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[151] Key 11 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[152] Key 12 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[153] Key 13 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[154] Key 14 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[155] Key 15 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[156] Key 16 I_____I_____I I_____I_____I I_____I_____I I_____I_____I

[181] Wireless Keys (1-16) Partition Assignment Default = 01

Valid entries are 01-08, where partition 1 is 01 and partition 8 is 08.

Key 1 I_____I_____I Key 5 I_____I_____I Key 9 I_____I_____I Key 13 I_____I_____I

Key 2 I_____I_____I Key 6 I_____I_____I Key 10 I_____I_____I Key 14 I_____I_____I

Key 3 I_____I_____I Key 7 I_____I_____I Key 11 I_____I_____I Key 15 I_____I_____I

Key 4 I_____I_____I Key 8 I_____I_____I Key 12 I_____I_____I Key 16 I_____I_____I

[900] General Wireless Options

NA

EU

Default

Default

ON ON I____I 1

OFF OFF I____I 2, 4 For Future Use

ON OFF I____I 3 Wall Tamper Disabled Wall Tamper Enabled

ON OFF I____I 5 For Future Use For Future Use

OFF OFF I____I 6 For Future Use

ON OFF I____I 7 RF Jam Detect Disabled RF Jam Detect Enabled

OFF OFF I____I 8 Global Placement Test Individual Placement Test

NOTE: For UL Listed installations, the RF Jam detect feature must be enabled.

[903] RF Jam Detect Zone

Default: 00 I_____I_____I Valid entries = 01-64, 00 = No RF Jam Zone Enabled.

Select an unused zone that will be set to the tamper state when a jamming signal is detected.

Option ON OFF

Harsh Repeater Placement Test

Disabled

Harsh Repeater Placement Test

Enabled

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

IC:160A-RFK55XX4.

The term IC before the radio certification number signifies that the Industry Canada technical specifications

were met.

Page 9

Wireless Programming (Power v4.5 and lower)

Enter Wireless programming by pressing [,][8][Installer’s Code][804].

[01]-[32] Wireless Device Serial Number

[01] Zone 1 I_____I_____I_____I_____I_____I_____I [17] Zone 17 I_____I_____I_____I_____I_____I_____I

[02] Zone 2 I_____I_____I_____I_____I_____I_____I [18] Zone 18 I_____I_____I_____I_____I_____I_____I

[03] Zone 3 I_____I_____I_____I_____I_____I_____I [19] Zone 19 I_____I_____I_____I_____I_____I_____I

[04] Zone 4 I_____I_____I_____I_____I_____I_____I [20] Zone 20 I_____I_____I_____I_____I_____I_____I

[05] Zone 5 I_____I_____I_____I_____I_____I_____I [21] Zone 21 I_____I_____I_____I_____I_____I_____I

[06] Zone 6 I_____I_____I_____I_____I_____I_____I [22] Zone 22 I_____I_____I_____I_____I_____I_____I

[07] Zone 7 I_____I_____I_____I_____I_____I_____I [23] Zone 23 I_____I_____I_____I_____I_____I_____I

[08] Zone 8 I_____I_____I_____I_____I_____I_____I [24] Zone 24 I_____I_____I_____I_____I_____I_____I

[09] Zone 9 I_____I_____I_____I_____I_____I_____I [25] Zone 25 I_____I_____I_____I_____I_____I_____I

[10] Zone 10 I_____I_____I_____I_____I_____I_____I [26] Zone 26 I_____I_____I_____I_____I_____I_____I

[11] Zone 11 I_____I_____I_____I_____I_____I_____I [27] Zone 27 I_____I_____I_____I_____I_____I_____I

[12] Zone 12 I_____I_____I_____I_____I_____I_____I [28] Zone 28 I_____I_____I_____I_____I_____I_____I

[13] Zone 13 I_____I_____I_____I_____I_____I_____I [29] Zone 29 I_____I_____I_____I_____I_____I_____I

[14] Zone 14 I_____I_____I_____I_____I_____I_____I [30] Zone 30 I_____I_____I_____I_____I_____I_____I

[15] Zone 15 I_____I_____I_____I_____I_____I_____I [31] Zone 31 I_____I_____I_____I_____I_____I_____I

[16] Zone 16 I_____I_____I_____I_____I_____I_____I [32] Zone 32 I_____I_____I_____I_____I_____I_____I

[41]-[56] Wireless Key Serial Number

[41] Key 1 I_____I_____I_____I_____I_____I_____I [49] Key 9 I_____I_____I_____I_____I_____I_____I

[42] Key 2 I_____I_____I_____I_____I_____I_____I [50] Key 10 I_____I_____I_____I_____I_____I_____I

[43] Key 3 I_____I_____I_____I_____I_____I_____I [51] Key 11 I_____I_____I_____I_____I_____I_____I

[44] Key 4 I_____I_____I_____I_____I_____I_____I [52] Key 12 I_____I_____I_____I_____I_____I_____I

[45] Key 5 I_____I_____I_____I_____I_____I_____I [53] Key 13 I_____I_____I_____I_____I_____I_____I

[46] Key 6 I_____I_____I_____I_____I_____I_____I [54] Key 14 I_____I_____I_____I_____I_____I_____I

[47] Key 7 I_____I_____I_____I_____I_____I_____I [55] Key 15 I_____I_____I_____I_____I_____I_____I

[48] Key 8 I_____I_____I_____I_____I_____I_____I [56] Key 16 I_____I_____I_____I_____I_____I_____I

Zone Serial Numbers Default = 000000

Wireless Key Serial Numbers Default = 000000

[61]-[76] Wireless Function Key Options

Function 1

Function 2

Function 3

Default 03

Default 04

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 1

[61]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 2

[62]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 3

[63]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 4

[64]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 5

[65]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 6

[66]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 7

[67]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 8

[68]

Default 27

Function 4

Default 30

Function 1

Default 03

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 9

[69]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 10

[70]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 11

[71]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 12

[72]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 13

[73]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 14

[74]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 15

[75]

I_____I_____I I_____I_____I I_____I_____I I_____I_____I

Key 16

[76]

Function 2

Default 04

Function 3

Default 27

Function 4

Default 30

Keypad Function Keys

Please see your system installation manual for a complete list of all the function key options available for your system.

[00] - Null [07] - System Test [17] - Activate Stay/Away [27] - Disarm

[03] - Stay Arm [13] - Command Output 1 [18] - Global Away Arm [28] - Fire Alarm

[04] - Away Arm [14] - Command Output 2 [19] - Command Output 3 [29] - Auxiliary Alarm

[05] - No Entry Arm [15] - Global Stay Arm [21] - Command Output 4 [30] - Panic Alarm

[06] - Chime On/Off [16] - Quick Exit [22] - Global Disarm [31] - Local PGM Activate

NOTE: Wireless keys must have an access code for global arm/disarm function.

[77] Wireless Keys (1-16) Partition Assignments Default = 01

Key 1 I_____I_____I Key 5 I_____I_____I Key 9 I_____I_____I Key 13 I_____I_____I

Key 2 I_____I_____I Key 6 I_____I_____I Key 10 I_____I_____I Key 14 I_____I_____I

Key 3 I_____I_____I Key 7 I_____I_____I Key 11 I_____I_____I Key 15 I_____I_____I

Key 4 I_____I_____I Key 8 I_____I_____I Key 12 I_____I_____I Key 16 I_____I_____I

[81] Wireless supervisory Window

Default: [NA] 96 = 24 hours / [EU] 10 =2.5 hours I_____I_____I

The window is programmed in 15 minute increments. Valid entries are 10 to 96, equal to 2.5 to 24 hours.

[82]-[85] Zone Device Supervision Options

[82]

Zone

Supervision

Default ON

Option 1 1 I_____I 9 I_____I 17 I_____I 25 I_____I

Option 2 2 I_____I 10 I_____I 18 I_____I 26 I_____I

Option 3 3 I_____I 11 I_____I 19 I_____I 27 I_____I

Option 4 4 I_____I 12 I_____I 20 I_____I 28 I_____I

Option 5 5 I_____I 13 I_____I 21 I_____I 29 I_____I

Option 6 6 I_____I 14 I_____I 22 I_____I 30 I_____I

Option 7 7 I_____I 15 I_____I 23 I_____I 31 I_____I

Option 8 8 I_____I 16 I_____I 24 I_____I 32 I_____I

ON/OFF

[83]

Zone

Supervision

ON/OFF

[84]

Zone

Supervision

ON/OFF

[85]

Zone

Supervision

ON/OFF

[90] Other Options

NA Default EU Default Option ON OFF

OFF OFF I____I 1,2,4 For Future Use

ON OFF I____I 3 Wall Tamper Disabled Wall Tamper Enabled

ON OFF I____I 5 RF Delinquency Disabled RF Delinquency Enabled

OFF OFF I____I 6 For Future Use

ON OFF I____I 7 RF Jam Detect Disabled RF Jam Detect Enabled

OFF OFF I____I 8 Global Placement Test Individual Placement T est

NOTE: For UL Listed installations, the RF Jam detect feature must be enabled.

NOTE: For DD243 installations, the RF delinquency feature should be enabled.

NOTE: Supervision must be enabled for RF Delinquency.

[93] RF Jam Detect Zone

Default: 00 I_____I_____I Valid entries = 01 - 32, 00 = No RF Jam tone selected.

Select an unused zone that will be set to the tamper state when a jamming signal is detected.

Page 10

Words Table

Item # Text Item # Text Item # Text Item # Text Item # Text Item # Text Item # Text Item # Text Item # Text

001 Aborted 028 Bypass 055 Downstairs 082 Gallery 109 Light 136 Panic 163 Shed 190 Window 217 P

002 AC 029 Bypassed 056 Drawer 083 Garage 110 Lights 137 Partition 164 Shock 191 Zone 218 Q

003 Access 030 Cabinet 057 Driveway 084 Gas 111 Living 138 Patio 165 Shop 192 0 219 R

004 Active 031 Cancelled 058 Duct 085 Glass 112 Load 139 Pet 166 Side 193 1 220 S

005 Activity 032 Car 059 Duress 086 Goodbye 113 Loading 140 Phone 167 Siren 194 2 221 T

006 Alarm 033 Carbon 060 East 087 Gym 114 Low 141 Please 168 Sliding 195 3 222 U

007 All 034 Central 061 Energy Saver 088 Hallway 115 Lower 142 PM 169 Smoke 196 4 223 V

008 AM 035 Chime 062 Enter 089 Heat 116 Main 143 Police 170 Son’s 197 5 224 W

009 Area 036 Closed 063 Entry 090 Hello 117 Master 144 Pool 171 Sound 198 6 225 X

010 Arm 037 Closet 064 Error 091 Help 118 Mat 145 Porch 172 South 199 7 226 Y

011 Armed 038 Closing 065 Exercise 092 High 119 Medical 146 Power 173 Special 200 8 227 Z

012 Arming 039 Code 066 Exit 093 Home 120 Memory 147 Press 174 Stairs 201 9 228 (Space)

013 Attic 040 Communica-

014 Auxiliary 041 Computer 068 Factory 095 In 122 Monoxide 149 Progress 176 Sun 203 B 230 - (Dash)

015 Away 042 Control 069 Failure 096 Install 123 Mother’s 150 Quiet 177 Supervisory 204 C 231 _ (Underscore)

016 Baby 043 Date 070 Family 097 Interior 124 Motion 151 Rear 178 System 205 D 232 *

017 Back 044 Daughter’s 071 Father’s 098 Intrusion 125 No 152 Receiver 179 Tamper 206 E 233 #

018 Bar 045 Degrees 072 Feature 099 Invalid 126 North 153 Report 180 Temperature 207 F 234 :

019 Basement 046 Delay 073 Fence 100 Is 127 Not 154 RF 181 Test 208 G 235 /

020 Bathroom 047 Den 074 Fire 101 Key 128 Now 155 Right 182 Time 209 H 236 ?

021 Battery 048 Desk 075 First 102 Kids 129 Number 156 Room 183 To 210 I

022 Bedroom 049 Detector 076 Floor 103 Kitchen 130 Off 157 Safe 184 Touchpad 211 J

023 Bonus 050 Dining 077 Force 104 Latchkey 131 Office 158 Schedule 185 Trouble 212 K

024 Bottom 051 Disarmed 078 Foyer 105 Laundry 132 OK 159 Screen 186 Unbypass 213 L

025 Breezeway 052 Door 079 Freeze 106 Left 133 On 160 Second 187 Unit 214 M

026 Building 053 Down 080 Front 107 Level 134 Open 161 Sensor 188 Up 215 N

027 Bus 054 Download 081 Furnace 108 Library 135 Opening 162 Service 189 West 216 O

067 Exterior 094 House 121 Menu 148 Program 175 Stay 202 A 229 ’ (Apostrophe)

tor

Page 11

LIMITED WARRANTY

Digital Security Controls (DSC) warrants that for a period of 12 months from

the date of purchase, the product shall be free of defects in materials and workmanship under normal use and that in fulfilment of any breach of such warranty,

DSC shall, at its option, repair or replace the defective equipment upon return of

the equipment to its repair depot. This warranty applies only to defects in parts

and workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond the control of Digital Security Controls such as lightning, excessive voltage, mechanical shock, water damage, or damage arising out

of abuse, alteration or improper application of the equipment. The foregoing

warranty shall apply only to the original buyer, and is and shall be in lieu of any

and all other warranties, whether expressed or implied and of all other obligations or liabilities on the part of Digital Security Controls. Digital Security Controls neither assumes responsibility for, nor authorizes any other person

purporting to act on its behalf to modify or to change this warranty, nor to

assume for it any other warranty or liability concerning this product. In no

event shall Digital Security Controls be liable for any direct, indirect or consequential damages, loss of anticipated profits, loss of time or any other losses

incurred by the buyer in connection with the purchase, installation or operation

or failure of this product. WARNING: Digital Security Controls recommends

that the entire system be completely tested on a regular basis. However, despite

frequent testing, and due to, but not limited to, criminal tampering or electrical

disruption, it is possible for this product to fail to perform as expected. IMPORTANT INFORMATION: Changes/modifications not expressly approved by

DSC could void the user’s authority to operate this equipment.

IMPORTANT - READ CAREFULLY: DSC Software purchased with or

without Products and Components is copyrighted and is purchased under

the following license terms:

• This End-User License Agreement (“EULA”) is a legal agreement between

You (the company, individual or entity who acquired the Software and any

related Hardware) and Digital Security Controls, a division of Tyco Safety Products Canada Ltd. (“DSC”), the manufacturer of the integrated security systems

and the developer of the software and any related products or components

(“HARDWARE”) which You acquired.

• If the DSC software product (“SOFTWARE PRODUCT” or “SOFTWARE”) is intended to be accompanied by HARDWARE, and is NOT accompanied by new HARDWARE, You may not use, copy or install the

SOFTWARE PRODUCT. The SOFTWARE PRODUCT includes computer

software, and may include associated media, printed materials, and “online” or

electronic documentation.

• Any software provided along with the Software Product that is associated

with a separate end-user license agreement is licensed to You under the terms of

that license agreement.

• By installing, copying, downloading, storing, accessing or otherwise using

the Software Product, You agree unconditionally to be bound by the terms of

this EULA, even if this EULA is deemed to be a modification of any previous

arrangement or contract. If You do not agree to the terms of this EULA, DSC is

unwilling to license the Software Product to You, and You have no right to use

it.

SOFTWARE PRODUCT LICENSE

The SOFTWARE PRODUCT is protected by copyright laws and international

copyright treaties, as well as other intellectual property laws and treaties. The

SOFTWARE PRODUCT is licensed, not sold.

1. GRANT OF LICENSE This EULA grants You the following rights:

(a) Software Installation and Use - For each license You acquire, You may

have only one copy of the SOFTWARE PRODUCT installed.

(b) Storage/Network Use - The SOFTWARE PRODUCT may not be

installed, accessed, displayed, run, shared or used concurrently on or from

different computers, including a workstation, terminal or other digital electronic

device (“Device”). In other words, if You have several workstations, You will

have to acquire a license for each workstation where the SOFTWARE will be

used.

(c) Backup Copy - You may make back-up copies of the SOFTWARE

PRODUCT, but You may only have one copy per license installed at any given

time. You may use the back-up copy solely for archival purposes. Except as

expressly provided in this EULA, You may not otherwise make copies of the

SOFTWARE PRODUCT, including the printed materials accompanying the

SOFTWARE.

2. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS

(a) Limitations on Reverse Engineering, Decompilation and Disassembly You may not reverse engineer, decompile, or disassemble the SOFTWARE

PRODUCT, except and only to the extent that such activity is expressly

permitted by applicable law notwithstanding this limitation. You may not make

any changes or modifications to the Software, without the written permission of

an officer of DSC. You may not remove any proprietary notices, marks or labels

from the Software Product. You shall institute reasonable measures to ensure

compliance with the terms and conditions of this EULA.

(b) Separation of Components - The Software Product is licensed as a single

product. Its component parts may not be separated for use on more than one

HARDWARE unit.

(c) Single INTEGRATED PRODUCT - If You acquired this SOFTWARE

with HARDWARE, then the SOFTWARE PRODUCT is licensed with the

HARDWARE as a single integrated product. In this case, the SOFTWARE

PRODUCT may only be used with the HARDWARE as set forth in this

EULA..

(d) Rental - You may not rent, lease or lend the SOFTWARE PRODUCT.

You may not make it available to others or post it on a server or web site.

(e) Software Product Transfer - You may transfer all of Your rights under this

EULA only as part of a permanent sale or transfer of the HARDWARE,

provided You retain no copies, You transfer all of the SOFTWARE PRODUCT

(including all component parts, the media and printed materials, any upgrades

and this EULA), and provided the recipient agrees to the terms of this EULA. If

the SOFTWARE PRODUCT is an upgrade, any transfer must also include all

prior versions of the SOFTWARE PRODUCT.

(f) Termination - Without prejudice to any other rights, DSC may terminate

this EULA if You fail to comply with the terms and conditions of this EULA. In

such event, You must destroy all copies of the SOFTWARE PRODUCT and all

of its component parts.

(g) Trademarks - This EULA does not grant You any rights in connection with

any trademarks or service marks of DSC or its suppliers.

3. COPYRIGHT - All title and intellectual property rights in and to the

SOFTWARE PRODUCT (including but not limited to any images,

photographs, and text incorporated into the SOFTWARE PRODUCT), the

accompanying printed materials, and any copies of the SOFTWARE

PRODUCT, are owned by DSC or its suppliers. You may not copy the printed

materials accompanying the SOFTWARE PRODUCT. All title and intellectual

property rights in and to the content which may be accessed through use of the

SOFTWARE PRODUCT are the property of the respective content owner and

may be protected by applicable copyright or other intellectual property laws and

treaties. This EULA grants You no rights to use such content. All rights not

expressly granted under this EULA are reserved by DSC and its suppliers.

4. EXPORT RESTRICTIONS - You agree that You will not export or

re-export the SOFTWARE PRODUCT to any country, person, or entity subject

to Canadian export restrictions.

5. CHOICE OF LAW - This Software License Agreement is governed by the

laws of the Province of Ontario, Canada.

6. ARBITRATION - All disputes arising in connection with this Agreement

shall be determined by final and binding arbitration in accordance with the

Arbitration Act, and the parties agree to be bound by the arbitrator’s decision.

The place of arbitration shall be Toronto, Canada, and the language of the

arbitration shall be English.

7. LIMITED WARRANTY

(a) NO WARRANTY - DSC PROVIDES THE SOFTWARE “AS IS”

WITHOUT WARRANTY. DSC DOES NOT WARRANT THAT THE

SOFTWARE WILL MEET YOUR REQUIREMENTS OR THAT

OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR

ERROR-FREE.

(b) CHANGES IN OPERATING ENVIRONMENT - DSC shall not be

responsible for problems caused by changes in the operating characteristics of

the HARDWARE, or for problems in the interaction of the SOFTWARE

PRODUCT with non-DSC-SOFTWARE or HARDWARE PRODUCTS.

(c) LIMITATION OF LIABILITY; WARRANTY REFLECTS

ALLOCATION OF RISK - IN ANY EVENT, IF ANY STATUTE IMPLIES

WARRANTIES OR

AGREEMENT, DSC’S ENTIRE LIABILITY UNDER ANY PROVISION OF

THIS LICENSE AGREEMENT SHALL BE LIMITED TO THE GREATER

OF THE AMOUNT ACTUALLY PAID BY YOU TO LICENSE THE

SOFTWARE PRODUCT AND FIVE CANADIAN DOLLARS (CAD$5.00).

BECAUSE SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY

TO YOU.

(d) DISCLAIMER OF WARRANTIES - THIS WARRANTY CONTAINS

THE ENTIRE WARRANTY AND SHALL BE IN LIEU OF ANY AND ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED

(INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE) AND OF ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF DSC. DSC MAKES

NO OTHER WARRANTIES. DSC NEITHER ASSUMES NOR

AUTHORIZES ANY OTHER PERSON PURPORTING TO ACT ON ITS

BEHALF TO MODIFY OR TO CHANGE THIS WARRANTY, NOR TO

ASSUME FOR IT ANY OTHER WARRANTY OR LIABILITY

CONCERNING THIS SOFTWARE PRODUCT.

(e) EXCLUSIVE REMEDY AND LIMITATION OF WARRANTY UNDER NO CIRCUMSTANCES SHALL DSC BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES

BASED UPON BREACH OF WARRANTY, BREACH OF CONTRACT,

NEGLIGENCE, STRICT LIABILITY, OR ANY OTHER LEGAL THEORY.

SUCH DAMAGES INCLUDE, BUT ARE NOT LIMITED TO, LOSS OF

PROFITS, LOSS OF THE SOFTWARE PRODUCT OR ANY

ASSOCIATED EQUIPMENT, COST OF CAPITAL, COST OF

SUBSTITUTE OR REPLACEMENT EQUIPMENT, FACILITIES OR

SERVICES, DOWN TIME, PURCHASERS TIME, THE CLAIMS OF

THIRD PARTIES, INCLUDING CUSTOMERS, AND INJURY TO

PROPERTY. WARNING: DSC recommends that the entire system be

completely tested on a regular basis. However, despite frequent testing, and due

to, but not limited to, criminal tampering or electrical disruption, it is possible for

this SOFTWARE PRODUCT to fail to perform as expected.

FCC Compliance Statement - CAUTION: Changes or modifications not

expressly approved by DSC could void your authority to use this equipment.

This equipment generates and uses radio frequency energy and if not installed

and used properly, in strict accordance with the manufacturer’s instructions, may

cause interference to radio and television reception. It has been type tested and

found to comply with the limits for Class B device in accordance with the specifications in Subpart “B” of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in any residential installation.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause interference to television or radio

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

• Re-orient the receiving antenna

• Relocate the alarm control with respect to the receiver

• Move the alarm control away from the receiver

• Connect the alarm control into a different outlet so that alarm control and

receiver are on different circuits.

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet

prepared by the FCC helpful: “How to Identify and Resolve Radio/Television

Interference Problems”. This booklet is available from the U.S. Government

Printing Office, Washington, D.C. 20402, Stock # 004-000-00345-4.

Operating Instructions shall be made available to the user.

CONDITIONS NOT STATED IN THIS LICENSE

© 2012 Tyco International Ltd. and its Respective Companies. All Rights Reserved. Toronto, Canada • www.dsc.com • Tech Support: 1-800-387-3630 (Canada, US), 905-760-3000 • Printed in Canada

Page 12

Instructions d’Installation

Les claviers PK55XX\RFK55XX peuvent être utilisés avec des systèmes

de sécurité ayant un maximum de 64 zones. Ces claviers sont compatibles avec la dernière version des centrales d'alarme DSC suivantes:

Français

•PC580 •PC585 •PC1555MX •PC1565

•PC1616 •PC1832 •PC1864 •PC5005

•PC5008 •PC5010 •PC5015 •PC5016

•PC5020

Les claviers RFK55XX combinent un récepteur sans fil avec le clavier

PK55XX correspondant.

Spécifications

• Plage de température: -10°C à +55°C (14°F to 131°F) Plage de

température pour UL/ULC: 0°C to +49°C (32°F to 120°F)

• Humidité (MAX): HR 93 %

• Degré de protection boîtier plastique : IP30, IK04

• Tension nominale : 12 Vc.c

• Raccordement au panneau de contrôle via le Keybus à 4 fils.

• Une entrée de zone et une sortie PGM*

• PK55XX Consommation de courant : 50mA (en veille)/125 mA (max)

• RFK55XX Consommation de courant: 75mA (en veille)/135mA (max)

• Installation murale anti-sabotage

• Cinq touches de fonctions programmables

• Voyants d’état Prêt (vert), et Armé (rouge), Trouble (Jaune), AC (vert)

• Capteur de basse température

• Fréquence: 433.92MHz (RFK55XX-433)

• 32 zones sans fil (Seulement RFK5500)

• 64 zones sans fil (Seulement RFK5564 et Power v4.6+)

* REMARQUE: Zone ne doit pas être programmée comme une

zone de type incendie (Feu) ou 24 h.

Déballage

La boîte du Power contient les éléments suivants:

•Un clavier

•Quatre vis de montage

•Deux résistance fin de lignes

•Un étiquette intérieure pour la porte du clavier

•Un commutateur anti-sabotage

•Un Manuel d’Installation

Montage

Pour le montage du clavier, choisissez un endroit près du point

d’entrée qui est sec, sécuritaire et accessible. Lorsque vous avez déterminé l’emplacement de montage, suivez les étapes suivantes.

Désassemblez le clavier

1. Insérez un tournevis plat dans la fente prévue (première fente des

deux).

2. Enfoncez le tournevis comme décrit dans le schéma ci-dessous. Cela

vous permettra de détacher une côté de la face avant.

3. Répétez étape 1 et 2 pour la deuxième fente pour enlever la face

avant du clavier afin de permettre le câblage.

3

1

2

Montage et câblage du clavier

alvéole défonçable

fente de câblage

alvéole

défonçable

crochets

alvéole

défonçable

anti-sabotage

1.

3.

1. Fixez le clavier à l’aide des trous de montage. Utilisez les 4 vis fournies à moins de faire le montage sur une seule boîte électrique.

2. Placez le clavier sur les crochets de la plaque arrière et faites basculer vers le bas pour engager.

3. Faites passez les fils dans la fente de câblage ou dans les alvéoles

défonçables. Connectez le câblage de zone Keybus et PGM au clavier. Placez l’interrupteur anti-sabotage dans le trou à cet effet sur

la plaque de montage.

4. Retirez le clavier des crochets. Placez le clavier sur la plaque de montage en vous assurant que le fil est poussé dans le mur autant que

possible. Faites passer le fil à l’intérieur du clavier en vous assurant

d’éviter les éléments sensibles. Fermez l’assemblage avant en vous

assurant que le clavier ne fait pas pression sur le fil qui est dessous.

REMARQUE : S’il y a une tension quelconque entre l’assemblage avant du

clavier et le câblage, ouvrez le clavier, déplacez le fil et refermer. Répétez

ces étapes jusqu’à ce que le clavier soit bien fermé.

Câblage

1. Avant de commencer à câbler l’unité, assurez-vous que l’alimentation (transformateur c.a. et batterie) du panneau de contrôle est

coupée.

2. Raccordez les quatre fils du Keybus qui

proviennent du panneau de contrôle

(rouge, noir, jaune et vert) sur les bornes

(R, B, Y et G) du clavier. Référez-vous au

schéma ci-dessous:

3. Si la borne ‘Z/P’ du PK55xx est programmée en tant qu’entrée, vous pouvez raccorder un dispositif sur cette borne, comme par exemple un

contact de porte. Ceci est un bon moyen d’économiser du temps et

crochets

antisabotage

2.

4.

Faites

basculer

pour engager

Appuyer pour fermer

Page 13

du câblage en évitant d’avoir à installer un câble entre le panneau de

contrôle et le contact de la porte qui se trouve à proximité du clavier.

Pour raccorder la zone, installez un câble entre le dispositif et le clavier

et raccordez un des fils provenant du dispositif sur la borne ‘Z/P’ du

clavier et un autre sur la borne B. Si le dispositif doit être alimenté,

raccordez le fil rouge à la borne R (positif) et le fil noir à la borne B

(négatif). Si une résistance de fin de ligne doit être utilisée, raccordez

la zone en vous conformant à l’une des configurations décrites dans le

manuel d’installation du système.

4. Si la borne ‘Z/P’ est programmée en tant que sortie, celle-ci suit la

programmation de la sortie PGM programmée dans la section de programmation de clavier numérique [080]. Un petit relais, un avertisseur sonore ou un autre dispositif qui fonctionne sous tension c.c. peut

être raccordé entre la borne d’alimentation positive et la borne ‘Z/P’

(consommation maximale de courant de 50mA).

REMARQUE : Pour les installations incendie homologuées UL,

utilisez au moins un clavier compatible DSC supplémentaire en

association avec le clavier RFK55XX ou installez les claviers

RFK55XX à moins de 3 pieds de l'unité de commande et protégez

mécaniquement les fils du bus de communication

Mise sous tension

Une fois que le câblage est fini et que le dispositif est fixé à la structure

de l’édifice avec au moins deux vis, mettez le panneau de contrôle sous

tension :

1. Raccordez les câbles de batterie à la batterie.

2. Branchez le transformateur CA.

Pour de plus amples informations sur les spécifications d’alimentation

du panneau de contrôle, référez-vous au manuel d’installation du panneau de contrôle.

Diffusion étiquettes LCD

Toute la programmation ACL est faite par clavier. Si plus d’un clavier

ACL est présent sur le système et si le PC5400 reçoit des intitulés, les

intitulés programmés à un clavier seront diffusés à tous les autres claviers ACL. Suivez la démarche suivante pour diffuser les intitulés:

Étape 1 - Programmez complètement un clavier ACL.

Étape 2 - Assurez-vous que tous les claviers ACL sont connectés sur le

KEYBUS.

Étape 3 - Entrez [,][8][code de l’installateur][,] pour accéder à la

programmation du clavier, puis dans la section [998] au clavier déjà

programmé. Saisir [,] pour confirmer le transfert du texte. Le clavier

diffusera tous les renseignements programmés aux autres claviers ACL

sur le système.

Étape 4 - Lorsque la diffusion est achevée, appuyez sur la touche [#]

pour sortir.

REMARQUE : La diffusion d’étiquette ce clavier est seulement compatibleavec la centrale PC1616/PC1832/PC1864 et d'autres claviers PK5500/

RFK5500/64.

Programmation de langue

Maintenir les touches (<>) pendant 2 secondes pour entrer le langage de programmation, faites défiler jusqu’au langage désiré et

appuyez sur [,] pour choisir.

REMARQUE : Si l’option 4 de la section [077] option 4 est désactivée, le langage de programmation ne peut se faire que dans la

programmation de l’installateur.

Attribution du clavier

Le clavier devra être assigné à une partition et à un emplacement si les

zones de supervision ou de clavier sont occupées. L’attribution du clavier et l’option de programmation de clavier doivent être faites individuellement à chaque clavier.

Le 1er chiffre de l’attribution du clavier est utilisé pour déterminer

l’attribution de la partition (1 à 8). S’il n’y a pas de partitionnement,

tapez [1]. Pour les claviers globaux, tapez [0].

Le 2e chiffre de l’attribution du clavier est utilisé pour déterminer l’attribution de l’emplacement pour le clavier de supervision. On assigne à

chaque clavier un numéro d’emplacement différent, de 1 à 8. Les clavier ACL PK5500 et RFK5500/64 LCD sont par défaut assignés à

l’emplacement 8. Si les claviers LCD sont utilisés un clavier LCD doit

être assigné à l’emplacement 8.

REMARQUE : Le RFK55XX est attribué en tant que deux modules :

Clavier 8 = section clavier du RFK55XX

RF5132 = section récepteur du RFK55XX

REMARQUE : L’annulation de tous les dispositifs sans fil du RFK55XX ou la

mise aux paramètres par défaut du RFK55XX provoquera une anomalie de

supervision.

Entrez ce qui suit pour chacun des claviers qui est installé dans le système:

1. Accédez au mode de programmation de l’installateur en entrant

[,][8][code de l’installateur]

2. Entrez [000] pour accéder à la programmation du clavier.

3. Appuyez sur [0] pour accéder à l’attribution de la partition et de

l’emplacement de mémoire du clavier.

4. Entrez le 1er chiffre (0 à 8 pour l’attribution d’une partition)

5. Entrez le 2e chiffre (1 à 8 pour l’attribution de l’emplacement de

supervision)

6. Pour quitter le mode de programmation, appuyez deux fois sur [#]

7. Après avoir assigné tous les claviers, effectuez une réinitialisation de

supervision en entrant [,][8][code de l’installateur][902] et attendre 60 secondes.

8. Appuyez sur [#] pour sortir de la programmation après 60 secondes.

Programmation d’étiquette

1. Entrez [,][8][code de l’installateur][,] pour accéder à la programmation du clavier. Entrez les trois chiffres de la section pour que l’intitulé soit programmé.

2. Utilisez les touches flèches (<>) pour déplacer le trait bas sous la

lettre à changer.

3. Appuyez sur la touche du chiffre [1] à [9] correspondant à la lettre

requise. La première fois que vous appuyez sur le chiffre, la première

lettre apparaît. En appuyant à nouveau sur la touche chiffre vous passerez à la lettre suivante.

[1] - A, B, C, 1 [4] - J, K, L, 4 [7] - S, T, U, 7 [0] - Espace

[2] - D, E, F, 2 [5] - M, N, O, 5 [8] - V, W, X, 8

[3] - G, H, I, 3 [6] - P, Q, R, 6 [9] - Y, Z, 9,0

4. Lorsque vous devez afficher une autre lettre ou un autre chiffre utilisez

les touches flèches (<>) pour faire défiler jusqu’à la lettre suivante.

5. Lorsque vous avez fini la programmation de l’intitulé de zone,

appuyez sur la touche [,], faites défiler jusqu’à “Sauvegarde” puis

appuyez sur [,].

6. Continuez à partir de l’étape 2 jusqu’à ce que tous les intitulés soient

programmés.

Bibliothèque de textes

La bibliothèque de textes est une base de données de mots fréquemment utilisés

lors de la programmation des textes. Les mots peuvent être combinés selon les

besoins. par ex. Porte + Devant. Chaque ligne de l'affichage permet un maximum de 14 caractères. Si un mot ne rentre pas dans une ligne, faites défiler

jusqu'à ce que le curseur apparaisse au premier caractère de la deuxième ligne

puis ajouter le mot.

Pour programmer un texte individualisé en utilisant la bibliothèque de textes :

1. Saisissez la programmation de clavier et choisir le texte à changer. Par ex.,

[,][8][Code de l'installateur][,][001] (pour paramétrer le texte pour la

zone 01).

2. Appuyez sur [,] pour ouvrir le menu « Sélection d'options ».

3. Appuyez à nouveau sur [,] pour sélectionner l'option « Mots ».

4. Saisissez le nombre à 3 chiffres correspondant à un mot (voir le tableau

Mots) ou utilisez les touches de défilement [<][>] pour faire défiler les

mots de la bibliothèque.

5. Appuyez sur [,] pour sélectionner le mot.

6. Pour ajouter un autre mot, répétez la procédure ci-dessus à partir de

l'étape 2.

7. Pour ajouter un espace, appuyez sur la touche de défilement de droite

[>].

Page 14

8. Pour effacer des caractères, sélectionnez « Effacer jusqu'à la fin » ou « Effacer affichage » sur le menu « Sélection

d'options ».

9. Pour sauvegarder le texte, appuyez sur [,] pour accéder au menu « Sélection d'options », faites défiler vers la

gauche [<] jusqu'à " Sauvegarde " puis appuyez à nouveau sur [,].

Changer la luminosité et le contraste

Claviers LCD

1. Tapez [,][6][code maître].

2. Utilisez les touches flèches [<>] pour le contrôle de la luminosité ou du contraste.

3. Tapez [,] pour sélectionner le paramètre que vous désirez ajuster.

4. a) “Contrôle de la luminosité” : Il y a 10 niveaux de rétro-éclairage. Utilisez les touches flèches pour faire

défiler jusqu'au niveau désiré.

b) “Contrôle du contraste” : Il y a 10 niveaux de contraste. Utilisez les touches flèches pour faire défiler

jusqu'au niveau de contraste désiré.

5. Pour sortir de cette programmation, appuyez sur [#].

Changement de volume du résonateur

Clavier LCD

1. Tapez [,][6][code maître].

2. Utilisez les touches flèches [<>] pour défiler jusqu'au contrôle de l'avertisseur.

3. Saisissez [,] pour sélectionner contrôle de l'avertisseur.

4. Utilisez les touches flèches [<>] pour défiler jusqu'au niveau d’avertisseur désiré parmi les 21 sélections

possibles.

5. Appuyez sur [#] pour sortir.

Transmission carillon de porte

La programmation carillon de porte est faite par clavier. Lorsqu'il y a plusieurs claviers dans le système, la

fonction carillon de porte programmé sur un clavier peut être transmis vers tous les autres claviers. Effectuez

la procédure suivante pour la transmission de la fonction carillon de porte:

Etape 1 - Programmez un clavier entièrement.

Etape 2 - Vérifiez si tous les claviers sont raccordé au keybus.

Etape 3 - Entrez dans la programmation du clavier avec [

l'adresse [994] au clavier qui a été programmé. Saisir [,] pour confirmer le transfert de programmation du carillon. Le clavier transmet maintenant la programmation carillon de porte vers

tous les autres claviers dans le système.

Etape 4 - Quand le clavier est prêt, appuyez la touche [#] pour quitter.

Attribution du clavier

Entrez [,][8][code de l’installateur][000] pour accéder à la programmation du clavier.

,][8][code installateur][,], puis entrez dans

[0] Partition/Adresse de l’emplacement

Chiffre Option

1er Attribution de partition (0=clavier global) 0 - 8 1 I_____I

2e Attribution d’emplacement 1 - 8 LED,ICON=1/LCD=8 I_____I

Portée

valable

Défaut

[1]-[5] Attribution de la touche de fonction

Attribution de la touche

de fonction

Touche

[1] Touche de fonction 1 00 - 32 03 Armement A domicile I_____I_____I

[2] Touche de fonction 2 00 - 32 04 Armement Absent I_____I_____I

[3] Touche de fonction 3 00 - 32 06 Carillon (MAR/ARR) I_____I_____I

[4] Touche de fonction 4 00 - 32 14 Reset détecteurs I_____I_____I

[5] Touche de fonction 5 00 - 32 16 Sortie Rapide I_____I_____I

Touches de fonction du clavier

Veuillez voir le manuel d’installation de votre système pour une liste complète de toutes les options touches

de fonction offertes par votre système.