Page 1

HS2LED/HS2ICN(P)(RF)x/HS2LCD(RF)(P)x v1.0

Installation Instructions, Instructions d’Installation, Instrucciones de instalación,

Instruções de Instalação

English, Français, Español, Português

WARNING: Refer to the PowerSeries Neo Reference manual for information on limitations regarding product use and function, and information on the limitations as to the liability of the manufacturer.

NOTE: These instructions must be used in conjunction with the system installation manual of the control panel with which this equipment is intended to be used. This installation sheet applies to the fol-

lowing models: HS2LED, HS2ICN, HS2ICNP, HS2ICNRFx, HS2ICNRFPx, HS2LCD, HS2LCDP, HS2LCDRFx and HS2LCDRFPx; x = 9 where the system operates in 912-919MHz, 8 where the

system operates in 868MHz band, and 4 where the system operates in 433MHz band. The Model HS2LED, HS2LCD(P), HS2ICN(P), HS2LCDRF(P)8, HS2ICNRF(P)8 keypads have been certified by

Telefication according to EN50131-1:2006 + A1:2009, EN50131-3:2009 for Grade 2, Class II.

Page 2

Installation Instructions

The HS2LED/HS2ICN(P)(RF)x/HS2LCD(RF)(P)x keypads are

compatible with the PowerSeries Neo HS2016/32/64, HS20144* and HS2128 panels. The RF keypads combine a wireless

transceiver with the respective HS2 keypad.

* Model not UL/ULC listed.

Specifications

• Temperature range: -10°C to +55°C (14°F to 131°F); Temperature range for UL/ULC: 0°C to +49°C (32°F to 120°F)

• Humidity (MAX): 93%R.H. non-condensing

• Plastic enclosure protection degree: IP30, IK04

• Voltage rating: 13.8V

compatible control panel)

• Connects to control panel Corbus via 4 wires

• 1 configurable zone input or PGM output*

• HS2LED/ HS2ICN(P)/HS2LCD(P)/HS2ICNRF(P)/

HS2LCDRF(P) Current draw:55mA(min)/105mA(max)

• Wall-mount tamper

• 5 programmable function keys

• Ready (Green LED), Armed (Red LED), Trouble (Yellow

LED), AC (Green LED)

• Dimensions (L x W x D): 168mm x 122mm x 20 mm

• Weight: 260g

• Low temperature sensor

• Frequency: 433 MHz (HS2ICNRF4/HS2LCDRF4)

• 868 MHz (HS2ICNRF8/HS2LCDRF8)

• 912-919MHz (HS2ICNRF9/HS2LCDRF9)

• Up to 128 wireless zones

* Zone not to be programmed as Fire type or 24h type.

NOTE: Keypads contain no serviceable parts.

NOTE: Only models operating in band 912-919MHz are UL/

ULC listed.

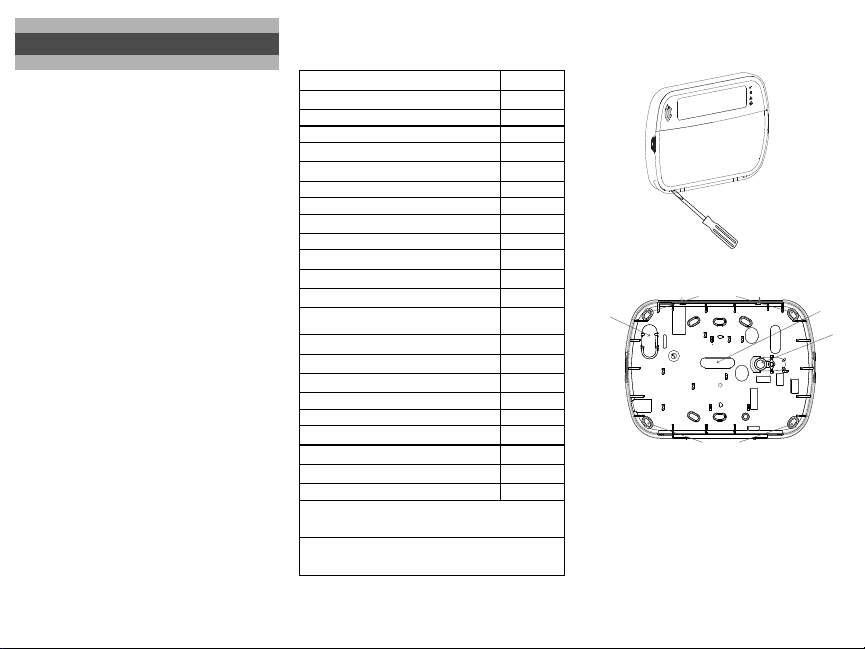

Unpack

The keypad package includes the following:

HS2LED/ICN(RF)/

LCD(RF)

• 1 keypad • 1 keypad

• 4 mounting screws • 4 mounting screws

• 2 end-of-line resistors • 2 end-of-line resistors

• Keypad inner door

labels

• 1 tamper switch • 1 tamper switch

DC nominal (power provided by the

HS2ICN(RF)P/LCD(RF)P

• Keypad inner door labels

• Installation Instructions • Installation Instructions

Table 1: Compatible Devices

Wireless PG smoke detector

Wireless PG smoke and heat detector

• Mini Proximity (prox) tag

(MPT)

UL

PGx926

UL

PGx916

Wireless PG CO detector PGx913

Wireless PG PIR motion detector PGx904(P)

Wireless PG PIR + camera motion detector

Wireless PG curtain motion detector

PGx934(P)

PGx924

UL

Wireless PG dual tech motion detector PGx984(P)

Wireless PG mirror motion detector PGx974(P)

Wireless PG outdoor motion detector

Wireless PG glass break detector PGx912

Wireless PG shock detector

Wireless PG flood detector

Wireless PG temperature detector (indoor)

Outdoor temperature probe (requires PGx905) PGTEMP-

Wireless PG key

Wireless PG key

Wireless PG panic key

Wireless PG 2-button key PGx949

Wireless PG indoor siren PGx901

Wireless PG outdoor siren

Wireless PG repeater

Wireless PG door/window contact

Wireless PG door/window contact w/AUX PGx945

NOTE: In this chart, x in the model number represents the

operating frequency of the device as follows: 9 (912-919 MHz),

8 (868MHz), 4 (433MHz).

NOTE: Only models operating in the band 912-919 MHz are

UL/ULC or cUL listed where indicated. Only UL approved

devices are to be used with UL/ULC listed systems.

Mount

Mount the keypad where it is accessible to designated points of

entry and exit. Once a dry and secure location is selected, perform the following steps to mount the keypad.

PGx994

PGx935

PGx985

PGx905

PROBE

PGx939

PGx929

PGx938

PGx911

PGx920

PGx975

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

Disassemble Keypad

1. Insert the tip of a flat-head screwdriver into the slots at the

bottom left and right of the keypad.

2. Gently pry open the faceplate. This will remove it and allow

access for mounting.

UL

UL

UL

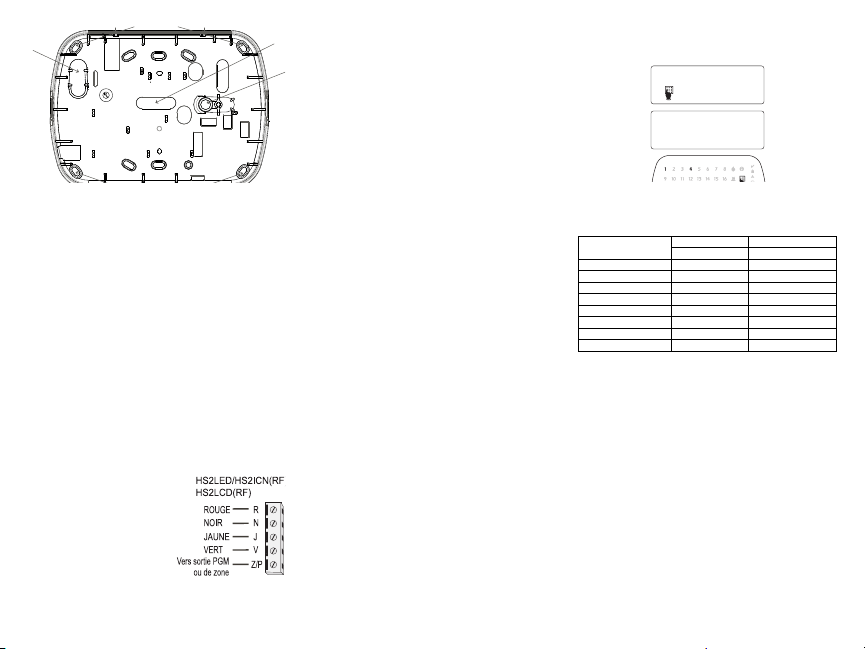

Mount and Wire Keypad

latchlatch

mounting holes

wiring slot

1. Secure keypad to wall using mounting holes. Use all four

screws provided unless mounting on a single gang box. Use

the plastic anchors supplied if the unit is to be mounted on

drywall.

2. If using the keypad tamper, secure the tamper plate to the

wall with a screw.

NOTE: For UL/ULC listed commercial burglary installations,

the use of the keypad tamper is mandatory.

3. Run wire through wiring slot or knockouts. Connect Corbus

and PGM/Zone wiring to keypad. Place tamper switch into

tamper hole on backplate.

4. Place keypad into backplate, ensuring the wire is pushed

back into the wall as much as possible. Route the wire inside

the keypad, ensuring high components are avoided. Snap the

front assembly closed, ensuring that there is no pressure to

the keypad from the wire below.

mounting holes

knockout

tamper

Page 3

NOTE: If any tension is found between the front keypad assem-

bly and the wiring, open the keypad, reroute the wire and close

again. Repeat these steps until the keypad is closed properly.

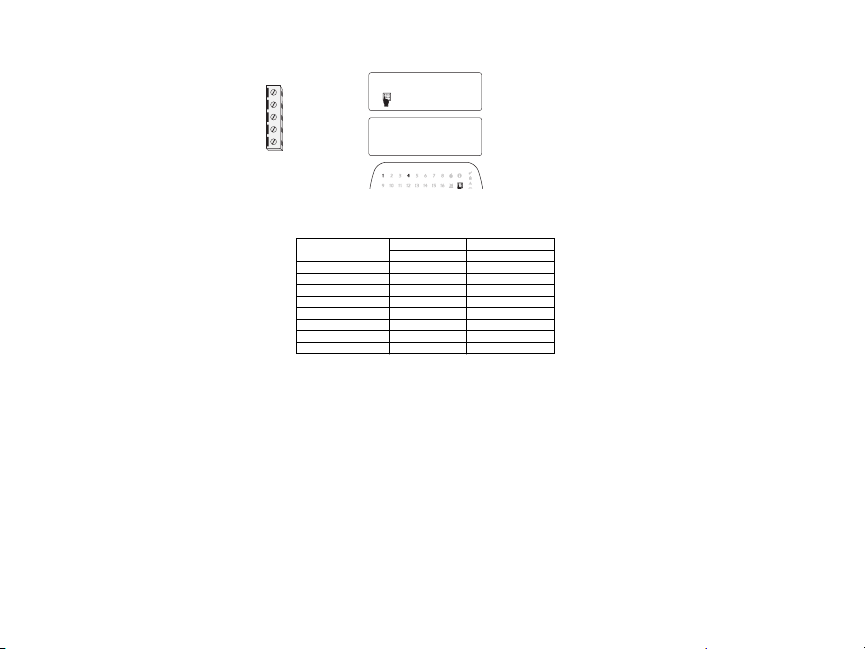

Wiring

1. Before wiring the unit, ensure

that all power (AC transformer and battery) is disconnected from the control panel.

2. Connect the four Corbus wires

from the control panel (red,

black, yellow and green) to

the keypad terminals. Refer to

the diagram:

3. If programmed as an input, a

device - such as a door contact

- may be connected to the ‘P/Z’ terminal of the keypad. This

eliminates the need to run wires back to the control panel for

the device. To connect the zone, run one wire from the device

to the ‘P/Z’ terminal and the other wire from the device to the

B (black) terminal. For powered devices, run the red wire to

the R (positive) terminal and the black wire to the B (negative) terminal. When using end of line supervision, connect

the zone according to one of the configurations described in

the PowerSeries Neo Reference manual.

NOTE: For UL/ULC installations, the zone input is a supervised

type (SEOL/DEOL). The supervision resistor is 5600Ω. If no EOL

supervision is used, there is a three foot maximum distance

required for the connected device. Use only in conjunction with

UL/ULC listed devices.

NOTE: This initiating device connected to this input contact is

not to be used for medical or fire applications.

4. If the ‘P/Z’ terminal is programmed as an output, a small

relay (such as DSC model RM-1 or RM-2) or buzzer or other

DC operated device may be connected between the positive

supply voltage and the ‘P/Z’ terminal (max.load is 50mA).

NOTE: For UL/ULC-listed installations, use UL/ULC listed

devices.

Apply Power

Once all wiring is complete, and the equipment is secured to the

building structure with at least two screws, apply power to the

control panel:

1. Connect the battery leads to the battery.

2. Connect the AC transformer.

For more information on control panel power specifications, see

the PowerSeries Neo Reference manual.

Program the Keypad

1. Press [*][8][Installer Code].

2. Use the [<][>] keys to navigate through the menus or jump

directly to a specific section by entering the section number.

Programming consists of toggling on and off options in each section or by populating data fields. Toggle options are enabled or

disabled by pressing the corresponding number on the keypad.

For example, to enable toggle options 1 and 4, press the [1] and

[4] keys. All enabled options are displayed (see the following diagram).

HS2LED/HS2ICN(RF)/

HS2LCD(RF)

________

RED R

____

BLK B

____

YEL Y

____

GRN G

____

To zone or P/Z

PGM output

1. To input data, use the [<][>] keys to select a character then

press the keypad button for the number/letter.

2. Using the [<][>] keys, scroll to the next character and repeat

the procedure. For information on entering HEX data, refer to

the PowerSeries Neo Reference manual.

Language Programming

Enter [000][000]. Enter the two-digit number corresponding to the

language desired:

Table 2: Languages

01 = English

(default)

02 = Spanish 12 = Norwegian 22 = Bulgarian

03 = Portuguese 13 = Danish 23 = Latvian

04 = French 14 = Hebrew 24 = Lithuanian

05 = Italian 15 = Greek 25 = Ukrainian

06 = Dutch 16 = Turkish 26 = Slovak

07 = Polish 17 = FFU 27 = Serbian

08 = Czech 18 = Croatian 28 = Estonian

09 = Finnish 19 = Hungarian 29 = Slovenian

Enroll the Keypad

Keypads can be enrolled automatically or manually. In either case,

the serial number of the device is used as an identifier.

NOTE: If there is no keypad enrolled on the system, once you

power up, the keypad will display the message: Press any key to

enroll. Other keypads can then be enrolled from the first keypad.

Use one of the following enrollment options:

[902][000] Auto Enroll

When this mode is selected, the total number of keypads currently

enrolled is displayed on the keypad.

1. Enter [902][000] to begin the auto-enrollment of new keypads. As each device is enrolled, the keypad displays the

model type, serial number and slot assignment. Keypads are

assigned to the next available slot.

[902][001] Manual Enroll

To manually enroll individual keypads:

1. Enter [902][001] or use the [<][>] keys and press [*].

2. When prompted, enter the serial number of the keypad found

on the back of the device.

3. An error tone is sounded if an invalid serial number is

received. Once enrolled, the device model, serial number and

slot assignment are displayed. Keypads are enrolled into the

next available slot for the device. The slot assignment can be

changed using the [<][>] keys.

4. To cancel the enrollment of a module, press [#].

41

Toggle (X) <>

“Toggle name” Y/N

10 = German 20 = Romanian

11 = Swedish 21 = Russian

NOTE: Once the maximum number of devices have been

enrolled, an error tone sounds and a warning message is displayed.

[902][002] – Module Slot Assignment (LED, LCD, ICON)

This section is used to change the slot number in which a module

is enrolled. To change the slot number:

1. Enter [902][002] or use the [<][>] keys and press [*].

2. Enter the serial number of the module.

3. When prompted, enter the new two-digit slot number. The

previous slot assignment is replaced with the new one. An

error tone sounds if an invalid slot number is entered.

[902][003] – Module Slot Assignment (LCD Keypad

Only)

Similarly to [002], this section is also used to change the slot number of a module. With this option, however, the serial number is

not required. To change the slot number:

1. Enter [902][003] or the use the [<][>] keys and press [*].

2. Use the [<][>] keys to locate the module then press [*] to

select.

3. Enter the new two-digit slot number. The previous slot

assignment is replaced with the new one. An error tone

sounds if an invalid slot number is entered.

[902][101] Unenroll Keypads

1. Enter [902][101] or use the [<][>] keys and press [*].

2. Use the [<][>] keys to scroll to the specific keypad to delete.

3. Press [*] to select the module and when prompted, press [*]

again to delete it.

[903][101] Confirm Keypad

To confirm the enrollment of individual keypads and to locate

them physically:

1. Enter [903][101] or use the [<][>] and press [*].

2. Use the [<][>] keys to scroll to the applicable keypad. The

module’s serial number and slot number are displayed on the

keypad and the status LEDs on the device flash.

3. To confirm the keypad, press [*]. If communication with a

module is lost at the time of confirmation, a warning message

is displayed for 1 second before exiting the section.

Assign a Partition to the Keypad

The keypad must be assigned to a partition if supervision or keypad zones are required. Keypad assignments and keypad option

programming must be done at each keypad individually.

At each keypad installed on the system:

1. Press [*][8][Installer Code].

2. Enter [861]-[876]for Keypad Programming and Keypad Partition Mask, corresponding to keypads 1-16.

3. Press [*] for partition assignment.

4. Enter 01 to 08 for partition assignment or use the [<][>] keys

to scroll to the specific partition If partitioning is not used,

enter [01]. For Global keypads, enter [00].

5. Press [#] twice to exit programming.

6. Continue this procedure for each keypad until all have been

assigned to the correct partition.

Program Labels (LCD keypads only)

1. Press [*][8][Installer Code].

2. Press [*] and use the [<][>] keys to scroll to Zone Labels and

press [*] again.The first zone is displayed. Alternatively,

enter, [000][001].

Page 4

3. Use the [<][>] keys to scroll to the zone label to be programmed and press [*] or enter the zone

number (e.g., 001, for zone label 1).

4. Use the [<][>] keys to scroll to the desired character ’s location, using the [<][>] keys.

5. Enter the number of the corresponding character group until the desired character is displayed

(see the following table). Example, press the “2” key three times to enter the letter “F”. Press

the “2” key four times to enter the number “2”. Press [*], then scroll to “Save”. Press [*]

again to save the label. To delete a character, use the [<][>] keys to move the cursor under the

character, then press [0]. If any key other than [<][>] is pressed before [0], the cursor moves

one space to the right and deletes that character.

CHANGE CASE – Will toggle the next letter entries between upper case (A, B, C...) and lower

case letters (a, b, c...).

ASCII ENTRY – Used to enter uncommon characters. Valid entries range from 000 to 255. Use the

[<][>] keys to scroll through the characters or enter a 3-digit number from 000-255. Press [*] to

enter the character into the label.

CLEAR TO END – Clears the display from the character where the cursor was located to the end of

the display.

CLEAR DISPLAY – Clears the entire label.

6. Continue from Step 2, until all labels are programmed.

Label Library

The Label Library is a database of words commonly used when programming labels. Individual

words can be combined as needed (e.g.,

mum of 14 characters. If a word will not fit on a line, scroll right until the cursor appears at the first

character of the second line and then add the word.

To program a custom label using the Label Library:

1. Press [*][8][Installer Code][000][001].

2. Enter [001] (to program the label for zone 01), or use the [<][>] keys to scroll to the Zone

Labels and then press [*]. The current label name is displayed for that zone.

3. Press [*] to open the menu.

4. Press [*] again to select the “Word Entry” option.

5. Enter the 3-digit number corresponding to a word (see Words Library) or use the [<][>] keys

to view words in the library.

6. Press [*] to select the word.

7. To add another word, repeat the previous procedures from step 3.

8. To add a space, press the right scroll key [>].

9. To clear characters, select “Clear to End” or “Clear Display” from the menu.

10.To save the current label and exit, press [#].

Broadcast LCD Labels

If more than one LCD keypad is present on the system, labels programmed on one keypad will be

broadcast to all other LCD keypads, after the change is confirmed.

Change Brightness/Contrast/Buzzer

LCD Keypads

1. Press [*][6][Master Code].

2. Use the [<][>] keys to scroll to either Bright Control, Contrast Control, or Buzzer Control.

3. Press [*] to select one of the following settings:

• Brightness/LED Bar Control: 15 backlighting levels are available.

• Contrast Control: 15 different display contrast levels are available.

• Buzzer Control: 15 different buzzer control levels are available.

4. Use the [<][>] keys to scroll to the desired setting.

[1] - A, B, C, 1 [5] - M, N, O, 5 [9] - Y, Z, 9, 0

[2] - D, E, F, 2 [6] - P, Q, R, 6 [0] - Space

[3] - G, H, I, 3 [7] - S, T, U, 7

[4] - J, K, L, 4 [8] - V, W, X, 8

[*] - Select

[#] - Escape

Front + Door). Each line of the display supports a maxi-

Keypad Programming

1. Press [*][8][Installer Code].

2. Select one of the programming options identified in the following.

[860] Keypad Slot Number

Not for programming; the two-digit slot number is displayed for informational purposes only.

[861]-[876] Keypad Programming Sections

[000] Address of Partition

A 2-digit entry is required to assign the keypad to a partition. Entering 00 assigns the keypad as

Global. Valid entries are 00-32. The default is 01.

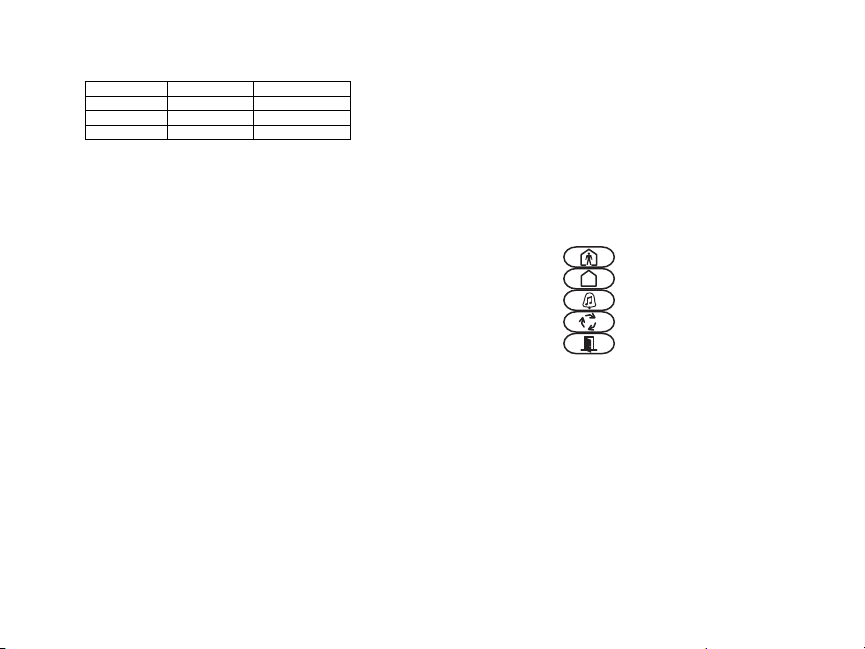

[001]-[005] Keypad Function Key Programming

To program a function key:

1. Press [*][8][Installer Code].

2. Enter [861]-[876] for keypad programming.

3. Enter [001]-[005] for function keys 1-5 or use the [<][>] keys and press [*].

4. Enter a 2-digit number to assign a function key operation - [00]-[68]. See the following table.

5. Repeat from step 3 until all function keys are programmed.

6. Press [#] twice to exit Installer Programming.

[001]-[005] Function Key Assignment

Function Key Button

[001] Key 1

[002] Key 2

[003] Key 3

[004] Key 4

[005] Key 5

Keypad Function Keys

Refer to your system installation manual for a complete list of available function key options.

[00] - Null [21] - [*][7][1]Command Output 1

[02] - Instant Stay Arm [22] - [*][7][2]Command Output 2

[03] - Stay Arm [23] - [*][7][3]Command Output 3

[04] - Away Arm [24] - [*][7][4]Command Output 4

[05] - [*][9] No-Entry Arm [29] - Bypass Group Recall

[06] - [*][4] Chime ON/OFF [31] - Local PGM Activate

[07] - [*][6]

[----][4]

System Test

[09] - Night Arm [33] - Bypass Recall

[12] - Global Stay Arm [34] - User Programming

[13] - Global Away Arm [35] - User Functions

[14] - Global Disarming [37] - Time & Date Program

[16] - [*][0] Quick Exit [39] - Trouble Display

[17] - Arm Interior [40] - Alarm Memory

[32] - Bypass Mode

Valid

Default Function

Range

00–68

03 Stay Arm I_____I_____I

00–68

04 Away Arm I_____I_____I

00–68

06

00–68

22

00–68

16

Chime ON/

I_____I_____I

OFF

Command

I_____I_____I

Output 2

Quick

I_____I_____I

Exit

[61]-[68] - Partition Select 1-8

[011] Keypad Input/Output Programming

Zone or PGM

Number

Default

000

I_____I_____I_____I

Page 5

[012] Local PGM Output Pulse Activation Time

I_____I_____I

Minutes (00-99)

I_____I_____I

Seconds (00-99)

[021] First Keypad Options

Default Opt. ON OFF

I_____I

ON

ON

ON

ON

1 Fire Key Enabled Fire Key Disabled

I_____I

2 Medical Key Enabled Medical Key Disabled

I_____I

3 Panic Key Enabled Panic Key Disabled

I_____I

4 Display Access Code When Pro-

gramming

Display Xs When Programming Access Codes

[022] Second Keypad Options

Default Opt. ON OFF

I_____I

ON

OFF

ON

ON

OFF

ON

ON

OFF

[023] Third Keypad Options

Default Opt. ON OFF

OFF

ON

OFF

OFF

OFF

[030] Downloaded LCD Message

[031] Downloaded LCD Message Duration

Default: 000 I_____I_____I_____I (Valid entries are 000-255, 000=Unlimited Msg Display)

This number represents the number of times the downloaded message must be cleared before it is

permanently removed. This message can be cleared by pressing any key.

[041] Indoor Temperature Zone Assignment

Default: 000

1 Local Clock Display ON Local Clock Display OFF

I_____I

2 Local Clock Displays 24-hr Clock Displays AM/PM

I_____I

3 Auto Alarm Mem Scroll ON Auto Alarm Mem Scroll OFF

I_____I

4 For Future Use For Future Use

I_____I

5 Power LED Enabled Power LED Disabled

I_____I

6 Power LED Indicates AC Present ON

I_____I

7 Alarms Displayed While Armed

I_____I

8 Auto-Scroll Open Zones ON Auto-Scroll Open Zones OFF

Power LED Indicates AC Present OFF

Alarms Not Displayed While

Armed

I____I

1 Armed LED Power Save Armed LED Off in Sleep Mode

I____I

2 Keypad Status Shows Stay Arm

I____I

3 5th Terminal is Keypad PGM Output 5th Terminal is Keypad Zone Input

I____I

7

Local Display of Temperature No Local Display of Temperature

Low Temperature Warning

I____I

8

Enabled

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____|

I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____I_____|

I_____I_____I_____I

Keypad Status Shows Stay/Away

Arm

Low Temperature Warning

Disabled

(Valid entries are 000-128)

[042] Outdoor Temperature Zone Assignment

Default: 000

I_____I_____I_____I

(Valid entries are 000-128)

[101]-[228] Door Chime for Zones 1-128

The keypad can be programmed to make up to four different chime sounds for individual zones.

(e.g., for Zone 1, enter section [101], for Zone 2 enter section [102]).

I_I_I

Default: 01

Valid Entries

01 6 beeps

02 Bing-Bing tone

03 Ding-Dong tone

04 Alarm tone (4 second duration)

05 Zone name

[991] Reset Keypad Programming to Factory Defaults

1. Press [*][8][Installer Code].

2. Enter [991].

3. Use the [<][>] keys to scroll to the applicable keypad.

4. Press [*] to select the keypad.

5. Re-enter [Installer Code].

6. Press [*] to reset the selected keypad to factory defaults.

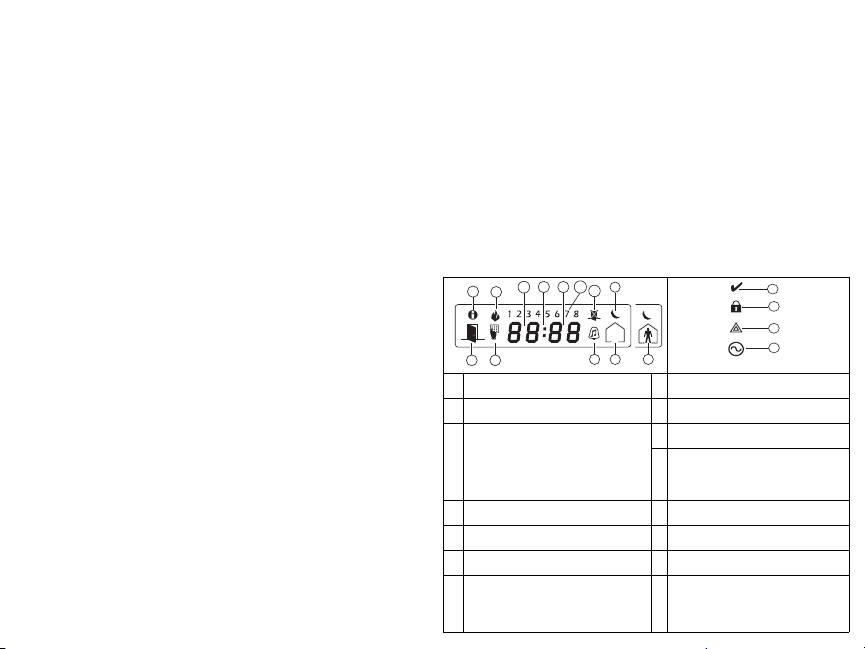

Table 3: Keypad Display Symbols

1

8

Memory – Indicates that alarms are in mem-

1

ory.

Fire – Indicates that fire alarms are in mem-

2

ory.

Clock Digits – These digits indicate the hour

and minutes when the local clock is active,

and also identify the zone when the OPEN or

3,4,

ALARM icons are active. These digits scroll

5

one zone per second from the lowest zone

number to the highest when scrolling through

zones.

1 to 8 – These numbers display toggles or dig-

6

its in binary while they are needed.

Bypass – Indicates that there are zones auto-

7

matically or manually bypassed.

Open – When zones are opened, this icon will

8

turn on and the open zones are displayed.

Program – If the system is in Installer’s or

User’s Programming, or the keypad is busy,

9

this icon flashes. If an access code is required

while accessing star menus, this LED is on

steadily to indicate that the code is required.

4

5

6

3

2

9

13

7

12

11

10

Chime – Turns on when Door Chime is ena-

10

bled and off when Door Chime is disabled.

Away – Indicates that the panel is armed in

11

away mode.

Stay – Indicates that the panel is armed in

12

stay mode.

Night – Indicates that the panel is armed in

13

night mode.

Ready Light (green) – If the Ready light is

14

on, the system is ready for arming.

Armed Light (red) – If the Armed light is

15

on, the system has been armed successfully.

System Trouble – Indicates that a system

16

trouble is active.

AC – Indicates that AC is present at the

17

main panel.

14

15

16

17

Page 6

Proximity (Prox) Tags Support (HS2ICNP/HS2ICNRFP/HS2LCDP)

The prox tag can perform any keypad function that would normally require a user access code. Present the tag to the tag reader or to the left of the keypad LCD.

Assign Proximity Tags

Using an LCD keypad:

1. Press [*][5][Master/Supervisor Code].

2. Enter a 2-digit user code.

3. Press 2.

4. Pass the enrolled tag near the tag reader on the keypad.

Delete Proximity Tags

To delete a prox tag, select the user as outlined previously.Swipe the associated prox tag. The alarm

system recognizes the tag. Press [*] to delete when prompted.

LED Bar

On the HS2ICNP/HS2ICNRFP/HS2LCDP keypads, a blue LED bar indicates that a prox tag is

approaching.

• The LED bar flashes three times when a valid prox tag is being read by the keypad.

• If the prox tag is invalid, the LED bar stays on steadily and the keypad sounds an error tone.

• The brightness of the LED bar is adjustable from the [*][6] menu. When the backlight brightness

is modified, the LED bar brightness is changed accordingly.

Downloading

The HS2LCDRF/HS2ICNRF products can be programmed over DLS V. This auto-detects the keypad type and downloads programming accordingly.

Wireless Device Setup and Programming (HS2ICNRF(P)x/HS2LCDRF(P)x)

This section describes how to enroll and program wireless devices such as contacts, motion sensors

and sirens on the alarm panel.

[804][000] Enroll Wireless Devices

1. Once the HSM2HOST is installed and enrolled on the alarm panel wireless devices can be

enrolled using the following method: Enter Installer Programming section [804][000]:

2. When prompted, either activate the device (see device installation sheet) to enroll immediately or

enter a device ID number. Do the latter to pre-enroll devices then enroll them later at the customer

site.

The alarm panel determines the type of device being enrolled and presents the appropriate programming options.

Table 4: Wireless Device Options

Device Type Programming Options

Zone

Wireless key

Siren

Repeater (01) Repeater label

3. Use the scroll keys or type in the corresponding number to select an option.

4. Scroll through the available selections, key in a number or enter text as appropriate.

5. Press [*] to accept and move to the next option.

6. Once all options are configured, the system prompts to enroll the next device.

7. Repeat the process described above until all wireless devices are enrolled.

NOTE: The configuration options listed above can be modified using [804][911] Modify Device.

[804][001]-[716] Wireless Device Configuration

To configure wireless devices:

(01) Zone type

(02) Partition assignment

(03) Zone label

(01) Partition assignment

(02) User label

(01) Partition assignment

(02) Siren label

1. Enter Installer Programming section [804] then select one of the following sub-sections:

Table 5: Wireless Zone Sub-Sections

Sub-Section Description

001-128 Configure wireless zones

551-556 Configure wireless sirens

601-632 Configure wireless keys

701-716 Configure wireless keypads

2. Select a device to configure using the scroll keys or go directly to a specific device by entering

a hotkey.

3. Use the scroll buttons or enter a hotkey to select a configuration option for the device. See

device sheets for details.

4. Press [*] to accept and move to the next option.

5. Once all options are configured, the system returns to the base configuration menu.

Repeat the process described above to configure other wireless devices.

[804][801] RF Jam Detect

RF jam detection (continuous interfering transmissions on the radio network) can be turned on or

off. When on, RF jamming is logged and reported.

To configure RF jamming:

1. Enter Installer Programming section [804][801].

2. Select one of the following options by scrolling or entering the hotkey:

Table 6: Jam Detect Options

00 Enabled/Disabled

01 UL 20/20-USA Continuous RF jamming for 20 seconds

02 EN 30/60-Europe 30 seconds of accumulated jamming within 60 seconds

03 Class 6 30/60-British

3. Press [*] to accept the selection.

4. Press [#] to exit the section.

[804][802] Wireless Supervision Window

This option is used to program the length of time a wireless device can be absent from the system

before a fault is generated.

NOTE: For EN installations, 1 hour or 2 hours must be selected.

When option 06 is used, which configures the system to generate fault conditions after a device has

been detected as absent for 24 hours, smoke detectors generate a fault condition after a maximum of

18 hours when the 200s supervision toggle option is disabled.

To program the Wireless Supervisory Window:

1. Enter Installer Programming section [804][802].

2. Select one of the following options by scrolling or entering the hotkey:

Table 7: Wireless Supervisory Window Options

00 Enabled/Disabled

01 After 1 Hour

02 After 2 Hour

03 After 4 Hour

04 After 8 Hour

05 After 12 Hour

06 After 24 Hour

3. Press [*] to accept the selection.

4. Press [#] to exit the section.

Jamming detection and reporting is enabled/disabled

Note: Must be Enabled for UL/ULC listed installations.

As EN (30/60) but reported only if the jamming duration

exceeds 5 minutes

Page 7

NOTE: For UL Residential Burglary (UL1023), Home Health Care (UL1637), ULC Residential

Burglary (ULC/ORD-C1023) installations, the maximum Supervision window shall be set to 24

hours.

For UL Residential Fire (UL985) installations, the maximum supervision window is set to 200s.

For UL Commercial Burglary (UL1610/UL365) and ULC Residential Fire (ULC-S545), the maximum supervision window shall be set to 4 hours.

[804][810] Wireless Option 1

To program wireless options:

1. Enter Installer Programming section [804][810].

2. Select one of the following options by scrolling or entering the hotkey:

Table 8: Wireless Options

01 RF Delinquency

Wireless Supervi-

02

sory/ RF Jam Alarm

03 Module Tamper

04 Fire Supervision

3. Press [*] to accept the selection and [#] to exit.

[804][841] Visual Verification Programming

To program wireless options:

1. Enter Installer Programming section [804][841].

2. Select one of the following options by scrolling or entering the hotkey:

Table 9: Visual Verification Sub-Sections

001 Visual Verification

002 View Time Window

003 View Other Alarms

[804][901]-[905] Delete Wireless Devices

To delete wireless devices:

1. Enter Installer Programming section [804] then select one of the following sub-sections:

Table 10: Module Label Sub-Sections

Sub-Section Description

901 Delete wireless zone devices

902 Delete wireless key

903 Delete sirens

On: the system cannot be armed if a wireless supervisory trouble

exists. An RF delinquency trouble is generated.

Off: wireless supervisory troubles do not prevent arming.

On: if a supervisory or jamming trouble occurs during Away arming,

the siren activates and the event is logged and reported.

Off: supervisory or RF jam troubles during Away arming do not activate the siren or get logged and reported.

On: module tampers are logged and reported.

Off: module tampers are not logged or reported.

On: fire devices are supervised every 200 seconds. If the device fails

to report within this window, a supervision trouble is generated.

Off: fire devices follow the supervision window programmed in section 802, up to a maximum of 18 hours. The supervisory window can

be programmed with a higher value, but detectors still go into fault

after 18 hours.

On: Alarms trigger image capture from PIR

Cameras

Off: Alarms do not trigger image capture

from PIR Cameras

01 Alarm + 5 Minutes

02 Alarm + 15 minutes

03 Alarm + 1 Hour

01 Fire key enabled/disabled

02 Duress key enabled/disabled

03 Medical key enabled/disabled

04 Panic key enabled/disabled

Table 10: Module Label Sub-Sections

904 Delete repeaters

905 Delete keypads

2. Select a device to delete using the scroll keys or go directly to a specific device by entering a

hotkey.

3. Press [*] to delete or [#] to exit.

[804][921]-[925] Replace Wireless Devices

Use this option to replace a faulty device enrolled on the system with another device of the same type

while maintaining the configuration of the original. The faulty device does not need to be deleted.

To replace a wireless device:

1. Enter Installer Programming section [804] then select one of the following sub-sections:

Table 11: Replace Device Sub-Sections

Sub-Section Description

921 Replace wireless zone devices

922 Replace wireless keys

923 Replace sirens

924 Replace repeater

925 Replace keypad

2. Press [*] to select a sub-section. The first available device is displayed.

3. Select a device to replace using the scroll keys or go to a specific device by entering a hotkey.

Press [*]. When prompted, activate the device (full enrollment) or enter the device ID (pre-enrollment). A message is displayed confirming enrollment.

[804][990][001 – 005] Show All Devices

Use this section to review wireless devices enrolled on the system and to view serial numbers associated with each device.

To review wireless device information:

1. Enter Installer Programming section [804][990] then select one of the following sub-sections:

• [001] – all zones

• [002] – repeaters

• [003] – sirens

• [004] – wireless keys

• [005] – keypads

2. Press [*] to select a wireless device type. The first available device is displayed.

3. Use the scroll keys to view the enrolled devices.

NOTE: This option is not fully supported by LED and ICON keypads.

[904] Placement Testing Wireless Devices

This test is used to determine RF signal status for wireless devices and can be performed at a system

keypad or at the individual device. These instructions pertain to testing at the keypad. For instructions on placement testing at the device, refer to the installation sheet provided with the wireless

equipment. The following test modes are available:

Table 12: Wireless Device Placement Test Modes

001-128 Test wireless zones Test wireless devices individually by zone.

520 Test all repeaters

550 Test all sirens

600 Test all wireless keys

Test each enrolled wireless repeater.

521-528 for repeaters 1-8

Test each enrolled wireless siren.

551-556 for sirens 1-16

Test individual wireless keys. Once in this section, press a button

on the wireless key to begin the test.

601-632 for wireless keys 1-32.

Page 8

Table 12: Wireless Device Placement Test Modes

700 Test all keypads

Two test results are provided:

• 24-hour: Average results of signal strength testing over a 24-hour period.

• Now: Signal status results of the current test.

During testing, the Ready and Armed LED's flash to indicate data is being received. A flashing

Trouble LED indicates RF interference. The following status indicators may be displayed:

Table 13: Wireless Device Status Indicators

LCD Icon* LED+ Status Repeater [905]

Strong 1 9 Strong signal strength Repeater 1

Good 2 10 Good signal strength Repeater 2

Poor 3 11 Poor signal strength Repeater 3

1-Way 4 12

Not Test 5 13

None 14

NOTE: For UL/ULC installations, only STRONG signal levels are acceptable.

*For Icon keypads, digit 1 indicates 24-hour test results; digit 2 indicates Now test results.

+For LED keypads, the first digit indicates 24-hour results; the second digit indicates Now test

results.

Troubleshooting

1. When attempting to assign a zone number to a wireless device, the keypad responds with a

long beep.

• Ensure that the keypad is properly connected to the Corbus.

2. After entering the ESN of a wireless device, then tripping it, the keypad does not indicate the

zone is open.

• Ensure the ESN has been entered correctly.

• Ensure that the zone is enabled for the partition (if partition programming is used).

• Ensure that the wireless zone is not assigned to a zone used by HSM2108 modules, an on-board

zone or a keypad zone.

• Ensure that the zone is programmed for something other than “Null Operation”. "Poor" or no

results are received from a module placement test.

• Verify that you are testing the correct zone.

• Verify that the device is in range of the keypad. Try testing the device in the same room as the

receiver.

• Confirm that the keypad is properly connected to the Corbus.

• Check that the zone is being tested correctly. Refer to the instructions that came with the device.

• Check that the batteries are working and installed correctly.

• Look for large metal objects that may be preventing the signal from reaching the keypad.

• The device must be located where consistent “Good” results are obtained. If several devices

show “Poor” results, or if panic pendants and wireless keys operate inconsistently, move the

receiver.

Test each enrolled keypad

701-716 for keypads 1-16

The device is operating in 1-way

mode only. The alarm panel cannot

configure or control the device

Displayed as the Now result if no

test was performed.

Always displayed as the 24-hour

result when testing wireless keys.

Repeater 4

Repeater 5

Repeater 6

NOTES:

Page 9

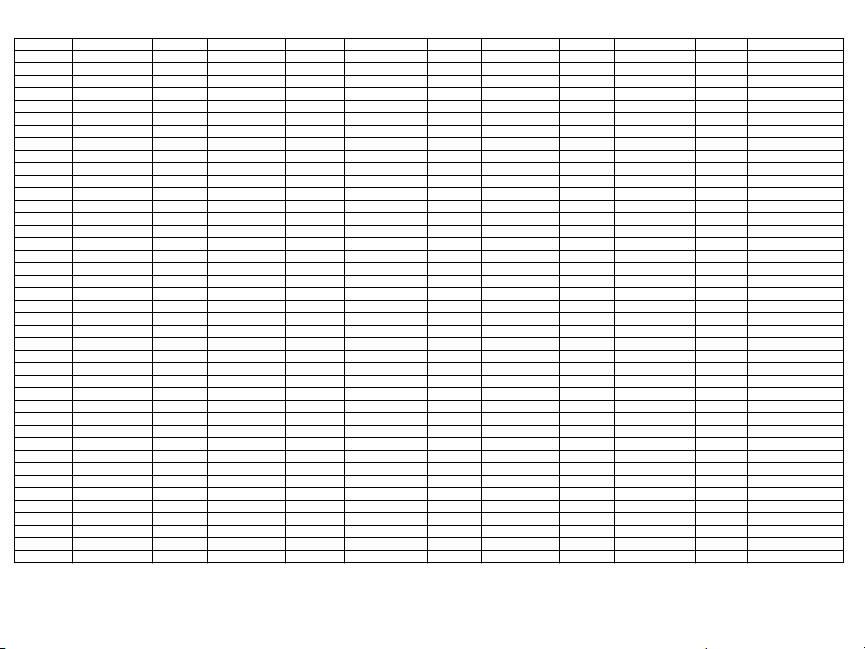

Word Library

Item # Text Item # Text Item # Text Item # Text Item # Text Item # Text

001 Aborted 042 Control 083 Garage 124 Motion 165 Shock 206 D

002 AC 043 Date 084 Gas 125 No 166 Shop 207 E

003 Access 044 Daughter’s 085 Glass 126 North 167 Side 208 F

004 Active 045 Degrees 086 Goodbye 127 Not 168 Siren 209 G

005 Activity 046 Delay 087 Gym 128 Now 169 Sliding 210 H

006 Alarm 047 Den 088 Hallway 129 Number 170 Smoke 211 I

007 All 048 Desk 089 Heat 130 Off 171 Son’s 212 J

008 AM 049 Detector 090 Hello 131 Office 172 Sound 213 K

009 Area 050 Dining 091 Help 132 OK 173 South 214 L

010 Arm 051 Disarmed 092 High 133 On 174 Special 215 M

011 Armed 052 Door 093 Home 134 Open 175 Stairs 216 N

012 Arming 053 Down 094 House 135 Opening 176 Stay 217 O

013 Attic 054 Download 095 In 136 Panic 177 Sun 218 P

014 Auxiliary 055 Downstairs 096 Install 137 Partition 178 Supervisory 219 Q

015 Away 056 Drawer 097 Interior 138 Patio 179 System 220 R

016 Baby 057 Driveway 098 Intrusion 139 Pet 180 Tamper 221 S

017 Back 058 Duct 099 Invalid 140 Phone 181 Temperature 222 T

018 Bar 059 Duress 100 Is 141 Please 182 Test 223 U

019 Basement 060 East 101 Key 142 PM 183 Time 224 V

020 Bathroom 061 Energy 102 Kids 143 Police 184 To 225 W

021 Battery 062 Enter 103 Kitchen 144 Pool 185 Touchpad 226 X

022 Bedroom 063 Entry 104 Latchkey 145 Porch 186 Trouble 227 Y

023 Bonus 064 Error 105 Laundry 146 Power 187 Unbypass 228 Z

024 Bottom 065 Exercise 106 Left 147 Press 188 Unit 229 Space

025 Breezeway 066 Exit 107 Level 148 Program 189 Up 230 ,

026 Building 067 Exterior 108 Library 149 Progress 190 West 231 027 Bus 068 Factory 109 Light 150 Quiet 191 Window 232 _ (Underscore)

028 Bypass 069 Failure 110 Lights 151 Rear 192 Zone 233 *

029 Bypassed 070 Family 111 Living 152 Receiver 193 0 234 #

030 Cabinet 071 Father’s 112 Load 153 Report 194 1 235 :

031 Canceled 072 Feature 113 Loading 154 RF 195 2 236 /

032 Car 073 Fence 114 Low 155 Right 196 3 237 ?

033 Carbon 074 Fire 115 Lower 156 Room 197 4

034 Central 075 First 116 Main 157 Safe 198 5

035 Chime 076 Floor 117 Master 158 Saver 199 6

036 Closed 077 Force 118 Mat 159 Schedule 200 7

037 Closet 078 Foyer 119 Medical 160 Screen 201 8

038 Closing 079 Freeze 120 Memory 161 Second 202 9

039 Code 080 Front 121 Menu 162 Sensor 203 A

040 Communicator 081 Furnace 122 Monoxide 163 Service 204 B

041 Computer 082 Gallery 123 Mother’s 164 Shed 205 C

Page 10

Limited Warranty

Digital Security Controls (DSC) warrants that for a period of 12 months from the date of purchase, the product shall be free of defects in materials and workmanship under normal use

and that in fulfillment of any breach of such warranty, DSC shall, at its option, repair or

replace the defective equipment upon return of the equipment to its repair depot. This warranty applies only to defects in parts and workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond the control of Digital Security Controls

such as lightning, excessive voltage, mechanical shock, water damage, or damage arising

out of abuse, alteration or improper application of the equipment. The foregoing warranty

shall apply only to the original buyer, and is and shall be in lieu of any and all other warranties, whether expressed or implied and of all other obligations or liabilities on the part of Digital Security Controls. Digital Security Controls neither assumes responsibility for, nor

authorizes any other person purporting to act on its behalf to modify or to change this warranty, nor to assume for it any other warranty or liability concerning this product. In no event

shall Digital Security Controls be liable for any direct, indirect or consequential damages,

loss of anticipated profits, loss of time or any other losses incurred by the buyer in connection with the purchase, installation or operation or failure of this product. WARNING: Digital

Security Controls recommends that the entire system be completely tested on a regular

basis. However, despite frequent testing, and due to, but not limited to, criminal tampering

or electrical disruption, it is possible for this product to fail to perform as expected. IMPORTANT INFORMATION: Changes/modifications not expressly approved by DSC could void the

user’s authority to operate this equipment.

IMPORTANT - READ CAREFULLY: DSC Software purchased with or without Products and

Components is copyrighted and is purchased under the following license terms:

This End-User License Agreement (“EULA”) is a legal agreement between You (the company, individual or entity who acquired the Software and any related Hardware) and Digital

Security Controls, a division of Tyco Safety Products Canada Ltd. (“DSC”), the manufacturer

of the integrated security systems and the developer of the software and any related products

or components (“HARDWARE”) which You acquired.

If the DSC software product (“SOFTWARE PRODUCT” or “SOFTWARE”) is intended to be

accompanied by HARDWARE, and is NOT accompanied by new HARDWARE, You may not

use, copy or install the SOFTWARE PRODUCT. The SOFTWARE PRODUCT includes computer software, and may include associated media, printed materials, and “online” or electronic documentation.

Any software provided along with the Software Product that is associated with a separate

end-user license agreement is licensed to You under the terms of that license agreement.

By installing, copying, downloading, storing, accessing or otherwise using the Software

Product, You agree unconditionally to be bound by the terms of this EULA, even if this EULA

is deemed to be a modification of any previous arrangement or contract. If You do not agree

to the terms of this EULA, DSC is unwilling to license the Software Product to You, and You

have no right to use it.

SOFTWARE PRODUCT LICENSE

The SOFTWARE PRODUCT is protected by copyright laws and international copyright treaties, as well as other intellectual property laws and treaties. The SOFTWARE PRODUCT is

licensed, not sold.

1. GRANT OF LICENSE This EULA grants You the following rights:

(a) Software Installation and Use - For each license You acquire, You may have only one

copy of the SOFTWARE PRODUCT installed.

(b) Storage/Network Use - The SOFTWARE PRODUCT may not be installed, accessed, displayed, run, shared or used concurrently on or from different computers, including a workstation, terminal or other digital electronic device (“Device”). In other words, if You have

several workstations, You will have to acquire a license for each workstation where the SOFTWARE will be used.

(c) Backup Copy - You may make back-up copies of the SOFTWARE PRODUCT, but You

may only have one copy per license installed at any given time. You may use the back-up

copy solely for archival purposes. Except as expressly provided in this EULA, You may not

otherwise make copies of the SOFTWARE PRODUCT, including the printed materials

accompanying the SOFTWARE.

2. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS

(a) Limitations on Reverse Engineering, Decompilation and Disassembly - You may not

reverse engineer, decompile, or disassemble the SOFTWARE PRODUCT, except and only to

the extent that such activity is expressly permitted by applicable law notwithstanding this

limitation. You may not make any changes or modifications to the Software, without the written permission of an officer of DSC. You may not remove any proprietary notices, marks or

labels from the Software Product. You shall institute reasonable measures to ensure compliance with the terms and conditions of this EULA.

(b) Separation of Components - The Software Product is licensed as a single product. Its

component parts may not be separated for use on more than one HARDWARE unit.

(c) Single INTEGRATED PRODUCT - If You acquired this SOFTWARE with HARDWARE,

then the SOFTWARE PRODUCT is licensed with the HARDWARE as a single integrated product. In this case, the SOFTWARE PRODUCT may only be used with the HARDWARE as set

forth in this EULA.

(d) Rental - You may not rent, lease or lend the SOFTWARE PRODUCT. You may not make it

available to others or post it on a server or web site.

(e) Software Product Transfer - You may transfer all of Your rights under this EULA only as

part of a permanent sale or transfer of the HARDWARE, provided You retain no copies, You

transfer all of the SOFTWARE PRODUCT (including all component parts, the media and

printed materials, any upgrades and this EULA), and provided the recipient agrees to the

terms of this EULA. If the SOFTWARE PRODUCT is an upgrade, any transfer must also

include all prior versions of the SOFTWARE PRODUCT.

(f) Termination - Without prejudice to any other rights, DSC may terminate this EULA if You

fail to comply with the terms and conditions of this EULA. In such event, You must destroy all

copies of the SOFTWARE PRODUCT and all of its component parts.

(g) Trademarks - This EULA does not grant You any rights in connection with any trademarks or service marks of DSC or its suppliers.

3. COPYRIGHT - All title and intellectual property rights in and to the SOFTWARE PRODUCT

(including but not limited to any images, photographs, and text incorporated into the SOFTWARE PRODUCT), the accompanying printed materials, and any copies of the SOFTWARE

PRODUCT, are owned by DSC or its suppliers. You may not copy the printed materials

accompanying the SOFTWARE PRODUCT. All title and intellectual property rights in and to

the content which may be accessed through use of the SOFTWARE PRODUCT are the property of the respective content owner and may be protected by applicable copyright or other

intellectual property laws and treaties. This EULA grants You no rights to use such content.

All rights not expressly granted under this EULA are reserved by DSC and its suppliers.

4. EXPORT RESTRICTIONS - You agree that You will not export or re-export the SOFTWARE

PRODUCT to any country, person, or entity subject to Canadian export restrictions.

5. CHOICE OF LAW - This Software License Agreement is governed by the laws of the Province of Ontario, Canada.

6. ARBITRATION - All disputes arising in connection with this Agreement shall be determined by final and binding arbitration in accordance with the Arbitration Act, and the parties

agree to be bound by the arbitrator’s decision. The place of arbitration shall be Toronto, Canada, and the language of the arbitration shall be English.

7. LIMITED WARRANTY

(a) NO WARRANTY - DSC PROVIDES THE SOFTWARE “AS IS” WITHOUT WARRANTY. DSC

DOES NOT WARRANT THAT THE SOFTWARE WILL MEET YOUR REQUIREMENTS OR THAT

OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE.

(b) CHANGES IN OPERATING ENVIRONMENT - DSC shall not be responsible for problems

caused by changes in the operating characteristics of the HARDWARE, or for problems in

the interaction of the SOFTWARE PRODUCT with non-DSC-SOFTWARE or HARDWARE

PRODUCTS.

(c) LIMITATION OF LIABILITY; WARRANTY REFLECTS ALLOCATION OF RISK - IN ANY

EVENT, IF ANY STATUTE IMPLIES WARRANTIES OR

LICENSE AGREEMENT, DSC’S ENTIRE LIABILITY UNDER ANY PROVISION OF THIS LICENSE

AGREEMENT SHALL BE LIMITED TO THE GREATER OF THE AMOUNT ACTUALLY PAID BY

YOU TO LICENSE THE SOFTWARE PRODUCT AND FIVE CANADIAN DOLLARS (CAD$5.00).

BECAUSE SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY

NOT APPLY TO YOU.

(d) DISCLAIMER OF WARRANTIES - THIS WARRANTY CONTAINS THE ENTIRE WARRANTY

AND SHALL BE IN LIEU OF ANY AND ALL OTHER WARRANTIES, WHETHER EXPRESSED

OR IMPLIED (INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE) AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON THE

PART OF DSC. DSC MAKES NO OTHER WARRANTIES. DSC NEITHER ASSUMES NOR

AUTHORIZES ANY OTHER PERSON PURPORTING TO ACT ON ITS BEHALF TO MODIFY OR

TO CHANGE THIS WARRANTY, NOR TO ASSUME FOR IT ANY OTHER WARRANTY OR LIABILITY CONCERNING THIS SOFTWARE PRODUCT.

(e) EXCLUSIVE REMEDY AND LIMITATION OF WARRANTY - UNDER NO CIRCUMSTANCES

SHALL DSC BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT

DAMAGES BASED UPON BREACH OF WARRANTY, BREACH OF CONTRACT, NEGLIGENCE,

STRICT LIABILITY, OR ANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE, BUT ARE

NOT LIMITED TO, LOSS OF PROFITS, LOSS OF THE SOFTWARE PRODUCT OR ANY ASSOCIATED EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTE OR REPLACEMENT

EQUIPMENT, FACILITIES OR SERVICES, DOWN TIME, PURCHASERS TIME, THE CLAIMS

OF THIRD PARTIES, INCLUDING CUSTOMERS, AND INJURY TO PROPERTY.

WARNING: DSC recommends that the entire system be completely tested on a regular basis.

However, despite frequent testing, and due to, but not limited to, criminal tampering or electrical disruption, it is possible for this SOFTWARE PRODUCT to fail to perform as expected.

FCC Compliance Statement - CAUTION: Changes or modifications not expressly approved

by DSC could void your authority to use this equipment.

This equipment generates and uses radio frequency energy and if not installed and used

properly, in strict accordance with the manufacturer’s instructions, may cause interference to

radio and television reception. It has been type tested and found to comply with the limits for

CONDITIONS NOT STATED IN THIS

Class B device in accordance with the specifications in Subpart “B” of Part 15 of FCC Rules,

which are designed to provide reasonable protection against such interference in any residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to television or radio reception,

which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Re-orient the receiving antenna

• Relocate the alarm control with respect to the receiver

• Move the alarm control away from the receiver

• Connect the alarm control into a different outlet so that alarm control and receiver are on

different circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician

for additional suggestions. The user may find the following booklet prepared by the FCC

helpful: “How to Identify and Resolve Radio/Television Interference Problems”. This booklet

is available from the U.S. Government Printing Office, Washington, D.C. 20402, Stock #

004-000-00345-4.

Operating Instructions shall be made available to the user.

Models: HS2LCDRF9, HS2LCDRFP9, HS2ICNRF9, HS2ICNRFP9 (operating in 912919MHz band) are compliant with applicable FCC Part 15.247 and IC RSS-210 rules.

WARNING! To comply with FCC and IC RF exposure compliance requirements, the HS2LCDRF(P)9 or HS2ICNRF(P)9 keypads should be located at a distance of at least 20 cm from

all persons during

normal operation. The antennas used for this product must not be co-located or operated in

conjunction with any other antenna or transmitter.

This device complies with FCC Rules Part 15 and with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2)this device must accept any interference that may be

received or that may cause undesired operation.

IC:160A - HS2KRFP9

The term "IC" before the radio certification number only signifies that Industry Canada technical specifications were met..

Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisee aux deux conditions suivantes :

(1)l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioelectrique subi, meme si le brouillage est susceptible d'en compromettre le fonctionnement.

+HUHE\ '6& GHFODUHV WKDW WKLV GHYLFH LV LQ FRPSOLDQFH ZLWK WKH HVVHQWLDO

UHTXLUHPHQWVDQGRWKHUUHOHYDQWSURYLVLRQVRI'LUHFWLYH(&

7KH FRPSOHWH 577( 'HFODUDWLRQ RI &RQIRUPLW\ FDQ EH IRXQG DW

KWWSZZZGVFFRPOLVWLQJVBLQGH[DVS[

&=( '6& MDNR Y¿UREFH SURKODģXMH ŀH WHQWR Y¿UREHN MH Y VRXODGX VH YģHPL

UHOHYDQWQ¯PLSRŀDGDYN\VPÝUQLFH(&

'$1'6&HUNO¨UHUKHUYHGDWGHQQHNRPSRQHQWHQRYHUKROGHUDOOHYLNWLJHNUDY VDPW

DQGUHEHVWHPPHOVHUJLWWLGLUHNWLY(&

'87+LHUELM YHUNODDUW'6& GDWGLW WRHVWHOLQ RYHUHHQVWHPPLQJLV PHWGH HLVHQHQ

EHSDOLQJHQYDQULFKWOLMQ(&

),1'6&YDNXXWWDDODLWWHHQW¦\WW¦Y¦QGLUHNWLLYLQ(&ROHQQDLVHWYDDWLPXNVHW

)5(3DU ODSU«VHQWH '6&G«FODUH TXH FHGLVSRVLWLI HVWFRQIRUPH DX[H[LJHQFHV

HVVHQWLHOOHVHWDXWUHVVWLSXODWLRQVSHUWLQHQWHVGHOD'LUHFWLYH(&

*(5+LHUGXUFKHUNO¦UW'6&GD¡GLHVHV*HU¦WGHQHUIRUGHUOLFKHQ%HGLQJXQJHQ XQG

9RUUDXVHW]XQJHQGHU5LFKWOLQLH(&HQWVSULFKW

*5(˂˜˞˱ˬ˲ ˭˞ˮ˹˪˱ˬ˯ˤ'6& ˡˤ˨˻˪ˢ˦˹˱˦˞˲˱˛ ˤ˰˲˰˧ˢ˲˛ˢ˜˪˞˦ ˰˺˩˳˶˪ˤ˩ˢ ˱˦˯

ˬ˲˰˦˻ˡˤ˯˞˭˞˦˱˛˰ˢ˦˯˧˞˦˩ˢ˹˨ˢ˯˱˦˯˙˨˨ˢ˯˰˴ˢ˱˦˧˚˯˞˪˞˳ˬˮ˚˯˱ˤ˯ˍˡˤˠ˜˞˯(&

,7$ &RQOD SUHVHQWH OD 'LJLWDO 6HFXULW\ &RQWUROV GLFKLDUDFKH TXHVWR SURGRWWR ª

FRQIRUPH DL UHTXLVLWLHVVHQ]LDOL HG DOWUH GLVSRVL]LRQL ULOHYDQWL UHODWLYH DOOD 'LUHWWLYD

&(

125'6&HUNO¨UHUDWGHQQH HQKHWHQHULVDPVYDUPHGGH JUXQQOHJJHQGHNUDYRJ

ºYULJHUHOHYDQWHNUDYLGLUHNWLY()

32/'6&RĝZLDGF]DľHXU]ÇG]HQLHMHVWZ]JRGQRĝFL]]DVDGQLF]\PLZ\PDJDQLDPL

RUD]SR]RVWDĄ\PLVWRVRZQ\PLSRVWDQRZLHQLDPL'\UHNW\Z\:(

3253RUHVWH PHLRD'6&GHFODUD TXHHVWHHTXLSDPHQWRHVW£ HPFRQIRUPLGDGH

FRP RV UHTXLVLWRV HVVHQFLDLV H RXWUDV GHWHUPLQD©·HV UHOHYDQWHV GD 'LUHFWLYD

(&

63$3RU ODSUHVHQWH'6& GHFODUDTXH HVWHHTXLSR HVW£HQFRQIRUPLGDG FRQORV

UHTXLVLWRVHVHQFLDOHV\RWURVUHTXLVLWRVUHOHYDQWHVGHOD'LUHFWLYD(&

6:('6&EHNU¦IWDU K¦UPHGDWW GHQQDDSSDUDWXSSI\OOHU GHY¦VHQWOLJD NUDYHQRFK

DQGUDUHOHYDQWDEHVW¦PPHOVHUL'LUHNWLYHW(&

© 2014 Tyco International Ltd. and its Respective Companies. All Rights Reserved. Toronto, Canada • www.dsc.com • Tech Support: 1-800-387-3630 (Canada, US), 905-760-3000

Page 11

Instructions d'installation

Ces instructions doivent être utilisées conjointement au

manuel d'installation du système de la centrale avec laquelle

il est prévu d'utiliser cet équipement.

Les pavés numériques HS2LED/HS2ICN(RF)/

HS2LCD(RF) sont compatibles avec les centrales

PowerSeries Neo HS2016/32/64, HS2014-4* et HS2128.

Les pavés numériques RF associent un émetteur-récepteur

sans fil et les pavés numériques respectifs HS2.

* Modèle non homologué UL/ULC.

Caractéristiques techniques

• Plage de Température : -10°C à +55°C (14°F à 131°F) Plage

de température pour UL/ULC : de 0°C à +49°C (de 32°F à

120°F)

• Humidité (MAX) : 93% du taux d'humidité relative, sans

condensation

• Degré de protection du boîtier plastique : IP30, IK04

• Tension nominale : 13.8 VCC nominale (en cas

d'alimentation par la centrale compatible)

• À connecter à une centrale par bus à 4 fils Corbus

• 1 entrée de zone ou une sortie PGM au choix*

• Appel de courant HS2LED/ HS2ICN(P)/HS2LCD(P)/

HS2ICNRF(P)/HS2LCDRF(P): 55mA(min)/105mA(max)

• Contact anti-sabotage à montage mural

• 5 touches de fonctions programmables

• Voyants d'état « Prêt » (vert), « Armé » (rouge), Problème

(Jaune), Alimentation Secteur (vert)

• Dimensions (H x l x P) : 168 mm x 122 mm x 20 mm

• Poids : 260 g

• Capteur de basse température

• Fréquence : 433 MHz (HS2ICNRF4/HS2LCDRF4)

• 868 MHz (HS2ICNRF8/HS2LCDRF8)

• 912-919 MHz (HS2ICNRF9/HS2LCDRF9)

• 128 zones sans fil max.

* Une zone ne doit pas être programmée comme une zone de type

incendie ou 24 h.

REMARQUE: Les pavés numériques ne possèdent aucune

pièce réparable.

REMARQUE: Seuls les modèles fonctionnant dans la plage

912-919 MHz sont homologués UL/ULC.

Contenu de l'emballage

Le coffret du pavé numérique comprend les composants

suivants : Fixation

HS2LED/ICN(RF)/

LCD(RF)

• 1 pavé numérique • 1 pavé numérique

• 4 vis de fixation • 4 vis de fixation

• 2 résistances d'extrémité

de ligne

• Des étiquettes de porte

intérieure du pavé

numérique

• 1 contact anti-sabotage • 1 contact anti-sabotage

• Instructions d'installation • Instructions d'installation

Tableau 1: Dispositifs compatibles

Détecteur de fumée PG sans fil

Détecteur de fumée et détecteur thermique PG

sans fil

Détecteur de gaz CO PG sans fil PGx913

Détecteur de mouvement IPR PG sans fil

Détecteur de mouvement IPR PG sans fil +

caméra

Détecteur de mouvement à rideaux PG sans fil

Détecteur de mouvement à double technologie

PG sans fil

Détecteur de mouvement à miroir PG sans fil

Détecteur de mouvement extérieur PG sans fil

Détecteur de bris de glace PG sans fil PGx912

Détecteur de chocs PG sans fil

Détecteur d'inondation PG sans fil

Détecteur de température PG sans fil (intérieur)

Sonde de température d'extérieur (PGx905

nécessaire)

Clé PG sans fil

Clé PG sans fil

Clé de demande d'aide PG sans fil

Clé à 2 boutons PG sans fil

Sirène intérieure PG sans fil

Sirène extérieure PG sans fil

HS2ICN(RF)P/LCD(RF)P

• 2 résistances d'extrémité de

ligne

• Des étiquettes de porte

intérieure du pavé numérique

• Mini balise (MPT) de proximité

(prox)

UL

PGx926

UL

PGx916

UL

PGx904(P)

UL

PGx934(P)

UL

PGx924

PGx984(P)

UL

PGx974(P)

UL

PGx994

UL

PGx935

UL

PGx985

UL

PGx905

PGTEMPPROB

E

UL

PGx939

UL

PGx929

UL

PGx938

UL

PGx949

UL

PGx901

UL

PGx911

Tableau 1: Dispositifs compatibles

Répétiteur PG sans fil

Contact de porte / fenêtre PG sans fil

Contact de porte / fenêtre PG sans fil avec

sortie AUX

REMARQUE: Dans ce tableau, la lettre x dans le numéro de

modèle représente la fréquence de fonctionnement du dispositif

comme suit : 9 (912-919 MHz), 8 (868 MHz), 4 (433 MHz).

REMARQUE: Seuls les modèles fonctionnant dans la plage

912-919 MHz sont homologués UL/ULC ou cUL si précisé.

Seuls les dispositifs approuvés UL sont utilisables avec les

systèmes homologués UL/ULC.

Fixation

Installez le pavé numérique où il est accessible aux points

désignés d'entrée et de sortie. Une fois un endroit sec et sûr

choisi, réalisez les opérations suivantes pour installer le

pavé numérique.

Désassembler le pavé numérique

1. Insérez la pointe d'un tournevis plat dans l'ouverture dans

la partie inférieure à droite et à gauche du pavé

numérique.

2. Soulevez doucement la façade de l'appareil. Elle sera

libérée et vous accéderez au montage.

PGx920

PGx975

PGx945

UL

UL

UL

Page 12

Montage et câblage du pavé numérique

o

mounting holes

latchlatch

ot

1. Fixez le pavé numérique en utilisant les trous de fixation.

Utilisez les 4 vis fournies à moins d'effectuer le montage

sur une seule boîte électrique. Utilisez les chevilles en

plastique fournies si l'unité est à monter sur une cloison

sèche.

2. Si vous utilisez le contact anti-sabotage du pavé, fixez la

plaque du contact au mur avec une vis.

REMARQUE:

homologuées UL/ULC, l'utilisation du contact anti-sabotage

arrière est requise.

3. Faites passez les fils dans le passage de câble ou dans les

alvéoles défonçables. Effectuez le câblage Corbus et des

zones/sorties PGM au pavé numérique. Placez le contact

anti-sabotage dans le trou à cet effet sur la plaque arrière.

4. Placez le pavé numérique sur la plaque arrière en vous

assurant que le fil est poussé dans le mur autant que

possible. Faites passer le fil à l'intérieur du pavé numérique

en vous assurant d'éviter les éléments sensibles. Remontez

la face avant en vous assurant que le pavé numérique ne

fait pas pression sur le fil qui est dessous.

REMARQUE:

avant du pavé numérique et le câblage, ouvrez le pavé numérique,

déplacez le fil et refermez. Répétez ces étapes jusqu'à ce que le

pavé numérique soit bien fermé.

Câblage

1. Avant de câbler l'unité,

vérifiez que toute la centrale

est privée d'alimentation

(Transformateur

d'alimentation secteur et

batterie).

2. Raccordez les quatre fils du

bus Corbus qui proviennent

de la centrale (rouge, noir,

jaune et vert) aux bornes du

pavé numérique. Référezvous au schéma ci-dessous :

3. Si prévu comme une entrée, un dispositif, comme un

contact de porte, peut être connecté à la borne « P/Z » du

Pour les installations anti-intrusion commerciales

S'il y a une contrainte quelconque entre la face

knock

pavé numérique. Il n'est pas alors nécessaire de tirer des

câbles vers la centrale pour le dispositif. Pour raccorder la

zone, installez un câble entre le dispositif et le pavé

numérique et raccordez un des fils provenant du dispositif

sur la borne 'Z/P' du pavé numérique et un autre sur la

borne B (noir). Si le dispositif doit être alimenté, raccordez

le fil rouge à la borne R (positif) et le fil noir à la borne B

(négatif). Lors de l'utilisation de la supervision d'extrémité

de ligne, connectez la zone selon l'une des configurations

précisées dans le manuel de référence PowerSeries Neo.

REMARQUE:

doit être de type supervisé (SEDL/DEDL). La résistance de

supervision est de 5600 Ω. Si aucune supervision EDL n'est

nécessaire, une distance maximale de 1 m (3 pieds) doit être

respectée pour le dispositif connecté. Utilisez-la conjointement et

exclusivement avec les dispositifs homologués UL/ULC.

REMARQUE: Ce dispositif de déclenchement connecté à ses

contacts d'entrée ne doit pas être utilisé pour les applications

médicales ou anti-incendie.

4. Si la borne 'Z/P' est programmée en tant que sortie, Il est

possible de relier un petit relais (comme le modèle DSC

RM-1 ou RM-2) ou un avertisseur sonore ou encore

d'autres dispositifs à courant continu entre la tension

d'alimentation positive et la borne ‘P/Z' (la charge

maximale est de 50 mA).

REMARQUE:

utilisez les dispositifs homologués UL/ULC.

Appliquer l'alimentation

Une fois que le câblage est fini et que le dispositif est fixé à la

structure de l'édifice avec au moins deux vis, mettez la

centrale sous tension :

1. Branchez les fils de la batterie aux bornes de la batterie.

2. Branchez le transformateur d'alimentation secteur.

Pour plus d'informations sur les caractéristiques de la

centrale, voir le manuel de référence PowerSeries Neo.

Programmation du pavé numérique

1. Tapez [*][8][Code de l'installateur].

2. Utilisez les touches [<][>] pour parcourir les menus ou

passez directement à une section donnée en tapant le

numéro de section.

La programmation consiste à faire basculer les options sur

« Activé » ou « Désactivé » dans chaque section ou en

renseignant les champs de données. Les options de bascule

sont activées ou désactivées en appuyant sur le numéro

correspondant sur le pavé numérique. Par exemple, pour

activer les options 1 et 4, appuyez sur les touches [1] et [4].

Toutes les options activées sont affichées (voir le diagramme

suivant).

1. Pour saisir les données, utilisez les touches [<][>] pour

sélectionner un caractère puis appuyez sur le bouton du

pavé numérique qui correspond au numéro ou à la lettre.

Pour les installations UL/ULC, l'entrée de zone

Pour les installations homologuées UL/ULC,

2. À l'aide des touches [<][>], passez au caractère suivant et

répétez la procédure. Pour savoir comment saisir des

données hexadécimales (HEX), consultez le manuel de

référence PowerSeries Neo.

Programmation de la langue

Saisissez [000][000]. Ensuite, entrez le numéro à deux

chiffres qui correspond à la langue souhaitée :

Tableau 2: Langue

01 = Anglais (défaut)

02 = Espagnol 12 = Norvégien 22 = Bulgare

03 = Portugais 13 = Danois 23 = Letton

04 = Français 14 = Hébreu 24 = Lituanien

05 = Italien 15 = Grec 25 = Ukrainien

06 = Néerlandais 16 = Turque 26 = Slovaque

07 = Polonais 17 = Utilisation 27 = Serbe

08 = Tchèque 18 = Croate 28 = Estonien

09 = Finlandais 19 = Hongrois 29 = Slovène

Attribution du pavé numérique

Les pavés numériques sont attribuables automatiquement ou

manuellement. Dans les deux cas, le numéro de série du

dispositif est utilisé comme identifiant.

REMARQUE:

système, à la mise sous tension, le pavé numérique affichera le

message : Appuyer sur une touche quelconque pour l'attribution.

D'autres pavés numériques peuvent ensuite être attribués, à partir

du premier pavé numérique. Utilisez l'une des options d'attribution

suivantes:

[902][000] Attribution automatique

Quand ce mode est sélectionné, le nombre total de pavés

numériques actuellement attribués est affiché sur le pavé

numérique.

1. Saisissez [902][000] pour lancer l'attribution automatique

des nouveaux pavés numériques. Chaque fois qu'un

dispositif est attribué, le pavé numérique affiche le type de

modèle, le numéro de série et l'affectation de

l'emplacement. Les pavés numériques sont attribués à

l'emplacement libre suivant.

[902][001] Attribution manuelle

Pour attribuer manuellement les pavés numériques un à un :

1. Saisissez [902][001] ou utilisez les touches [<][>] et

appuyez sur [*].

41

Toggle (X) <>

“Toggle name” Y/N

10 = Allemand 20 = Roumain

11 = Suédois 21 = Russe

Si aucun pavé numérique n'est attribué sur le

Page 13

2. Quand vous y êtes invité, entrez le numéro de série du pavé numérique qui est situé sur

l'arrière du dispositif.

3. Un signal d'erreur est émis si un numéro de série non valide est reçu. Une fois attribué, le

modèle du dispositif, le numéro de série et l'emplacement assigné sont affichés. Les pavés

numériques sont attribués à l'emplacement libre suivant du dispositif. L'affectation de

l'emplacement est modifiable en utilisant les touches [<][>].

4. Pour annuler l'attribution d'un module, appuyez sur [#].

REMARQUE:

émis et un message d'avertissement est affiché.

[902][002] – Affectation d'un emplacement de module (DEL, ACL, ICÔNES)

Cette section est utilisée pour modifier le numéro de l'emplacement avec lequel un module

est attribué. Pour modifier le numéro de l'emplacement :

1. Saisissez [902][002] ou utilisez les touches [<][>] et appuyez sur [*].

2. Saisissez le numéro de série du module.

3. Quand vous y êtes invité, saisissez le nouveau numéro de l'emplacement à deux chiffres.

La précédente affectation de l'emplacement est remplacée par la nouvelle. Un son d'erreur

est produit si un numéro d'emplacement non valide est saisi.

[902][003] – Affectation d'un emplacement de module (pavé numérique ACL

uniquement)

Comme pour la section [002], cette section est aussi utilisée pour modifier le numéro

d'emplacement d'un module. Cependant, avec cette option, le numéro de série n'est pas

nécessaire. Pour modifier le numéro de l'emplacement :

1. Saisissez [902][003] ou utilisez les touches [<][>] puis appuyez sur [*].

2. Utilisez les touches [<][>] pour rechercher le module puis appuyez sur [*] pour

sélectionner.

3. Saisissez le nouveau numéro de l'emplacement à deux chiffres. La précédente affectation

de l'emplacement est remplacée par la nouvelle. Un son d'erreur est produit si un numéro

d'emplacement non valide est saisi.

[902][101] Annulation de l'attribution du pavé numérique

1. Saisissez [902][101] ou utilisez les touches [<][>] et appuyez sur [*].

2. Utilisez les touches [<][>] pour défiler jusqu'au pavé numérique à supprimer.

3. Appuyez sur [*] pour sélectionner le module puis, à l'invitation, appuyez à nouveau sur

[*] pour la suppression.

[903][101] Confirmation de l'attribution du pavé numérique

Pour confirmer l'attribution des pavés numériques individuels et pour les localiser

matériellement :

1. Saisissez [903][101] ou utilisez les touches [<][>] puis appuyez sur [*].

2. Utilisez les touches [<][>] pour défiler jusqu'au pavé numérique en question. Le numéro

de série du module et le numéro de l'emplacement sont affichés sur le pavé numérique et

les témoins lumineux d'état du dispositif clignotent.

3. Pour confirmer le pavé numérique, appuyez sur [*]. Si la communication avec un module

est coupée au moment de la confirmation, un message d'avertissement est affiché pendant

1 seconde avant de quitter la section.

Affectation d'une partition à un pavé numérique

Le pavé numérique doit être affecté à une partition si la supervision ou les zones de pavé

numérique sont utilisées. L'attribution du pavé numérique et l'option de programmation du

pavé numérique doivent être faites individuellement à chaque pavé numérique.

Sur chaque pavé numérique installé avec le système :

1. Tapez [*][8][Code de l'installateur].

2. Saisissez [861][876] pour accéder à la programmation et au masque de partition du pavé

numérique, correspondant aux pavés 1-16.

3. Appuyez sur [*] pour assigner la partition.

Une fois le nombre maximum de dispositifs à attribuer atteint, un son d'erreur est

4. Tapez de 01 à 08 pour l'assignation de la partition ou utilisez les touches [<][>] pour

défiler jusqu'à la partition particulière. Si la fonction de partition n'est pas utilisée,

saisissez [01]. Pour les pavés numériques globaux, tapez [00].

5. Appuyez deux fois sur la touche [#] pour quitter la programmation.

6. Continuez cette procédure sur chaque pavé numérique jusqu'à ce qu'il soit attribué à la

bonne partition.

Étiquettes de programmation (uniquement pavés DEL)

1. Tapez [*][8][Code de l'installateur].

2. Appuyez sur [*] et utilisez les touches [<][>] pour faire défiler les étiquettes de zone et

appuyez à nouveau sur [*]. La première zone est affichée. Autrement encore, saisissez

[000][001].

3. Utilisez les touches [<][>] pour défiler jusqu'à l'étiquette de zone à programmer et

appuyez sur [*] ou tapez le numéro de zone (par exemple, 001 pour l'étiquette 1 de zone).

4. Placez-vous sur le caractère souhaité à l'aide des touches [<][>].

5. Entrez le numéro du groupe de caractères correspondants tant que le caractère souhaité

n'est pas affiché (voir le tableau suivant). Par exemple, appuyez trois fois sur la touche

« 2 » pour entrer la lettre « F ». Appuyez quatre fois sur la touche « 2 » pour entrer le

numéro « 2 ». Appuyez sur [*] puis faites défiler jusqu'à « Enregistrer ». Appuyez à

nouveau sur [*] pour enregistrer l'étiquette. Pour effacer un caractère, utilisez les touches

[<][>] pour déplacer le curseur sous le caractère puis appuyez sur [0]. Si toute autre touche

que [<][>] est appuyée avant [0], le curseur se déplace d'un espace à droite et efface ce

caractère.

MODIFIER LA CASE : fait basculer la saisie des lettres suivantes entre les majuscules (A,

B, C...) et les minuscules (a, b, c...).

SAISIR ASCII : pour saisir les caractères les moins utilisés. Des saisies valides sont de 000 à

255. Utilisez les touches [<] [>] pour faire défiler les caractères ou entrez un numéro à 3

chiffres de 000 à 255. Appuyez sur la touche [*] pour saisir le caractère dans l'étiquette.

EFFACER JUSQU'À LA FIN : efface l'afficheur du caractère de la position du curseur

jusqu'à la fin.

EFFACER AFFICHAGE : efface l'étiquette entière.

6. Continuez à partir de l'étape 2 jusqu'à ce que toutes les étiquettes soient programmées.

Bibliothèque de mots

La bibliothèque de mots est une base de données de mots fréquemment utilisés lors de la

programmation des étiquettes. Les mots peuvent être combinés selon les besoins. par ex.

Porte + Devant.

ne rentre pas dans une ligne, faites défiler jusqu'à ce que le curseur apparaisse au premier

caractère de la deuxième ligne puis ajouter le mot.

Pour programmer une étiquette personnalisée en utilisant la bibliothèque de mots :

1. Saisissez la commande [*][8][Code [000][001].

2. Saisissez [001] (pour programmer l'étiquette de zone 01) ou utilisez les touches [<][>]

pour faire défiler les étiquettes de zone puis appuyez sur [*]. Le nom de l'étiquette

courante est affiché pour cette zone.

3. Appuyez sur [*] pour ouvrir le menu.

4. Appuyez à nouveau sur [*] pour sélectionner l'option « Saisie de mot ».

[1] - A, B, C, 1 [5] - M, N, O, 5 [9] - Y, Z, 9, 0

[2] - D, E, F, 2 [6] - P, Q, R, 6 [0] - Espace

[3] - G, H, I, 3 [7] - S, T, U, 7

[4] - J, K, L, 4 [8] - V, W, X, 8

[*] - Sélectionner

[#] - Quitter

Chaque ligne de l'affichage permet un maximum de 14 caractères. Si un mot

Page 14

5. Saisissez le numéro à 3 chiffres correspondant à un mot (voir Bibliothèque de mots) ou