Page 1

PowerSeries Neo Alarm Controller

V1.2 Reference Manual

Models:

HS2016-4/HS2016/HS2032/HS2064/HS2064 E/

HS2128/HS2128 E

WARNING: This manual contains information on limitations regarding product use and function and information on the lim-

itations as to liability of the manufacturer. The entire manual should be carefully read.

Page 2

2.0 Safety Instructions for Service Personnel

Warning: When using equipment connected to the telephone network, always follow the basic safety instructions provided

with this product. Save these instructions for future reference. Inform the end-user of the safety precautions that must be

observed when operating this equipment.

Before Installing The Equipment

Ensure your package includes the following items:

l Installation and User manuals, including the SAFETY INSTRUCTIONS.

READ and SAVE these instructions!

Follow all WARNINGS AND INSTRUCTIONS specified within this document and/or on the equipment.

l HS2016-4/HS2016/2032/2064/2128 alarm controller

l Power Supply, direct plug-in

l Mounting hardware

Selecting A Suitable Location For The Alarm Controller

Use the following list as a guide to find a suitable location to install this equipment:

l Locate near a telephone socket and power outlet.

l Select a location free from vibration and shock.

l Place alarm controller on a flat, stable surface and follow the installation instructions.

Do NOT locate this product where people may walk on the secondary circuit cable(s).

Do NOT connect alarm controller to electrical t he same circuit as large appliances.

Do NOT select a location that exposes your alarm controller to direct sunlight, excessive heat, moisture, vapors, chemicals or dust.

Do NOT inst all this equipment near water. (e.g., bath tub, kitchen/laundry sink, wet basement, near a swimming pool).

Do NOT inst all this equipment and accessories in areas where risk of explosion exists.

Do NOT connect this equipment to electrical outlets controlled by wall switches or automatic t imers.

AVOID interference sources.

AVOID installing equipment near heaters, air conditioners, ventilators, and refrigerators.

AVOID locating equipment close to or on top of large metal objects (e.g., wall studs).

See "Locating Detectors and Escape Plan" on page 248 for information on locating smoke and CO detectors.

SAFETY Precautions Required During Installation

l NEVER install this equipment and/or telephone wiring during a lightning storm.

l NEVER touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the net-

work interface.

l Position cables so that accidents can not occur. Connected cables must NOT be subject to excessive mechanical

strain.

l Use only the power supply provided with this equipment. Use of unauthorized power supplies may cause damage.

l For direct plug-in versions, use the transformer supplied with the device.

WARNING: THIS EQUIPMENT HAS NO MAINS ON/OFF SWITCH. THE PLUG OF THE DIRECT PLUG-IN POWER SUPPLY IS INTENDED

TO SERVE AS THE DISCONNECTING DEVICE IF THE EQUIPMENT MUST BE QUICKLY DISCONNECTED. IT IS IMPERATIVE THAT

ACCESS TO THE MAINS PLUG AND ASSOCIATED MAINS SOCKET/OUTLET IS NEVER OBSTRUCTED.

IMPORTANT NOTE FORNORTHAMERICA!

- 2 -

Page 3

This alarm system must be installedand used within an environment that provides the pollution degree max 2 and over-voltages category II NON-

HAZARDOUS LOCATIONS, indoor only. The equipment is DIRECT PLUG-IN (external transformer) and is designed to be installed, serviced

and/or repaired by servicepersons only; [service person is defined as a person having the appropriate technicaltraining and experience necessary

to be aware of hazards to which that person may be exposed in performing a task and of measures to minimize the risksto that person or other

persons]. This equipment has no mains on/off switch; if the equipment must be quickly disconnected, the plug of the direct plug-in power supply is

intended to serve as the disconnecting device; it is imperative that accessto the mains plug and associated mains socket/outlet, isnever obstructed.

There are no parts replaceable by the end-user within this equipment. The wiring (cables) used for installation of the alarm system and

accessories, shall be insulated with PVC, TF E, PTFE, FEP, Neoprene or Polyamide.

(a) The equipment enclosure must be secured to the building structure before operation.

(b) Internal wiring must be routed in a manner that prevents:

- Excessive strain or loosening of wire on terminal connections;

- Damage of conductor insulation

(c) Disposalof used batteries must be made in accordance with local waste recovery and recycling regulations.

(d) Before servicing, DISCONNECT the power and telephone connection.

(e) DO NOT route any wiring over circuit boards.

(f) The installer is responsible to ensure that a readilyaccessibledisconnectdevice is incorporated in the building for permanently connected

installations.

The power supplymust be ClassII, FAIL SAFE with double or reinforced insulation between the PRIMARY and SECONDARY

CIRCUIT/ENCLOSURE and be an approved type acceptable to the localauthorities.All national wiring rules must be observed.

IMPORTANT NOTE FORINTERNATIONALMARKET (EU, AUS, NZ)!

This equipment is stationary-fixed and must be installed by Service Persons only (Service Person is defined as a person having the appropriate

technicaltraining and experience necessary to be aware of hazards to which that person may be exposed in performing a task and of measures to

minimize the risks to that person or other persons). It must be installedand used within an environment that provides the pollution degree max 2,

over voltages category II, in non-hazardous, indoor locationsonly.

When using equipment connected to the mains and/or to the telecommunication network, there are basic safety instructions that should always be

followed. Refer to the safety instructions provided with this product and save them for future reference. To reduce the risk of fire, electric shock

and/or injury, observe the following:

Do not attempt to servicethis product yourself. Opening or removing the cover may expose you to dangerous voltage or other risk. Refer servicing

to qualified service persons. Never open the deviceyourself. Use authorized accessories only with this equipment. DO NOT leave and/or deposit

ANY object on the top of the cabinet of this equipment! The cabinet as it is installed on the wall is not designed to support any supplementary weight!

Do not spill any liquids on the cabinet. Do not touch the equipment and its connected cables during an electricalstorm; there may be a risk of electric

shock.Never touch uninsulated wires or terminals unless the equipment has been disconnected from the mains supply and from the

telecommunication network! Ensure that cablesare positioned so that accidentscannot occur. Connected cables must not be subject to excessive

mechanicalstrain. Do not spillany type of liquid on the equipment. Do not use the Alarm system to report a gas leak if the system is near a leak. Do

not subject the connected cablesto an excessivemechanical strain.

These safety instructions should not prevent you from contacting the distributor and/or the manufacturer to obtain any further clarification and/or

answers to your concerns.

- 3 -

Page 4

Contents

2.0 Safety Instructions for Service Personnel 2

Section 1: Introduction 6

1.1 About the System 6

Section 2: Installation 11

2.1 Overview of Installation Process 11

2.2 Alarm Controller Installation 12

2.3 Wiring 12

3.1 Installing Modules 17

Section 4: Configuration 29

4.1 Basic Configuration Steps 29

4.2 Using the Keypad 29

4.3 Enrollment 31

4.4 Working with Partitions 32

4.5 Trouble Indicators 33

4.6 Keypad Partition Setup 33

4.7 Alternate Communicator Setup 36

4.8 Local Firmware Upgrade 37

4.9 Testing the System 37

Section 5: System Operation 39

5.1 Arming and Disarming 39

5.2 Partition vs. Global Keypad 39

5.3 Labels 40

5.4 Annunciation 41

5.5 Keypad Function Keys 42

5.6 Language Selection 45

5.7 [*] Commands 45

5.8 SMS Command and Control 60

5.9 Visual Verification 61

Section 6: Programming 62

6.1 How to Program 62

6.2 Programming Methods 62

6.3 Programming Descriptions 67

Section 7: Programming Worksheets 138

7.1 Label Programming 138

7.2 Zone Setup 143

7.3 System Times 146

- 4 -

Page 5

7.4 Access Codes 147

7.5 PGM Programming 147

7.6 System Lockout 160

7.7 System Options 161

7.8 Auto-Arm_Disarm 165

7.9 Partition and Zone Assignment 170

7.10 Communications 172

7.11 Call Directions 179

7.12 DLS Programming 183

7.13 Virtual Inputs 184

7.14 Schedule Programming 185

7.15 Audio Module Programming 190

7.16 Wireless Programming 195

7.17 Alternate Communicators 196

7.18 Keypad Programming 196

7.19 Template Programming 198

7.20 System Information 199

7.21 Module Programming 199

7.22 Wireless Placement Testing 200

7.23 Battery Settings 201

7.24 Restoring Factory Defaults 201

Section 8: Troubleshooting 203

8.1 Testing 203

8.2 Troubleshooting 203

Appendix 1: Reporting Codes 211

Appendix 2: Word Library 221

Appendix 3: Template Programming Tables 223

Appendix 4: Regulatory Approvals 230

4.1 SIA False Alarm Reduction Installations: Quick Reference 233

4.2 Australia Compliance Mark 237

4.3 New Zealand Telepermit Grant 237

Appendix 5: ASCII Characters 240

Appendix 6: Wiring Diagrams 241

Appendix 7: Specifications 246

8.0 Index 254

- 5 -

Page 6

Section 1: Introduction

CP-01

EN

NFA2P

UK

1.1 About the System

The PowerSeries Neo alarm panel is a feature-rich, scalable alarm system designed for residential and light commercial

use. The alarm panel supports both hardwired and wireless devices. This section lists the features of the alarm panel, avail-

able models, and compatible devices.

The following symbols are used to indicate features or methods of operation that are only available in a particular market. No

symbol indicates the feature or operation is available for all markets unless noted specifically otherwise.

- North America

- Europe

- France

- United Kingdom

1.1.1 Features

The following features are available on the PowerSeries Neo alarm controller.

Zones, Wireless Keypads, Wireless Keys, Panic Pendants and Proximity Tags

l 16, 32, 64, or 128 wireless or hardwired zones supported, including 6 or 8 hardwired zones available on the con-

troller.

l 40 zone types and 14 programmable zone attributes

l Up to 16 separate wireless keypads supported

l Up to 32 separate wireless keys or supported

l Up to 999 separate proximity tags supported

Access Codes

l Up to 1002 access codes: 1000 (level 2-EN) including one system master code (level 3-EN). In addition, one installer

code (level 3-EN), and one maintenance code are available.

Note: EN50131-1 compliant systems using 1000 access codes shall set the access code to 8 digits (section [041],

option 02).

l Programmable attributes for each user code (see "Access Code Attributes" on page 53)

Programmable Outputs (PGMs)

l Up to 4 programmable outputs (PGM) on the alarm controller with 49 available options

l 22, 38, 80, 148 maximum programmable outputs

System Supervision Features

The PowerSeries Neo continuously monitors a number of possible trouble conditions and provides audible and visual indic-

ation at the keypad. Trouble conditions include:

l AC power failure

l Zone trouble

l Fire trouble

l Telephone line trouble

l Communicator trouble

l Low battery condition

Page 7

Section 1: Introduction

l RF jam

l AUX power supply fault

l Failure to communicate

l Module fault (supervisory or tamper)

Additional Features

l 2-way wireless device support

l Visual verification (images + audio)

l Proximity tag support

l PGM scheduling

l Quick arming

l User, partition, module, zone and system labels

l Programmable system loop response

l Keypad and panel software versions viewable through keypad

l Doorbell zone type

l Low battery PGM type

1.1.2 Available Models

The following alarm controller models are available:

l HS2016-4

l HS2016

l HS2032

l HS2064

l HS2064 E

l HS2128

l HS2128 E

Note: Not all models are available in all markets.

Model Differences

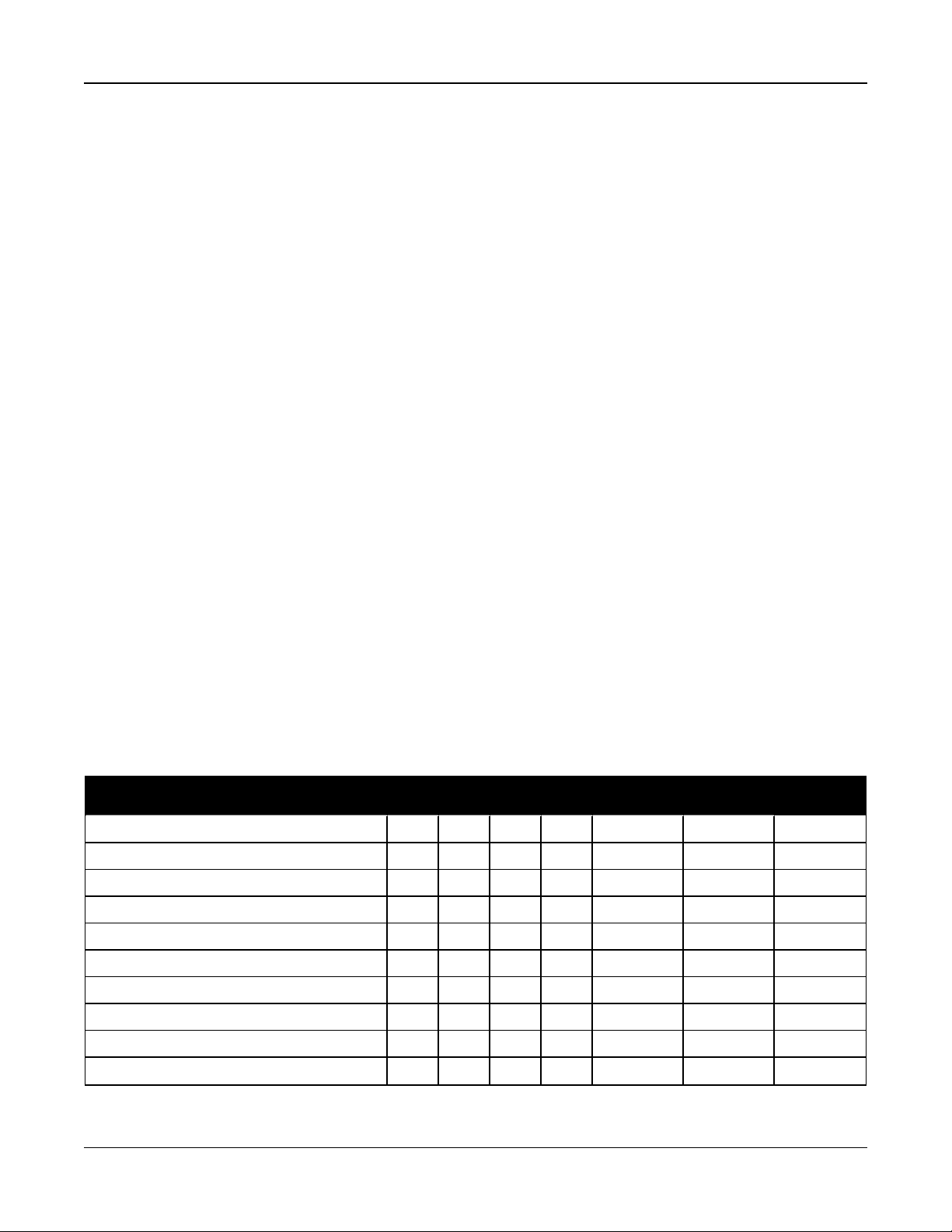

The table below lists the features of each alarm system model.

Table 1-1 Model Differences

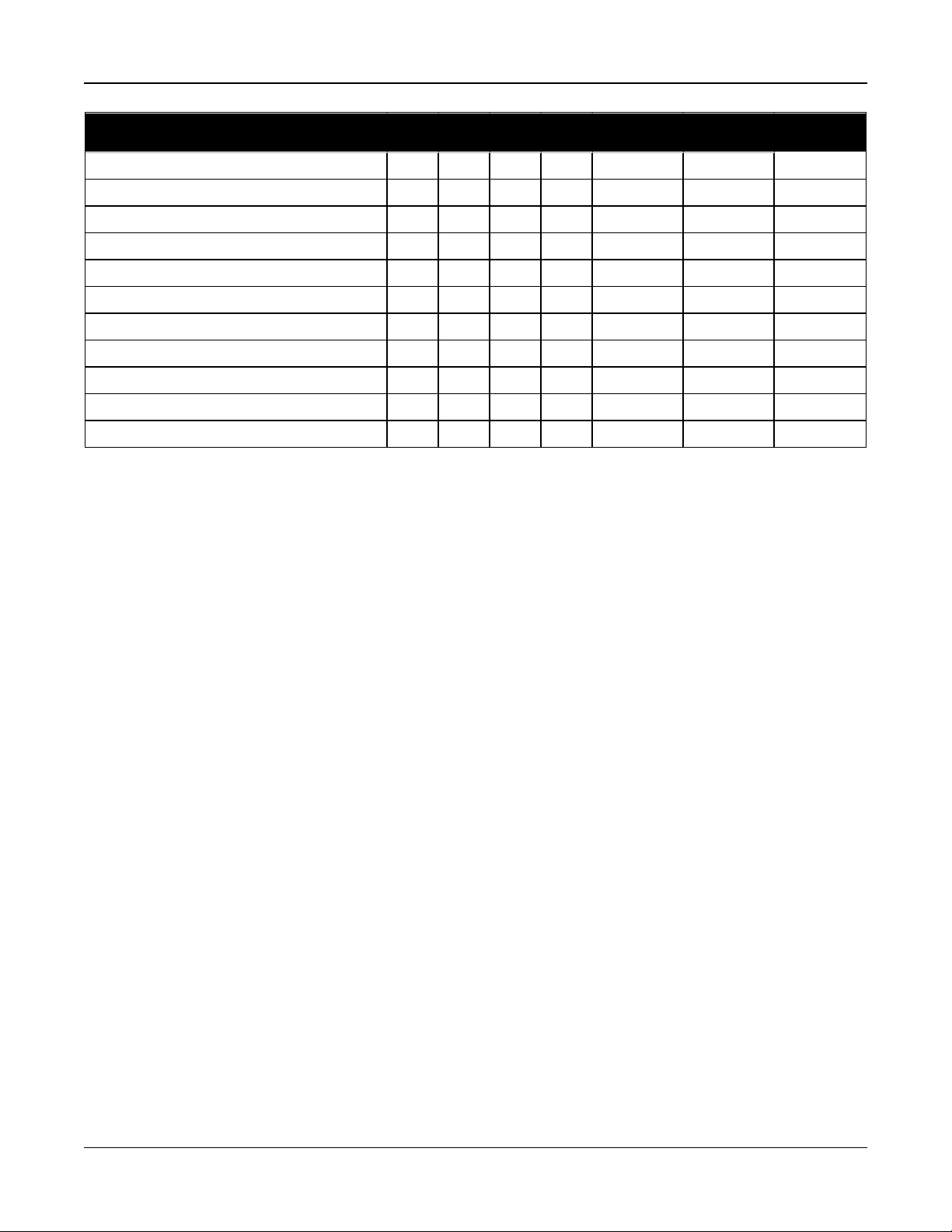

Features HS2128EHS2128 HS2064EHS2064 HS2032 HS2016 HS2016-4

Hardwired zones 128 128 64 64 32 16 16

Onboard zone inputs 8 8 8 8 8 6 8

Wirelesszones 128 128 64 64 32 16 32

Partitions 8 8 8 8 4 2 8

Users 1000 95 500 95 72 48 48

Onboard outputs 4 4 4 4 2 2 4

Max outputs 148 148 80 80 38 22 24

Keypads 16 16 8 8 8 8 8

Wirelesskeys 32 32 32 32 32 16 16

Wirelesssirens 16 16 8 8 8 4 4

- 7 -

Page 8

Section 1: Introduction

Features HS2128EHS2128 HS2064EHS2064 HS2032 HS2016 HS2016-4

Wirelessrepeaters * 8 8 8 8 8 4 4

Proximitytags 999 94 499 94 71 47 47

Alt Comm. phone #’s 4 4 4 4 4 4 4

User-programmable phone #’s 8 8 8 8 8 8 8

Event buffer 1000 1000 500 500 500 500 500

8-zone expander HSM2108 15 15 7 7 3 1 1

Power supplyHSM2300 4 4 3 3 3 3 3

Power supply/high-current output expander HSM2204 4 4 3 3 1 1 1

8-output expander HSM2208 16 16 8 8 4 2 2

2- way wireless integration module 1 1 1 1 1 1 1

Audio verification module HSM2955 1 1 1 1 1 1 1

*For UL installations, 2 repeaters must be installed for proper signal routing.

- 8 -

Page 9

Section 1: Introduction

1.1.3 Compatible Devices

The following wireless devices and modules are compatible with this alarm controller.

Note: On the table below and throughout this document, x in the model number represents the operating frequency of the

device as follows: 9 (912-919 MHz), 8 (868MHz), 4 (433MHz).

Note: Only models operating in the band 912-919 MHz are UL/ULC listed where indicated. OnlyULapproved devices are to

be used with UL/ULC listed systems.

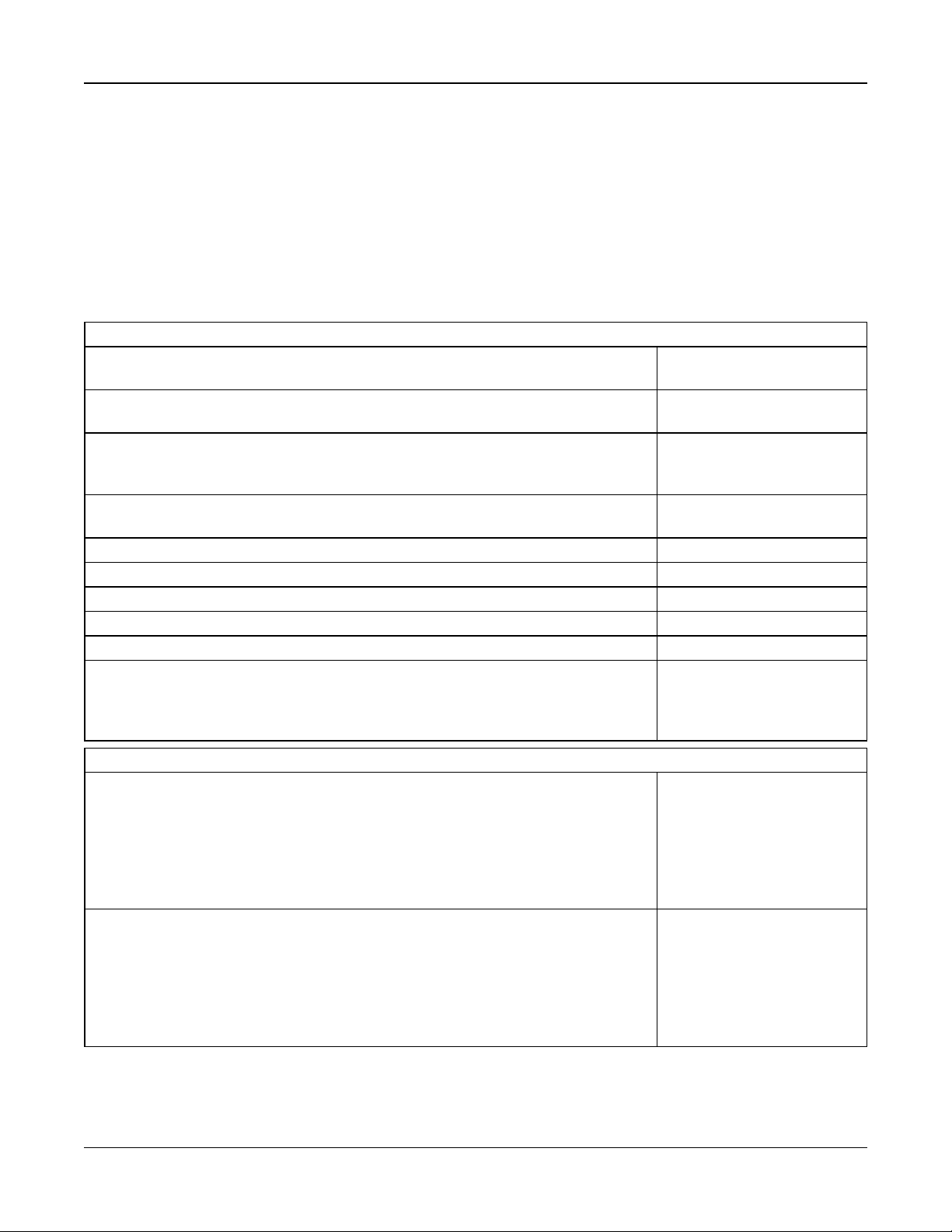

Table 1-2 Compatible Devices

Modules

Wireless keypads HS2LCDWFx

HS2LCDWFPx

Hardwired keypads with 2-way wireless integration module HS2LCDRFx

HS2LCDRFPx

HS2LCDP

HS2ICN

HS2TCHP

UL

UL

UL

UL

Hardwired keypads HS2LCD

Touchscreen Keypad

Note: For ULC-s559 Listed applications the HS2TCHP touchscreen keypad is for supplementary use only.

2-way wireless integration module HSM2HOSTx

8-zone expander HSM2108

8-output expander HSM2208

Power supply HSM2300

4 high current output expander HSM2204

Alternate communicator 3G2080

3G2080R

TL280

TL280R

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

HS2LCDWFPVx

HS2ICNRFx

UL

HS2ICNRFPx

HS2ICNP

HS2LED

TL2803G

TL2803GR

PCL-422

UL

UL

UL

UL

UL

UL

Hardwired Devices

2-wire smoke detector

y= A, B, or C

A: ULC listed models

B: UL list ed models

C: European and Australian models

4-wire smoke detector

x= A, B, or C

A: ULC listed models

B: UL list ed models

C: European and Australian models

- 9 -

FSA-210y

UL

FSA-210yT

FSA-210yS

FSA-210yST

FSA-410y

UL

FSA-410yT

FSA-410yS

FSA-410yST

UL

UL

UL

FSA-210yRT

FSA-210yRS

FSA-210yRST

FSA-410yR

FSA-210yR

UL

UL

UL

FSA-410yRT

FSA-410yRS

FSA-410yRST

UL

UL

UL

UL

UL

UL

UL

UL

Page 10

Section 1: Introduction

CO detector CO-12/24

12-24SIR

FW-CO12

UL

UL

UL

FW-CO1224

CO1224

UL

UL

Wireless Devices

Wireless PG smoke detector PGx926

Wireless PG smoke and heat detector PGx916

Wireless PG CO detector PGx913

Wireless PG PIR motion detector PGx904(P)

Wireless PG PIR + camera motion detector PGx934(P)

Wireless PG curtain motion detector PGx924

Wireless PG dual tech motion detector PGx984(P)

Wireless PG mirror motion detector PGx974(P)

Wireless PG outdoor motion detector PGx994

Wireless PG glass break detector PGx912, PGx922

Wireless PG shock detector PGx935

Wireless PG flood detector PGx985

Wireless PG temperature detector (indoor use) PGx905

Outdoor temperature probe (requires PGx905) PGTEMP-PROBE

Wireless PG key PGx939

Wireless PG key PGx929

Wireless PG panic key PGx938

Wireless PG 2-button key PGx949

Wireless PG indoor siren PGx901

Wireless PG outdoor siren PGx911

Wireless PG repeater PGx920

Wireless PG door/window c ontact PGx975

Wireless PG door/window c ontact w/ AUX PGx945

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

UL

Central Station Receivers

SG-System I, II, III, IV, 5

Enclosures

The PowerSeries Neo main board can be installed in the metal enclosures listed below: Tamper protection switches can be installed on all

enclosures, including door opening protection and/or removal from the mounting position. Doors can be secured using screws or keylock.

• Model PC5003C (removable door) made of 22Ga steel, painted, dimensions: 248mm(L) x 298mm(W) x 76mm(H), weight: 4.5Kg (with PCB,

7AH battery and transformer included)

• Model Power UC1 made of 18Ga steel, painted, dimensions: 315mm(L) x 319mm(W) x 100mm(H), weight: 6.15Kg (with PCB, 7AH battery and

transformer included).

Model PC4051C made of 18Ga steel, painted. 427mm(L) x 265mm(W) x 105mm(H).

For EN50131-1 Grade 2 compliant installations, all holes on the side of the cabinets shallbe covered (plugged) if no accessories are installed in

the cabinet that will use these mounting holes.

The equipment enclosure shallbe secured to the building structure before operation. Use 4 screws (appropriate for the wall material on which it is

attached) inserted through the four mounting holes provided in the back of the enclosure base.

- 10 -

Page 11

Section 2: Installation

2.1 Overview of Installation Process

The steps below are provided to assist with the installation of the alarm system. Read over this section to get an overall

understanding of the order of installation. Working from this plan can help reduce problems and reduce the overall time

required for installation.

Step 1 – Create a Layout

Draw a rough sketch of the site and include all alarm detection devices, zone expanders, keypads and other required mod-

ules.

Step 2 – Mount the Panel

Decide on a location for the alarm panel and secure it to the wall using suitable mounting hardware. see "Mounting the

Enclosure" on page 12.

Step 3 – Wire the Alarm Controller

Wire each of the modules to the alarm controller following the guidelines provided in "Corbus Wiring" on page 14.

Step 4 – Wire Zones

Complete all zone wiring. Follow the guidelines provided in "Zone Wiring" on page 21 to connect zones using normally

closed loops, single EOL resistor, double EOL resistors, fire zones and keyswitch arming zones.

Step 5 – Complete Wiring

Complete all other wiring including bells or sirens, telephone line connections, ground connections or any other wiring

necessary. Follow the guidelines provided in "Terminal Descriptions" on page 12.

Step 6 – Power up the Control Panel

Once all zone and alarm controller wiring is complete, connect the battery before applying AC, and power up the system.

The alarm controller will not power up if only the battery is connected.

Step 7 – Enroll Keypads and Modules

All keypads must be enrolled in order to operate on the system. To enroll the first keypad, see "Enrolling the First Keypad "

on page 31. To enroll optional keypads, enter installer's programming section [902][000]. For more information, see "Module

Programming" on page 133.

Step 8 – Confirm Module Supervision

By default, all modules are supervised upon installation. Supervision is enabled at all times. To confirm that each module is

properly supervised, see "[903] Confirm Module" on page 134.

Step 9 – Enroll Wireless Devices

Wireless devices are enrolled via the wireless transceiver module (HSM2HOSTx) or RF keypad and Installer Programming

section [804]. See "Wireless Programming" on page 131 to enroll wireless devices.

Step 10 – Program the System

Section 5 on "Programming" on page 62 provides a complete description of how to program the alarm controller. It contains

complete descriptions of the various programmable features and options. Fill out the programming worksheets starting at

"Programming Worksheets" on page 138 completely before attempting to program the system.

Step 11 – Test the System

Test the panel completely to ensure that all features and functions operate as programmed.

Page 12

Section 2: Installation

2.2 Alarm Controller Installation

Begin the installation by mounting the alarm controller in the metal enclosure using the stand-offs provided. Optional mod-

ules, such as the HSM2108 and HSM2208, can also be mounted in the enclosure.

Install hardware in the sequence indicated on the following pages.

2.2.1 Mounting the Enclosure

Locate the panel in a dry area, preferably near an unswitched AC power source and the incoming telephone line. Complete

all wiring before applying AC or connecting the battery.

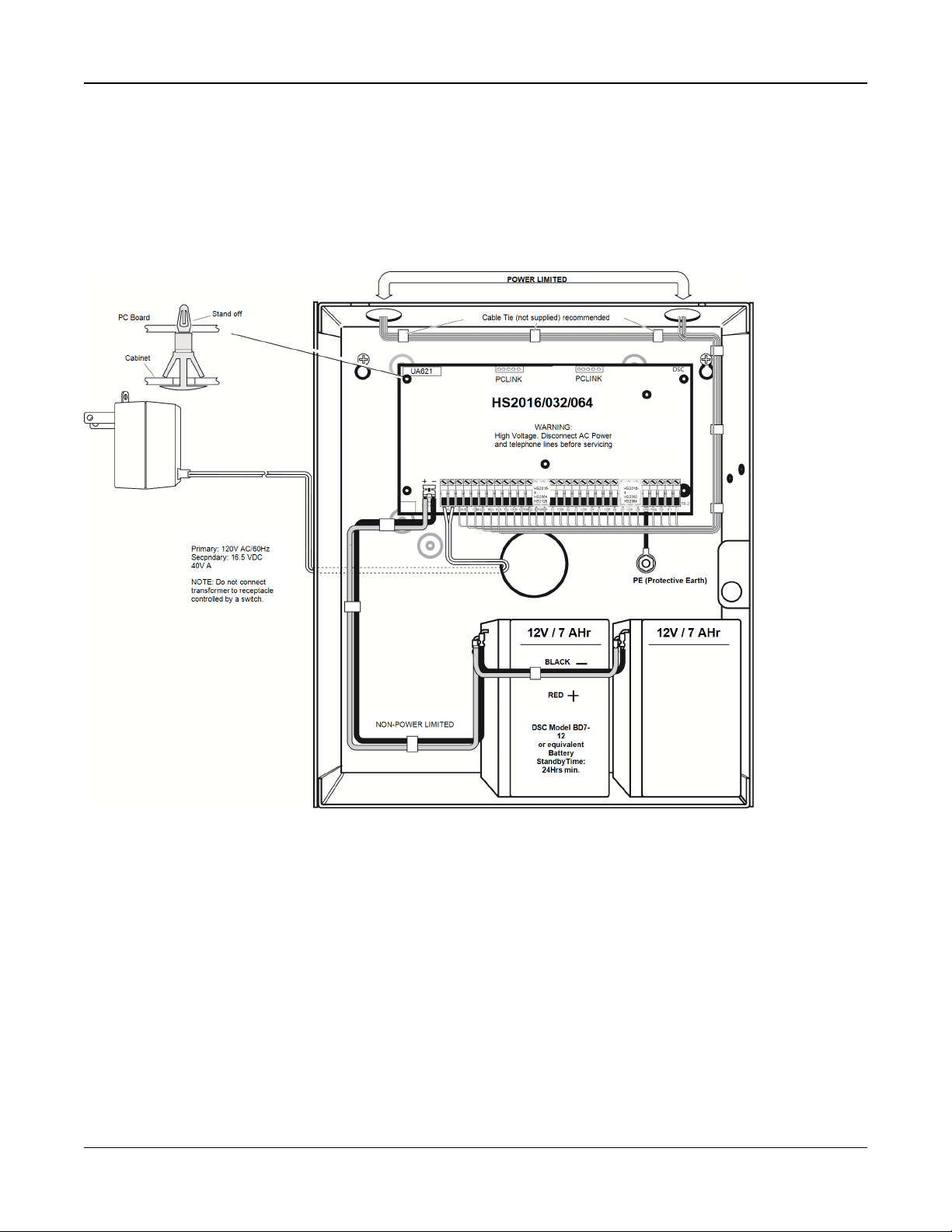

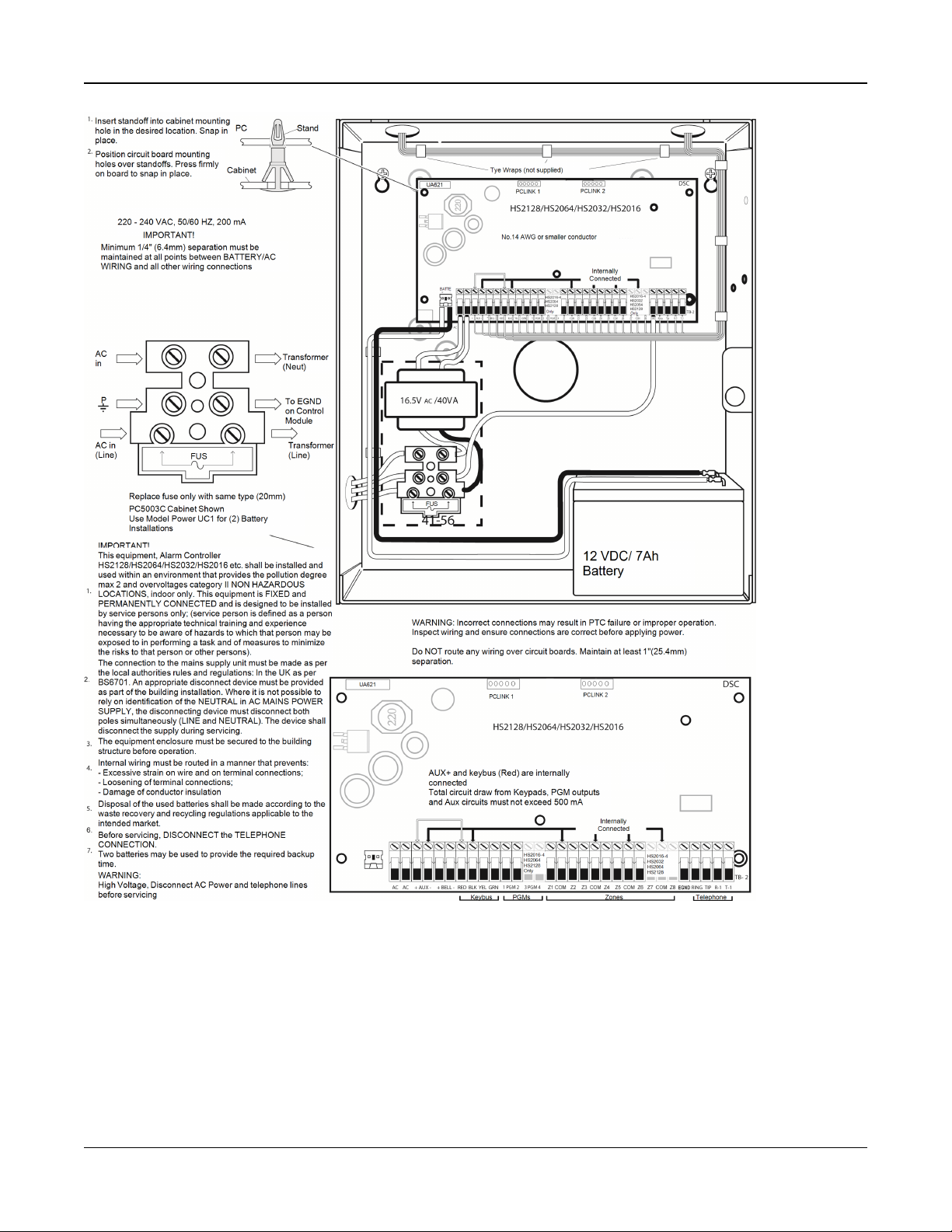

2.3 Wiring

All wiring entry points on the enclosure are designated by arrows. All circuits are classified UL power limited except for the

battery leads. Minimum 1/4” (6.4mm) separation must be maintained at all points between power limited and non-power lim-

ited wiring and connections.

2.3.1 Terminal Descriptions

The following terminals are available on the PowerSeries Neo alarm controller.

Terminal Description

BAT+, BAT- Battery terminals.Use to provide backup power and additional current when system demands exceed the power output of the

transformer, such as when the system is in alarm.

Do not connect the battery untilall other wiring is complete.

AC Power terminals.

Connect the battery before connecting the AC. Do not connect the battery or transformer until allother wiring is complete.

AUX+, AUX- Auxiliary terminals. Use to power modules, detectors, relays, LEDs, etc. (700mA MAX). Connect the positive side of device to

AUX+, the negative side to AUX-.

BELL+, BELL- Bell/Siren power (700mA MAX). Connect the positive side of any alarm warning device to BELL+, the negative side to BELL-.

RED, BLK,

YEL, GRN

PGM1 to

PGM4

Z1 to Z8

COM

EGND Earth ground connection.

TIP, RING, T-

1, R-1

Corbus terminals. Use to provide communication between the alarm controller and connected modules. Each module has four

Corbus terminals that must be connected to the Corbus.

Programmable output terminals. Use to activate devices such as LEDs.

(PGM1, PGM3, and PGM4: 50mA PGM2: 300mA or can be configured as an input)

Zone input terminals. Ideally,each zone should have one detection device; however, multipledetection devicescan be wired to

the same zone.

Telephone line terminals.

PCLINK_1 DLS/SA

PCLINK_2 DLS/SA, Alternate Communicator

- 12 -

Page 13

Section 2: Installation

2.3.2 Wire Routing for Power & Non-Power Limited

All wiring entry points are designated on the diagram by arrows. All circuits are classified UL installation power limited

except for the battery leads which are not power limited.

A minimum ¼” (6.4mm) separation must be maintained at all points between power limited and non-power limited wiring

and connections. See "Wiring Diagrams" on page 241 for expanded diagrams.

Note: Wire entry for power limited wiring must be separated by a different entry access from non-power limited wiring.

Figure 2-1 Wiring Routing (North America only)

- 13 -

Page 14

Section 2: Installation

Figure 2-2 Wiring Routing (EN50131 only)

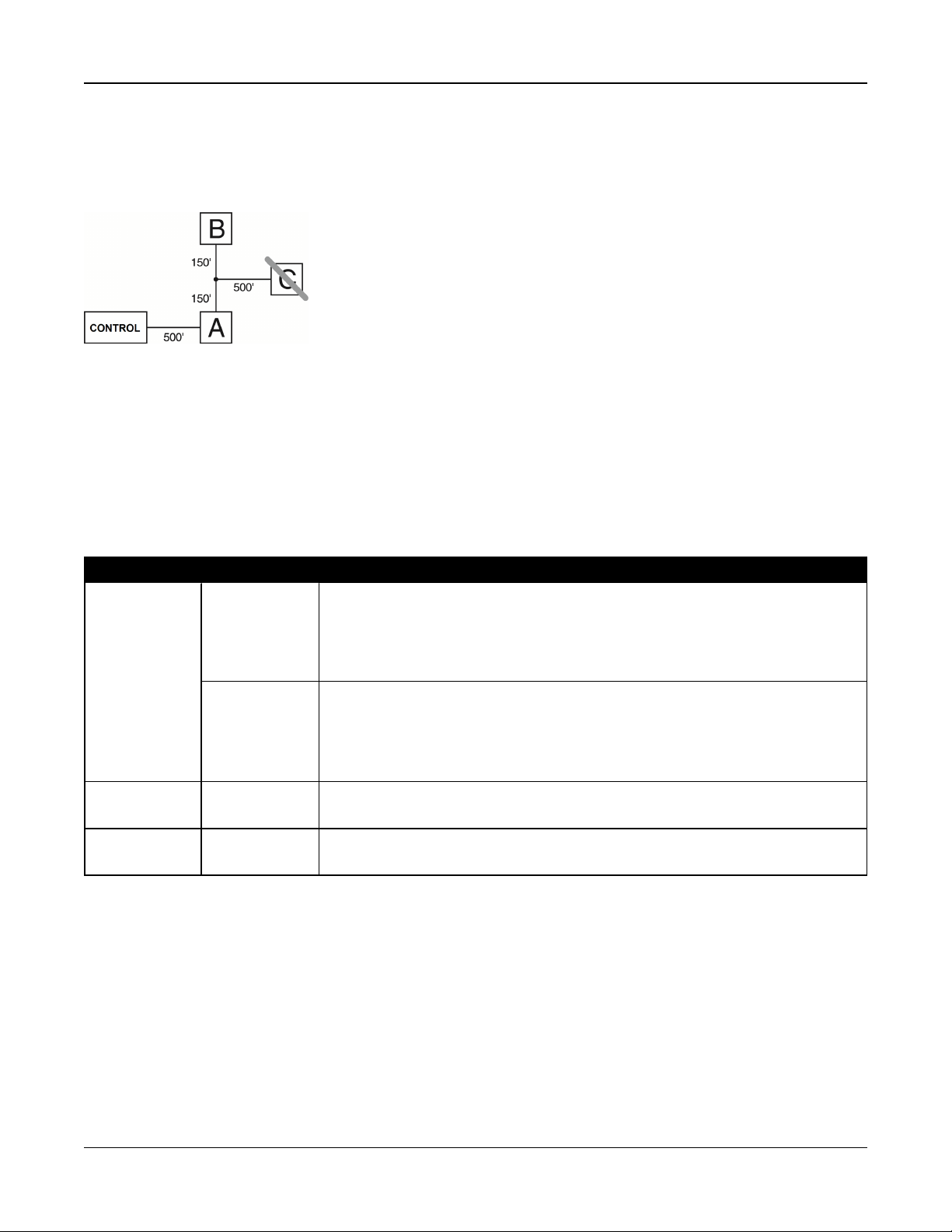

2.3.3 Corbus Wiring

The RED and BLK Corbus terminals are used to provide power while YEL and GRN are used for data communications. The

4 Corbus terminals of the alarm controller must be connected to the 4 Corbus terminals or wires of each module.

The following conditions apply:

l Corbus should be run with minimum 22 gauge quad, two pair twisted preferred.

l The modules can be home run to the panel, connected in series or can be T-tapped.

- 14 -

Page 15

Section 2: Installation

l Do not use shielded wire for Corbus wiring.

Note: Any module can be connected anywhere along the Corbus. Separate wire runs for keypads, zone expanders etc. are

not necessary.

Note: No module can be more than 1,000'/305m (in wire length) from the panel. Do not use shielded wire for Corbus wiring.

Figure 2-3 Corbus Wiring

Module (A) is wired correctly as it is within 1,000'/305m of the panel, in wire distance. Module (B) is wired correctly as it is

within 1,000'/305m of the panel, in wire distance. Module (C) is NOT wired correctly as it is farther than 1,000'/305m from the

panel.

Current Ratings

In order for the system to operate properly, the power output of the alarm controller and power supply modules cannot be

exceeded. Use the following data to ensure that the available current is not exceeded.

Table 2-1 System Output Ratings

Device Output Rating (12VDC)

AUX: 700mA. Subtract the listed rating for each keypad, expansion module and accessory connected to

HS2016-4

HS2016

HS2032

HS2064

HS2064 E

HS2128

HS2128 E

HSM2208 AUX: 250mA. Continuous rating. Subtract for each device connected. Subtract the total load on this

HSM2108 AUX: 100mA. Subtract for each device connected. Subtract the total load on this terminal from the panel

BELL: 700mA. Continuous rating.

AUX or Corbus. At least 100mA must be reserved for the Corbus.

2.0A. short term. Available only with standby battery connected. Not for UL/ULC or EN certified

applications.

terminal from the alarm panel AUX/Corbus output.

AUX/Corbus output.

- 15 -

Page 16

Alarm Controller Current Calculation

Maximum (Standby or Alarm)

AUX (700mA max. including PGMs 1-4)

Corbus (700mA max.)***

PCLink+ (Alt. Com.:125mA)

Total (must not exceed 700mA)

***See Corbus Current Calculation Chart.

For UL, ULC and Commercial Listed applications, the total standby and alarm current cannot exceed 700mA.

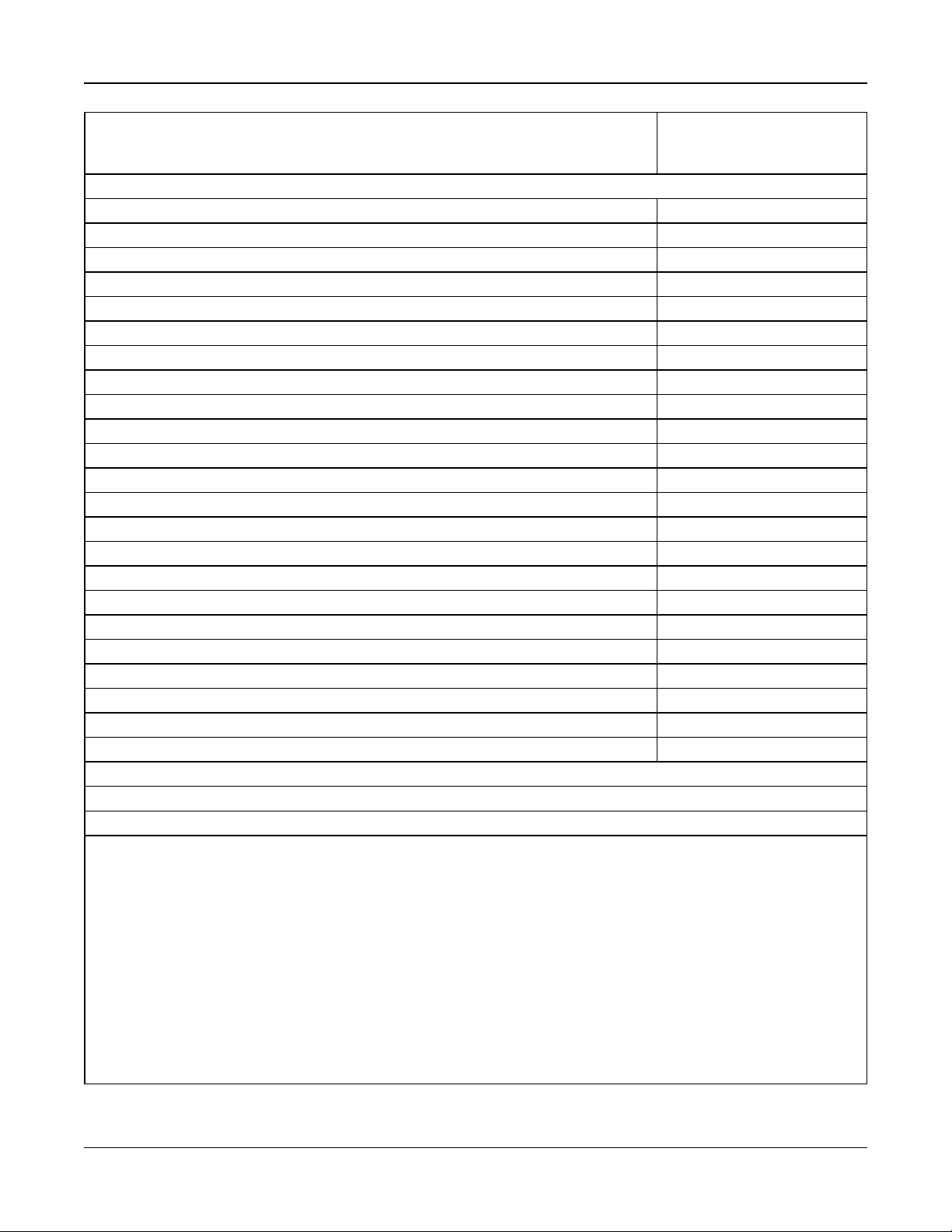

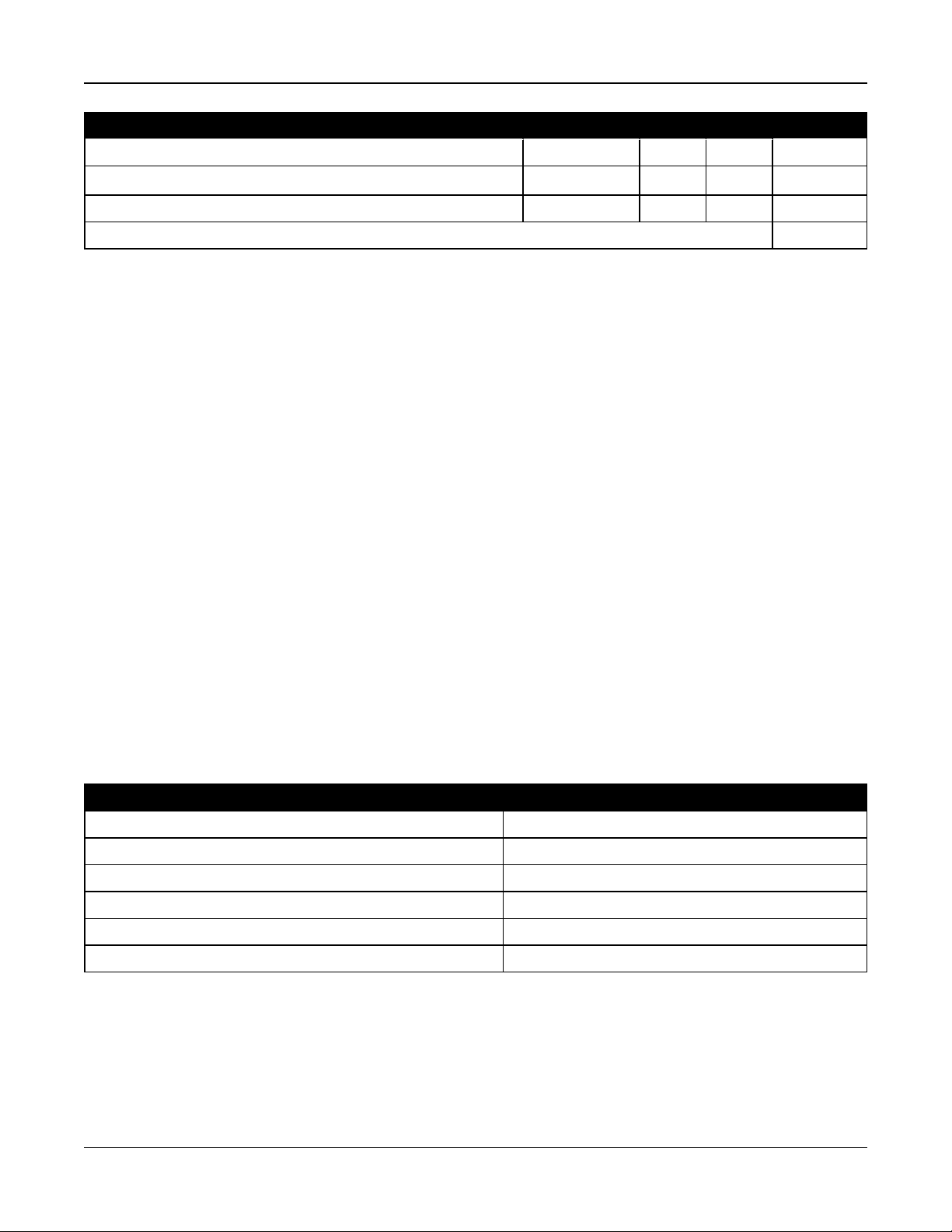

Table 3-1 Corbus Current Calculation Chart

Item Current (mA) x Quantity Total (mA)

HS2016-4/HS2016/HS2032/HS2064/HS2064 E/HS2128/HS2128 E 85 X 1 85

HS2LCD 105 x

HS2ICN 105 x

HS2LED 105 x

HS2LCDP 105 x

HS2ICNP 105 x

HS2LCDRF 105 x

HS2ICNRF 105 x

HS2ICNRFP 105 x

HS2TCHP 160 x

Current required for connected devices =

HSM2108* 30 x

AUXoutput current of HSM2108

HSM2208* 40 x

AUXoutput current of HSM2208

HSM2300/2204* 35 x

- 16 -

Page 17

Item Current (mA) x Quantity Total (mA)

HSM2HOSTx 35 x

HSM2955** x

3G2080(R)/TL2803G(R)/TL280(R) 125 (PCLINK) x

Total Corbus Current =

*These units draw current from the Corbus to power devices external to the module. This current must be added to the total

Corbus current. See manufacturer's specifications for the current draw of each device.

** For HSM2955 current draw refer to HSM2955 installation manual.

Line Loss

Voltage loss through wire resistance must be considered for all installations. To ensure proper operation, at least 12.5VDC

must be applied to all modules on the system (when AC is connected and the battery is fully charged). If less than 12.5VDC is

applied, system operation is adversely affected.

To correct the problem, try any or all of the following:

1. Connect a HSM2300/2204 power supply between the alarm controller and the module to provide additional power to the

Corbus.

2. Reduce the length of the Corbus run to the module.

3. Increase the gauge of wire.

Capacitance Limits

An increase in capacitance on the Corbus affects data transmission and causes the system to slow down. Capacitance

increases for every foot of wire added to the Corbus. The capacitance rating of the wire used will determine the maximum

length of the Corbus.

For example, 22-gauge, non-shielded, 4-conductor wire has a typical capacitance rating of 20 picofarads per foot (which is

20nF/1000’). For every 1000' of wire added – regardless of where it is run – the capacitance of the Corbus increases by

20nF.

The following table indicates the total wire distance allowed for the capacitance rating of the wire used:

Table 3-2 Wire Capacitance

Wire Capacitance per 1000’ (300m) Total Corbus Wire Length

15nF 5300’/1616m

20nF 4000’/1220m

25nF 3200’/976m

30nF 2666’/810m

35nF 2280’/693m

40nF 2000’/608m

3.1 Installing Modules

Remove all power from the system while connecting modules to the alarm controller.

- 17 -

Page 18

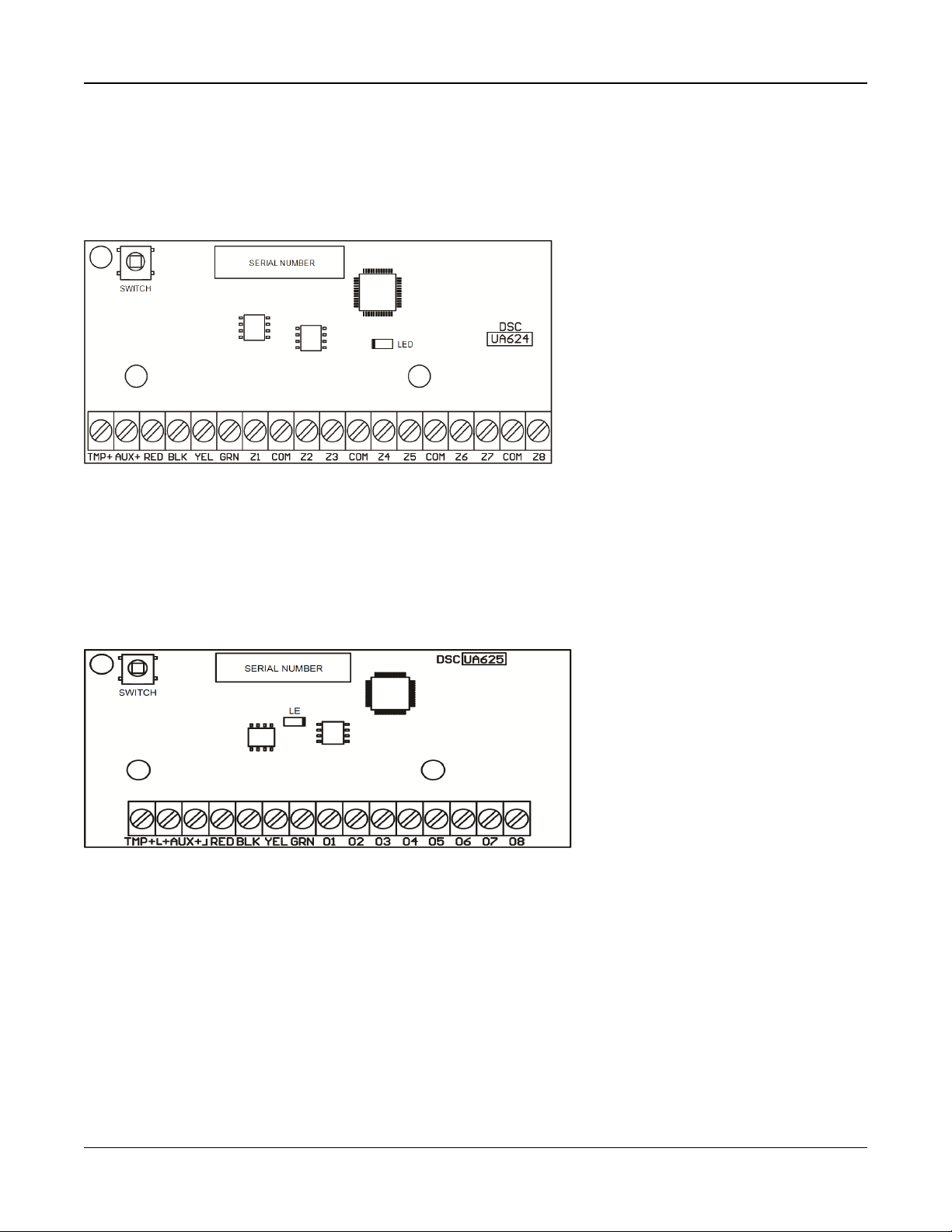

3.1.1 Zone Expander

The main alarm controller has connection terminals for zones 1 to 8. Additional HSM2108 zone expanders may be added to

increase the number of zones on the system. Each zone expander consists of one group of 8 zones. At enrollment, the zone

expander is automatically assigned to the next available zone slot. Connect the RED, BLK, YEL and GRN terminals to the

Corbus terminals on the alarm panel. Board current draw: 30mA.

Figure 3-1 HSM2108 Zone Expander

Refer to the HSM2108 installation sheet for more information.

3.1.2 Output Expander

The HSM2208 module is used to add up to 8 low-current programmable outputs to the alarm system.

The 4-wire Corbus connection is used by the panel to communicate with the module. Connect the RED, BLK, YEL and GRN

terminals to the Corbus terminals on the alarm panel. Board current draw: 40mA.

Figure 3-2 HSM2208 Output Expander

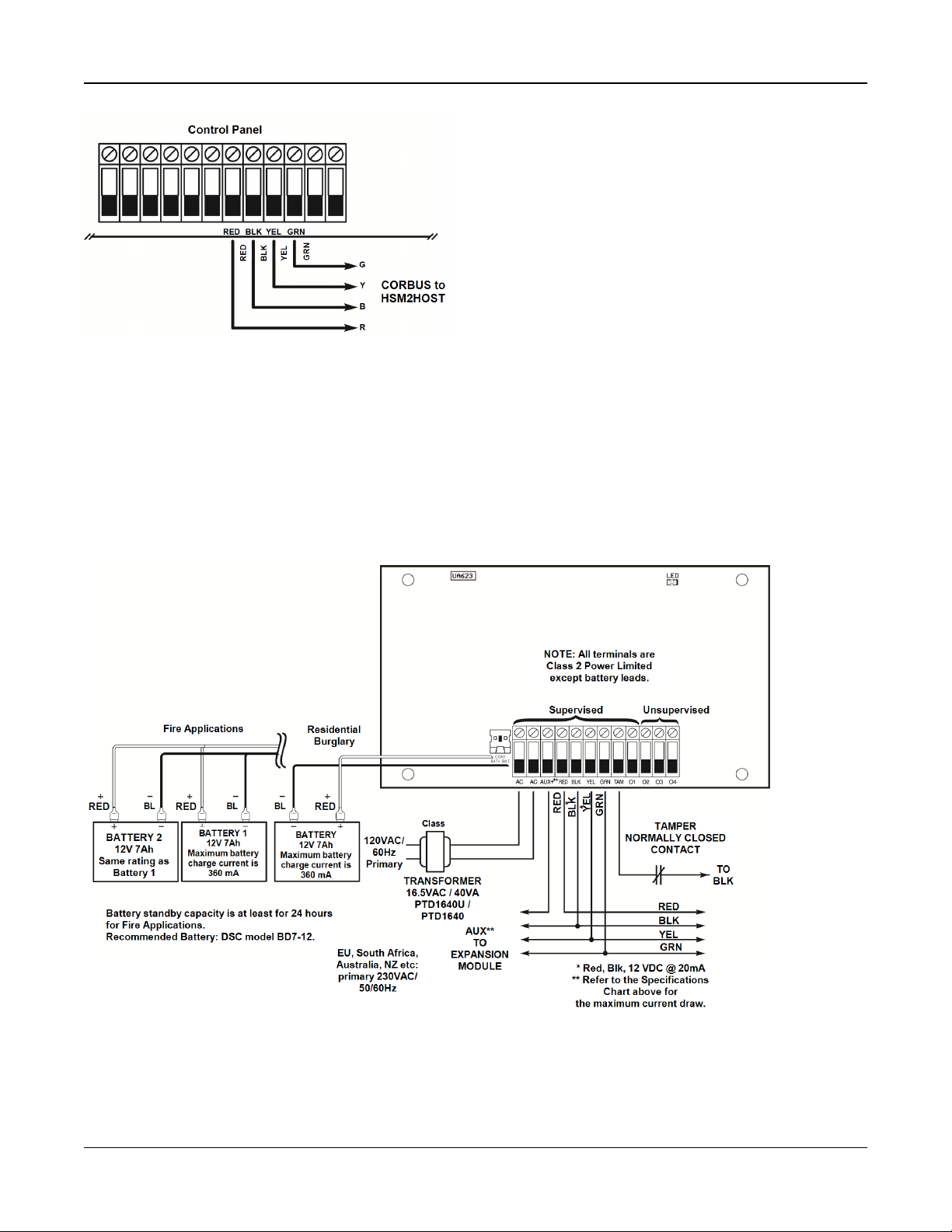

3.1.3 Wireless Transceiver Module

The HSM2HOSTx 2-way wireless integration module provides communication between wireless devices and the alarm con-

troller.

Connect the HSM2HOSTx to the 4-wire Corbus of the alarm controller according to the following diagram.

- 18 -

Page 19

Figure 3-3 HSM2HOSTx Wiring Diagram

After you have completed the wiring, reconnect power to the security system. Board current draw: 35mA

3.1.4 Power Supply Wiring

The HSM2300/2204 power supply/high-current output module provides up to 1.0A of additional current and can be used to

add up to four programmable outputs (HSM2204 only) to the alarm system.

The 4-wire Corbus connection provides communication between the module and alarm panel. Connect the RED, BLK, YEL

and GRN terminals to the Corbus terminals on the alarm controller. If O1 is not used, connect to Aux with a 1K resistor. Board

current draw: 1.2A.

Figure 3-4 Power Supply Wiring

- 19 -

Page 20

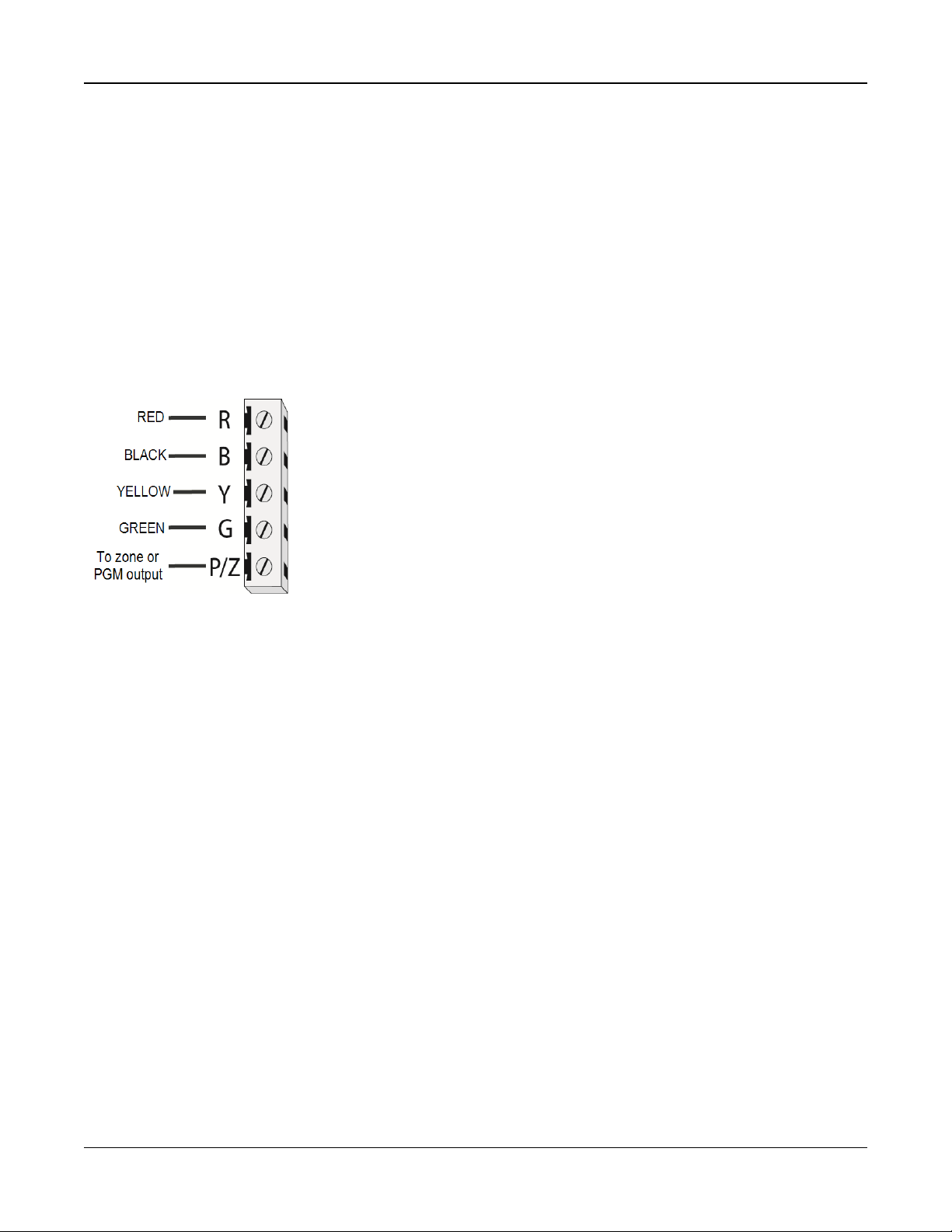

3.1.5 Keypad Wiring

To wire a keypad to the alarm controller, remove the keypad backplate (refer to the keypad installation sheet) and connect

the RED, BLK, YEL and GRN terminals to the corresponding terminals on the alarm controller.

Keypad Zone/PGM Wiring

Hardwired devices can be connected to hardwired keypads with inputs (zone) or outputs (PGM). This saves from running

wires back to the control panel for every device.

To connect a zone device to HS2LCD, HS2ICON, HS2LED and HS2TCHP keypads, run one wire to the P/Z terminal and the

other to B. For powered devices, use red and black to supply power to the device. Run the red wire to the R (positive) ter-

minal and the black wire to the B (negative) terminal.

Keypad zones support Normally Closed Loops, Single End of Line and Double End of Line.

To connect the PGM output, run one wire to the P/Z terminal and the other to R.

Figure 3-5 Keypad P/Z Terminals

Note: When using end of line supervision, connect the zone according to one of the configurations outlined in "Zone Wiring"

on page 21. End of line resistors must be placed on the device end of the loop, not at the keypad.

Assigning Keypad Zones

When using keypad zone inputs, each input used must be assigned a zone number in Installer Programming.

First, ensure that you have enrolled all installed keypads into the desired slots (See "[902] Add/Remove Modules" on page

133). Next, assign keypad zones by entering programming section [861]-[876], subsection 011 for keypads 1-16. Enter a 3-

digit zone number for each of the keypad zones. This number must be programmed into the slot location that the keypad is

assigned to.

Note: If a keypad zone input is assigned to zone number 1 to 8, the corresponding zone cannot be used on the main control

panel.

Once the keypad zones are assigned, you must also program zone definitions and zone attributes. See "[001] Zone Types"

on page 70 and See "Zone Setup" on page 70.

3.1.6 HSM2955 Wiring

For wiring information refer to HSM2955 Installation manual #29008435xxx.

3.1.7 Alternate Communicator Wiring

See Alternate Communicator installation manual.

- 20 -

Page 21

3.1.8 Zone Wiring

Power down the alarm controller and complete all zone wiring.

Zones can be wired to supervise normally open devices (e.g., smoke detectors) or normally closed devices (e.g., door con-

tacts). The alarm panel can also be programmed for single end-of-line or double end-of-line resistors.

Zone programming is done using the following programming sections:

l [001] selects zone definition

l [013] Opt [1] for normally closed or EOL; Opt [2] for SEOL or DEOL

l [201 - 208] partition assignment.

Observe the following guidelines when wiring zones:

l For UL listed installations use SEOL or DEOL only

l Minimum 22 AWG wire, maximum 18 AWG

l Do not use shielded wire

Do not exceed 100Ω wire resistance. Refer to the following table:

l

Table 3-3 Burglary Zone Wiring Chart

Wire Gauge Maximum Length to EOL Resistor (ft/meters)

22 3000 / 914

20 4900 / 1493

19 6200 / 1889

18 7800 / 2377

Figures are based on maximum wiring resistance of 100

Ω.

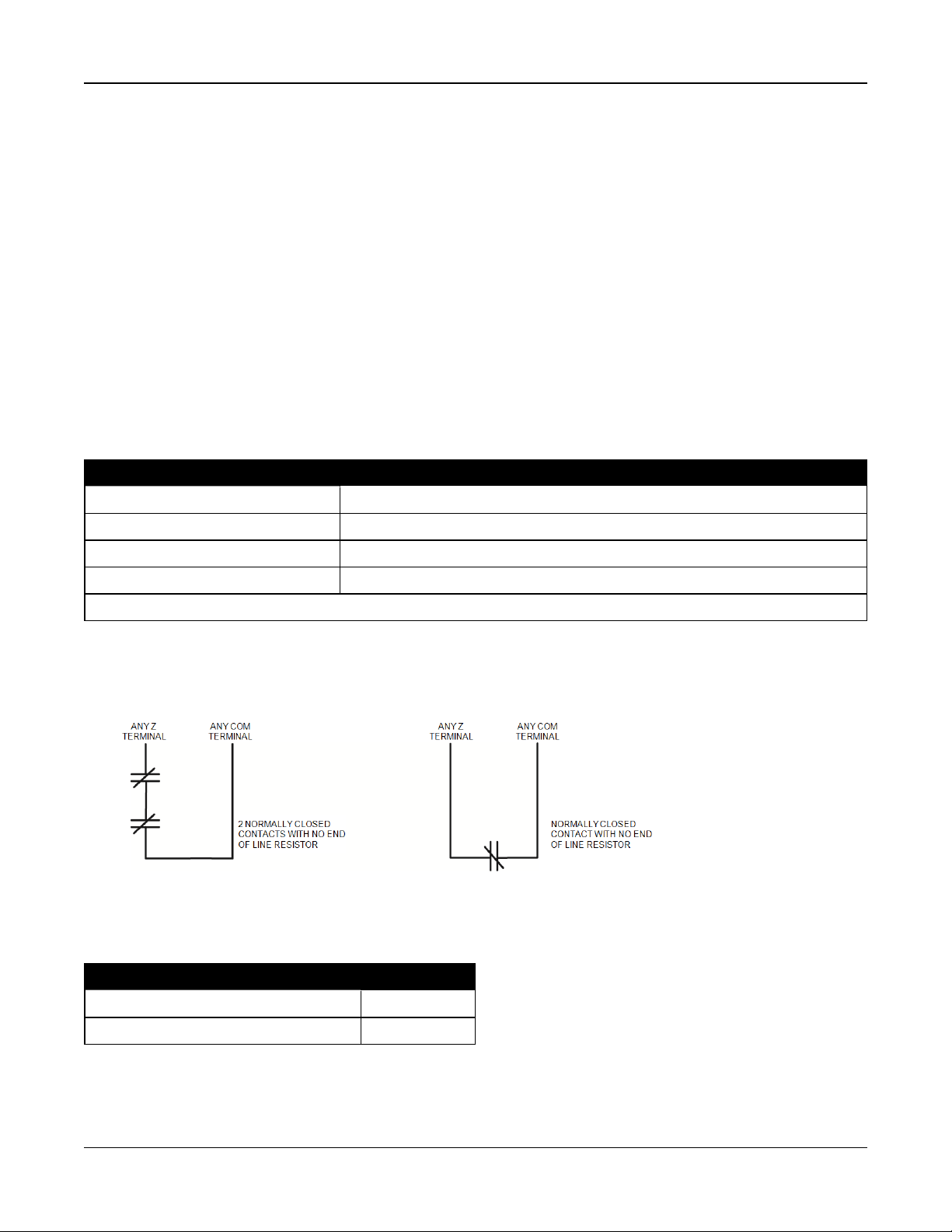

Normally Closed

Connect hardwired devices to any Z terminal and any Com terminal. Wire normally closed devices in series.

Note: For UL Installations, do not use normally closed loops.

Figure 3-6 Normally Closed

The following table shows zone status under certain conditions for NC Loops:

Table 3-4 NC Loop Status

Loop Resistance Loop Status

0Ω(shorted wire, loop shorted)

Infinite (broken wire, loop open) Violated

Secure

- 21 -

Page 22

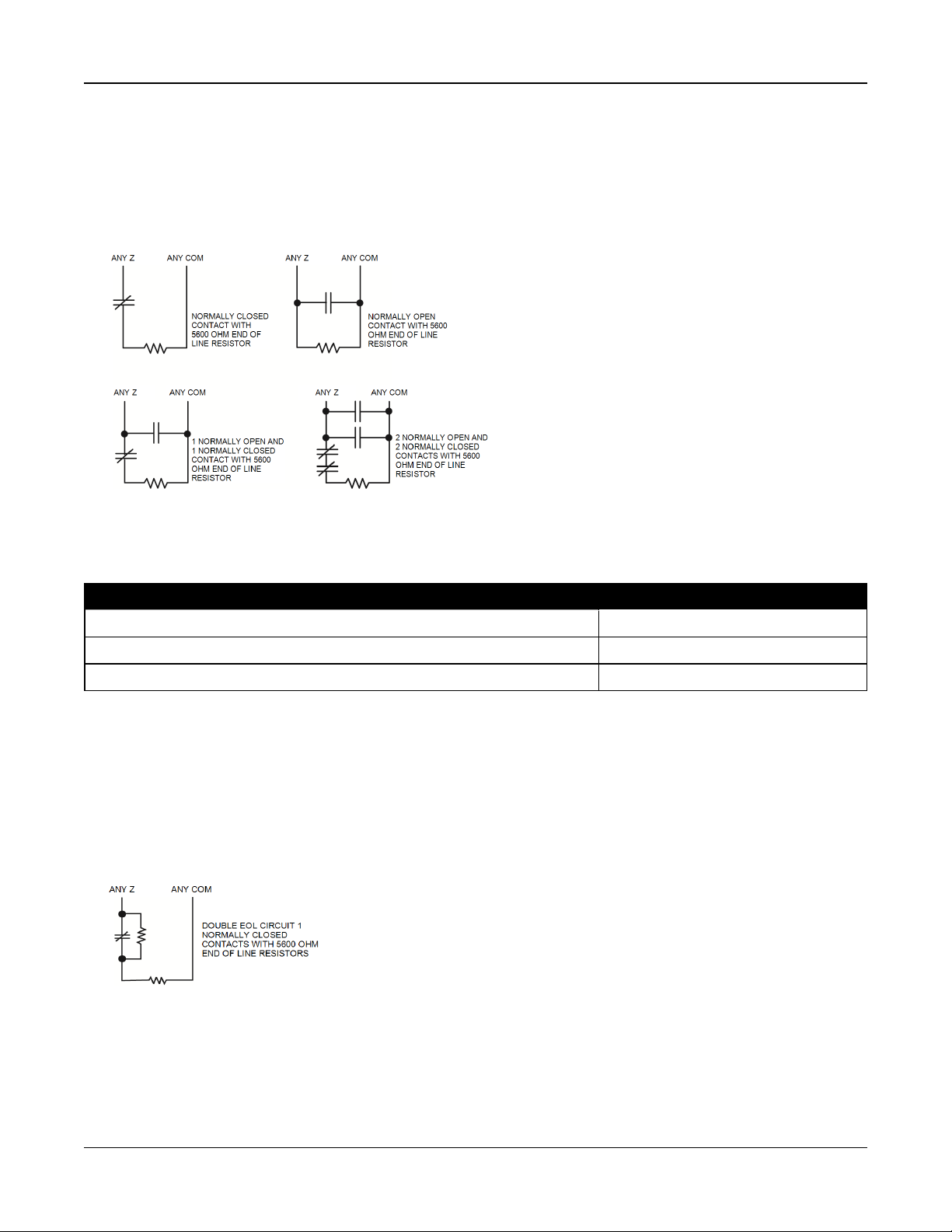

Single End-of-Line (SEOL) Resistor

When SEOL resistors are installed at the end of a zone loop, the alarm panel detects if the circuit is secure, open, or shorted.

The SEOL resistor must be installed at the end of the loop for proper supervision.

To enable SEOL supervision, program section [013], options [1] and [2] to OFF.

Note: This option should be selected if either normally closed or normally open detection devices or contacts are used.

Figure 3-7 SEOL Wiring

The following table shows zone status under certain conditions for SEOL:

Table 3-5 SEOL Loop Status

Loop Resistance Loop Status

0Ω (shorted wire, loop shorted) Violated

5600Ω (contact closed) Secure

Infinite (broken wire, loop open) Violated

Double End of Line (DEOL) Resistors

When double end-of-line (DEOL) resistors are installed at the end of a zone loop, the second resistor enables the panel to

determine if the zone is in open, closed, tampered or faulted.

Note: Any zone programmed for Fire or 24-hr Supervisory must be wired with a SEOL resistor regardless of the type of zone

wiring supervision selected for the panel. If you change the zone supervision options from DEOL to SEOL or from NC to

DEOL, power the system down completely, then power it back up for correct operation.

To enable DEOL supervision, program section [013], option [1] to OFF and option [2] to ON.

Figure 3-8 DEOL Wiring

Note: If the DEOL supervision option is enabled, all hardwired zones must be wired for DEOL resistors, except for Fire and

24 Hour Supervisory zones. Do not use DEOL resistors for Fire zones or 24 Hour Supervisory zones.

Note: Do not wire Fire zones to keypad zone terminals if the DEOL supervision option is selected.

- 22 -

Page 23

Note: This option can only be selected if N/C detection devices or contacts are used. Only one N/C contact can be con-

nected to each zone.

The following table shows zone status under certain conditions for DEOL:

Table 3-6 DEOL Loop Status

Loop Resistance Loop Status

0Ω(shorted wire, loop shorted)

5600Ω(contact closed)

Infinite (broken wire, loop open) Tamper

11200Ω(contact open)

Fault

Secure

Violated

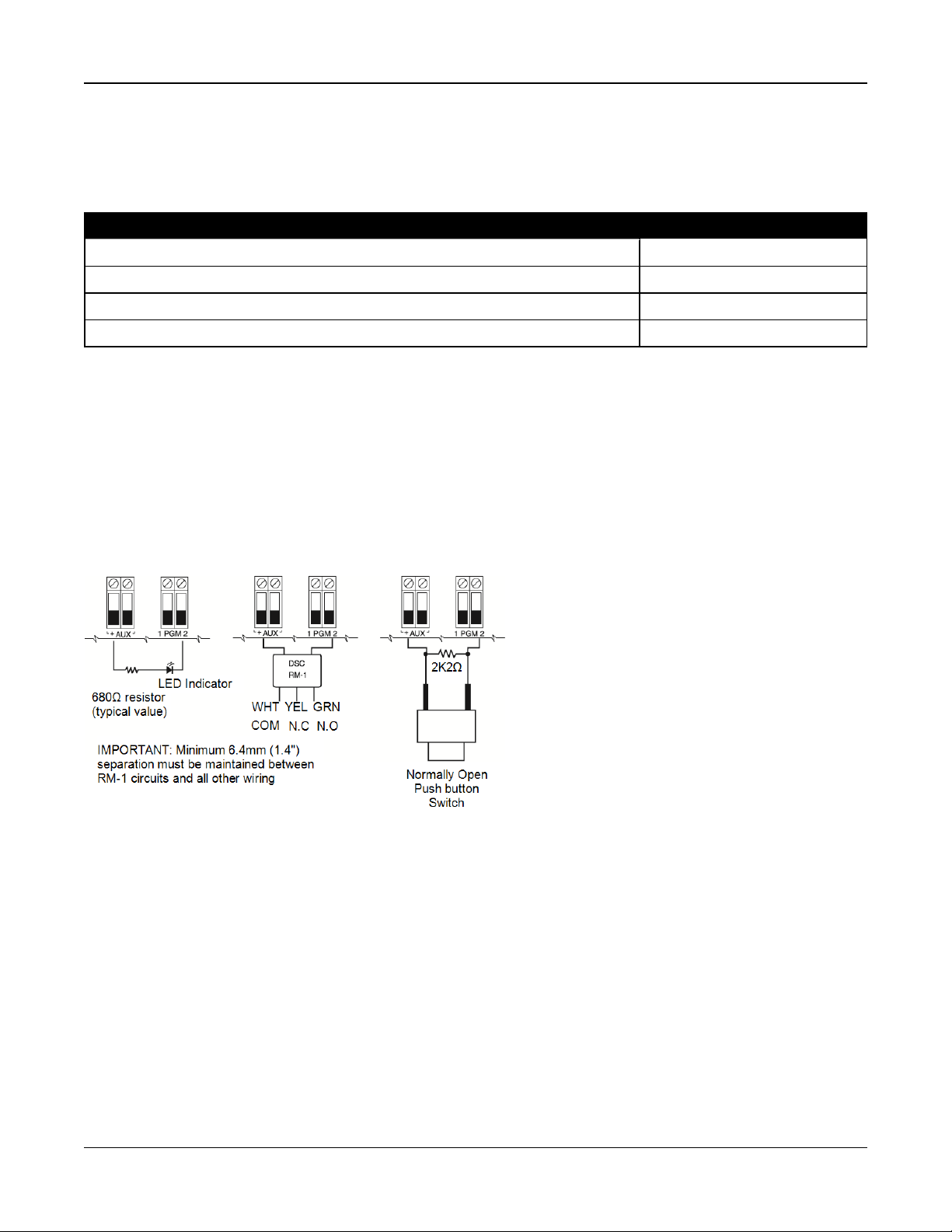

3.1.9 PGM Wiring

Min/max operating voltages for devices, sensors and modules is 9.5VDC - 14VDC.

PGMs switch to ground when activated from the alarm controller. Connect the positive side of the device to the AUX+ ter-

minal and the negative side to a PGM terminal.

PGM 1, 3, 4 supply up to 50mA; PGM 2 supplies up to 300mA.

A relay is required for current levels greater than 50mA or 300mA. PGM2 can also be used for 2-wire smoke detectors, 24-hr

burglary input alarm.

Note: Use SEOL resistors on Fire zones only.

Figure 3-9 LED Output with Current Limiting Resistor and Optional Relay Driver Output.

UL Compatibility ID For FSA-210B Series is: FS200

Note: For ULC listed installations, use FSA-210A and FSA-410A series.

3.1.10 Bell Wiring

These terminals supply 700mA of current at 10.4 - 12.5VDC for commercial/ residential installations. To comply with NFPA

72 Temporal Three Pattern requirements, section [013] Opt [8] must be ON. Note that steady, pulsed alarms are also sup-

ported.

- 23 -

Page 24

Figure 3-10 Bell Wiring

The Bell output is supervised and power limited by 2A thermistor. If unused, connect a 1000Ω resistor across Bell+ and Bell-

to prevent the panel from displaying a trouble. See "Troubleshooting" on page 47.

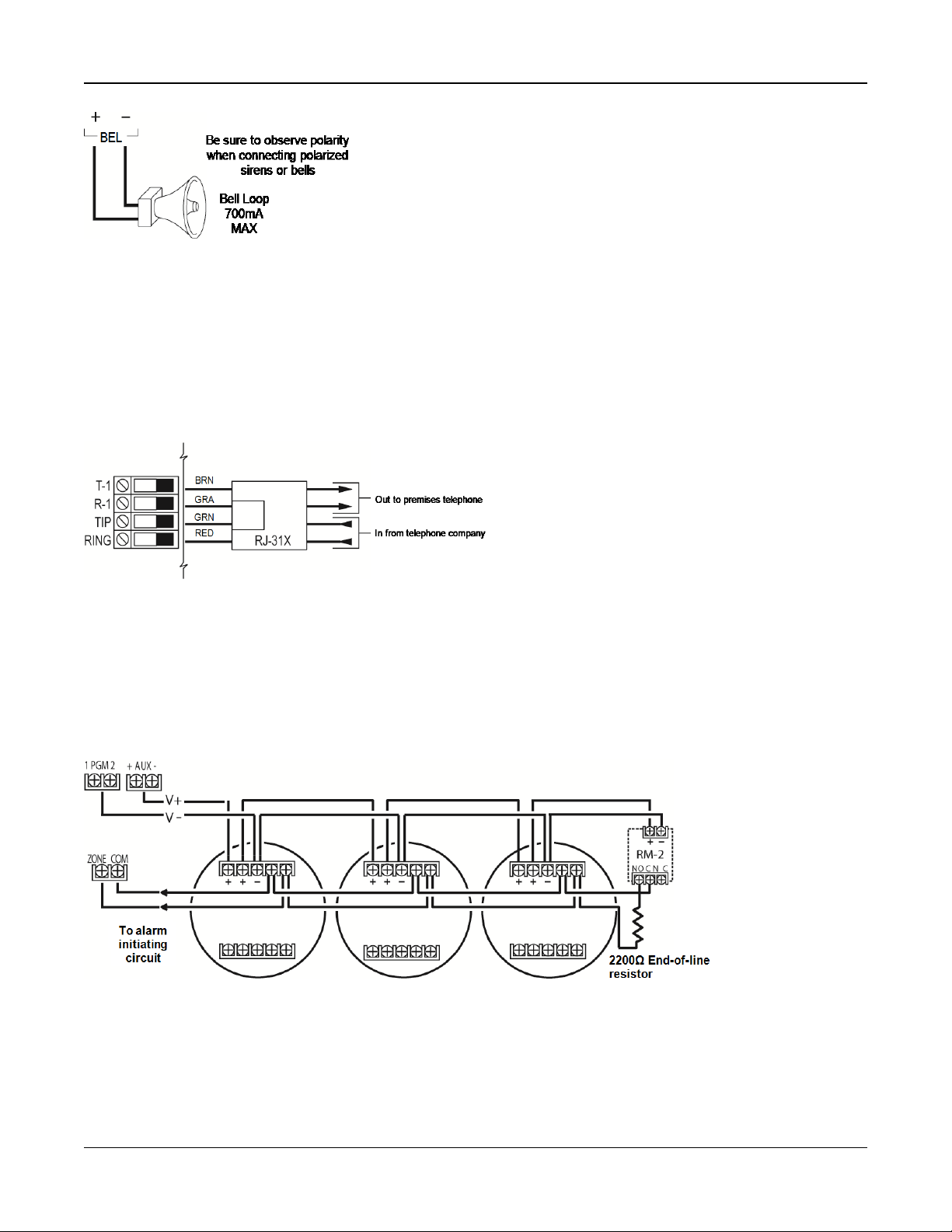

3.1.11 Telephone Line Wiring

Wire the telephone connection terminals (TIP, Ring, T-1, R-1) to an RJ-31x connector as indicated in the following diagram.

For connection of multiple devices to the telephone line, wire in the sequence indicated. Use 26 AWG wire minimum for wir-

ing.

Figure 3-11 Telephone Line Wiring

Note: Ensure that all plugs and jacks meet the dimension, tolerance and metallic plating requirements of 47 C.F.R. Part 68,

Sub-Part F. For proper operation, no other telephone equipment must be connected between the control panel and the tele-

phone company facilities.

3.1.12 Smoke Detector Wiring

All zones defined as Fire must be wired according to the following diagram:

Figure 3-12 Smoke Detector Wiring

See"[001] Zone Types" on page 70 for fire zone operation.

Note: Smoke detectors must be latching type. To reset a smoke detector, enter [*][7][2].

- 24 -

Page 25

Table 3-7 Compatible 4-Wire Smoke Detectors

FSA-410B FSA-410BLST FSA-410BRST

FSA-410BT FSA-410BR FSA-410BLRST

FSA-410BS FSA-410BRT

FSA-410BST FSA-410BRS

Current ratings for DSC FSA-410 Series: 25mA - 90mA

Fire Zone Wiring: 2-wire Smoke Detectors

If PGM 2 is programmed for 2-wire smoke detector connection, the detectors must be wired according to the following dia-

gram:

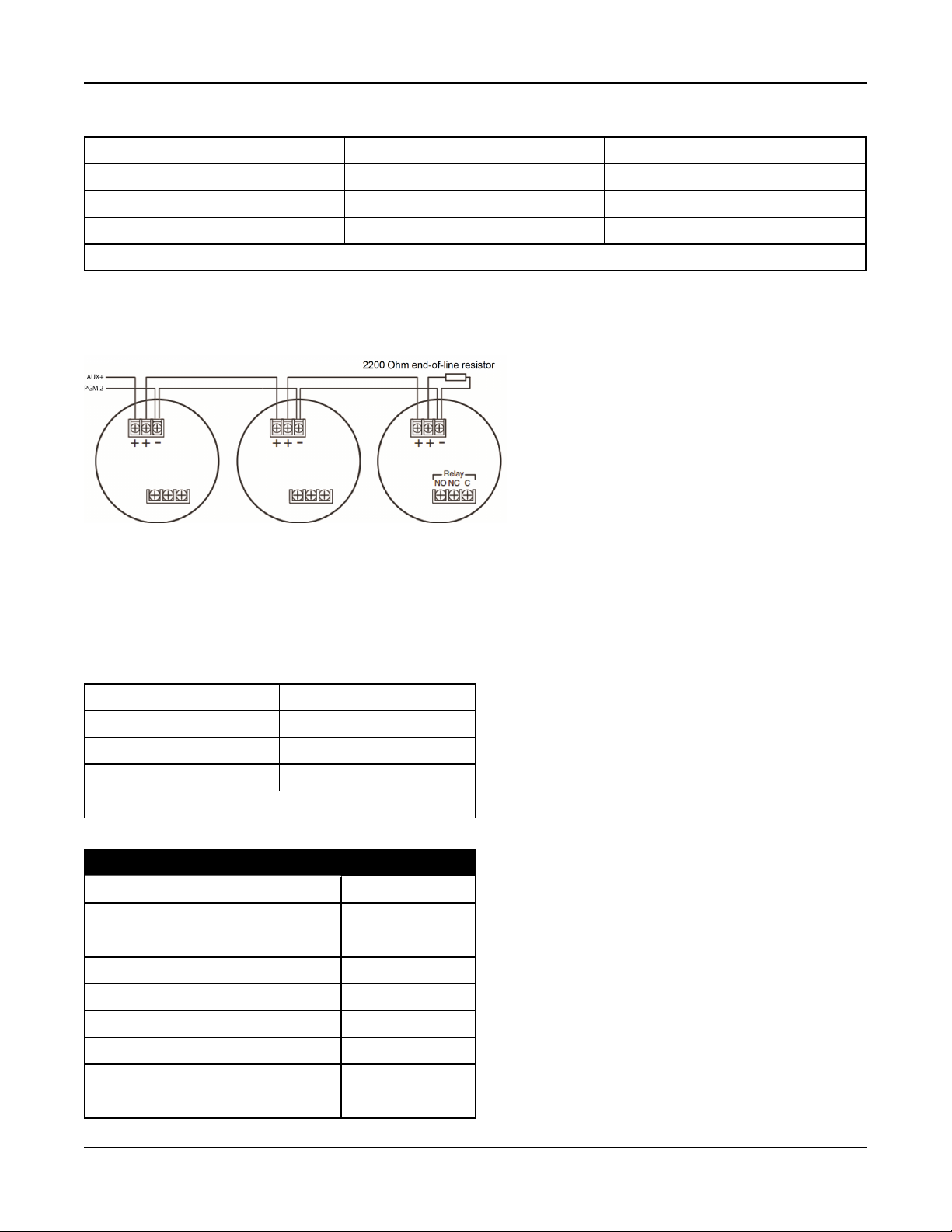

Figure 3-13 2-Wire Smoke Detector Wiring

Note: Additional 2-wire smoke detectors must be connected in parallel as shown above. The maximum number of smoke

detectors on a 2-wire loop is 18.

Note: Do not combine smoke detector models from different manufacturers on the same circuit. Operation may be impaired.

Refer to the smoke detector installation sheet when positioning detectors.

Table 3-8 Compatible 2-Wire Smoke Detectors

FSA-210B FSA-210BR

FSA-210BT FSA-210BRT

FSA-210BS FSA-210BRS

FSA-210BST FSA-210BRST

Current ratings for DSC FSA-210B series: 35mA - 75mA

Table 3-9 2-Wire Smoke Detector Initiating Circuit

Item Specification

Style/Class, Supervised, Power Limited Style B (Class B)

CompatibilityIdentifier HS2-1

DC Output Voltage 9.7-13.8 VDC

Detector Load 2mA (MAX)

Single End of Line Resistor (SEOL)

Loop Resistance

Standby Impedance

Alarm Impedance

Alarm Current 86mA (MAX)

2200

Ω

24Ω(MAX)

3000Ω(NOM)

1200Ω(MAX)

- 25 -

Page 26

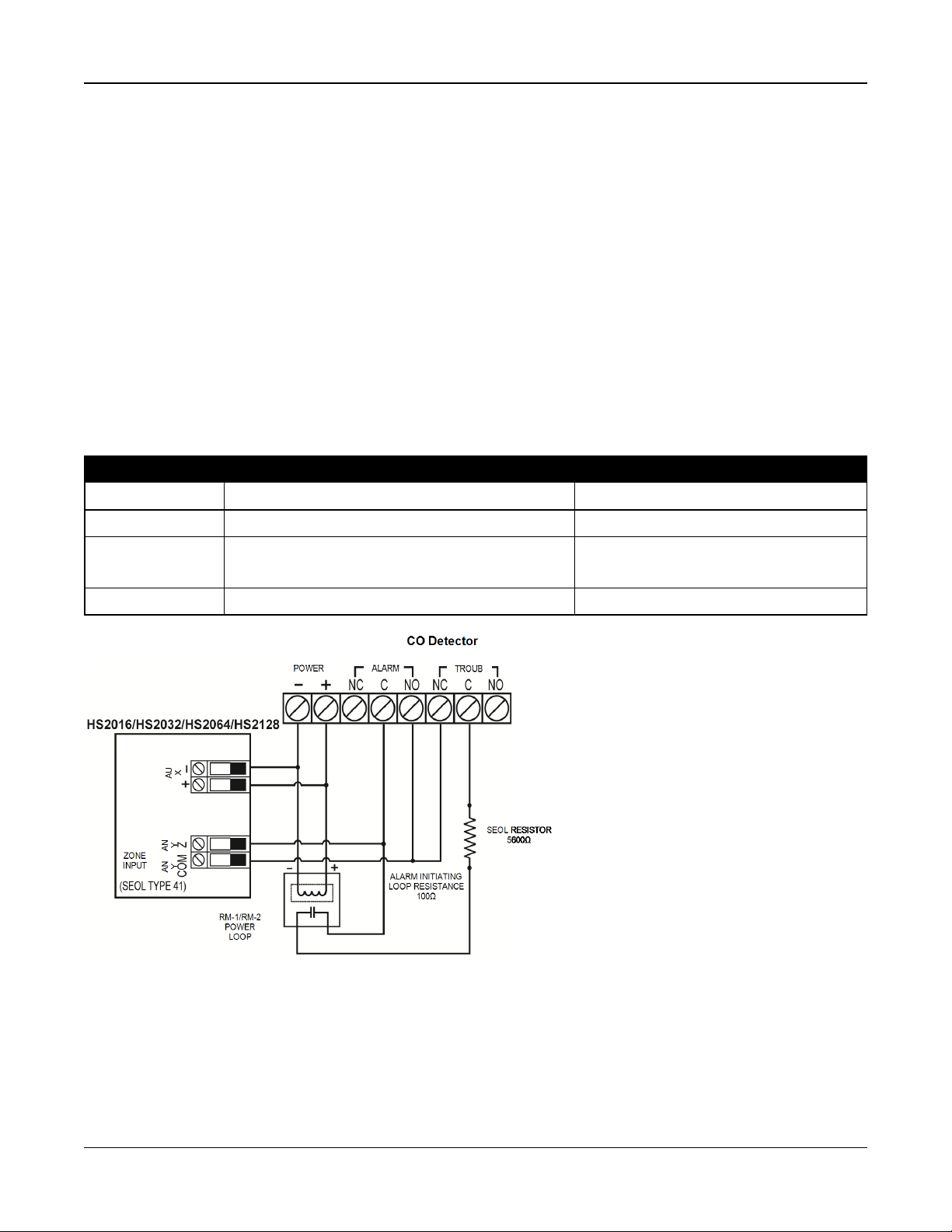

3.1.13 CO Detector

The following hardwired CO detector models can be used with PowerSeries Neo alarm controllers:

l Potter Model CO-12/24, UL File E321434

l Quantum Model 12-24SIR, UL File E186246

l NAPCO Model FW-CO12 or FW-CO1224, UL File E306780

l System Sensor Model CO1224, UL File E307195

Note: For multiple unit connections, the leads between CO detectors must be broken. The power supervision relay must be

powered from the last detector in the loop.

Wireless CO detectors are also available. When installing wireless CO detectors, use only model PG9913UL, PG8913,

PG4913. An HSM2HOSTx (x=9UL/8/4) wireless receiver or HS2LCDRF(P)x/HS2ICNRF(P)x (x=9UL/8/4) wireless keypad are

required when installing wireless CO detectors. For more details on these wireless devices, refer to their respective install-

ation manuals.

Note: Use onlyULapproved devices with UL/ULC listed systems.

Table 3-10 CO Detector Ratings

Device Description Max Rating @12VDC

CO-12/24 Potter model CO detector 40mA

12-24SIR Quantum model CO detector 75mA

FW-CO12

FW-CO1224

CO1224 System Sensor model COdetector 40mA

NAPCO model CO detector 90mA

Figure 3-14 CO Detector Wiring

- 26 -

Page 27

3.1.14 Ground Wiring

Figure 3-15 Ground Installation

Note: Using an insulated green wire (minimum 22AWG), connect the EGND terminal on the Corbus and the grounding wire

from the building electrical installation to any of the available holes on the back or side of the metal cabinet. See the diagram

attached to the cabinet for suggested GND point location and hardware recommendations.

Note: Wire and installation hardware not included.

3.1.15 Connecting Power

Batteries

Do not connect the battery until all other wiring is complete.

Note: A sealed, rechargeable, lead acid battery or gel type battery is required to meet UL requirements for power standby

times.

Connect the RED battery lead to the positive battery terminal and the BLACK battery lead to the negative battery terminal.

The panel can be programmed to charge the battery at 400mA or 700mA. (See "[982] Battery Settings" on page 136).

Note: Refer to "Aux Loading and Battery Selection" on page 1.

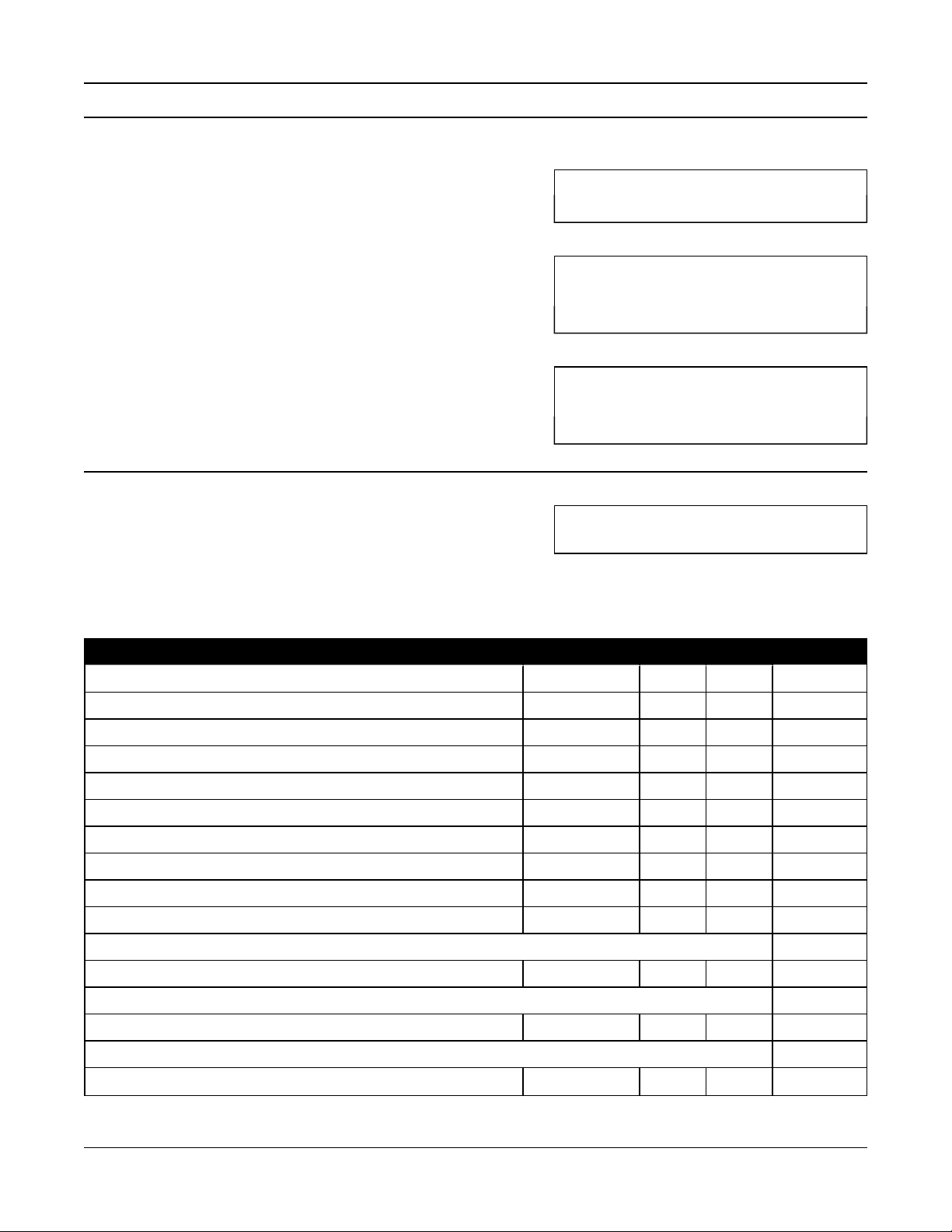

Battery Selection Chart

After calculating the battery capacity (B) for each specific installation use the following table to determine the battery

required to support the main panel in standby mode for:

l 4 hours (UL commercial burglary/residential burglary)

l 12 hours (EN50131)

l 24 hours (UL/ULC residential fire, ULC residential burglary, ULC commercial burglary, ULC commercial fire mon-

itoring - no bell load allowed; INCERT [Belgium])

The battery size is measured in amp hours (Ah). The current values in the table denote the maximum current draw permitted

to achieve the desired standby time with the listed battery types.

Table 3-11 Standby Battery Guide

Battery Size Desired Standby Time

4h 12h 24h 36h

- 27 -

Page 28

4Ah 700mA ------ ------ ------

7Ah 700mA 500mA 250mA ------

14Ah * 700mA 470mA ------

18Ah ----- - ---- -- ----- - 300mA*

26Ah ----- - ---- -- ----- - 500mA*

* use 2 x 7Ah batteries connected in parallel, UL/ULC installations only

Battery capacity deteriorates with age and the number of charge/discharge cycles. Replace every 3-5 years.

Refer to "Regulatory Approvals" on page 230 for detailed Aux. loading and battery charging information.

Connecting AC Power

The alarm controller requires a 16.5V, 40VA transformer. While unplugged, connect the transformer to the AC terminals on

the controller. The alarm controller can be programmed to accept a power line frequency of either 50Hz AC or 60Hz AC. See

programming section [024], option [1].

Note: For UL/ULC installations use only 60Hz.

Note: For ULC S559 applications, Standex transformer (Model FTC3716) shall be employed for direct-wiring.

- 28 -

Page 29

Section 4: Configuration

4.1 Basic Configuration Steps

Once basic installation of the alarm panel is complete, the following general configuration options should be set:

l create partitions, See "Working with Partitions " on page 32

l assign keypads to partitions, see "Keypad Partition Setup " on page 33

l assign sirens to partitions, see "Bell/Siren Operation " on page 33

l create global zones, see "Global Zones " on page 34

l set up partition account codes, see "Communications" on page 34

l set up partition timers, see "System Times" on page 77

l enroll wireless modules and devices, see "Enrolling Modules" on page 31

l assign zone types, see "[001] Zone Types" on page 70, and attributes, see "[002] Zone Attributes" on page 75

l create zone labels, see "Adding Labels" on page 67

l add users, see "Assign Access Codes" on page 51

l set up the alternate communicator if equipped, see "Alternate Communicator Setup" on page 36

l program phone numbers, see "System Communications" on page 119

l set up call directions for the central monitoring station, see "System Communications" on page 119

l set up system timers, see "System Times" on page 77

l configure reporting codes, see "Reporting" on page 113

l test the system, see "Testing the System" on page 37

4.2 Using the Keypad

The PowerSeries Neo alarm panel is compatible with several different keypad types (see "Compatible Devices" on page 9);

However, all keypads have certain basic functionality in common.

4.2.1 Special Keys

Scroll symbols < > on keypads with LCD displays indicate that options can be viewed by pressing the scroll keys.

These keys can also be used to position the cursor.

The [*] key is similar in function to the “Enter” key on a personal computer. It is generally used to accept the existing pro-

gramming option. It is also the first key entry for [*] commands and can be used to enter the letters A-F when in Installer Pro-

gramming mode.

The [#] key is similar in function to the “ESC” (escape) key on a personal computer. It is generally used to exit the current pro-

gramming section or to return to the previous one.

4.2.2 LED Indicators

Keypads have the following status lights that provide visual indication of basic system status:

Ready: Panel is ready to be armed.

Armed: Panel is armed.

Trou ble: System trouble. Enter [*][2] to view troubles.

AC Power: ON=AC present. OFF=AC absent.

Panel Status LED Operation

The red status LED, located on the alarm controller PCB, indicates the following:

Page 30

Section 4: Configuration

l Power up sequence – flashes rapidly until the end of the power-up sequence.

l Firmware indication – flashes during the firmware upgrade process. If the firmware upgrade fails, the LED flashes rap-

idly.

l Trouble indication – Flashes when troubles are present. Troubles are indicated according to the following priority:

1 flash - no keypads enrolled

2 flashes - module supervision trouble

3 flashes - bus low voltage

4 flashes - low battery trouble

5 flashes - AC trouble

6 flashes - AUX trouble

7 flashes - bell trouble

8 flashes - TLM trouble

How to Enter Data

Conventions Used In This Manual

Brackets [] indicate numbers or symbols that must be entered on the keypad.

e.g., [*][8][Installer Code][804] requires the following key entries:

[*][8][5555][804]

[*] initiates a special command.

[5555] is the default installer code. The default installer code should be changed during initial programming of the system.

[804] indicates the particular programming section being accessed.

Entering Letters Manually (System Labels)

1. In Installer Programming, enter the section requiring text input.

2. Use the arrow keys [<][>] to move the cursor to a blank space or existing character.

3. Press the number key corresponding to the appropriate letter. Each number button accesses three letters and a number.

The first press of the number key displays the first letter. The second press displays the second letter, etc.

1

A, B, C, 12D, E, F, 23G, H, I, 3

4

J, K, L, 45M, N, O, 56P, Q, R, 6

7

S, T, U, 78V, W, X, 89Y, Z, 9,0

4. To select lower case letters press [*]. The Select Options list opens. Scroll to “lower case” and press [*] again to select.

5. When the required letter or number is displayed use the arrow keys [<][>] to scroll to the next letter.

6. When finished, press the [*] key, use the [<][>] keys to scroll to “Save” then press [*].

0

Space

7. Continue from step 2 until all labels are programmed.

For information on entering hexadecimal data, see "Programming Hex and Decimal Data" on page 65.

- 30 -

Page 31

Section 4: Configuration

4.3 Enrollment

All optional modules and devices must be enrolled on the system. During enrollment, the electronic serial number (ESN) of

each device is identified to the control panel and zones are assigned. A wireless transceiver HSM2HOST or an RF keypad

must be enrolled first before wireless devices can be enrolled.

4.3.1 Enrolling Modules

During automatic and manual enrollment, if an attempt is made to enroll more than the maximum number of modules, an

error tone sounds and a message is displayed on LCD keypads.

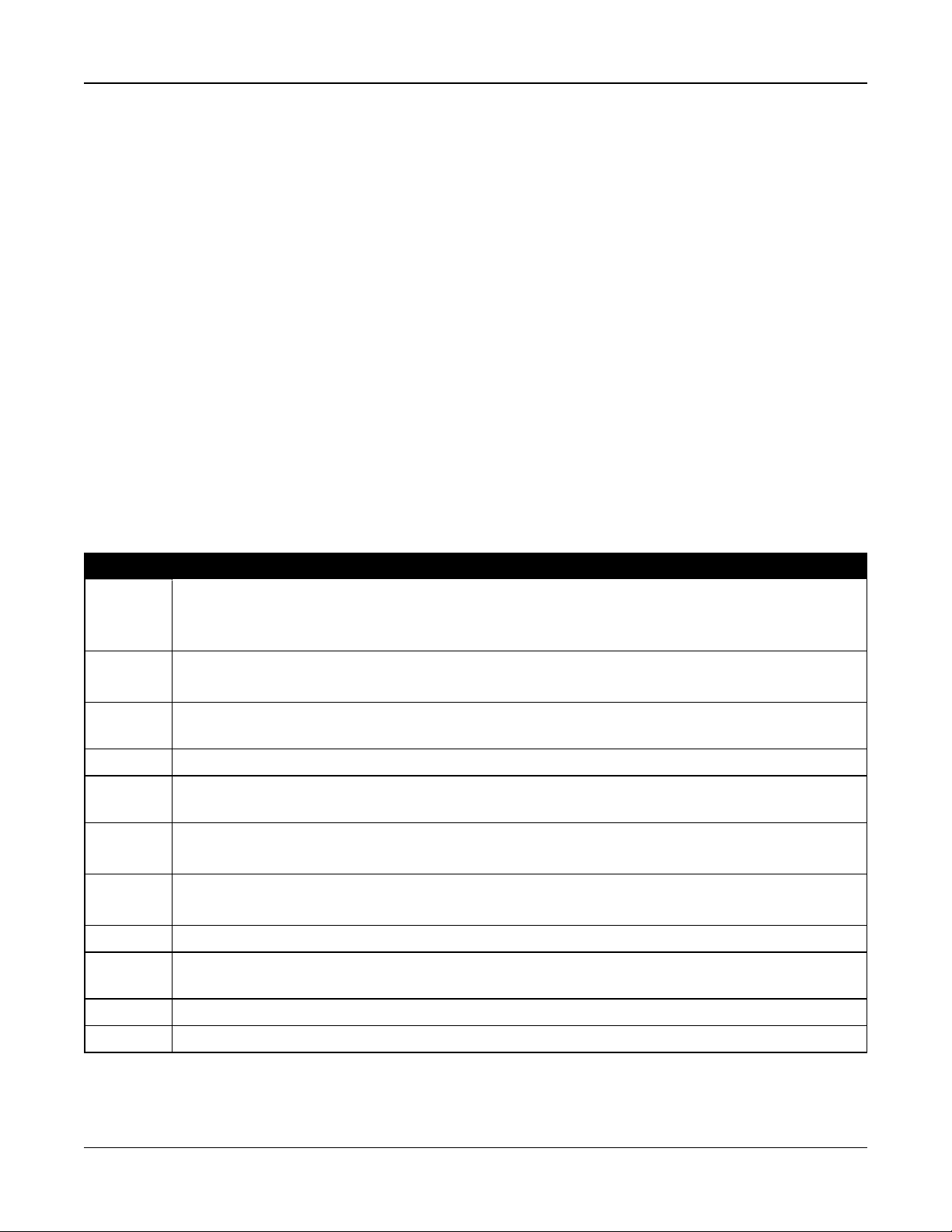

Table 4-1 Module Capacity

Module HS2016-4HS2016 HS2032 HS2064/

HS2064 E

HSM2108 8 Zone expander

1

1 3 7 15

HS2128/HS2128 E

HSM2208 8 Output expander

WirelessKeypad:

HS2LCDRF(P)4

HS2ICNRF(P)4

HS2LCDWF(P)(V)4

HS2TCHP Touchscreen Keypad

HSM2300 Power Supply1A

HSM2204 4 High-current Output

HSM2HOSTx Transceiver

HSM2955

(not UL evaluated)

2

8

8

3

1

1

1

2 4 8 16

8 8 8 16

8 8 8 16

3 3 3 4

1 1 3 4

1 1 1 1

1 1 1 1

Modules can be enrolled automatically or manually using section [902] of Installer programming. For instructions on

enrolling modules, see "Module Programming" on page 133.

To confirm that a module has been successfully enrolled, use Installer Programming section [903]. See "[903] Confirm Mod-

ule" on page 134 for details.

Enrolling the First Keypad

To enroll a hardwired keypad, connect the keypad to the alarm controller, power up the alarm panel then press any button

on the keypad.

To enroll a wireless keypad, first connect the HSM2HOSTx wireless integration module to the alarm controller. Next, power

up the alarm panel and a wireless keypad. Press any button on the keypad to enroll it on the HSM2HOSTx. The

HSM2HOSTx is then enrolled on the alarm panel. To enroll other keypads, see "Module Programming" on page 133.

4.3.2 Module Supervision

By default, all modules are supervised upon installation. Supervision is enabled at all times so that the panel can indicate a

trouble if a module is removed from the system.

To check which modules are currently connected and supervised, see "[903] Confirm Module" on page 134.

If a module is connected but is not recognized by the system, it may be due to any of the following reasons:

- 31 -

Page 32

Section 4: Configuration

l the module is incorrectly wired to the alarm controller

l the module has exceeded its maximum wire run length

l the module does not have enough power

l the module is not enrolled on the wireless receiver

Removing Modules

Enrolled modules can be deleted from the system via programming section [902]. For instructions, see "[902] Add/Remove

Modules" on page 133.

4.3.3 Enroll Wireless Devices

Wireless devices are enrolled via the wireless transceiver module and Installer Programming section [804][000]. See "Com-

patible Devices" on page 9 for a list of supported wireless devices.

Wireless devices are enrolled using one of the following methods:

Auto Enrollment

To enroll a wireless device using this method, press and hold the Enroll button on the device for 2-5 seconds until the LED

lights then release the button. The alarm panel automatically recognizes the device and the keypad displays a confirmation

message. The device ID and next available zone number are displayed. Press [*] to accept or scroll to another available

zone number. Batteries must be installed in the wireless device in order to enroll.

Various zone features are programmable depending on the type of device. See "Zone Setup" on page 70 for details.

Pre-Enrollment

Pre-enrollment is a two step process. The first step requires entering each device ID ([804][001]-[716]). Every wireless device

has an ID printed on the sticker attached to the device. The format is XXX-YYYY where:

l XXX identifies the type or model of the device

l YYYY is a short encrypted ID used by the system to identify the specific device

Pre-enrollment can be done at a remote location and using DLS/SA. The second step is to press the enrollment button on

the device, usually done on location. Installer Programming does not have to be entered at this step. Both steps must be per-

formed in order to complete the enrollment.

4.4 Working with Partitions

A partition is a limited area of the premises that operates independently from the other areas. Partitioning a system can be

beneficial if the property has outbuildings that need to be secured independently of a main area or if the home has a sep-

arate apartment.

Each partition can have its own keypad or a keypad can have access to all partitions (only if all partitions belong to the same

owner). User access to partitions is controlled via access codes. A master code can access the entire system and partitions,

while a user code is limited to assigned partitions.

Setting up a partition requires configuration of the following:

l create the partition

l define bell/siren operation

l assign keypads

l assign zones

l assign users

- 32 -

Page 33

Section 4: Configuration

4.4.1 Setting Up a Partition

Partitions are added or removed from the system by applying or removing a partition mask via Installer Programming section

[200]. The number of available partitions depends on the alarm panel model. See "[200] Partition Mask" on page 111 for

more information.

4.4.2 Bell/Siren Operation

Each partition must have a siren. The system siren connected to the bell output of the alarm controller can be mounted in a

central location within hearing range of all partitions. Each partition can also have wireless sirens activated only on the

assigned partition. See "Wireless Programming" on page 131 for details.

Single Siren Output Operation

With a siren shared across all partitions, control over activation/deactivation of the output depends on the partition that ini-

tiated the alarm sequence. Only the partition that originated the alarm can deactivate the bell output.

Global zones, such as smoke detectors shared by multiple partitions, can deactivate the siren on all partitions the zone is

assigned to.

Multiple Siren Output Operation

When multiple sirens are used in the installation, they can be programmed to sound alarm conditions for all partitions, or for

individual partitions by using a partition enable mask.

If hardwired sirens are used, this is accomplished via bus power supplies with a supervised high-current output. The output

is then programmed as a Fire and Burglary PGM output type.

Note: Only the first output of the HSM2204 output module has bell supervision. Some conditions, such as an installer system

test, may override the partition assignment and cause all sirens to activate. User system tests only activate the sirens/outputs

assigned to that partition.

4.5 Trouble Indicators

Both audible and visual trouble indications are available on all partitions. For more information, see "Troubleshooting" on

page 47.

Programming section [013] option 3 controls whether or not troubles are indicated when the alarm system is armed.

4.6 Keypad Partition Setup

Keypads can be configured to control an individual partition or all partitions. In general, a partition keypad controls the par-

tition it is assigned to. A Global keypad controls all partitions. Global keypads should be placed in common areas of the

premises, such as points of entry or reception areas, where the ability to arm and disarm more than one partition at a time is

required.

Partition keypads can also be temporarily loaned to other partitions.

To select a keypad operating mode:

1. Enter Installer Programming: [*][8][installer code].

2. Select [861]-[876] to program keypads 1-16.

l Press [000] for partition assignment.

l For Global operation, key in 00.

l To assign a keypad to a partition, key in 01-08 for partition 1-8.

- 33 -

Page 34

Section 4: Configuration

3. Press the [#] and reapeat step 2 for next keypad. When finished programming all keypads, press the [#] key twice to exit

programming.

Users are assigned partition access rights via the [*][5] menu.

4.6.1 Loaned Partition Setup

To loan a keypad to another partition:

1. Press and hold [#] then key in a valid access code. The keypad switches to Global display.

2. Use the arrow keys to scroll through available partitions. Press [*] to select. The keypad is temporarily loaned to another

partition.

If the keypad is inactive for more than 30 seconds, it reverts to its assigned partition.

4.6.2 Global Zones

If a zone is added to more than one partition, it becomes a global zone. A global zone is only armed when all assigned par-

titions are armed and is disarmed when any assigned partition is disarmed.

Global zones behave as follows:

l A global Stay/Away type zone is not activated until all partitions the zone is assigned to are armed in the Away mode.

Interiors must be activated on all partitions for the global Stay/Away zone to be active.

l A shared zone bypassed on one partition is bypassed on all partitions the zone is assigned to.

l An entry delay started on a global zone sounds an entry delay on all keypads assigned to partitions the global zone

is assigned to.

l A global Delay type zone follows the longest programmed delay time of the partitions it is assigned to.

4.6.3 Fire and CO Zone Types

Fire zones only place the partition they are assigned to into alarm. Other partitions retain their current state.

A fire reset only resets partitions they are assigned to.

One or more fire zones may be located on any partition.

On alarm, the fire auto-scroll display appears on all partition keypads and on all global keypads. Fire alarm silence and fire

system reset may be done directly on any partition keypad. To silence a fire or CO alarm from a global keypad requires that

the global keypad be loaned to one of the partitions the zone is assigned to.

4.6.4 Bell/PGM Support

PGMs must be assigned to one or more partitions. See section [007] for partition assignment.

Note: Bell PGM type requires supervision and follows arming squawks by partition.

4.6.5 Communications

Account codes are assigned to all system and partition events.

For SIA communications, a single account code (programmed in section [310][000]) is used for all events. The partition is

identified via Nri1-8. System events use Nri0.

When using communication formats other than SIA, individual account codes can be programmed for each partition. See "

[310] Account Codes" on page 120.

- 34 -

Page 35

Section 4: Configuration

4.6.6 Assign Zones

Partition zone assignments are completed using sections [201] - [208] for partitions 1 - 8. Subsections [001 - 016] are then

used to enable or disable banks of 8 zones on the partition.

4.6.7 Assign Users

Acess [*][5] using the master code, select the desired user code and enter digit 4 to modify the partitions that can accept the

user code.

4.6.8 Factory Defaults

Individual modules, as well as the alarm panel itself, can have their programming returned to factory default settings. Hard-

ware is defaulted via the following Installer Programming sections:

l [991] Default Keypads

l 000 – Default all keypad programming

l 001-016 – Default keypads 1-8

l [993] Default alternate communicator

l [996] Default wireless receiver

l [998] Default HSM2955

l [999] Default system

See "Defaults" on page 137 for more information.

Default All labels

Use programming section [000][999]. The following labels are returned to factory default settings:

l Zone Label

l Partition Labels

l Module Labels

l Partition 1-8 Command Output 1 to 4 Labels

l Schedule 1 to 4 Labels

l Event Labels

l User Labels

System and module programming is not affected.

Hardware Reset Main Control Panel

Perform the following to restore the main control panel to default settings:

1. Power down the system.

2. Remove all wires between Zone 1 and PGM 1 on the alarm controller.

3. Connect a short between Zone 1 and PGM.

4. Power up the system (AC only) for 60 seconds.

5. Power down the system and remove the short.

6. Power up the system again. Factory defaults are restored.

Hardware default is logged to the event buffer.

Note: Hardware default is not available when installers lockout is enabled.

- 35 -

Page 36

Section 4: Configuration

4.7 Alternate Communicator Setup

The alternate communicator is an optional wireless or ethernet communications device that can be used as a backup to the

PSTN connection or as a primary means of communication between the alarm panel and the central monitoring station. The

alternate communicator communicates via 3G (HSPA) or Ethernet.

The following configuration steps are required to set up the alternate communicator:

l Install the alternate communicator and wire it to the alarm panel (use PCLINK_2 header)

l Enroll the alternate cellular communicator with Connect 24

l Set the communication path: [300]

l Enable the alternate communicator: [382] option 5

l Enable event reporting: [307]/[308]

l Program communication delay timer: [377]

l Program DLS access: [401] option 07

Refer to the 3G2080(R)/ TL2803G(R)/ TL280(R) installation manual for details.

4.7.1 Real Time Clock

This feature synchronizes the alarm panel time and date with that of the alternate communicator, provided real time clock

support is available. Time and date are updated at 4:05 PM or when the system time is lost. This feature is enabled/disabled

in Installer Programming section [024] option 5.

4.7.2 Communication Paths

The path of communication between the alarm panel and the central station must be established through either the alarm

panel’s on-board Public Switched Telephone Network (PSTN) connection or through the alternate communicator (cellular or

Ethernet) if equipped.

Paths to four receivers can be programmed in Installer Programming section [300] options 001 - 004.

For more information, see "[300] Panel/Receiver Communication Paths " on page 112.

4.7.3 Communications Options

The following alarm panel options must be programmed when configuring the alternate communicator:

[300] option 02: communication path (see "[300] Panel/Receiver Communication Paths " on page 112)

[380] option 01: communications enabled/disabled (see "[380] Communicator Option 1" on page 123)

[382] option 05: enable communicator and all associated options: telephone number, reporting code and call direction (see "

[382] Communicator Option 3" on page 125)

[308][351]-[356] reporting codes (see "[351] Alternate Communicator 1")

[401] option 7: DLS access (see "[401] System Test Events")

4.7.4 Communication Attempt Limit

If a telephone line monitoring (TLM) trouble is present, the number of PSTN dialing attempts is reduced from the pro-

grammed value to 0 attempts. See programming section [380] Communicator Option 1 for details.

- 36 -

Page 37

Section 4: Configuration

4.7.5 Supervision Restore

If the alarm system experiences a failure to communicate (FTC) with the central monitoring station, it automatically attempts

to transmit the event when communications are restored.

4.7.6 Remote Firmware Upgrade

Firmware upgrades can be automatically pushed to the alarm panel and modules from Connect 24 or DLS. A message is dis-

played on LCD keypads indicating a firmware upgrade is available. On all keypads, the blue proximity tag bar flashes one

second on - one second off.

Users authorize the firmware upgrade through [*][6][Master Code][17].

During the update, a message indicating that a firmware upgrade is in progress is displayed on the LCD keypad. If the firm-

ware update fails, an error message is displayed on LCD keypads.

Firmware updates are performed under the following conditions:

l The system is not armed

l No AC trouble is present

l No low battery trouble is present

l No FTC trouble is present

l Every alarm in memory has been viewed

l No events are being communicated

l An alternate communicator is present

Remote firmware upgrade is possible for the following modules:

l hardwired keypads, including HS2LCDRF

l wireless transceivers

l alternate communicators

Note: For UL listed installations, do not use remote programming unless an installer is on the premises.

4.8 Local Firmware Upgrade

Alarm panel firmware can be upgraded locally via DLS. Firmware upgrade prevention rules are ignored when performing a

local firmware upgrade.

Note: [382][5] must be enabled to perform a local firmware upgrade.

To perform a local firmware upgrade:

1. Remove the front cover of the alarm panel and plug the DLS header into the PCLink 2 connector on the alarm controller.

2. Open the Flash Utility within DLS, select the latest firmware file from the Web or browse to a saved flash file on your hard

drive. Follow the steps as prompted by the Flash Utility application. A message is displayed when download is complete.

3. Once the firmware update is complete, the system powers up.

4.9 Testing the System

Installer Walk Test

Walk test enables the installer to test the operation of each detector by tripping zones, causing an actual alarm. Enter section

[901] to initiate a walk test. When a zone is tripped, all system sirens emit a tone to indicate that the zone is working correctly.

After 15 minutes without zone activity, the walk test terminates automatically. To manually exit walk test mode, enter [901]

again.

- 37 -

Page 38

Section 4: Configuration

4.9.1 Viewing the Event Buffer

The event buffer contains logs of events that have occurred on the alarm system beginning with the most recent. The capa-

city of the event buffer is scalable and can hold 500/1000 events (depending on panel model) before rolling over. The buffer

displays events according to their time stamp, beginning with the most recent. The event buffer can be uploaded using DLS.

Each event displays the time and date, a description of the event, the zone label, access code number or any other pertinent

information. To view the event buffer, press [*][6][Master Code][*].

- 38 -

Page 39

Section 5: System Operation

5.1 Arming and Disarming

The following table describes the various arming and disarming methods available.

Table 5-1 Arming/Disarming Methods

Method Description

Away Arm

for 2 seconds + [AccessCode*]

Stay Arm

Night Arm when ar med in stay mode [*][1] + [AccessCode*]

Disarm [AccessCode]

No-Entry Arming [*][9] + [Access Code]

Quick Arm/QuickExit [*][0]

for 2 seconds + [AccessCode*]

* - requiring an access code can be programmed in Section [015]

For detailed arming/disarming instructions, see the PowerSeries Neo User Manual.

5.2 Partition vs. Global Keypad

Keypads can be configured to control an individual partition or all partitions (see "Keypad Partition Setup " on page 33).

Loaning a keypad to another partition does not require an access code; However, no function that requires an access code

can be performed on that partition unless the user’s code has sufficient permission.

5.2.1 Single Partition Operation

Single partition keypads provide access to alarm functionality for an assigned partition.

Single partition keypads behave as follows:

l Display the armed state of the partition

l Display open zones, if the zone belongs to the partition the keypad is on

l Display bypassed zones and allow zone bypassing or creating bypass groups of zones assigned to the keypad par-

tition

l Display system troubles (system low battery, system component faults/tampers)

l Display alarms in memory that occurred on the partition

l Allow the door chime to be enabled/disabled

l Activate system test (sounds bells/PGMs assigned to the partition)

l Allow label programming (user labels for the partition)

l Control command outputs (those assigned to the partition, or global outputs such as smoke detector reset)

l Display temperature (not evaluated by UL)

5.2.2 Global/Multiple Partition Operation

Global keypads display a list of all active partitions or assigned partitions along with their current state. A valid access code

is required to view partition status. The Global status screen displays the following:

12345678 (RA!N----)

R = Ready

A = Armed

Page 40

Section 5: System Operation

! = Alarm

N = Not Ready

X = Exit Delay

E = Entry Delay

P = Pre-Alert

- = Partition not enabled

In the following example, partition 1 is armed, partition 2 is disarmed and ready, partition 3 is disarmed and not ready, par-

tition 4 is in alarm, partition 5 is indicating exit delay, partition 6 is in entry delay, partition 7 is in auto-arm pre-alert and par-

tition 8 is not enabled.

1 2 3 4 5 6 7 8

A R N ! X E P -

Global keypads behave as follows:

l Troubles are displayed and sounded on the global keypad. Troubles can be viewed from the global keypad display

by pressing the right scroll key then (*). The Troubles menu is displayed. An access code may be required to enter

the [*][2] menu depending on system programming.

l Keypad function keys can be programmed for Global Stay Arm, Global Away Arm and Global Disarm.

l Multiple partition arming/disarming may be done from a global keypad, assigned to the same partitions as the user,

by keying in an access code then pressing [*].

5.3 Labels

Various custom labels can be created to make identification of the alarm system, partitions, zones and modules simpler.

Labels are created by inputting text manually, by selecting words from the Word Library or by downloading/uploading using

DLS. See "[000] Label Programming" on page 67

5.3.1 System Label

This feature is used to program a custom label for the security system. This label is used in the event buffer when system

events occur. The maximum label size is 14 ASCII characters.

See "[100] System Label" on page 69 for programming details.

5.3.2 Zone Labels

Customized labels can be created for each zone on the alarm system. These labels are used on various displays and events

to identify the zone. The maximum label size is 14 x 2 ASCII characters.

See "[001]-[128] Zone Labels" on page 67 for more details.

5.3.3 Partition Labels

Each partition on the alarm system can have a unique label to identify it. This label is displayed on partition keypads and

event messages. The maximum label size is 14 x 2 ASCII characters.

See "[101]-[108] Partition 1-8 Labels" on page 69 for more details.

5.3.4 Module Labels

Labels can be created for the following optional system modules:

- 40 -

Page 41

Section 5: System Operation

l keypads

l 8 zone expander modules

l 8 output expander modules

l wireless transceiver

l power supply

l 4 high-current output module

l alternate communicator module

l audio module

l siren

l repeater

The maximum label size is 14 ASCII characters.

See "[801] Keypad Labels" on page 70 for more details.

5.3.5 Event Labels

Customizable labels can be created for the following events:

l Fire alarm

l Fail to arm

l Alarm when armed

l CO alarm

The maximum label size is 14 ASCII characters. See page 67 for more details.

5.3.6 Partition Command Output Labels

This feature is used to program custom labels for command outputs. These labels are used with output activation events in

the event buffer. The maximum label size is 14 x 2 ASCII characters. See "[201]-[208][001]-[004] Partition Command Output

Labels" on page 69 for more details.

5.4 Annunciation

5.4.1 Door Chime

The keypad can be programmed to use one of four different door chime tones for each zone on the system. Chime is active

only during the disarm state. Only one door chime option can be enabled for each zone.

l Beeps

l Bing-Bong

l Ding-Dong

l Alarm Tone

l Zone Name - Voice Annunciation (HS2LCDWF keypads only)

Chime is enabled/disabled on a partition using the [*][4] command.

5.4.2 Temperature Display

Indoor and outdoor temperature can be displayed on system keypads if configured in keypad programming section [861]-

[876]>[023] option 7, and sections [041]-[042]. Temperature is detected using wireless temperature sensors installed on the

system. Refer to "Compatible Devices" on page 9.

Global keypads only display outdoor temperature.

- 41 -

Page 42

Section 5: System Operation

5.4.3 Low Temperature Warning

Keypads can be configured to detect low ambient temperature.

If the temperature at the keypad drops to 6° C ± 2° C (43° F ± 3°F), the keypad zone goes into alarm. When the temperature

rises above 9° C ± 2° C (48° F ± 3° F), the keypad zone is restored.

When this option is enabled, the keypad’s zone input functionality is disabled.

Refer to section [861]-[876]>[023] option 8 for more information.

Note: This feature has not been evaluated by UL/ULC.

5.5 Keypad Function Keys

Keypads have 5 programmable function keys that can be configured to perform one of the following actions:

Table 5-2 Function Key Programming Options

[00] Null Function Key [17] Arm Interior