DSC FSA-410D Series, FSA-410DS, FSA-410DST, FSA-410DRS, FSA-410DRST Installation And Operating Instructions Manual

...Page 1

FSA-410D Series Smoke Alarm

Installation and Operating Instructions

Read this instruction sheet thoroughly before installation and use of the FSA-410D Smoke Alarm

LED/Test Button

Piezo Sounder

T

N

I

A

P

T

O

N

DO

Alignment Marks

Introduction

The FSA-410D is a 4-wire photoelectric smoke alarm with

optional: fixed temperature heat detector, auxiliary form C relay,

and/or remote LED output.

Operation

Approximately every 7 to 8 seconds the unit tests for a smoke or

heat alarm condition. During this sequence the unit also performs

self diagnostics, and checks for faults. During normal operation

the LED will remain on to indicate energization of the unit and the

sounder will not sound.

Smoke Alarm

The smoke detector has a nominal fixed alarm sensitivity (refer to

Specifications on back page) and it will go into alarm when the

signal level exceeds the 'alarm' threshold. During an alarm the

LED will shut off, the sounder will sound continuous beeps and

the alarm relay will be activated.

Remote Alarm - Interconnection

Multiple alarms can be connected using the PRM-4W Polarity

Reversal Module. When a fire alarm occurs, the unit will signal the

PRM-4W to reverse the polarity of the 4-wire loop. This will activate the sounders of all units connected on the loop. Refer to the

PRM-2W/4W Installation Manual for installation details.

Smoke - Drift Compensation

The unit automatically compensates for long-term environmentally induced changes to maintain a constant smoke sensitivity.

When the drift compensation has reached its high or low limit of

adjustment, the unit will go into the trouble state.

Heat Alarm

The heat detector will go into alarm when the heat signal level

exceeds the heat alarm threshold (135ºF/57ºC). During an alarm

the LED will shut off. The sounder will sound continuous beeps

and the alarm relay will be activated.

Alarm Restore

When the smoke clears from the unit and the heat signal falls

below the ‘restore’ level, the unit will automatically reset itself.

Alarm Indications

Condition LED Sounder

Normal/Sensitivity in

Production Range

Smoke Alarm OFF Steady See Note A

Heat Alarm OFF Steady A See Note

Alarm Restore ON OFF D D

Remote Alarm ON Steady D D

Low Power Trouble ON OFF D D

Other Fault / Trouble ON CHIRP 1/50s D D

Test Switch - Failed ON CHIRP 1/50s D D

Test Switch - Pass OFF Steady A A

A = Activated / D = Deactivated

ON OFF D D

NOTE: For models FSA-410DFIS, the relay is deactivated, for all

other models the relay is activated during the condition.

Alarm Aux.

Relay

FormA

Relay

FormC

Installer Instructions

1. Smoke Alarm Placement

On smooth ceilings, units may be spaced 9.1m (30 ft) apart as a

guide. Other spacing may be required depending on ceiling

height, air movement, the presence of joists, uninsulated ceilings,

etc. Refer to CAN/ULC-S553-02 for installation recommendations.

Do NOT locate smoke alarms at

the top of peaked or gabled ceilings; the dead air space in these

locations may prevent the unit

from detecting smoke. Avoid areas

with turbulent air flow, such as

near doors, fans or windows.

Rapid air movement around the

detector may prevent smoke from

entering the unit.

Do NOT locate units in areas of

high humidity.

Do NOT locate units in areas where the temperature rises above

38ºC (100ºF) or falls below 5ºC (41ºF).

2. Mount Smoke Alarm Backplate

Locking

Tab

Mounting Holes

Mount backplate on standard 4” octagonal electrical box using the screws provided.

NOTE: Power must be supplied from a

ULC Listed power supply or alarm control unit auxiliary output. Install wiring

in accordance with the appropriate

national and local electrical codes.

CAUTION: The dust cover protects the

unit when not in service. Remove the

dust cover before use.

Page 2

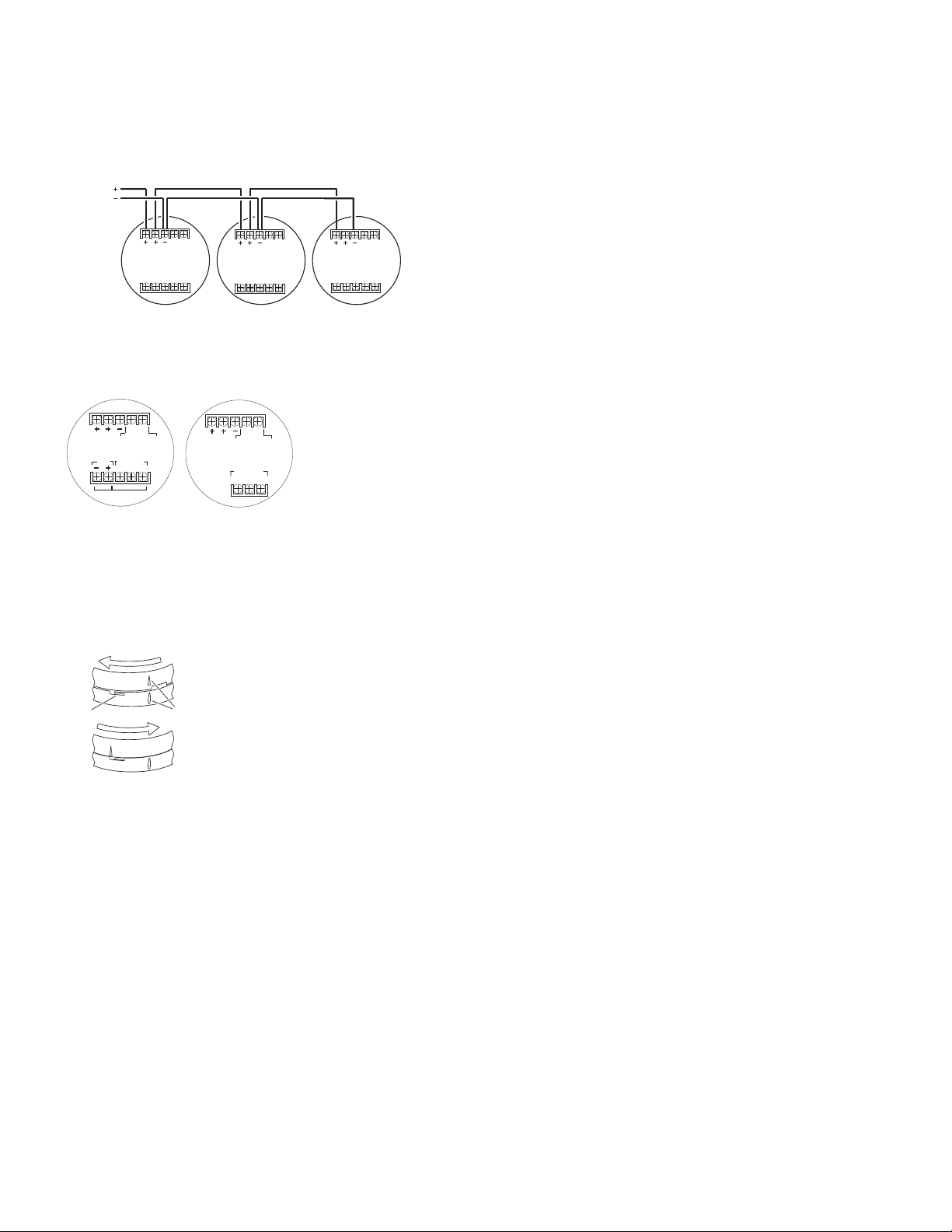

3. Wiring

Refer to the wiring diagrams in this installation sheet and those

provided in the Installation Manual of the alarm control panel

being used with the unit. Before connecting the unit, prepare

the wires from the electrical box for connection; Do not use

frayed or bent wire.

10-30 VDC

V

V

NO C

NOTE: Power supply shall be rated for the application.

Refer to electrical ratings when calculating the maximum

current required for an installation.

NO C NO C

NOTE: Optional Remote

NO C

Alarm Relay

Aux Relay

LED

NO NC C

OPTIONAL

NO C

Heat Alarm

Relay 'A'

FSA-410DFIS

Smoke Alarm

Relay 'C'

NO NC C

LED must have a series

resistor. Please see specifications.

When wiring is completed, inspect the wiring and correct any

errors before applying power to the unit. When the wiring has

been thoroughly reviewed, neatly insert the wires into the electrical box and secure the unit to the mounting plate.

4. Mounting

Detector Installation:

Close

Position the detector on to the

base plate using the detector and

base plate alignment marks. Press

the detector gently in place while

Tab

Open

Alignment

Marks

rotating the detector clockwise

until the detector snaps into

place. Remove the side tab from

the locking tab to lock in place

(optional).

Removal: If the side tab is removed to lock the detector,

depress tab with a small flat blade screwdriver and rotate detector counter-clockwise until the alignment marks line up. Remove

detector.

5. Test Unit

Initiate test by pressing the test button for greater than 5 seconds.

Alarm activation is indicated by the LED, the sounder, and the

alarm reporting to the control panel. If the smoke detectors are

inter-connected using model PRM-4W and a detector is tested,

then all detectors will sound. The detector restores to normal

when the test button is released or when the magnet is

removed.

NOTE: Allow a minimum of 20 seconds between test activations.

NOTE: If the detector is in one of the following states when a

test is initiated; it will not enter an alarm state.

1. Compensation trouble.

2. Failure of heat or smoke detector.

3. Other internal faults that could prevent a smoke or heat

alarm.

NOTE: Smoke sensitivity of installed detectors can be measured

without removal or an alarm being generated using the FSD-100

Smoke Detector Test Meter.

Test Unit with FSD-100 Smoke Detector Test Meter

To test the unit using the FSD-100, set the test meter up to read

devices as per the instructions supplied with the test instrument.

Depress the test button (or place the FSD-100 on the outside

edge of the plastics beside the test button to activate the reed

switch on units without sounder) on the smoke detector for 1

second and release.

NOTE: If the test button is held for 5 seconds or longer, an

alarm will be generated.

Move the test meter over the center of the detector, wait until

you hear the test meter beep, remove the unit and the information can be immediately reviewed. Please see the instructions

supplied with the FSD-100 Smoke Detector Test Meter for more

information.

6. Compensation Reset

Cleaning, replacement of the smoke sensor, or other changes

may change the background signal/noise of the detector; this

requires the drift compensation be reset. Compensation trouble

is one of the faults indicated when the LED indicator is OFF while

the sounder is chirping.

1. Remove power from the unit, then press and hold the test

button for 30 seconds to power down unit.

2. Power up unit while pressing the test button. The LED will

flash; when 5 seconds has elapsed. Release the test button

within 1 second after the fifth LED flash.

3. The LED will flash every 8 seconds for 1 minute. When the

detector stops flashing test the detector to verify normal

operation.

Page 3

Owners Instructions

Fire Safety In The Home

Most fires occur in the home, and to minimize this danger, it is

recommended that a household fire safety audit be conducted

and a family escape plan be developed.

Household Fire Safety Audit

1. Are all electrical appliances and outlets in safe condition?

Check for frayed cords, overloaded lighting circuits, etc. If

you are uncertain about the condition of your electrical

appliances or household service, have a professional evaluation.

2. Are all flammable liquids safely stored in closed containers,

and in a cool and well ventilated area? Avoid cleaning the

unit with flammable liquids.

3. Are hazardous materials such as matches out of the reach of

children?

4. Are furnaces and wood burning appliances properly

installed, clean, and in good working order? If in doubt,

have a professional evaluation.

Family Escape Planning

There is often very little time between the detection of a fire and

the time it becomes deadly. Because of this, it is very important

that a family escape plan be developed and rehearsed.

• Include every family member when developing the escape

plan.

• Study the possible escape routes from each location within

the house. Since many fires occur at night, give special

attention to the escape routes from sleeping quarters.

• It is essential that escape from a bedroom be possible without opening the interior door. Consider the following when

making your escape plans:

• Ensure that doors and windows that open to the outside are

easily opened. Ensure that they are not painted shut and

that the locking mechanisms operate smoothly.

• Develop specific rescue plans if opening the exit or using the

exit is too difficult for children, the elderly or handicapped.

This plan includes making sure that those who are to perform the rescue can promptly hear the fire warning signal.

• If the exit is above the ground level, provide an approved fire

ladder or rope, as well as training in its use.

• Keep exits on the ground level clear. Be sure to remove snow

from exterior patio doors in the winter and that outdoor furniture or equipment does not block exits.

• Have a predetermined assembly point where everyone can

be accounted for; for example, across the street or at a

neighbour’s house.

• Once everyone is out of the house, call the Fire Department.

• A good plan emphasizes a quick escape. Do not investigate

first or attempt to fight the fire, and do not attempt to rescue belongings or valuables as this takes up time. Once outside, do not re-enter the house; wait for the Fire

Department.

• Write the plan down and rehearse it frequently so that

should an emergency ever arise, everyone will know what to

do. Revise the plan as conditions change; for example, when

there are more or fewer family members in the home or if

there are changes to the house.

• Make sure your fire warning system is operational by conducting weekly tests. If you are unsure about system operation, contact your smoke detector installer or dealer.

• DSC recommends that you contact your local Fire Department and request further information on home fire safety

and escape planning. If available, have your local fire prevention officer conduct an in-house fire safety inspection.

Testing Your Smoke Alarm

Follow the test procedure described here or contact your smoke

alarm dealer or installer for testing instructions.

DSC recommends that you test the entire alarm system at least

once a week to verify the operation of all system functions.

To test the smoke alarm, press and hold the test button on the

front of the unit for 5 seconds minimum, the sounder initiates a

clicking noise during this time. When the button is pressed, the

unit’s alarm will sound, the LED will shut off and the relay will be

activated. When the button is released, the alarm will cease.

Upon completing the functional testing of the smoke alarm,

check the unit’s sensing chamber to ensure proper operation. To

test the sensing chamber, wave a lit cotton wick or punk stick

around the outside of the unit until a generous amount of

smoke enters the sensing chamber or the unit alarms. If the

smoke detector does not function properly, call your smoke

alarm installer or dealer for service.

Maintenance

The smoke alarm is designed to require minimum maintenance.

If the case becomes dusty, vacuum with a small brush attachment. If the case is greasy, wipe the case gently with a soft cloth

slightly dampened with soapy water.

Never disassemble the smoke alarm; there are no user serviceable parts inside the unit. Never paint the unit. Paint may prevent smoke from entering the unit. If you are planning

renovations or repainting, contact your installer and ask that the

unit be temporarily removed until work is complete.

If the unit is located in an area where it is exposed to high levels

of dust or insects and causes false alarms, it may require service;

contact your smoke alarm installer or dealer.

Testing and maintenance procedures shall be in accordance with

the CAN/ULC-S552 standard.

Page 4

Smoke Detector Family

4-Wire Smoke

Detector Family

FSA-410D YYYY

L = Remote LED Output

R = Auxiliary Form C Relay

S = Sounder

T = Fixed Temperature Heat Sensor

F = Form C Alarm Relay

I = Isolated Heat Alarm Output

Model Heat Sounder

FSA-410DS NO YES NO NO 75mA

FSA-410DST YES YES NO NO 75mA

FSA-410DRS NO YES YES NO 90mA

FSA-410DRST YES YES YES NO 90mA

FSA-410DLRST YES YES YES YES 90mA

FSA-410DFIS YES YES NO NO 90mA

Aux

Relay

LED

Output

Current

Draw

Specifications

Diameter (base) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8in (147mm)

Height (including base) . . . . . . . . . . . . . . . . . . . . . . 2.077in (528mm)

Operating Temperature . . . . . . . . . . . . . . . . . . . 32º-100ºF (0º-37.8ºC)

Humidity . . . . . . . . . . . . . . . . . . . . . . . 5%-93% RH, non-condensing

Operating Voltage Range. . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30V

Maximum Standby Current . . . . . . . . . . . . . . . . . 10mA@12 or 24V

Maximum Alarm Current: . . . . . . . . . . . . . . . . . . . . . . . . . . 75-90mA

Alarm Sensitivity ULC. . . . . . . . . . . . . . . . . 2% ± 0.5%/ft obscuration

Heat Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135ºF (57ºC)

Sounder Alarm Pattern ULC. . . . . . . . . . . . . . . . . . . Continuous beeps

Minimum Remote LED Resistance:

12V system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 Ohm

24V system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 Ohm

Maximum Remote LED output (if equipped): . . . . . . .25mA

Auxiliary Relay Rating (Form C Relay) . . . . . . . .2A @ 30V

Alarm Relay Rating (Form A Relay) . . . . . . . . . 2.0A @ 30V

(Resistive)

DC

(Resistive)

DC

Limited Warranty

Digital Security Controls Ltd. warrants that for a period of twelve months from the

date of purchase, the product shall be free of defects in materials and workmanship

under normal use and that in fulfillment of any breach of such warranty, Digital

Security Controls Ltd. shall, at its option, repair or replace the defective equipment

upon return of the equipment to its repair depot. This warranty applies only to

defects in parts and workmanship and not to damage incurred in shipping or handling, or damage due to causes beyond the control of Digital Security Controls Ltd.

such as lightning, excessive voltage, mechanical shock, water damage, or damage

arising out of abuse, alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in

lieu of any and all other warranties, whether expressed or implied and of all other

obligations or liabilities on the part of Digital Security Controls Ltd. Digital Security

Controls Ltd. neither assumes, responsibility nor authorizes any other person purporting to act on its behalf to modify or to change this warranty, nor to assume for it

any other warranty or liability concerning this product.

In no event shall Digital Security Controls Ltd. be liable for any direct, indirect or

consequential damages, loss of anticipated profits, loss of time or any other losses

incurred by the buyer in connection with the purchase, installation or operation or

failure of this product.

Smoke Detectors

Smoke detectors that are a part of this system may not properly alert occupants of a

fire for a number of reasons, some of which follow. The smoke detectors may have

been improperly installed or positioned. Smoke may not be able to reach the smoke

detectors, such as when the fire is in a chimney, walls or roofs, or on the other side of

closed doors. Smoke detectors may not detect smoke from fires on another level of

the residence or building.

Every fire is different in the amount of smoke produced and the rate of burning.

Smoke detectors cannot sense all types of fires equally well. Smoke detectors may

not provide timely warning of fires caused by carelessness or safety hazards such as

smoking in bed, violent explosions, escaping gas, improper storage of flammable

materials, overloaded electrical circuits, children playing with matches or arson.

Even if the smoke detector operates as intended, there may be circumstances when

there is insufficient warning to allow all occupants to escape in time to avoid injury

or death.

Warning: Digital Security Controls Ltd. recommends that the entire system be completely tested on a regular basis. However, despite frequent testing, and due to, but

not limited to, criminal tampering or electrical disruption, it is possible for this product to fail to perform as expected.

DC

Important Information: Changes or modifications not expressly approved by Digital

DC

Security Controls Ltd. could void the user’s authority to operate this equipment.

Industry Canada Compliance Statement

This Class B digital apparatus meets all requirements of the Canadian interferencecausing equipment regulations.

Cet appareil numérique de la Classe B respecte toutes les exigences de règlement sur

le matériel brouilleur du Canada.

©2003 Digital Security Controls

Canada • www.dsc.com

To r on t o

•

Technical Support: 1-800-387-3630

Printed in Canada • 29006020 Rev 002

29006020R002

Loading...

Loading...