DSB 235-TP Operation Manual

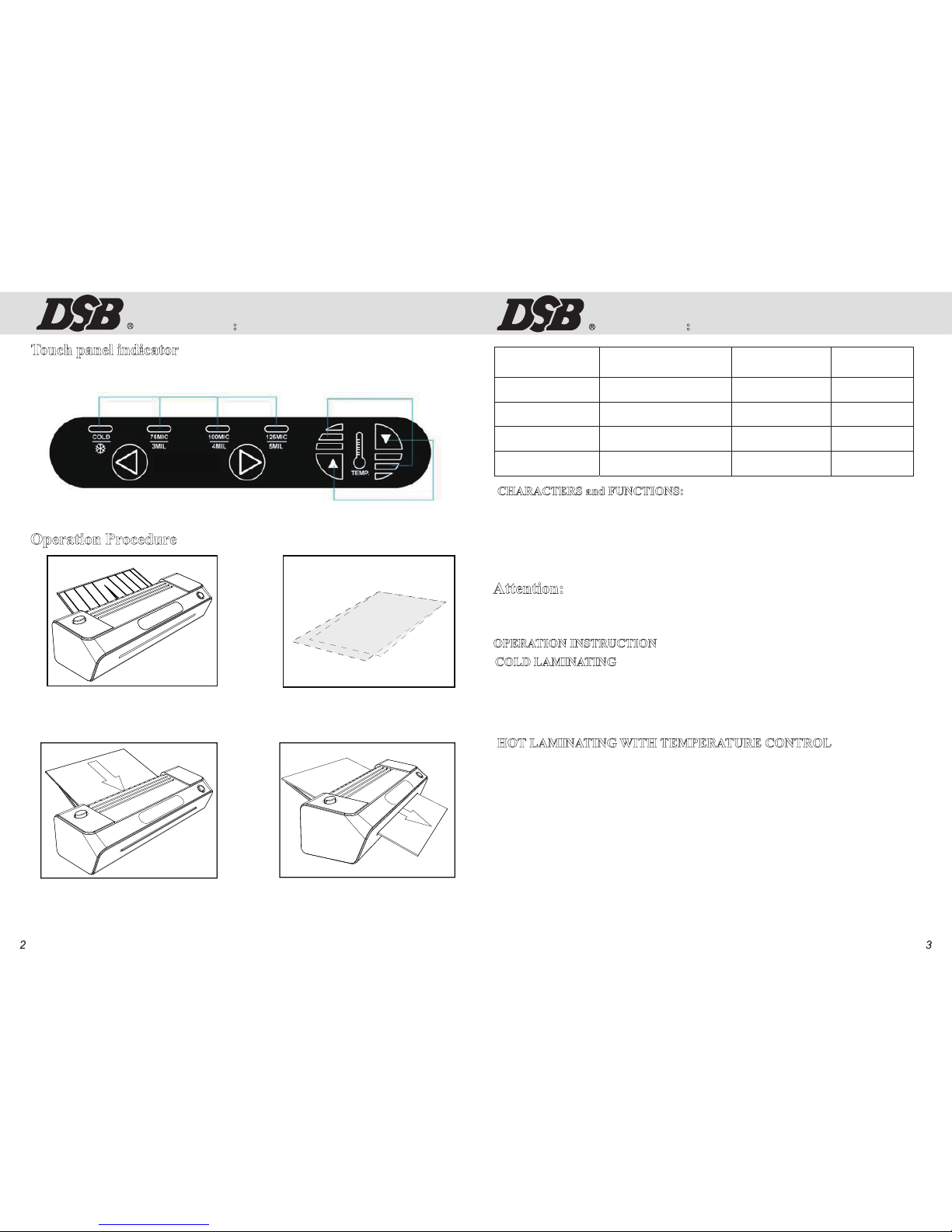

Touch panel indicator

:

Pouch indicators Temperature indicators

Temp. Up Temp. Down

Operation Procedure

1.

Flip the support tray and wait for Green 2.Insert the documents to be laminated at

light to start lamination. center pouch location..

3. Place the laminated document at the arrow 4. Lamination will start

location.

automatically.

Laminating speed 300mm/min No. of rollers 2

Pouch thickness 75MIC 100MIC 125MIC Voltage 220V

Max. width 238mm Pre-heating time 4-5min

Max. thickness 0.4mm File size Up to A4 size

Dimension N.W. 1.5Kg

CHARACTERS and FUNCTIONS:

This machine can be used to laminate pouches under COLD &HOT

conditions, in which the interlayer can be pictures, cards, document paper,

etc (with thickness less than 0.4mm). The pouches can take size up to A4

paper.

Attention:

1. Keep this machine horizontally with sufficient space for operation.

2. Please use voltage of 220V/ 50Hz during operation.

OPERATION INSTRUCTION

COLD LAMINATING

Lift back support tray,turn on the power switch, adjust the touch

panel to the position of the “Cold ” and it will start laminating

automatically.

HOT LAMINATING WITH TEMPERATURE CONTROL

1. According to pouch thickness, adjust the temperature transfer switch on

the touch panel in accordingly. The indicator is red during the preheating

stage.

2. After 4~5 minutes of warming up,the indicator will turn green.

3. Put one interlayer which you want to be laminated into a folio pouch

and insert them together into the entrance of the laminator horizontally

for immediate lamination.

4. Adjust the temperature from the temperature indicator for your ideal

result.

Laminator Operation Manual

Model No:

235-TP

Laminator Operation Manual

Model No:

235-TP

369*120*95mm

Laminator Operation Manual

Model No:

235-TP

Laminator Operation Manual

Model No:

235-TP

Key parts

1. Reverse Switch

2. Support Tray

3. Touch Panel

4. Power Switch

Please read this manual and observe the instructions thoroughly

b

efore operating machine.

Keep this instruction in a convenient location for future reference.

Reverse Button

Press this button when jamming occurs during operation to release

your documents.

REMARKS:

Make sure the interlayer is evenly folded before laminating

and the folded side will be inserted into the entrance of the laminator at

first. Please do not insert the open side of the pouch into the entrance first

and the pouch can’t be scissored apart before use. Moreover, please

follow the guideline in back of the entrance when inserting to make sure

that your pouch is inserted vertically to the entrance.

1. AFTER LAMINATING

After lamination, the documents are very hot. Please be careful not

to injure your hands.

CAUTIONS & MAINTENANCE:

To ensure safety and prevent potential accidents, such as crispation

of pouch or fire, please follow below steps.

Attention: please make sure that the machine has been turned off

and unplugged before maintenance.

1. As to the dirt on the covers of machine, please wipe them off by wet

cloth. To avoid the danger of short circuit, please do not place the

machine in wet conditions or nearby the window of air-conditioner,and

also please make sure that the machine is dry before operation!

2. Do not operate the laminator for more than two hours at a time. Wait at

least fifteen seconds between each lamination. Allow the laminator to

cool at least thirty minutes after power off.

3. Do not touch or place any objects on the hot surfaces of the machine,

wait for the machine to cool before moving or cleaning.

4. The color of heat-sensitive documents may change during lamination.

5. Interlayers over 0.4mm in thickness are not suitable for lamination.

6. The documents with material that are easy melting, sticky or thinner

than 70g/m² paper are not ideal for lamination.

4

Loading...

Loading...