Page 1

5695031

Edition 04 – January 2019 (Edition 01 – March 2014)

en

Instruction manual P4000

Dräger MSI GmbH

Rohrstraße 32

D - 58093 Hagen

Tel.: 0049 - 2331 / 9584 - 0

Fax: 0049 - 2331 / 9584 - 29

e-mail: info@draeger-msi.de

Page 2

Instruction manual Dräger P4000

1

Inhalt

1. Information ....................................................................................................................... 3

1.1 Warning signs ............................................................................................................. 3

1.2 For your safety ............................................................................................................ 3

1.3 Safety instructions and warnings ................................................................................ 4

1.4 Bluetooth ..................................................................................................................... 4

1.5 Disclaimer ................................................................................................................... 5

1.6 Maintenance and servicing ......................................................................................... 5

1.7 Disposal ...................................................................................................................... 5

2. Application ....................................................................................................................... 6

3. The instrument ................................................................................................................. 7

4. Operation of the instrument ............................................................................................. 8

4.1 General ....................................................................................................................... 8

4.2 Switch ON / OFF ......................................................................................................... 8

4.3 Buttons ........................................................................................................................ 9

4.4 Input .......................................................................................................................... 10

4.5 Integrated instruction manual .................................................................................... 10

4.6 Start a measurement ................................................................................................ 11

4.7 Result display............................................................................................................ 11

4.8 Documentation menu ................................................................................................ 11

5. Main menu ..................................................................................................................... 12

6. Auswahl und Eingabe von Kundendaten ....................................................................... 12

7. Pressure measurements ................................................................................................ 13

8. Performance of tightness and stress tests ..................................................................... 14

9. General tightness test .................................................................................................... 15

10. Gas pipe tests .............................................................................................................. 16

10.1 General Information ................................................................................................ 16

10.2 Selection of gas pipe test ........................................................................................ 16

10.3 Tightness test according to DVGW TRGI 2008 worksheet G 600........................... 16

10.4 Stress test according to DVGW TRGI 2008 worksheet G 600 ................................ 17

10.4.1 Pipings with operating pressures up to and including 100 mbar ....................... 17

10.4.2 Pipings with operating pressures over 100 mbar up to and including 1 bar ...... 18

11. Liquid gas pipe tests .................................................................................................... 19

11.1 General information ................................................................................................ 19

11.2 Auswahl der Flüssiggasleitungsprüfung .................................................................. 19

11.3 Tightness test according to DVFG TRF 2012 ......................................................... 19

11.4 Strength test according to DVFG TRF 2012 ........................................................... 20

12. Water pipe checks ....................................................................................................... 20

12.1 General Information ................................................................................................ 20

12.2 Selection of drinking-water installation test ............................................................. 21

12.3 Tightness test with air ............................................................................................. 21

12.4 Stress test with air up to DN 50 3 bar and up to DN 100 1 bar ............................... 22

12.5 Tightness test with water for crimped connections (untight if not crimped) ............. 22

12.6 Tightness test with water for metal-, multi-layer composite- and PVC pipings ........ 23

12.7 Tightness test with water for PP, PE, PE-X- and PB pipes, and with these combined

pipings ............................................................................................................................ 23

13. Checklists .................................................................................................................... 24

14. Data storage ................................................................................................................ 24

14.1 Store measurements ............................................................................................... 24

14.2 Data storage functions ............................................................................................ 25

Page 3

Instruction manual Dräger P4000

2

14.3 Data storage information ......................................................................................... 25

14.4 Display stored measurements ................................................................................ 25

14.5 Inspector table ........................................................................................................ 26

14.6 Delete measurement data ....................................................................................... 26

15. Device information ....................................................................................................... 27

16. Adjustments ................................................................................................................. 27

16.1 Date and time.......................................................................................................... 27

16.2 Key beep ................................................................................................................. 28

16.3 MSI infrared printer ................................................................................................. 28

16.4 Display lighting ........................................................................................................ 28

16.5 Overlaying of the integrated help function ............................................................... 28

16.6 Automatic daylight saving time................................................................................ 28

16.7 Printer footer text .................................................................................................... 28

16.8 Language ................................................................................................................ 28

17. Warning notes and error messages ............................................................................. 29

18. Power supply ............................................................................................................... 30

18.1 General information about the power supply .......................................................... 30

18.2 Battery charging ...................................................................................................... 30

19. Technical data ............................................................................................................. 31

19.1 General technical data ............................................................................................ 31

19.2 Technical Data Pressure Measurements ................................................................ 31

20. Care and maintenance ................................................................................................. 32

21. Consumables and accessories .................................................................................... 32

22. PC measurement data management ........................................................................... 32

Page 4

Instruction manual Dräger P4000

3

1. Information

The manufacturer of this product, Dräger MSI GmbH, is referred to as Dräger MSI in the

following.

The displays shown in this manual are examples!

1.1 Warning signs

Symbol Text

Warning

Indication of a potential dangerous situation. Avoiding this warning can lead

to death or severe injuries.

Caution

Indication of a potential dangerous situation. Avoiding this warning can lead

to injuries or damages to the product or the environment. Can also be used

as a warning against improper use.

Information

Additional information regarding the use of the product.

1.2 For your safety

Please read these operating instructions and those for the corresponding products

carefully before using the product.

The operating instructions must be strictly followed. The user must completely under-

stand the instructions and follow them precisely. This product may only be used in

compliance with the designated use.

Do not dispose of the operating instructions. Ensure safekeeping and proper use by

the users.

Only trained and competent personnel are permitted to use this product.

Observe local and national guidelines pertaining to this product.

Maintenance work may only be conducted by Dräger MSI or by qualified personnel

trained by Dräger MSI- Otherwise the responsibility for the proper functioning of the

product after maintenance and for the validity of approvals is rejected by Dräger MSI.

Only use original Dräger parts and accessories for maintenance work. Otherwise the

proper use of the product can be compromised.

Do not use defective or incomplete products. Do not modify the product in any way.

Page 5

Instruction manual Dräger P4000

4

1.3 Safety instructions and warnings

Do not operate the product if there is damage to the housing, power supply or supply

lines. Mark the product, to protect it against further use.

Do not conduct any measurements, which could lead to contact with uninsulated, hot

parts.

Only use the product appropriately and as intended and within the parameters spec-

ified in the technical specifications. The improper use of this product can result in

death, severe injuries or the destruction or damage of the product.

Do not use this product in environments exposed to explosion hazards.

This product is equipped with a magnetic holder. The magnetic field can be hazard-

ous to the health of persons with pacemakers.

Do not open rechargeable batteries or batteries and do not throw them into fire.

Store this product in a place at room temperature without exposure to solvents, plas-

ticizers agents, emissions or combustible materials.

Only use this product in closed and dry rooms. Protect it against rain and moisture.

Independent modifications to the product can lead to malfunctions and are prohibited

for safety reasons. Dräger MSI otherwise refuses the responsibility for the proper

functioning of the product after modification and for the validity of the certifications.

This product is equipped with a magnetic holder. The magnetic field can damage

other products. Keep a safe distance from other products (e.g. mobiles, computers,

monitors, credit cards, memory cards, etc.).

1.4 Bluetooth

Changes or modifications not specifically approved by the responsible admissions

office can lead to the revocation of the operating license. Devices transmitting in the

same ISM radio band, e.g. mobiles, WLAN, microwaves, etc, can destroy data trans-

mission.

Among others, the use of radio communication is prohibited in aircraft and hospitals.

Page 6

Instruction manual Dräger P4000

5

1.5 Disclaimer

Dräger MSI does not assume any liability or warranty for damages or consequential

damage arising from non-compliance with technical regulations, instructions and rec-

ommendations. Dräger MSI and the sales companies are not liable for costs or damages resulting from the use of the product by the user or third parties, especially in the case

of improper use of the product. Neither Dräger MSI nor the sales companies are liable for

the incorrect use of the product.

1.6 Maintenance and servicing

To ensure proper functioning and measurement accuracy, service specialists trained

by the Dräger MSI GmbH should conduct calibration and adjustment annually.

The device can be cleaned with a damp, not wet, cloth. Do not use any chemical

cleaning agents. Please make sure that the device connections are not clogged or dirty.

1.7 Disposal

The EU-wide directives for the disposal of electrical and electronic equipment apply.

Please observe the applicable local environmental regulations for disposal or return

the product to Dräger MSI or your national dealer for disposal. Defective rechargeable batteries are considered hazardous waste and must be brought to the designated collection points for disposal.

Page 7

Instruction manual Dräger P4000

6

2. Application

The Dräger P4000 is an electronic measuring instrument, to measure pressure at air, gas

or water filled pipings and containers.

It is not suitable for continuous operation or as a safety or alarm device.

All tests and measurements can be documented through print outs or storage.

Every use of a Dräger P4000 requires the exact knowledge and compliance of this

instruction manual, the corresponding norms and standards, the applicable legal

provisions, and the regulations and rules for health and safety at work.

The instrument is only destinated for the applications, as described in this instruction manual.

Before each measurement make sure that the instrument and the accessories are in

a perfect condition. Provisional sealing plugs (rubber plugs) of pressurized pipings

that are used over an operating pressure of 0.5 bar represent an increased safety risk.

Only use a 5 V DC / 1 A USB power supply unit, to always fully charge the Dräger

FG7000 via the USB port. Incomplete charging affects the charging capacity of the

battery in the long run.

The shown display screen shots in this instruction manual are examples!

Pressure tests with water may only be carried out with the external pressure sensor

EP250. The internal pressure sensor and the external pressure sensor EP35 can be

damaged by tests with water.

Page 8

Instruction manual Dräger P4000

7

3. The instrument

The Dräger P4000 allows to perform versatile pressure and tightness tests at air, gas or

water filled pipings and containers.

All tests and measurements can be documented by printing them out or by storing them in

the data storage.

USB interface

Illuminated colour display Charge control indicator,

with touchscreen IR transmitter

Interfaces

Charge control indicator + IR transmitter USB interface

External sensor

(-)mbar sensor (+) mbar sensor

Page 9

Instruction manual Dräger P4000

8

4. Operation of the instrument

4.1 General

The Dräger P4000 is operated by a touchscreen display. You can execute the touch and

wipe functions on the screen via your finger or a plastic stylus. Inappropriate are ballpoint

pens, pencils, metal pens and suchlike.

The display is a resistive touchscreen and so you have to apply more pressure to operate

it, than you may know it from modern Smartphones with a capacitive touchscreen.

Menus and lists can be moved upwards and downwards by up and down moving ges-tures

(wiping).

Menus and list positions are marked by tapping. The selected position can be activated by

tapping the 'SELECT' button or by tapping it again.

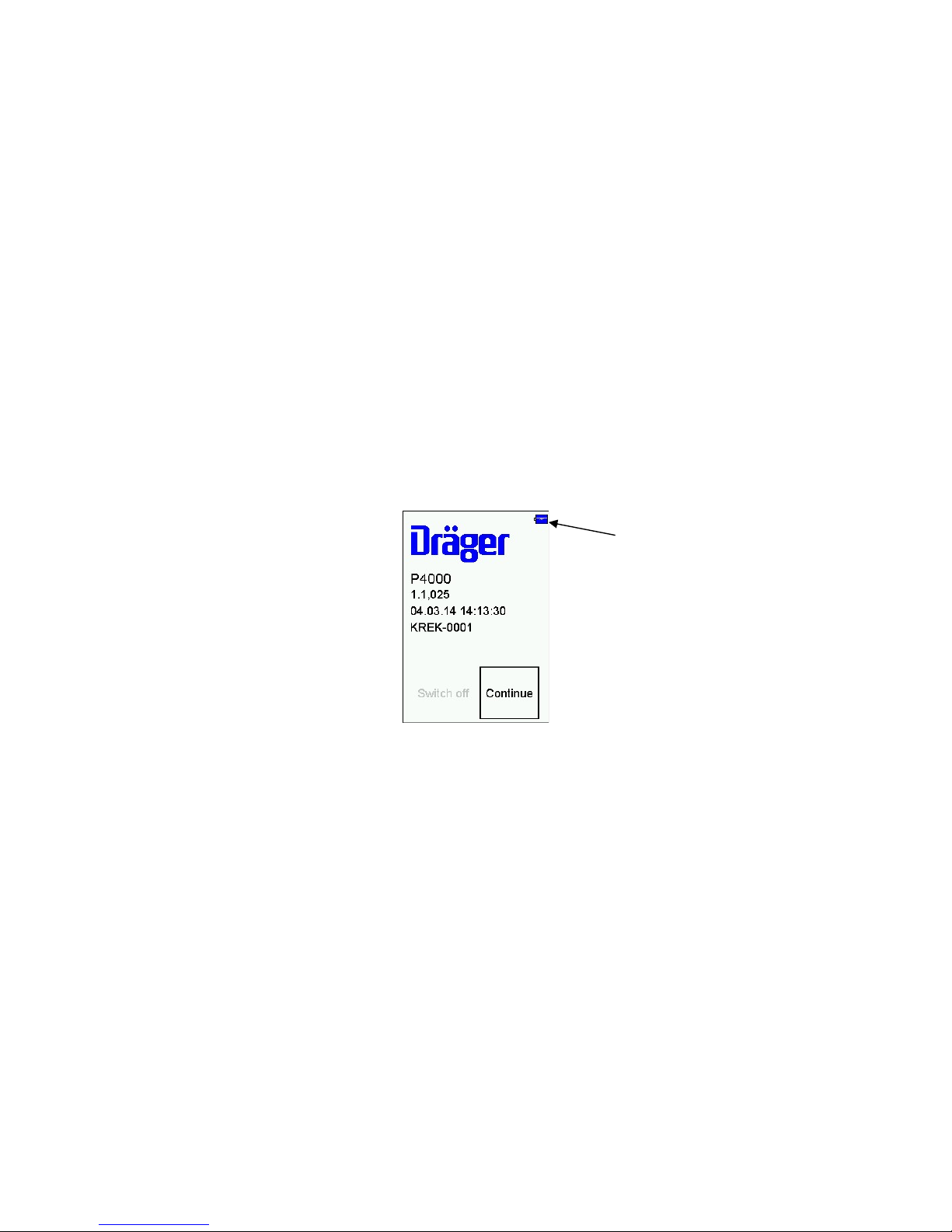

4.2 Switch ON / OFF

Switch ON: Touch the display for 1 second until it is illuminated.

Battery symbol

The start screen displays device type, software version, date and time and the serial number.

The battery symbol indicates the state of charge.

Via tapping the 'OK' button, the main menu will appear. If the button won't be tapped within

5 seconds after switching ON the instrument, it will switch OFF automatically.

Switch OFF: Choose in the main menu 'OFF' or hold the touch screen tapped for at least

5 seconds from any menu option.

Page 10

Instruction manual Dräger P4000

9

4.3 Buttons

Menu = opens a context menu for selection and editing of facility data

Select = activates the marked position

OK = confirms a selection

Ready = continues to the next step after an action

Continue = continues to the next step of a function

Cancel = ends a function, moves to the main menu

>> = scrolls forwards, displays diagram

<< = scrolls backwards, displays statistical data

Zero = adjusts the zero point of the pressure sensor

Start = starts the measurement

Stop = stops the measurement

New = prepares a new measurement

Docu = moves to the documentation menu

Back = moves from the documentation menu to the result display

Customer = moves from the documentation menu to the facility selection

Print = prints out the test result via the IR transmitter

Store = stores the test result in the data storage

End = moves from the documentation menu to the main menu

Finish = ends the measurement time prematurely

Input = opens the editing function for printer texts

Page 11

Instruction manual Dräger P4000

10

4.4 Input

Via the button 'MENU' a context menu opens. In addition to the menu

option the context menu offers various editing functions and commands.

Customer data and comments can be edited via an overlaid keypad.

The penetration of the display with sharp or pointed items can destroy the display.

4.5 Integrated instruction manual

Via the menu function 'Settings' the integrated instruction manual can

be activated. If the integrated instruction manual is activated the particular operation hints will be shown at the start.

With '>>' and '<<' you can scroll between the pages.

Via the 'Continue' button the test will be started.

Page 12

Instruction manual Dräger P4000

11

4.6 Start a measurement

Before the beginning of a test, a connection diagram note will be displayed, that will be used for each particular test.

4.7 Result display

After ending of a test, the results will be displayed.

For pressure and tightness tests the start pressure, the end pressure, the pressure drop and

the measurement time are displayed, for tightness tests additionally the stabilization time.

4.8 Documentation menu

After ending a test the documentation menu can be called up.

If no customer has been selected, before the test, it is possible to select

or create a customer from here.

Via the 'Save' button the test result will be allocated to the particular

customer. If no customer has been selected, the test result will be

stored only with time and date.

Via the 'Print' button the test result can be transmitted to an infrared

printer via the integrated IR transmitter.

Page 13

Instruction manual Dräger P4000

12

5. Main menu

Selectable menu options are:

Switch off: Switch off the instrument

Customer / Facility: Select and edit facility data sets

Pressure: General pressure measurements

General test: Tightness test with free input of measuring parameters

Gas pipes: Gas pipe tests according to DVGW TRGI 2008 G 600

Liquid gas pipes: Liquid gas pipe tests according to TRF 2012

Water pipe test: Water pipe tests according to DIN EN 806

Checklists: Select, edit and store checklists

Data storage: data storage information, measurement data and inspector table

Info: Instrument information

Settings: Edit instrument settings, set clock

6. Auswahl und Eingabe von Kundendaten

Via the PC software it is possible to create customer numbers, customer names and customer data and transfer these data to the instrument.

If customer data are stored in the instrument it is possible to select a

customer and to store measurements to this customer via this function.

Are there no customer data stored they can putted in via this function.

Select: The displayed customer number will be overtaken.

Menu: The context menu opens.

Without: Measurements will be stored without facility allocation.

New: New customer data can be created.

Search: A character string can be searched for (e.g. a name).

Delete: Selected data set can be deleted. That is only

possible, if there are no measurement data stored in

the instrument.

Page 14

Instruction manual Dräger P4000

13

Via 'Edit' function the marked customer number and corresponding

data, if any, will be displayed.

Via 'Select' these data can be edited and taken over by tapping 'Ready'.

Customer number, name, kind of installation, installation location, installation number, street, post code, city, customer name, customer

street, customer post code, customer city and customer phone number

can be typed in.

The overtaken customer number is valid for all following tests, as long

as the instrument is switched on or another customer number is chosen.

7. Pressure measurements

Connect the test nipple of the pressure container or pressure pipe, that

has to be measured, via a pressure hose to the corresponding pressure

input of the instrument. For the high pressure measurement (3.5 bar /

25 bar) the external sensor (optional) has to be connected.

Selectable functions:

Zero: displayed measurement value will be set to zero

>> / <<: switch between statistical data and diagram

Start: start of the pressure measurement

Cancel: cancels current pressure measurement

After starting the pressure measurement the actual pressure, the start

pressure, the difference to the start pressure and the elapsed duration

are displayed.

After ending of the measurement the results are displayed.

Page 15

Instruction manual Dräger P4000

14

8. Performance of tightness and stress tests

During the test an info text informs about the current progress.

Each tightness and stress test consists of a stabilisation phase for the

temperature compensation, and following measurement. Test pressure

and duration of stabilization phase and measurement depend on the

corresponding norms. (TRGI, TRF, TRWI, …).

At the beginning of a tightness or stress test, the particular test pressure

has to be applied.

If the test pressure has been applied, or the pressurization has been

stopped prematurely, the stabilization phase starts with 'Ready'.

During the stabilization phase the actual pressure, the start pressure of

the stabilization phase, the pressure drop and the elapsed stabilization

time are displayed.

A negative pressure drop (e.g. -0.1 mbar) means an increase in pressure. A possible reason for that is influence of temperature.

If the stabilization time has elapsed or the stabilization phase has been

ended prematurely with 'Continue', the measurement starts.

During the measurement the actual pressure, the start pressure of the

measurement, the pressure drop during the measurement, the stabilization time and the elapsed measuring time are displayed.

After the measuring time is elapsed or the measurement has been

ended prematurely, the results are displayed.

The start pressure of the measurement, the end pressure of the measurement, the pressure drop during the measurement, the stabilization

time and the measuring time are displayed.

Page 16

Instruction manual Dräger P4000

15

9. General tightness test

Via this function it is possible to perform tightness tests with freely selectable nominal pressure, stabilization time and measuring time.

For the general tightness test it is possible to adjust the test pressure,

the stabilization time and the measuring time.

The test pressure is adjustable between 20 and 25,000 mbar, the stabilization time and the measuring time is adjustable between 5 minutes

and 6 hours.

Via the selection buttons, behind the displayed values, the input function opens.

The nominal pressure can be putted in freely, the times can be selected from a list.

'Continue' starts the test. During the measurement you can scroll with

'>> / <<' anytime between the table and diagram display.

Pressurization: In this phase the instrument waits for the increase of

pressure. 'Ready' confirms the achieving of the test pressure.

Stabilization phase: The instrument awaits the given time and switches

automatically to measurement.

The stabilization phase can be ended by tapping 'Continue'.

Measurement: Within the measuring time the pressure history, as start

pressure, end pressure and the differential pressure are monitored.

The given measuring time can be shortened via the 'Ready' button.

Ready: After the measurement the monitored results will be available.

Page 17

Instruction manual Dräger P4000

16

10. Gas pipe tests

10.1 General Information

For the installation and maintenance of gas pipes, a stress test and a tightness test according to DVGW TRGI 2008 worksheet G600 has to be performed.

For new laid pipings a stress test and a tightness test has to be performed, before the pipings

are plastered or covered.

New or existing pipings, which are being worked upon, are only allowed to fill with gas if the

stipulated tests have passed.

For tightness and stress tests pipings, that have to be inspected, have to be discon-

nected from gas-carrying lines and have to be metal-to-metal seated.

The tests have to be performed with air or inert gas (e.g. Nitrogen)

10.2 Selection of gas pipe test

Selectable functions:

Tightness test: Tightness test at 150 mbar

Stress test 1 bar: Stress test at 1 bar

Stress test 3 bar: Stress test at 3 bar

10.3 Tightness test according to DVGW TRGI 2008 worksheet G 600

A tightness test has to be performed and documented for every new or significantly modified

installation with operation pressures up to and including 100 mbar.

It surrounds the piping including fittings, though without gas appliances and associated control and safety fittings.

For the tightness test the pressure in the gas pipe, that has to be tested, has to be increased

according to DVGW TRGI 2008 to some more than 150 mbar.

After a stabilisation phase for the temperature balance, the pressure in the pipe, that has to

be tested, will be measured for the stipulated time.

The stabilisation times and test times are defined according to the pipe's volume (pipe section), that has to be tested.

Page 18

Instruction manual Dräger P4000

17

For the determination of the stabilisation time and test time, the volume

of the pipe section, that has to be tested, has to be determined.

Via the selection buttons behind the displayed values, the input function

opens.

Stabilisation time and measuring time at tightness tests according to TRGI G 600

1. Determine measuring time via volume input.

2. Increase pressure in the pipe, that has to be tested, to some more than 150 mbar.

For that connect a pump via a valve to the pipe and increase the pressure.

3. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

4. After the stabilization time the measurement time starts automatically.

10.4 Stress test according to DVGW TRGI 2008 worksheet G 600

10.4.1 Pipings with operating pressures up to and including 100 mbar

For new gas installations of low-pressure systems (operating pressure ≤ 100 mbar) a stress

test has to be performed, before the tightness test. It surrounds the piping without fittings,

gas control appliances, gas meters gas appliances and associated control and safety fittings.

For the stress test the pressure in the gas pipe has to be increased to 1 bar. After a temperature balance (no specific time is stipulated, 10 minutes are appropriated), the pressure in

the pipe will be measured for 10 minutes.

1. Increase pressure in the pipe, that has to be tested, to some more than 1 bar. For

that connect a pump via a valve to the pipe and increase the pressure.

2. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

3. After the stabilization time the measurement time starts automatically.

Pressure Volume Stabil. time Meas. time

150 mbar < 100 l 10 min 10 min

150 mbar ≥ 100 l < 200 l 30 min 20 min

150 mbar ≥ 200 l 60 min 30 min

Page 19

Instruction manual Dräger P4000

18

10.4.2 Pipings with operating pressures over 100 mbar up to and including 1 bar

For pipings of new middle-pressure systems (operating pressure 100 mbar up to 1 bar) a

combined stress test and tightness test has to be performed. It surrounds the piping including fittings, though without gas control appliances, gas meters, gas appliances and associated control and safety fittings, as far as they are not designed for that test pressure.

For the combined stress test and tightness test the pressure in the gas pipe has to be increased up to 3 bar.

After a temperature balance (3 hours) the pressure in the pipe is measured for 2 hours.

For a pipe volume over 2,000 liters, the test time has to be increased for 15 minutes each

additional 100 liters pipe volume.

For the determination of the measurement time, the volume of the gas

pipe has to be determined.

Via the selection buttons, behind the displayed values, the input function opens.

1. Determine measuring time via volume input.

2. Increase pressure in pipe, that has to be tested, to 3 bar. For that connect a pump

via a valve to the pipe and increase the pressure.

3. Confirm the pressure increase by tapping 'Ready', the stabilisation time starts.

4. After the stabilisation time the measurement time starts automatically.

Page 20

Instruction manual Dräger P4000

19

11. Liquid gas pipe tests

11.1 General information

Liquid gas pipes have to be checked by experts, qualified persons and / or by specialized

companies for a proper condition:

- before the first start-up,

- after modifications,

- after an interruption of operation for more than one year,

- recurring.

Filling of a stationary liquid gas container is regarded as first start-up.

Stipulated tests are: strength test and tightness test

11.2 Auswahl der Flüssiggasleitungsprüfung

Wählbare Prüfungen sind:

Dichtheitsprüfung: Dichtheitsprüfung bei 150 mbar

Festigkeit frei: Festigkeitsprüfung 1 bar an freiliegenden Flüssiggasleitungen

Festigkeit erdgedeckt: Festigkeitsprüfung 1 bar an teilweise erdgedeckten

Flüssiggasleitungen

11.3 Tightness test according to DVFG TRF 2012

Immediately before the start-up all pipes (up to the adjustment elements) have to be tested

for tightness with air and an overpressure of 150 mbar.

Pipes are regarded as tight, when after a temperature balance of 10 minutes the test pressure does not drop within the following test duration of 10 minutes.

1. Increase pressure in liquid gas pipe that has to be tested, to some more than 150

mbar. For that connect a pump via a valve to the liquid gas pipe and increase the

pressure.

2. Remove the pump and confirm the pressure increase by tapping 'Ready', the stabilization time starts.

3. After the stabilization time the measurement time starts automatically.

Page 21

Instruction manual Dräger P4000

20

11.4 Strength test according to DVFG TRF 2012

The strength test can be performed sectional. Apply the 1.1-fold value of the permissible

operating pressure with air or nitrogen, at least the pressure has to be 1 bar.

At exposed pipes a balancing time of 10 minutes is necessary, at partially earth-covered

pipes a balancing time of 30 minutes is necessary.

Read off the pressure from gauge (measurement accuracy 1% of measuring range final

value). Check the gauge for pressure drop earliest after additional 10 minutes.

1. Select strength test 1 bar exposed or 1 bar earth-covered.

2. Increase pressure in gas pipe, that has to be tested, to some more than 1 bar. For

that connect a pump via a valve to the liquid gas pipe and increase the pressure.

3. Remove the pump and confirm the pressure increase by tapping 'Ready', the stabilization time starts.

4. After the stabilization time the measurement time starts automatically.

12. Water pipe checks

12.1 General Information

According to DIN EN 806-4 water pipes have to be pressure tested after new installations,

modification and repair. Demanded is a hygienically proper tightness test. The stipulated

tests can be performed with water, oil-free clean air or inert gas.

The tightness test with inert gas (e.g. Nitrogen) has to be performed where increased hygienic requirements, e.g. in hospitals, retirement homes, kindergartens or medical practices.

The tightness test with air has to be performed, when a prolonged downtime period is expected.

The tightness test with drinking water can be performed, when the water exchange starts up

according to its dedicated operation latest 72 hours after the tightness test.

Tests of drinking-water installations may only be performed via the optional external

high-pressure sensor EP250. If these tests were performed via the internal pressure

sensor or with the external high-pressure sensor EP35, the instrument can be seri-

ously damaged!

Page 22

Instruction manual Dräger P4000

21

12.2 Selection of drinking-water installation test

Selectable functions are:

Tightness air: Tightness test with air 150 mbar

Stress test air 1 bar: Stress test with air 1 bar up to DN 100

Stress test air 3 bar: Stress test with air 3 bar up to DN 50

Tightness crimp: Tightness test with water 6 bar for (untight if not crimped)

crimp connections

Tightness metal, PVC: Tightness test with water 11 bar for metal, multi-layer composite

and PVC pipes

Tightness plastic: Tightness test with water 11 bar for PP, PE, PE-X- and

PB pipes and with these combined pipings

12.3 Tightness test with air

The tightness test of drinking-water installations has to be performed before the stress test.

For the tightness test the pressure in the gas pipe, that has to be tested, has to be increased

to some more than 150 mbar.

After an appropriated stabilisation phase, the pressure in the pipe will be measured within

the stipulated time. The measuring time is determined according to the pipe's volume.

For the determination of the measurement time, the volume of the pipe

section, that has to be tested, has to be determined.

Via the selection buttons, behind the displayed values, the input function opens.

For the measurement up to 100 l pipe volume, a test time of 120

minutes is stipulated. For each additional 100 l pipe volume the test

time has to be increased for 20 minutes.

The duration of the stabilization phase shall be adequate.

A duration of 10 minutes is empirically appropriate.

The measuring time will be calculated automatically in dependence to the pipe volume.

1. Determine measuring time via volume input.

2. Increase pressure in pipe that has to be tested, to some more than 150 mbar. For

that connect a pump via a valve to the pipe and increase the pressure.

3. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

4. After the stabilization time the measurement time starts automatically

Page 23

Instruction manual Dräger P4000

22

12.4 Stress test with air up to DN 50 3 bar and up to DN 100 1 bar

The stress test of drinking-water installations has to be performed after the tightness test, in

combination with a visual inspection of all pipe connections.

The measuring pressure for nominal diameters up to DN 50 is maximally 3 bar, and for

nominal diameters up to DN 100 maximally 1 bar.

The test time is stipulated with 10 minutes. The duration of the stabilization phase shall be

adequate. A duration of 10 minutes is empirically appropriate.

For safety reasons higher pressures than 3 bar are not permitted for tests with air.

1. Select stress test 1 bar (up to DN 100) or 3 bar (up to DN 50).

2. Increase pressure in pipe to test pressure. For that connect a pump via a valve to the

drinking-water installation and increase the pressure.

3. Remove the pump and confirm the pressure increase by tapping 'Ready', the stabilization time starts.

4. After the stabilization time the measurement time starts automatically.

12.5 Tightness test with water for crimped connections (untight if not crimped)

Untight if not crimped connections have to be tested with a test pressure of 6 bar, or according to their manufacturer’s specifications, before the actual tightness test.

The stabilization time is 10 minutes and the test time is 15 minutes. During the test time a

pressure drop shall not occur, and no leak shall be detectable.

1. Increase pressure in pipe to test pressure. For that connect a pump via a valve to the

drinking-water installation and increase the pressure.

2. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

3. After the stabilization time the measurement time starts automatically.

Page 24

Instruction manual Dräger P4000

23

12.6 Tightness test with water for metal-, multi-layer composite- and PVC pipings

Drinking-water installations of metal-, multi-layer composite- and PVC pipings have to be

tightness tested with water, at a test pressure of 11 bar.

The stabilization time is 10 minutes and the test time is 30 minutes. During the test time a

pressure drop shall not occur and no leak shall be detectable.

1. Increase pressure in pipe that has to be tested, to 11 bar. For that connect a pump

via a valve to the drinking-water installation and increase the pressure.

2. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

3. After the stabilization time the measurement time starts automatically.

12.7 Tightness test with water for PP, PE, PE-X- and PB pipes, and with

these combined pipings

The tightness test with water for PP, PE, PE-X- and PB pipes, and with these combined

installations made of metal and multi-layer composite pipings, consists of a stabilization

phase and a measuring phase.

The stabilization time is 30 minutes, the test pressure is for that test 11.0 bar.

During these 30 minutes the test pressure has to be kept up by re-pumping.

After that the test pressure has to be decreased to 5.5 bar. With the decreased pressure a

test time of 120 minutes has to be kept. During the test time a pressure drop shall not occur

and no leak shall be detectable.

1. Increase pressure in pipe that has to be tested, to 11.0 bar. For that connect a pump

via a valve to the drinking-water installation and increase the pressure.

2. Confirm the pressure increase by tapping 'Ready', the stabilization time starts.

3. Keep up the test pressure within the 30 minutes of the stabilization phase by repumping.

4. Decrease after the stabilization time the test pressure to 5.5 bar and start the measuring time.

Page 25

Instruction manual Dräger P4000

24

13. Checklists

Measurement regulations often contain visual and other inspections that have no context to

the actual test. The checklists offer a possibility to gather such additional information for

these tests or facilities. In addition, work instructions can be created and worked through.

With the PC software it is possible to configure up to 4 checklists with each up to 20 checkpoints. Each checkpoint can be configured that an answering with Yes / No, or with a max.

5 character long input is possible.

If no input is done yet, the value will be displayed with ---.

14. Data storage

14.1 Store measurements

If no facility number has been selected, before the measurement, a facility can be allocated, before storing the result, with 'Customer' in the

documentation menu.

Without a facility allocation the measurement will be stored with time

and date.

With a facility allocation additionally a facility number will be displayed.

Page 26

Instruction manual Dräger P4000

25

14.2 Data storage functions

Selectable functions are:

Info: Data storage information

Show data: Display data set

Inspector table: Select and edit inspector table

Delete measurements: Delete all measurement data storage

14.3 Data storage information

In the data storage information the number of stored customers, stored

measurements and the total number of used storage spaces are displayed.

14.4 Display stored measurements

Measurements are stored with date, time and facility number -if allocated- .

'Select' calls up the result display of a measurement.

Page 27

Instruction manual Dräger P4000

26

'Docu' displays the allocated facility, and the measurement result can

be printed out with facility and inspector.

14.5 Inspector table

The inspector table contains inspectors with inspector number, street,

postcode, city and telephone number.

The selected inspector will be allocated with the stored measurement

data set.

An inspector can only be deleted if no measurement data is stored in

the instrument.

14.6 Delete measurement data

Delete measurement data: All stored measurements will be deleted.

Page 28

Instruction manual Dräger P4000

27

15. Device information

This function informs about the manufacturer (Dräger), instrument type

(P4000), version of the instrument software (1.0,25), the serial number

of the instrument, the set date, the set time and the identification number of the connected external sensor.

Without external sensor a dash is displayed.

16. Adjustments

The instrument can be configured to the users requirements.

Via the buttons, the functions will be enabled or disabled, or switched

to input.

Via '>>' the input of an IR printer footer text will be called up.

16.1 Date and time

Adjustment and change of date and time.

Page 29

Instruction manual Dräger P4000

28

16.2 Key beep

Via that function you can activate or deactivate the key beep.

16.3 MSI infrared printer

Via this function you can choose between printer protocols for MSI printers or HP printers.

Printer MSI IR3: The data transfer and the print outs are faster than those of the HP protocol

compatible printers.

Printer HP: The data transfer complies to the HP protocol and is usable for all HP protocol

compatible printers, of course also for the MSI IR3.

16.4 Display lighting

Via that function the display brightness can be set to 50%, 75% or 100%. The display brightness influences the run time of the battery.

16.5 Overlaying of the integrated help function

Via that function the integrated help function can be activated or deactivated.

16.6 Automatic daylight saving time

Via that function the automatic daylight saving time can be enabled or disabled.

16.7 Printer footer text

Via that function it is possible to put in and edit the footer text for infrared printers on print outs.

16.8 Language

Select country specific language setting.

Page 30

Instruction manual Dräger P4000

29

17. Warning notes and error messages

During the start-up phase and while measurements, the instrument monitors its proper function. Warning notes and error messages will be displayed after the start-up or during the

regular use.

Clock not set

Date and time has to be set, e.g. after deep discharge of the battery.

Charge level

The battery has to be charged.

Settings

Check settings and change them if necessary.

Printer footer text

An error in the printer footer text has occurred. Put in the printer footer text or transfer it from

PC.

Data storage

Confirm the prompt request 'Reinitialise data storage?'. The whole data storage will be deleted!

Calibration

An error in the calibration has occurred. Give instrument to your nearest service partner.

Options

An error in the options has occurred. Give instrument to your nearest service partner.

Page 31

Instruction manual Dräger P4000

30

18. Power supply

18.1 General information about the power supply

A built-in lithium-ion battery allows a mains independent use.

The run time with a fully charged battery is up to 10 hours, but depends to kind of measurement and display lighting.

Measurements can be proceeded during charging.

18.2 Battery charging

The charge level is permanently monitored and displayed by the instrument.

The battery symbol on the display indicates the charge level. Red flashing of the charge

control indicator on the side of the instrument indicates a discharged battery.

The instrument should be charged from this moment. Charge the Dräger P4000 only with

an USB power supply with 5V DC / 1 A. If the instrument will not be used for a longer time,

we recommend a monthly charging for at least 8 hours. The included USB power supply is

designed for a mains voltage of 100 – 240 Volts AC. For safety reasons the proper condition

of the USB power supply should be checked regularly.

The charging takes, depending on its charge level, 1 to 4 hours. During the charging, the

LED of the charge control indicator, on the instrument's side, is flashing red. After the end

of charging, the flashing of the LED turns into a steady light. That means that the battery is

from now on charged with a trickle charge.

If charging has been forgotten, the instrument switches off automatically. If it is impossible

to switch on the instrument, because of low voltage, plug in the charger and switch on the

instrument again!!

Avoid a deep discharge, because that can shorten the lifetime of the battery.

Page 32

Instruction manual Dräger P4000

31

19. Technical data

19.1 General technical data

Display: Colour display with touchscreen

Interfaces: USB, IR

Power supply : Li-ion Battery, 4.8 V, 1500 mAh, charge level indicator

power supply primary 100 - 240 VAC; secondary 5 VDC; 1 A

PC connection/

Charging cable: USB cable max. 1.8 m

Dimensions: 75 x 170 x 27 mm (W x H x D)

Weight: ca. 217 g

Operating temperature: + 5 °C ... + 40 °C

Storage temperature: - 20 °C ... + 50 °C

Humidity: 10 - 90 % RH, non-condensing

Atmospheric pressure: 800 to 1100 hPa

19.2 Technical Data Pressure Measurements

Display Measuring range Resolution Accuracy Max. over pressure

Medium pressure I - 10 … + 100 mbar 0.01 mbar < ± 0.5 mbar or

< ± 1 % f. MV*

750 mbar

Medium pressure II - 10 … + 160 mbar 0.1 mbar < ± 5 % f. MV* 750 mbar

Pressure

(ext. sensor, option)

- 100 … + 3,500 mbar 1 mbar < 1 % f. MR** 4,000 mbar

High pressure

(ext.Sensor, Option)

0.1 … + 25.00 bar 0.01 bar < 1 % f. MR** 35 bar

*MV = Measurement value

**MR = Measuring range

Page 33

Instruction manual Dräger P4000

32

20. Care and maintenance

The instrument shall be given to an authorized service partner annually, where it can be

maintained and recalibrated if necessary, and to keep up the precision of measurements

and a safe function.

The instrument can be cleaned with a damp cloth. Make sure that the instrument's connectors are not clogged or soiled.

21. Consumables and accessories

5600876 Pump adapter 150 mbar with quick connector and Schrader valve

to connect a pump

required is also the ½“ adapter or the single pipe cover

5600875 Pressure sensor EP35 3.5 bar with quick connector and Schrader valve

with a possibility to connect a pump

required is also the ½“ adapter or the single pipe cover

5600877 Pressure sensor EP250 25 bar with quick connector

required is also the ½“ adapter or the single pipe cover

to pressurize up to 10 bar with air additionally the pump adapter 10 bar is

required

5600882 Pump adapter 10 bar with quick connector and Schrader valve

required is also the ½“ adapter or the single pipe cover

5600813 ½“ adapter with quick connector

5600842 Single pipe cover (≤ 3.5 bar) with quick connector

5610709 Gas pressure hose P4000

5600401 Printer IR3 with infrared data transmission

5690151 Printing paper for printer

5600880 Hand pump

5600881 Equipment case P4000

22. PC measurement data management

At our web site www.draeger-msi.de you can find, under the tab Download, the PC driver

for your instrument.

Please register your instrument together with its serial number - to get the download link for

the measurement data management software, click on Service → product registration.

Loading...

Loading...