Page 1

!

Oxylog

Emergency Ventilator

Instructions for Use

Deutscher Text: Bitte umdrehen

Page 2

For Your Safety and that

of

Your

Patients

For correct and effective use of the apparatus

and to avoid hazards it is essential to read the

following recommendations and to act accordingly’):

Strictly follow the instructions for use

~ Any use of the apparatus requires full

understanding and strict

observatton

of

these instructions. The apparatus is on/y to

be used for purposes specified here.

MaintenancE

The apparatus must be inspected” and

serviced” by experts at regular 2 years

intervals (and a record kept).

We recommend obtaining a service contract

with

DMgerService.

Repairs21

and general overhaul on the

apparatus may on/y be carried out by

experts.

General overhaul by

DragerService

of pressure reducers should occur every 6 years.

On/y original

Drtiger

spare parts may be used

for maintenance.

e

owner or operator to the extent that the

apparatus has been

serviced

or repaired by

personnel not employed or

authonzed

by

DrtigerService

or when the apparatus was

used /n a manner not conforming to its

untended

use.

Dragerwerk

Akt/engese//schaft

cannot be

he/d responsible for damage caused by

non-compliance with the recommendations

given above. The warranty and

//ab/hty

provisions of the terms of sale and delivery of

Dragerwerk

Aktiengesellschaft

are likewise

not

mod/fled

by the recommendations

gfven

above.

Dragerwerk

Akt/engese//schaft

standards, these are based on

the

legal system of

the federal

Republic

of Germany

2,

In accordance

wth

DIN

31051’

Inspection

= exammarIon

of actual

cond/t/on

Serwce

= measures to

mafntaln

desired

I

cond,t,on

Liability for proper function or damage

RepaIr

= measures to restore

desired

condmon

The liability for the proper function of the

Maintenance

tnspectfon, serwce

and.

of

apparatus is irrevocably transferred to the

applfcable, repa,r

Contents

Page

lntented Use

..............................................

3

What’s What?

............................................

3

Mounting and Usage of Holder

.................

6

Initial Preparation ......................................

6

Determination of Compressed-Gas

1

Supply and Usage Period .........................

11

Functional Check

......................................

11

Operational Use

........................................

11

Shut-Down Actions

...................................

13

Page

Oxylog with demand valve to

facilitate spontaneous breathing

...............

14

Care

..........................................................

19

Inspection

..................................................

20

Storage ......................................................

20

Trouble Shooting .......................................

21

Technical Data

..........................................

22

Order List

..................................................

24

Parts List

...................................................

27

2

Page 3

Intended Use

The Oxylog is a ventilator for providing

controlled ventilation of infants as of 5

kg body weight and adults on a

time-

cycled, volume-constant basis. The

device is designed for mobile use by

rescue services, for transportation to

hospitals in ambulances or helicopters,

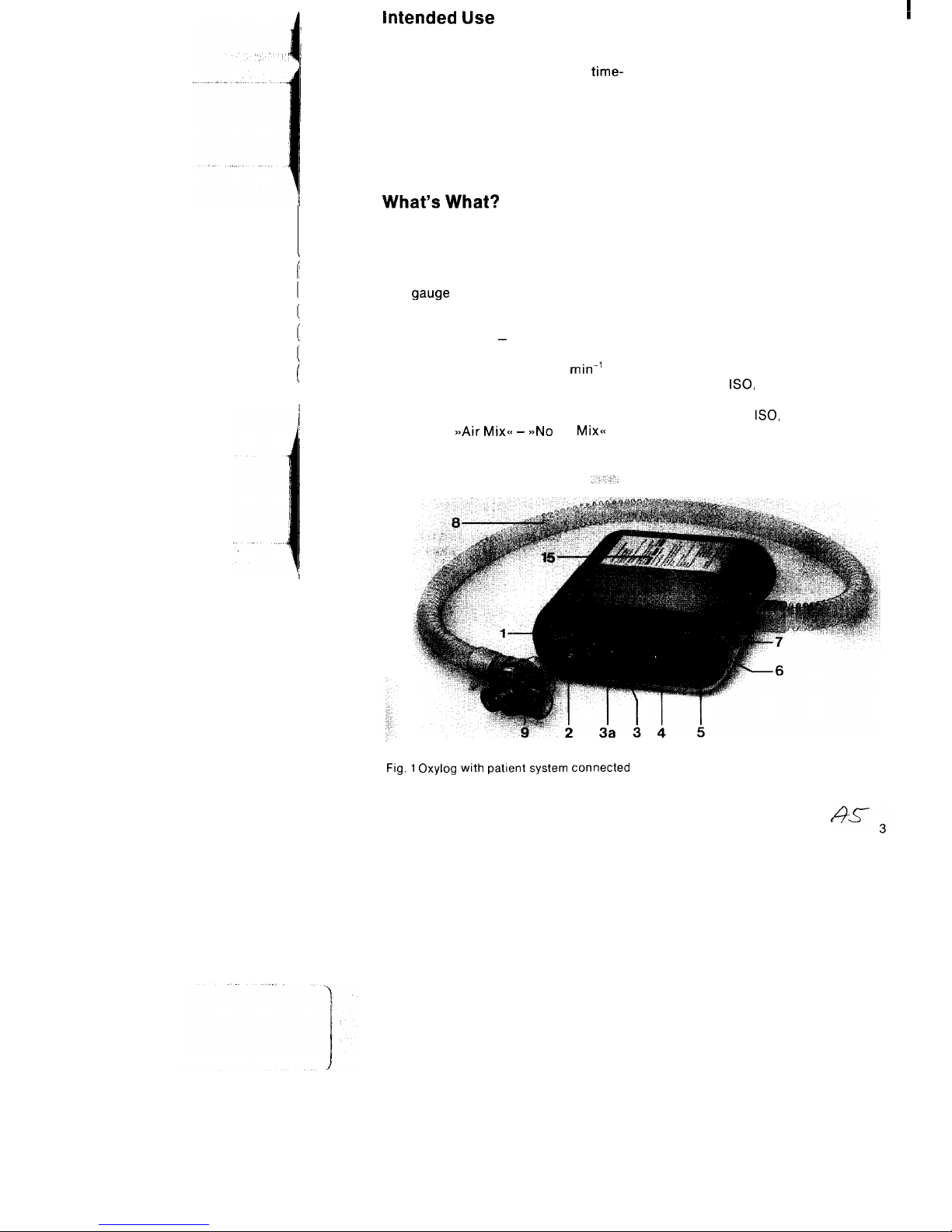

What’s What?

(Figs. 1-3)

Oxylog (Figs. 1 and 2)

1 Airway pressure gauge (scale

range -10 mbar to + 80 mbar)

2

Zero adjustment of airway pressure

gauge

3

Rotary knob for setting ventilation

ratio

3a Heart symbol - adjustment aid for

ventilation during cardiopulmonary resuscitation: ratio 12

min’

4 Rotary knob for setting minute

volume (MV)

5

Pneumatic main switch I-O

6

Switch

asAir Mix<< - >>No

Air

Mix<<

for transferring patients by road or air,

for ventilation in the emergency admissions department and for transferring

patients receiving ventilation from one

department to another, e. g. from the

operating theatre to the intensive-care

ward.

7 Stud for attaching carrying strap

(also serves to secure device in

holder)

Patient system (Items 8-10)

8 Ventilation tubing

9 Non-rebreathing valve (with exter-

nal taper

ISO,

dia. 22) for breathing

mask or catheter connector (with

internal taper

ISO,

dia. 15) for tube

15

Operating instructions in brief

Fig. 1 Oxylog with patient system connected

Page 4

I

n

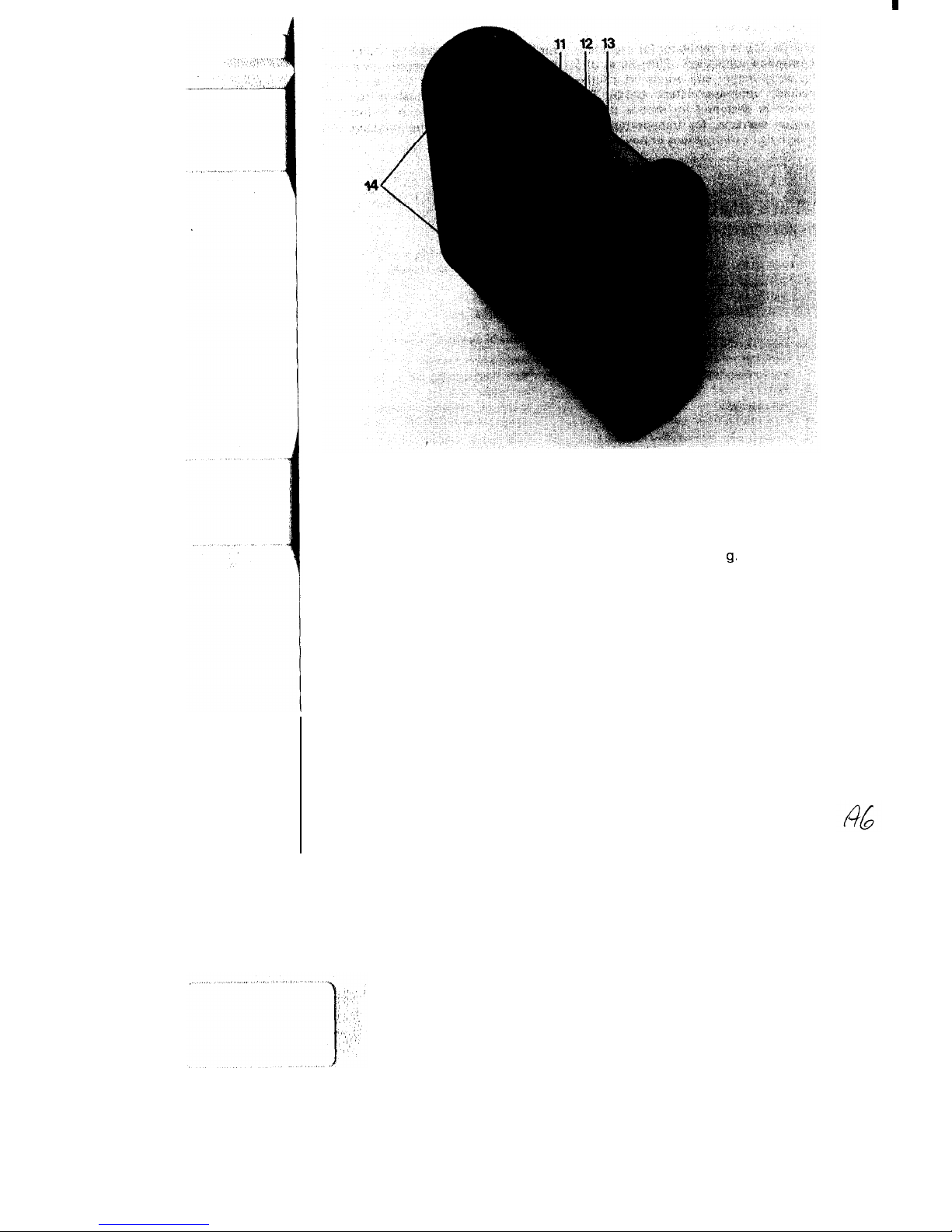

Fig. 2 Oxylog -gas inlets and outlets

11

Socket for ventilation tubing

13

Compressed-gas connection (male

12 Filter for purifying ambient air

thread M 15 x 1)

drawn in

14 Slot for alternative fastening of

carrying strap, e. g. when using

holder

4

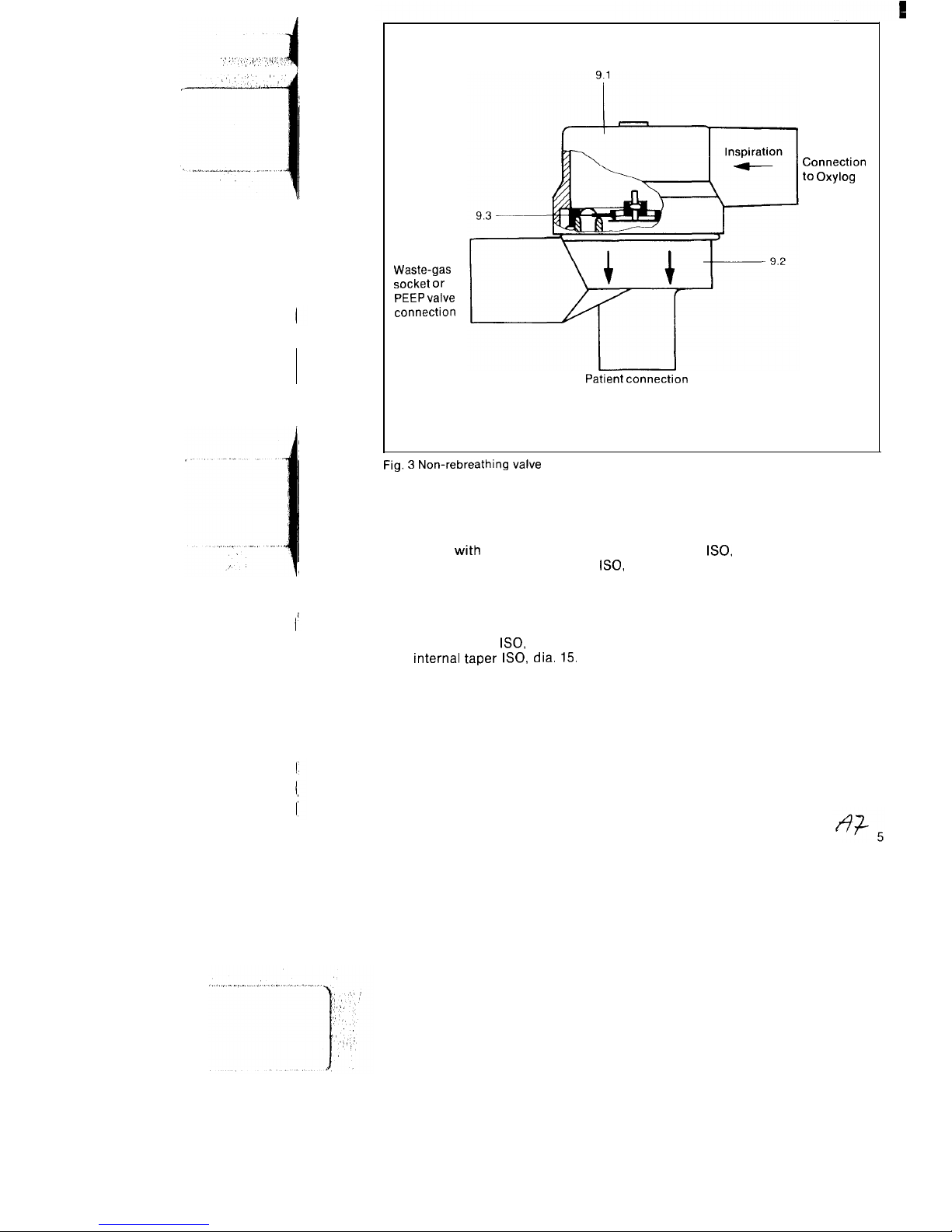

Page 5

Waste-gas

socket or

PEEP valve

connection

Patient connection

Connection

to Oxylog

Fig. 3 Non-rebreathing valve

Non-rebreathing valve

(Fig. 3, Items 9.1-9.3)

9.1 Cover

with

connection for ventila-

tion tubing (external taper

ISO,

dia. 22)

9.2

Valve housing with patient connection and waste-gas socket.

The patient connection features an

external taper

ISO,

dia. 22 and an

internal taper

ISO,

dia. 15.

The

waste-gas socket has an internal

taper

ISO,

dia. 22 for connection of

a PEEP valve.

9.3 Diaphragm (complete) comprising

control diaphragm and checkvalve.

The control diaphragm and check

valve are marked yellow and red to

enable their presence and correct

installation position in the valve

housing to be checked.

Page 6

e

’ .;,,,:,,

‘;

/’

_ .-.-.-.-:i:&.. .A.!.i

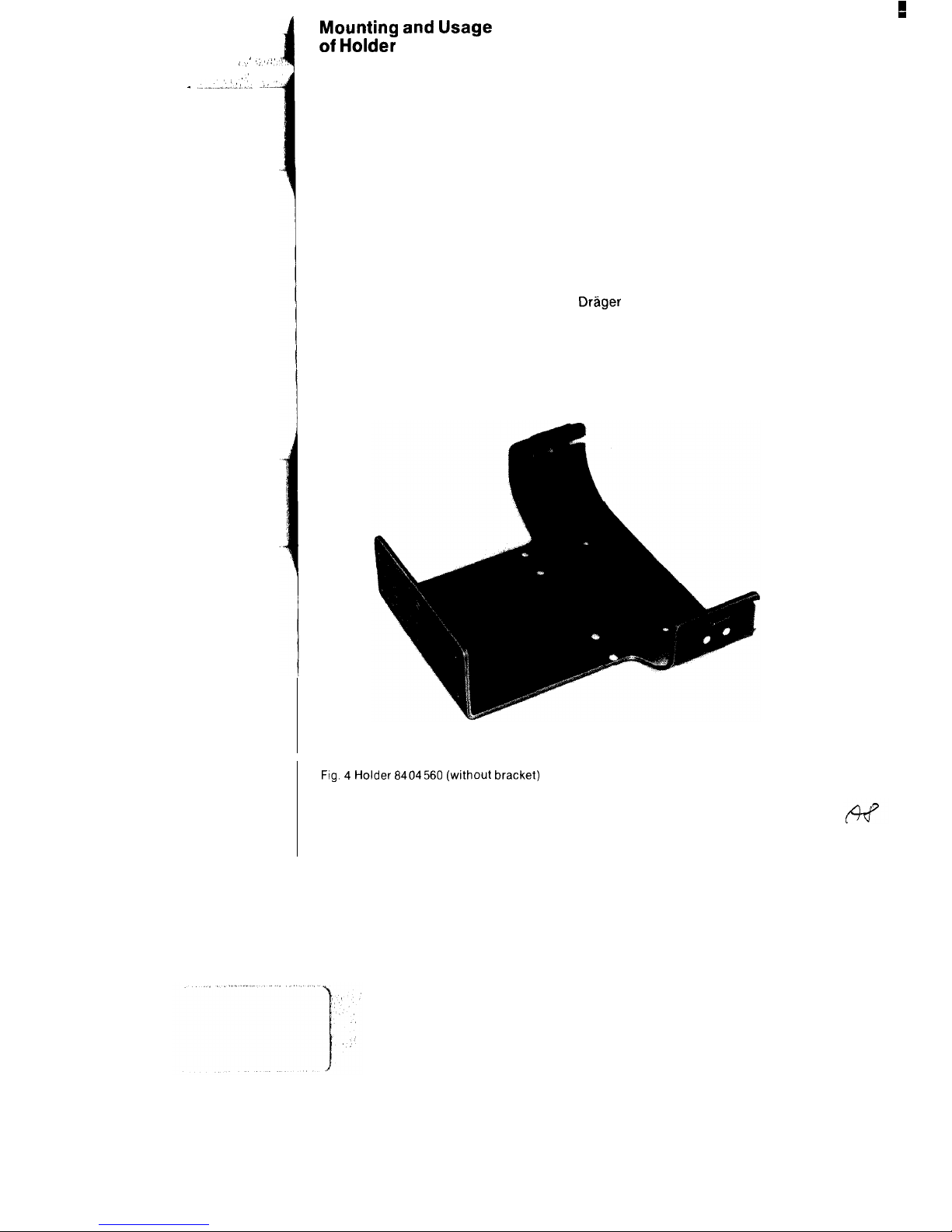

Mounting and Usage

of Holder

The Oxylog is secured in position in the

rescue vehicle by way of the holder

8404560 (Fig. 4).

The screws for attaching the basic

element are provided.

Mounting of holder

The basic element 16 is provided with

sufficient holes for the fastening screws.

At least 3 screws (with maximum

possible spacing between them) are to

be used in each case. The installation

location is arbitrary.

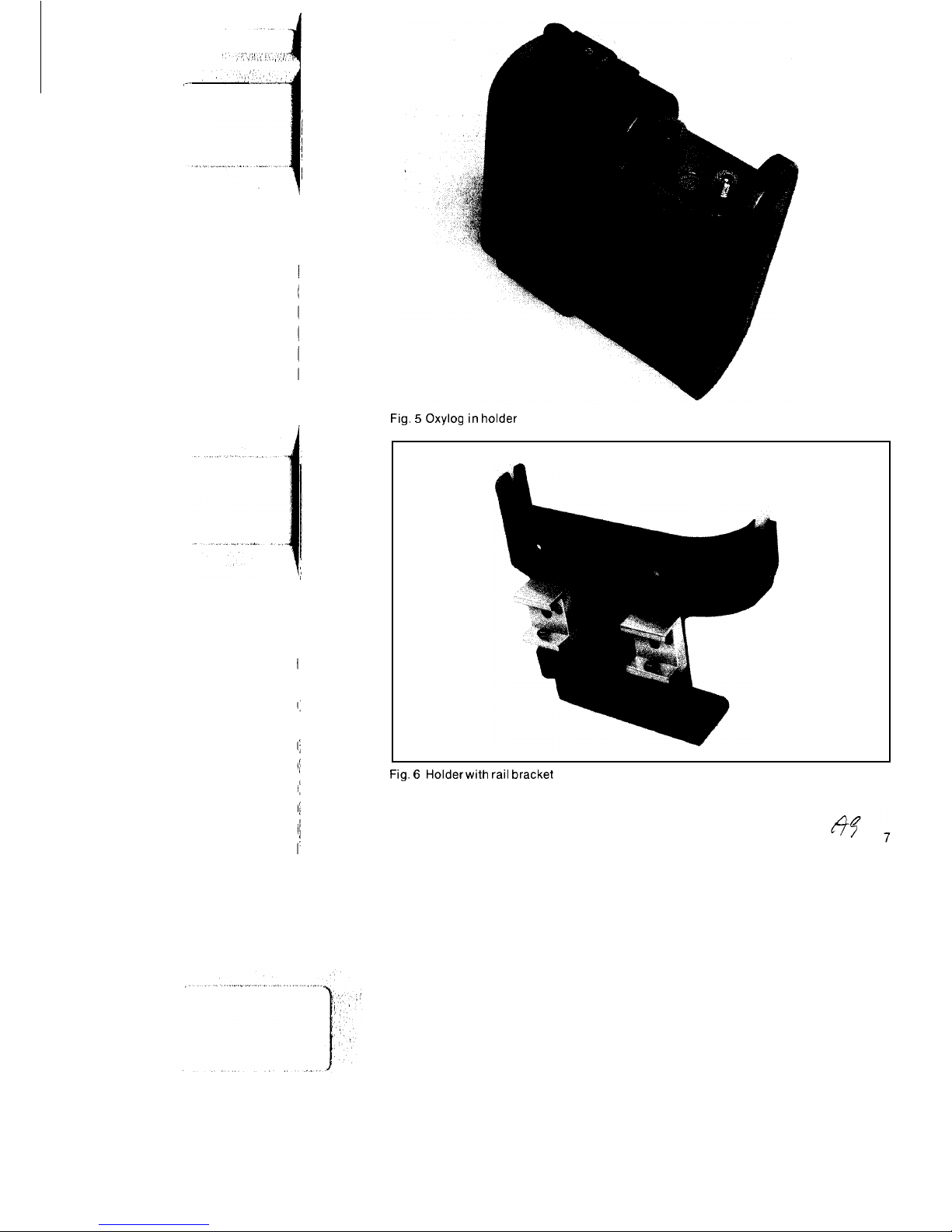

Insertion of Oxylog into holder

Push device into holder such that stems

of two studs 7 on housing slide into slots

Fig. 4 Holder 6404560 (without bracket)

6

16a of holder. Studs must engage in

hole in brackets 17.

Press on brackets 17 to ensure that the

device is firmly secured in position in

the holder.

The guide stud 19 secures the device on

the back. Fig. 5 illustrates the Oxylog in

position in the holder.

Removing Oxylog

Pressing open the two brackets 17

releases the studs 7 and enables the

device to be removed from the holder.

Holder with rail bracket (Fig. 6)

The holder is used for attachment to the

Drager

wall rail system (10 x 25 mm

section).

Handling is the same as for the holder

8404560.

Page 7

Fig. 5 Oxylog in holder

Fig. 6

Holder with

rail

bracket

Page 8

,,

--- _...___.. _.,.L._

:

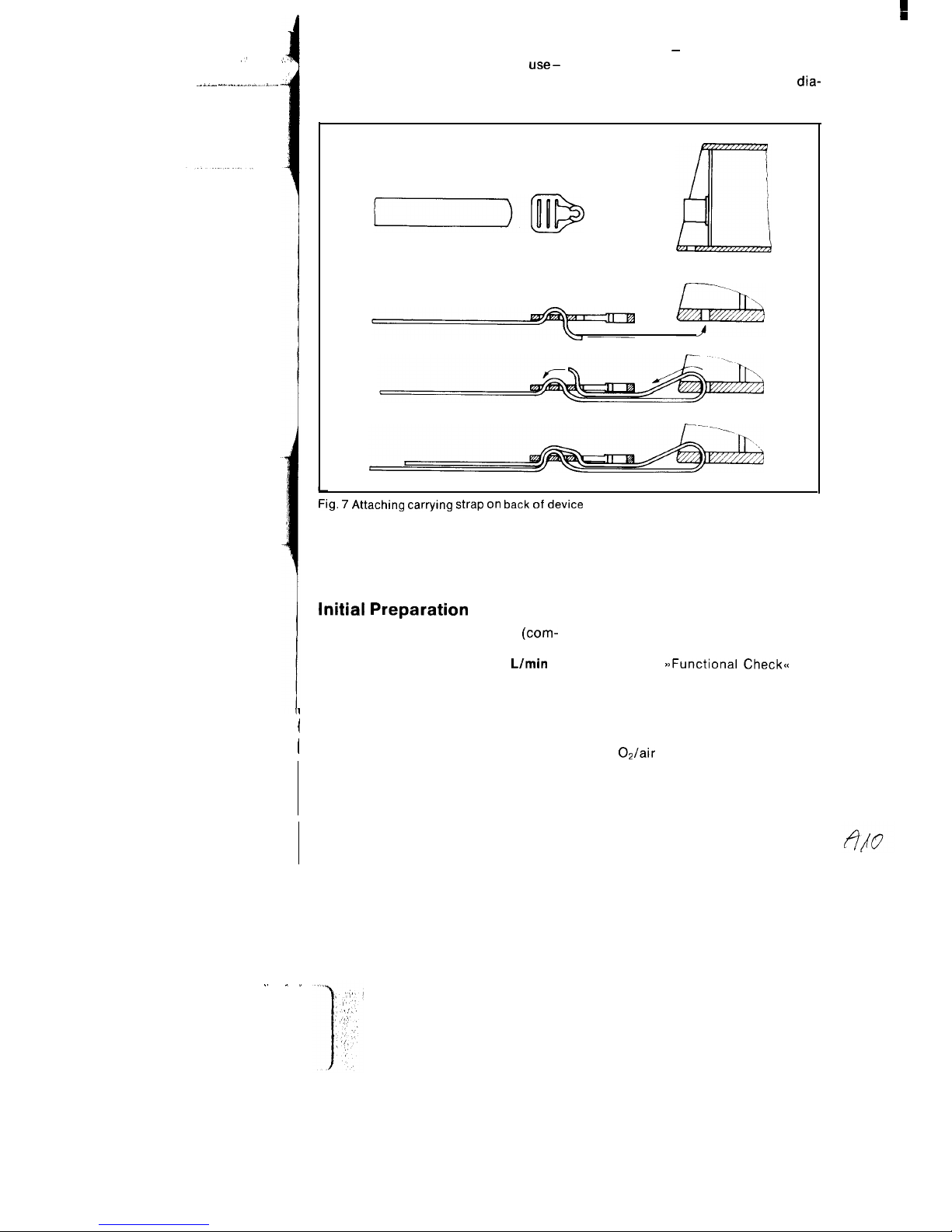

Attachment of carrying strap on back

event of constant mobile use outside the

of device

rescue vehicle - the carrying strap can

If the carrying strap is constantly in

use-

be secured in position in the slots in the

e. g. including cases where Oxylog is

Oxylog housing. See attachment

dia-

accommodated in holder and in the

gram in Fig. 7.

Fig. 7 Attaching carrying strap on back of device

Initial Preparation

An inlet pressure at the device

(com-

The functioning of the Oxylog can be

pressed-gas connection 13 in Fig. 2) of

checked with the compressed-gas

at least 2 bar at a flow rate of 60

L/min is

source (see

B>Functional Check<<

on

required for operation of the Oxylog.

page 11).

The drive sources used (central gas

’

1

supply or gas cylinder with pressure

reducer) must always comply with the

(

aboveprerequisite.

Operation from a central gas supply

Screw

OJair

connecting hose (3 m or 5

Any upstream closing or metering

m, see Order List) to device and insert

elements must be fully open!

connector into wall outlet valve.

8

,. .

”

Page 9

Operation from a gas cylinder

Screw pressure reducer to cylinder.

Check 2-6 bar delivery-pressure setting. Screw connecting hose (1.5 m or 3

m, see Order List) to device and to

pressure reducer. Fully open cylinder

valves.

Use with

DrSger OxatoP

The connection piece 2M 19051 is

exclusively designed for use of the

Oxylog on the Oxator head (Fig. 8). This

connection piece is screwed to the

Oxator head and consists of a

self-

closing, standard

O2

coupling for

connection of the Oxylog using the

standard, gas-specific connector

(02/

air). A self-closing inlet screw connection for O2 makes it possible (in addition

to the use of cylinders) to supply the

Oxylog and the other components

connected to the Oxator head (e. g.

humidifier/nebulizer or aspiration ejector) from a central gas supply unit (see

Oxator Operating Manual).

The Oxylog may not be fed via the flow

control valves at the Oxator head!

Fig. 8 Oxator head with connection piece

for Oxylog

Use of gas blenders

.

In the case of lengthy ventilation, e. g.

during repatriation flights, low, defined

O2

concentrations may be required.

For this purpose a compressed-gas

blender can be connected upstream of

the Oxylog (see Order List).

Caution!

The inlet pressure at the Oxylog must

however be at least 2 bar at a flow rate of

approx. 60

L/min

(see

BjFunctional

Check<<

on page 11).

The switch is to be set to

a>No

Air

Mix<<.

Equipping

(Fig. 9)

0

Assemble non-rebreathing valve as

per Fig. 10. Ensure that entire

diaphragm is correctly positioned

and take particular care to ensure

that red check valve is present and

not out of shape. Screw cover to

valve housing (turn 45” in clockwise

direction).

0

Attach ventilation tubing to socket at

Oxylog as well as to

~~lnspiration~~

socket on non-rebreathing valve.

0

If use is made of an (optional)

externally adjustable pressure limiting valve (see Order List), attach this

valve first to the socket at the Oxylog

and then connect the ventilation

tubing to the socket of the pressure

limiting valve.

0

If PEEP is being applied, insert PEEP

valve (see Order List) into waste-gas

socket of non-rebreathing valve.

0

Set airway pressure gauge to zero.

0

Preselect O2 concentration

a>Air Mix<<

setting reduces drive-gas

consumption by roughly 50% as

ambient air is sucked in.

Page 10

e

a_/,,.. . . .

..,y”

,I

r ,_,. .,

.---,. . .

..-,‘.:““‘, “.‘*tT..’

,:

,‘,’ :

Wh3

Silicone tubing E 1.1 m

Silicone tubing E 1 .l m

l

Non-rebreathing valve

Ambu PEEP valve

* Only for operation with extended ventilation hose

1

Fig. 9 Oxylog with patient system

2-

Fig. 10 Individual components of non-rebreathing valve

1 Cover

2 Diaphragm

3 Valve housing

10

Page 11

e

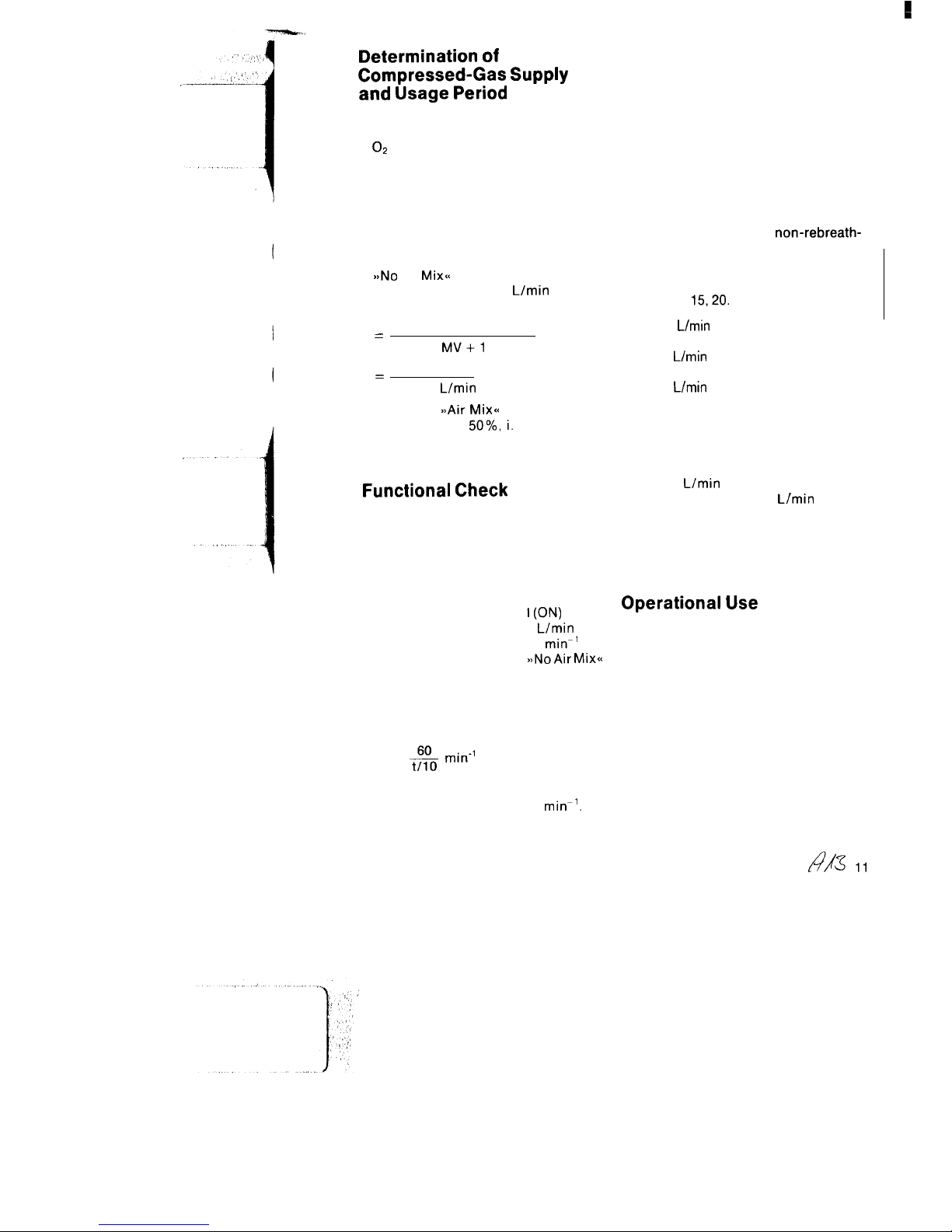

Determination of

Compressed-Gas Supply

and Usage Period

Example:

Compressed-gas supply

O2

cylinder: 3 L

Cylinder pressure (at cylinder pressure gauge):

200 bar

Available compressed-gas supply,

200 x 3 = approx. 600 L

Usage period

Switch setting at Oxylog:

>)No

Air

Mix=

Minute volume MV: 10

L/min

Usage period

=

Compressed-gas supply

MV+l

600 L

zz

= approx. 54 min

(10 + 1)

L/min

Switching to

)jAir Mixes

reduces the gas

consumption by

50%, i.

e. the usage

period is increased to roughly 100 min.

Testing safety valve

With the same device settings and with

the patient connection sealed at the

non-rebreathing valve the max. airway

pressure should be between 50 and 80

mbar.

Testing compressed-gas supply and

minute volume

Insert catheter adapter, size 5 (M 25569)

into patient connection of

non-rebreath-

ing valve.

Read off the max. inspiration pressure

at the airway pressure gauge for the MV

settings: 7,

15,20.

MV 7

L/min

Airway pressure 4 to 8 mbar

MV 15

L/min

Airway pressure 15 to 24 mbar

MV 20

L/min

Airway pressure 28 to 38 mbar

The Oxylog should switch at regular

intervals from inspiration to expiration.

The operating prerequisites (at least 2

Functional Check

bar at 60

L/min

at Oxylog) are checked

indirectly in the MV = 20

L/min

setting.

Following device upkeep and assembly,

the Oxylog is to subjected to the

Remove catheter adapter from patient

following functional checks:

connection; the device is now ready for

operation.

Testing ventilation ratio

Device settings

Pneum. main switch

1 (ON)

MV

3

L/min

Ventilation ratio

15

mini’

Switch

,,NoAir Mix<<

Seal non-rebreathing valve at patient

connection and using stopwatch take

the time t for 10 complete cycles and

determine ventilation frequency f

f =

& min-’

The ventilation ratio of the Cxylog

should be between 13 and 17

min’.

Operational Use

The airway pressure gauge must be

observed all the time so that incorrect

ventilation can be detected in due time,

thus precluding risks for the patient!

Set ventilation ratio and minute volume

(MV) to suit patient concerned.

For rapid presetting:

The ventilation ratio and minute volume

(MV) scales each have three colour

bands for the specific patient groups

infants, children and adults.

Page 12

_ . _ .:

If both rotary knobs are set to a band of

the same colour, the following ventilation values are obtained:

Green band

for infants

(5-20 kg

body weight)

Blue band

for children

(20-40 kg

body weight)

Brown band

for adults

(as of 40 kg

body weight)

Ventilation MV

ratio

min-’

Llmin

28-35

l-3.5

18-28 3.5-7

lo-18

7-20

The switch is to be set to

a>No

Air

Mix<<

or

to

a,Air Mix<<

depending on the patient’s

requirements:

High O2 concentration required:

b>No

Air

Mixa

(and O2 drive)

In the case of a toxic atmosphere (and

respiratory standstill):

DNO

Air

Mix<<

a>No

Air

Mix<<

setting:

The drive gas, e. g.

Op,

is routed

unblended to the patient. The

ventilation ratio and MV settings

remain unchanged irrespective of

the switch setting.

Low O2 concentrations required:

BBAir Mix<<

(with 02 drive)

or compressed-air drive

Small gas supply:

a>Air Mix<<

a>Air Mix=

setting:

The drive gas

(0,

or air) is blended

with ambient air. With O2 drive and

an MV setting in excess of 7 Llmin

the percent by volume added is

approximately

50%,

i. e. the

O2

concentration is roughly 50 vol. %.

With an MV setting less than 7

Urnin

the O2 concentration in-

creases up to 80 vol.

%.

Connect non-rebreathing valve to mask

or tube.

Make sure that airways are completely

free.

Check airway pressure gauge.

In normal circumstances the inspiratory

airway pressure values should be

approximately 20 mbar.

Atypical airway pressures

In the event of an excessively high

airway pressure reading, the MV

setting should first be checked as well

als the functioning of the

non-rebreath-

ing valve.

Ensure that airways are completely

free!

High airway pressure (50-70 mbar) in

conjunction with a buzzing noise (safety

valve in device blowing out) are an

indication of incorrectly positioned

airways or a kinked tube.

If the airway pressure reading is too

low, the MV setting must likewise be

checked.

The hose connections are also to be

tested for tightness and freedom from

leaks and the non-rebreathing valve is

to be checked for proper functioning.

Ventilation ratio for cardiopulmonary

resuscitation

Within the scope of cardiopulmonary

resuscitation of adults employing a ratio

of

1:5,

it must be ensured that a

ventilatory impulse is given after every

5th cardiac compression.

Given a cardiac massage frequency of

60

min-’

this means that ventilation

must be effected with a ratio of

min-‘.

y=

12

To facilitate setting, the ventilation ratio

12

min-’

on the Oxylog is provided with

a heart symbol.

I

12

Page 13

e

Use in toxic atmosphere

The Oxylog can also be used for

controlled ventilation of injured persons in a toxic ambient atmosphere. The

switch setting

>>No

Air

Mix<<

is to be

employed for this purpose.

If the patient breathes spontaneously or

if spontaneous breathing has been

restored after resuscitation the partially

spontaneous intake of toxic ambient air

is not prevented by the Oxylog.

It is for this reason that the special

Oxylog with spontaneous breathing

device (cf. Order List) must be used.

This device facilitates spontaneous

breathing with an airway pressure 0 to

be carried out in addition to controlled

ventilation (pay attention to respective

Operating Manual).

Note

In the case of spontaneous breathing

the mask must always fit snugly, so as to

prevent the intake of toxic ambient air.

Ventilation with PEEP

(Special accessory)

Pay attention to respective Operating

Manual.

Set PEEP valve to 0 and push it onto the

waste-gas socket of the

non-rebreath-

ing valve:

Determine inspiratory airway pressure

at airway pressure gauge.

Set PEEP value:

The endinspiratory pressure increases

approximately by the set PEEP value.

Should the airway pressure rise higher

or not change its value at all, the PEEP

valve is defective and must be replaced.

Upon termination of the PEEP mode the

PEEP valve must be removed from the

valve of the airway pressure gauge.

Use of pressure limiting valve

(special accessory)

Set rotary knob at optional pressure

limiting valve (located on inspiration

socket at Oxylog) and check inspiration

pressure limited in this manner on

airway pressure gauge.

Caution!

In the case of pressure-limited ventila-

tion the set MV does not have the full

effect. It is advisable to set the pressure

limitation roughly 10 mbar in excess of

the inspiration pressure, so that the

pressure limitation only becomes effec-

tive in exceptional circumstances (e. g.

coughing).

Use of expiratory volume measurement (special accessory)

Insert hose nozzle into waste-gas

socket of non-rebreathing valve.

Connect Volumeter 3000 to silicone

tubing (1.1 m).

The Volumeter 3000 can be used to

measure both the tidal volume and the

MV (pay attention to the respective

Operating Manual).

Caution!

Expiratory volume measurement is not

possible when using the PEEP valve.

Shut-Down Actions

Set main switch to

~~0~~.

When using

compressed-gas cylinder, close cylinder valve.

Page 14

:

Option: Oxylog with demand valve to facilitate

spontaneous breathing

Pinpointed intended use

Description

Time-cycled, volume-constant ventilation

and spontaneous breathing in a toxic

at-

mosphere.

No

spontaneous breathing under

posi-

tive airway pressure (CPAP)!

-

An equipment combination of Oxylog

and demand valve switched in parallel

for supply of spontaneous breathing

-

Without Air-Mix switch

-

Non-rebreathing valve with expiratory

check valve.

The following configuration is a prerequisite for use in a toxic atmosphere:

1

2 3'

2'

14

1

Oxylog with

5

Face mask,

M25572

demand valve

size 1 small

1

2

Silicone hose E (adults)1.lm84 04 063

6 Face mask,

M 25 573

3*

Socket IS0

M 25 647

size 2, medium

4

Non-rebreathing valve

7

Face mask,

M 25 574

with check valve

8408568

size 3, large

* Only for operation with extended ventilation hose

Page 15

3

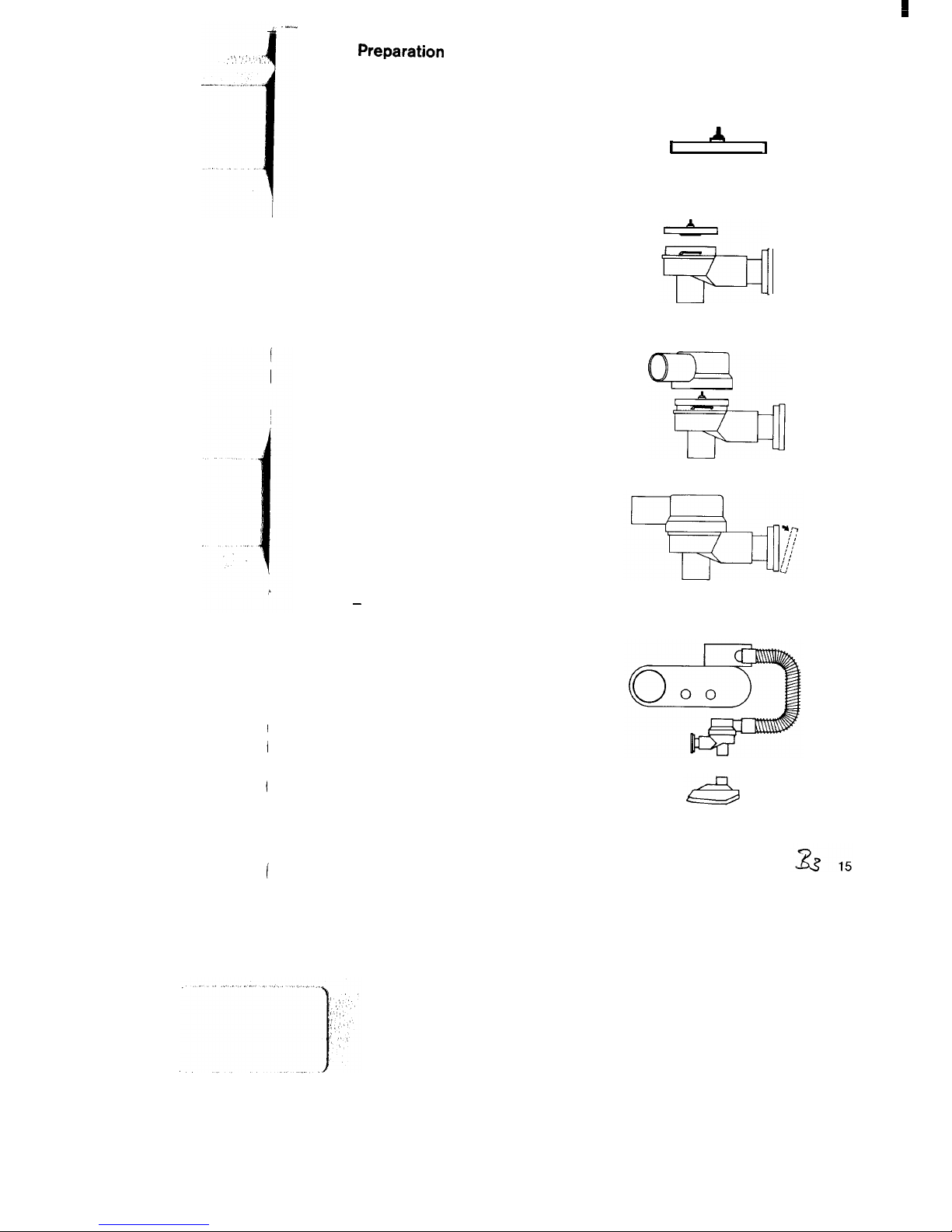

Preparation

Assembly of non-rebreathing valve:

Make sure that the red check valve is

fitted in the diaphragm and makes

even contact with the diaphragm.

Fit the diaphragm into the valve housing so that the disc of the check valve

points towards the housing.

The bulge of the diaphragm makes

even contact with the edge of the

housing.

Fit the cover by applying slight

pressure and turn clockwise by about

45”.

Make sure that the diaphragm sits

smoothly in the housing.

Pull the perforated cap at the outlet

over the edge and take it off to check

whether the rubber ring makes even

contact with the outlet.

Replace the cap by applying slight

pressure

-

until it rests in place.

Assembly of the Oxylog:

Connect Oxylog and non-rebreathing

valve with the ventilation hose.

Attach Oxylog to gas supply.

I

A

1

Page 16

Check the demand valve for

operational readiness

-

Prior to each use

Push a catheter adapter size 5 into the

patient port of the non-rebreathing

valve. Generate a suction with your

mouth:

0

Gas should begin to flow.

Stop sucking:

0

The gas flow is cut off.

Remove the catheter adapter.

Operation

Push the face mask onto the patient

port of the non-rebreathing valve and

make sure that the mask makes a

tight seal with the face.

Upon commencement of spontane-

ous breathing:

0

Set pneumatic main switch to 0.

Spontaneous breathing with posi-

tive airway pressure CPAP is not

possible!

Care

Stripping down

0

Detach ventilation hose from

Oxylog *

0

Detach non-rebreathing valve from

hose.

0

Detach mask from non-rebreathing

valve.

0

Turn cover of non-rebreathing

valve anti-clockwise by 45” and

remove.

0

Remove diaphragm from valve

housing.

Cleaning

Clean disassembled patient system

using water to which a detergent has

been added, and dry well.

Disinfection

The disinfected patient system can

be subjected to bath disinfection

e.g. using Tego 103 G (Messrs.

Th. Goldschmidt AG,

Essen)

and

observe the manufacturer’s instruc-

tions for use.

Sterilization

The valve housing of the

non-re-

breathing valve must not be sub-

jected to thermal disinfection.

The diaphragm, the cover and the

ventilation hose can be

autoclaved

at

134°C.

16

Page 17

^

.,. ,” -._.. .f

j

’ !I’

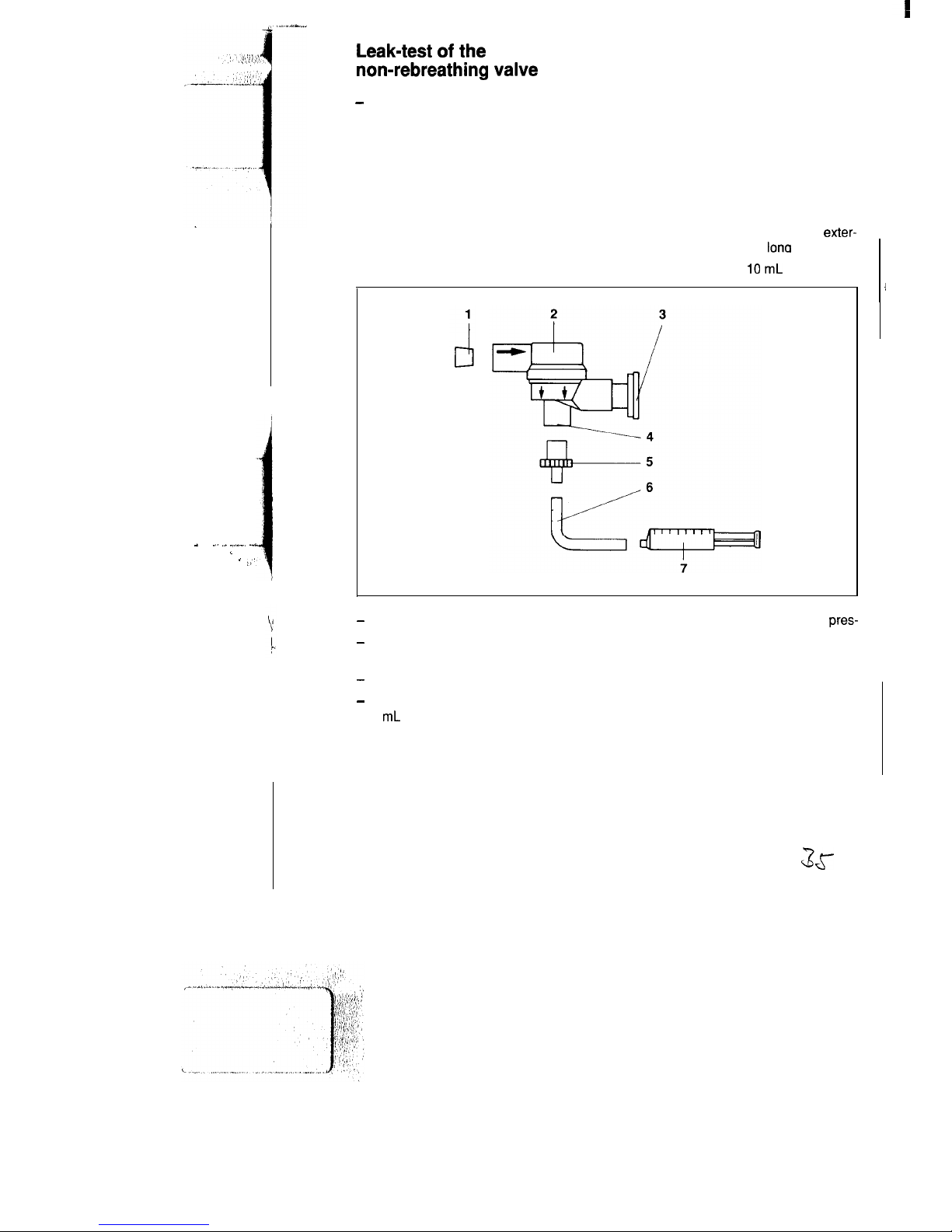

Leak-test of the

non-rebreathing valve

-

Following each assembly.

Establish test setup

1 Conical sealing plug, smallest dia.

15mm

2 Non-rebreathing valve with check

valve

4 Patient connection

5 Catheter connector, dia. 4.5 mm

6 Silicone hose, internal dia. 4 mm,

exter-

nal dia. 6 mm, 100 mm

lona

3 Cap of check valve

7 Disposable syringe, IO

mL

-

Detach cap from check valve.

-

Attach syringe together with catheter

connector.

-

Seal inspiratory port with sealing plug.

-

Using the syringe, extract a volume of

3 mL and keep plunger of syringe in this

position. By force of the negative

pres-

sure, the black diaphragm of the check

valve adapts to the shape of the valve

body.

Within 15 seconds, the diaphragm must

not

come back to its original

state.

3s

17

I

Page 18

e

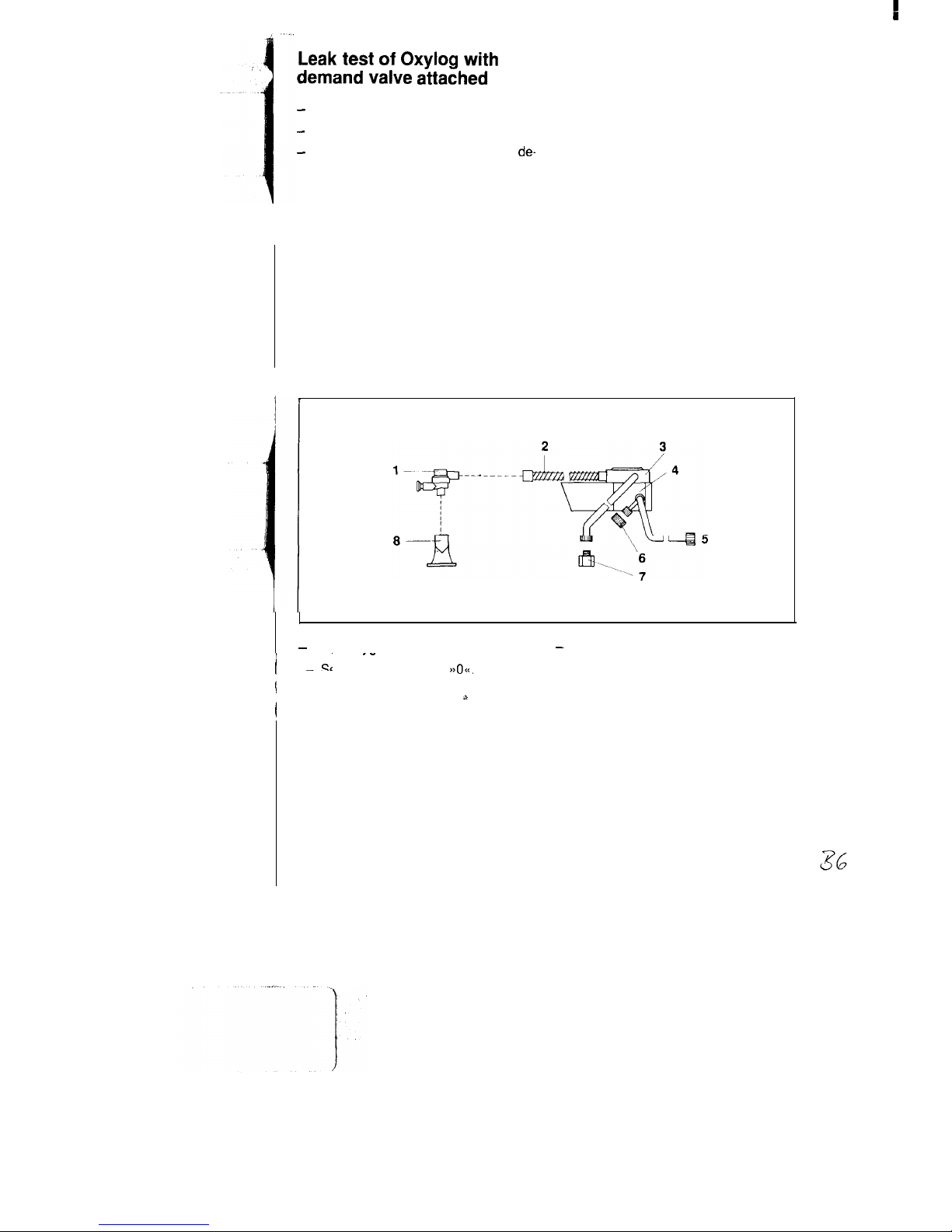

Leak test of Oxylog with

demand valve attached

-

Every 6 months.

-

Remove Oxylog from its mount.

-

Unscrew pressure-gas

line of the

de-

mand valve and seal th

e connections.

Establish test setup

Components 6, 7,

8 are

comprised in

test

set 84 10 072.

1 Non-rebreathing

valve

with

5

Pressure-gas

line,5bar

check valve

84 08

568

6

Cap nut

84 08 298

2 Ventilation hose

84 04

063

7

Screw plug

84 08 299

3 Demand valve

8

Mouthpiece

84 07 303

4 Oxylog

-

Open oxygen-cylinder valve.

-

Generate a negative pressure of about

i -.

.-

Set switch at Oxylog to

>>Oc(.

-10 mbar with your mouth.

I

Fit non-rebreathing valve to silicone

The unit is sufficiently leakproof if the

I

hose.

s

pressure change from -6 mbar to

-2 mbar takes at least 20 seconds.

18

Page 19

Care

Following termination of ventilation the

Oxylog is to be prepared for thorough

cleaning and disinfection:

Remove mask or tube from patient

connection of non-rebreathing valve.

Detach ventilation tubing from

non-

rebreathing valve and from Oxylog.

Disassemble non rebreathing valve into

its component parts (Fig. 10). Turn

cover 45” in anti-clockwise direction

with respect to valve housing (= valve

open).

Caution!

The red check valve must not be

removed from the yellow control valve!

The PEEP valve is to be disassembled

into its 3 main components.

The disassembled parts of the patient

system are to be thoroughly cleaned

either in running hot water or in a

mixture of

detergent’)/water

with sub-

sequent rinsing under running water.

Important: Do not use a hard brush for

cleaning purposes!

”

Recommended detergents are, for example,

lncldbn

Perfect

(Henkel

Co ) and

Caraform (Welgert

Co.)

The surface of the device can be

cleaned using a soft cloth impregnated

with a mixture of detergent/water.

Caution!

Do not use petrol, ether or similar

solvents for cleaning the device.

Carefully rinse Volumeter 3000 in

direction of flow

with

hot running water.

Caution!

Do not allow water to flow into drain

holes in control section.

Carefully remove residual water from

Volumeter.

All parts are to be thoroughly dried

following cleaning and rinsing.

The component parts can also be

washed in the

Drager Purfactor@,

which

automatically subjects the material to

be washed to disinfection and drying.

Disinfection in liquid disinfectant

The cleaned and dried parts of the

patient system can be disinfected in a

cold disinfectant solution.

The surface of the device can be

disinfected by wiping over it.

Caution!

Use may only be made of disinfectants

which do not attack the materials used.

Compliance with the prescribed concentrations is to be ensured. In case of

doubt consult the disinfectant manu-

facturer.

Following disinfection and drying of its

component parts, the Oxylog is to be

assembled as described under

aylnitial

Preparation<<

on Page 8 and subjected

to a functional check as described

under

a>Functional Check<<

on Page

il.

Disinfection in

Drlger Aseptor@

The cleaned and dried components of

the patient system as well as the device

itself can be disinfected in the Aseptor.

Caution!

The ventilation tubing and breathing

f

masks (silicone rubber) must not be

disinfected in the Aseptor.

Following disinfection in the Aseptor,

the device is to be assembled as

described under

a,lnitial Preparation<<

on Page 8 and subjected to a functional

check as described under

b,Functional

Check*

on Page 11.

3?-

19

Page 20

Sterilization

in steam

The valve housing of the Oxylog with demand valve to facilitate spontaneous breathing is not suitable for sterilization.

The cleaned and dried parts of the

patient system can be sterilized in

superheated steam.

The component parts of the PEEP valve

and Volumeter 3000 can be sterilized at

121 “C.

The component parts of the

non-

rebreathing valve and the ventilation

tubing can be sterilized at 134°C.

The Oxylog cannot be sterilized.

Plastic and rubber mouldings are to be

disassembled prior to sterilization.

Following sterilization in an autoclave,

the device is to be disassembled as

described under

aalnitial Preparation<<

on Page 8 and subjected to a functional

check as described under

a>Functional

Check<<

on Page 11.

20

Inspection

The device is to be inspected at regular

2 years intervals by trained personnel.

Storage

The Oxylog and its accessories are to be

kept dust-free and dry.

Permitted storage conditions:

-20°C to

+70°c

O-100%

relative humidity

600-l 200 mbar

Page 21

e

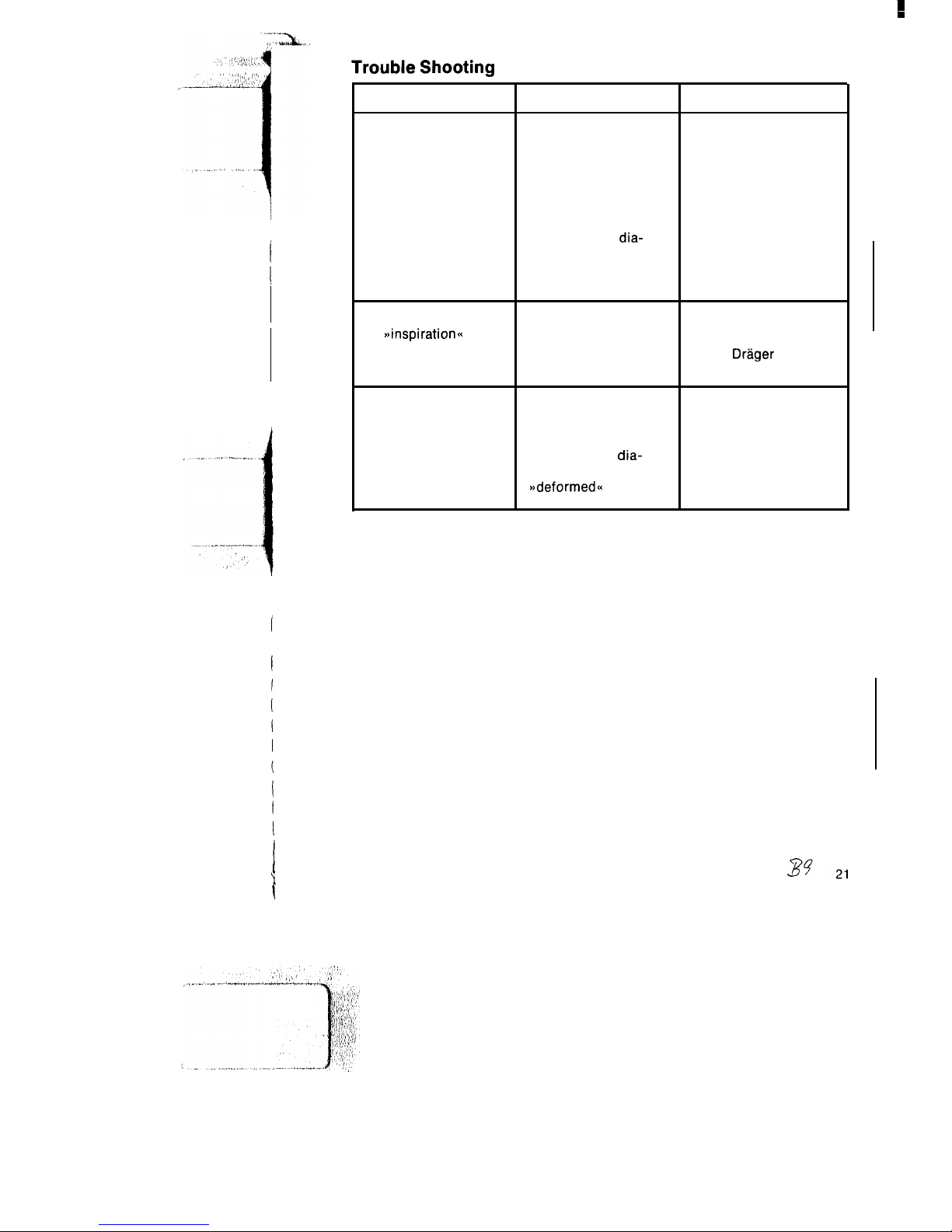

Trouble Shooting

Fault

Device does not build

up pressure

Cause

Remedy

No gas in cylinder

Immediately connect

device to another full

gas cylinder

Gas pressure at device

Establish adequate

inlet too low

supply pressure:

2-6 bar

Yellow control

dia-

Open non-rebreathing

phragm in non-rebreath- valve and assemble

ing valve deformed or

correctly

out of shape

Device comes to a halt

on

~~inspirati0r-r~~

Inadequate supply

pressure

Oxylog defective

Establish adequate

supply pressure: 2-6 bar

Notify

Drlger

Inspection Service

Patient cannot exhale or Ventilation tubing

Eliminate any kinks in

only with difficulty

kinked

tubing

Red check valve in

Open non-rebreathing

yellow control

dia-

valve and assemble

phragm missing or

correctly

~~deformed~~

Page 22

c

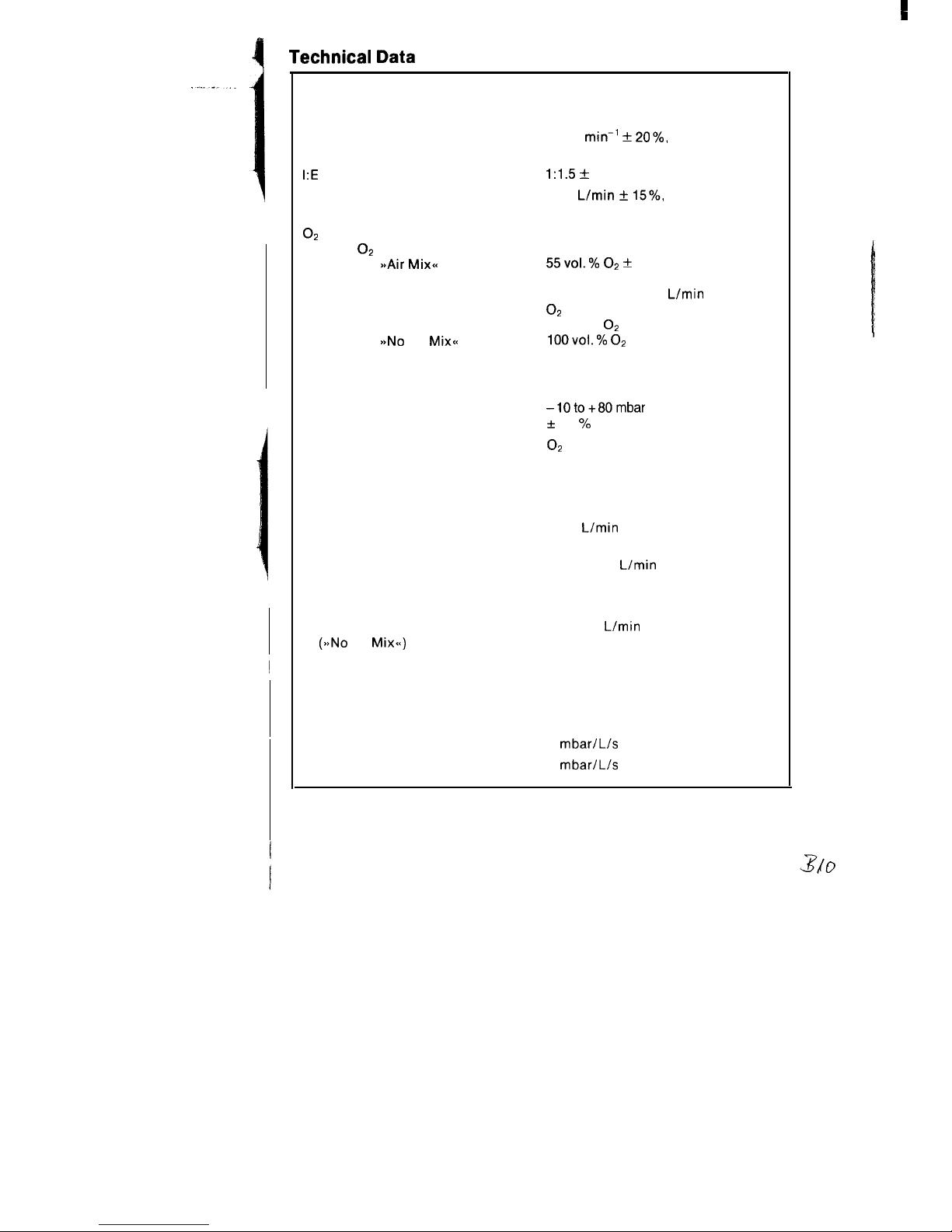

Technical Data

Principle of operation

Control

Ventilation ratio

I:E

ratio

Minute volume

Flow chopper

Time-cycled, volume-constant

10-35

min-’ + 20%,

infinitely adjustable

1:1.5 +

10%

2-20

L/min + 15%,

infinitely adjustable

O2

concentration of breathing

gas with O2 drive

Switch on

SsAir Mixa

Switch on

>bNo

Air

Mix<<

Safety valve

Opening pressure

Airway pressure reading

55vol.% 02 +

10%

(with MV greater than 7 L/min)

with MV less than 7

L/min

O2

concentration increases up to

80 vol. %

O2

100v0l.% 02

50 mbar to 80 mbar

Pressure gauge

-1Oto+80mbar

+

2.5 % full scale

Drive gas

Quality

Pressure at device inlet

O2

or air

Dry, oil-free and dust-free from a

central supply unit or from compressed-gas cylinders’.

min. 2, max. 6 bar with a flow rate

of 60

L/min

Gas consumption

Control

approx. 0.8

L/min

MV (Air Mix)

approx. 50 % of set MV

MV (No Air Mix)

approx. 100 % of set MV

Typical usage period

with 3 L cylinder/200 bar

MV = 10

L/min

(see also Page 11)

(>aNo

Air

Mix<<)

54 min

Pneumatic main switch

I-O

Patient system

Comprising silicone tubing 1.1 m

a

Non-rebreathing valve

Compressible volume

approx. 3.3 mL/mbar

Inspiration resistance

3

mbar/L/s

Expiration resistance

3

mbar/L/s

22

Page 23

Dead space

approx. 12

mL

Dimensions (W x H x D)

200 x 80 x 200

mm

Weight

approx. 2 kg

Ambient conditions during operation*:

Temperature

-5°C to

+5O”C

Humidity

O--100%

relative humidity

Ambient pressure

600-1200 mbar

Vibration

Tested in accordance with MIL STD

810 C

514.2-111

curve M (helicopter)

In toxic atmosphere

Switch to

a,No

Air Mix- setting with

controlled ventilation in the event of

respiratory standstill.

Storage conditions:

Temperature

Humidity

Ambient pressure

Caution! In the event of spontaneous

breathing possible intake of toxic

ambient atmosphere.

-23°C to

+70°c

O--100%

relative humidity

600-l 200 m bar

Materials used

Oxylog housing

Impact-resistant ABS

(Acrylonitrile-Butadiene-Styrene)

Ventilation tubing

Silicone rubber

Non-rebreathing valve

Housing

PSU (Polysulfone)

Control diaphragm

Silicone rubber

.

Non-complmce wtt,

these

reqummenls w\ll

lead to reduced

effwency

or

failure

Of

dewce functmns

Caution!

The following is to be noted when using oxygen:

All parts which carry gas must be kept free of oil and grease!

Smoking and naked flames are prohibited!

Oxylog with demand

valve

to

facilitate

spontaneous breathing

Demand valve

Opening pressure

Max. output

rci

’

Oxylog

No

apAir-Mix<<

switch

Pressure limiting valve

Non-rebreathing valve

0 to -4 mbar

100

Umin

at -7 mbar

ambient air is not sucked in

(50+30)

mbar

with additional expiratory check valve.

Page 24

, .._. ..- ,...._^,, I,

-. ,* .,.. p’”

.“*

,‘.

:

;I

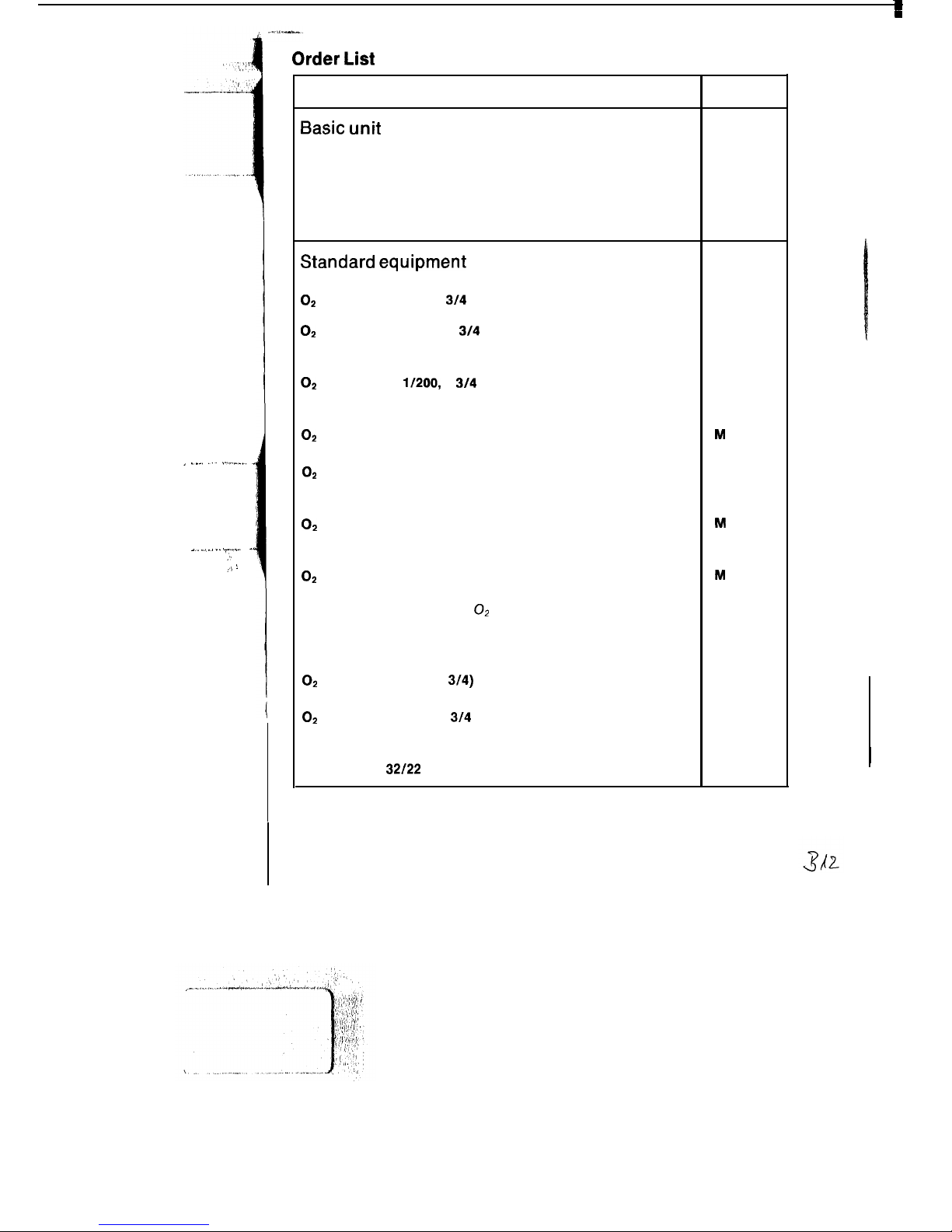

Order List

Name and description

Order No.

Basic unit

Oxylog

84 09 520

time-cycled, volume constant ventilator for controlled ventilation

in emergency medicine. Including accessories, comprising:

ventilation tubing and non-rebreathing valve.

Oxylog with spontaneous breathing

84 09 585

Standard equipment

For operation from oxygen cylinder:

O2

pressure reducer, G

314

and

D 17251

O2

cylinder AG 2.51200, G

314

straight valve, filled

or

B 03 580

O2

cylinder AG 1

l/200,

G

314

straight valve, filled

and

B 02710

OS

compressed-air connecting hose, 1.5 m

or

M

17816

O2

compressed-air connecting hose, 3 m

For operation from central supply unit

option of:

M 17617

O2

compressed-air connecting hose, 3 m

(angled plug connector)

or

M

22 494

O2

compressed-air connecting hose, 5 m

(angled plug connector)

M

22 495

For operation from portable O2 cylinder pack

Cylinder support

for two 2 L cylinders

M 23 370

Use of 2 x 2 L cylinders is possible

OS

pressure reducer (G

3/4)

and

D 20 225

O2

cylinder AG 21200, G

314

straight valve, filled

and

Spanner SW

32/22

(hexagonal)

B 02 352

M 12401

24

Page 25

----

--y

-‘(

Name and description

Order No.

Special accessories for pressure reducer D 20225:

O2

coupling hose, 0.15 m

Connection hoses between Oxylog and cylinder pack

option of:

a) screw-type both ends, option of

O2

compressed-air connecting hose, 1.5 m

or

M

23 874

M

17616

O2

compressed-air connecting hose, 3 m

b) When using O2 coupling hose M 23874,

plug-type via quick-release coupling,

thread M 15 x 1 at device end, option of:

O2

compressed-air connecting hose, 3 m

(angled plug connector)

or

M

17617

M

22 494

O2

compressed-air connecting hose, 5 m

(angled plug connector)

M

22 495

Special accessories

Silicone mask, No. 2

Silicone mask, No. 5

Holder

to secure Oxylog in mobile units

Holder with rail bracket

to attach Oxylog to wall rail

Connecting hose, 3 m

(Oxett/Oxylog)

Pressure limiting valve

adjustable from IO to 45 mbar, to be latched onto patient

connection

Volume measurement Oxylog

auxiliary means for measurement of expired volume com-

prising: Volumeter, support, silicone hose 1.1 m and 2 sockets

PEEP valve (Ambu PEEP)

adjustable from 0 to 10 mbar

Polymed 201 (gas blender)

and

21 20 194

21 20 186

84 04 560

84 05 009

M

25 879

84 05 390

84 06 995

84 07 475

D 21 800

02

compressed-air connecting hose, 1.5 m

M

17716

Continued next page

Page 26

Name and description

For checking compressed-gas

supp/y

and

minute volume:

Standard connector, size 5 (stainless

steel)

For operation with extended ventilation hose:

Connection hose, silicone, 1.1 m

Socket

IS0

Spare and wearing parts

for sterilisation

Non-rebreathing valve 2

Connection hose

Silicone, 1.1 m

Carrying strap

Order No.

M

25

589

84 04

063

M

25

647

84

06

600

84

04 063

a4

04 773

26

1

Page 27

e

No. in

Fig. 11

Designation and description

Order No.

‘age

28

l-7

Oxyfog with ventilation accessories

84 09 520

1

Oxylog

84 08 500

2

Silicone tubing E 1.1 m

84 04 063

3-5

Non-rebreathing valve

84 06 600

3

Cover

84 06 585

4

Diaphragm

84 03 552

5

Valve housing

84 06 595

67

Carrying strap

84 04 773

6

Strap

84 04 078

7

Buckle

8405 179

8

Pressure limiting valve

84 05 390

9

PEEP valve (Ambu) O-10 mbar

84 07 475

10

Silicone mask, No. 2

21 20 194

10

Silicone mask, No. 5

21 20 186

12

Holder

84 04 560

13

Holder with bracket

84 05 009

2,

14-17

Voiumeter connection

84 06 995

14

Socket

M

25 647

15

Socket, complete

84 05 155

16

Volumeter 3000

2M 18250

17

Retainer

84 06 677

Parts List

c/t

27

Page 28

,

17

+!a

13+izv

-.

I

F.

I.L\

Fig.

11

Gomponent

parts (see rans

LISIJ.

*

Optional, only for operation with extended ventilation hose.

The item Nos. are not identical with the item Nos. in the other figures.

28

Page 29

These Instructions for Use apply only to

Oxylog

with Serial No.:

If no Serial No. has been filled in by

Drager these Instructions for Use are

provided for general information only and

are not intended for use with any specific

machine or device.

Drlgerwerk

Aktiengesellschaft

Germany

&

Moislinger Allee 53

-

55

D-23542 Liibeck

$3

(451)882-O

q 26807 -0

FAX

(4 51) 8 82-20 80

90 27 547 - GA 5503.1

0 Dragerwerk

AG

4th edition - November

Subject to alteration

40 e

.1993

Loading...

Loading...