Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

DrägerService

RETURN TO CD-ROM TABLE OF CONTENTS

®

Technical

Service

Manual

Part Number: S002011

Date: 20 May 2002

© 2002 Draeger Medical, Inc.

Rev: Y

Narkomed 2B

Anesthesia System

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO CD-ROM TABLE OF CONTENTS

DrägerService

®

Narkomed 2B Service Manual Table of Contents

Summary of What's New in Rev. Y

DESCRIPTION PAGE

SECTION 1:

Introduction ............................................................... 1-1

SECTION 2:

Diagnostics ............................................................... 2-1

2.1 Service Menu Screen ............................................ 2-2

SECTION 3:

Troubleshooting ............................................................ 3-1

3.1 Power Supply and Voltage Distribution .............................. 3-1

3.2 Battery ...................................................... 3-3

3.3 Troubleshooting Guides .......................................... 3-3

SECTION 4:

Replacement Procedures ..................................................... 4-1

4.1 Cylinder Yoke Assemblies ........................................ 4-2

4.2 Cylinder Pressure Regulators ...................................... 4-5

4.3 Cylinder Cutoff Valves (Canada) ................................... 4-8

4.4 Cylinder and Pipeline Pressure Gauges ............................. 4-11

4.5 Flowmeters .................................................. 4-15

4.6 Flow Control Valves ............................................ 4-19

4.7 Oxygen Supply Pressure Failure Protection Device ..................... 4-22

4.8 Oxygen Supply Pressure Alarm Switch (earlier machines) ............... 4-25

4.9 Oxygen Supply Pressure Alarm Whistle (Canada) ..................... 4-28

4.10 Oxygen Ratio Monitor/Controller .................................. 4-30

4.11 Oxygen Ratio Controller (later machines) ............................ 4-34

4.12 Vaporizers ................................................... 4-37

4.13 O

4.14 AV-E Ventilator Controller Assembly ............................... 4-44

4.15 AV-E Ventilator Solenoid Valve ................................... 4-47

4.16 AV-2 Ventilator Controller Assembly ............................... 4-50

4.17 Convenience Outlet AC Power Filter ............................... 4-53

4.18 AV-E Inspiratory Flow Regulator .................................. 4-56

4.19 Ventilator Bellows Valve and Guide Assembly (AV-E Ventilator) .......... 4-59

4.20 Ventilator Bellows Valve and Guide Asm w/Press Lim Ctrl (AV-2) ......... 4-69

4.21 Alarm Channel (without oxygen supply pressure alarm switch) ........... 4-73

4.22 Alarm Channel and Oxygen Supply Pressure Alarm Switch .............. 4-76

4.23 Caster ...................................................... 4-80

4.24 Battery ..................................................... 4-83

4.25 Power Supply ................................................. 4-86

4.26 Processor Assembly ............................................ 4-89

4.27 CRT Assemblies ............................................... 4-92

4.28 Keypads ..................................................... 4-96

4.29 SPIROMED Respiratory Volume Sensor ............................. 4-99

Flush Valve ................................................ 4-40

2

Rev. T

i

Page 4

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

CONTENTS (continued) NM2B

DESCRIPTION PAGE

4.30 Oxygen Sensor .......................................... 4-101

4.31 Manual Sphygmomanometer ............................... 4-103

4.32 Auxiliary Oxygen Flowmeter ............................... 4-105

4.33 PEEP Valve Magnet Assembly Replacement ................... 4-107

SECTION 5:

Adjustment and Calibration Procedures ...................................5-1

5.1 Cylinder Pressure Regulator Adjustment (except CO

5.1A CO

Cylinder Pressure Regulator Adjustment ....................5-4

2

) ..............5-2

2

5.2 Oxygen Supply Pressure Alarm Switch Adjustment (earlier machines) . 5-5

5.3 Oxygen Supply Pressure Alarm Switch Adjustment (later machines

with switch on alarm channel) ................ 5-8

5.4 Oxygen Ratio Monitor/Controller (ORMC) Adjustment ............. 5-11

5.5 Oxygen Ratio Controller (ORC) Adjustment ..................... 5-15

5.5A Low Flow Oxygen Ratio Controller (ORC) Adjustment ............5-17A

5.6 Oxygen Sensor Calibration .................................. 5-18

5.7 Breathing Pressure Monitor Calibration ........................ 5-21

5.8 Vaporizer Interlock Adjustment .............................. 5-23

SECTION 6:

PMS Procedure ......................................................6-1

6.1 Electrical Safety ........................................... 6-2

6.2 Self-Diagnostics ...........................................6-4

6.3 Battery Circuit ............................................ 6-5

6.4 Configuration ............................................. 6-5

6.5 Service Data .............................................6-6

6.6 Calibrations ..............................................6-7

6.7A Scavenger, A/C ............................................6-8

6.7B Scavenger, Open Reservoir ...................................6-9

6.7C Scavenger Interface .......................................6-11

6.7D Suction Regulator ........................................ 6-13

6.8 Breathing System ........................................ 6-14

6.9 Manual Sphygmomanometer ................................ 6-22

6.10 Vapor Exclusion System .................................... 6-23

6.11 Yokes & Gauges .......................................... 6-24

6.12 High Pressure Regulator ................................... 6-26

6.13 High Pressure Leak ....................................... 6-28

6.14 Oxygen Supply Failure Protection ............................ 6-31

6.15 Flowmeters ............................................. 6-35

6.16 O

Med................................................. 6-38

2

6.17 Oxygen Concentrations .................................... 6-40

6.18 Auxiliary Oxygen flowmeter ................................. 6-43

6.19A Oxygen Ratio Controller .................................... 6-44

6.19B Oxygen Ratio Monitor Controller ............................. 6-45

6.20 Baromed ............................................... 6-47

6.21 Ventilator .............................................. 6-49

6.22 Bellows Drive Gas Leak: Adult .............................. 6-50

6.23 Spiromed ............................................... 6-51

ii

Rev. W

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B CONTENTS (continued)

DESCRIPTION PAGE

6.24 Manual Sphygmomanometer ................................ 6-39

6.24A Bellows: Adult ........................................... 6-53

6.24B Ventilator Relief Valve: Adult ............................... 6-53

6.25A Bellows: Pediatric External .................................6-54

6.25B Bellows: Pediatric Internal .................................. 6-56

6.26 Trace & Trend ........................................... 6-58

6.27 Pressure Limit Controller .................................. 6-58

6.28 Bellows Peep Valve .......................................6-59

6.29 Audio Silence ............................................ 6-59

6.30 Oxygen Flush Valve ....................................... 6-60

6.31 Final Tests .............................................. 6-61

SECTION 7:

Software Update Procedure .............................................7-1

SECTION 8:

Spare and Replacement Parts

ASSEMBLY/PART PAGE

Monitor Chassis, Front Bezel, Power Supply, Processor Assembly, CRT Assemblies ...... 8-2, 8-3

AV-E Ventilator Box Assembly, Incl. Controller ................................. 8-4, 8-5

AV-2 Ventilator Controller Assembly ......................................... 8-6, 8-7

AV-E Ventilator Bellows Valve & Guide Assembly ............................... 8-8, 8-9

AV-2 Valve Case and Guide Assembly, Press. Limit Control, Bellows Assembly. ...... 8-10, 8-11

Bellows valve assembly details ......................................... 8-11A, 8-11B

Pipeline Inlet Fittings .................................................. 8-12, 8-13

Failsafe Assemblies, Minimum O2Flow Valve Assembly ........................ 8-14, 8-15

Gas Selector Switch and Valves ........................................... 8-16, 8-17

Vapor Exclusion System .............................................. 8-17A, 8-17B

ORMC (Earlier Config.) O2Alarm Switch, Alarm Channel, Alarm Whistle ........... 8-18, 8-19

ORC Assembly ........................................................ 8-20, 8-21

Alarm Channel Assembly with O2Alarm Switch (Later Configurations) ............. 8-22, 8-23

Flowmeter Shields, Knobs, Labels, Gauges .................................. 8-24, 8-25

Flow Tubes, Restrictor Assemblies, Flow Control Valve ......................... 8-26, 8-27

Cyl. Regulator Assemblies, O2Flush Valve and related parts ..................... 8-28, 8-29

CSA Items: Relief Valve, Cylinder Cutoff Valves .............................. 8-30, 8-31

Canada Fresh Gas Outlet ............................................. 8-31A, 8-31B

Cylinder Yokes, Common Parts, Labels ..................................... 8-32, 8-33

Sensor Interface Panel Asms., AC Power, Casters ............................. 8-34, 8-35

Absorber Assembly, Breathing Pressure Hoses, Oxygen Sensor ................... 8-36, 8-37

Ultrasonic Flow Sensor ............................................... 8-37A, 8-37B

Ultrasonic Flow Sensor Mounting Bracket .................................8-37C, 8-37D

Man/Auto Selector Valve ................................................ 8-38, 8-39

Man/Auto Selector Valve (Later Design) .................................... 8-40, 8-41

Auxiliary O2Flowmeter Assembly ......................................... 8-42, 8-43

Open Reservoir Scavenger ............................................... 8-44, 8-45

Open Reservior Scavenger, old style ....................................... 8-46, 8-47

A/C Scavenger ........................................................ 8-48, 8-49

Suction Scavenger ..................................................... 8-50, 8-51

Rev. X

iii

Page 6

NARKOMED 2B ANESTHESIA SYSTEM

R

Y

A

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

BOOM

RM

ALARM

DISPLAY

SYSTEM

CONTROL

KEYS

DATA DISPLA

MONITO

CONTROL

KEYS

MANUAL

SPHYGMOMANOMETER

(OPTIONAL)

BREATHING

SYSTEM SENSOR

INTERFACE PANEL

SV20001

1-0 Rev. F

Page 7

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B INTRODUCTION

1.0 Recommendations

Because of the sophisticated nature of Draeger Medical, Inc. anesthesia equipment and its critical

importance in the operating room setting, it is highly recommended that only appropriately

trained and experienced professionals be permitted to service and maintain this equipment.

Please contact DrägerService® at (800) 543-5047 for service of this equipment.

Draeger Medical, Inc. also recommends that its anesthesia equipment be serviced at three-month

intervals. Periodic Manufacturer’sService Agreementsare availablefor equipmentmanufactured

by Draeger Medical, Inc. For further information concerning these agreements, please contact us

at (800) 543-5047.

Draeger Medical, Inc. products/material in need of factory repair shall be sent to:

DrägerService

3124 Commerce Drive

Telford, PA 18969

(Include RMA Number)

HOW TO USE THIS MANUAL

The manual is divided into several sections. The DIAGNOSTICS section describes self-test and

service diagnostics for checking the system functions. An understanding of the on-board service

capabilities is necessary before any attempt is made to troubleshoot the unit. The

TROUBLESHOOTING section lists error codes and provides troubleshooting guides to assist the

TSR in locating the source of a problem. The REPLACEMENT PROCEDURES section contains

instructions for removal and replacement of the assemblies that are considered field-replaceable.

The ADJUSTMENT AND CALIBRATION PROCEDURES section contains the field procedures

needed to restore original system specifications. The Periodic Manufacturer’s Service (PMS)

PROCEDURE section outlines the steps required to verify the electrical, mechanical and

pneumatic safety of the unit and also identifies components requiring periodic replacement.

GENERAL TROUBLESHOOTING GUIDELINES

Troubleshooting the Narkomed 2B should always begin by communicating with those who

observedor experienced a problem with the unit.This mayeliminate unnecessary troubleshooting

steps. Once a general problem is identified, refer to the troubleshooting flow charts in Section 3

to determine the proper corrective action to be taken.

After a component has been replaced, verify that the unit is operating properly by running the

appropriate diagnostic procedure. The PMS PROCEDURE in Section 6 must also be performed

after any component has been replaced.

The general arrangement of the Narkomed 2B Anesthesia System is shown on the opposite page.

WARNINGS are used in this manual before procedures which if not performed correctly could

result in personal injury.

CAUTIONS are used in this manual to alert service personnel to the possibility of damage to the

equipment if a procedure is not performed correctly.

Rev. K

1-1

Page 8

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION NM2B

Copyright

Copyright © 2001 by Draeger Medical, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, or stored in a retrieval system in any form or

by any means, electronic or mechanical, including photocopying and recording, without the

written permission of Draeger Medical, Inc.

Trademark Notices

CliniDAS, Datagrip, NAD Information Systems, NAD Logo, Narkomed, O.R. Data Manager,

O.R. Link, ORM, PC Prep/View, Quality Service For Life, Vigilance Audit, Vitalert, Vitalink

and Narkomed GS are registered trademarks of Draeger Medical, Inc. All other products or

name brands are trademarks of their respective owners.

Disclaimer

The content of this manual is furnished for informational use only and is subject to change

without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

1-2

Rev. N

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B DIAGNOSTICS

2.0 DIAGNOSTICS

The Narkomed 2B contains a diagnostic system that monitors certain system functions and

records their operational status. A series of tests is performed when the system is powered

up and the results are displayed on the diagnostics screen shown in Figure 2-1. Further

diagnostic functions are available through service screens that can be called up by a TSR at

the display panel. The following paragraphs provide a description of each service screen that

can be accessed through system control keys on the display panel. If no display is present

upon system power-up, refer to Section 3 of this manual for troubleshooting assistance.

NARKOMED 2B

VIDEO TEST PASS VERSION 2.02 DIAGNOSTICS

FIRMWARE TEST PASS COPYRIGHT, NAD INC. 1987-89

MEMORY TEST PASS

TIMERS TEST PASS

ANALOG TEST PASS

AUDIO TEST - PRIMARY PASS

- BACKUP PASS

SERIAL I/O TEST PASS

CLOCK TEST PASS

BACKUP MEMORY TEST PASS

AC POWER TEST PASS

RESERVE POWER TEST PASS

FUNCTIONAL

Figure 2-1: POWER-UP DIAGNOSTICS SCREEN

TRACE

TREND

2-1

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM2B

2.1 Service Menu Screen

To access the Service Menu Screen, press and hold the CONFIG key, and

(while holding the CONFIG key) simultaneously press the 21% and APNEA

ALARM DISABLE keys. These keys are located on the monitor control key

panel. The Service Menu Screen appears as shown in Figure 2-2. Access to the

other service functions is gained through the keys to the right of the service

screen which temporarily function according to their corresponding on-screen

labels.

SERVICE MENU DIAGNOSTICS

CALIBRATION

EXIT

Figure 2-2: SERVICE MENU SCREEN

TRACE

TREND

2-2

Rev. A

Page 11

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B DIAGNOSTICS (continued)

2.1.1 Diagnostics Menu Screen

Pressing the DIAGNOSTICS key on the Service Menu Screen brings up

the Diagnostics Menu Screen. Figure 2-3 shows a typical Diagnostics

menu which displays the last service date and an error log. To reset the

last service date to the current date, press the RESET DATE key.

NOTE: The RESET DATE key also clears all stored error codes,

so the date should not be reset until the indicated

problems are resolved. If the processor assembly must be

replaced, the original assembly should be returned to the

NAD Technical Service Department with all of its stored

error codes.

Each line in the Error Log is displayed as three groups of hexadecimal

characters, with each group having a left and right character (see

Figure 2-3). Tables 2-1, 2-2 and 2-3 on the following pages list the

possible errors that correspond to the displayed characters in each

group.

DIAGNOSTICS MENU KEY TEST

LAST SERVICE DATE 14-JUN-91

ERROR LOG 00

Group 1 Group 2 Group 3

00 40 RESET DATE

EXIT

Figure 2-3: DIAGNOSTICS MENU SCREEN

TRACE

TREND

Rev. L

2-3

Page 12

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM2B

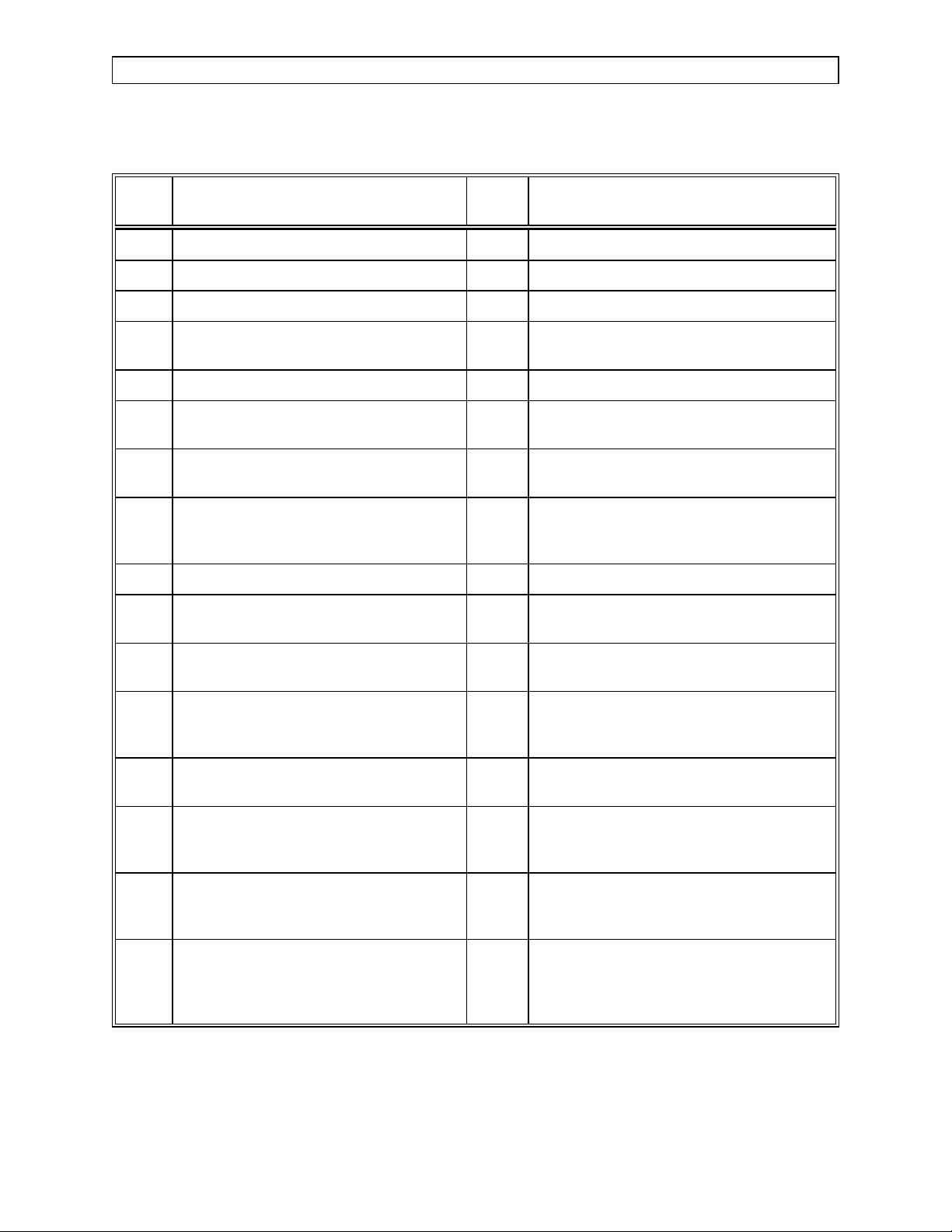

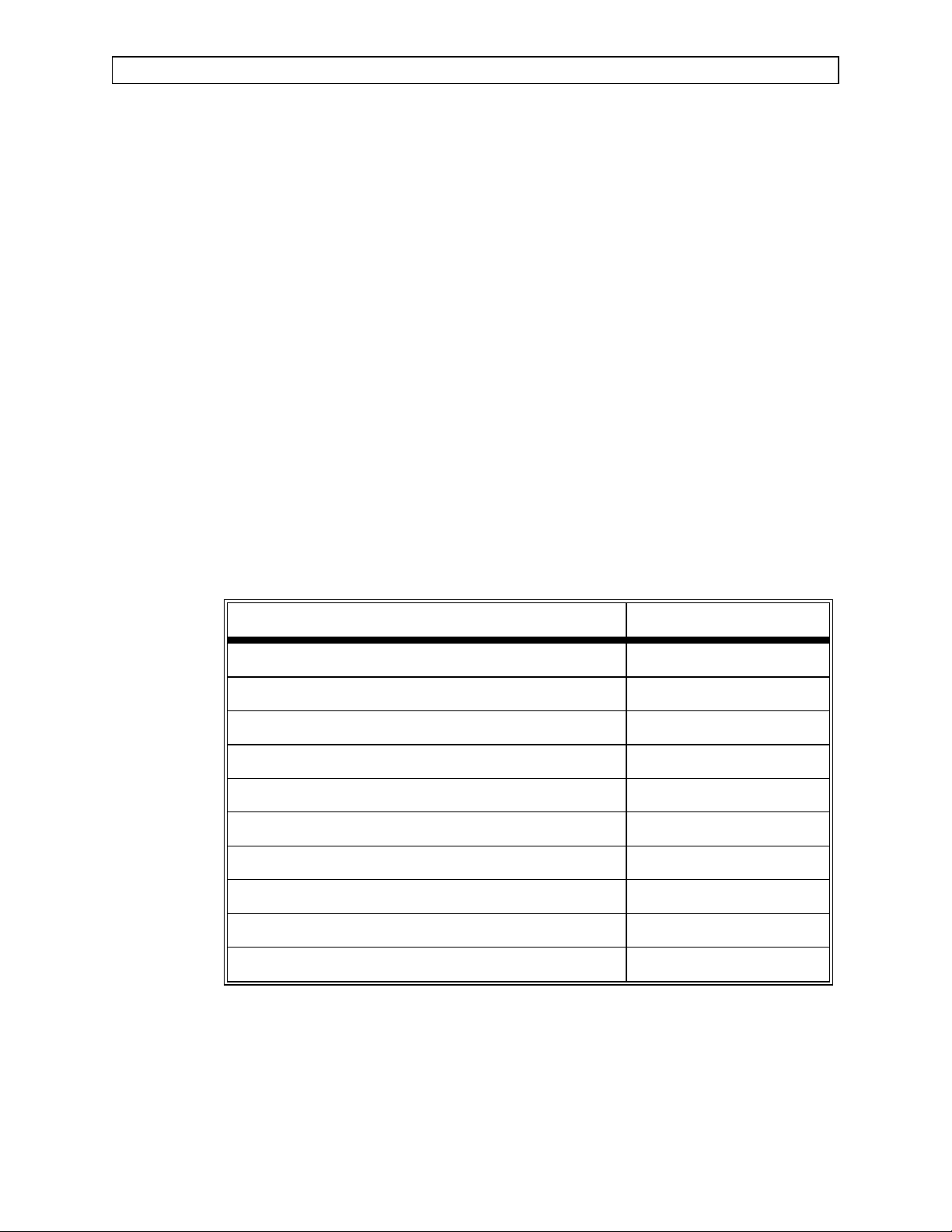

Table 2-1: NARKOMED 2B ERROR CODES, GROUP 1

Left

Char. Error(s)

0 No Error 0 No Error

1 System memory fail (checkerboard test) 1 CRT controller fail (readback test)

2 System memory fail (ROM compare test) 2 CRT memory fail (checkerboard test)

3 System memory fail (checkerboard test)

System memory fail (ROM compare test)

4 CTC fail (timer function test) 4 CRT memory fail (ROM compare test)

5 CTC fail (timer function test)

System memory fail (checkerboard test)

6 CTC fail (timer function test)

System memory fail (ROM compare test)

7 CTC fail (timer function test)

System memory fail (ROM compare test)

System memory fail (checkerboard test)

8 CTC fail (interrupt logic test) 8 ROM fail (firmware CRT test)

9 CTC fail (interrupt logic test)

System memory fail (checkerboard test)

Right

Char. Error(s)

3 CRT controller fail (readback test)

CRT memory fail (checkerboard test)

5 CRT memory fail (ROM compare test)

CRT controller fail (readback test)

6 CRT memory fail (ROM compare test)

CRT memory fail (checkerboard test)

7 CRT memory fail (ROM compare test)

CRT memory fail (checkerboard test)

CRT controller fail (readback test)

9 ROM fail (firmware CRT test)

CRT controller fail (readback test)

A CTC fail (interrupt logic test)

System memory fail (ROM compare test)

B CTC fail (interrupt logic test)

System memory fail (ROM compare test)

System memory fail (checkerboard test)

C CTC fail (interrupt logic test)

CTC fail (timer function test)

D CTC fail (interrupt logic test)

CTC fail (timer function test)

System memory fail (checkerboard test)

E CTC fail (timer function test)

CTC fail (interrupt logic test)

System memory fail (ROM compare test)

F CTC fail (interrupt logic test)

CTC fail (timer function test)

System memory fail (ROM compare test)

System memory fail (checkerboard test)

A ROM fail (firmware CRT test)

CRT memory fail (checkerboard test)

B ROM fail (firmware CRT test)

CRT memory fail (checkerboard test)

CRT controller fail (readback test)

C ROM fail (firmware CRT test)

CRT memory fail (ROM compare test)

D ROM fail (firmware CRT test)

CRT memory fail (ROM compare test)

CRT controller fail (readback test)

E ROM fail (firmware CRT test)

CRT memory fail (ROM compare test)

CRT memory fail (checkerboard test)

F ROM fail (firmware CRT test)

CRT memory fail (ROM compare test)

CRT memory fail (checkerboard test)

CRT controller fail (readback test)

2-4

Rev. L

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B DIAGNOSTICS (continued)

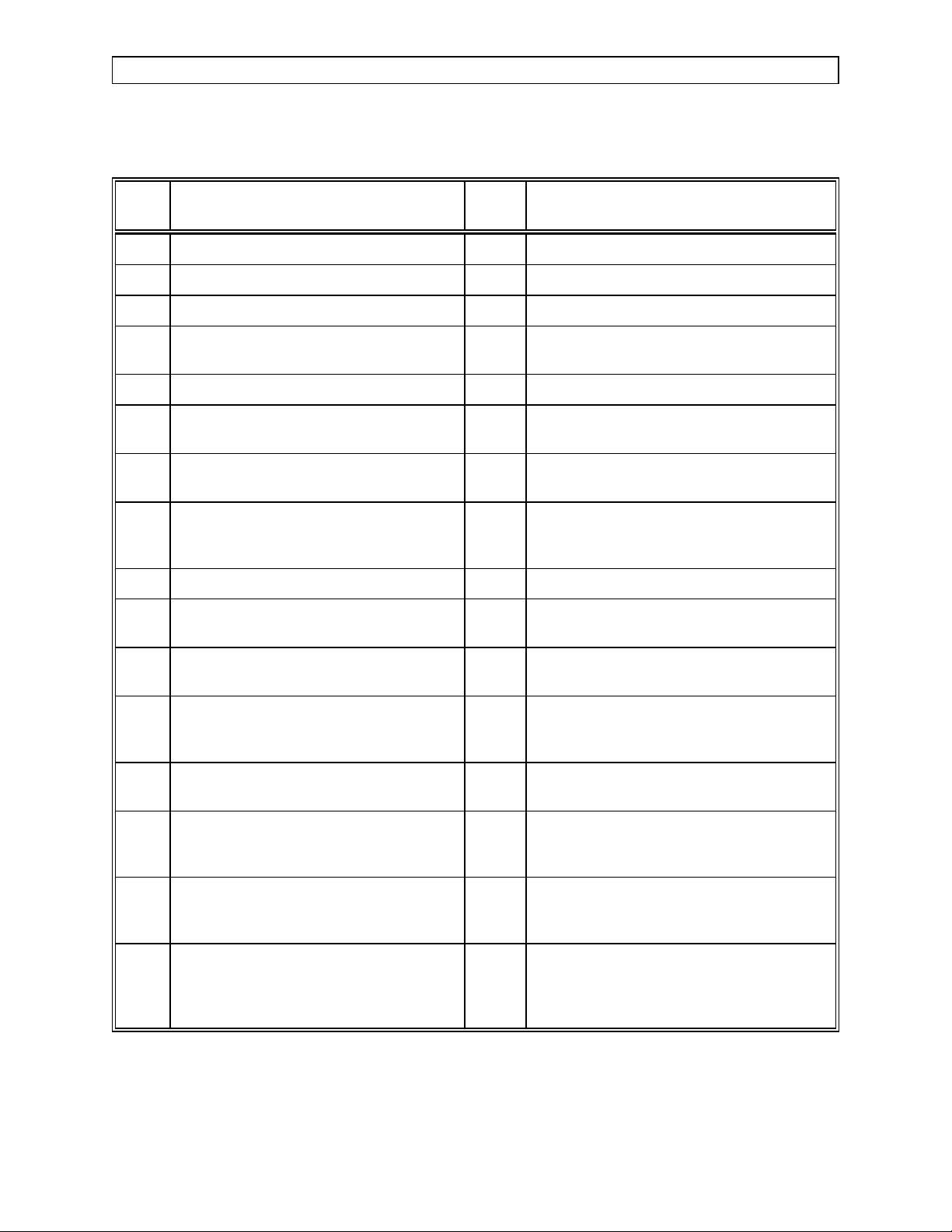

Table 2-2: NARKOMED 2B ERROR CODES, GROUP 2

Left

Char. Error(s)

0 No Error 0 No Error

1 Backup audio fail (sound generation test) 1 A/D conv. fail (analog V out of range)

2 Serial port B fail (channel A on UART) 2 Primary audio fail (speaker test)

3 Backup audio fail (sound generation test)

Serial port B fail (channel A on UART)

4 Serial port A fail (channel B on UART) 4 Primary audio fail (sound gen. test)

5 Serial port A fail (channel B on UART)

Backup audio fail (sound generation test)

6 Serial port A fail (channel B on UART)

Serial port B fail (channel A on UART)

7 Serial port A fail (channel B on UART)

Serial port B fail (channel A on UART)

Backup audio fail (sound generation test)

8 Clock fail (cannot read) 8 Backup audio fail (speaker test)

9 Clock fail (cannot read)

Backup audio fail (sound generation test)

Right

Char. Error(s)

3 A/D conv. fail (analog V out of range)

Primary audio fail (speaker test)

5 Primary audio fail (sound gen. test)

A/D conv. fail (analog V out of range)

6 Primary audio fail (sound gen. test)

Primary audio fail (speaker test)

7 Primary audio fail (sound gen. test)

Primary audio fail (speaker test)

A/D conv. fail (analog V out of range)

9 Backup audio fail (speaker test)

A/D conv. fail (analog V out of range)

A Clock fail (cannot read)

Serial port B fail (channel A on UART)

B Clock fail (cannot read)

Serial port B fail (channel A on UART)

Backup audio fail (sound generation test)

C Clock fail (cannot read)

Serial port A fail (channel B on UART)

D Clock fail (cannot read)

Serial port A fail (channel B on UART)

Backup audio fail (sound generation test)

E Clock fail (cannot read)

Serial port A fail (channel B on UART)

Serial port B fail (channel A on UART)

F Clock fail (cannot read)

Serial port A fail (channel B on UART)

Serial port B fail (channel A on UART)

Backup audio fail (sound generation test)

A Backup audio fail (speaker test)

Primary audio fail (speaker test)

B Backup audio fail (speaker test)

Primary audio fail (speaker test)

A/D conv. fail (analog V out of range)

C Backup audio fail (speaker test)

Primary audio fail (sound gen. test)

D Backup audio fail (speaker test)

Primary audio fail (sound gen. test)

A/D conv. fail (analog V out of range)

E Backup audio fail (speaker test)

Primary audio fail (sound gen. test)

Primary audio fail (speaker test)

F Backup audio fail (speaker test)

Primary audio fail (sound gen. test)

Primary audio fail (speaker test)

A/D conv. fail (analog V out of range)

Rev. L

2-5

Page 14

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM2B

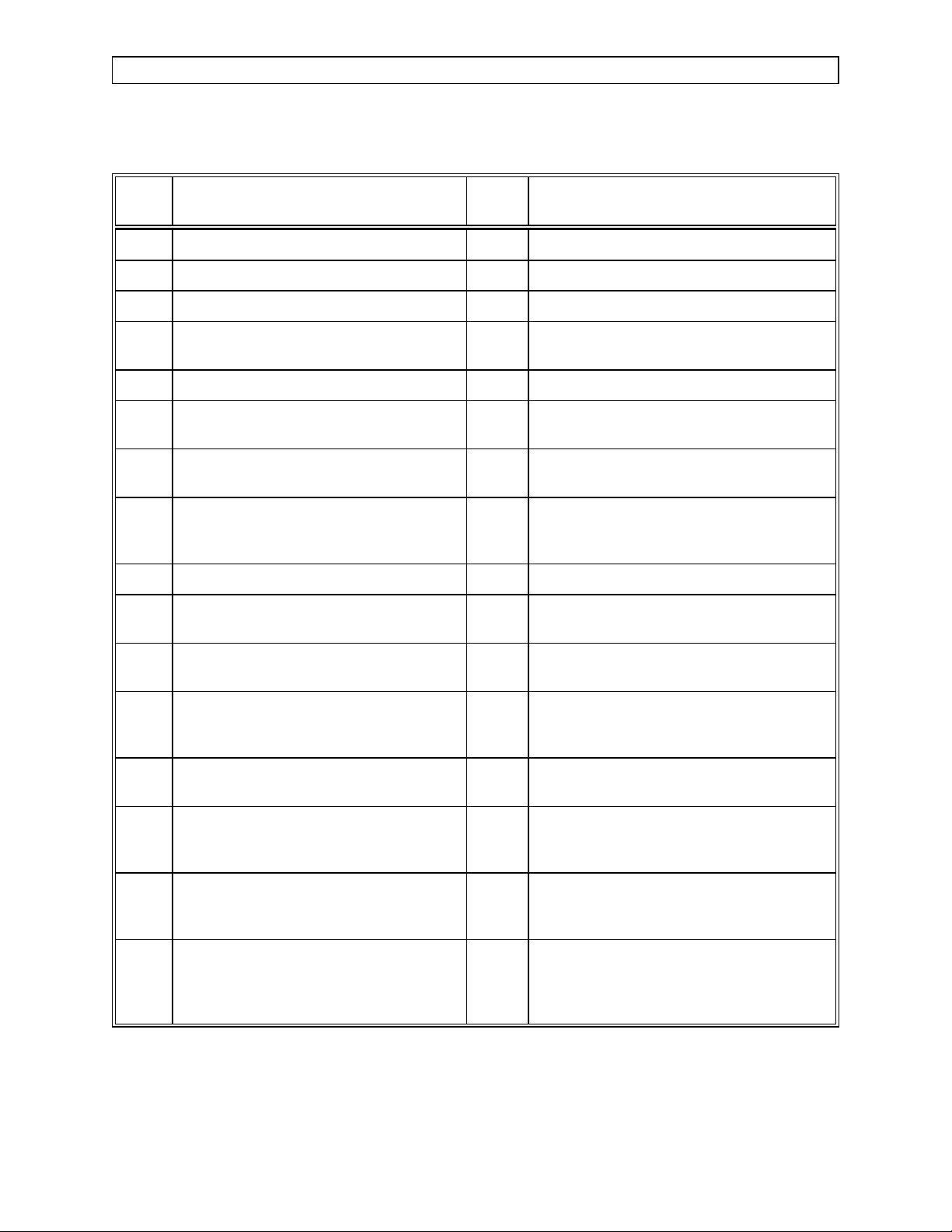

Table 2-3: NARKOMED 2B ERROR CODES, GROUP 3

Left

Char. Error(s)

0 No Error 0 No Error

1 Backup memory fail (ROM compare test) 1 Clock fail (write/readback test)

2 Backup memory fail (array recall test) 2 Clock fail (original time test)

3 Backup memory fail (ROM compare test)

Backup memory fail (array recall test)

4 AC power fail 4 Clock fail (seconds not incrementing)

5 AC power fail

Backup memory fail (ROM compare test)

6 AC power fail

Backup memory fail (array recall test)

7 AC power fail

Backup memory fail (array recall test)

Backup memory fail (ROM compare test)

8 Reserve power fail (batt. low/disconnected) 8 Backup memory fail (checkerboard test)

9 Reserve power fail (batt. low/disconnected)

Backup memory fail (ROM compare test)

Right

Char. Error(s)

3 Clock fail (write/readback test)

Clock fail (original time test)

5 Clock fail (seconds not incrementing)

Clock fail (write/readback test)

6 Clock fail (seconds not incrementing)

Clock fail (original time test)

7 Clock fail (seconds not incrementing)

Clock fail (original time test)

Clock fail (write/readback test)

9 Backup memory fail (checkerboard test)

Clock fail (write/readback test)

A Reserve power fail (batt. low/disconnected)

Backup memory fail (array recall test)

B Reserve power fail (batt. low/disconnected)

Backup memory fail (array recall test)

Backup memory fail (ROM compare test)

C Reserve power fail (batt. low/disconnected)

AC power fail

D Reserve power fail (batt. low/disconnected)

AC power fail

Backup memory fail (ROM compare test)

E Reserve power fail (batt. low/disconnected)

AC power fail

Backup memory fail (array recall test)

F Reserve power fail (batt. low/disconnected)

AC power fail

Backup memory fail (array recall test)

Backup memory fail (ROM compare test)

A Backup memory fail (checkerboard test)

Clock fail (original time test)

B Backup memory fail (checkerboard test)

Clock fail (original time test)

Clock fail (write/readback test)

C Backup memory fail (checkerboard test)

Clock fail (seconds not incrementing)

D Backup memory fail (checkerboard test)

Clock fail (seconds not incrementing)

Clock fail (write/readback test)

E Backup memory fail (checkerboard test)

Clock fail (seconds not incrementing)

Clock fail (original time test)

F Backup memory fail (checkerboard test)

Clock fail (seconds not incrementing)

Clock fail (original time test)

Clock fail (write/readback test)

2-5A Rev. L

Page 15

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B DIAGNOSTICS (continued)

With the exception of the error codes corresponding to AC power and battery

failure, the codes listed in Tables 2-1 thru 2-3 indicate a possible problem in

the NARKOMED 2B processor assembly.

Troubleshooting should begin with a check of the power supply voltages on the

processor board (see Section 3) followed by a check of all connections to the

processor assembly. Refer to Section 4 for removal and replacement procedures

for the field-replaceable assemblies in the NARKOMED 2B.

Rev. L

2-5B

Page 16

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM2B

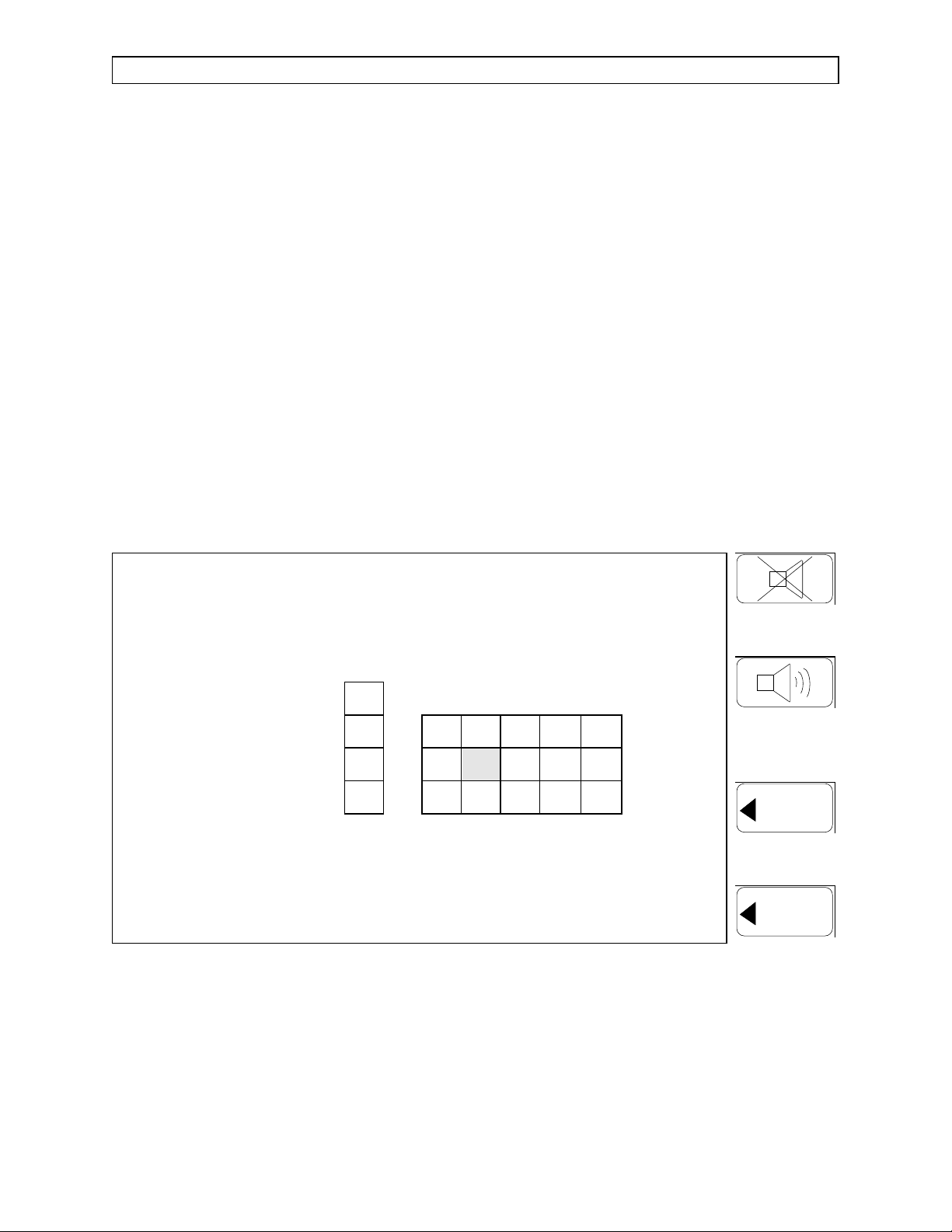

2.1.1.1 Key Panel Test Screen

Pressing the KEY TEST key in the Diagnostics Menu

Screen allows the TSR to check each key on the display

panel. As each key on the display panel is pressed, a

corresponding key is illuminated on the Key Panel Test

Screen as shown in Figure 2-4.

NOTE: The TREND key should be pressed last,

because it also exits the Key Panel Test

Screen.

If the correct keypanel response is not obtained, refer to

Section 3 for the appropriate troubleshooting procedure.

Figure 2-4: KEY PANEL TEST SCREEN

2-6

EXIT

TRACE

TREND

Page 17

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B DIAGNOSTICS (continued)

2.1.2 Calibration Menu Screen

Pressing the CALIBRATION key on the Service Menu Screen brings up

the Calibration Menu Screen. This menu allows the TSR to perform

calibration for the Oxygen Analyzer sensor and the Breathing Pressure

Monitor. Figure 2-5 shows a typical Calibration Menu Screen. The fourdigit numbers in the left column show the current values, while the

numbers in the right column show the values stored from the previous

calibration.

For a valid zero calibration of the Oxygen Analyzer sensor, the two

offset readings should be between 125 and 145, and the difference

between Cell A and Cell B should be no greater than 8. Pressing the

O2MED key stores the values, and the message OXYGEN OFFSET

READINGS STORED appears on the screen. Refer to Section 5 of this

manual for the complete calibration procedure.

For a valid calibration of the Breathing Pressure Monitor, the pressure

span reading at 60 cm H

the BAROMED key stores the value, and the message PRESSURE

SPAN READING STORED appears on the screen. Refer to Section 5 of

this manual for the complete calibration procedure.

O should be between 465 and 519. Pressing

2

CALIBRATION MENU O2MED

OFFSET O2 CELL A 0138 0127

OFFSET O2 CELL B 0138 0129

BAROMED

OXYGEN OFFSET READINGS STORED

TRACE

PRESSURE SPAN (60 cm H2O) 0243 0481

Figure 2-5: CALIBRATION MENU SCREEN

Rev. A

2-7

EXIT

TREND

Page 18

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 19

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE

3.0 TROUBLESHOOTING

This section contains information to assist the Draeger Medical, Inc. qualified

Technical Service Representative (TSR) in locating electrical faults affecting the

NARKOMED 2B monitoring and display devices. Since most troubleshooting efforts

begin with verifying power supply voltages, the following paragraph outlines the

voltage distribution scheme within the machine along with test points for each of the

voltages.

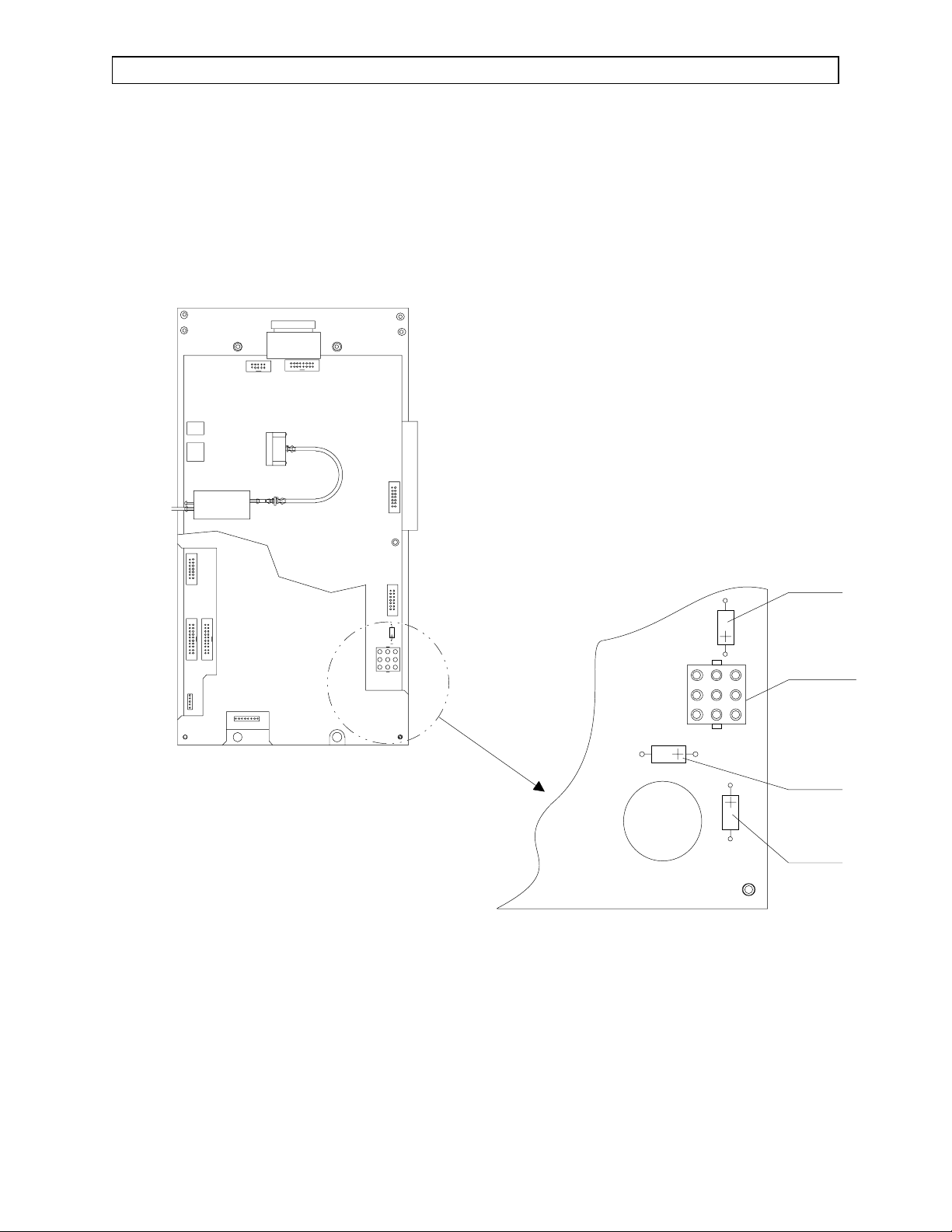

3.1 Power Supply and Voltage Distribution

In the NARKOMED 2B the power supply outputs at J10 are connected to J5

on the processor board for distribution. The CRTs are powered by 12 VDC; the

ventilator controller and the alarm channel are powered by 8 VDC. The

processor is powered by 5 VDC along with the other voltages. Under normal

load conditions these voltages are measured at the (+) end of capacitors C23,

C24 and C31 on the processor board. See Figure 3-1. The voltmeter return

should be connected to the (-) end of one of the capacitors. Table 3-1 lists the

acceptable range for each voltage.

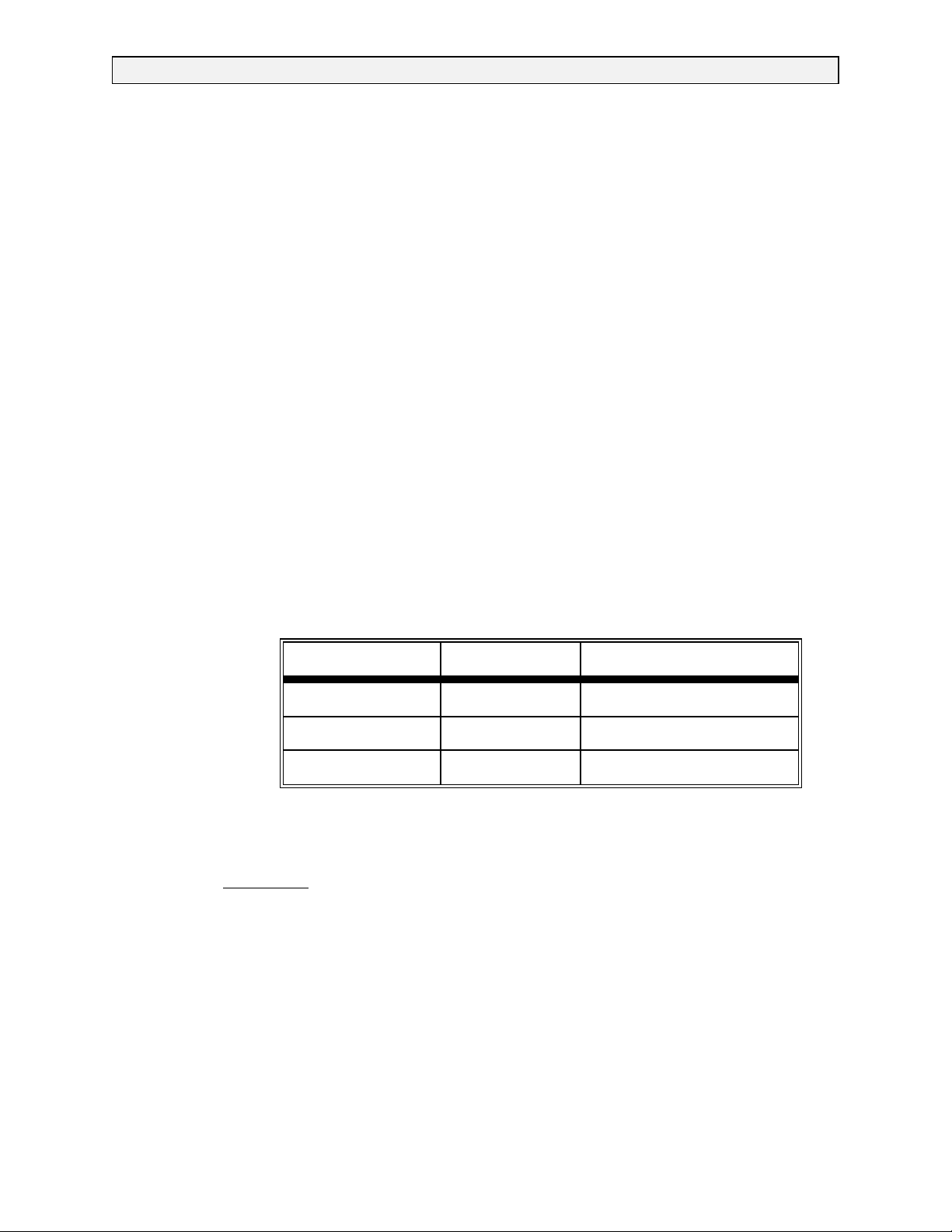

TABLE 3-1: PROCESSOR BOARD VOLTAGES

LOCATION VOLTAGE ACCEPTABLE RANGE

+ End of C23 + 5 VDC 4.85 to 5.15 VDC

+ End of C24 + 8 VDC 7.45 to 8.47 VDC

+ End of C31 +12VDC 11.52 to 12.24 VDC

The power supply voltages can also be measured in an unloaded condition.

CAUTION

: Before disconnecting the output cable from J10 on the power

supply assembly, turn the System Power switch to STANDBY,

and disconnect the data cable from J9 on the power supply

assembly.

The test points are:

+5V: J10-3,-4

+8V: J10-1,-2

+12V: J10-5,-6

Com: J10-7,-8

Rev. H

3-1

Page 20

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

TOP VIEW OF

PROCESSOR ASSEMBLY

SV20313

C31

J5

C24

C23

Figure 3-1: PROCESSOR BOARD VOLTAGE TEST POINTS

3-2

Rev. A

Page 21

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

3.2 Battery

While the machine is operating from an AC line, the battery voltage at full

charge should be within the range of 12.83 to 14.18 VDC. Battery voltage can

be measured between J7-3(+) and J7-4(-). During battery operation, the low

battery cutoff voltage should be within the range of 9.79 to 10.82 VDC.

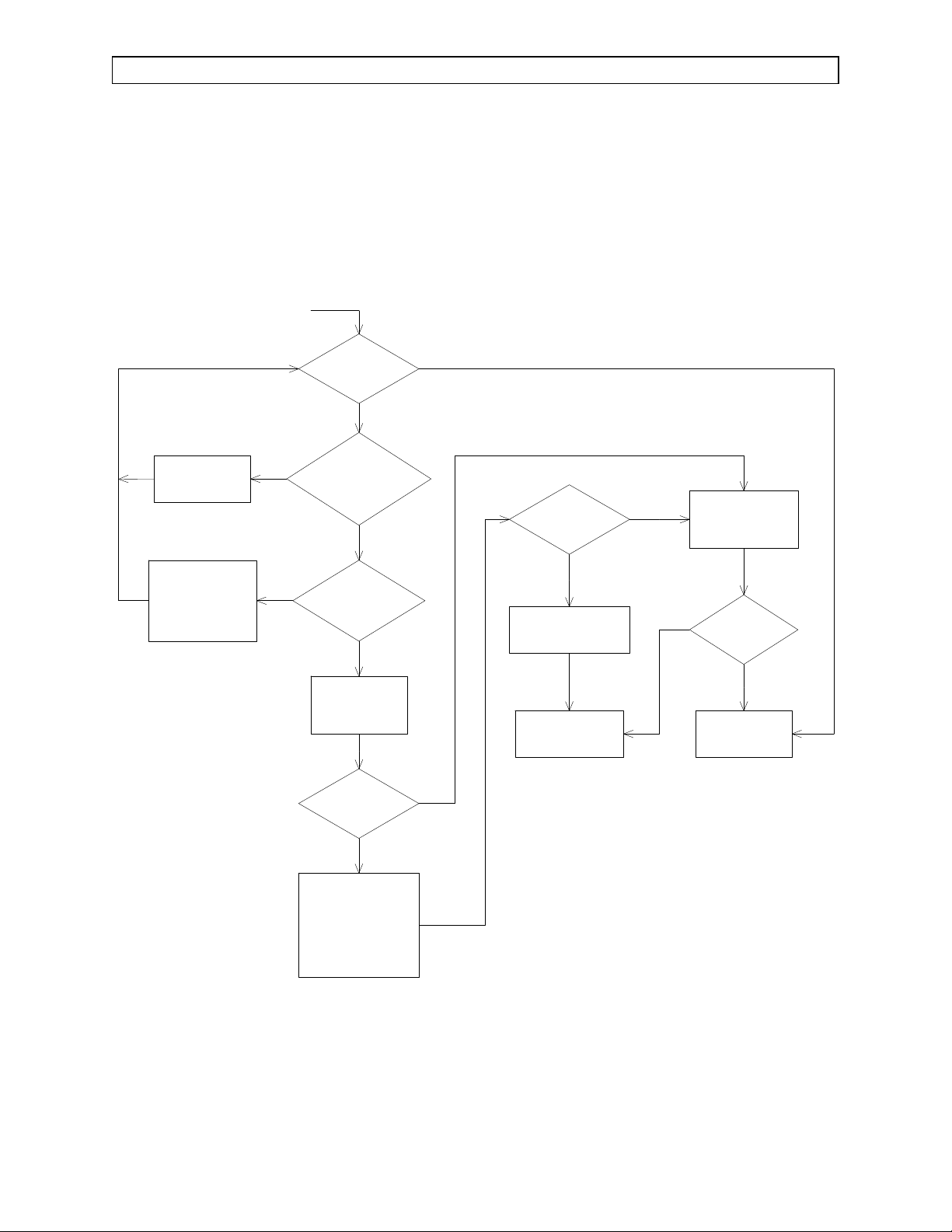

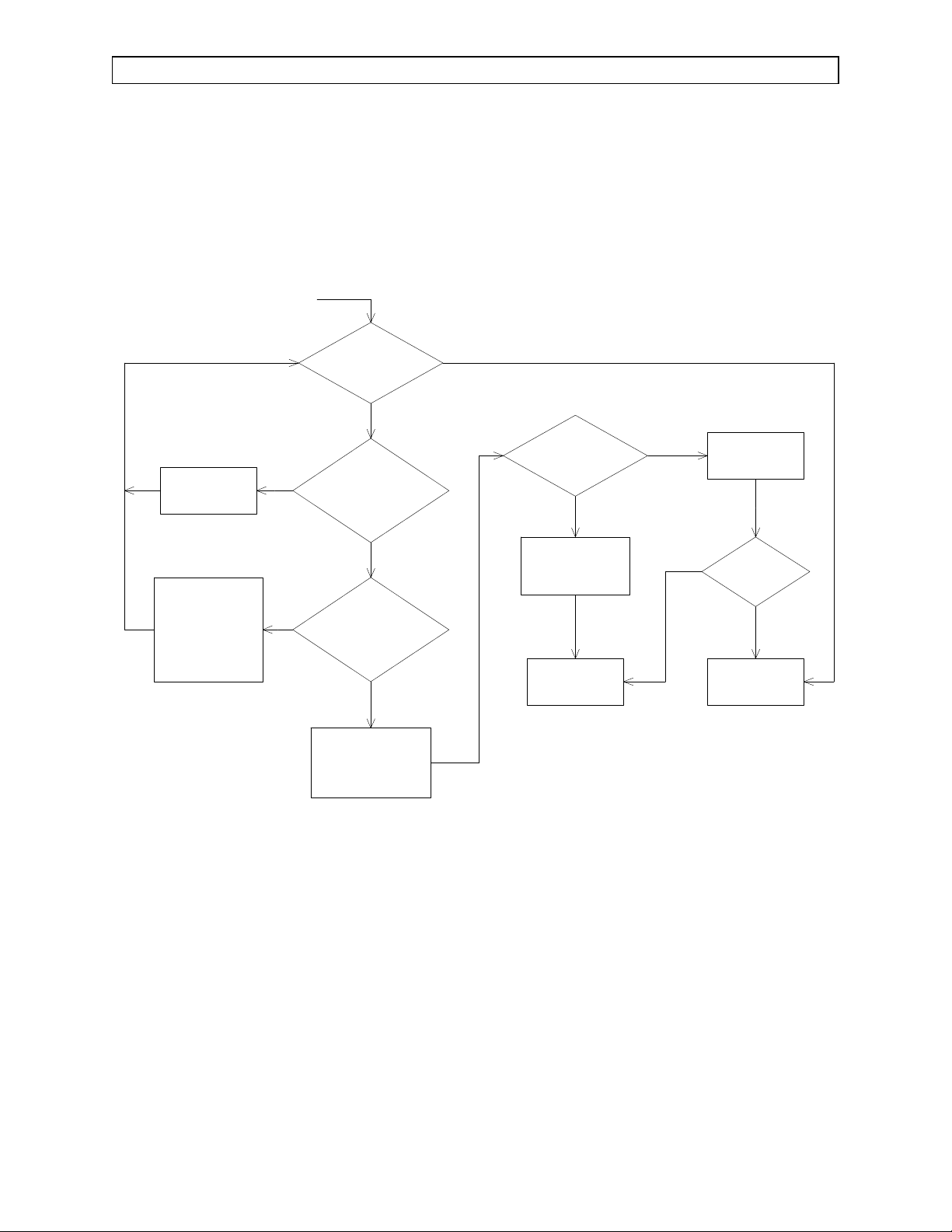

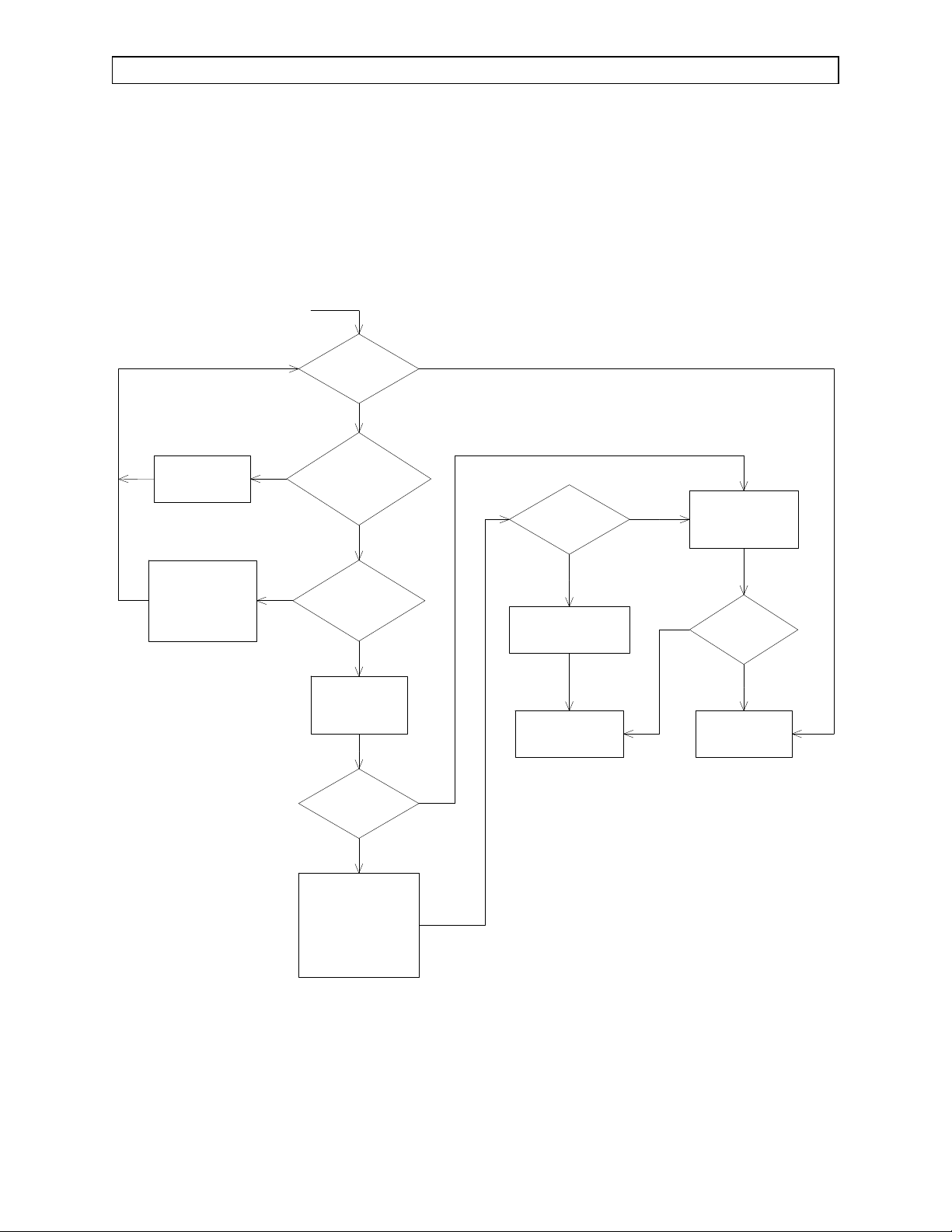

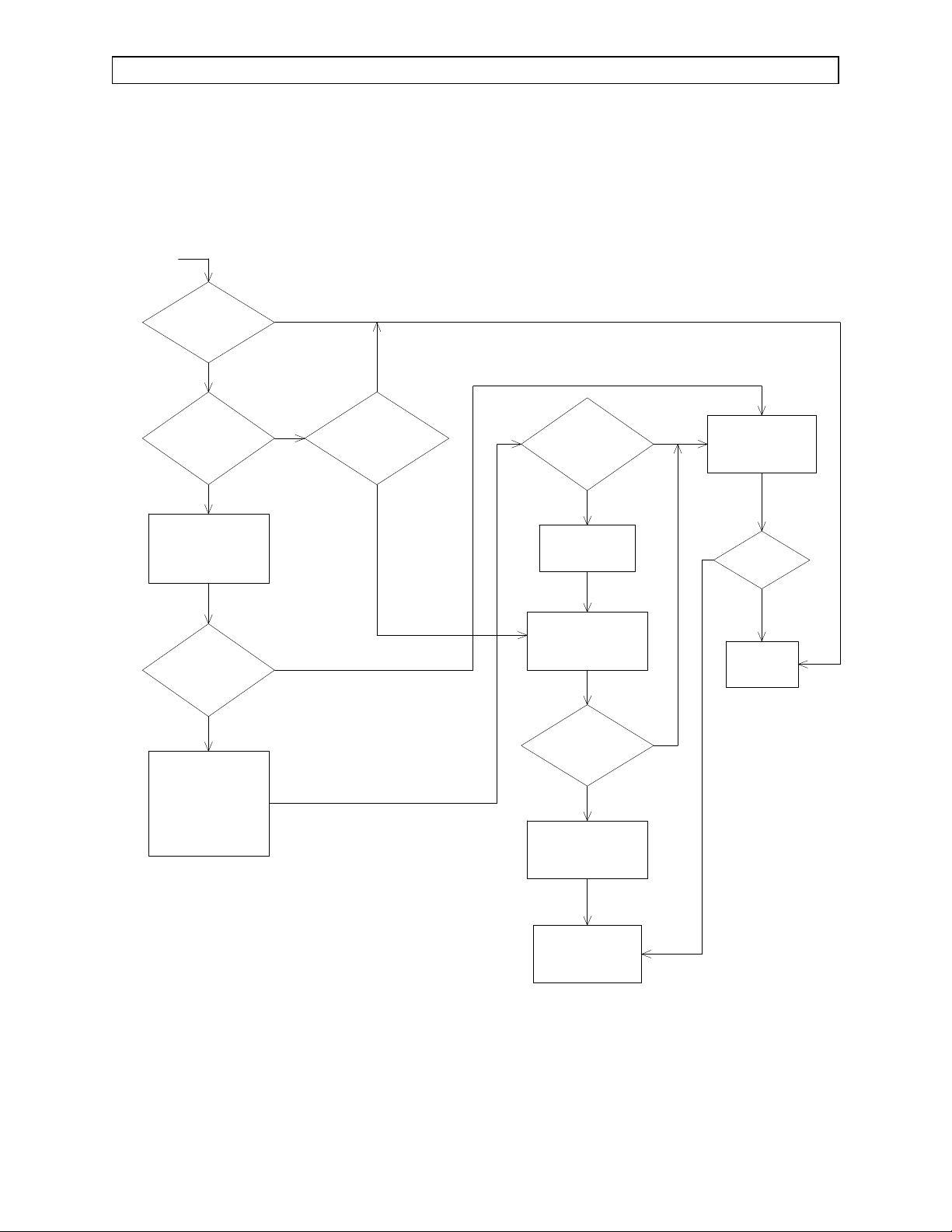

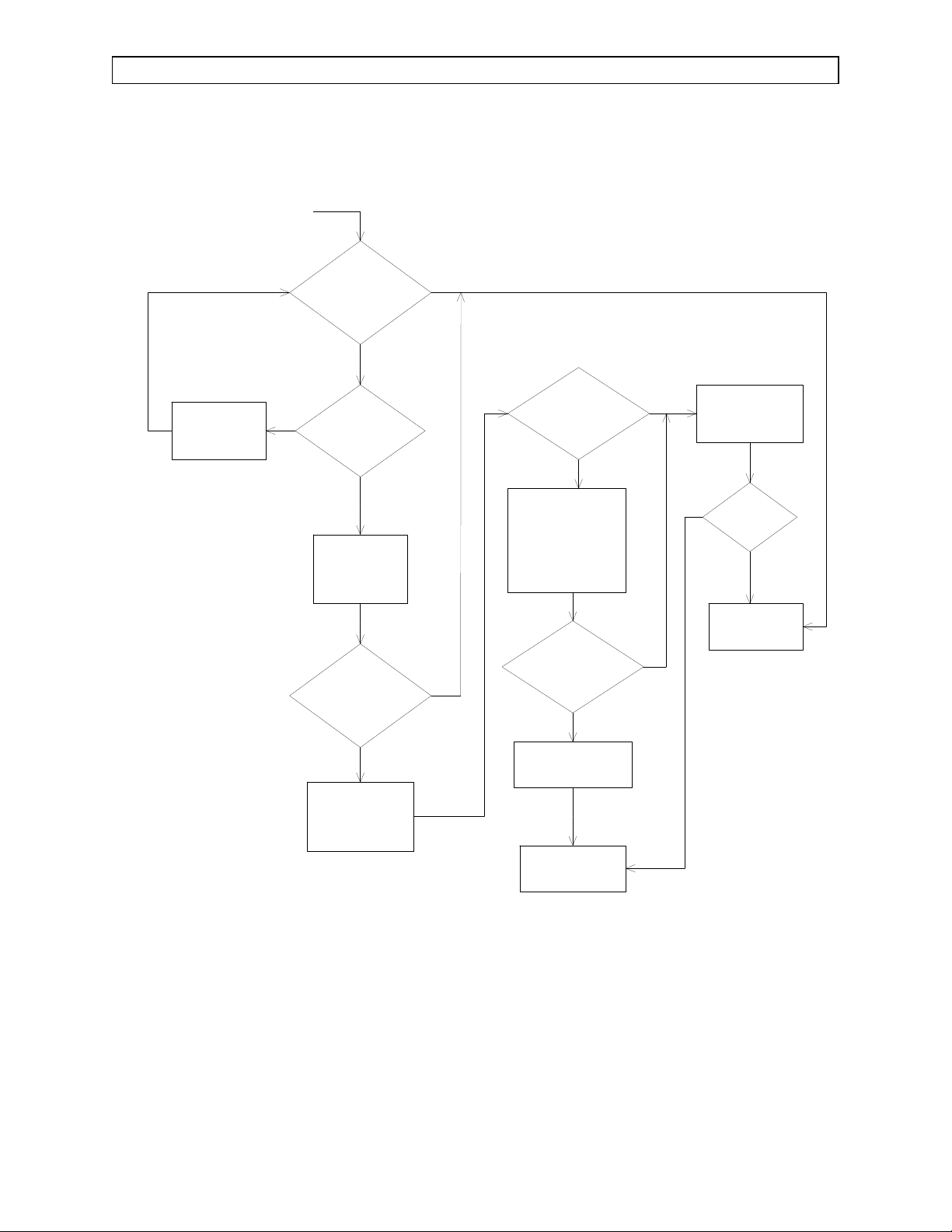

3.3 Troubleshooting Guides

Table 3-2 lists common failure modes and symptoms (excluding simultaneous

multiple faults) for the monitoring and display devices in the NARKOMED 2B.

Each failure mode or symptom is keyed to a troubleshooting guide flow chart

on the following pages to assist in locating a problem. These flow charts

assume that the machine is plugged into an AC outlet with the correct voltage,

and the machine is not running on its backup battery.

TABLE 3-2: NARKOMED 2B FAILURE MODE AND SYMPTOM LIST

FAILURE MODE / SYMPTOM CORRECTIVE ACTION

Loss of O2Monitor Guide 1

Loss of Breathing Pressure Monitor Guide 2

Loss of Respiratory Volume Monitor Guide 3

No Audio Alarms Guide 4

Vitalink Failure Guide 5

Incorrect Display Guide 6

No Oxygen Ratio Monitor Alarms Guide 7

No Oxygen Supply Pressure Alarms Guide 8

Display Screens Blank Upon System Power-up Guide 9

No Keypanel Response Guide 10

Rev. A

3-3

Page 22

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

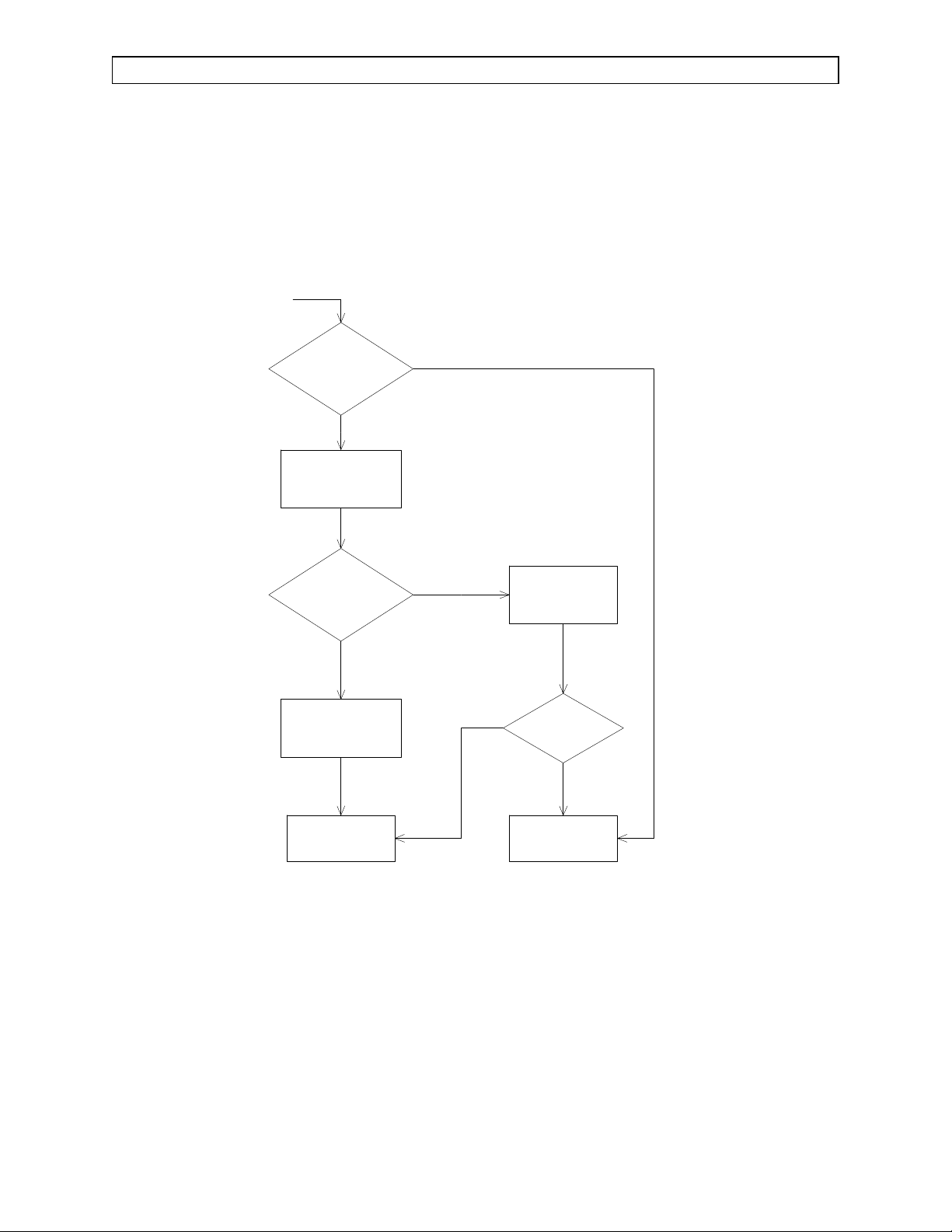

GUIDE 1: Loss of O

CONNECT OXYGEN

SENSOR CABLE TO

INTERFACE PANEL

CONNECT CABLE TO

J10 ON PROCESSOR

BOARD (ALSO

CHECK CONTINUITY OF

INTERNAL CABLE)

Monitor

2

START

Y

CENTRALERT ALARM

N

IS

OXYGEN ANALYZER

FUNCTIONAL?

N

IS

"O2 SENS DISC"

DISPLAYED ON

DISPLAY?

N

IS CABLE

CONNECTED TO

J10 ON PROCESSOR

BOARD?

Y

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES UNIT

PASS PMS?

IS

OXYGEN ANALYZER

FUNCTIONAL?

N

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

Y

REPLACE

OXYGEN SENSOR

ASOUTLINED IN

PROCEDURE 4.30

IS

OXYGEN ANALYZER

FUNCTIONAL?

N

REINSTALL ORIGINAL

OXYGEN SENSOR

-----------------------REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

Y

CONTACT NAD

SERVICE DEPT.

Y

UNIT IS

FUNCTIONAL

3-4

Rev. A

Page 23

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

GUIDE 2: Loss of Breathing Pressure Monitor

START

CONNECT

PILOT LINE

AT BOTH ENDS

CONNECT TUBING TO

TRANSDUCER ON

PROCESSOR BOARD

(ALSO CHECK

CONTINUITY OF

INTERNAL TUBING

CONNECTIONS)

PRESSURE MONITOR

FUNCTIONAL?

N

N

CONNECTED TO

INTERFACE PANEL AND TO

PATIENT Y-PIECE OR

PRESSURE TUBING

CONNECTED TO

TRANSDUCER ON

PROCESSOR

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

IS

BREATHING

N

IS

PILOT LINE

ABSORBER?

Y

IS

BREATHING

BOARD?

Y

REPLACE

Y

IS

BREATHING

PRESSURE MONITOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

PROCESSOR

ASSEMBLY

CONTACT NAD

SERVICE DEPT.

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Rev. A

3-5

Page 24

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

GUIDE 3: Loss of Respiratory Volume Monitor

START

CONNECT VOLUME

SENSOR CABLE TO

INTERFACE PANEL

CONNECT CABLE TO

J9 ON PROCESSOR

BOARD (ALSO

CHECK CONTINUITY OF

INTERNAL CABLE)

VOLUME MONITOR

Y

CENTRALERT ALARM

N

J9 ON PROCESSOR

VOLUME MONITOR

IS

FUNCTIONAL?

N

IS

"VOL SENS DISC"

DISPLAYED ON

DISPLAY?

N

IS CABLE

CONNECTED TO

BOARD?

Y

REPLACE

VOLUME SENSOR

ASOUTLINED IN

PROCEDURE 4.29

IS

FUNCTIONAL?

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

IS

VOLUME MONITOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

CONTACT NAD

SERVICE DEPT.

Y

Y

N

REINSTALL ORIGINAL

VOLUME SENSOR

-----------------------REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

3-6

Rev. A

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

GUIDE 4: No Audio Alarms

START

ARE

WARNINGS AND

CAUTIONS AUDIBLY

ANNUNCIATED?

N

REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

ARE

WARNINGS AND

CAUTIONS AUDIBLY

ANNUNCIATED?

N

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

Y

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES

UNIT PASS

PMS?

Y

Rev. A

CONTACT NAD

SERVICE DEPT.

3-7

UNIT IS

FUNCTIONAL

Page 26

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

GUIDE 5: Vitalink Failure

START

CONNECT

PERIPHERAL CABLE

TO SERIAL

HOST FAIL TO

COMMUNICATE WITH

N

CABLE CONNECTED

TO SERIAL INTERFACE

CHECK PERIPHERAL

& HOST SERIAL

CONFIGURATION

HOST FAIL TO

COMMUNICATE WITH

DOES

PERIPHERAL

DEVICE?

Y

IS

PERIPHERAL

PORT?

Y

PORT

SETTINGS

DOES

PERIPHERAL

DEVICE?

N

N

DOES

HOST FAIL TO

COMMUNICATE WITH

PERIPHERAL

DEVICE?

N

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

Y

CONTACT NAD

SERVICE DEPT.

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

3-8

Rev. A

Page 27

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

GUIDE 6: Incorrect Display

START

IS WRONG

MONITOR SCREEN

DISPLAYED?

Y

REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

IS WRONG

MONITOR SCREEN

DISPLAYED?

Y

N

N

PERFORM A

COMPLETE PMS

ON UNIT

Rev. A

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

CONTACT NAD

SERVICE DEPT.

3-9

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Page 28

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

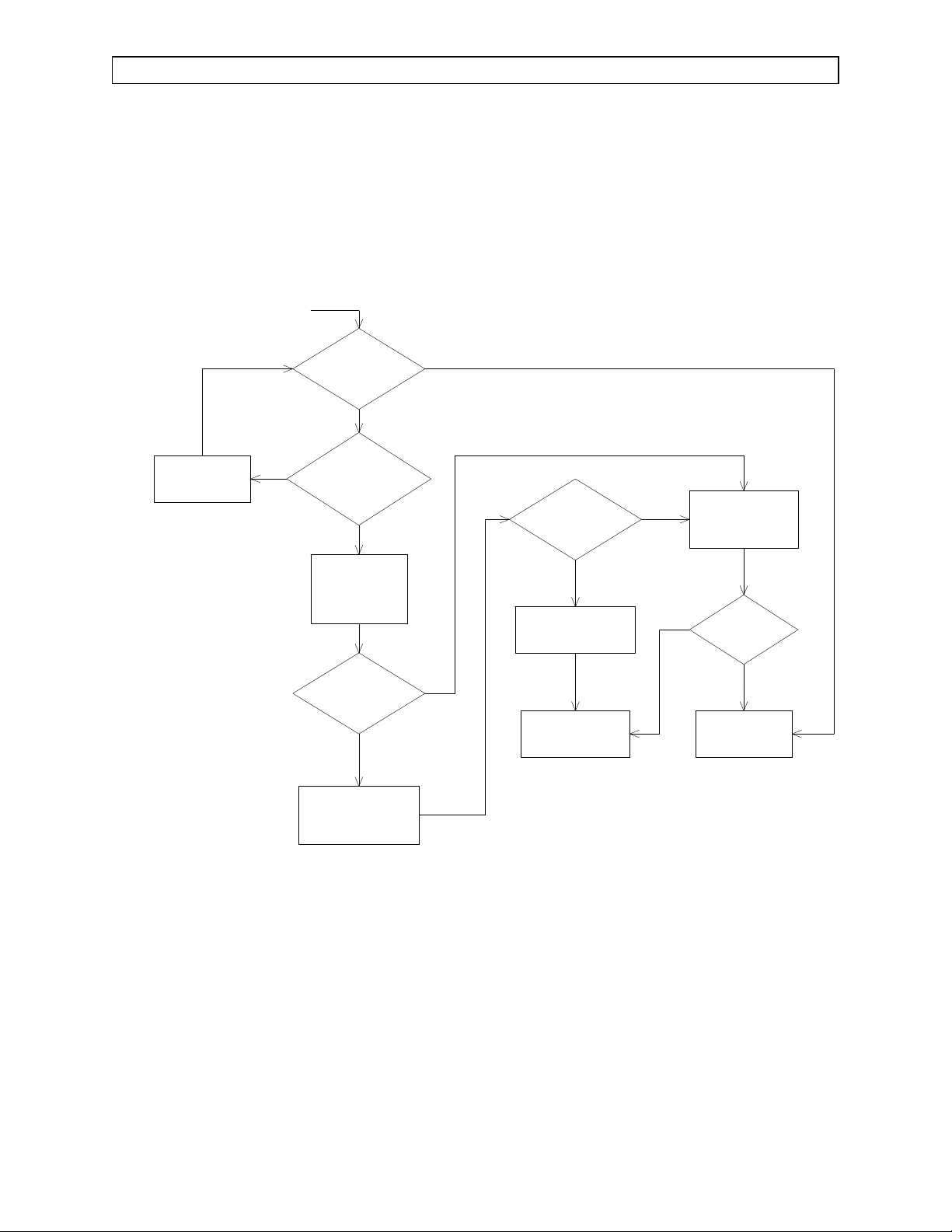

GUIDE 7: No Oxygen Ratio Monitor Alarms

START

ARE O2 / N2O

RATIO ALARMS

FUNCTIONAL?

N

IS O2 / N2O

FLOW RATIO

LED INDICATOR

FUNCTIONAL?

N

CHECK ORMC

ADJUSTMENTS

AS OUTLINED IN

PROCEDURE 5.4

IS O2 / N2O

FLOW RATIO

LED INDICATOR

FUNCTIONAL?

N

REPLACE ALARM

CHANNEL ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.21

Y

Y

IS

Y

Y

"O2 / N20 LOW"

DISPLAYED ON

CENTRALERT ALARM

PANEL?

N

IS O2 / N2O

FLOW RATIO

LED INDICATOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

ORMC

REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

ARE O2 / N2O

RATIO ALARMS

FUNCTIONAL?

N

Y

Y

COMPLETE PMS

N

FUNCTIONAL

PERFORM A

ON UNIT

DOES

UNIT PASS

PMS?

Y

UNIT IS

IS O2 / N2O

FLOW RATIO

LED INDICATOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

ALARM CHANNEL

-------------------REPLACE ORMC

AS OUTLINED IN

PROCEDURE 4.10

REINSTALL ORIGINAL

PROCESSOR

ASSEMBLY

Y

CONTACT NAD

SERVICE DEPT.

3-10

Rev. A

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

GUIDE 8: No Oxygen Supply Pressure Alarms

START

ARE

OXYGEN SUPPLY

PRESSURE ALARMS

FUNCTIONAL?

N

IS O2

SUPPLY PRESSURE

LED INDICATOR

FUNCTIONAL?

N

REPLACE OXYGEN

SUPPLY PRESSURE

ALARM SWITCH

AS OUTLINED IN

PROCEDURE 4.8 OR 4.22

IS O2

SUPPLY PRESSURE

LED INDICATOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

OXYGEN SUPPLY

ALARM SWITCH

--------------------

REPLACE

ALARM CHANNEL

AS OUTLINED IN

PROCEDURE 4.21 OR 4.22

Y

Y

IS

Y

Y

"LOW O2 SUPPLY"

DISPLAYED ON

CENTRALERT ALARM

PANEL?

N

IS O2

SUPPLY PRESSURE

LED INDICATOR

FUNCTIONAL?

N

REINSTALL ORIGINAL

ALARM CHANNEL

REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

ARE

OXYGEN SUPPLY

PRESSURE ALARMS

FUNCTIONAL?

N

REINSTALL ORIGINAL

PROCESSOR

ASSEMBLY

Y

Y

COMPLETE PMS

N

FUNCTIONAL

PERFORM A

ON UNIT

DOES

UNIT PASS

PMS?

Y

UNIT IS

Rev. A

3-11

CONTACT NAD

SERVICE DEPT.

Page 30

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM2B

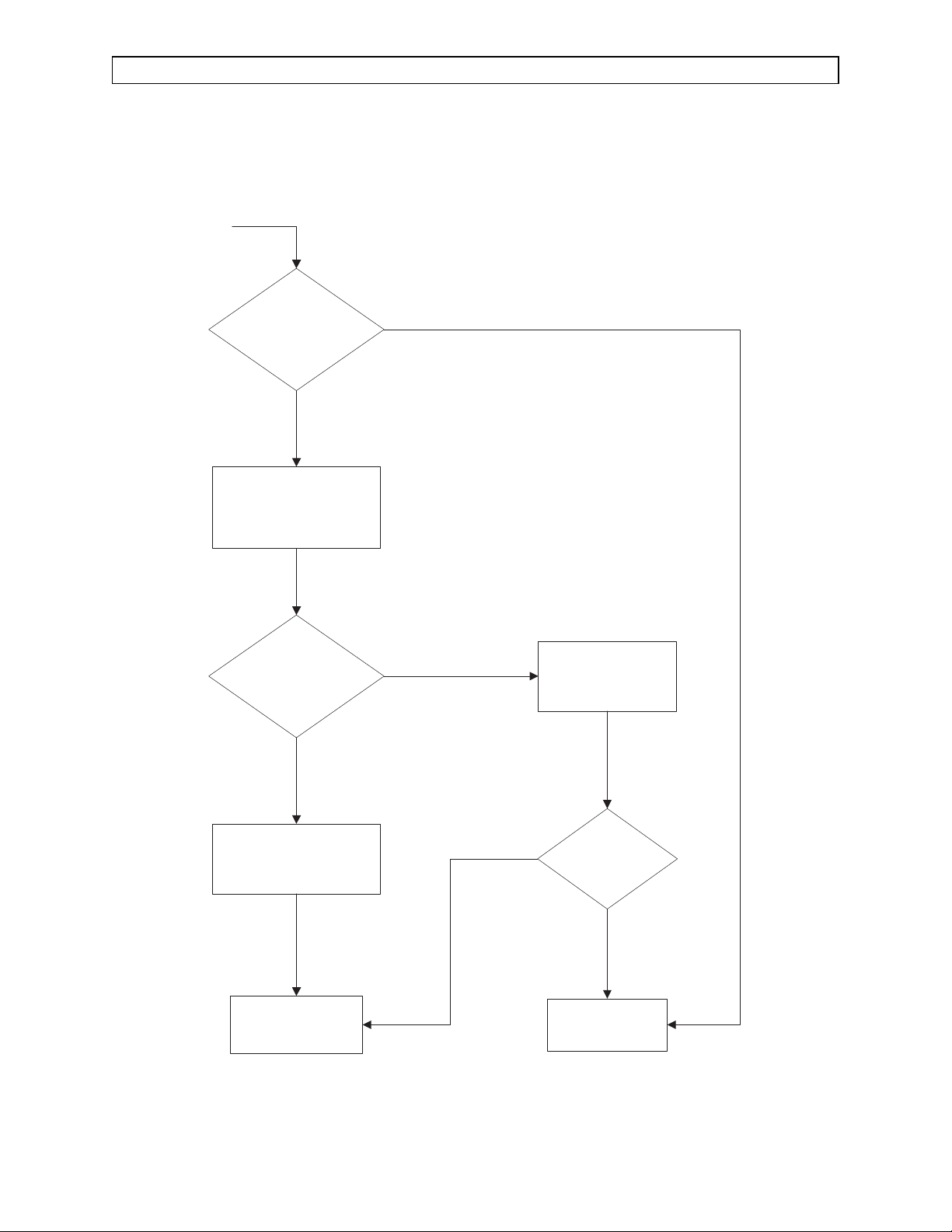

GUIDE 9: Display Screens Blank Upon System Power-Up

START

CONNECT

CABLES

TO J3 & J4 ON

PROCESSOR

ARE

DISPLAY SCREENS

BLANK UPON SYSTEM

POWER-UP?

ARE

N

CABLES

CONNECTED TO J3 & J4

ON PROCESSOR

BOARD?

CHECK POWER

SUPPLY

VOLTAGES

AS OUTLINED IN

SECTION 3.1

ARE

DISPLAY SCREENS

BLANK UPON SYSTEM

POWER-UP?

N

Y

ARE

DISPLAY SCREENS

BLANK UPON SYSTEM

POWER-UP?

Y

Y

N

REINSTALL ORIGINAL

CRT ASSEMBLY

----------------------REPLACE

PROCESSOR

ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

ARE

DISPLAY SCREENS

BLANK UPON SYSTEM

POWER-UP?

Y

N

N

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES UNIT

PASS PMS?

FUNCTIONAL

Y

UNIT IS

Y

REPLACE

CRT ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.27

3-12

REINSTALL ORIGINAL

PROCESSOR

ASSEMBLY

CONTACT NAD

SERVICE DEPT.

Rev. D

Page 31

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B TROUBLESHOOTING GUIDE (continued)

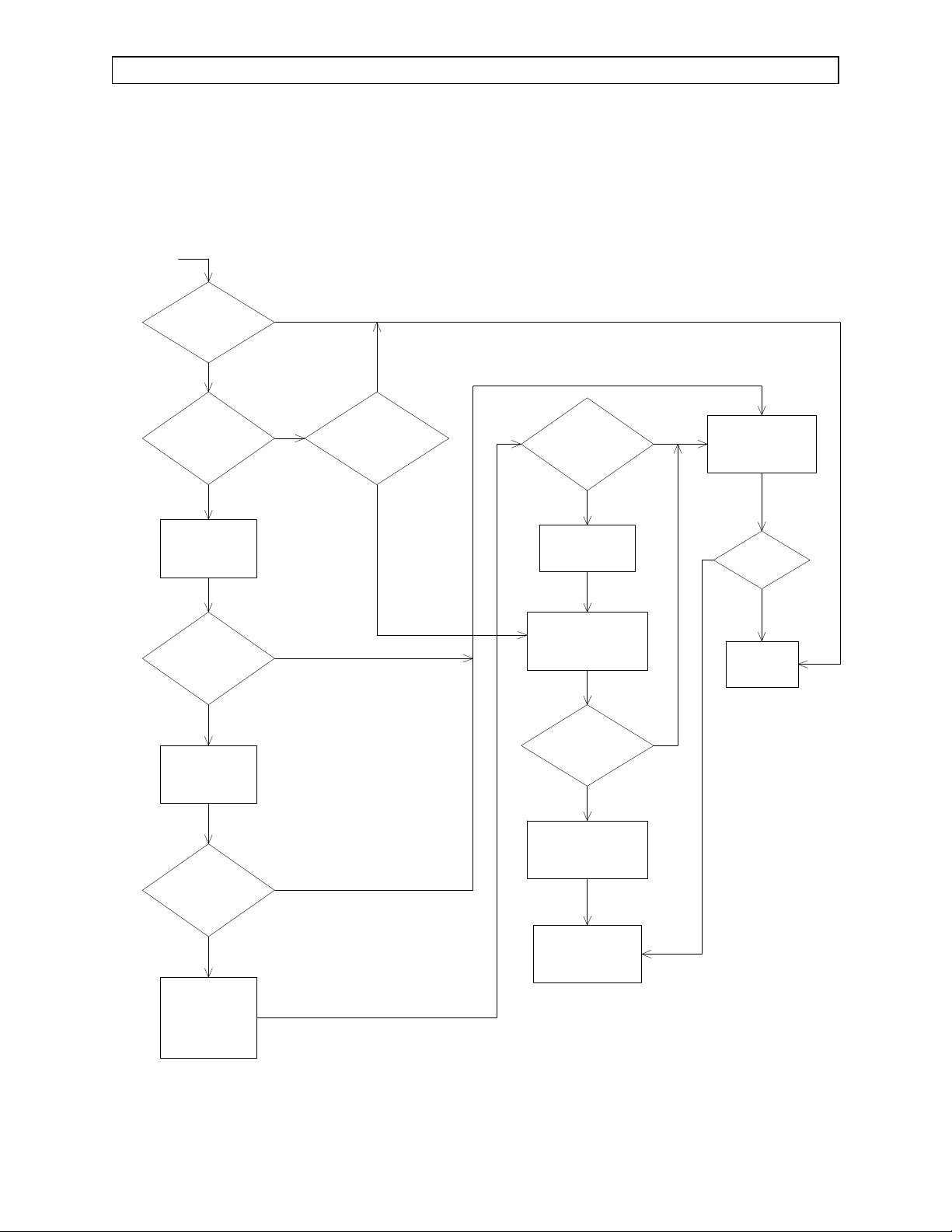

GUIDE 10: No Keypanel Response

START

CONNECT CABLES

TO J1 & J2 ON

PROCESSOR BOARD

ARE

DISPLAY PANEL

KEYS WORKING

PROPERLY?

N

ARE

CABLES

CONNECTED TO J1 & J2

ON PROCESSOR

BOARD?

REPLACE KEYPAD

AS OUTLINED IN

PROCEDURE 4.28

ARE

DISPLAY PANEL

KEYS WORKING

PROPERLY?

Y

N

ARE

DISPLAY PANEL

KEYS WORKING

PROPERLY?

N

Y

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

CONTACT NAD

SERVICE DEPT.

Y

Y

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

Rev. A

N

REINSTALL ORIGINAL

KEYPAD

-----------------------REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.26

3-13

Page 32

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES

4.0 REPLACEMENT PROCEDURES

This section outlines removal and replacement procedures for the field-replaceable

assemblies of the NARKOMED 2B Anesthesia System.

These procedures are to be performed only by a Draeger Medical, Inc. qualified

Technical Service Representative (TSR).

The following are the only procedures authorized by Draeger Medical, Inc. to be

performed in the field. All other service procedures shall be referred to NAD’s

Technical Service Department.

NOTE: The PMS PROCEDURE detailed in Section 6 must be

performed after any replacement, removal, calibration or

adjustment procedure.

Rev. H

4-1

Page 34

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.1 Cylinder Yoke Assemblies

Each cylinder yoke contains a replaceable filter and check valve assembly.

Replacement of this assembly requires that the yoke be removed from the

anesthesia machine. Figure 4-1 shows a typical cylinder yoke mounting

arrangement. Access to the yoke mounting screws and gas line connection

requires that the table top be removed from the machine.

4.1.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.1.2 Close all cylinder valves except the O

valve.

2

4.1.3 Set the oxygen flow to 5 liters per min.

4.1.4 Open the other gas flow control valves to drain pressure from the

system.

4.1.5 Close the O

the O

Flush valve to drain oxygen pressure from the system.

2

cylinder valve, and close the flow control valves. Press

2

4.1.6 Set the System Power switch to STANDBY.

4.1.7 Remove the cylinder where the yoke is to be replaced.

WARNING: Store the cylinder in a safe place and lay it on its side.

4.1.8 Remove the screws holding the table top to the machine and lift out

the table top.

4.1.9 Pull the writing or keyboard tray out to its fully extended position.

4.1.10 Disconnect the gas line fitting at the yoke and remove the two yoke

mounting screws.

4.1.11 Remove the filter and check valve assembly from the yoke and install

a replacement assembly.

NOTE: If the entire yoke assembly is being replaced, ensure that the

replacementyoke has the correct label and pinindexing arrangement.

NOTE: If the yoke spacer is removed from the frame rail of the machine, be

sure to re-install it in its original position.

4-2

Rev. A

Page 35

YOKE

ASSEMBLY

(TYPICAL)

FILTER AND

CHECK VALVE

ASSEMBLY

GAS LINE

YOKE

SPACER

SV40601

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

Figure 4-1: CYLINDER YOKE ASSEMBLY

Rev. J

4-3

Page 36

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.1.12 Position the yoke on the spacer, and install the two mounting screws

and lockwashers. Tighten the screws securely. Connect the gas line

fitting to the yoke.

4.1.13 If a new cylinder is being installed, remove the old sealing washer

from the gas inlet of the yoke and install a new washer.

4.1.14 Install the correct cylinder in the yoke, making sure that the index

pins are properly engaged before tightening the handle bolt. The

cylinder should hang vertically after the handle is tight.

4.1.15 Perform the following leak test on the yoke assembly:

4.1.15.1 Open the cylinder valve and check for a pressure

indication on the corresponding gauge at the gas

instrumentation panel.

NOTE: The cylinder used for this test must

contain the following minimum pressure:

O

N

: 1000 PSI

2

O : 700 PSI

2

HE : 1000 PSI

CO

: 800 PSI

2

AIR : 1000 PSI

N

O

: 1000 PSI

2

-He : 1000 PSI

2

4.1.15.2 Closethe cylinder valve and remove the cylinder from the

yoke.

4.1.15.3 For any gas, the pressure should not drop more than 50

PSI in two minutes.

4.1.16 Re-install the cylinder in the yoke.

4.1.17 Replace the table top and its retaining screws.

4.1.18 Replace the pipeline hoses.

4.1.19 Perform the PMS Procedure given in Section 6.

4-4

Rev. A

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.2 Cylinder Pressure Regulators

Access to the cylinder pressure regulators requires that the table top be

removed from the anesthesia machine. Figure 4-2 shows the mounting

arrangement of the regulators and typical connections.

4.2.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.2.2 Close all cylinder valves except the O

valve.

2

4.2.3 Set the oxygen flow to 5 liters per min.

4.2.4 Open the other gas flow control valves to drain pressure from the

system.

4.2.5 Close the O

the O

Flush valve to drain oxygen pressure from the system.

2

cylinder valve, and close the flow control valves. Press

2

4.2.6 Set the System Power switch to STANDBY.

4.2.7 Remove the cylinder corresponding to the regulator to be replaced.

4.2.8 Remove the screws holding the table top to the machine and lift out

the table top.

4.2.9 Remove the top drawer from the cabinet and pull the writing or

keyboard tray out to its fully extended position.

4.2.10 Disconnect the three compression fittings at the regulator.

4.2.11 Loosen the two setscrews holding the regulator to its mounting

bracket and remove the regulator.

Rev. A

4.2.12 Record the serial number of the regulator that was removed, and

record the serial number of the replacement regulator.

NOTE: If fittings must be installed in the replacement regulator, use Loctite

#271 (red). Refer to the parts list in Section 8.

NOTE: For Canadian machines, verify that the correct relief valve is

installed in the regulator. Refer to the parts list in Section 8 for CSA

items.

4.2.13 Position the replacement regulator in its mounting bracket, and

connect the three compression fittings. Do not tighten the fittings yet.

4-5

Page 38

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

TOP VIEW OF NARKOMED 4

WITH TABLE TOP REMOVED

O CYLINDER

2

PRESSURE

REGULATOR

SET

SCREWS

N O CYLINDER

2

PRESSURE

REGULATOR

AIR OR OPTIONAL

3RD GAS CYLINDER

PRESSURE REGULATOR

TEST GAUGE

CONNECTION

(TYPICAL)

CPR

Figure 4-2: CYLINDER PRESSURE REGULATORS

4-6

SIDE VIEW

ADJUSTMENT

SCREW

ACORN NUT

Rev. J

Page 39

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.2.14 Tighten the regulator mounting setscrews to a torque of 50 to 55 in.

lbs.

4.2.15 Tighten the compression fittings.

4.2.16 Locate the TEE fitting in the ¼ in. diameter regulator output line,

and remove the plug from the TEE fitting.

4.2.17 Set the regulator output pressure in accordance with the Cylinder

Pressure Regulator Adjustment given in Section 5.

4.2.18 Perform the following leak test on the high pressure side of the

regulator:

4.2.18.1 Open the cylinder valve and check for a pressure

indication on the corresponding gauge at the gas

instrumentation panel.

NOTE: The cylinder used for this test must

contain the following minimum pressure:

O

N

: 1000 Psi

2

O : 700 Psi

2

HE : 1000 Psi

CO

: 800 Psi

2

AIR : 1000 Psi

2

: 1000 Psi

N

4.2.18.2 Closethe cylinder valve and remove the cylinder from the

yoke.

4.2.18.3 For any gas, the pressure should not drop more than 50

Psi in two minutes.

4.2.19 Re-install the cylinder in the yoke.

4.2.20 Replace the table top and its retaining screws.

4.2.21 Replace the top drawer in the cabinet.

4.2.22 Connect the pipeline hoses.

Rev. A

4.2.23 Perform the PMS Procedure given in Section 6.

4-7

Page 40

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.3 Cylinder Cutoff Valves (Canada)

Access to the cylinder cutoff valves requires removal of the table top from the

anesthesia machine. Figure 4-3 shows the locations of the O

andN

Ocutoff valve assemblies. The instructions apply to all three assemblies.

2

, Air or 3rd gas,

2

On earlier machines the tubing arrangement may be slightly different from

that illustrated.

NOTE: Replacement of the O

Cutoff Valve Assembly shall be performed every

2

24 months. Documentation shall be created by the service person and a copy

distributed to the owner institution. Testing of the O

Cutoff Valve shall be

2

performed at each PMS. (Perform the flow test given at the end of the

following procedure)

4.3.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.3.2 Close all cylinder valves except the O

valve.

2

4.3.3 Set the oxygen flow to 5 liters per min.

4.3.4 Open the other gas flow control valves to drain pressure from the

system.

4.3.5 Close the O

the O

Flush valve to drain oxygen pressure from the system.

2

cylinder valve, and close the flow control valves. Press

2

4.3.6 Set the System Power switch to STANDBY.

4.3.7 Remove the screws holding the table top to the machine and lift out

the table top.

4.3.8 Remove the top drawer from the cabinet and pull the writing or

keyboard tray out to its fully extended position.

4.3.9 Disconnect the compression fittings indicated at points marked C on

the illustration.

4.3.10 Cut the tie-wrap clamp and disconnect the flexible tubing from the

cutoff valve assembly at the point marked A on the illustration.

NOTE: On later machines with assemblies that have brass fittings instead

of nylon, the flex tubing is attached with a press-on hose clamp

instead of a tie strap.

4.3.11 Remove the cylinder cutoff assembly.

4.3.12 Connect the flexible tubing to the replacement cutoff valve assembly

and secure it with a new tie-wrap clamp.

4-8

Rev. D

Page 41

SV50526

O2 CYLINDER

CUTOFF VALVE

ASSEMBLY

AIR OR 3RD GAS

CYLINDER

CUTOFF VALVE

ASSEMBLY

N2O CYLINDER

CUTOFF VALVE

ASSEMBLY

A

C

C

C

A

C

C

C

C

A

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

Figure 4-3: CYLINDER CUTOFF VALVES (CANADA)

Rev. J

4-9

Page 42

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.3.13 Connect and tighten the compression fittings at points marked C on

the illustration.

4.3.14 Perform the following test: --Remove the plug from the test gauge

connection at the Tee fitting in the regulator outlet piping, and install

a test gauge.

NOTE: The cylinders used for this test must contain the following minimum

pressure: O

O

: 1000 PSI AIR : 1000 PSI

2

+He : 1000 PSI N2O : 745 PSI

2

--Set the System Power switch to ON.

--For the O

cutoff valve: open the O2cylinder valve and set the oxygen flow to

2

4 liters per min.

--For the N

O cutoff valve: open the O2cylinder valve and the N2O cylinder

2

valve. Set each flow to 4 liters per min.

--Verify that regulator outlet pressure is between 43 and 49 PSI.

--Connect the pipeline hoses and pressurize to 50 PSI.

--Turn off the pipeline supply and observe the pipeline pressure gauge.

--The cutoff valve shall open when the pipeline pressure drops through the

range of 45 to 40 PSI.

--Close the cylinder valve(s), and close the flow control valve(s).

--Disconnect test pressure gauge and reinstall the plug in the regulator outlet

piping.

4.3.15 Replace the table top and its retaining screws.

4.3.16 Replace the top drawer in the cabinet.

4.3.17 Connect the pipeline hoses.

4.3.18 Perform the PMS Procedure given in Section 6.

O

Flow Test:

2

--Disconnect all pipeline supplies.

--Install a full O2cylinder on the machine, and open the cylinder valve.

--Turn the System Power switch to ON.

--Set the Inspiratory Flow control to maximum high, and turn the ventilator switch to ON.

--Set the oxygen flow to 10 l/min.

--Verify that the oxygen flow does not drop below 8 l/min. while the ventilator is running.

--Press and hold the O2FLUSH button while observing the O2flowmeter, and verify that the

oxygen flow does not drop below 8 l/min.

--If the oxygen flow in either of the above two steps drops below 8 l/min., replace the O2cutoff

valve assembly.

4-10

Rev. D

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.4 Cylinder and Pipeline Pressure Gauges

Replacement of the cylinder and pipeline pressure gauges requires that the

plexiglass front cover be removed from the gas instrumentation panel, and also

the rear cover for access to the gauge connections. Figure 4-4 shows

disassembly and mounting details.

4.4.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.4.2 Close all cylinder valves except the O

valve.

2

4.4.3 Set the oxygen flow to 5 liters per min.

4.4.4 Open the other gas flow control valves to drain pressure from the

system.

4.4.5 Close the O

the O

Flush valve to drain oxygen pressure from the system.

2

cylinder valve, and close the flow control valves. Press

2

4.4.6 Set the System Power switch to STANDBY.

4.4.7 Remove the screws holding the rear cover, and remove the cover.

4.4.8 Remove the screws holding the table top to the machine and lift out

the table top.

4.4.9A Early models: Remove the two screws (from the back) holding the

front plate at the top of the plexiglass cover. Hold the front plate as

the screws are removed from the back.

4.4.9B Later models (without the O

O ratio alarm lamp): Remove the six

2/N2

screws holding the flowmeter shield and vapor box cover panel, and

remove the panel.

Rev. A

4.4.10 Remove the O

flow control knob. The knob has two setscrews.

2

NOTE: If the knob must be rotated to allow access to a setscrew,

carefully note its position so that it can be re-assembled

in the same position with the "Off Stop" properly set.

4.4.11 Remove the two screws holding the knob guard in place, and remove

the knob guard. (For earlier machines with the bar-type knob guard,

the screws holding the guard assembly are accessible through the

back of the flowmeter housing.)

4.4.12 Remove the screws holding the plexiglass cover over the flow tubes

and gauges, and carefully remove the cover.

4-11

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

REAR VIEW OF

FLOWMETER HOUSING

WITH REAR COVER REMOVED

FRONT COVER

RETAINER SCREWS

FLEXIBLE

TUBING

CONNECTION

(PIPELINE

PRESSURE

GAUGES)

COMPRESSION FITTING

(CYLINDER PRESSURE GAUGES)

GAUGE

MOUNTING

NUTS (TYPICAL)

SV40644

Figure 4-4: CYLINDER AND PIPELINE PRESSURE GAUGES

4-12

Rev. J

Page 45

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

NOTE: Intermediateassemblies may need to be removed to allow

access to the gauge connections and mounting hardware.

Be sure to keep a record of the disassembly sequence so

that all tubing can be correctly re-assembled.

4.4.13A For the cylinder pressure gauges:

Disconnect the compression fitting at the back of the gauge.

Remove the gauge mounting nuts, and remove the gauge from

the front of the panel.

Install the replacement gauge in the panel using the flat

washers, lock washers and mounting nuts that were previously

removed.

Connect the gas line to the gauge and tighten the compression

fitting.

4.3.13B For the pipeline pressure gauges:

Locate the flexible tubing connecting the gauge to the pipeline

inlet assembly, cut the tie-wrap tubing clamp at the pipeline

inlet and disconnect the tubing.

NOTE: Onlater machines that have brass fittings instead

of nylon, the flex tubing is attached with a presson hose clamp instead of a tie strap.

Remove the gauge mounting nuts, and remove the gauge from

the front of the panel.

Cut the tie-wrap tubing clamp and disconnect the flexible tubing

from the gauge.

Connect a new 7-inch length of tubing (8-inch for the air pipeline

pressure gauge) to the replacement gauge and secure it with a

new tie-wrap clamp.

Place the gauge in the panel and secure it with the flat washers,

lock washers and mounting nuts that were previously removed.

Rev. C

Connect the other end of the flexible tubing to the pipeline inlet

assembly and secure it with a tie-wrap clamp.

4.4.14 If a cylinder pressure gauge was replaced, perform the following leak

test:

4-13

Page 46

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.4.14.1 Open the cylinder valve and check for a pressure

indication on the corresponding gauge at the gas

instrumentation panel.

NOTE: The cylinder used for this test must

contain the following minimum pressure:

O

N

: 1000 PSI

2

O : 700 PSI

2

HE : 1000 PSI

CO

: 800 PSI

2

AIR : 1000 PSI

N

O

: 1000 PSI

2

-He : 1000 PSI

2

4.4.14.2 Closethe cylinder valve and remove the cylinder from the

yoke.

4.4.14.3 For any gas, the pressure should not drop more than 50

PSI in two minutes.

4.4.15 Reinstall the cylinder in the yoke.

4.4.16 Place the plexiglass cover over the gauges and flow tubes, and

reinstall the cover screws. Do not over-tighten these screws as the

plexiglass may crack.

4.4.17 Place the knob guard over the flow control valves and install its two

retaining screws. (Reinstall the bar-type knob guard on earlier

machines.)

4.4.18 Reinstall the O

knob is installed properly, the O

flow control knob and tighten its setscrews. If the

2

label will be straight when the knob

2

is against its clockwise stop.

4.4.19 Replace the front plate at the top of the plexiglass cover and secure

it with the hardware that was previously removed.

4.4.20 Replace the rear cover and its retaining screws.

4.4.21 Replace the table top and its retaining screws.

4.4.22 Connect the pipeline hoses.

4.4.23 Perform the PMS Procedure given in Section 6.

4-14

Rev. A

Page 47

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.5 Flowmeters

The flowmeter tubes are held by compression in gaskets at the top and bottom

of each tube. Each upper gasket is seated in an adjustable retainer that allows

removal of the tube as shown in Figure 4-5. Access to the flow tubes and their

retainers requires removal of the plexiglass cover on the gas instrumentation

panel.

4.5.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.5.2 Close all cylinder valves except the O

valve.

2

4.5.3 Set the oxygen flow to 5 liters per min.

4.5.4 Open the other gas flow control valves to drain pressure from the

system.

4.5.5 Close the O

the O

Flush valve to drain oxygen pressure from the system.

2

cylinder valve, and close the flow control valves. Press

2

4.5.6 Set the System Power switch to STANDBY.

4.5.7 Remove the screws holding the table top to the machine and lift out

the table top.

4.5.8 Early models: Remove the flowmeter housing rear cover.

4.5.9A Early models: Remove the two screws (from the back) holding the

front plate at the top of the plexiglass cover. Hold the front plate as

the screws are removed from the back.

4.4.9B Later models (without the O

O ratio alarm lamp): Remove the six

2/N2

screws holding the flowmeter shield and vapor box cover panel, and

remove the panel.

Rev. A

4.5.10 Remove the O

flow control knob. The knob has two setscrews.

2

NOTE: If the knob must be rotated to allow access to a setscrew,

carefully note its position so that it can be re-assembled

in the same position with the "Off Stop" properly set.

4.5.11 Remove the two screws holding the knob guard in place, and remove

the knob guard. (For earlier machines with the bar-type knob guard,

the screws holding the guard assembly are accessible through the

back of the flowmeter housing.)

4.5.12 Remove the screws holding the plexiglass cover over the flow tubes

and gauges, and carefully remove the cover.

4-15

Page 48

FLOW TUBE

RETAINE R SC REW

UPPER FLOW

TUBE RETAINER

FLOW TUBE

LIGHTING CHANNEL

FLOW

RESTRICTOR

SV40605

GASKET

GUIDE RING

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

Figure 4-5: FLOWMETERS

4-16

Rev. J

Page 49

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.5.13 Loosen the screw directly above the flowmeter tube to be replaced.

Turning the screw counter clockwise will raise the upper flow tube

retainer. Raise the retainer far enough to be able to pull the top of

the tube outward, and remove the tube.

NOTE: If the bottom of the tube is seated in a flow restrictor, be

sure that the arrangement of the restrictor and its

gaskets is not disturbed.

4.5.14 Make sure that the replacement flow tube bears the correct markings

and has a ball.

4.5.15 Place the bottom of the flowmeter tube into the guide ring of the

lower gasket seal, and position the top of the flow tube into the center

guide ring of the top gasket seal. It will be easier to hold the tube if

the adjacent lighting channel is pulled forward and temporarily

removed.

CAUTION: The flowmeter tube must be properly centered over the

guide rings or damage to the flowmeter tube may occur.

4.5.16 Ensure that the markings on the flow tube are facing forward, and

turn the upper retainer screw clockwise until the flow tube is firmly

held in place.

CAUTION: Do not over-tighten the screw as the flowmeter tube may

break.

4.5.17 Perform the following leak test on the system:

4.5.17.1 Disconnect the absorber hose from the freshgas outlet.

4.5.17.2 Connecta test gauge and B.P. bulb to the freshgas outlet,

and pressurize the system to 50 cm H

4.5.17.3 The pressure should not drop more than 10 cm H

2

O.

Oin

2

thirty seconds.

4.5.18 Disconnect the test gauge and re-connect the absorber hose to the

freshgas outlet.

Rev. A

4.5.19 Replace any lighting channels that were previously removed.

4-17

Page 50

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.5.20 Place the plexiglass cover over the gauges and flow tubes, and

reinstall the cover screws. Do not over-tighten these screws as the

plexiglass may crack.

4.5.21 Place the knob guard over the flow control valves and reinstall its two

retaining screws. (Reinstall the bar-type knob guard on earlier

machines.)

4.5.22 Reinstall the O

knob is installed properly, the O

flow control knob and tighten its setscrews. If the

2

label will be straight when the knob

2

is against its clockwise stop.

4.5.23 Replace the front cover plate at the top of the plexiglass cover and

secure it with the hardware that was previously removed.

4.5.24 If applicable, replace the flowmeter housing rear cover.

4.5.25 Replace the table top and its retaining screws.

4.5.26 Connect the pipeline hoses.

4.5.27 Perform the PMS Procedure given in Section 6.

4-18

Rev. A

Page 51

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.6 Flow Control Valves

The flow control valves have replaceable elements that are removable from the

front of the gas instrumentation panel as shown in Figure 4-6. Each flow

control knob has a clockwise positive stop arrangement that prevents damage

to the valve seat. Whenever a valve cartridge is replaced, the "off stop" must

be set as outlined in the following procedure.

4.6.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.6.2 Close all cylinder valves except the O

valve.

2

4.6.3 Set the oxygen flow to 5 liters per min.

4.6.4 Open the other gas flow control valves to drain pressure from the

system.

4.6.5 Close the O

Flush valve to drain oxygen pressure from the system.

O

2

cylinder valve and the O2flow control valve. Press the

2

4.6.6 Set the System Power switch to STANDBY.

4.6.7 Remove the O

flow control knob, and the knob on the valve to be

2

replaced.

4.6.8 Remove the two screws holding the knob guard in place, and remove

the knob guard. (For earlier machines with the bar-type knob guard,

the screws holding the guard assembly are accessible through the

back of the flowmeter assembly.)

4.6.9 Remove the stop pin nut.

4.6.10 Remove the flow control valve by holding it at the wrench flats and

turning it counter-clockwise.

Rev. A

4.6.11 Install the replacement flow control valve in the valve housing.

CAUTION: Before tightening the cartridge, rotate the valve shaft

several turns counter-clockwise to prevent bottoming the

valve element into the seat when the cartridge is

tightened.

4.6.12 Replace the stop pin nut.

4.6.13 Replace the knob guard and secure it with the two mounting screws.

(Replace the bar-type knob guard on earlier machines.)

4-19

Page 52

VALVE

HOUSING

FLOW CO NT ROL

VALVE

WRENCH

FLATS

KNOBLABEL

SV20606

STOP PIN

NUT

KNOB GUARD

(NEW STYLE)

KNOB GUARD

(OLD STYLE)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

Figure 4-6: FLOW CONTROL VALVES

4-20

Rev. J

Page 53

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2B REPLACEMENT PROCEDURES (continued)

4.6.14 Set the System Power switch to ON.

4.6.15A For the O

flow control valve:

2

Open the oxygen cylinder valve.

Turn the flow control valve clockwise until the flow rate will not

drop any further. (If the machine has been modified to eliminate

the minimum flow feature, turn the valve until the flow rate is

zero.)

4.6.15B For the other gas flow control valves:

Open the oxygen cylinder valve, and open the cylinder valve

corresponding to the flow control valve replacement.

Set the oxygen flow rate to four liters per minute.

Turn the other gas flow control valve clockwise until the flow

rate is zero.

4.6.16 Place the knob on the flow control valve shaft and turn it clockwise

until it engages the stop pin. Tighten one of the knob setscrews.

4.6.17 Turn the knob in both directions and ensure that the flow can be

controlled over its entire range. When the valve is closed, the knob

should be against the clockwise stop. Tighten the remaining setscrew.

4.6.18 If the knob label is not horizontal when the valve is closed, remove

the label and install a new label in the correct position.

4.6.19 Connect the pipeline hoses.

4.6.20 Perform the PMS Procedure given in Section 6.

Rev. A

4-21

Page 54

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) NM2B

4.7 Oxygen Supply Pressure Failure Protection Device

The oxygen supply failure protection devices (failsafe assemblies) are located

behind the gas instrumentation panel. Access to these assemblies requires

removal of the rear cover. For earlier machines, replacement assemblies are

supplied with all hardware out to the first compression fitting in each line.

On later machines with flowmeter assemblies having an Oxygen Ratio

Controller (ORC), failsafe assemblies have an additional inlet port that allows

both pipeline and cylinder supplies to be connected directly to the failsafe

assemblies. Figure 4-7 shows the arrangement for both types of assemblies.

4.7.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.7.2 Close all cylinder valves except the O

valve.

2

4.7.3 Set the oxygen flow to 5 liters per min.

4.7.4 Open the other gas flow control valves to drain pressure from the

system.

4.7.5 Close the O

Flush valve to drain oxygen pressure from the system.

O

2

cylinder valve and the O2flow control valve. Press the

2

4.7.6 Set the System Power switch to STANDBY.

4.7.7 Remove the screws holding the rear cover, and remove the cover.

4.7.8 Cut the tie-wrap clamp on the flexible O

control line, and disconnect

2

the flexible tube.

NOTE: On later machines with assemblies that have brass fittings instead

of nylon, the flex tubing is attached with a press-on hose clamp

instead of a tie strap.