Drytac JetMounter JM63 Fuzion XD, JetMounter JM55 Force Operator's Manual

Operator’s Manual

JetMounter™ JM63 Fuzion XD

The JM63 Fuzion XD is a heavy-duty, wide-format roller laminator with a heat assist top roller. Excellent for

laminating vehicle wraps, creating window decals and mounting graphics to substrates, it is ideal for shops

wanting to add roll-to-roll laminating capabilities at a lower price point. Standard features include heavyduty metal construction, large diameter non-stick silicone rollers, variable speed control, fold down front

table, built-in fl ip open storage compartments, top and bottom auto-grip supply shafts with brake tension

control on operator side, top auto-grip take-up shafts with adjustable clutch speed, single mechanical

height/pressure adjustment, interchangeable 110V or 220V electrical confi guration, and photocell safety

protection.

WWW.DRYTAC.COM

Rev February 2017

USA 800.280.6013 CANADA 800.353.2883

Operator’s Manual

Contents

Overview .................................................................................................................................................................... 1

Warranty ..................................................................................................................................................................... 2

Registration Information ............................................................................................................................................. 3

Important Safety Information .....................................................................................................................................4

Safety Symbols.................................................................................................................................................................4

Safety Features ................................................................................................................................................................ 6

Setup Procedures .......................................................................................................................................................7

Installation and Training Service ......................................................................................................................................7

Unpacking and Installation ..............................................................................................................................................7

Power Supply ...................................................................................................................................................................7

Parts Identifi cation ...........................................................................................................................................................8

Setting Roller Pressure ..................................................................................................................................................11

Adjusting Supply and Take-up Shaft Tensions ..............................................................................................................12

Mounting Applications ..............................................................................................................................................13

Selecting Mounting Board and Adhesive ......................................................................................................................13

Pre-Coating Mounting Board ........................................................................................................................................13

Mounting Graphics to Pre-Coated Boards ....................................................................................................................14

Laminating Applications ............................................................................................................................................16

Selecting Pressure Sensitive Overlaminating Film.........................................................................................................16

Laminating Single Unmounted Image ...........................................................................................................................16

Laminating Single Mounted Image ...............................................................................................................................17

Laminating Multiple Mounted Images ..........................................................................................................................18

Using a Leader Board ....................................................................................................................................................19

Carrier Boards and Preparing Mounting Board ............................................................................................................19

Care & Maintenance .................................................................................................................................................20

Roller Alignment Instructions .................................................................................................................................... 21

JetMounter JM63 Fuzion XD Operation Sequence .................................................................................................. 23

JetMounter JM63 Fuzion XD Schematic ...................................................................................................................24

WWW.DRYTAC.COM

USA 800.280.6013 CANADA 800.353.2883

Operator’s Manual

Overview

Thank you for purchasing a Drytac® JetMounter™ JM63 Fuzion XD. The information contained in this Operator’s

Manual will explain the basic methods of mounting and laminating with this easy-to-use roller laminator.

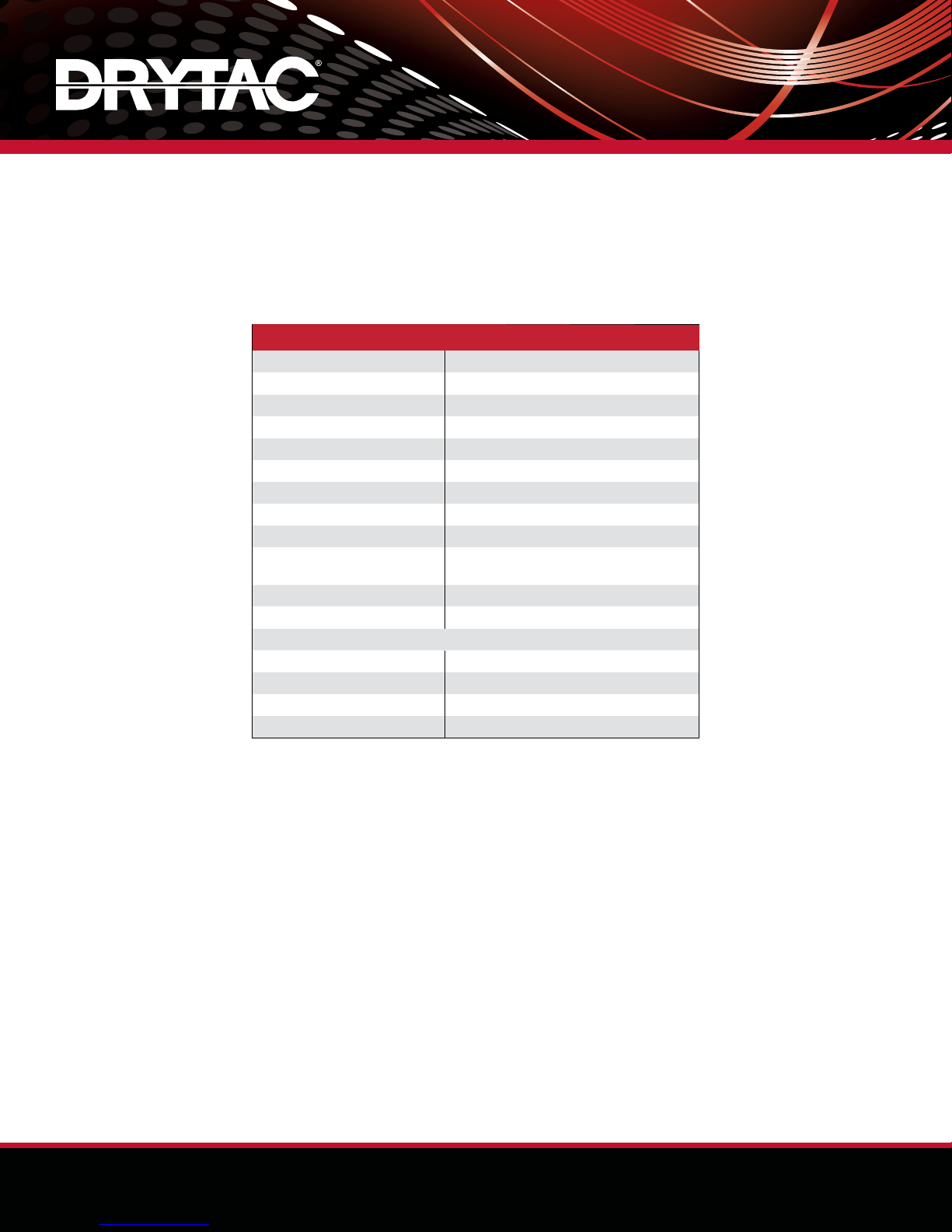

JM63 FUZION XD Technical Specifi cations

Max Laminating Width 63” (1600mm)

Roller Diameter 4.7” (120mm)

Roller Construction Steel with High-Release Silicone Covering

Width 81.5” (2070mm)

Depth 28” (711mm)

Height 50.5” (1282mm)

Weight 752 lbs (341 kg)

Max Board Thickness 1” (25mm)

Max Material Roll Diameter 10” (254mm)

Electrical Requirements Dual Voltage: 110V, 8A or

Single Phase: 220V, 13A, 50/60Hz***

Speed Range 1 - 20 fpm (0.5 - 6 mpm)

Roll Core Size 3” (76mm)

Packaged for Shipment

Width 85” (2159mm)

Depth 34” (864mm)

Height 56” (1422mm)

Weight 875 lbs (397 kg)

The Infeed/Outfeed Table height of the JM63 Fuzion XD is 35.25” (895mm).

*** A power cord is provided for a standard 110V circuit. If a 220V circuit is needed, the customer is responsible for providing the

proper power cord and outlet to meet electrical requirements.

1

Operator’s Manual

Warranty

Every Drytac machine is designed and manufactured to provide years of dependable service. To achieve the best

results, the machine should be set up and operated in accordance with the instructions provided in its corresponding

Operator’s Manual.

Our equipment warranty covers parts for twelve (12) months and labor for three (3) months from the date of

purchase. During the fi rst three months of the warranty period, Drytac or its dealer will arrange for the machine to be

repaired, replaced or refunded at Drytac’s discretion (excluding shipping and travel costs). Rollers are guaranteed

against manufacturing defects for three (3) months.

Return your warranty card to Drytac as soon as possible. By doing so, we will be able to more effi ciently address your

concerns in the unlikely event that you encounter an issue. You will fi nd a section in the Operator’s Manual for recording

this important information and for noting any future parts or service requests.

Normal wear and tear, damage to the rollers, and damage due to abuse, improper operation or installation is not

covered by this warranty. Conditions that will void the warranty include, but are not limited to:

• Failure to follow the instructions contained in the Operator’s Manual

• Unauthorized changes or modifi cations to the equipment or the stand

• Misuse of the equipment for purposes other than specifi ed in the Operator’s Manual

Drytac will not be held responsible for any damage or consequential damage caused by the equipment. After the

warranty period has expired, Drytac will provide all reasonable product assistance and support to resolve any problems

that may arise.

Before calling the Drytac Technical Services department, note the Registration Information for your machine and have it

available for reference.

2

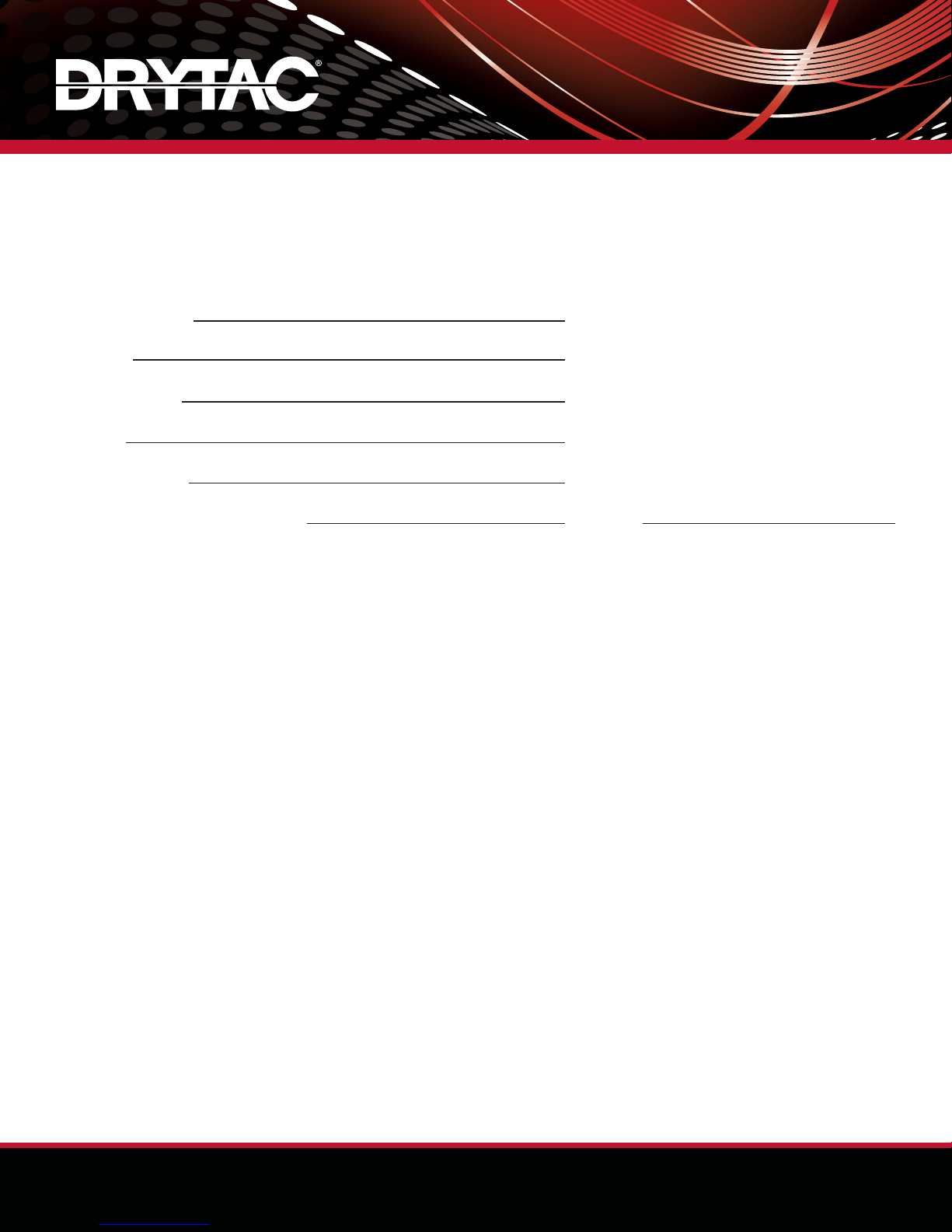

Registration Information

JetMounter™ JM63 Fuzion XD Registration Information

COMPANY NAME:

ADDRESS:

CITY, STATE, ZIP:

SERIAL #:

PURCHASE DATE:

WARRANTY CARD RETURN DATE: BY:

Operator’s Manual

USA

Drytac Corporation

5601 Eastport Boulevard

Richmond, VA 23231

+1 800-280-6013

+1 804-222-3094

customerservice@drytac.com

CANADA

Drytac Canada, Inc.

105 Nuggett Court

Brampton, Ontario L6T 5A9

+1 800-353-2883

+1 905-660-1748

toronto@drytac.com

3

Operator’s Manual

Important Safety Information

Before operating the JetMounter™ JM63 Fuzion XD for the fi rst time, read and understand the following safety-related

information. Failure to follow these procedures may result in serious personal injury and/or damage to the equipment

and materials being used.

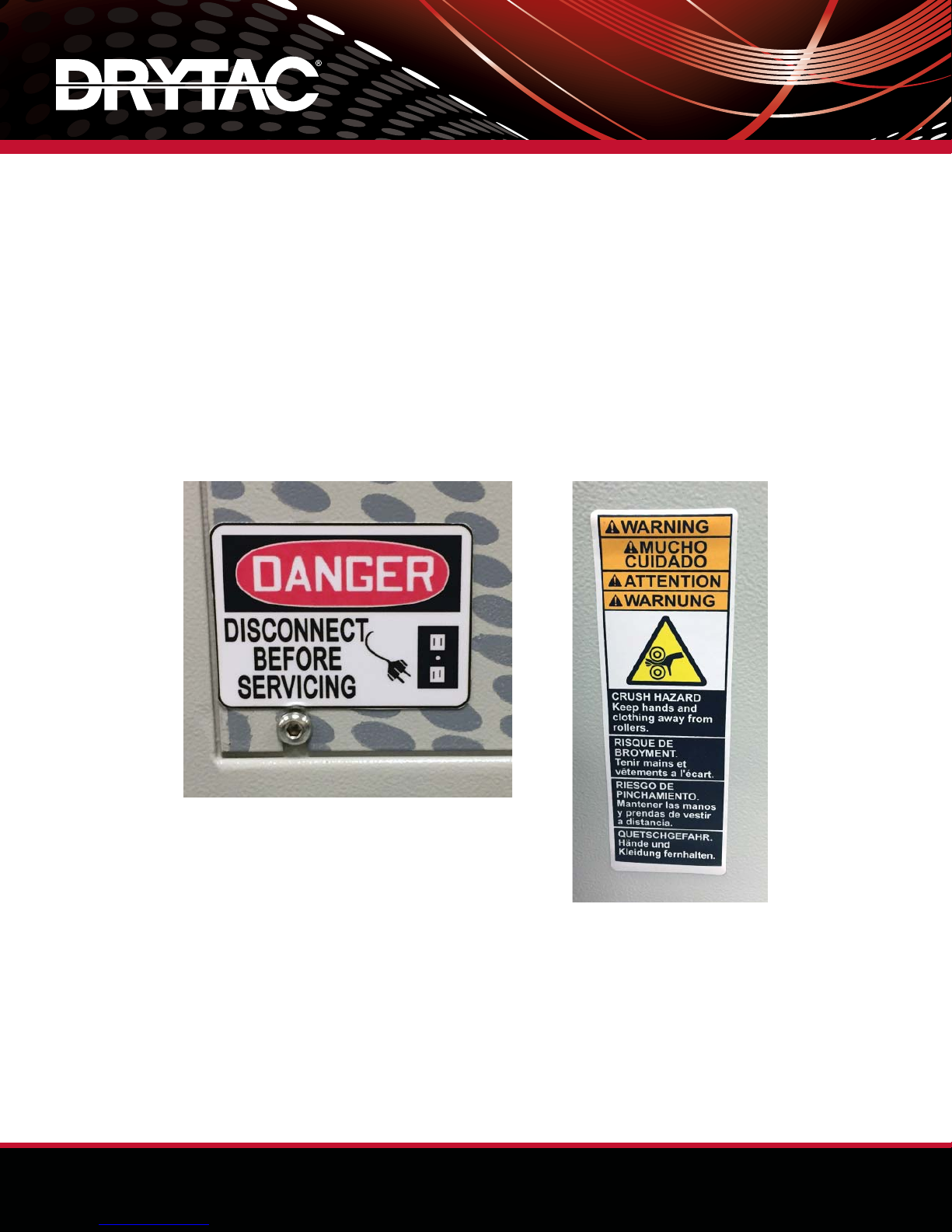

Safety Symbols

Danger and/or warning symbols indicate imminently and/or potentially hazardous situations that, if not avoided, may

result in serious injury or death.

4

Operator’s Manual

Important Safety Information

The JetMounter™ JM63 Fuzion XD performs mounting and laminating applications by using two

rollers to apply uniform pressure to mounting adhesives and overlaminating fi lms. The point where

the rollers touch these materials is called the “Nip”. This area creates a potential pinch hazard for

fi ngers or other objects. TO AVOID INJURY, ALWAYS KEEP YOUR FINGERS AWAY FROM THE

NIP AREA.

When using a large supply roll, be aware that a pinch hazard may exist between the top roller and

the supply shaft. When working from the rear of the machine, be aware of the pinch point (Nip) of

the contacting rollers and exercise extreme caution to avoid injury.

Exercise caution when lifting rolls of adhesive or laminate due to their weight. Obtain assistance to

avoid personal injury or damage to the equipment and materials.

No persons under the age of 16 should be allowed to operate the equipment.

DO NOT operate the equipment while under the infl uence of alcohol, prescription drugs or any other substance that

could impair your judgment or reaction time.

Remove any jewelry such as rings, bracelets and necklaces prior to operating the equipment. Keep loose clothing,

neckties, artifi cial fi ngernails, long hair, and anything else that might easily be drawn into the rollers away from the

machine.

Always work at a slow speed until you become familiar with the equipment.

Power “Off” the machine when loading rolls of adhesive or laminate, cleaning the rollers, or performing other activities

that require close proximity of fi ngers to the Nip area. Doing so will prevent the machine’s rollers from inadvertently

turning. During machine operation, keep fi ngers away from the Nip area.

Always disconnect the equipment from the power supply before removing any panels for

service.

5

Operator’s Manual

Important Safety Information

Safety Features

The following safety features are designed to offer a reasonable measure of protection against injury while maintaining

an operator-friendly machine. Please do not attempt to disable or alter their functionality in any way. Any modifi cations

will void the warranty and may pose a serious risk to the operator. If any malfunction occurs, stop using the

machine immediately and contact the Drytac Technical Services department.

The JM63 Fuzion XD has electric eyes or photocells installed in front of the Nip area for safety. When interrupted,

they will stop the rollers immediately, a photocell status LED on the Control Panel will light up, and a buzzer will sound

as a warning to indicate that an object is breaking the photocell circuit. Be particularly cautious when operating the

equipment with the Foot Pedal as the rollers WILL NOT STOP when the photocells are interrupted. An audible alarm

will sound, but the rollers will continue to turn at a reduced speed.

Prior to operating the equipment, always check that the photocells and buzzer are working properly. Use a piece of

cardboard to block the photocells to confi rm that the alarm sounds and the rollers stop.

The JM63 Fuzion XD is also equipped with two red Emergency Stop Buttons, located on the top of both the left and

right end cases. The Emergency Stop Buttons will stop the machine immediately, shutting off power to the Control

Panel. The machine can also be stopped by lifting your foot off the Foot Pedal, turning the Speed Control Knob to zero

(0), turning off the Power Button on the Control Panel, or turning off the main Power Switch on the back of the left

end case. If there is a “No Power” condition, check to see if the Emergency Stop Buttons are depressed before further

troubleshooting.

6

Loading...

Loading...