Drytac Jet Mounter JM18, Jet Mounter JM26, Jet Mounter JM34, Jet Mounter JM44, Jet Mounter JM44 SHA Operator's Manual

...

COLD-MOUNT LAMINATOR SERIES

OPERATORS MANUAL

Models: JM18, JM26, JM34, JM44, JM44 SHA, JM54, JM54SHA

Manual Version 13-08-10

2

Copyright © 2006 Drytac Corporation / Revised © 2008 Drytac Corporation

All rights reserved. No part of this publication may be utilized or reproduced in a retrieval system, or

transmitted in any form or by any means; electronic, mechanical, photocopying, recording, or

otherwise,

without prior written permission from Drytac Corporation.

3

Welcome to the World of Drytac

Over the past three decades, Drytac has evolved into one of the world‟s most highly

regarded manufacturers of products for graphics finishing and display. Our core product line

consists of a wide range of pressure-sensitive, heatset and thermal overlaminating films. In

addition, we offer an extensive line of mounting adhesives, backing films, inkjet media,

finishing equipment, accessories, and banner stands.

4

Our “Start To Finish” strategy sums up Drytac‟s unique ability to manage all phases of the

customer experience: product quality and performance, manufacturing and distribution,

training and technical support and the industry‟s best customer service.

Jet Mounter™ Professional Quality Entry-Level Models

JM18, JM26, and JM34

These solid mid-size models deliver superior results for beginners and experienced users

alike. Easy to set up and operate, the JM18‟s and JM26‟s are widely used by photography

studios, picture framers, digital art studios and other creative shops, and our newest model

the JM34 are sure to also be as popular. Standard features include: all-steel construction,

variable speed electric drive, forward and reverse, foot pedal control, silicone rollers, photoelectric safety stop and supply shaft.

Since all three models have many of the same features, consider references in this manual

pertaining to the JM26 to be applicable to the JM18 and the JM34.

Jet Mounter™ Wide Format Laminators

Drytac‟s Pressure-Sensitive Cold-Mount Models deliver economy and versatility for graphics

finishing. The JetMounter™ motorized laminator series is engineered by Drytac to deliver a

combination of performance and value unequalled in the finishing industry. Compatible with

any pressure-sensitive overlaminating film, JetMounters are also ideal for permanently

mounting graphics onto cardstock, foam board, MDF or rigid PVC board.

All electric models include variable-speed electric drive, silicone rollers, all-steel

construction, forward and reverse, supply shaft, foot pedal and photo-electric safety stop.

The three heavy-duty wide-format models, (JM44, JM54, and the new JM63) are the

culmination of our three decades in the mounting and laminating business. Equipped with

the performance features our customers demand, JetMounter™ wide format models are

unmatched for value.

5

Table of Contents

Overview .......................................................................................................................... 6

Important Safety Information ......................................................................................... 6

Specific Moving Instructions .................................................................................. 10

Unpacking and Installation..................................................................................... 11

JM Components .................................................................................................... 12

Component Illustrations ........................................................................................ 14

Setting Roller Pressure .......................................................................................... 15

JM44SHA/JM54SHA Roller Pressure Adjustment ................................................. 16

Adjusting Shaft Tensions ....................................................................................... 17

Mounting With the JetMounter™ Laminators

Mounting Board Selection...................................................................................... 18

Adhesive Selection ................................................................................................ 18

Pre-coating the Mounting Board ............................................................................ 18

Mounting a Graphic to a Pre-Coated Board ........................................................... 20

Laminating with the JetMounter™ Laminators

Selecting a Laminate Film ..................................................................................... 21

Single Unmounted Graphic .................................................................................... 22

Single Mounted Graphic ........................................................................................ 23

Laminating Multiple Mounted Images .................................................................... 24

Using a Leader Board ............................................................................................ 25

Carrier Boards ................................................................ ....................................... 26

Preparing Mounting Boards ................................................................................... 26

Care and Maintenance .................................................................................................... 27

Service .................................................................................................................. 28

Technical Specifications ........................................................................................ 29

Contact Information ............................................................................................... 30

Warranty .......................................................................................................................... 31

Appendix

Replacement Parts ................................................................................................ 32

B Revision Functional Requirements ..................................................................... 33

JM44SHA/JM54SHA Nip Adjustment Procedure ......................................................34

6

Overview

Thank you for purchasing a Drytac JetMounter™ Cold Mount Laminator. The information

contained in this manual will familiarize you with the basic methods of mounting and

laminating using this easy-to-use two roller laminator. This manual covers five JetMounter™

models:

Model

Width

Maximum Laminate

JM18

25.5” (64.8 cm)

18.25” (46.4 cm)

JM26

33.25” (84.5 cm)

26.25” (66.7 cm)

JM34

TBA

TBA

JM44/JM44SHA

52.75” (134.0 cm)

44.125” (112.1 cm)

JM54/54SHA

62.5” (135.3 cm)

54.125” 137.5 cm)

These models are similar in operation, but not identical. Unless otherwise indicated, the

instructions are for the JM26 model. Specific comments regarding the JM44, JM54 and

JM54SHA models are made where differences occur.

Important Safety Information

Before operating this equipment for the first time, it is crucial that you take the time to read

and understand all of the following safety-related information. Failure to follow these

procedures could result in serious personal injury and/or damage to the equipment and work

piece.

Safety Signal Words and Symbols

Danger symbols indicate imminently hazardous situations that, if not avoided, will result in

serious injury or death.

7

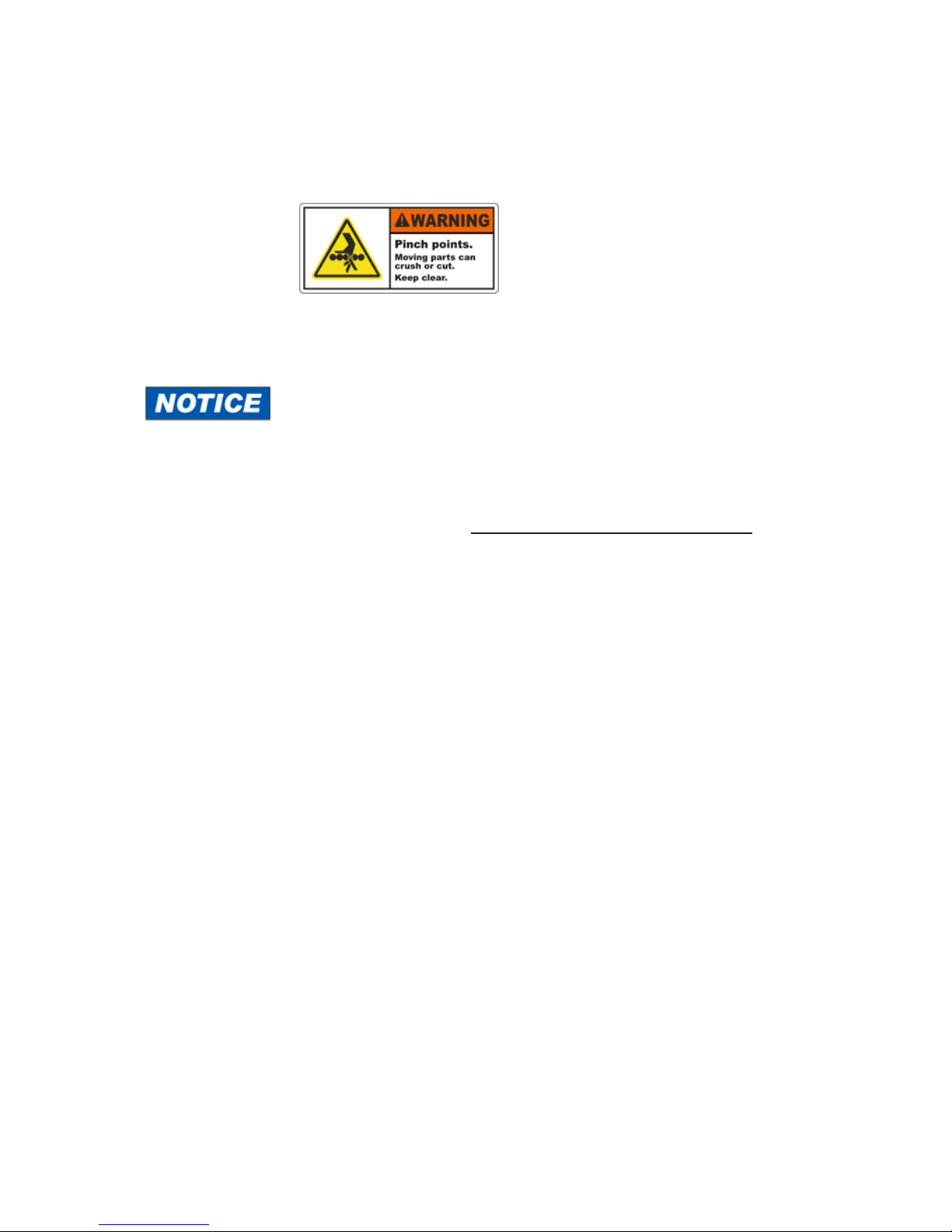

!

Pinch

Hazard

Inside

Panel

Warning symbols indicate a potentially hazardous situation that, if not avoided, could result

in severe injury or death.

Caution headings indicate a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

This symbol indicates a statement of company policy directly or indirectly related to the

safety of personnel or protection of property.

!

Pinch

Hazard

Inside

Panel

!

Pinch point.

Keep hands

clear during

operation.

These symbols indicate a dangerous pinch hazard exists.

This caution label indicates that a heavy object is involved and assistance is needed to avoid

injury.

The JetMounter™ performs mounting and laminating using two rollers to apply

uniform pressure to adhesives and overlaminating films. The point where the rollers touch

the material is called the Nip. This area creates a potential pinch hazard for fingers or other

8

objects. DO NOT OPERATE THIS EQUIPMENT IF YOU ARE UNWILLING TO ACCEPT

THIS HAZARD! TO AVOID INJURY, ALWAYS KEEP YOUR FINGERS AWAY FROM THE

NIP AREA.

No persons under the age of 16 should be allowed to operate the equipment.

The following safety features are designed to offer a reasonable measure

of protection against injury while maintaining an operator-friendly machine. Please do not

attempt to disable or alter their functionality in any way. Any modifications will void the

warranty and pose a serious risk to the operator. Contact Drytac Technical Services if

any malfunction of the equipment occurs and stop using the machine immediately!

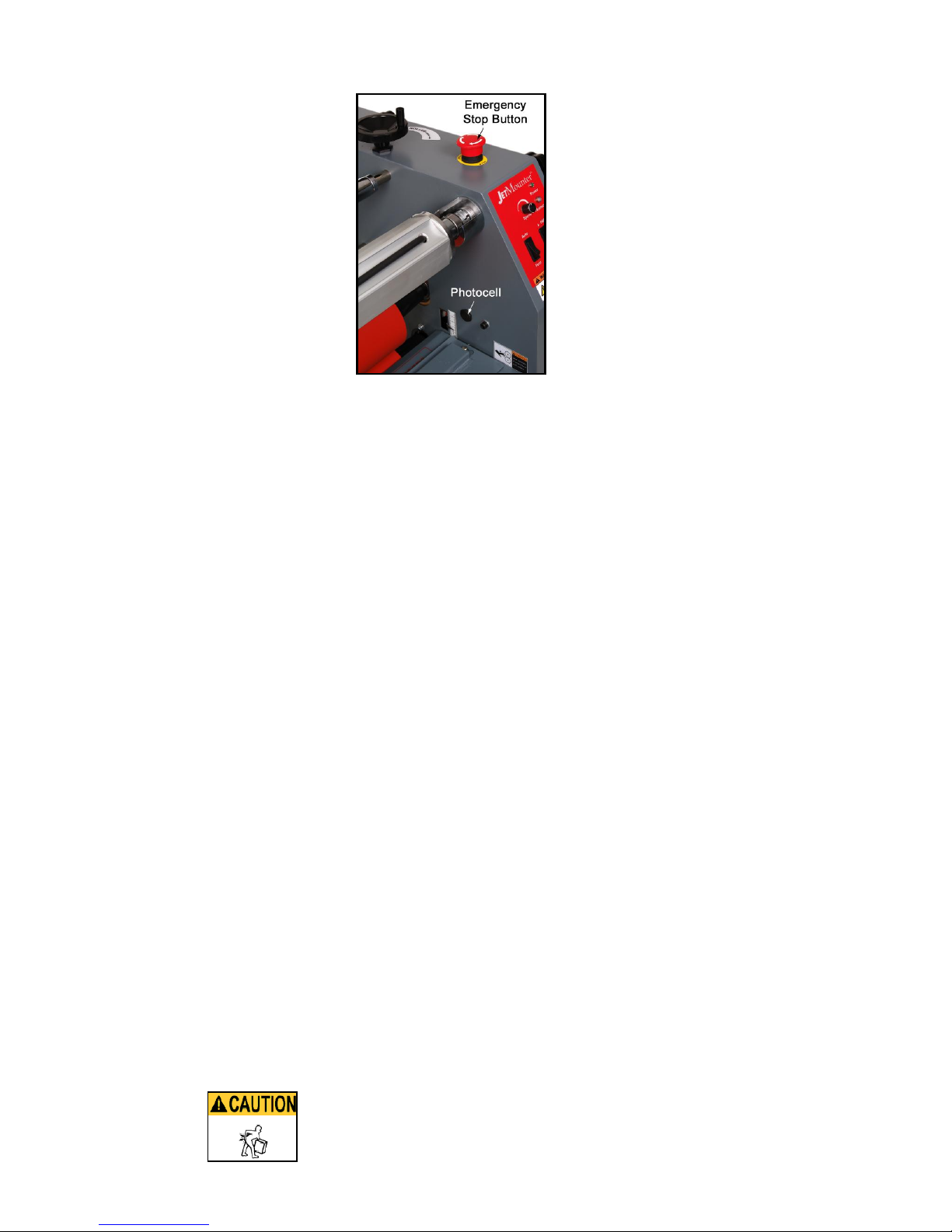

Models are equipped with an electric eye in front of the roller Nip which, when interrupted,

will stop the rollers immediately and sound a buzzer as a warning to indicate that an object is

breaking the photocell circuit. This occurs when the mode switch is set to “Auto”. Please be

particularly cautious when operating the JetMounter™ in the Foot Pedal mode because in

this mode the rollers WILL NOT STOP when the photocells are interrupted. An audible alarm

will sound, but the rollers will continue to turn at a reduced speed.

Prior to operating the laminator, always check that the photocell and buzzer are working

properly. Select the Auto mode and use a piece of cardboard to block the photocells to

confirm that the alarm sounds and the rollers stop.

9

All JetMounters are also equipped with red Emergency Stop buttons located on the top on

one or both sides of the laminator. The Emergency Stop button will stop the machine

instantly. Stopping the machine in the Foot mode can also be accomplished by lifting your

foot off the pedal, turning the speed to zero (0) OR turning off the power switch.

DO NOT operate this equipment when you are alone. As with all motorized equipment, it is

advisable that other adults be present to assist if required.

DO NOT operate the JetMounter™ while under the influence of alcohol, prescription drugs or

any other substance that could impair your judgment or reaction time.

Remove any jewelry such as rings, bracelets and necklaces prior to operating the

equipment. Keep loose clothing, neckties, artificial fingernails, long hair and anything else

that might easily be drawn into the rollers away from the machine.

Turn the JetMounter™ power OFF if you are loading adhesives or film, cleaning the rollers or

performing other activities that require close proximity of your fingers to the Nip. This will

avoid the possibility of inadvertently starting the machine. Keep all safety guards in place

and your fingers away from the Nip area when the machine is operating.

Always work at a slow speed until you become familiar with the machine.

Exercise caution when lifting rolls of laminate and adhesive due to their weight. Use

assistance to avoid personal injury or damage to the equipment and materials.

10

Prior to lifting a supply shaft into the laminator, position the T-Slot in the hub on the

machine‟s right side to receive the shaft. The use of an assistant is strongly recommended.

When using a large supply roll, be aware that a pinch hazard can exist

between the top roller and the supply shaft. When working from the rear of

the laminator the operator must be aware of the Nip point of the contacting

rollers and exercise extreme caution to avoid injury.

The sound pressure level this machine generates at the operators‟ position is less than

70dB.

Keep this manual near the machine for future reference. Also check our website for any

additional or updated safety information. (www.drytac.com)

An instructional DVD and a demonstration/training session from a Drytac representative are

also available so you can become familiar with all the features of your new JetMounter™.

Contact our Customer Service Department for details or if you have any questions about the

operation of this equipment. (Contact information can be found on page 30).

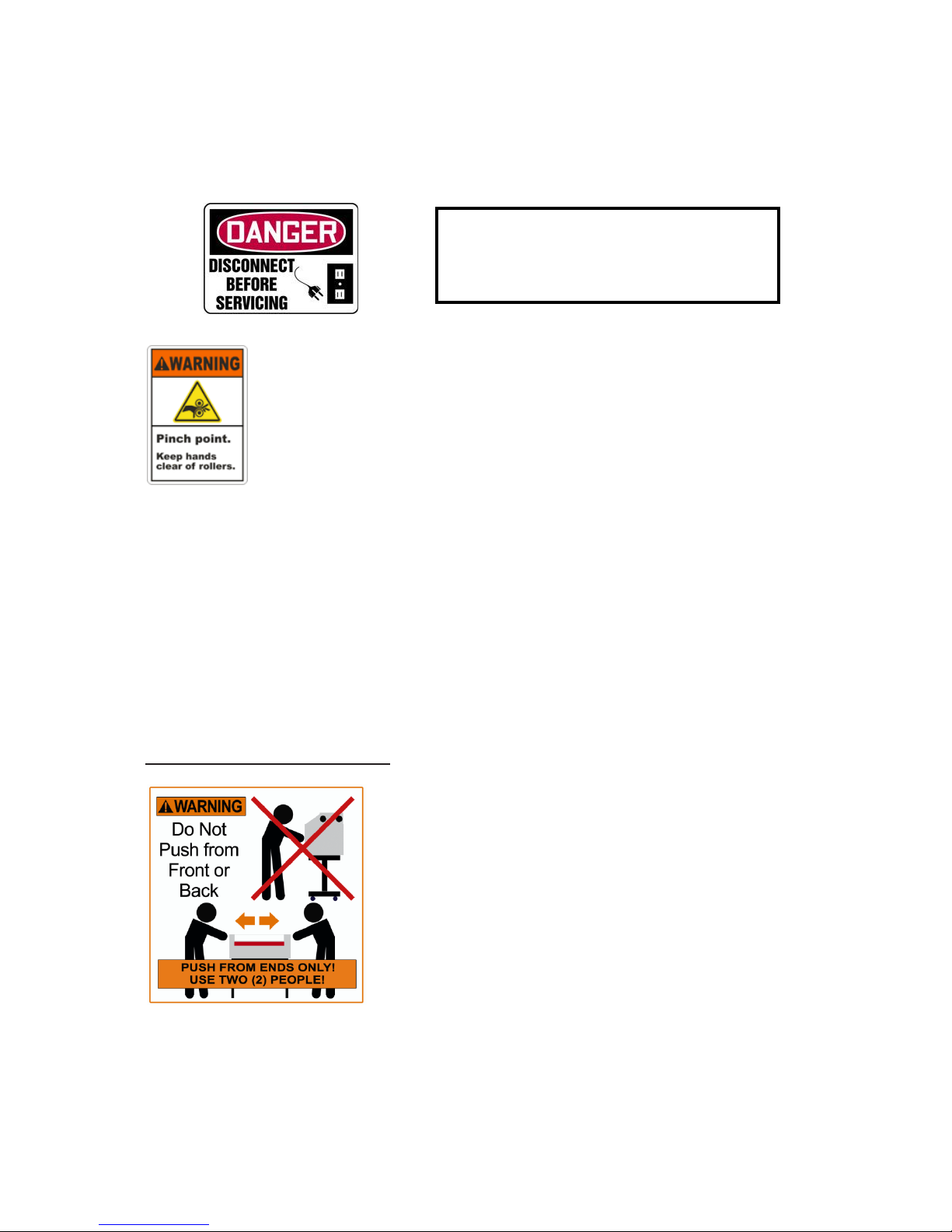

Specific Moving Instructions:

The Drytac JetMounter™ 44 and 54 should be handled with

care to avoid personal injury or collateral damage.

Whenever the machine is moved, we strongly recommend

utilizing at least two people. The adage: “Better safe than

sorry,” applies here.

The JetMounter™ stands are designed with fixed wheels on

one side and lockable swivel casters on the other for a very

good reason. When moving the machine, the movers

should be positioned at both sides. Do not push the JetMounter™ from the front or

back! This eliminates the possibility of having the machine tip over onto the mover or their

helper.

Always disconnect the laminator from the

power supply before removing any panels

for service.

11

Unpacking and Installation

Upon receipt of your new JetMounter™, inspect the carton(s) carefully for signs of physical

damage or mishandling. Report any damage to the shipping company immediately and

contact Drytac Corporation if replacement parts are needed. If no damage is apparent,

proceed with the unpacking.

It is recommended that two people unpack the JM18, JM 26 and

JM34 to avoid damage to the equipment or personal injury. To

unpack the JM44 and 54 you must follow the instructions affixed to

the top of the crate in the sequence described. If the instructions

are missing be sure to contact Drytac Technical Services before attempting to unpack or

install the machine.

Due to the weight of the JM44 and JM54 laminators a hoist or suitable lift must

be used to position the machine on an appropriate table or stand.

Select a clean, well-lighted working area that allows access to both the front and back of the

machine. Position the machine on a level, sturdy surface that can support the weight of the

machine and is at an optimum working height for the operator. (See Technical Specifications

Chart on page 30 for individual weight and size dimensions). The JM44‟s and JM54‟s are

available with optional stands that have casters for ease of movement as well as a storage

rack for preloaded supply shafts.

JetMounter™ laminators, depending on the country in which the machine was purchased, are

supplied in either a 115 VAC or 230 VAC versions. The power requirements for your

particular machine are marked on the rear panel adjacent to the power connector. Please

confirm that you have the correct power source available at the chosen location. If there are

any questions about electrical requirements for the equipment, please contact a qualified

electrician prior to attempting to power up the machine! Be absolutely certain that the

voltage supplied at the outlet corresponds with the voltage marked on the plate attached to

your machine. Do not rely on the cord or outlet configuration to determine the correct power

supply voltage!

ALLOW ENOUGH WORKSPACE AROUND THE MACHINE TO BE ABLE

TO FEED AND REMOVE YOUR WORKPIECE SAFELY!

Loading...

Loading...