DryMax MHT100A-1 Owner's Manual

DryMax Canada

320 Brunel Road

Mississauga, On, L4Z 2C2

Phone: 1.905.897.8485

Toll Free: 1.888.486.4445

e-mail: sales@drymaxairdryers.ca

wwwww.drymaxairdryers.ca

Visit our website @ www.drymaxairdryers.ca - For brocheurs, manuals, drawings & technical data

DRYMAX

DRYMAX

DRYMAX

DRYMAX

905.897.8485

RECEIVING AND INSPECTION

1. The dryer cannot be tilted on its side or upside down during shipping.

2. Use forklift from the bottom of the dryer when installing or moving.

3. Dryers are shipped F.O.B. factory. Immediately upon arrival check the dryer for possible

damage. If damage is found, report it to the carrier and file a damage claim.

4. Check dryer data label to be sure you have the right dryer. Check the data labels voltage and

amperage to be sure it is correct and the one you ordered.

5. Check the refrigeration gauges for pressure. If gauges read 0 PSIG STOP. Do not start dryer. Call

your distributor for service. This could mean there is a leak and the refrigerant has leaked out.

HOW THE AIR DRYER WORKS

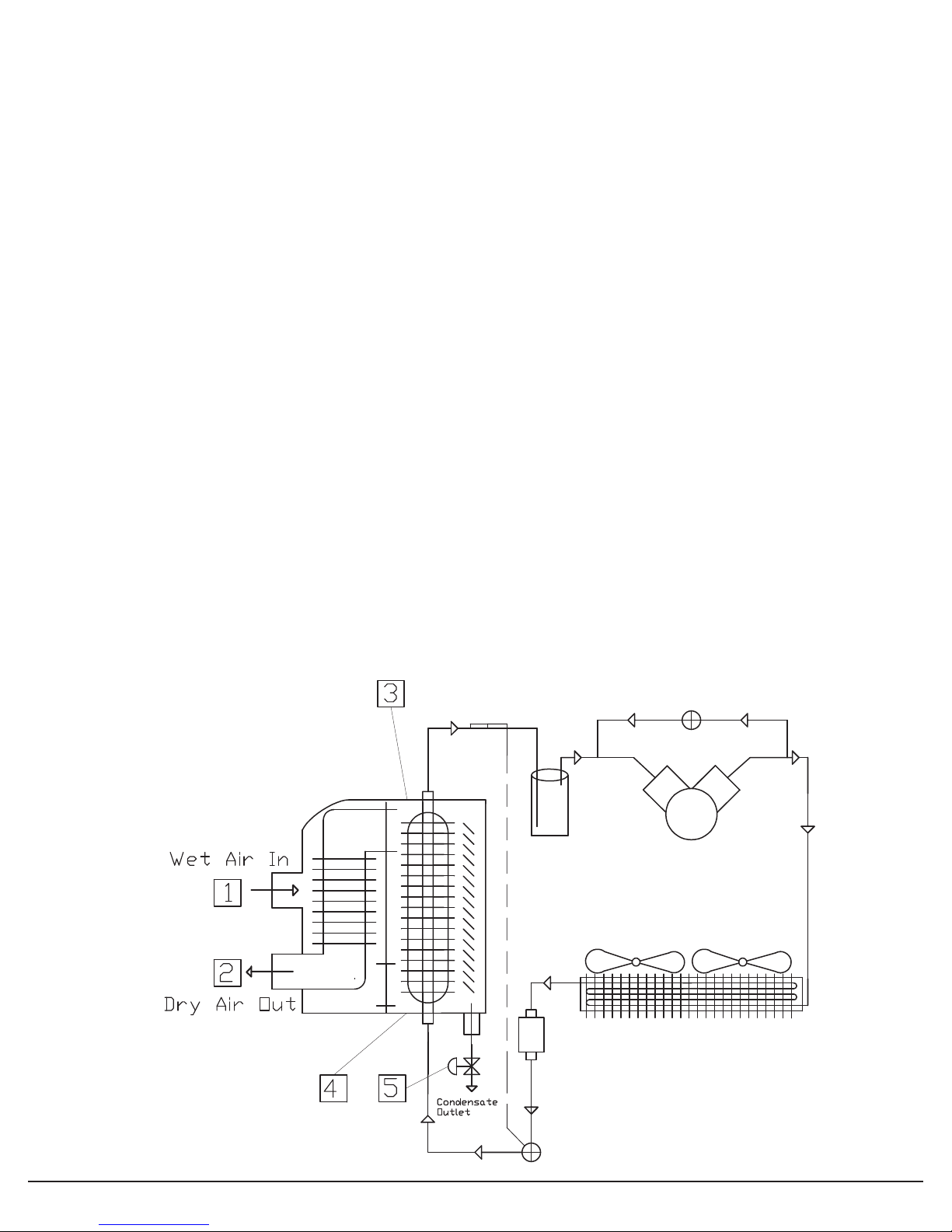

MHT Series refrigerated compressed air dryers use refrigeration cooling to condense entrained

moisture out of the compressed air stream. Warm saturated air enters the air-to-air heat exchanger

at the dryer inlet. (1)

In the air –to- air heat exchanger the inlet air is pre-cooled by the outgoing cold air. The

pre-cooled air then enters the air to refrigerant heat exchanger (3) were it is cooled to its lowest

point by the refrigeration in the evaporator. As the air is cooled moisture in the air changes from

a vapor to a liquid. The liquid condensate is removed from the airstream by the separator (4)

and discharged from the dryer by the automatic drain valve. (5) The cold air is reheated by

incoming warm air as it passes back through the air-to-air heat exchanger. Pre-cooling the inlet

air reduces the heat load on the refrigerant compressor, permitting the use of a smaller refrigerant

compressor. (2) The out going cold air is reheated by the in coming hot air. As a result the outlet

air is warmed up as it leaves the dryer. This prevents the outlet pipe from sweating. The air exits

the dryer and is now clean and dry, ready for use.

3

INSTALLATION AND LOCATION

1. Ventilation – Install dryer only in a well-ventilated clean, dry area only and keep at least 3 feet

between the dryer, other equipment and the walls.

2. Dryer Location – Make sure there is approximately 3 feet around the dryer for service and

maintenance purposes. Do not install the dryer outside. The air dryer must not be exposed

to direct sunlight, rain or snow. Do not install the dryer in an environment with fire, high

temperatures or low temperatures.

Make sure the dryer is installed in an environment that is clean and dry. Dust and dirt particles

will clog the air-cooled condenser. A clogged and dirty condenser will reduce the performance

of the dryer and will eventually cause damage to the dryer.

3. Ambient Temperatures – Suitable ambient temperature for the refrigerant dryer is a minimum

of 35 F to a maximum of 110 F. The performance of the dryer will be significantly decreased

when the air dryer is subject to temperatures higher than 110 F. For installations with ambient

temperatures higher than 110 F it is recommended to use a water-cooled condenser on the

dryer. Contact your dealer for details.

4. Selecting Proper In and Out Piping and Piping Design – Pipe diameter should be

sized according to air flow requirements. Do not mix the air inlet and outlet air flow. It

is recommended that a vibration absorber be installed on the dryer inlet and outlet to

eliminate vibration from the compressor. Do not use the inlet and outlet of the air dryer to

support the weight of the air piping.

5. 3 valve bypass and Isolation valves - should be installed on the air dryer outlet and inlet ports

to allow for bypassing, depressurizing, and proper maintenance and servicing of the air dryer.

6. Condensate Drains – Condensate drains must be properly piped from the dryer to prevent

moisture re-entrainment. The dryer is equipped with an automatic drain valve that controls the

discharge of the condensate and a manual valve to manually drain condensate. The user must

run a drain line to an environmentally approved condensate collection/disposal system.

7. Electrical Installation – The dryer data label lists the electrical power requirements for the air

dryer. The user must confirm that the line voltage matches the voltage listed on the data label.

(Warning – Operating the air dryer with improper line voltage will void the warranty.) Provide

the proper size wire, disconnect switches and fuses in accordance with applicable codes. Field

wiring must comply with local and national fire safety and electrical codes. Standard dryer’s

enclosures and controls are designed to meet NEMA 1 Type 1 electrical standards. All wiring

is complete. Connect power leads as indicated in the electrical schematic. Ground the frame

properly. Once power is connected turn the power on to the dryer. Leave the power on for 6

hours before you turn the dryer on. This will energize the crank case heater and boil off any

liquid refrigerant in the crank case. Failure to do this may damage the refrigerant compressor

and will void the warranty.

4

Loading...

Loading...