Dryer Master AM3 Product Manual

Dryer Master AM

3

Product Manual

Revision 1.0 July, 2008

Revision 1.2 February, 2009

Revision 1.3 March, 2009

Revision 1.4 September, 2013

Revision 1.5 September, 2014

Revision 1.6 March, 2016

Revision 1.7 June, 2017

Prepared by:

Dryer Master Inc.

©Dryer Master Inc. 2008, 2009, 2013, 2014, 2016

Dryer Master® is a registered trademark of Dryer Master Inc.

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 1

Table of Contents

1. INTRODUCTION ........................................................................................................................................ 7

MOISTURE MEASUREMENT TECHNOLOGY.................................................................................................................... 7

MOISTURE CONTROL TECHNOLOGY ........................................................................................................................... 7

INFORMATION DISPLAY............................................................................................................................................. 7

2. SYSTEM OVERVIEW ................................................................................................................................... 8

3 SYSTEM OPERATION ................................................................................................................................ 11

3.1 SYSTEM DISPLAYS ............................................................................................................................................ 11

3.2 SYSTEM SCREENS MAP .................................................................................................................................... 13

3.3 SYSTEM START DISPLAYS ................................................................................................................................... 14

3.4 MAIN OPERATIONS DISPLAYS ............................................................................................................................ 15

3.4.1 Main Display – Local Mode - Sensor Empty ............................................................................................ 15

3.4.2 Main Display – Local Mode ....................................................................................................................... 15

3.4.3 Main Display – Manual Mode ................................................................................................................... 15

3.4.4 Main Display – Automatic Mode .............................................................................................................. 16

3.4.5 Alarm screen ............................................................................................................................................... 16

3.4.6 Main Display – Active Alarm ..................................................................................................................... 16

3.5 MOISTURE TREND DISPLAYS .............................................................................................................................. 17

3.5.1 One Hour Moisture trend display............................................................................................................. 17

3.5.2 Two Hour Moisture trend display ............................................................................................................. 17

4 OPERATING THE DRYER FROM THE AM3 ............................................................................................... 18

4.1 OPERATING THE SYSTEM .................................................................................................................................. 18

4.1.1 Main Display – Local Mode ....................................................................................................................... 18

4.1.2 Operating Mode Select Screen .................................................................................................................. 18

4.1.3 Setting Drying Rate ..................................................................................................................................... 19

4.2 AUTO SETUP .................................................................................................................................................. 20

4.2.1 Auto Setup – Setting Speed Limits and Delay time ................................................................................. 20

4.2.2 Auto Setup –Limits and Rate Mode selection .......................................................................................... 21

4.2.3 Auto Setup – Moisture Targets, Moisture Limits and Rate Settings selection ...................................... 22

4.2.4 Auto Setup –Rate Selection Mode A.......................................................................................................... 23

4.2.5 Auto Setup –Rate Selection Mode B ......................................................................................................... 24

4.2.6 Auto Setup –Rate Selection Mode C ......................................................................................................... 25

5 THE MENU TREE ....................................................................................................................................... 26

5.1 MAIN MENUS ................................................................................................................................................. 26

5.1.1 Menu – Screen 1 ......................................................................................................................................... 26

5.1.2 Menu – Screen 2 ......................................................................................................................................... 26

5.1.3 Menu – Screen 3 ......................................................................................................................................... 26

5.1.4 Menu – Screen 4 ......................................................................................................................................... 27

5.2 CHANGE PRODUCT .......................................................................................................................................... 27

5.2.1 Menu – Screen 1 – Change Product ......................................................................................................... 27

5.2.2 Change Product .......................................................................................................................................... 27

5.3 CALIBRATE SENSOR ......................................................................................................................................... 28

5.3.1 Calibrate Sensor – Menu Selection ........................................................................................................... 28

5.3.2 Calibrate Sensor – Standard Method ...................................................................................................... 28

5.3.3 Calibrate Sensor – Enhanced Method – Start Calibration – Enter Calibration ................................... 29

5.3.4 Calibrate Sensor – Enhanced Method – Online Sample value display ................................................. 30

5.3.5 Calibrate Sensor – Enhanced Method – Sample entry ........................................................................... 30

5.4 SET ALARMS ................................................................................................................................................... 32

5.4.1 Set Alarms – Menu selection ..................................................................................................................... 32

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 2

5.4.2 Set Alarms – Moisture Alarm values selection ........................................................................................ 32

5.4.3 Set Alarms – Temperature Alarms values selection ............................................................................... 32

5.4.4 Set Alarms – Values Entry .......................................................................................................................... 33

5.5 ALARM LOG ................................................................................................................................................... 33

5.5.1Alarm Log – Menu selection ....................................................................................................................... 33

5.5.2 Alarm Log – Data screen ........................................................................................................................... 33

5.6 ALARM DELAY ................................................................................................................................................ 34

5.6.1 Alarm Delay – Menu selection .................................................................................................................. 34

5.6.2 Alarm Delay – Data Entry selection .......................................................................................................... 34

5.6.3 Alarm Delay – Value entry ......................................................................................................................... 35

5.7 REMOTE ALARM DELAY .................................................................................................................................... 35

5.7.1 Remote Alarm Delay – Menu selection .................................................................................................... 35

5.7.2 Remote Alarm Delay – Enable & Delay entry selection .......................................................................... 36

5.7.3 Remote Alarm Delay – Value entry ........................................................................................................... 36

5.8 PRINTING ....................................................................................................................................................... 37

5.8.1 Printing – Menu selection .......................................................................................................................... 37

5.8.2 Printing – Select ID – Printing On, Off – Print Header functions ........................................................... 37

5.8.3 Printing – View ID number ........................................................................................................................ 37

5.8.4 Printing – Set ID number – Value entry.................................................................................................... 38

5.8.5 Printing – Printout sample ........................................................................................................................ 39

5.9 TEMPERATURE SCALE ....................................................................................................................................... 40

5.9.1 Temperature Scale – Menu selection ....................................................................................................... 40

5.9.2 Temperature Scale – Scale Change Warning .......................................................................................... 40

5.10 SYSTEM SETTINGS ......................................................................................................................................... 41

5.10.1 System Settings – Menu selection ........................................................................................................... 41

5.10.2 System Settings – Screen Saver – Data / Time – Contrast selection ................................................... 41

5.10.3 System Settings – Screen Saver – Items selection ................................................................................. 41

5.10.4 System Settings –Screen Saver – Timeout ............................................................................................. 42

5.10.5 System Settings – Selecting Date & Time ............................................................................................... 42

5.10.6 System Settings – Setting Date ................................................................................................................ 43

5.10.7 System Settings – Setting Time ............................................................................................................... 43

5.10.8 System Settings – Changing Display Contrast ....................................................................................... 43

5.11 ENG. FUNCTIONS .......................................................................................................................................... 44

5.11.1 Engineering Functions – Menu selection ............................................................................................... 44

5.11.2 Engineering Functions – Password Entry............................................................................................... 44

5.11.3 Engineering Functions 1 – Slope, Offset entry....................................................................................... 45

5.11.4 Engineering Functions 2 – Slope, Offset entry....................................................................................... 47

5.11.5 Engineering Functions 3 – Slope, Offset entry....................................................................................... 47

5.11.6 Engineering Functions 4 – FF&TC Corn value entry .............................................................................. 48

5.11.7 Engineering Functions 5 – TC value entry .............................................................................................. 48

5.11.8 Engineering Functions 6 – Input Voltage Diagnostics display ............................................................. 49

5.11.9 Engineering Functions 7 – Moisture sensor calibration method selection ........................................ 49

5.11.10 Engineering Functions 8 – Calibration Factor..................................................................................... 50

5.11.11 Engineering Functions 9 – Moisture Output scaling .......................................................................... 50

5.11.12 Engineering Functions 10 – Changing Temperature Scale “deg F” “deg C” ...................................... 51

5.12 LANGUAGES ................................................................................................................................................. 51

5.12.1 Languages – Menu selection ................................................................................................................... 51

5.12.2 Languages – Changing display language, English, French, Spanish................................................... 52

5.13 TRENDING OPTIONS ...................................................................................................................................... 53

5.13.1 Trending Options – Menu selection ....................................................................................................... 53

5.13.2 Trending Options – Clearing data .......................................................................................................... 53

5.13.3 Trending Options – Changing Moisture range ...................................................................................... 53

5.13.4 Trending Options – Changing trend time scale .................................................................................... 54

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 3

5.14 INFORMATION .............................................................................................................................................. 54

5.15 REMOVABLE MEDIA ....................................................................................................................................... 54

5.16 AUTO SETUP ................................................................................................................................................ 55

6 DISPLAY UNIT INSTALLATION................................................................................................................ 56

6.1 PANEL MOUNT (SELF-INSTALL) ......................................................................................................................... 56

6.1.1 Display Dimensions ................................................................................................................................... 56

6.1.2 Display Panel cut out ................................................................................................................................. 57

6.1.3 Display (PLC) Electrical Connections ........................................................................................................ 58

6.1.4 Field Electrical Connections ...................................................................................................................... 59

6.2 AM

3

PANEL ................................................................................................................................................... 60

6.2.1 In Panel Electrical Connections ................................................................................................................ 60

6.2.2 Field Electrical Connections ...................................................................................................................... 61

6.3 PRINTING OPTION ........................................................................................................................................... 62

7 MOISTURE SENSOR GENERAL SPECIFICATIONS ................................................................................... 63

7.1 MOISTURE SENSOR INSTALLATION .................................................................................................................... 63

7.1.1 Moisture Range & Temperature range. ................................................................................................... 63

7.1.2 Sensor signal conversion ........................................................................................................................... 63

7.2 2200-11-BTC-RB, Fin Sensor ......................................................................................................................... 64

7.2.1 Sensor Power requirements ...................................................................................................................... 65

7.2.2 Grounding ................................................................................................................................................... 65

7.2.3 Signal Output .............................................................................................................................................. 65

7.2.4 Sensor Not Reading Empty with no product present ............................................................................. 65

7.3 SENSOR SETUP & DIAGNOSTICS ......................................................................................................................... 65

8 INSTALLATION REQUIREMENTS & SPECIFICATIONS ........................................................................... 67

8.1 BYPASS CHUTE INSTALLATION EXAMPLES ........................................................................................................... 68

8.1.1 Bypass Chute Installation square chute with screw metering .............................................................. 68

8.1.2 Bypass Chute Installation round chute with screw metering ................................................................ 69

8.1.3 Bypass Chute metering screw ................................................................................................................... 70

8.1.4 Bypass Chute screw metering RPM table ................................................................................................ 71

8.1.5 Bypass Chute Installation rotary valve or airlock metering .................................................................. 72

8.1.6 Bypass Chute rotary valve or airlock metering RPM table .................................................................... 72

8.1.7 Bypass Chute Example .............................................................................................................................. 74

8.1.8 Bypass Chute Example: Dimensions ........................................................................................................ 74

8.1.9 Bypass Chute Example feeding back on itself ......................................................................................... 75

8.1.10 Bypass Chute Example mechanical metering ....................................................................................... 76

8.2 IN LINE CHUTE INSTALLATION EXAMPLES ........................................................................................................... 77

8.2.1 In Line Chute Example mechanical metering ......................................................................................... 77

8.2.2 In Line Chute Example: Dimensions ......................................................................................................... 78

9 APPENDIX A .............................................................................................................................................. 79

9.1 HISTORY & CALIBRATION FILES DATA FORMAT .................................................................................................... 79

9.1.1History data example ................................................................................................................................. 79

9.1.2 Calibration data example ......................................................................................................................... 80

10 APPENDIX B – WARRANTY .................................................................................................................... 81

11 APPENDIX C - IMO SET-UP GUIDE ........................................................................................................ 82

12 APPENDIX D. SENSOR CHUTE W/ ROTARY FEED ................................................................................ 87

13 APPENDIX E MOTOR SPEED CONTROL WIRING DIAGRAM ............................................................... 89

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 4

List of Figures and Tables

Figure 1. – Typical System with enhanced display and options 8

Figure 2. – Typical System with standard display mounted in Dryer Control panel and options 9

Figure 3. – Information display 10

Figure 4. – Fin Moisture sensor 10

Figure 5. – Information display in enclosure 10

Figure 6. –System display items description. 11

Figure 7. –Screen map 13

Figure 8. –Startup diagnostics display 14

Figure 9. –Product information display 14

Figure 10. –Main Display 14

Figure 11. –Main Display – Sensor Empty, 15

Figure 12. –Main Display – Local Mode 15

Figure 13. –Main Display – Manual Mode 15

Figure 14. –Main Display – Automatic Mode 16

Figure 15. –Alarm screen 16

Figure 16. –Main Display – Active Alarm 16

Figure 17. –One (1) hour Moisture Trend 17

Figure 18. –Two (2) hour Moisture Trend 17

Figure 19. –Main Display 18

Figure 20. –Mode Select screen 18

Figure 21. –Drying rate setting screen 19

Figure 22. – Auto Setup – Speed limits and delay time 20

Figure 23. – Auto Setup – Limits and Rate mode selection 21

Figure 24. – Auto Setup – Moisture targets, Moisture Limits and Rate settings selection 22

Figure 28. –Menu One (1) 26

Figure 29. –Menu Two (2) 26

Figure 30. –Menu Three (3) 26

Figure 31. –Menu Four (4) 27

Figure 32. –Menu One (1) – Change Product 27

Figure 33. – Change Product 27

Figure 34. – Calibrate Sensor 28

Figure 35. – Calibrate Sensor (Standard method) 28

Figure 36. – Calibrate Sensor (Enhanced method) Start & Enter 29

Figure 37. – Calibrate Sensor (Enhanced method) Sample Display 30

Figure 38. – Calibrate Sensor (Enhanced method) Sample Entry 30

Figure 39. – Set Alarms 32

Figure 40. – Set Alarms – Moisture Alarms values selection 32

Figure 41. – Set Alarms – Temperature Alarms 32

Figure 42. – Set Alarms – Value Entry 33

Figure 43. – Alarm Log 33

Figure 44. – Alarm Log – Data screen 33

Figure 45. – Alarm Delay 34

Figure 46. – Alarm Delay –Entry selection 34

Figure 47. – Alarm Delay – Value Entry 35

Figure 48. – Remote Alarm Delay 35

Figure 49. – Remote Alarm Delay – Enable & Entry selection 36

Figure 50. – Remote Alarm Delay – Value Entry 36

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 5

Figure 51. – Printing 37

Figure 52. – Printing – Enable, Set ID & Print Header selection 37

Figure 53. – Printing – Set ID 37

Figure 54. – Printing – ID Value Entry 38

Figure 55. – Printing – Information example and explanation. 39

Figure 56. – Temperature Scale 40

Figure 57. – Temperature Scale change Warning 40

Figure 58. – System Settings 41

Figure 59. – System Settings – Items Selection 41

Figure 60. – System Settings – Screen Saver – Items Selection 41

Figure 61. – System Settings – Screen Saver – Time delay entry 42

Figure 66. – Engineering Functions 44

Figure 67. – Engineering Functions – Password 44

Figure 68. – Engineering Functions – Password Entry 44

Figure 69. – Engineering Functions 1 – Slope, Offset entry 45

Figure 70. – Engineering Functions 2 – Slope, Offset entry 47

Figure 71. – Engineering Functions 3 – Slope, Offset entry 47

Figure 72. – Engineering Functions 4 – FF & TC Corn value entry 48

Figure 73. – Engineering Functions 5 – TC value entry 48

Figure 74. – Engineering Functions 6 – Input Voltage diagnostics display 49

Figure 75. – Engineering Functions 7 – Calibration Method screen 49

Figure 76. – Engineering Functions 8 – Calibration Factor screen 50

Figure 87. –Display Dimensions 56

Figure 88. –Display Panel cutout 57

Figure 89. –Display Electrical connections 58

Figure 90. –Electrical connections Field devices 59

Figure 91. –AM3 In Panel connection terminal strip 60

Figure 92. –Electrical connections Field devices 61

Figure 93. –Moisture Sensor 64

Figure 94. –Sensor Setup & diagnostics 66

Figure 95. –Moisture Sensor Bypass Chute design #1 square pipe 68

Figure 96. –Moisture Sensor Bypass Chute design #2 round pipe 69

Figure 97. –Moisture Sensor Bypass Chute conceptual metering screw design 70

Figure 98. – Table of metering device RPM – screw conveyor 71

Figure 99. –Moisture Sensor, Example of a Sample Bypass Installation 72

Figure 100. – Table of metering device RPM – rotary airlock or rotary valve 72

Figure 101. –Moisture Sensor, Example of a bypass Chute Installation 73

Figure 102. –Bypass Chute Example 74

Figure 103. –Bypass Chute Example: Dimensions 74

Figure 104. –Moisture Sensor, Example of a bypass Chute Installation, product feeding back on itself 75

Figure 106. –In Line Chute Example 77

Figure 107. –In Line Chute Example: Dimensions 78

Figure 108. –History file data format 79

Figure 109. –Calibration file data format 80

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 6

To Our Customer

Thank you for purchasing the Dryer Master AM3 (Automatic Mini Moisture Manager) System. The

Dryer Master AM3 is a robust system that employs state logic for control. It is simple to use and can be

applied to most if not all grain moisture measurement applications.

The AM3 is part of the Dryer Master family of moisture monitoring and moisture control systems that

have at their heart Dryer Master's stainless steel fin type capacitance based moisture sensors. These

sensors were initially developed to drive Dryer Master's industry leading computerized moisture

control systems, where they are placed at the inlet and the outlet of the dryer. With over 30 years of

field proven experience they are now being offered as part of the AM3 moisture monitoring and state

logic control solution.

We trust that you will be pleased with the operation of the AM3 and that you will enjoy benefits similar

to those provided by the world renowned Dryer Master moisture control system.

Dryer Master Inc.

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 7

1. Introduction

This document provides the operational specification for an on-line moisture display system with a

single sensor; product moisture and product temperature are displayed. Moisture control is achieved

using state logic. The system consists of a display unit and a moisture sensor. Both the display unit

and the sensor require less than 15 watts of power and are powered from a low voltage 24-volt direct

current instrumentation power supply. Depending on the options purchased the system may include

other components and devices.

Moisture measurement technology

The Dryer Master Moisture sensor measures the dielectric properties, in effect the capacitance of the

product in the vicinity of the sensor fin. This method is the most effective in measuring the total water

in a given volume of product. The installation ensures a large sample of product is presented to the

sensor at all times. This large sample contributes to a better product moisture representation than

other methods and generally provides a very good representation of the product in the total sample

stream. This technology is particularly suited to the measurement of product with moisture gradients.

A moisture gradient occurs any time product is processed either by heating or cooling but not limited

to either. The sensor’s robust construction and conservative installation specifications ensure long

product life.

Moisture control technology

The Dryer Master AM3 state control technology employs a 3 state model triggered by user settable

moisture targets, time delays and speed set points for continues dryers. Instead of constantly

switching between a high and low discharge speed as used in many smaller on farm drying systems the

system switches between higher discharge speed triggered by drier product to normal speed, to lower

speed triggered by higher moisture product. Depending on the operating mode the 3 speeds can be

either individually manually set, set as a % of the normal operating speed, or a specific deviation from

the normal speed. The trigger points are actual moistures measured by the moisture sensor and

delays to activation are user settable from 1 second to 999 seconds or 16.65 minutes. The system can

also be configured for recirculation batch type dryers. Where the product is re- circulated in the dryer

until a specific moisture target is reached and the dryer is unloaded.

Information display

The information display is a micro PLC (Programmable Logic Controller) with an integrated graphics

LCD display and keypad. This combination of integrated items is also referred to as an OCS (Operator

Control Station). The Dryer Master Moisture sensor calibration software embedded in this device

provides the same reliability and accuracy previously once only available in the Dryer Master dryer

control systems.

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 8

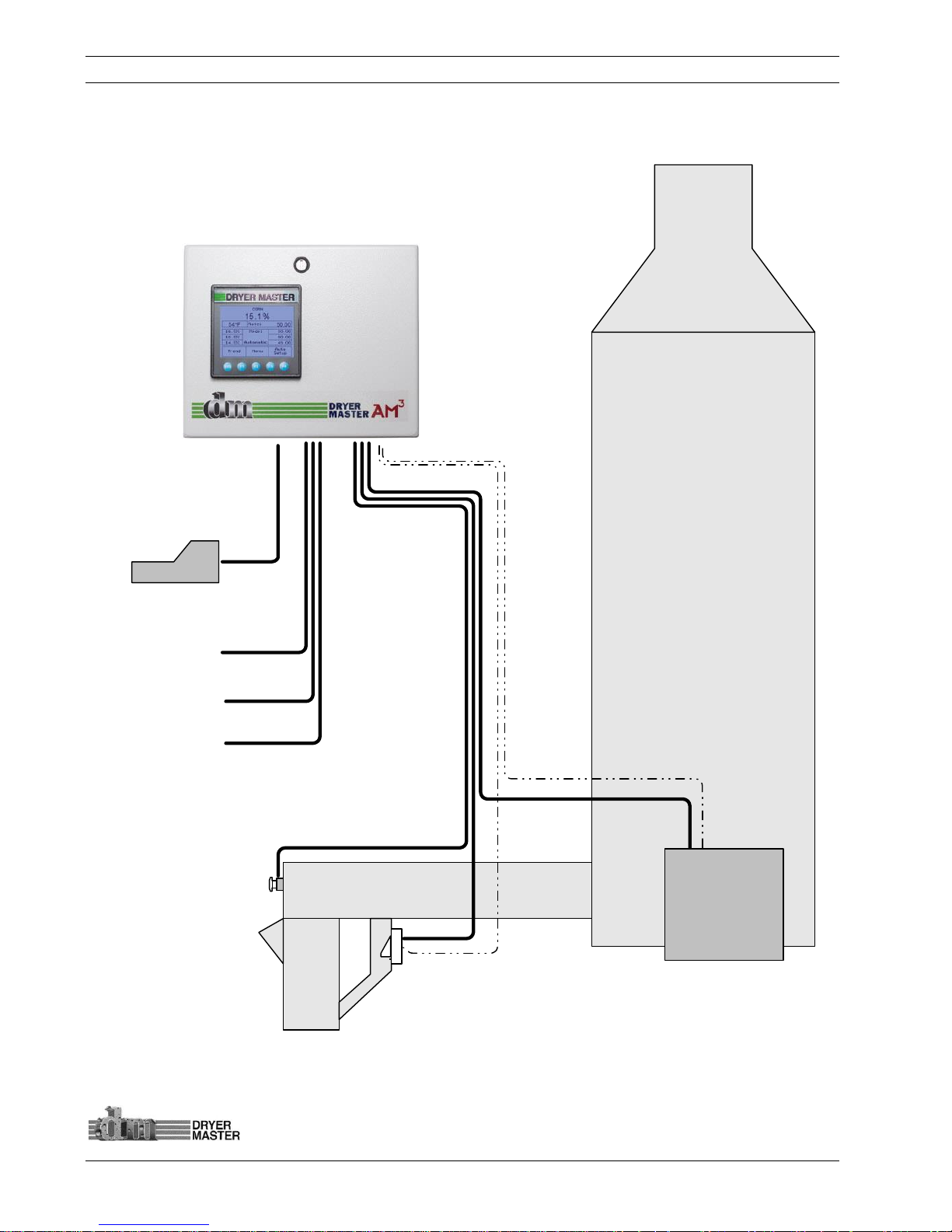

Optional

Printer

Outlet Moisture

&

Temperature

Sensor

Optional Moisture

Sample Start Button

Dryer Control

Panel

(

Discharge

Speed

)

DRYER

Instrumentation

cables

Ground

cables

24

vdc time delayed

Remote alarm output

24

vdc time delayed

alarm output

0 – 10

Volt Moisture

signal output to

Automation system

2. System Overview

The system is comprised of 2 key elements, the industry proven Dryer Master Moisture sensor and a

Micro PLC with integrated touch screen information display.

Figure 1. – Typical System with enhanced display and options

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 9

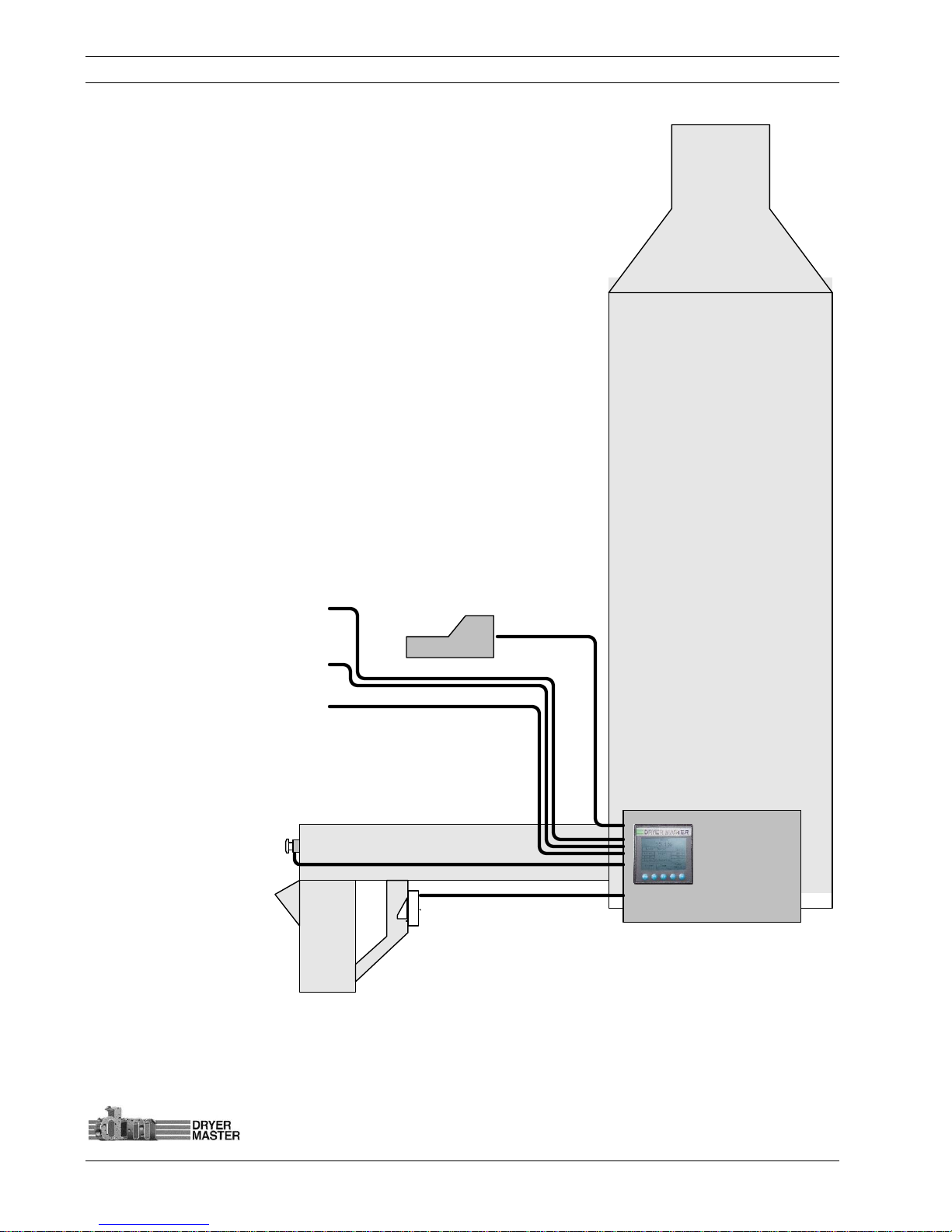

Figure 2. – Typical System with standard display mounted in Dryer Control panel and options

Optional

Printer

Outlet Moisture

&

Temperature

Sensor

Optional Moisture

Sample Start Button

Dryer Control

Panel

(

Discharge

Speed

)

DRYER

24

vdc time delayed

Remote alarm output

24

vdc time delayed

alarm output

0 – 10

Volt Moisture

signal output to

Automation system

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 10

1. The Display unit is the information provider. Product

moisture, product temperature as well as alarms and moisture

trends are information continuously displayed. Product

selection, Discharge Rate settings, as well as sensor calibration,

alarm function and system setup are all functions accomplished

through menus accessed via the key pad and Action Keys. The

display has a screen saver that shuts down the back lighting to

prolong lamp life.

Figure 3. – Information display

2. The Moisture sensor is the heart of the system. The sensor is

located in what is called a compacted product flow situation. This is

a chute where the product is slowed and allowed to compact. The

sensor measures the free water in the product in this chute. Even

and consistent product flow is key to obtaining stable moisture

readings.

Figure 4. – Fin Moisture sensor

3. The enhanced system adds an enclosure for the

display unit, easy to connect terminals and a universal

voltage system power supply to power both the Display

and Moisture sensor. The supply may also be used to

activate low voltage low current alarm devices or alarm

contacts. On systems equipped with a Dryer Master

Power supply the unit is capable of supplying 24Volts DC

at up to 1 Amp and is current limited and designed to

shut down in the event of a short circuit.

Figure 5. – Information display in enclosure

4. The optional industrial grade point of sale terminal printer provides hard copy records of

operation with a record printed every 10 minutes.

5. A calibrations pushbutton may also be used. This illuminated push button when installed

and configured can assist moisture calibration by automating this function. When so

configured the system will gather and average the moisture passing by the sensor during the

period the button lamp is flashing, and then remain lit until the calibration result is entered.

6. Alarm outputs with time delay settings can be used sound alarm devices and or trigger

events.

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 11

3 System Operation

This section will deal with the most common items needed to operate the unit. Included is a screen

map of the various screens displayed during start up and operation when alarm conditions occur,

continuing on to product selection and sensor calibration. Also included in this section are common

setup functions such as alarm limit settings, alarm action settings and common system settings. The

detailed Engineering and device setup functions will be described in another section.

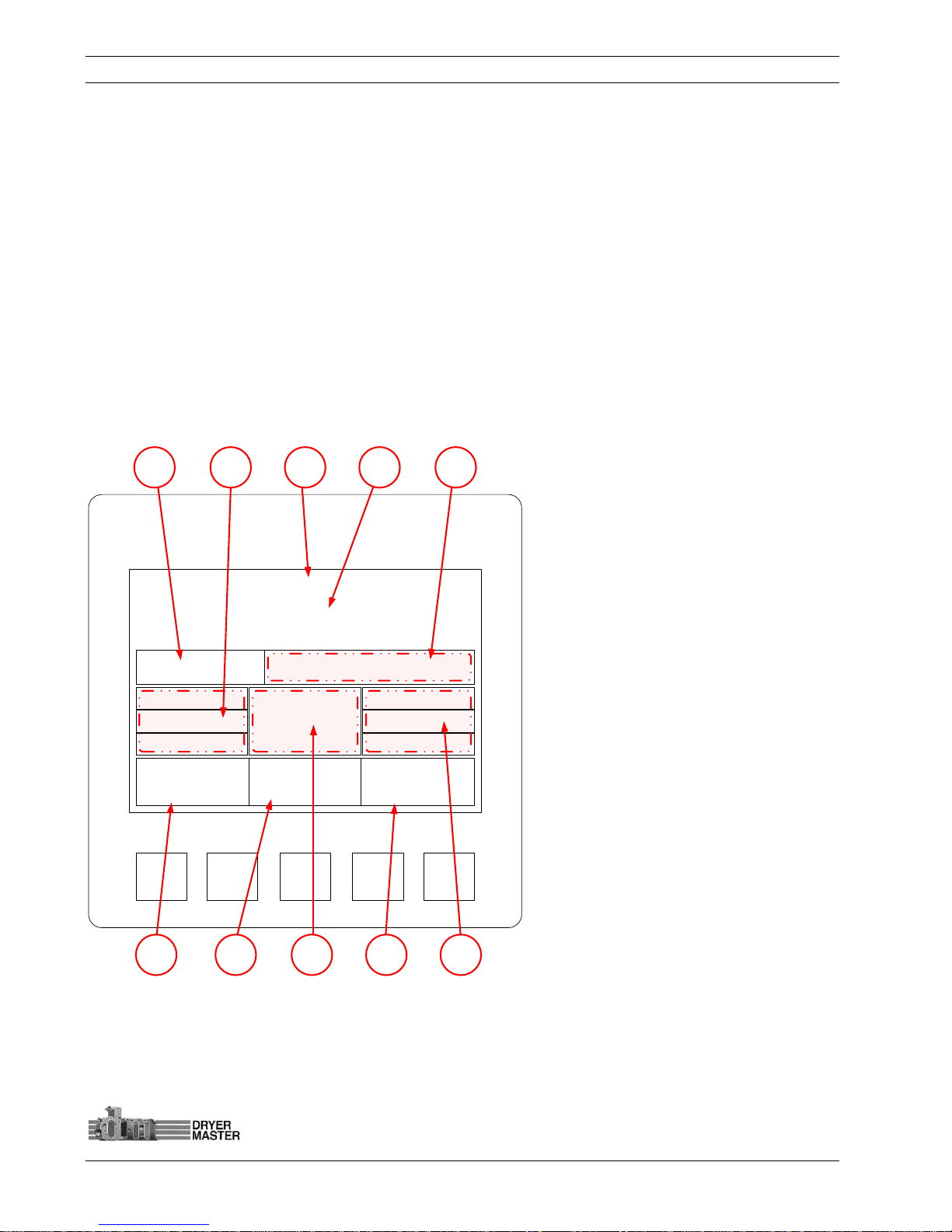

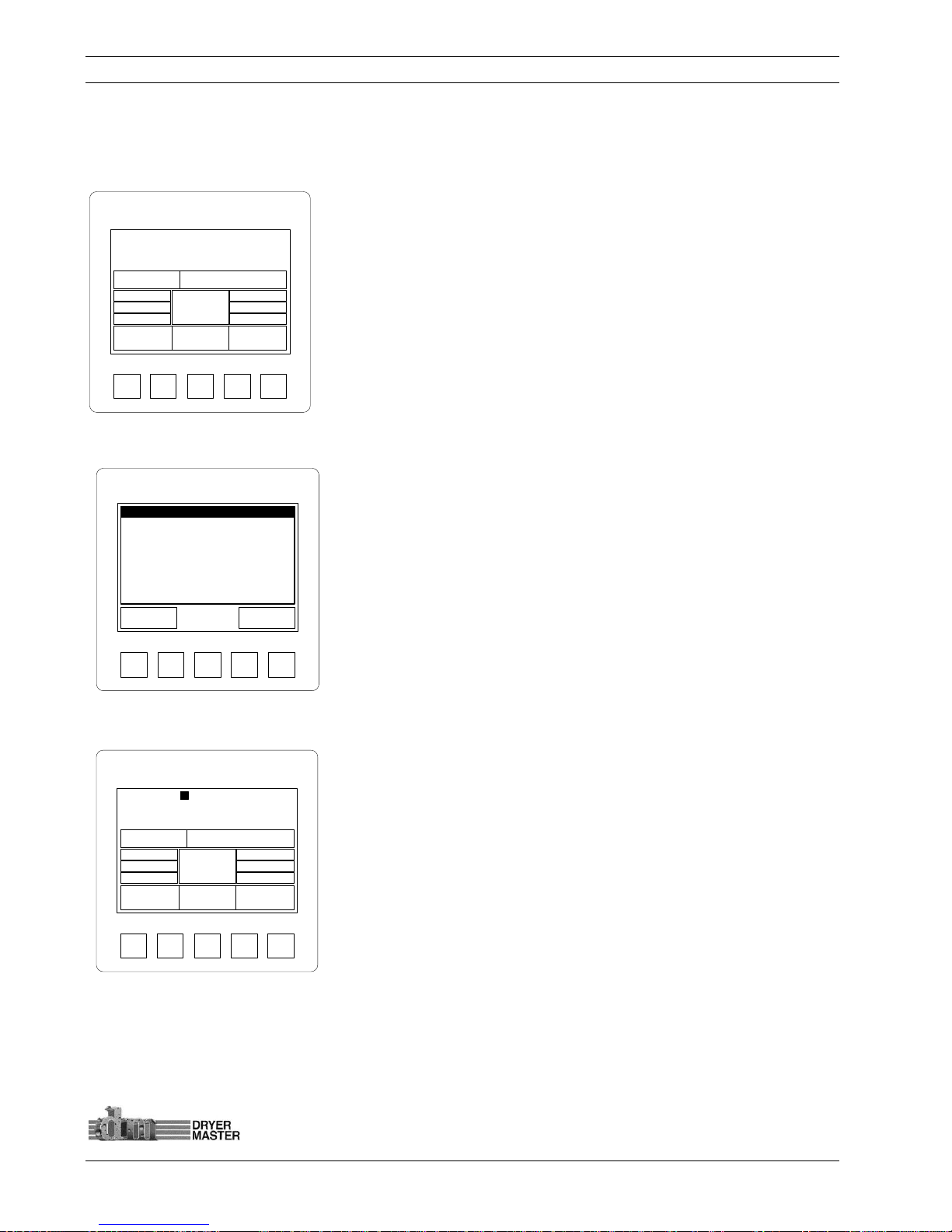

3.1 System displays

This is a Touch screen system. Throughout this document there may be references to “Touch Keys” or

“Touch areas” which refer to values or text on the LCD display. These “Touch Keys” or “Touch areas”

will access various functions as you navigate through the screens & menus. The Display may also be

referred to as a PLC (Programmable Logic Controller) or an OCS (Operator Control Station).

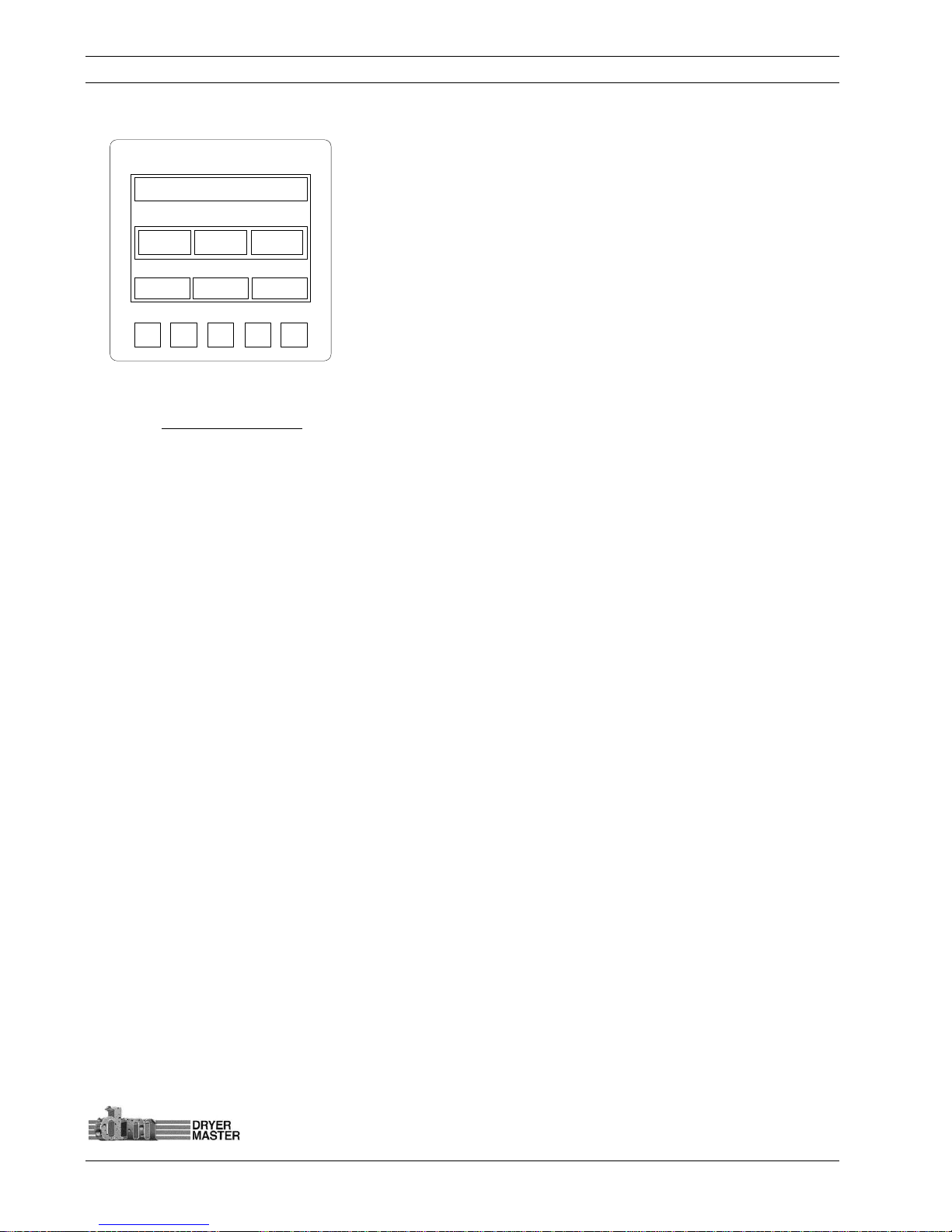

Figure 6. –System display items description.

SYSTEM

F1 F2 F3 F4

Corn

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

3 4 51 2

9 810 7 6

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 12

Product Temperature: Actual temperature of product as detected by the Moisture sensor

temperature probe.

Moisture targets: Indicates, top to bottom “High” moisture trip point, “Target” moisture,

“Low” moisture trip point. This is an active touch area. Press to change values.

Product Name: This is the currently selected product. The text is replaced by an alarm

indicator in the event either the product temperature or product moisture is in alarm.

Product Moisture display: Actual moisture of the product as detected by the Dryer Master

Moisture sensor. Note this will indicate “Empty” when the sensor output is below critical trigger

threshold either by being empty, not connected or moisture so low that reading is not possible.

Rate: Discharge Rate Set point. This is the speed signal sent to the Dryers Discharge system.

This value is displayed when the dryer speed selection is switched to the AM3 (Manual or

Automatic). This is an active touch area. Press to change values.

Rate Targets: Indicates, top to bottom “High” rate value triggered by low moisture trip point,

“normal” Rate, “Low” rate value triggered by high moisture trip point. This is an active touch

area. Press to change values.

Auto Setup Touch key: Use to set operating limits and Auto modes.

Mode: Operating Mode, choices are “Local”, Speed set at the Dryers Speed potentiometer or

display, “Manual” Speed is set manually at the AM3, “Automatic” Speed set point is Automatic

via the programmed settings.

Menu: Product selection, Sensor calibrations, Alarms and others are available through the

Menu screens.

Trend: Switches to current operation trend graph.

1234568910

7

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 13

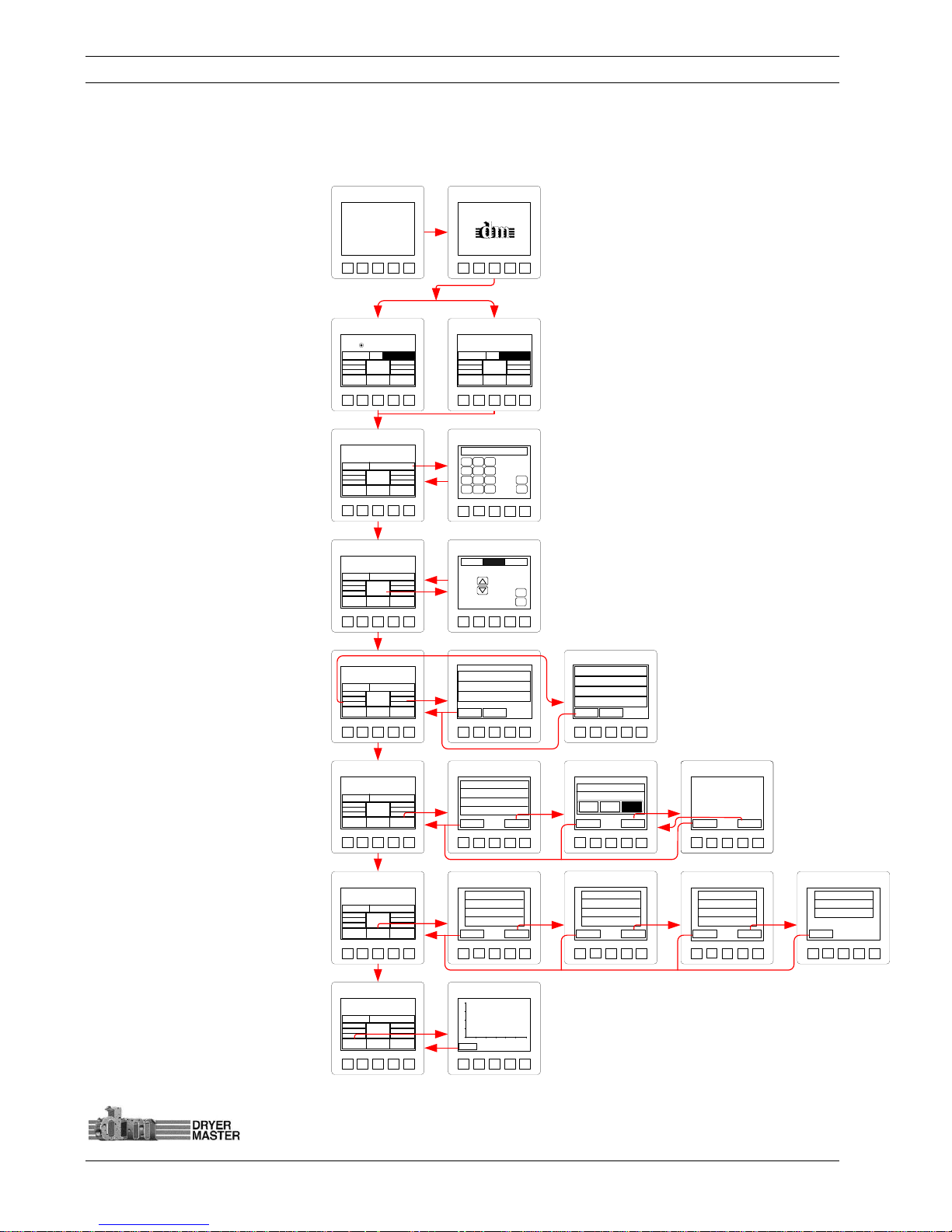

3.2 System Screens Map

This screens map shows the first layer screens available from the Main display. In-depth description and

navigation is detailed in the document.

Start-up “Self Test”

System Information

Main Operations Screens

Main Operations Screen,

setting discharge rate while in

MANUAL mode.

Main Operations Screen,

changing operations modes

Main Operations Screen,

changing Moisture targets and

trip points as well as operating

speeds

Main Operations Screen,

navigating Auto Setup.

Main Operations Screen,

navigating the Menu.

Main Operations Screen,

selecting the Trend displays

Figure 7. –Screen map

SYSTEM

F1

F2 F3 F4

XT105N

*** Self-Test Passed ***

SYSTEM

F1

F2 F3 F4

AM3

Grain

Moisture

Control System

by

Dryer Master

SYSTEM

F1

F2 F3 F4

0.00

_QZ

1

ABC2DEF

3

GHI4JKL5MNO

6

PRS7TUV

8

WXY

9

0+ / -

.

Esc

Enter

SYSTEM

F1

F2 F3 F4

Automatic

Esc

Enter

SYSTEM

F1

F2 F3 F4

Exit

Next

Max Safe Speed 100.00

Min Safe Speed 10.00

Hi/Low Delay Time 300s

Norm Spd Delay Time 300s

SYSTEM

F1

F2 F3 F4

Exit

Help

Max Safe Speed 100.00

MODE A

MODE CMODE B

Rate Mode Select

SYSTEM

1 QZ

F1

2 ABCF23 DEFF34 GHI

F4

Exit

Help

Max Safe Speed 100.00

MODE A

MODE CMODE B

Rate Mode Select

SYSTEM

F1

F2 F3 F4

Exit

Back

Mode A: All speeds set manually.

Mode B: “H/L Rate Change” setting

determines high and low speeds.

Mode C: “Rate Change” determines

high and low speeds.

See manual for further info.

SYSTEM

F1

F2 F3 F4

Exit

Next

F1 Change Product

F2 Calibrate Sensor

F3 Set Alarms

F4 Alarm Log

SYSTEM

F1

F2 F3 F4

Exit

Next

F1 Alarm Delay

F2 Remote Alm Delay

F3 Printing

F4 Temp. Scale

SYSTEM

F1

F2 F3 F4

Exit

F1 Information

F2 Removable Media

F3 Auto Setup

SYSTEM

F1

F2 F3 F4

Exit

Next

F1 System Settings

F2 Eng. Functions

F3 Languages

F4 Trending Options

SYSTEM

F1

F2 F3 F4

Exit

2

0

%

1

0

Time (10min/DIV)

SYSTEM

F1 F2 F3 F4

CORN

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

Empty

SYSTEM

F1 F2 F3 F4

CORN

15.0%

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Manual

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

Exit

Normal Rate 50.00

High Rate 55.00

Low Rate 45.00

Back

SYSTEM

F1 F2 F3 F4

Exit

Target Moisture 15.0%

High Moist. Limit 16.0%

Low Moist. Limit 14.0%

Rate Settings

Back

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 14

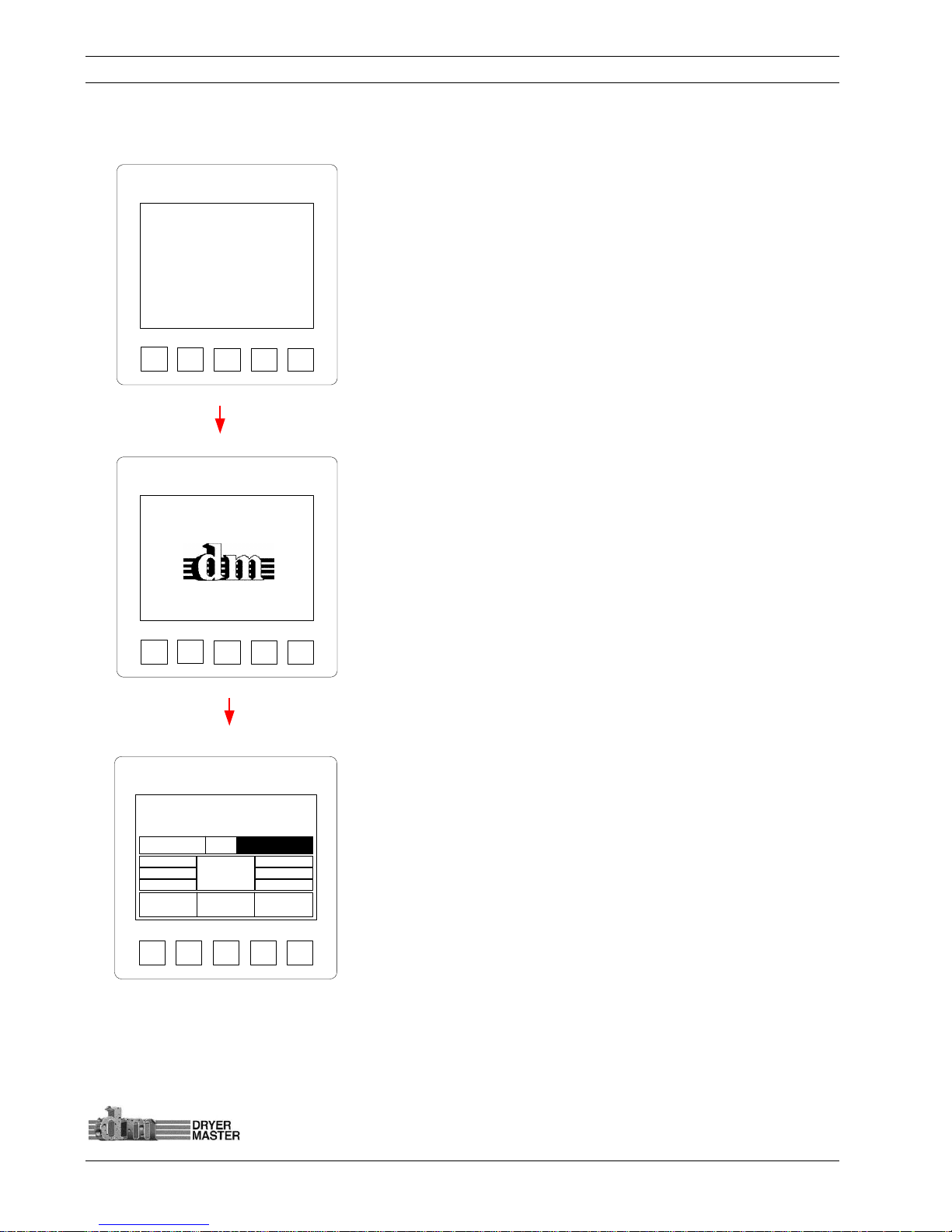

3.3 System start displays

At System start the unit will display the start-up diagnostic screen.

Figure 8. –Start-up diagnostics display

Once the diagnostics are complete the unit will execute the

installed program, during this time the product information screen

will display.

Figure 9. –Product information display

The Main Operations screen displays product moisture, product

name, product temperature, and Dryer discharge rate when in

Manual or Auto Mode.

Depending on the system state, different information may be

displayed

Figure

10.

–Main Display

SYSTEM

F1

F2 F3 F4

XT105N

*** Self-Test Passed ***

SYSTEM

F1

F2 F3 F4

AM3

Grain

Moisture

Control System

by

Dryer Master

SYSTEM

F1 F2 F3 F4

CORN

15.0%

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 15

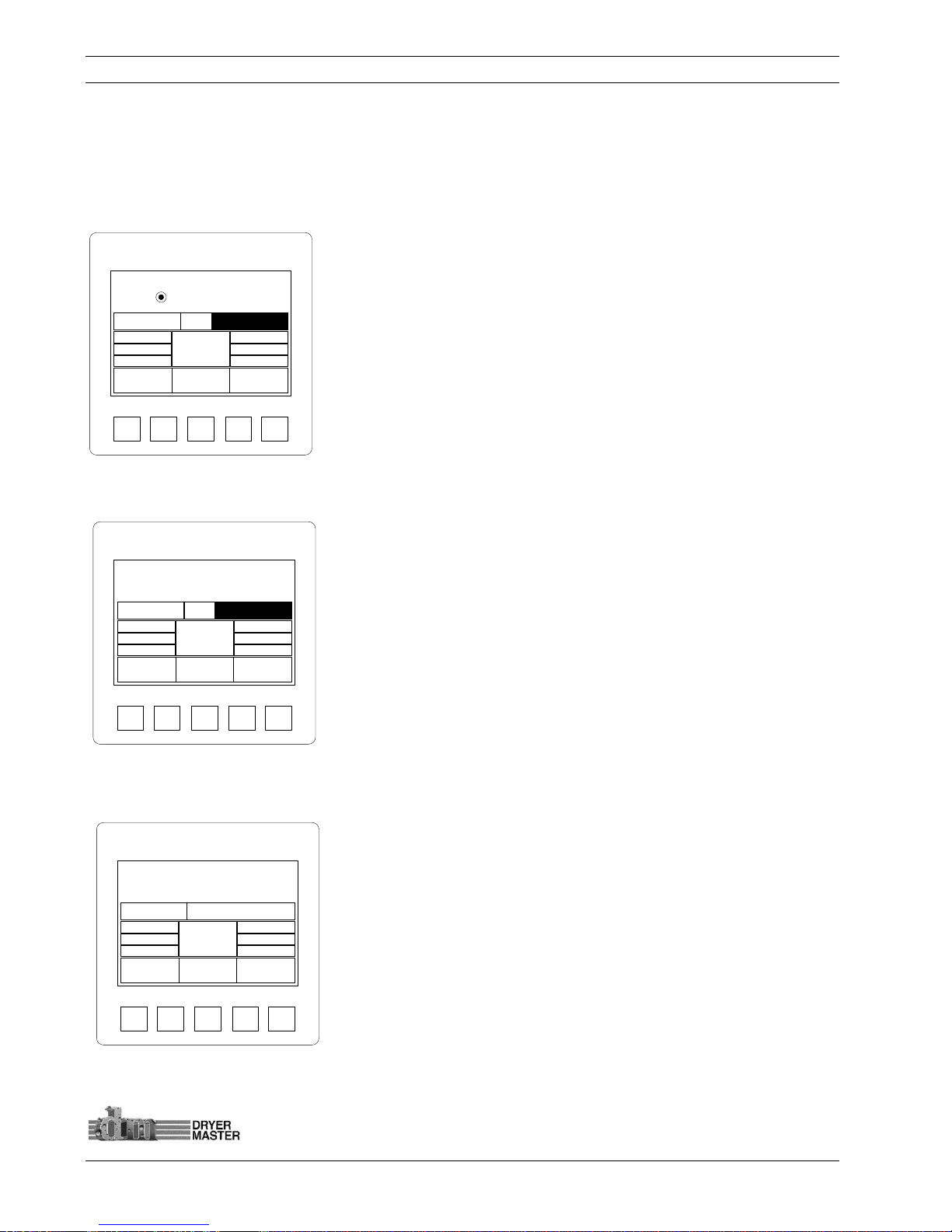

3.4 Main operations displays

3.4.1 Main Display – Local Mode - Sensor Empty

The Main Operations screen displays product moisture, product name, product temperature and the

dryer discharge rate while in Manual or Automatic mode. It is shown here with the Sensor Empty and

the dryer rate set at the dryer.

The Main Operations screen will display “Empty” under the following

conditions

• The moisture sensor is partially or completely empty

• The product is flowing too quickly.

• The product moisture is below the sensors reading threshold

• The sensor is not sending a signal

• The sensor is not connected

Figure

11.

–Main Display – Sensor Empty,

3.4.2 Main Display – Local Mode

Note the Moisture is displayed as well as the product name.

The system is in “Local” mode; dryer discharge rate is set at the dryer

thus there is no rate display.

Press the “Touch Area” <Rate :> or the text <See Dryer> to

display the rate entry screen and set a rate value prior to

switching modes.

Figure

12.

–Main Display – Local Mode

3.4.3 Main Display – Manual Mode

The system is in “Manual” mode; dryer discharge rate is set here at

the display.

Press the “Touch Area” <Rate :> or the rate value <10.00> to display

the rate entry screen.

Figure

13.

–Main Display – Manual Mode

SYSTEM

F1 F2 F3 F4

CORN

15.0%

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

CORN

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

Empty

SYSTEM

F1 F2 F3 F4

CORN

15.0%

Mode:

Manual

75 °F Rate: 10.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 16

3.4.4 Main Display – Automatic Mode

The system is in “Automatic” mode; dryer discharge rate is set here at the display. Depending on the

product moisture the system will switch between the 3 rates displayed. The rate values can be set by

pressing the Rate values touch area or in the “Auto setup” section. The Main rate will continue to need

periodic manual adjustment to maintain the operating window.

Press the “Touch Area” <Rate :> or the rate value <50.00> to display

the rate entry screen.

Press the “Touch Area” <Rate Values> to display the rate entry

screen.

Press the “Touch Area” <Moisture targets> to display the moisture

target and moisture trigger point entry screen.

Figure

14.

–Main Display – Automatic Mode

3.4.5 Alarm screen

The Alarm screen will display when the displayed moisture or

product temperature is in alarm. The active alarms will flash.

Press the “Touch area” <Exit> to return to the main screen

Press the “Touch area” <Alarm Log> to view the alarm history. See

section “Alarm settings” for additional information.

Figure

15.

–Alarm screen

3.4.6 Main Display – Active Alarm

The Main Operations screen with active Alarm

The product label is replaced with an alarm event indicator. The

alarm Indicator will stay active until the condition clears

See section “Alarm settings” for information on setting the alarm

limits.

Figure

16.

–Main Display – Active Alarm

SYSTEM

F1

Exit

Cr i t . Lo w Temp.

F2 F3 F4

Active Alarms

War n. Lo w Temp.

Cr i t . Lo w Moi s t .

War n. Lo w Moi s t .

Alarm

Log

SYSTEM

F1 F2 F3 F4

CORN

15.1%

Mode:

Automatic

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

SYSTEM

F1 F2 F3 F4

ALARM

5.1%

Mode:

Automatic

75 °F Rate: 50.00

Trend Menu

Auto

Setup

16.0%

15.0%

14.0%

55.00

50.00

45.00

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 17

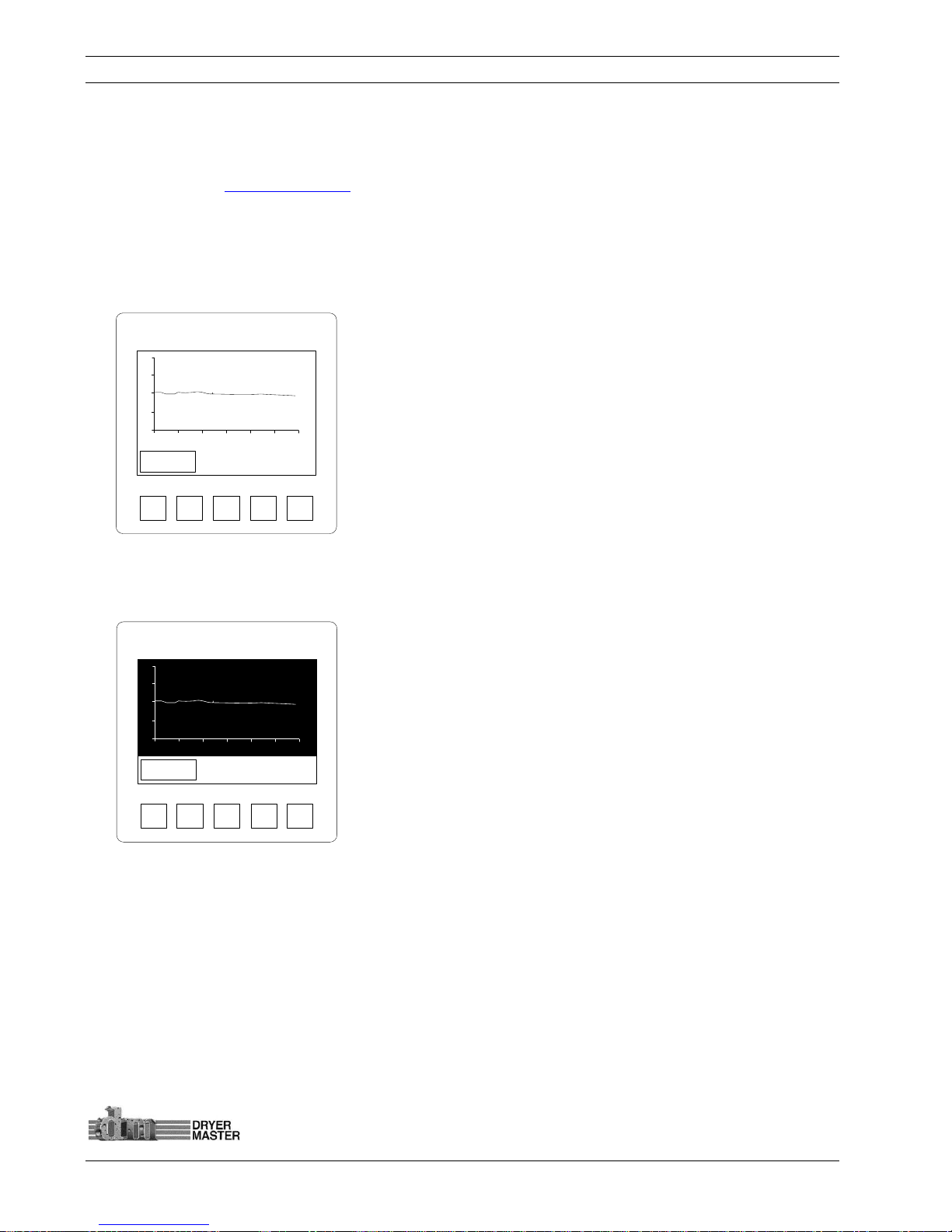

3.5 Moisture trend displays

One (1) hour or two (2) hour moisture trends in 3 moisture ranges are available for display, 0-10%, 10%20% and 20%-40%.. Trending must be enabled and configured before this function becomes active.

See the section on Trending Options to enable and configure moisture trending.

Note trending is an integrated function of the displays firmware. The information and display scaling is

limited.

3.5.1 One Hour Moisture trend display

One (1) hour moisture trend

Press the “Touch area” <Exit> to return to the main screen

Figure

17.

–One (1) hour Moisture Trend

3.5.2 Two Hour Moisture trend display

Two (2) hour moisture trend

Press the “Touch area” <Exit> to return to the main screen

Figure

18.

–Two (2) hour Moisture Trend

SYSTEM

F1 F2 F3 F4

%

Time (10min/DIV)

Exit

2

0

1

0

SYSTEM

F1 F2 F3 F4

Exit

%

Time (20min/DIV)

2

0

1

0

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 18

4 Operating the Dryer from the AM3

This section will describe how to operate the dryer from the AM3. The modes of operation are

reviewed as well as an in-depth description of the 3 modes of Automatic. This section assumes the AM3

has already been calibrated and set up to work with your dryer. Refer to the section “The Menu Tree”

to set up the various alarm settings and especially the rate output setup in the engineering section.

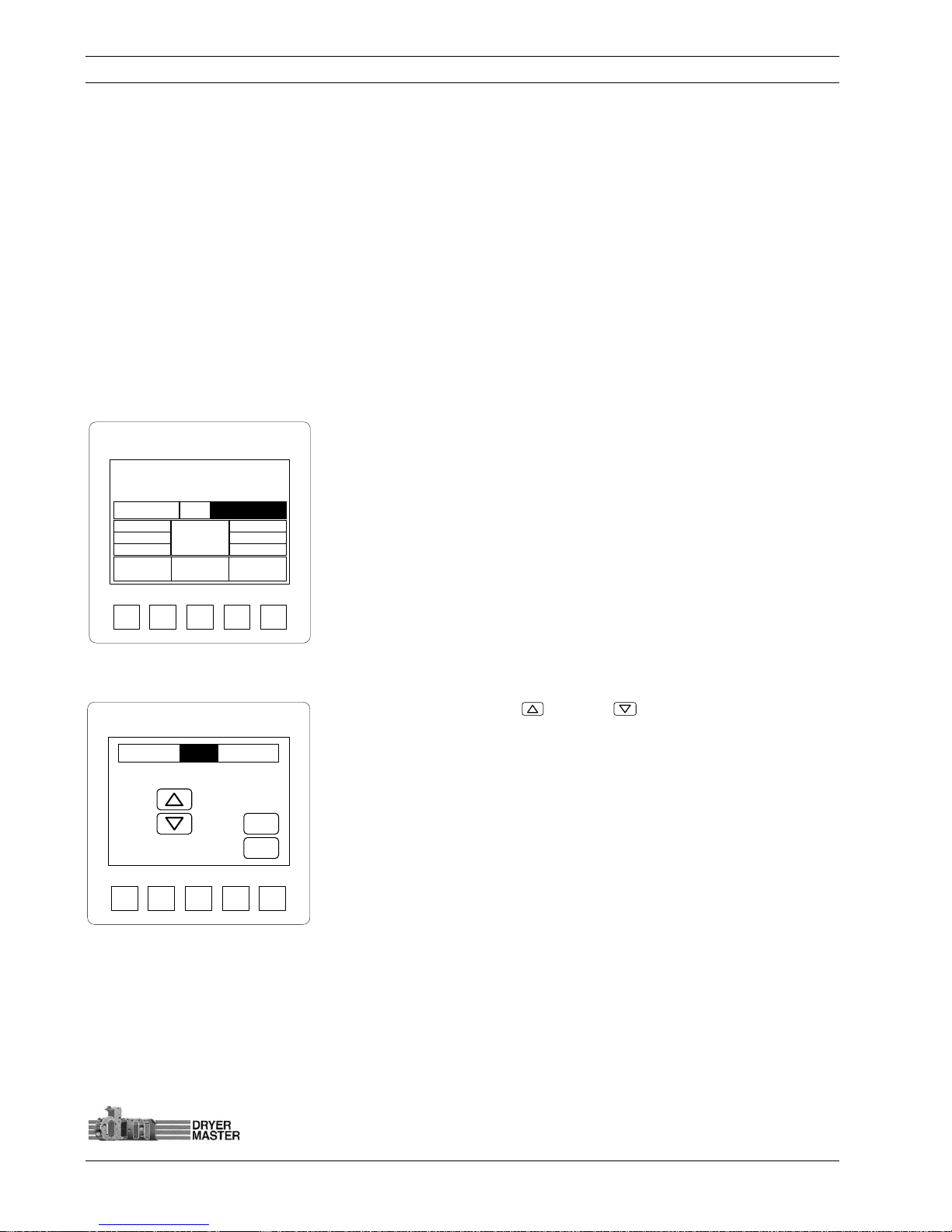

4.1 Operating the System

At start-up the system will boot to this current operation or main screen. While in manual mode the

rate set point will display whether the dryer is running or not.

4.1.1 Main Display – Local Mode

With the dryer running and discharging product you will see a moisture reading, the product

temperature, and the rate is displayed if in “Manual” or Automatic” mode. There is no feed back so we

do not know what the rate is in “Local” mode.

Press the “Touch area” <Mode: > to display the Mode change screen.

Press the “Touch area” <Rate: > to display dryer discharge speed

“Rate” entry screen.

Press the “Touch area” <Auto Setup> to adjust or modify the

Automatic operation settings.

Figure

19.

–Main Display

4.1.2 Operating Mode Select Screen

Press the “Touch area” Up or down arrow to toggle between

the modes “Local”, “Manual”, and “Automatic”

Press the “Touch area” <Enter> to select the item and return to the

main screen.

Press the “Touch area” <Esc > to return to the Main screen.

Figure

20.

–Mode Select screen

Local

SYSTEM

F1 F2 F3 F4

Enter

Esc

Local

SYSTEM

F1 F2 F3 F4

CORN

15.0%

75 °F

Rate: 10.00

Trend Menu

Auto

Setup

See Dryer

Mode:

Local

16.0%

15.0%

14.0%

55.00

50.00

45.00

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 19

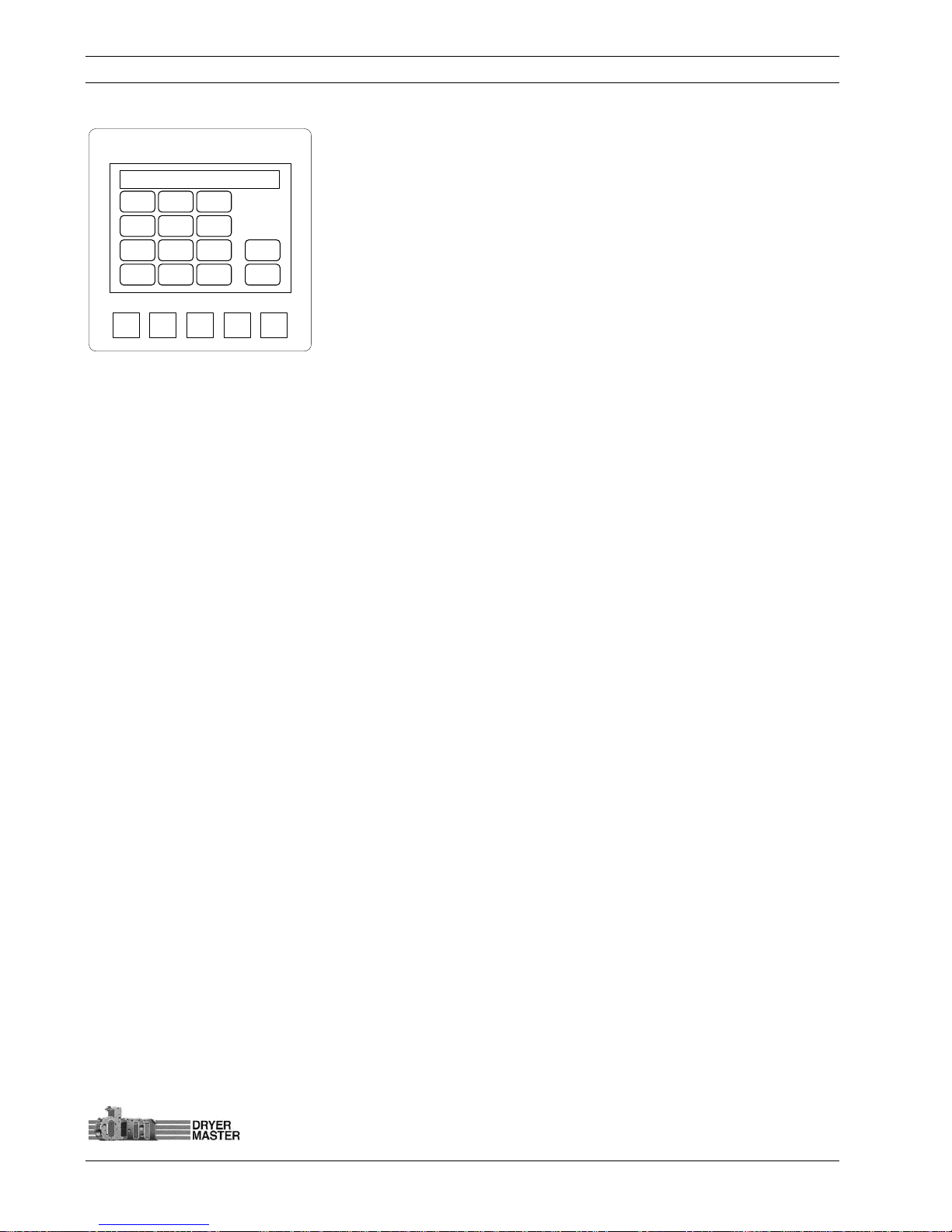

4.1.3 Setting Drying Rate

Press the “Touch area” Keypad to type a dryer discharge rate.

Press the “Touch area” <Enter> to select the item and return to the

main screen.

Press the “Touch area” <Esc > to return to the Main screen.

Figure

21.

–Drying rate setting screen

How setting the Rate works:

There are 3 modes of operation:

1. “Local” – Speed is set at the dryers speed potentiometer or keypad. This is manual mode

and the operator will need to decide what speed needs to be selected. The Moisture and

product temperature display is available so even this manual mode is enhanced with

continuous moisture information.

2. “Manual” – The speed is set from the Dryer Master AM3. This is also a manual mode and the

operator still needs to decide what speed needs to be selected. The advantage is the speed is

now set digitally from the AM3 panel. Speeds are recorded and printed if the printer and

compact flash option where ordered as part of the system.

3. “Automatic” – The normal or primary speed is also set from the Dryer Master AM3. This is a

semi automatic mode. The operator adjusts the speed so that the target moisture is achieved.

The system will then switch between normal running or primary speed and the high speed set

point or the low speed set point. Depending on the product moisture and trigger targets.

Periodic adjustment of the normal speed is required if the system deviates from target

significantly.

37.00

_QZ

1

GHI

4

PRS7TUV8WXY

9

.

SYSTEM

F1 F2 F3 F4

0+/-

ABC2DEF

3

JKL5MNO

6

Enter

Esc

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 20

4.2 Auto Setup

There are various features available in Automatic mode. These should be reviewed and set up to best

reflect your operation and needs. The setup can be changed at any time should the need arise.

4.2.1 Auto Setup – Setting Speed Limits and Delay time

Press the “Touch area” <Max safe Speed> to display the numeric

touch pad data entry screen for setting the maximum speed.

Press the “Touch area” <Min safe Speed> to display the numeric

touch pad data entry screen for setting the minimum speed.

Press the “Touch area” <Hi/low delay Time> to display the numeric

touch pad data entry screen to set the delay before changing the

speed. Time is in seconds.

Press the “Touch area” <Norm Spd. delay Time> to display the

numeric touch pad data entry screen to set the delay before changing

the speed back to normal speed. Time is in seconds.

Press the “Touch area” <Exit > to return to the Main screen.

Press the “Touch area” <Next > to continue to the next menu screen.

Figure

22.

– Auto Setup – Speed limits and delay time

How the speed limits and delay time work:

The Speed limits and delay times serve as constraints to ensure safe and reliable operation. These

should be set with care and possibly experimentation to ensure optimum performance

1) Max Safe Speed – This is the maximum speed your drying system can operate at. Before

setting this speed consider the takeaway and feed systems to ensure this setting will not

overload the equipment. Also look at the real operation. If you know your dryer should never

operate above 70 for any reason this should be set to 70 or possibly less.

2) Min Safe Speed – This is the minimum speed your drying system can operate. Same as before

there is a minimum speed below which the system should never need to operate.

3) Hi /Low Delay Time – This is the time in seconds the moisture has to be either above the “high

limit moisture target” or below the “low limit moisture target” before the speed will change to

either the “low speed setpoint” or the “high speed setpoint”. Time is in seconds, 300 seconds is

5 minutes. 999 seconds or about 16 minutes 39 seconds is the maximum delay available.

4) Norm Spd Delay Time – (Normal Speed Delay Time) This is the time in seconds the moisture has

to have returned to normal (the window between the “high and low moisture target”) or have

moved to the other side of the target moisture ( mode dependent) before the speed is again

returned to normal mode. 999 seconds or about 16 minutes 39 seconds is the maximum delay

available.

SYSTEM

F1 F2 F3 F4

Exit Next

Max Safe Speed 100.00

Min Safe Speed 10.00

Hi / Low Delay Time 300s

Norm Spd Delay Time 300s

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 21

4.2.2 Auto Setup –Limits and Rate Mode selection

Press the “Touch area” <Moist. And Rate Limits> to display the

moisture target, moisture limits and Rate Settings selection menu

screen

Press the “Touch area” <Mode A, Mode B, or Mode C> to select

the Automatic operating mode.

Press the “Touch area” <Exit > to return to the Main screen.

Press the “Touch area” <Back > to return to the previous menu

screen.

Figure

23.

– Auto Setup – Limits and Rate mode selection

How Control works:

There are 3 Automatic modes: This is a state machine. Control is achieved by triggering 1 of 3 speed

set points using target moisture, moisture limits and delay times. All these items are user settable and

may require periodic adjustment for optimum performance. The operator decides which mode bests

suits the operation. Automatic modes can de changed at any time.

1) Mode A – This mode requires input from the operator for all 3 speed settings. The normal

running speed as well as the high and low default speeds need to be set. If the normal speed

is adjusted the high and low speed settings must also be reviewed and adjusted if need be.

2) Mode B – This mode once set up requires input from the operator with occasional adjustments

of the normal or primary running speed. The high speed set point and low speed set point

track the normal or primary speed to maintain a constant operating window.

3) Mode C – This mode once set up also only requires input from the operator with occasional

adjustments of the normal or primary running speed. The high speed set point and low speed

set point track the normal or primary speed to maintain a operating window as a percentage of

the primary speed.

SYSTEM

F1 F2 F3 F4

Exit Help

Moist. And Rate Limits

Rate Mode Select

Mode A

Back

Mode B Mode C

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 22

4.2.3 Auto Setup – Moisture Targets, Moisture Limits and Rate Settings selection

Press the “Touch area” <Target Moisture > to set the moisture

target

Press the “Touch area” <High Moist Limit> to set the High

Moisture trigger point for Automatic operating mode.

Press the “Touch area” <Low Moist Limit> to set the Low

Moisture trigger point for Automatic operating mode.

Press the “Touch area” <Rate Setup> to continue to the rate

setup screen.

Press the “Touch area” <Exit > to return to the Main screen.

Press the “Touch area” <Back > to return to the previous menu

screen.

Figure

24.

– Auto Setup – Moisture targets, Moisture Limits and Rate settings selection

How to set up Control:

This section will explain what happens.

In all Automatic modes it is prudent for the operator to operate the dryer manually to attain the

desired moisture, before selecting Automatic. It is important to monitor the operation and adjust the

settings to permit the dryer and Dryer Master AM3 to operate effectively.

SYSTEM

F1 F2 F3 F4

Exit

Target Moisture 15.0%

High Moist. Limit 16.0%

Low Moist. Limit 14.0%

Rate Settings

Back

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 23

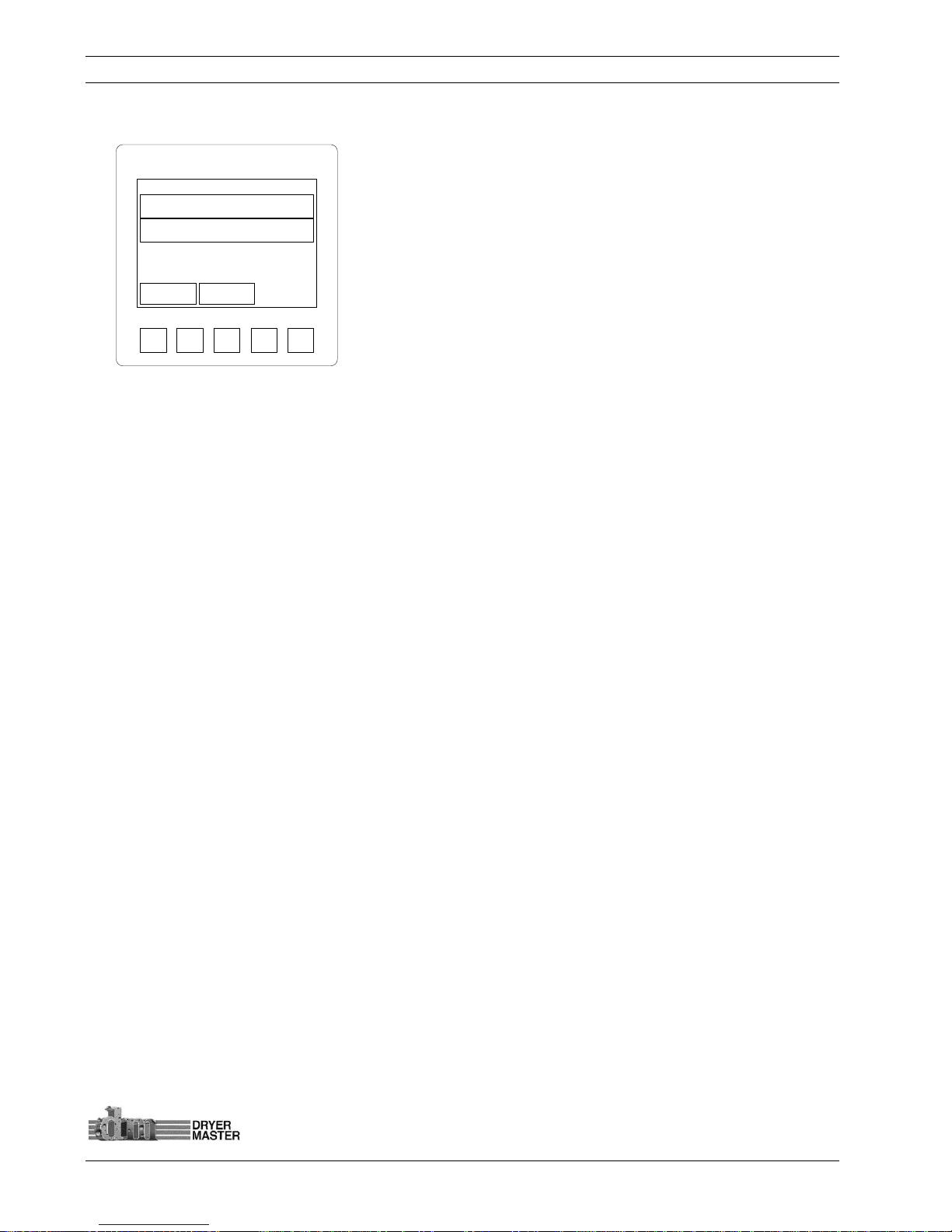

4.2.4 Auto Setup –Rate Selection Mode A

Press the “Touch area” <Normal Rate > to display the numeric

touch pad data entry screen for setting the “Normal” running

speed.

Press the “Touch area” <High Rate > to display the numeric

touch pad data entry screen for setting the High Rate speed. This

is the speed the system will run will moisture is below the “Low

Moist. Limit”

Press the “Touch area” <Low Rate > to display the numeric

touch pad data entry screen for setting the Low Rate speed. This

is the speed the system will run will moisture is above the “High

Moist. Limit”

Figure

25.

– Auto Setup –Rate selection Mode A

Press the “Touch area” <Exit > to return to the Main screen.

Press the “Touch area” <Back > to return to the previous menu

screen.

1) Mode A:

a. An event happens and the moisture drifts away from target.

b. The moisture goes high. The moisture goes above the High limit target occasionally but

nothing happens. Note, there is a timer that is triggered anytime the moisture goes

above the high limit target or low limit target.

c. Once the moisture stays above the High limit target for the programmed length of time

(default is 300 seconds = 5 minutes). The low speed setting is activated.

d. The system will now operate at this slower speed setting until the moisture is once

again below the High limit target.

e. When the moisture has been below the High moisture target for the programmed

length of time (default is 300 seconds = 5 minutes) system will return to the normal or

primary speed.

f. A second event happens and the moisture again drifts away from target

g. This time the moisture goes dry. The moisture goes below the Low limit target. Again

the moisture has to stay below the Low limit target for the programmed length of time

(default is the same 300 seconds = 5 minutes)

h. Once the moisture stays below the Low Limit target for the programmed length of time

(default is 300 seconds = 5 minutes). The high speed setting is activated.

i. The system will now operate at this higher speed setting until the moisture is once

again above the Low limit target.

j. When the moisture has been above the Low moisture target for the programmed

length of time (default is 300 seconds = 5 minutes) system will return to the normal or

primary speed.

The system will cycle between the speed settings triggered by the moisture target and limits. In

Mode A all 3 speeds are manually set, as well as the moisture target and limits, and the delay time.

SYSTEM

F1 F2 F3 F4

Exit

High Rate 55.00

Normal Rate 50.00

Low Rate 45.00

Back

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 24

4.2.5 Auto Setup –Rate Selection Mode B

Press the “Touch area” <Normal Rate > to display the numeric

touch pad data entry screen for setting the “Normal” running

speed.

Press the “Touch area” <H / L Rate > to display the numeric touch

pad data entry screen for setting the “High Rate speed”. This the

difference value from the “Normal Rate”.

In this example, “Normal rate” + “H/L rate” = “High Rate”, 50 + 5 =

55 and “Normal rate” - “H/L rate” = “Low Rate”, 50 - 5 = 45

Press the “Touch area” <Exit > to return to the Main screen.

Press the “Touch area” <Back > to return to the previous menu

screen.

Figure

26.

– Auto Setup –Rate selection Mode B

2) Mode B:

a. Events are identical to Mode A. An event happens and the moisture drifts away from

target.

b. The moisture goes high. The moisture goes above the High limit target.

c. Once the moisture stays above the High limit target for the programmed length of time

(default is 300 seconds = 5 minutes). The low speed setting is activated.

d. The system will now operate at this slower speed setting until the moisture is once

again below the High limit target.

e. Only in Mode B the slower as well as the higher speed settings are a fixed value change,

an offset from the normal or primary speed. This is a parameter settable by the user.

f. If an adjustment is require to the normal or primary operating speed the High and Low

speed settings will also change by the programmed offset.

The system will cycle between the speed settings triggered by the moisture target and limits. In

Mode B the normal or primary speed is manually set, as well as the moisture target and limits, and

the delay time and possibly an occasional tweak of the speed offset.

SYSTEM

F1 F2 F3 F4

Exit

Normal Rate 50.00

H / L Rate Change 5.00

Back

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 25

4.2.6 Auto Setup –Rate Selection Mode C

Press the “Touch area” <Normal Rate > to display the numeric

touch pad data entry screen for setting the “Normal” running

speed.

Press the “Touch area” <% Rate Change> to display the numeric

touch pad data entry screen for setting the % Rate Change. This

the difference value from the “Normal Rate” as a percent of the

normal rate.

In this example, “Normal rate” + “% Rate Change” = “High Rate”, 50

+ (50/100*10) = 55 and “Normal rate” - “% Rate Change” = “Low

Rate”, 50 – (50/100*10) = 45

Press the “Touch area” <Exit > to return to the Main screen.

Figure

27.

– Auto Setup –Rate selection Mode C

Press the “Touch area” <Back > to return to the previous menu

screen.

3) Mode C:

a. Events are identical to Mode A. and B

b. If an adjustment is require to the normal or primary operating speed the High and Low

speed settings will also change by the programmed offset. In this case this offset is

dynamic because it is a percentage of the normal or primary running speed. Therefore

the amount of change will be smaller at lower speeds and larger for higher speeds thus

reducing the input required by the user.

The system will cycle between the speed settings triggered by the moisture target and limits. In

Mode C the normal or primary speed is manually set, as well as the moisture target and limits, and

the delay time and possibly a tweak of the speed offset percentage.

4) All modes will require some tuning to optimize the system operation. Different dryers and

different products will require slightly different operating parameters. The default parameters

should allow the system to operate and provide good results. Adjusting the moisture targets

and limits and finding the optimum speed offsets for your application should allow the system

to maintain very good moisture control.

5) The key is to maintain the normal running rate settings where it needs to be and provide a

sufficient window with the high and low rate change settings to allow the system to operate

effectively.

SYSTEM

F1 F2 F3 F4

Exit

Normal Rate 50.00

% Rate Change 10.0%

Back

Dryer Master AM3 Product Manual

©Dryer Master Inc. Page: 26

5 The Menu Tree

This section describes the various menus and screens and details functions, such as changing product,

adjusting the moisture sensor calibration, setting alarms, reviewing the alarm log and others are all

available by pressing the “Touch area” <Menu>. Each item will be covered in detail in the following

pages. We have attempted to place the more used functions to the front and the progressively less

used items to the rear.

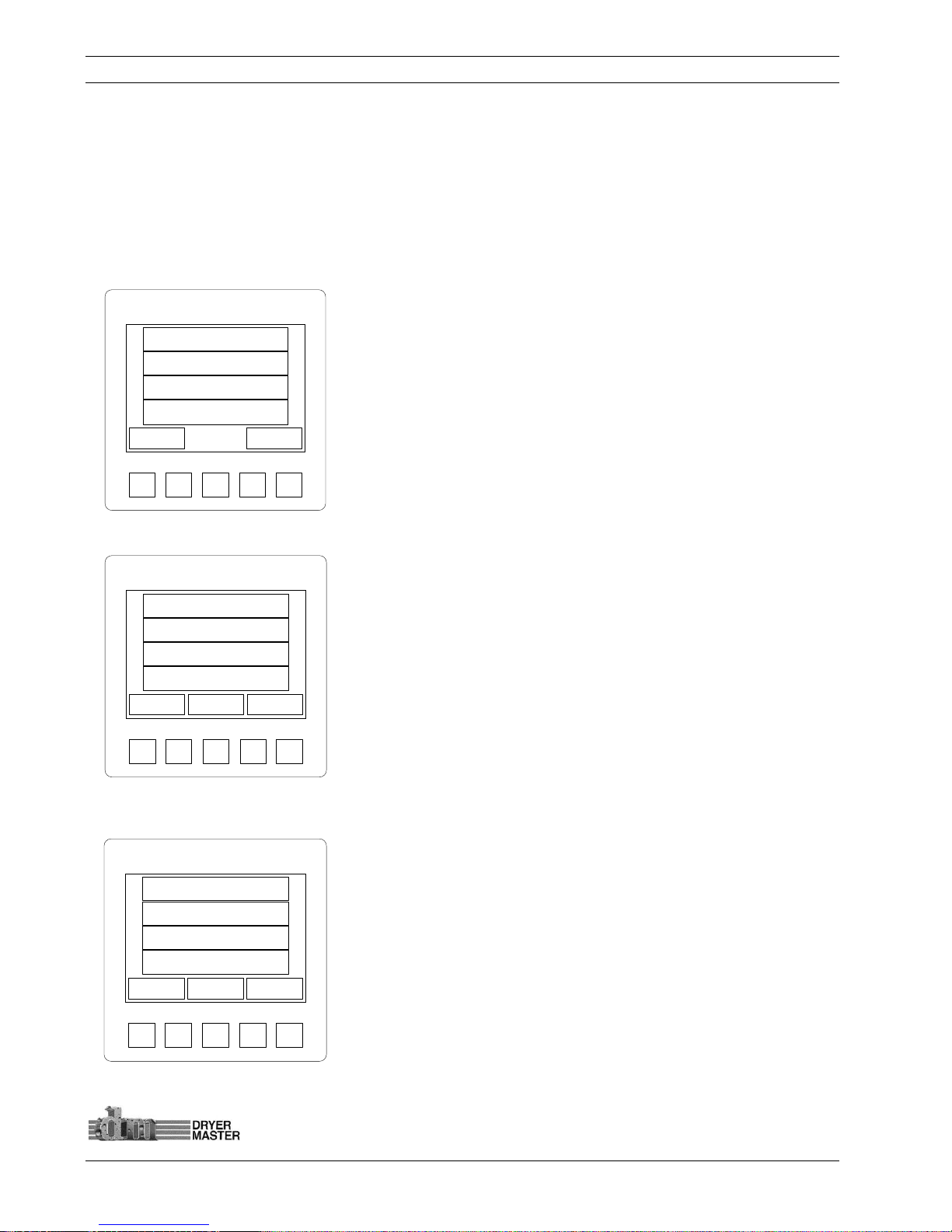

5.1 Main Menus

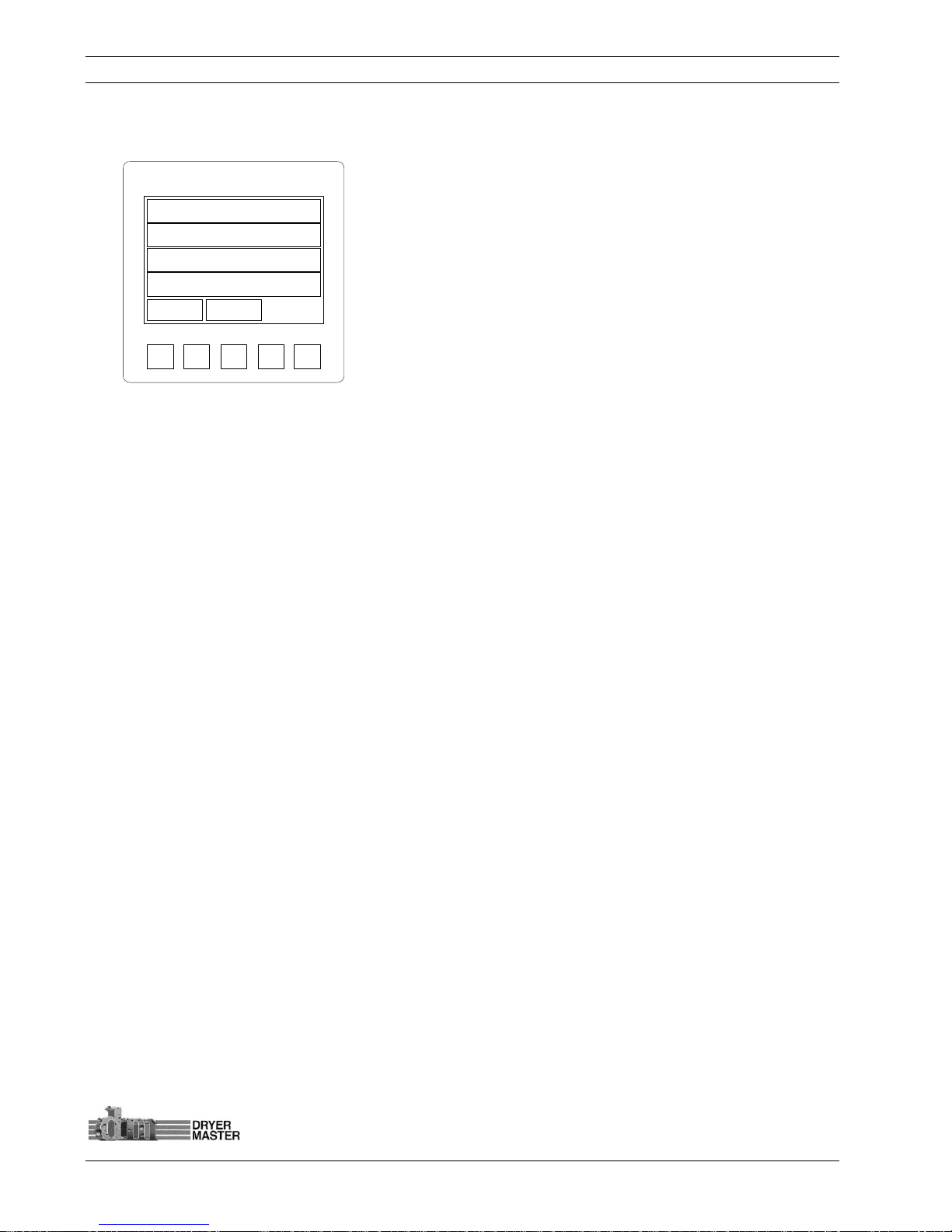

5.1.1 Menu – Screen 1

Press the “Touch area” <F1 Change Product> or the <F1> button to enter

the Product selection screen.

Press the “Touch area” <F2 Calibrate Sensor> or the <F2> button to enter

the Sensor Calibration adjustment screen.

Press the “Touch area” <F3 Set Alarms> or the <F3> button to enter the

Product moisture and Product Temperature Alarms adjustment screen.

Press the “Touch area” <F4 Alarm log> or the <F4> button to review a

recent history of alarm occurrences.

Press the “Touch area” <Exit> to return to the main screen

Press the “Touch area” <Next > to move to the next screen

Figure

28.

–Menu One (1)

5.1.2 Menu – Screen 2

Press the “Touch area” <F1 Alarm Delay> or the <F1> button to enter the

Local alarm activation delay screen.

Press the “Touch area” <F2 Remote Alarm Delay> or the <F2> button to

enter the Remote alarm activation delay screen.

Press the “Touch area” <F3 Printing > or the <F3> button to enter the

Printing setup and enable screen.

Press the “Touch area” <F4 Temp. Scale> or the <F4> button to enter the

screen to switch the temperature display from degrees Fahrenheit to

degrees Celsius

Press the “Touch area” <Exit> to return to the main screen

Press the “Touch area” <Back> to return to the previous screen

Press the “Touch area” <Next > to move to the next screen

Figure

29.

–Menu Two (2)

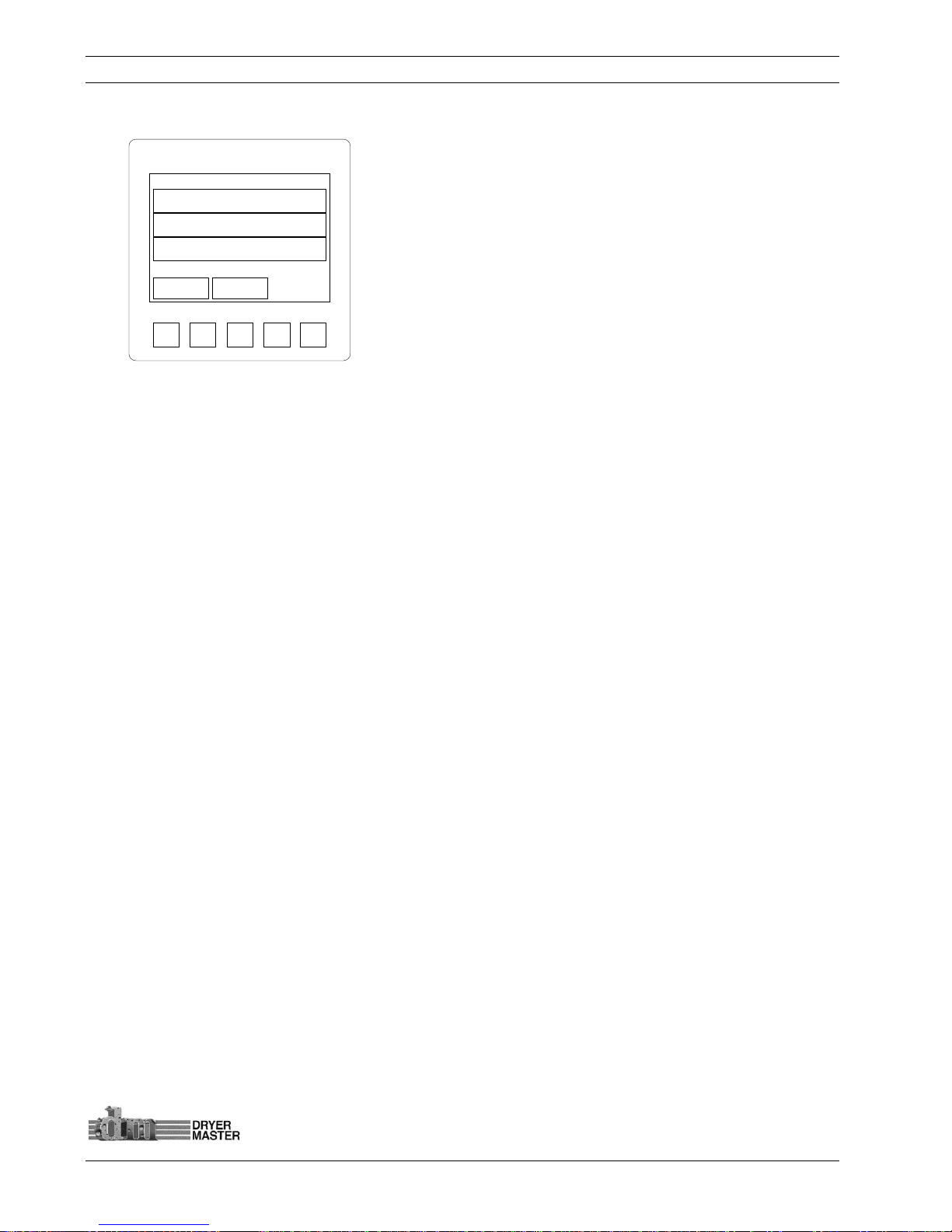

5.1.3 Menu – Screen 3

Press the “Touch area” <F1 System Settings> or the <F1> button set

various device related items. Date & time, contrast and the screen saver

Press the “Touch area” <F2 Eng. Functions> or the <F2> button to enter

the Engineering setup screens. Password protected. ___________________

Press the “Touch area” <F3 Languages > or the <F3> button to change the

displayed language.

Press the “Touch area” <F4 Trending Options> or the <F4> button to enter

the screen to Trending moisture scaling and time.

Press the “Touch area” <Exit> to return to the main screen

Press the “Touch area” <Back> to return to the previous screen

Press the “Touch area” <Next > to move to the next screen

Figure

30.

–Menu Three (3)

SYSTEM

F1 F2 F3 F4

Exit Next

F1 Change Product

F2 Calibrate Sensor

F3 Set Alarms

F4 Alarm Log

SYSTEM

F1 F2 F3 F4

Exit Next

F1 Alarm Delay

F2 Remote Alarm Delay

F3 Printing

F4 Temp. Scale

Back

SYSTEM

F1 F2 F3 F4

Exit Next

F1 System Settings

F2 Eng. Functions

F3 Languages

F4 Trending Options

Back

Loading...

Loading...