AIR MOVER MANUAL

TEMPEST™ TYPHOON™

Congratulations on your purchase of a Dry Air Technology Air Mover. Dry Air Technology Air Movers

are conveniently small and extremely lightweight yet powerful enough to create airflow beyond your

expectations. They have been engineered to be durable, long lasting and high performing. These air

movers have been rigorously tested for heavy-duty us.

Your new unit was designed to provide the maximum performance. Please read this owner’s manual

carefully to insure that you get the most from your unit.

SAFETY INFORMATION

CAUTION!

Unit operates on alternating current:

110/120 volt, 60 Hz or 220/240 volt, 50 Hz

Do not operate your air mover with a cut or frayed power cord. Do not unplug your unit by pulling on its

cord. Grasp the plug firmly and pull it out of the wall socket or power receptacle. The plug has a safety

ground pin installed that must not be removed. If the pin is damaged or missing, have the power cord

replaced at once. Visually inspect the power cord before each use. Ignoring these safety precautions

may result in a fire or an electric shock.

To reduce the risk of fire or electric shock, do not use this fan with any solid state speed control device.

Never operate electrical equipment in standing water. There is a shock hazard.

Never drop the unit. Sudden and severe impact may result in damage to internal components.

Your air mover should never be operated with the safety grills removed. Personal injury may result.

Drop cloths or other loose fabrics can be drawn against the unit thereby restricting airflow. This

condition may cause the unit to overheat. Keep the air inlet clear of any obstructions.

Save the shipping carton in case your air mover must be returned for repair.

This unit should never be serviced or cleaned while it is plugged into a live electrical power source.

WARNING: Ignoring these safety precautions may result in serious personal injury.

TEMPEST

™ TYPHOON™

OPERATING INSTRUCTIONS

Please inspect your unit upon receipt for any freight damages. Be sure to keep all original packaging.

Original packaging will help protect unit from freight damage upon return.

If you discover any damages during inspection, please contact Dry Air Technology.

The unit as packaged is ready to be put into service. If you have a 220v model, attach the appropriate

plug for your region.

Inspect the unit completely for any shipping damage. Place the unit on the ground or on a very stable

platform.

Plug the unit into a grounded alternating current circuit and switch the unit on.

MAINTENANCE

When turning on equipment for use, always check to make sure the unit is running properly.

When the unit is first turned on, check for excessive vibration or noise. This would indicate a major

problem. If your unit is running abnormally, troubleshoot to find the cause and make any necessary

adjustments or repairs. Do not allow the unit to run when problem persists. A simple adjustment

problem can turn into complete motor failure if not corrected.

Warning

Disconnect the unit from the power supply before cleaning or servicing.

SPECIFICATIONS

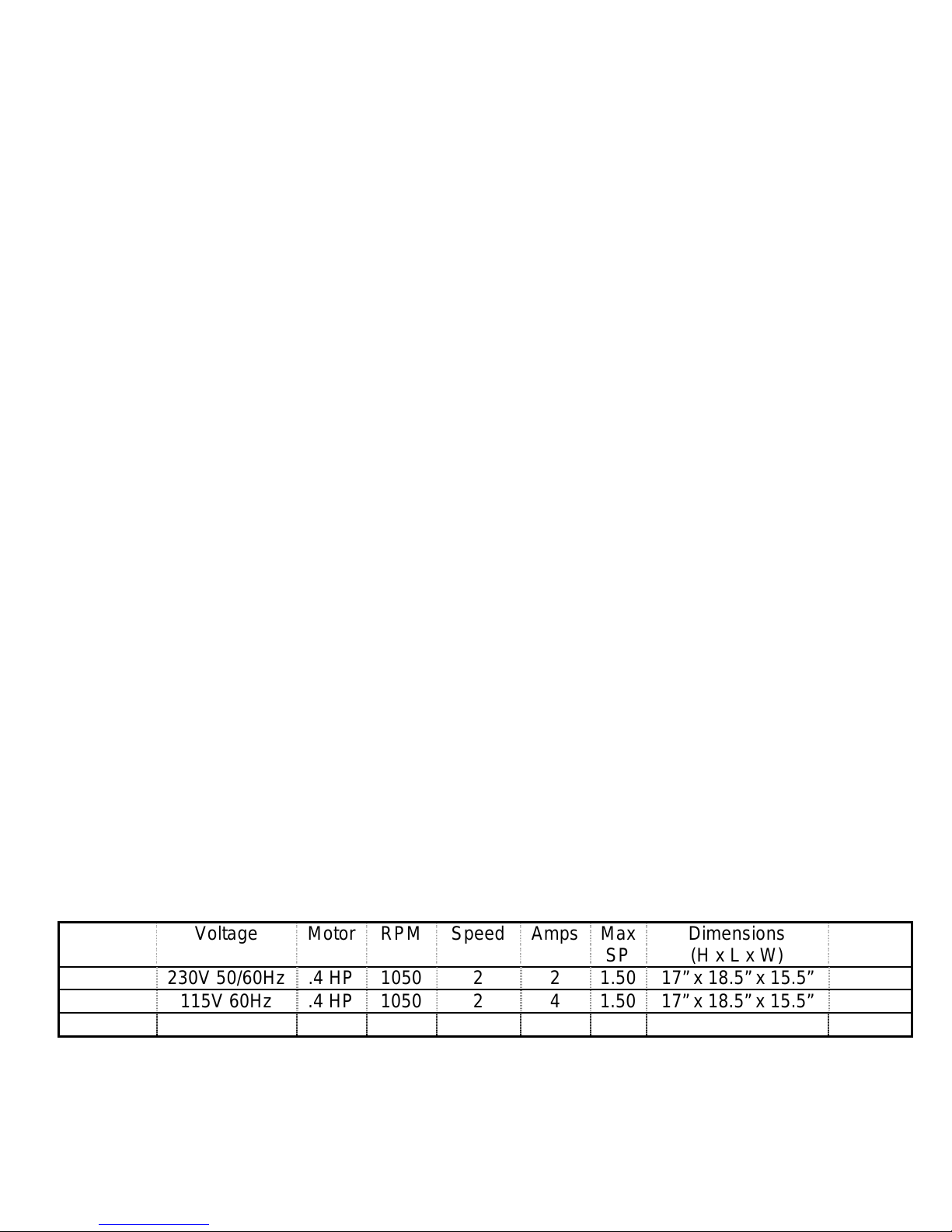

Model Voltage Motor RPM Speed Amps Max

SP

Tempest 230V 50/60Hz .4 HP 1050 2 2 1.50 17” x 18.5” x 15.5” 28 lbs

Tempest 115V 60Hz .4 HP 1050 2 4 1.50 17” x 18.5” x 15.5” 28 lbs

Typhoon 115V 60Hz .4 HP 1050 3 4 1.50 17” x 18.5” x 15.5” 28 lbs

Wheel Size for all units is 9.5” x 9.5”.

Dimensions

(H x L x W)

Weight

ATTN: PRODUCT UPDATE

The new Typhoon Air Mover is now equipped with a .4 HP motor, GFCI receptacle and 15 amp breaker. The GFCI

Receptacle and 15 amp breaker gives you the ability to plug one fan into another, reducing the chaos and clutter of extension

cords and power cords crisscrossing the drying site. This outlet is GFCI (Ground Fault Circuit Interrupter) protected and

incorporates a dedicated circuit breaker. You can plug three Typhoon Air Movers into each ot her on a 15 amp circuit

your convenience a

motor.

3mm Allen Wrench is included to remove the intake grill to provide access to the blower wheel and

TROUBLE SHOOTING

Problem Cause Solution

Unit will not run. 1. GFCI has tripped

2. No power to unit.

3. Switch not on.

4. Switch is faulty.

5. Faulty/broken cord or motor wire.

Unit runs but fan makes

loud scraping noise.

Unit runs but vibrates

excessively.

Unit runs but fan does not

turn.

Unit runs briefly, and then

shuts off.

1. Unit has been severely jolted causing fan

to rub against housing.

2. Unit has been severely jolted causing

housing to deform.

1. Severe jolt has bent motor shaft causing

unit to be out of balance.

2. Fan blade damaged.

3. Dirt build up on one side of

fan blade.

1. Fan is jammed against housing.

2. Capacitor wire has broken/come loose,

capacitor has failed.

3. Housing has been damaged such that it

presses on fan blade.

1. Motor bearings are failing or motor has

developed an internal electrical fault.

2. Intake grill and/or exhaust grill

is obstructed.

3. Excessive duct length.

1. Reset GFCI, it must be a properly

grounded receptacle.

2-A. Check the 15 amp circuit breaker

on control panel. Reset if necessary.

2-B. Check the building fuse or circuit

breaker. Reset breaker or replace fuse.

3. 3. Place in “ON” position.

4. Replace switch.

5. Perform continuity check, using

volt/amp meter. Repair/replace faulty

broken wire.

1. Remove motor and replace damaged

motor mounts.

2. Replace fan blade.

1. Remove and replace motor.

2. Replace blade if necessary.

3. Clean fan blade.

1. Remove motor and replace damaged

motor mounts. Replace fan blade if

necessary.

2. Repair/replace wires/capacitor as

necessary.

3. Replace housing/unit as necessary.

1. Replace motor.

2. Remove obstruction.

3. Reduce the duct length to the

recommended maximum.

. For

Trouble Shooting

Problem Cause Solution

Unit will not run. 1. No power to unit.

2. Switch not on.

3. Switch is faulty.

4. Faulty/broken cord or motor wire.

Unit runs but air

mover makes loud

scraping noise.

Unit runs but vibrates

excessively.

Unit runs but blower

wheel does not turn.

Unit runs briefly, then

shuts off on overload.

1. Unit has been severely jolted

causing blower wheel to rub against

housing.

2. Unit has been severely jolted

causing housing to deform.

1. Severe jolt has bent motor shaft

causing unit to be out of balance.

2. Air mover blade damaged.

3. Dirt build up on one side of

air mover blade.

1. Blower wheel is jammed against

housing.

2.Capacitor wire has broken/come

loose, capacitor has failed.

3. Housing has been damaged such

that it presses on blower wheel.

1. Motor bearings are failing or

motor has developed an internal

electrical fault.

2. Intake grill and/or exhaust grill

is obstructed.

3. Excessive duct length.

1. Plug unit in. Check circuit

breaker.

2. Place in “ON” position.

3. Replace switch.

4. Perform continuity check, using

volt/amp meter. Repair/replace

faulty broken wire.

1. Remove motor and replace

damaged motor mounts.

2. Replace blower wheel.

1. Remove and replace motor.

2. Replace blade if necessary.

3. Clean air mover blade.

1. Remove motor and replace

damaged motor mounts. Replace

blower wheel if necessary.

2.Repair/replace wires/capacitor

as necessary.

3. Replace housing/unit as

necessary.

1. Replace motor.

2. Remove obstruction.

3.Reduce duct length to

recommended maximum.

Dry Air Technology 10 Year Limited Warranty

Axial and Centrifugal Air Flow Products

Warrantor: Dry Air Technology, 313 North Oak Street, Burlington, WA 98233. Telephone: 888-755-

9176, local: 360-755-9176, fax: 360-755-9236.

Who Is Covered: This warranty extends to the original end-us er of ax ial and centrifugal air flow devices

manufactured by Dry Air Technology, and may not be assigned or transferred.

Warranty Period: The term of the warranty coverage from the date of purchase is:

10 years on the cabinet, chassis and housing

1 year on parts, labor and reasonable shipping costs, excluding filters and accessories.

Warranty Coverage: Dry Air Technology warrants that, for one year, axial and centrifugal air flow

devices manufactured by Dry Air Technology will operate free from defects in material or workmanship, or

Dry Air Technology, at its option, will repair or replace the defective part(s), free of charge.

Dry Air Technology further warrants that for a period of ten (10) years, the cabinet, chassis and housing of

axial and centrifugal air flow devices manufactured by Dry Air Technology, will be free from defects in

material or workmanship, or Dry Air Technology, at its option, will repair or replace the def ective part(s),

provided that all labor and shipping costs for the defective part(s) shall be borne by the end-user.

This warranty does not cover any defect, malfunction, etc. resulting from misuse, abuse, lack of normal care,

corrosion from chemicals, freezing, tampering, modification, unauthorized or improper repair or operation,

accident, acts of nature or any other cause beyond Dry Air Technology’s reasonable control.

End-User Responsibilities: Warranty service must be performed by a firm or individual authorized by

Dry Air Technology. If the end-user is unable to locate or obtain warranty service from an authorized firm or

individual, he should contact Dry Air Technology at the above location, which will arrange for covered

warranty service. All covered warranty service will be performed during normal business hours.

Limitations and Exclusions: If any part of a axial or centrifugal air flow device manufactured by Dry

Air Technology is repaired or replaced, the new part shall be warranted only for the remainder of the original

warranty period of the air flow device (but all warranties will be extended by the period of time, if any, that

the Dry Air Technology air flow device is out of service while waiting f or covered warran ty service).

UPON THE EXPIRATION OF THE WRITTEN WARRANTY APPLICABLE TO THE DRY AIR TECHNOLOGY AIR FLOW

DEVICE OR ANY PART THEREOF, ALL OTHER WARRANTIES IMPLIED BY LAW, INCLUDING MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, SHALL ALSO EXPIRE. ALL WARRANTIES MADE BY DRY AIR

TECHNOLOGY ARE SET FORTH HEREIN, AND NO CLAIM MAY BE MADE AGAINST DRY AIR TECHNOLOGY

BASED ON ANY ORAL WARRANTY. IN NO EVENT SHALL DRY AIR TECHNOLOGY, IN CONNECTION WITH THE

SALE, OPERATION, REPAIR OR REPLACEMENT OF ANY DRY AIR TECHNOLOGY AIR FLOW DEVICE OR PART

THEREOF BE LIABLE UNDER ANY LEGAL THEORY FOR ANY SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES INCLUDING WITHOUT LIMITATION WATER DAMAGE (THE END-USER SHOULD TAKE

PRECAUTIONS AGAINST SAME), LOST PROFITS, DELAY, OR LOSS OF USE OR DAMAGE TO ANY REAL OR

PERSONAL PROPERTY.

Some states do not allow limitations on how long an implied warranty lasts, and some do not allow the

exclusion or limitation of incidental or consequential damages, so one or both of these limitations may not

apply to you.

Legal Rights: This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

DRY AIR TECHNOLOGY, BURLINGTON, WASHINGTON

Loading...

Loading...