Drummond MRB-36HWN1-X14B, MRB-60HWN1-X14, MRB-48HWN1-X14 Installation Instructions Manual

INSTALLATION INSTRUCTIONS

PACKAGE 14 SEER - HEAT PUMP

3 - 5 TONS.

3Ph

MRB-36HWN1-X14B, MRB-48HWN1-X14,

MRB-60HWN1-X14.

R-410A Refrigerant

MAN-I-IDP14HP-1115

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION

WARNING

These instructions are intended as an aid to qualified

licensed service personnel for proper installation,

adjustment and operation of this unit. Read these

instructions thoroughly before attempting installation

or operation. Failure to follow these instructions may

result in improper installation, adjustment, service or

maintenance possibly resulting in fire, electrical

shock, property damage, personal injury or death.

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference by a serviceman.

TABLE OF CONTENTS

1.0 SAFETY...................................................................................................

1.1 INSPECTION............................................................................................................4

1.2 LIMITATIONS............................................................................................................4

2.0 INSTALLATION...............................................................................................................4

2.1 PRE-INSTALLATION....................................................................................

2.2 CLEARANCE............................................................................................................5

2.3 RIGGING AND HANDING........................................................................................5

3.0 DUCTWORK...................................................................................................................8

4.0 CONDENSATE DRAIN CONNECTION..........................................................................8

4.1 INSTALL DRAIN PIPE……………………………………………….............

4.2 REMOVAL AND CLEAN THE DRAIN PAN………………….....................................9

5.0 FILTERS..........................................................................................................

6.0 ELECTRICAL WIRING.....................................................................................

6.1 POWER WIRING......................................................................................................9

6.2 GROUNDING..............................................................................................

6.3 CONTROL WIRING..................................................................................................9

7.0 AIRFLOW PERFORMANCE................................................................................

7.1 AIRFLOW PERFORMANCE DATA…………………………………...................

8.0 SYSTEM OPERATION………………………………………………………............

8.1 COMPRESSOR CRANKCASE HEATER (OPTIONAL)….......……....................…19

8.2 PROTECTION (FOR HP SYSTEM ONLY).............................................................19

8.3 DEFROST MODE (FOR HP SYSTEM ONLY)……..............………..............

8.4 MANUAL DEFROST MODE (FOR HP SYSTEM ONLY).......……......................…20

8.5 THERMOSTAT SIGNALS.......................................................................................20

8.6 PHASE SEQUENCE PROTECTION......................................................................21

9.0 OPERATION CHECK-UP..........................................................................................

10.0 TROUBLE SHOOTING ...........................................................................................

................3

........

.......

.........

.............4

..........8

......9

.......

.......9

....

..........9

.....

....14

.......14

...

...... 19

.....

.....19

....

...

21

21

LIST OF TABLES

TABLE 2-1 UNIT CLEARANCE………………………………………..………..........…………6

TABLE 6-1 14 SEER HEAT PUMP W/WITHOUT ELECTRIC HEAT……...................…....12

TABLE 6-2 14 SEER COOLING ONLY W/WITHOUT ELECTRIC HEAT..................…

TABLE 6-3 14 SEER PHYSICAL DATA……….................................................…........

TABLE 7-1 SIDE DUCT APPLICATION…………….....…...............…................…...

TABLE 7-2 BOTTOM DUCT APPLICATION……….........………………….............….....…

TABLE 7-3 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…...............16

TABLE 7-4 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…...............16

TABLE 7-5 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…...............17

TABLE 7-6 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…...............17

TABLE 7-7 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…..............18

TABLE 7-8 REFRIGERANT CHARGE FOR H/P SYSTEM.............................…...............18

TABLE 8-1 THERMOSTAT SIGNALS…………………………………………................

......12

…..13

......

.......20

…14

15

LIST OF FIGURES

FIG. 2-1 COMPONENT LOCATION.....………………………………...............…..................5

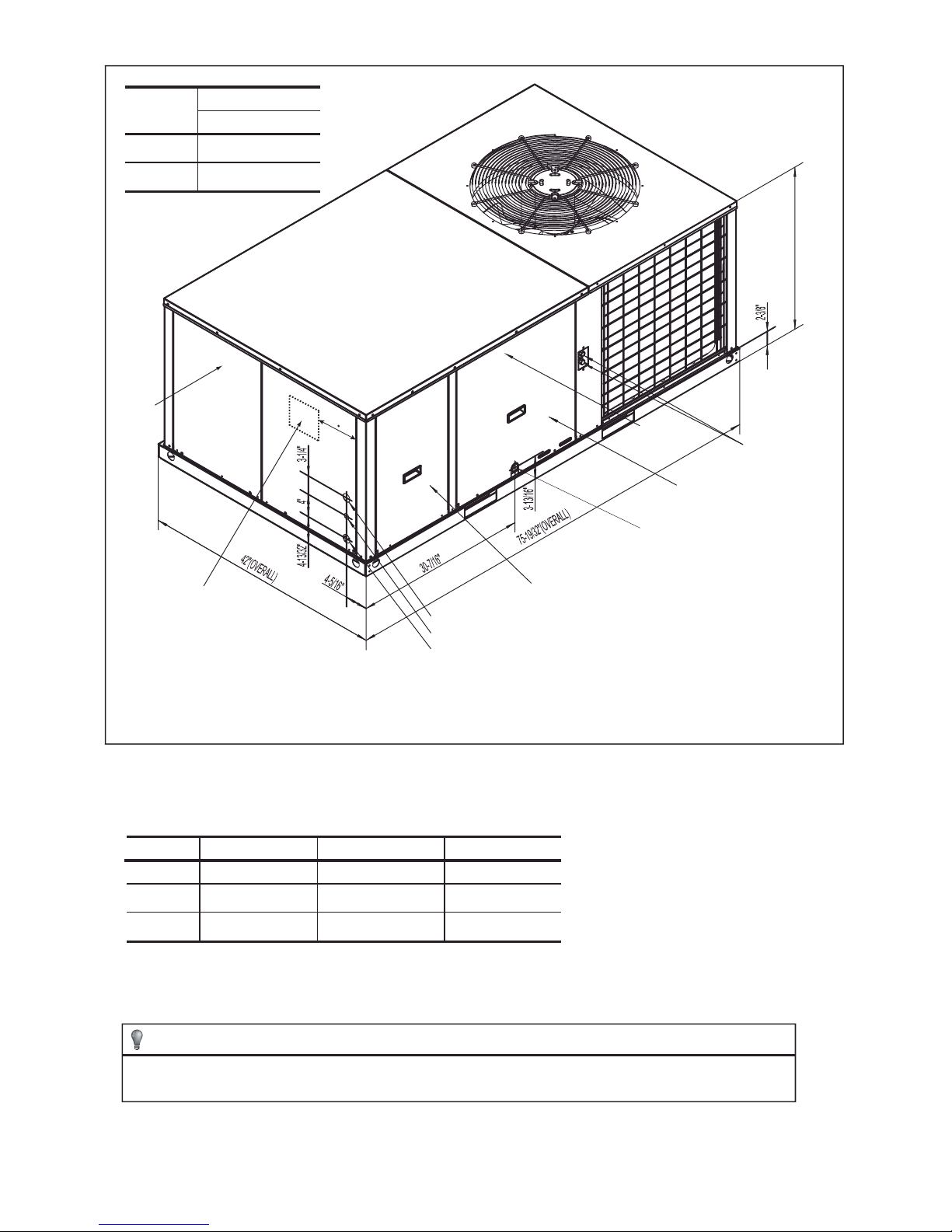

FIG. 2-2 UNIT DIMENSIONS…………………………………………...................................

FIG. 2-3 DIMENSIONS BACK AND BOTTOM............................………..............................7

FIG. 4-1

FIG. 6-1 TYPICAL FIELD CONTROL WIRING DIAGRAM…………………….....……….....11

FIG. 6-2 TYPICAL FIELD POWER WIRING DIAGRAM…………………………………....

HP SYSTEM WIRING DIAGRAM...................................................................................

REMOVABLE CONDENSATE DRAIN PAN AND REMOVAL PROCEDURE

......................9

...6

...11

.....22

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations of systems nor

does it provide for every possible contingency to be met in connection with

installation.

All phases of this installation must comply with NA TION, STATE AND LOCAL

CODES. If additional information is required please contact your local

distributor.

1.0 SAFETY

When you see the symbols below on labels or in the manual, be alert to the

potential or immediate hazards of personal injury, property and/or product

damage. It is the owner’s or installer’s responsibility to comply with all safety

instructions and information accompanying these symbols.

WARNING: This is a safety alert symbol indicating a potential hazardous situation, which could result in personal injury, property and/or

product damage or death.

CAUTION: This is a safety alert symbol indicating a potential hazardous situation, which could result in moderate personal injury, and/or

property and product damage.

WARNING

These instructions are intended as an aid to qualified, licensed service

personnel for proper installation, adjustment and operation of this unit. Read

these instructions thoroughly before attempting installation or operation.

Failure to follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

WARNING

The manufacturer’s warranty does not cover any damage or defect to the

heat pump caused by the attachment or use of any components, accessories or devices (other than those authorized by the manufacturer) into, onto

or in conjunction with the heat pump. You should be aware that the use of

unauthorized components, accessories or devices may adversely affect the

operation of the heat pump and may also endanger life and property. The

manufacturer disclaimer any responsibility for such loss or injury resulting

from the use of such unauthorized components, accessories or devices.

WARNING

Disconnect all power to the unit before starting maintenance. Failure to do

so can result in severe electrical shock or death.

WARNING

Do not, under any circumstances, connect return ductwork to any other heat

producing device such as a fireplace insert, stove, etc. Unauthorized use of

such devices may result in fire, carbon monoxide poisoning, explosion,

property damage, severe personal injury or death.

3

WARNING

The unit must be permanently grounded. A grounding lug is provided. Failure to

ground this unit can result in fire or electrical shock causing property damage,

severe personal injury or death.

WARNING

Only electric heater kits supplied by this manufacturer as described in this

publication have been designed, tested, and evaluated by a nationally recognized safety testing agency for use with this unit. Use of any other manufactured electric heaters installed within this unit may cause hazardous conditions

resulting in property damage, fire, bodily injury or death.

WARNING

Proposition 65: This appliance contains fiberglass insulation. Respirable

particles of fiberglass are known to the state of California to cause cancer.

1.1 INSPECTION

As soon as unit is received, it should be inspected and noted for possible shipping

damage during transportation. It is carrier’s responsibility to cover the cost of

shipping damage. Manufacturer or distributor will not accept the claims from dealer

for any transportation damage.

1.2 LIMITATIONS

Refer to Fig. 2-2, 2-3 for unit physical data and to Table 7-1 for electrical data.

If components are to be added to a unit they must meet local codes, they are to

be installed at the dealer’s and /or the customer’s expense.

Size of unit for proposed installation should be based on heat loss / heat gain

calculations made in accordance with industry recognized procedures identified

by the Air conditioning contractors of America.

2.0 INSTALLATION

2.1 PRE-INSTALLATION

Before installation, carefully check the following:

1. Unit should be installed in accordance with national and local safety codes,

including but not limit to ANSI/NFPS No. 70 or Canadian Electrical Code Part 1,

C22.1, local plumbing and waste water codes and any other applicable codes.

2. For rooftop installation, be sure the structure has enough strength to support

the weight of unit. Unit should be installed on roof curb and leveled.

3. For ground level installation, a level slab should be used.

4. Condenser airflow should not be restricted.

5. On applications when a roof curb is used, the unit must be positioned on the

curb so the front of the unit is tight against the curb.

4

2.2 CLEARANCE

All units require certain clearance for proper operation and service. Refer to

Table 2-1 for the clearances required for construction, servicing and proper

unit operation.

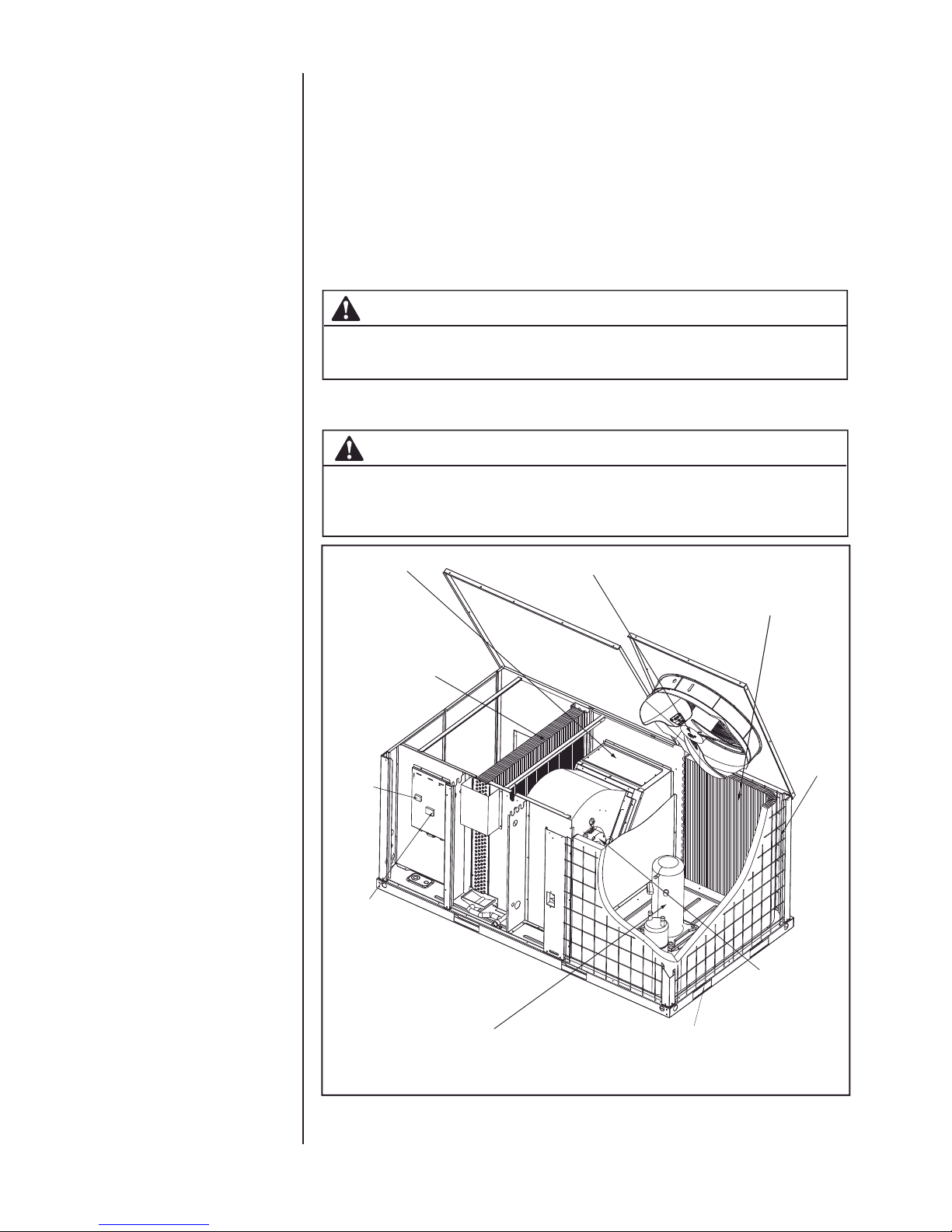

2.3 RIGGING AND HANDING

Exercise care when moving the unit. Do not remove any packaging until the

unit is near the place of installation. Rig the unit by attaching chain or cable

slings to the lifting holes provided in the base rails. Spreader bars, whose

length exceeds the largest dimension across the unit, MUST be used across

the top of the unit.

CAUTION

Before lifting, make sure the unit weight is distributed equally on the rigging

cables so it will lift evenly.

Units may be moved or lifted with a forklift. Slotted openings in the base rails

are provided for this purpose.

CAUTION

All panels must be secured in place when the unit is lifted.

The condenser coils should be protected form rigging cable damage with

plywood or other suitable material.

Electric heater assembly (optional)

Highly efficient enhanced

copper tube / aluminum fin

indoor coil

Compressor

contactor

Low voltage

terminal block

Condenser fan motor

Highly efficient enhanced copper

tube/Aluminum fin outdoor coil

Decorative

protective coil

guard

Blower motor with

slide-out blower assembly

Compressor

Fig. 2-1 Component Location

* The above figure for reference purpose only.

Heavy gauge removable

base rails

5

Unit size

Dimensions

A

036

048, 060

Left

Recommended unit

disconnect location

28-3/32”

33-3/64”

6-1/2”

Electrical service access

compapartment panel

High voltage conn. 1-23/64” dia. knockout

Low vlotage entrance 7/8” Dia.

High voltage conn. 1-23/64” Dia.

Front

Drain pan service access

compartment panel

Condensate drain

connection 3/4” NPTI

(Trap required)

A

Hi./Lo. pressure

detected valve

1/4’’ SAE

Fig. 2-2 Unit Dimensions

* The above figure for reference purpose only.

Table 2-1: Unit Clearance

Direction

1

Top

Front

Rear

Distance (in.)

60

30

2

18

Direction

Right

Left

Bottom

3

Duct clearance: 1 inch clearance for all sides of air supply duct.

1. Units must be installed outdoors. Over hanging structure or shrubs should not obscure condenser air discharge outlet.

2. The minimum clearance without economizer/fresh air damper. For distance with Economizer/fresh air damper, please refer

to the relevant Install requiremnt.

Distance (in.)

12

24

0

NOTE

For units applied with a roof curb, the minimum clearance may be reduced from 1 inch to 1/2 inch between

combustible roof curb material and this supply air duct.

6

Loading...

Loading...