Drummond MOV-90CN1-D, MVA-90CWN1-V, MVA-120CWN1-V, MOV-120CN1-D Installation Manual

INSTALLATION MANUAL

SPLIT SYSTEM

COOLING ONLY

MVA-90CWN1-V, MOV-90CN1-D,

MVA-120CWN1-V, MOV-120CN1-D.

R-410A Refrigerant

MAN-I-SSD-1115

CONTENTS PAGE

WARNING

PRECAUTIONS........................................................................................1

ACCESSORIES (INDOOR UNIT).............................................................. 2

INSTALLATING INDOOR UNIT ...............................................................2

INSTALLATING OUTDOOR UNIT............................................................4

HEAT INSULATION OF THE PIPE ............................................................8

INSTALL THE CONNECTIVE PIPE............................................................8

INSTALL THE DRAIN PIPE.....................................................................10

ELECTRIC CONNECTION.......................................................................11

TRIAL RUN .........................................................................................12

MAINTENANCE....................................................................................13

1. PRECAUTIONS

Precautions before reading the installation manual.

Read this user manual carefully before installing the equipment.

The air conditioner must be installed by professional technicians.

When installing the indoor unit and its accessory pipes, adhere to

this user’s manual as far as possible.

Inspect and make sure the piping and cabling are correct before

powering on the air conditioner.

This information may change with the update of this machine, and

no further notice will be given for such change.

Do not throw or slam the remote controller.

Operate the remote controller within the receiving scope of the

indoor unit, and direct the transmitting part of the remote controller to the receiver of the indoor unit.

The remote controller should be over 1m away from the

television or sound box.

Do not place the remote controller at a moist place, near the

heat sources such as stove, or expose it directly in the sunlight.

Ensure correct positive and negative poles when loading the

batteries.

Decide the correct way of conveying the equipment.

Try to transport this equipment with the original package.

If the a ir conditioner needs to be installed on a metal part of the

building, electric insulation must be performed, and the installation must meet the relevant technical standards of electric

devices.

The appliance must be installed 2.3m above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked by word, or

by symbols, with the direction of the fluid flow.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or a similarly qualified

person in order to avoid a hazard.

An all-pole disconnection switch having a contact

separation of at least 3mm in all poles should be

connected in fixed wiring.

The safety precautions listed here are divided into two categories. In

either case, important safety information is listed which must be read

carefully.

WARNING

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage

to the equipment.

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

on how to operate the unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

the owner's manual for future reference.

CAUTION

Install the unit where enough space of installation and maintenance is available.

Install the unit where the ceiling is horizontal and enough for

bearing the weight of the indoor unit.

Install the unit where the air inlet and outlet are not baffled and

are the least affected by external air.

Install the unit where the supply air flow can be sent to all parts

in the room.

Install the unit where it is easy to lead out the connective pipe

and the drain pipe.

Install the unit where no heat is emitted from a heat source

directly.

Installation Manual

1

Installing the equipment in any of the following places may lead

to faults of the equipment (if that is inevitable, consult the

supplier):

The site contains mineral oils such as cutting lubricant.

Seaside where the air contains much salt.

Hotpring area where corrosive gases exist, e.g., sulfide gas.

Factories where the supply voltage fluctuates seriously.

Inside a car or cabin.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable ga ses or materials exist.

Place where acid or alkali gases evaporate.

Other special environments.

Install the unit where enough space of installation and mainte-

nance is available.

Install the unit where the air inlet and air outlet are free from

obstacles and strong wind.

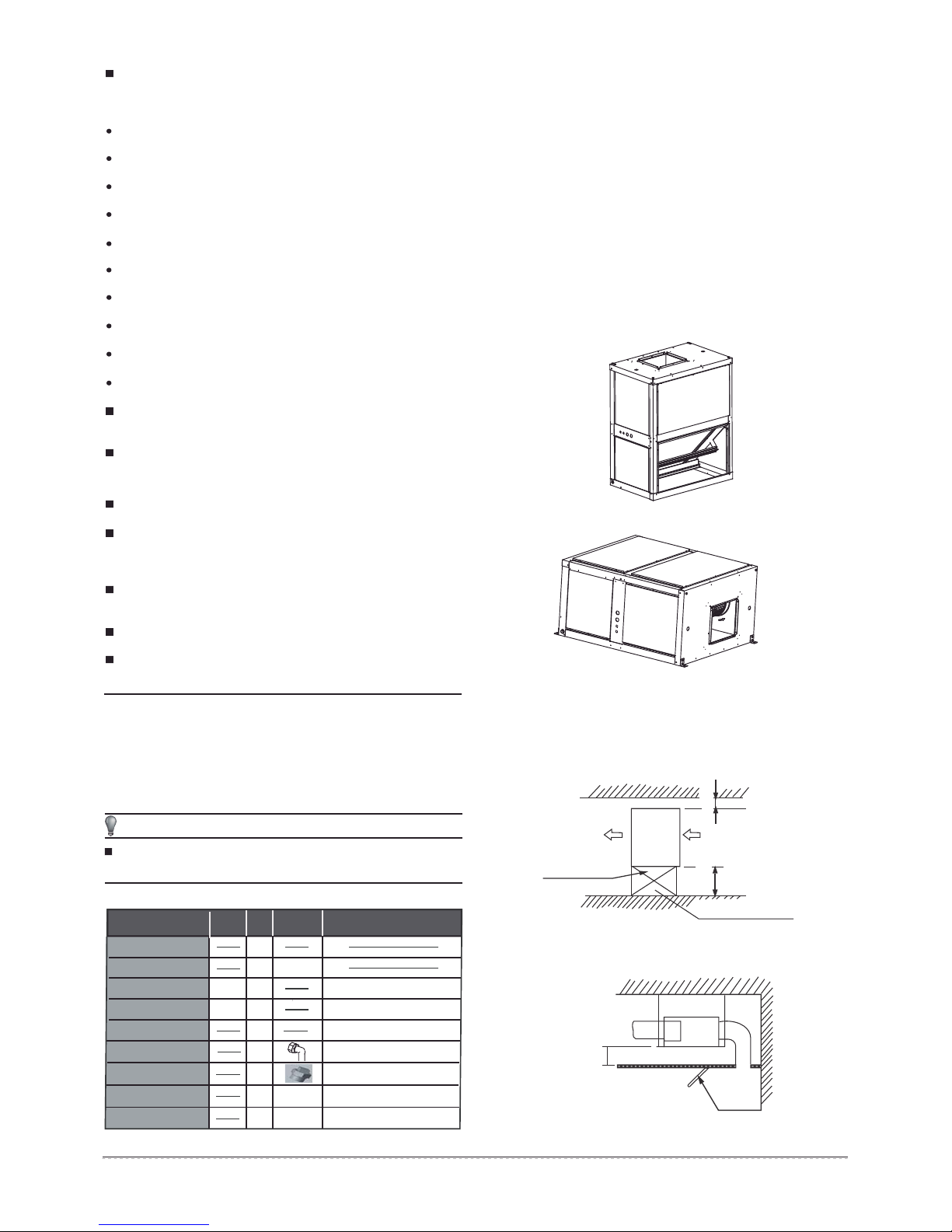

3. INSTALLATING INDOOR UNIT

UNIT FEATURES

HORIZONTAL OR VERTICAL--All models are designed for either

application and can be installed in either position as supplied from the

factory.

DRAIN PAN (NOT VISIBLE)--The zinc coating steel drain pan is

designed to trap condensate in either vertical or horizontal

installations.All pans are insulated with insulation between the bottom

of the pan and the unit and may be connected for either right or left

hand drains,if unit is to be installed over a finished ceiling and in an

unconditioned space, it is recommended an auxiliary drain pan be

placed under the entire unit.

MANIFOLD--All models are furninshed with dual circuit manifolds for

dual condensing unit application. The circuitry is so arranged to

provide full face coil operation from each unit, Fitting may be installed

for either right or left hand tubing connections.

Install the unit in a dry and well ventilated place.

Install the unit where the bearing surface is level and can bear

weight of the unit, and is suitable for installing the unit horizontally without increasing noise or vibration.

Install the unit where the operation noise and the expelling of air

do not affect neighbours.

Install the unit where no flammable gas is leaked.

Install the unit where it is convenient for pipe connection and

electric connection.

2. ACCESSORIES (INDOOR UNIT)

NOTE

If in the wire control mode, the accessories do not include

display panel assembly remote controller or mounting bracket.

Table 2-1

Accessory name Qty. Purpose

Owner’s manual

Installation manual

refrigerant pipe

refrigerant pipe

Y type refrigerant pipe

Drain outlet

Drain plug

Sealing tape

Plastic ring

Installation Manual

Model

90

120

2

Shape

1

This manual

1

7

6

2

1

1

1

5

Connect to system

Connect to system

Connect to system

Connect to water drainage pipe

Sealing drain

Protect copper pipe and wire

Vertical

Horizontal

3.1 Installation Space

Ensure enough space required for installation and maintenance.

Over 500 mm

Maintenance space

Over 600 mm

600mmX600mm

Inspection orifice

Fig.3-1

Note: Ensure that the minimum

drain gradient is over 1/100.

Inspection orifice

Fig.3-2

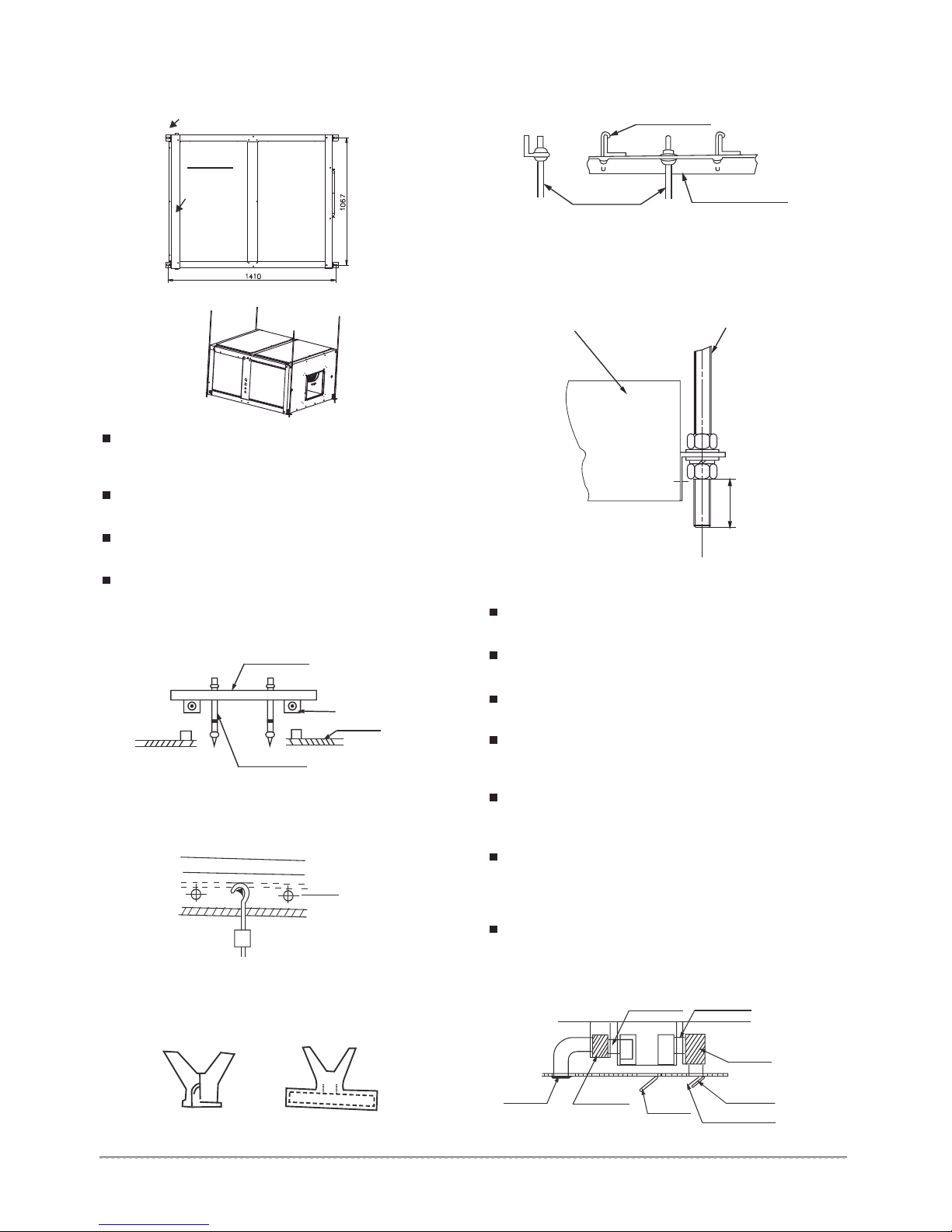

3.2 Install ĭ10 or bigger Pendant Bolts Or

Ground Bolts

Pendant bolt hole

4-12×2 5

D. Steel beam and girder structure

Set and use supportive angle steel.

Suspended bolt

Air inlet side

Fig.3-3

MVA-90CWN1-V MVA-120CWN1-V (Unit:mm)

Fig.3-4

Use ĭ10 or bigger screws. The screw material is high-quality

carbon steel (whose surface is zinc plated or undergoes other

rustproof treatment) or stainless steel.

The treatment of the ceiling varies between buildings. For

detailed measures, consult with the fitting-out staff.

Fix the pendant bolts firmly and reliably in light of the specific

situation.

Installation of the pendant bolt in different environments.

A. Wooden structure

Put rectanglar sticks across the beams, and set pendant bolts.

Wooden span

Pendant bolt

Beam

Ceiling

Fig.3-5

B. New concrete roughcast

Use embedded bolts, embedded pulling plugs, and embedded

stick harness.

Steel bar

Embedded bolt

Pipe pendant embedded bolt

Fig.3-6

C. New concrete roughcast

Set it with embedded bushes or embedded bolts.

Pendant bolt

Supportive

angle steel

Fig.3-8

3.3 Suspending The Indoor Unit

Use a hoisting device to hoist the indoor unit, align it with the

installation screw, adjust the horizontality and then tighten it.

Unit body

Pendant bolt

Not less than 30

Fig.3-9

3.4 Design And Connection Of Duct

The duct design must comply with the national heating air

conditioner pipeline design specifications.

The duct accessories and materials must be produced by

professional manufacturers.

In order to prevent air flow shorting, do not keep the air inlet pipe

near the air outlet pipe.

Install a filter at an easy-to-maintain place such as intake pipe.

(Otherwise, the duct will gather on the air heat exchanger and

lead to fault and water leak of the air conditioner.)

In order to suppress noise effectively, install noise suppression

and sound insulation devices, especially in the noise-sensitive

spaces such as meeting rooms.

For connection of the flange plane, use non-flammable canvas

adapter to prevent transmission of vibration. For its size, see the

indoor unit outline diagram. Use M6X20 screws (configured on

site) for connection.

All pipelines must be connected closely and soundly without

leak of air. The pipelines must be adiabatic and free from

condensation.

Key points of duct connection

Canvas adapter

Canvas adapter

Blade plug-in unit

Slide plug-in unit

Fig.3-7

Air outlet

Noise

suppression chamber

orifice

Inspection

Noise suppression chamber

Air inlet

Air filter

Fig.3-10

Installation Manual

3

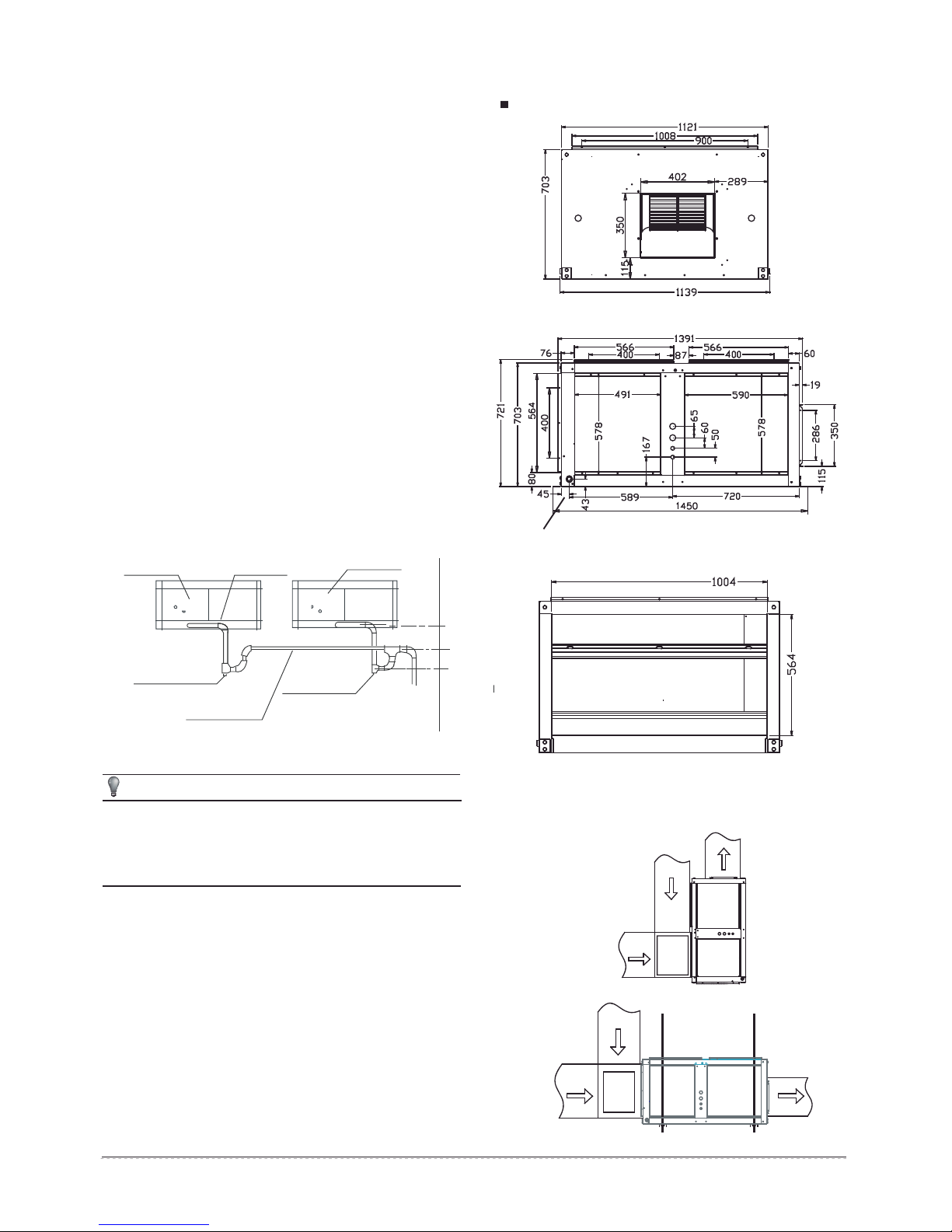

3.5 Install the condensate drainpipe

1. Install the indoor unit drainpipe

Two drain couplings are provided on alll models.select either one

for condensate outlet and plug the other.

consult local codes or ordinances for specific requirement regarding

condensate drain.

condensate drain is open to atmosphere and must be trapped. trap

must be at least 3 inches deep and made of flexible material or

fabricated to prevent freeze-up.

if air handler is installed in a non-conditioned space,it is

recommended an auxillary drain pan be fabricated and installed

under entire unit.

Do not reduce the drain line size from the connection size provided

on the unit.

Install a drain stream trap in the drainpipe to prevent water from

overflowing. (The drainpipe absorbs the odor. When the outside

static pressure is high (especially the air inlet),it is difficult to drain

the water.)

Drainage should be natural. When constructing, the outside pipe of

outdoor unit should be inclined (1/50~1/100).

The bending part of drainpipe should be fewer than 2. Furthermore,

to reduce the depositing dust, avoid bending the pipe as possible as

you can.

Make sure there is no dust or rubbish falling into indoor unit drain

elbow and drainpipe.

After installation, remove the checking panel, pour some water in the

drain elbow to see whether it drains smoothly.

Checking panel

Drain pipe

Checking panel

3.6 Dimension˄Unit:mm˅

MVA-90CWN1-V MVA-120CWN1-V

Front view (Air supply outlet)

3/4”NPT FEMALE

Side view (Pipes)

Fig.3-12

Fig.3-13

100mm or more

Sheath

(Checking orifice˅

General drain pipe

Sheath

(Checking orifice)

e

50mm or mor

Fig.3-11

CAUTION

Rubbish is easy to accumulate at drain stream trap. Make sure

to install a plug or other things which is easy to clean.

Unit must be slightly inclined toward drain,

Use drain connection size or larger,

Do not operate unit without trap

2. Test draining

Open the clapboard of indoor unit, pour the water in to see whether it

drain smoothly and whether there is water leakage.

3. Heat insulation

After confirming that drainage is smoothly and there is no leakage,

wrap the drainpipe with insulation material, or there will be

condensed water.

Rear view (Air return vent)

Fig.3-14

3.7 Field Installed Mixing Box Accessory

2876,'($,5

5(7851$,5

0,;,1*%2;

2876,'($,5

5(7851$,5

0,;,1*%2;

6833/<$,5

Fig.3-15

6833/<$,5

Installation Manual

4

Fig.3-16

Loading...

Loading...