Page 1

200 Shadylane Drive

Philipsburg, PA 16866

Phone: (814) 342-6205

Fax: (814) 342-4510

www.druckerdiagnostics.com

Service Manual

Model Apex 6 Centrifuge

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 1

Page 2

CONTENTS

1 PREFACE ............................................................................................................................................ 3

2 GENERAL DESCRIPTION OF MAJOR COMPONENTS ......................................................................... 3

3 WARRANTY INFORMATION .............................................................................................................. 3

4 SPECIFICATIONS ................................................................................................................................ 3

5 TROUBLESHOOTING ......................................................................................................................... 4

6 SERVICE INSTRUCTIONS .................................................................................................................... 5

7 ASSEMBLY DRAWINGS ...................................................................................................................... 9

8 REVISION HISTORY .......................................................................................................................... 13

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 2

Page 3

1 PREFACE

1.1 The purpose of this manual is to provide the service technician with information for

troubleshooting, testing, and repair of laboratory centrifuge model Apex 6. Only qualified

technically trained personnel should attempt any of the servicing described in this document.

Failure to follow the procedures in this document may result in personal injury or instrument

damage. Drucker Diagnostics will not be held liable for any injury or damage as a result of

improper servicing.

1.2 Information contained within this manual is subject to change without notice.

2 GENERAL DESCRIPTION OF MAJOR COMPONENTS

2.1 Motor: Brushless DC Motor

2.2 Printed Circuit Board: The PCB is the microcontroller based control center of the centrifuge. All

control signals are generated in the PCB.

2.3 Lid Locking Tray Assembly: The lid tray assembly contains a solenoid and limit switch that are used

to determine the state of the lid (Open or Closed) and to keep the lid locked during centrifugation

cycles.

2.4 Rotor: The centrifuge rotor is the main component that spins in the centrifuge. The rotor is loaded

with tube holders, and the samples are placed into the tube holders for processing.

3 WARRANTY INFORMATION

3.1 Drucker Diagnostics warrants its centrifuges to be free from defects in workmanship and parts for

two years.

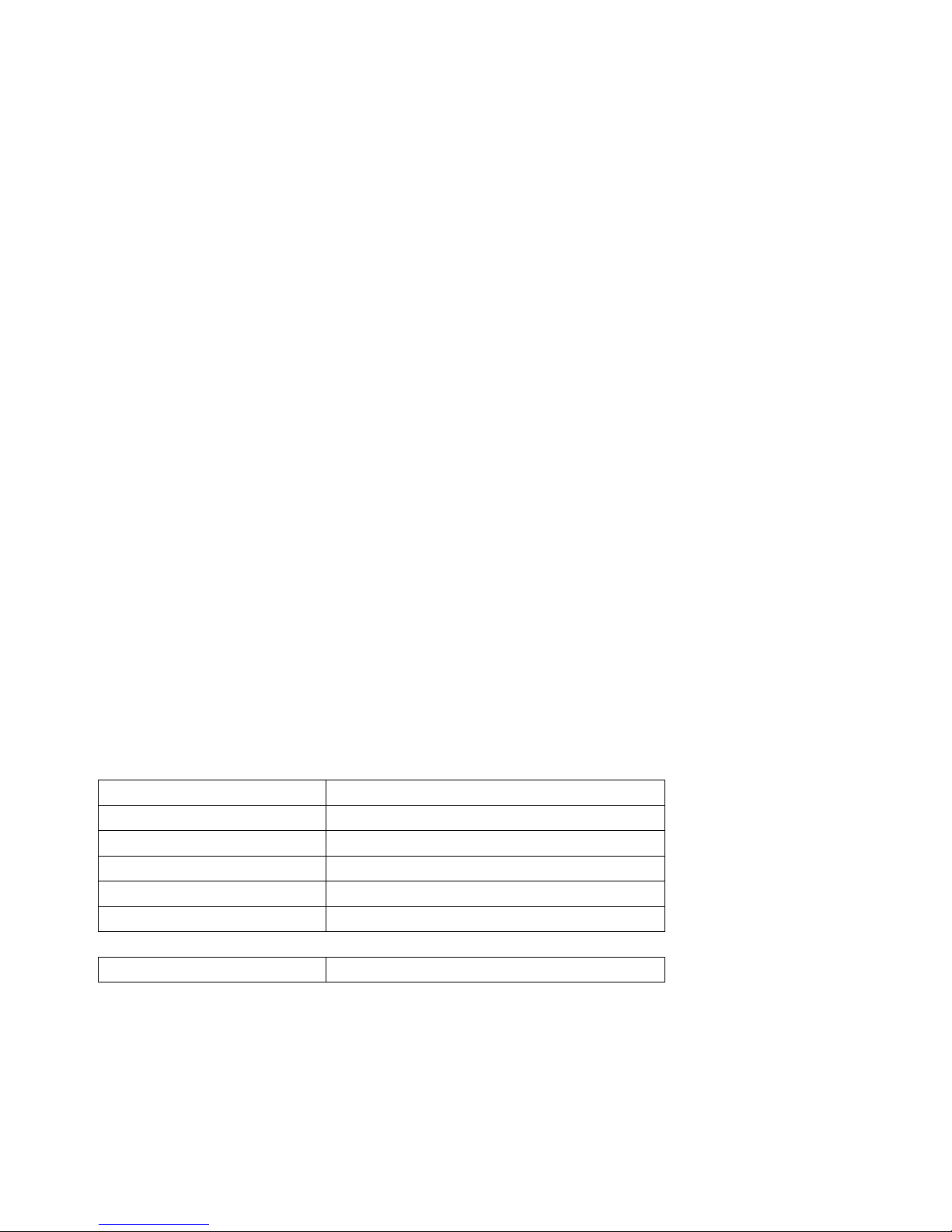

4 SPECIFICATIONS

Maximum Speed 5300 RPM

Maximum RCF 4000 xg

Maximum Capacity 6 Tubes (17 x 100mm)

Dimensions (in) 9.0 (H) x 12.0 (W) x 13.75 (L)

Environmental Operating Range 0-38 deg C

Typical Noise Level (At Maximum Speed) < 62 dB A

Electrical Ratings 115/230VAC (+/- 10V) power supply input (48VDC output)

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 3

Page 4

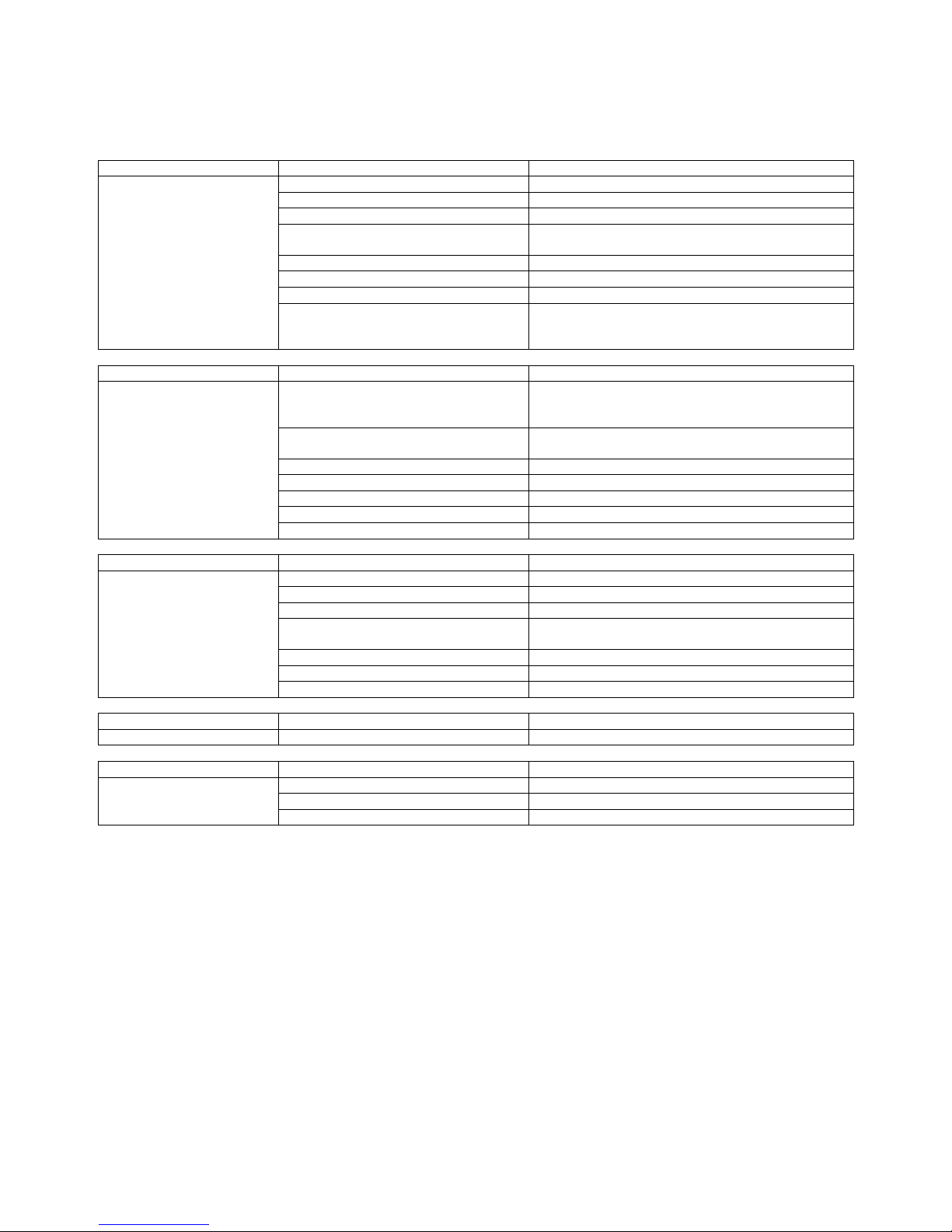

PROBLEM

POSSIBLE CAUSE

SOLUTION

No Power

Check line cord.

No Power

Check external power supply.

No Power

Check wall outlet.

Rotate the lid knob fully clockwise before pressing the

‘OPEN’ button.

Lid lock is active (Unlock timed out)

Press the ‘OPEN’ button to de-activate the lid.

Lid tray is unplugged from PCB or defective

Requires service.

PCB is damaged

Requires service.

To gain access to the rotor - Remove the ‘OPEN/CLOSE’

centrifuge. This will unlock the lid.

PROBLEM

POSSIBLE CAUSE

SOLUTION

Load equally filled tubes symmetrically in the rotor. All

whether loaded, or empty.

Debris lodged within the rotor or tube

carriers

Carefully inspect all rotor pockets, tube holders and

crevasses for debris.

Centrifuge housing is loose

Requires service.

Missing/damaged feet

Requires service.

Motor failure

Requires service.

Rotor windshield damage

Requires service.

Rotor damaged

Replacement required.

PROBLEM

POSSIBLE CAUSE

SOLUTION

No Power

Check line cord.

No Power

Check external power supply.

No Power

Check wall outlet.

Press down firmly on lid and rotate lid knob clockwise until

the ‘Locked’ light illuminates.

Internal connection failure

Requires service.

PCB failure

Requires service.

Motor Failure

Requires service.

PROBLEM

POSSIBLE CAUSE

SOLUTION

Clicking noise during braking

Rotor is loose

Tighten rotor screw.

PROBLEM

POSSIBLE CAUSE

SOLUTION

Debris in air intake / exhaust ports

Remove power before clearing debris.

Gasket failure

Requires service.

Gasket failure

Requires service.

5 TROUBLESHOOTING

Lid knob is ajar

The lid does not open.

Excessive vibration

Rotor does not spin

Rotor improperly loaded

Lid not properly latched

sticker and slide the lid latch lever toward the front of the

carriers and/or tube holders must be present in the rotor,

Whistling noise while running

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 4

Page 5

6 SERVICE INSTRUCTIONS

6.1 Cleaning

a) Use appropriate Personal Protective Equipment (PPE)

b) The cabinet, rotor top and accessories shall be thoroughly cleaned using soap and

water, isopropyl alcohol, or a mild bleach solution.

c) Under no circumstances should any of the following be used: Fully/Partially

Halogenated Hydrocarbons, Ketones and Esters.

d) Use of any chemicals not prescribed by the manufacturer may cause damage to the

rotor and tube carriers / holders and shall not be used.

6.2 Removing the Rotor Core

a) Use a 1/8” hex driver to loosen the center rotor screw (turn counter-clockwise).

b) Lift the rotor core straight up and out of the rotor chamber.

c) To install the rotor core reverse steps A and B above.

d) Take care to align the hub spines with the rotor cone and the tube numberings 1

through 6 with the windshield cover.

e) Tighten the rotor screw with a 1/8” hex driver to 2.0 Nm.

6.3 Maintaining the Rotor

a) Keep the rotor clean; any corrosive materials must not be allowed contact with the

rotor and should be cleaned immediately.

b) The rotor should be checked periodically for signs of wear.

c) Remove the rotor from service if any of the following are found: cracks, deep scratches,

corrosion or discoloring.

6.4 Rotor Screw

a) If the rotor screw needs to be tightened, use a 1/8” hex driver and tighten to 2.0 Nm.

6.5 Speed Calibration

a) Check the centrifuge speed periodically, at least every two years.

b) Important: When verifying rotor speed, make certain that all tube holders are installed

in the rotor.

c) No calibration adjustment of speed can be made, only a verification of rotor speed.

6.6 Removing the Cabinet (Upper Housing)

a) There are six screws that fasten the centrifuge cabinet to the base.

b) Begin by unplugging the centrifuge and waiting 10 minutes for internal voltages to

dissipate.

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 5

Page 6

c) Use a #2 Phillips screwdriver to remove the cabinet screws (three on the back, six on the

underside).

d) The centrifuge control panel is attached to the base internally with cable harnesses. Be

careful not to stress the cables when removing the cabinet.

e) Stand directly in front of the centrifuge and lift the cabinet straight up and off the base,

setting it down on its right side.

f) Gently remove the motor harness from the PCB.

g) Gently remove the power supply harness from the PCB.

h) Disconnect the PCB grounding strap from the base panel using a 11/32” nut driver.

6.7 Replacing the Lid Tray Assembly

a) The lid tray assembly is accessible once the cabinet has been removed.

b) The lid tray assembly is held in place with four screws.

c) Peel the ‘open/close’ label off of the cabinet.

d) Use a #2 Phillips screwdriver to remove the two lid tray screws concealed beneath the

label.

e) Gently remove the lid tray wire harness from the PCB.

f) Use a #2 Phillips screwdriver to remove the two lid tray screws inside the cabinet

g) To install the lid tray, reverse steps F through C above

h) Complete the installation by gently plugging the lid tray wire harness into the PCB

header ‘J2’.

6.8 Replacing the PCB

a) The PCB is accessible once the cabinet has been removed. Make certain that all wire

harnesses have been disconnected.

b) The PCB has capacitors that will remain charged for a period after the centrifuge is

unplugged. Make certain to use standard precautions for handling potentially charged

capacitors when working with the PCB.

c) The PCB is held in place with nine #6 screws.

d) Use a #2 screwdriver to remove the PCB screws. The screw on the lower left corner of

the PCB also secures the grounding strap.

e) To install the PCB, align the PCB with the mounting standoffs of the front panel.

f) Use a #2 screwdriver to install the PCB screws. Ensure the grounding strap is installed at

the lower left corner of the PCB.

g) Important: over tightening the PCB screws can cause malfunction by stripping the screw

threads away from the plastic mounting boss.

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 6

Page 7

6.9 Replacing the Rotor

a) The rotor is accessible once the cabinet has been removed.

b) The rotor is held in place with the rotor screw and washer.

c) Use a 1/8” hex driver to remove the center rotor screw and washer (turn counter-

clockwise).

d) Pull up on rotor to remove from guard bowl. Make sure the red rotor hub stays on the

motor shaft.

e) Place new rotor onto rotor hub and fully seat inside the guard bowl.

f) Place washer onto center of rotor core and insert rotor screw. Use a 1/8” hex driver and

tighten to 2.0 Nm.

6.10 Replacing the Motor

a) Make certain that a new rubber gasket is used on the motor mounting studs when

installing a motor.

b) Position the motor assembly so its wires are adjacent to the notch in the bottom rim of

the guard bowl.

c) Install the motor and gasket into the guard bowl with the wire harness positioned as

described above.

d) Secure the motor to the guard bowl using four #8 washers and four #8 Nylok nuts.

e) Drive the four #8 Nylok nuts onto the motor studs with an 11/32” nut driver.

f) Turn the guard bowl assembly upside down.

g) Place the base assembly onto the guard bowl.

h) Ensure the motor wires pass through the notch in the bottom rim of the guard bowl.

i) Ensure the guard bowl and base assembly are oriented such that the motor wires exit

the guard bowl closest to the back left corner of the base assembly.

j) IMPORTANT: Make certain that no wires are pinched between the guard bowl and

base!

k) Fasten the guard bowl to the base with six #8 thread cutting screws.

l) Install the exhaust air cover with three #8 screws and washers.

m) Secure the wire harnesses to the base assembly with zip ties.

n) The lower assembly is complete.

6.11 Power Connections and Final Assembly

a) Make certain that the lower assembly is unplugged from the external power supply.

b) Connect the motor/power connector to J14 on the PCB.

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 7

Page 8

c) Connect the motor/hall sensor connector to J10 on the PCB.

d) Connect the power supply harness connector to J17.

e) Connect the grounding strap to the base assembly using a 11/16” nut driver.

f) Carefully place the cabinet onto the base taking care not to pinch any wires between the

two.

g) Complete the assembly by replacing the nine screws and three washers using a #2

Phillips screwdriver.

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 8

Page 9

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 9

7 ASSEMBLY DRAWINGS

7.1 FINAL CENTRIFUGE ASSEMBLY

7.1.1 Reference drawing 01-076-109-000

Page 10

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 10

7.2 CABINET ASSEMBLY

7.2.1 Reference drawing 02-002-0-0043

Page 11

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 11

7.3 LOWER ASSEMBLY

7.3.1 Reference drawing 02-003-0-0105

Page 12

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 12

7.4 MOTOR ASSEMBLY

7.4.1 Reference drawing 02-005-1-0010

Page 13

Revision #

Date

Details of Change

A

11/17/2015

Original Issue - DR-4324

B

7/11/2018

DR-5998

8 REVISION HISTORY

DRUCKER DIAGNOSTICS SM013

MODEL APEX 6 SERVICE MANUAL REV: C 13

Loading...

Loading...