Page 1

p/n 7711011

Rev. A

Operator/Service Manual

Model 842VES • Laboratory Centrifuge

Page 2

Table of Contents

Model Description page 3

Supplied Equipment page 3

Warranty Information page 3

Specications page 4

Control Panel / Parts of the Centrifuge page 5

Setup Location page 6

Initial Setup Procedure pages 6,7

Operation page 7

Tube Holder Congurations

Performance Plus Horizontal Rotor page 7

6-Place Horizontal Rotor page 8

6-Place Fixed Angle Rotor page 9

Control Panel Functions

Time Adjustment and Timer Operation page 10

Speed Adjustment / RCF Display page 10

Starting and Stopping a Run page 10

Unlocking the Lid page 10

Advanced User Settings

Acceleration Rate page 10

Braking Rate page 11

Countdown Delay page 11

Imbalance Detection page 11

Audible Setting page 11

Memory Locations / Storing and Recalling page 12

Digital Cycle Counter page 12

Care and Preventative Maintenance page 13

Rotor Removal and Installation page 14

Troubleshooting page 15

Safety page 16

Emergency Rotor Chamber Entry page 16

Calibration and Earth Ground Testing page 16

Replacement Parts page 17

page 2

Page 3

WARNING: For the safety of both the operator and service personnel,

care should be taken when handling substances that are known to be toxic,

radioactive or contaminated with pathogenic microorganisms when using

this centrifuge. When Risk Group II materials are used (as identied in the

World Health Organization “Laboratory Bio-Safety Manual”), a Bio-Seal should

be employed. The rotor and rotor accessories should not be considered as

Bio-Seals. More than one level of protection must be provided in the case of

materials of a higher group. The use of ammable or explosive materials as

well as those materials which chemically react vigorously is prohibited.

Model Description

The Horizon Model 842VES is a continuous-duty, digitally-controlled centrifuge

designed for the separation of uid samples. The 842VES oers control over almost

every aspect of the unit’s operation from variable acceleration and deceleration to

easy time and speed input. High speed and force capability produces platelet-poor/

free plasma and greatly reduce processing times. The exclusive Drucker horizontal

rotor allows for quick and easy sample loading and complete horizontal separation.

Save settings in one of 10 memory locations and recall them at the touch of a

button.

Intended Use

General purpose laboratory centrifuge for sample

seperation.

Supplied Accessories (Standard)

See the next

page for a

description of

optional

One (1) 6-Place

Horizontal Rotor

p/n 7786021

Six (6)

100mm Tube Holders

p/n 7713040

Six (6)

75mm Tube Holders

p/n 7713043

accessories.

Also included (not shown):

• One (1) 10’ Line Cord • One (1) Operator’s Manual • 5/32” Allen Wrench

WARRANTY:

The Drucker Company warranties that this centrifuge is free from

defects in workmanship and parts for 2 years.

Made in the USA by

200 Shadylane Drive • Philipsburg, PA 16866

Phone: 814-342-6205 or 814-692-7661 • Fax: 814-692-7662 • www.druckercompany.com

page 3

Page 4

Specications:

General Specications for the Horizon Model 842VES Centrifuge

Overall Dimensions (H x W x D): 8.0 in. x 11.0 in. x 13.5 in.

Centrifuge Motor: 1/2 H.P. Brushless DC

Protection Breaker: 4 Amp. re–settable

Timer: electronic, with hold

or 0 to 99 minutes, +/- 1%

Weight: 23 lbs.

Permitted Environmental Conditions

Ambient Temperature During Operation: 2 oC - 40 oC

Maximum Relative Air Humidity: 90%

Electrical Requirements:

Power: 200 Watts

Voltage: North America: 115 Volts (+/- 10%)

Japan: 100 Volts (+/- 10%)

Europe: 230 Volts (+/- 10%)

Frequency: 50/60 Hz

Any use other than those specied by the Manufacturer is explicitly prohibited.

Maximum sample density is 1.15 grams / mL, (water density = 1.0 grams / mL)

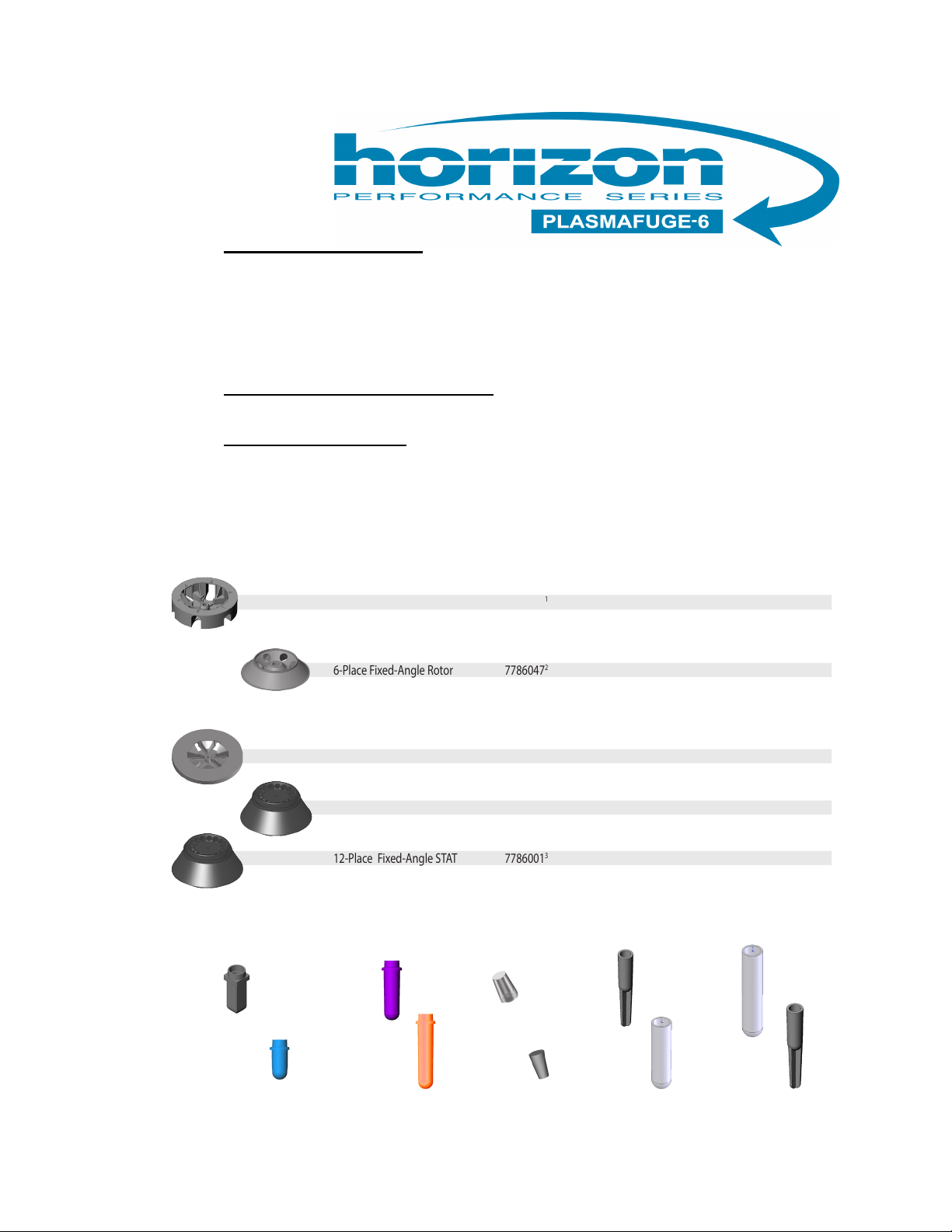

PART NO. # MAX TUBE SIZE SPEED RANGE FORCE RANGE

6-Place Horizontal (Standard) 77860211

75mm tube holders 77130431 6 17mm x 75mm 1000 to 4,500 RPM 140 to 2,260 xg

100mm tube holders 77130401 6 17mm x 100mm 1000 to 4,500 RPM 140 to 2,800 xg

Refer to serial number label

on rear of centrifuge to

conrm voltage requirement.

6-Place Fixed-Angle Rotor 7786047

2

75mm tube holder 77130431 6 17mm x 75mm 1000 to 4,000 RPM 140 to 1,500 xg

100mm tube holder 77130401 6 17mm x 100mm 1000 to 4,000 RPM 140 to 1,730 xg

125mm tube holder 77130442 6 17mm x 125mm 1000 to 4,000 RPM 140 to 1,950 xg

6-Place Performance Plus Horizontal 7786017

3

75mm tube holder 77130563 6 13mm x 75mm 1000 to 6,500 RPM 140 to 5,000 xg

12-Place combo Fixed-Angle STAT 7786003

75mm tube locations n/a3 6 13mm x 75mm 1000 to 7,000 RPM 140 to 4,880 xg

3

100mm tube locations n/a3 6 13mm x 100mm 1000 to 7,000 RPM 140 to 5,700 xg

12-Place Fixed-Angle STAT 7786001

NOTE: Contact the Drucker Company for assistance when changing the installed rotor. The installed rotor may

only be changed by qualied personnel.

13 x 75mm

Performance Tube

Holder

p/n 7713056

3

75mm tube locations n/a3 12 13mm x 75mm 1000 to 7,000 RPM 140 to 4,880 xg

100 mm

Tube Holder

p/n 7713040

1

125 mm

Tube Holder

75 mm Tube

Holder

p/n 7713043

1

This rotor or rotor accessory is rated for a rotational speed of 5000 RPM and a force of 3000 xg.

2

This rotor or rotor accessory is rated for a rotational speed of 4500 RPM and a force of 2500 xg.

3

This rotor or rotor accessory is rated for a rotational speed of 7000 RPM and a force of 5500 xg.

1

p/n 7713044

3

Tube Holder

Cap

p/n 7713011

2

1” Cushion

Spacer

p/n 1525

1.5 to 2mL

tube Adapter

p/n 7713065

13 x 75mm

insert, p/n

7713064

13 x 100 mm

insert, p/n

7713066

.5 to 1 ml tube

Adapter

p/n 7713068

page 4

Page 5

Control Panel / Parts of the Centrifuge:

Lid

Lid Knob

Lid Safety

Interlock System

Control Panel

(see below)

Cabinet

RCF Conversion

Button

Start

Button

Open /

Stop

Button

Time Display

Up/Down RPM

Change Buttons

RPM Display

Up/Down Time

Change Buttons

Running

Indicator

Light

Brake

Display

Latched

Indicator

Light

Program

Button

Unlocked

Indicator

Light

Memory

Preset

Display

Memory

Button

page 5

Page 6

Setup Location:

1. Unpack the centrifuge and verify that all of the supplied equipment is present.

2. Choose a setup location which meets the following criteria:

a) A bench top clearance height of 16” is required in order to open the lid.

b) The clearance envelope is the space around the centrifuge which is required for

safety. Choose a setup location which will allow for a clearance envelope of at least

24” x 24”, (with the centrifuge at the center). No person or hazardous material shall

be permitted in the clearance envelope during operation. The operator time within

the envelope shall be limited to the time necessary for loading, unloading and

centrifuge operation only.

c) Proper ventilation is necessary to prevent the overheating of samples as well as

premature failure of the centrifuge. Choose an area which will allow unencumbered

air ow.

d) The centrifuge is designed to rest on its four rubber feet. No adjustment is necessary

for leveling the centrifuge, however, the surface should be at and level.

e) Be sure the outlet is always within reach as the line cord is the means of

emergency disconnection!

Initial Setup Procedure:

If any problems are found during the initial setup procedure, refer to the troubleshooting

section. For further assistance, contact The Drucker Company at 814-342-6205 or 814-342-6205.

1. Plug the female end of the line cord into the rear of the centrifuge. Plug the male end into

an approved electrical outlet. For electrical safety, the unit must always be properly

grounded.

2. For operator safety, the locking system is always active; requiring power and direction

from the user to disengage it (the lid also automatically unlocks at the end of a run when

it is safe to do so). To unlock the lid (in order to access the rotor chamber) press the

‘OPEN / STOP’ button on the control panel. The ‘UNLOCKED’ indicator light should

illuminate. If it does not, refer to the section on troubleshooting. The lid will remain

unlocked for 15 seconds after pressing the ‘OPEN / STOP’ button.

3. Turn the latch counterclockwise and open the lid.

4. Spin the rotor by hand; check for free and level rotation. If the rotor does not spin freely,

refer to the section on troubleshooting.

5. Place the test tube holders inside the rotor and verify that they are seated properly.

6. Close the lid. Rotate the lid knob clockwise to its complete stop position. The

’LATCHED’ indicator light should be illuminated. If it is not, make sure that the lid is

latched properly. The centrifuge will not run unless the lid is latched properly and the

’LATCH’ indicator light is illuminated.

7. Use the up arrow button next to the RPM display to set the speed to 4000 RPM.

8. Initiate a test run by pressing the ‘START’ button.

9. The ‘RUNNING’ indicator light will illuminate.

10. The test tube carriers will slide up into the horizontal position (horizontal rotor only) and

the unit will accelerate to the current set speed.

11. Listen to the sound of the centrifuge. A smooth whirring sound should be heard. If there

are any loud or unusual sounds, stop the centrifuge by pressing the ’OPEN / STOP’ button

immediately and refer to the section on troubleshooting.

12. Press the ‘OPEN / STOP’ button to terminate the test run. The rotor will decelerate to a

complete stop and the lid will then unlock automatically for sixty (60) seconds.

13. Take time now to familiarize yourself with the various additional user settings. Turn to

page 11.

14. The centrifuge is now ready for operation.

page 6

Page 7

Operation:

NOTE: Follow the initial setup procedure before initial operation.

1. Press the ‘OPEN / STOP’ button to unlock the lid and then open the lid.

2. Insert cushions (if needed) into the tube carriers (holders) for the tube size you are

using. Refer to ‘Tube Holder Congurations’ for assistance.

3. Place the test tube samples into the tube carriers (holders). Be sure to follow the

rules for balanced loads.

4. Close the lid and turn the lid knob clockwise to its complete stop position. The

’LATCHED’ indicator light should illuminate to indicate that the latch is closed

properly. If the lid knob is not completely latched, the ‘LATCHED’ indicator light will not

illuminate and the centrifuge cannot be operated.

5. Set the desired speed and run time using the appropriate up and down arrow buttons.

6. If desired, adjust the braking level, acceleration rate, countdown delay, imbalance

sensitivity and audible indication. Turn to page 11 for a description of these features.

7. Begin the run by pressing the ‘START’ button on the control panel.

8. The centrifuge should begin to spin. The ‘RUNNING’ indicator light should illuminate.

IF A PROBLEM IS FOUND DURING A SPIN THAT REQUIRES THE CENTRIFUGE TO SHUT

DOWN, PRESS THE ‘OPEN / STOP’ BUTTON IMMEDIATELY !

9. After time has elapsed, the ‘RUNNING’ indicator light will extinguish and the rotor will

decelerate to a complete stop.

11. The ‘UNLOCKED’ indicator light will illuminate and the locking mechanism will

disengage, allowing entry into the rotor chamber. If the automatic unlock times out

(after 60 seconds) simply press the ‘OPEN / STOP’ button.

12. Turn the lid knob counterclockwise and open the lid.

13. Remove the samples.

14. The centrifuge may be used immediately.

Tube Holder Congurations:

The next three pages will describe proper balancing and tube loading. Use the appropriate section

for the rotor installed in your centrifuge. Improper loading can result in damage to the centrifuge or

test tube samples.

Six-Place, Performance-Plus Horizontal Rotor (optional):

This rotor is designed to hold up to six (6) test tubes, up to 17mm x 75mm.

Your centrifuge must contain a balanced load in order to

work properly. To ensure that the load is balanced, keep

these rules in mind when inserting test tube samples.

1. Opposing tube holders must be identical.

2. Opposing tube holders must be empty or loaded equally weighted samples.

3. If an odd number of samples is to be spun, use a water-lled tube to mate

with the unpaired one.

12 Place, 12 Place combo Fixed-Angle STAT Rotor (optional):

This rotor is designed to hold up to twelve (12) test tubes, up to 17mm x 100mm.

Your centrifuge must contain a balanced load in order to

work properly. To ensure that the load is balanced, keep

these rules in mind when inserting test tube samples.

1. Opposing tube locations must be empty or loaded with equally

weighted samples.

2. If an odd number of samples is to be spun, use a water-lled tube to

mate with the unpaired one.

page 7

Page 8

Tube Holder Congurations (cont.):

Six (6) Place Horizontal Rotor (Standard):

This rotor is designed to hold up to six (6) tube holders.

It comes with two tube holder types. The purple holders

are designed to hold tubes up to 10mL (up to 17mm x

100mm). The blue holders are designed to hold tubes up

to 5mL (up to 17mm x 75mm).

Your centrifuge must contain a balanced load in order

to work properly. To ensure that the load is balanced,

keep these rules in mind when inserting test tube

samples into the six (6) position horizontal rotor:

1. Opposing tube holders must be identical.

2. Opposing tube holders must be empty or loaded

equally weighted samples.

3. If an odd number of samples is to be spun, use a

water-lled tube to mate with the unpaired one.

A.

B.

DIRECTIONS:

1. Compare the tube to be spun with the boxes shown at left.

2. Find the box that most closely matches the tube’s length. NOTE:

The tube length with its stopper or cap must be shorter then the

chosen box.

3. Match the letter from the chosen box with one of the

congurations shown.

For Example: A tube is found to be as long as box B. Accordingly, we

can use a 100 mm tube holder with a 1525 cushion or a 75mm tube

holder with no cushion, (congurations B1 or B2).

C.

A.

PURPLE

100mm

Tube

Holder

B1. B2.

PURPLE

100mm

Tube

Holder

with

1525

cushion

BLUE

75mm

Tube

Holder

C.

BLUE

75mm Tube

Holder

with

1525 cushion

page 8

Page 9

Tube Holder Congurations (cont.):

Six (6) Place Fixed-angle Rotor (optional):

This rotor is designed to hold up to six (6) tube holders. It comes

with three tube holder types. The orange holders are designed

to hold tubes up to 15mL (up to 17mm x 125mm). The purple

holders are designed to hold tubes up to 10mL (up to 17mm x

100mm). The blue holders are designed to hold tubes up to 5mL

(up to 17mm x 75mm).

Your centrifuge must contain a balanced load in order to work properly. To ensure

that the load is balanced, keep these rules in mind when inserting test tube samples.

1. Opposing tube holders must be identical.

2. Opposing tube holders must be empty or loaded equally weighted samples.

3. If an odd number of samples is to be spun, use a water-lled tube to mate

with the unpaired one.

DIRECTIONS:

1. Compare the tube to be spun with the four boxes shown below.

2. Find the box that most closely matches the tube’s length. NOTE: The tube length with

its stopper or cap must be shorter then the chosen box.

3. Match the letter from the chosen box with one of the congurations shown.

For Example: A tube is found to be as long as box B. Accordingly, we can

A.

use a 125 mm tube holder with a 1525 cushion or a 100mm tube holder

with no cushion, (congurations B1 or B2).

B.

C.

D.

A.

BLACK

ORANGE

125mm

Tube

Holder

C1. C2.

PURPLE

100mm

Tube

Holder

with

1525

cushion

BLUE

75mm

Tube

Holder

B1. B2.

or

PURPLE

100mm

Tube

Holder

ORANGE

125mm

Tube

Holder

with

1525

cushion

D.

BLUE

page 9

75mm Tube

Holder

with

1525 cushion

Page 10

Control Panel Functions:

Time Adjustment and Timer Operation - The run time may be set from 30 seconds to 99

minutes and 30 seconds. Press the up and down arrow buttons next to the time display to adjust

the run time. Adjustments may be made prior to a run or after a run begins. A quick tap will adjust

the time by 30 seconds. Hold down the button for 1 minute adjustments - continue to hold for 5

minute adjustments.

Press the down button once while 00:30 is displayed to access the “hold” feature. When a

“hold” run is initiated, the timer will count up to keep track of total run time. The unit will run for a

maximum of 99 minutes and 30 seconds and will then shut off automatically. The “hold” run may

also be terminated by pressing the STOP/OPEN button. The total run time during a “hold” run is

displayed on the time display until the operator unlocks the lid by pressing the OPEN button or

opens the lid (during the automatic unlock after the run ends).

Speed Adjustment / RCF Display - Press the up and down arrow buttons next to the speed

display to change to run speed. Adjustments may be made prior to a run or after a run begins. A

quick tap will adjust the speed by 50 RPMs. Hold down the button for 100 RPM adjustments.

Continue to hold for 500 RPM adjustments.

Press the RCF button at any time to convert the current speed setting to the corresponding force

value (xg). The speed may be set by RCF by holding down the RCF button while using the up/

down speed set buttons. The jumps made in the RCF value while holding down the RCF button

and pressing the up and down arrow buttons correspond to 50 RPM adjustments in speed. Since

the RCF is a function of the square of the speed, this jump size will vary.

Starting and Stopping a Run - With the lid switch closed, press the START button to

begin a run. Press the STOP/OPEN button at any time during a run to terminate it.

Unlocking the Lid - The lid is unlocked whenever the red UNLOCKED indicator light is

illuminated. The lid unlocks automatically for 60 seconds at the end of a run. The lid can also be

unlocked for an additional 15 seconds by pressing the OPEN/STOP button while the unit is idle.

The lid cannot be unlocked while the rotor is spinning.

Imbalance Detection Reset - This centrifuge is equipped with imbalance detection. If an

imbalance is detected, the centrifuge will terminate the current run and will begin to brake to a stop.

The words “BALANC” and “ERROR” will ash on the speed display. Once the rotor has stopped,

open the lid the cancel the error reporting, balance the load and begin a new run. Alternately, the

error reporting can be canceled by pressing the OPEN/STOP button.

Advanced User Settings:

This centrifuge allow for total control of the run by the user. You may adjust the acceleration rate,

adjust the braking rate, adjust the imbalance sensitivity level, select from several audible settings,

and use the optional countdown delay.

Acceleration Rate - The user may adjust the acceleration rate from minimum (1) to maximum

(10) using the following procedure:

1. While the centrifuge is idle, press the PROGRAM button.

2. Use the UP/DOWN arrow buttons next to the speed display until “ACCEL” is

displayed in the speed display.

3. The current acceleration rate is displayed in the time display. Use the ‘UP/

DOWN arrow buttons next to the time display to adjust the acceleration rate

from 1 (minimum) to 10 (maximum).

4. Press the PROGRAM button to exit or use the UP/DOWN arrow buttons next to

the speed display to adjust additional settings.

page 10

Page 11

Advanced User Settings (continued):

Braking Rate - The user may adjust the braking rate from minimum ( slowest deceleration, 0) to

maximum (quickest deceleration, 9) using the following procedure:

1. While the centrifuge is idle, press the PROGRAM button.

2. Use the UP/DOWN arrow buttons next to the speed display until “BRAKE” is

displayed in the speed display.

3. The current braking rate is displayed in the brake display. Use the UP/DOWN

arrow buttons next to the brake display to adjust the braking rate from 0

(minimum) to 9 (maximum).

4. Press the PROGRAM button to exit or use the UP/DOWN arrow buttons next to

the speed display to adjust additional settings.

Countdown Delay - When the countdown delay is turned on, the timer will not begin

decrementing until the rotor has reached full speed as set by the user. This feature ensures that

the samples see full force for the total run time.

1. While the centrifuge is idle, press the PROGRAM button.

2. Use the UP/DOWN arrow buttons next to the speed display until “CNTDLY” is

displayed in the speed display.

3. The current status of this feature (ON or OFF) is displayed in the time display.

Press UP/DOWN arrows next to the time display to toggle the status between

ON and OFF.

4. Press the PROGRAM button to exit or use the UP/DOWN arrow buttons next to

the speed display to adjust additional settings.

Imbalance Detection - This centrifuge is equipped with imbalance detection. This ensures

that the centrifuge will safely shut down in the event that an imbalanced load is run or a malfunction

occurs. This feature is intended to provide for operator safety and to extend the life of the

centrifuge. The LOW setting will allow for a greater imbalance before shutting the centrifuge down.

1. While the centrifuge is idle, press the PROGRAM button.

2. Use the UP/DOWN arrow buttons next to the speed display until “BALANC” is

displayed in the speed display.

3. The current status of this feature (LOW or HI) is displayed in the time display.

Press UP/DOWN arrows next to the time display to toggle the status between

LOW and HI.

4. Press the PROGRAM button to exit or use the UP/DOWN arrow buttons next to

the speed display to adjust additional settings.

Audible Settings - The user may select from six different audible indicator levels:

Setting Button Press Beep? End-of-run audible notication

1 NO NONE

2 YES NONE

3 NO YES, 5 beeps

4 YES YES, 5 beeps

5 NO YES, continuous, user must press STOP/OPEN button to cancel

6 YES YES, continuous, user must press STOP/OPEN button to cancel

1. While the centrifuge is idle, press the PROGRAM button.

2. Use the UP/DOWN arrow buttons next to the speed display until “BEEPER” is

displayed in the speed display.

3. The current audible selection is displayed in the time display. Use the UP/

DOWN arrow buttons next to the time display to select a setting (1 to 6).

4. Press the PROGRAM button to exit or use the UP/DOWN arrow buttons next to

the speed display to adjust additional settings.

page 11

Page 12

Memory Locations / Storing and Recalling:

The Performance Series centrifuges are capable of storing up to 10 user-dened presets. These

memory presets contain all of the settings needed to dene a specic run, (run time, speed,

acceleration rate, braking rate, etc.). The user can use these memory locations to quickly congure

the centrifuge for a specic test type and ensure that the test is run in the same way each time by

recalling this same setting.

Store a conguration in a memory location

1. Adjust the various settings (speed, time, acceleration rate, etc.) for the

conguration to be saved.

2. Press and hold the PROGRAM button until the preset display begins to ash.

3. Press the MEMORY button to increment the memory location by one. Continue

to press the memory button until the desired location is displayed.

4. Press the program button to store the current conguration into the memory

location that is displayed.

Recall a conguration from a memory location

1. Press the MEMORY button until the desired memory location is displayed in the

memory display.

2. As you review the presets, the settings on the control panel will change to

reect the settings stored in the memory preset currently displayed.

3. When the desired preset is found, pause and the memory display will

momentarily ash. The stored conguration is now loaded.

Notes:

Once a conguration has been loaded, it will remain active until any change is made on the control

panel. If for instance the user adjusts the time, the current conguration will no longer match the

previously loaded conguration and the memory display will change to a “-” dash. The previous

conguration may be recalled using the procedure described above.

Memory locations my be overwritten by selecting them during the store procedure.

Digital Cycle Counter:

This centrifuge is equipped with a digital cycle counter to monitor machine usage and for routine

maintenance.

To display the current cycle count, perform the following:

1. Unlock the lid by pressing the OPEN/STOP button.

2. Open the lid latch so that the yellow LATCHED indicator light is not illuminated.

3. Press and hold the START button for approximately ve seconds. The word

“CYCLES” will be displayed in the speed display and the current cycle count will

be displayed in the time display. If the current cycle count exceeds 9,999

cycles, the cycle count will be displayed by showing the rst part of the number

and then the end of the number. For example: the 1st shown is 0002 and the

2nd shown is 4537 represents 24,537 cycles.

page 12

Page 13

Care and Preventative Maintenance:

With proper care and maintenance your Horizon centrifuge will provide years of laboratory service.

For proper care, the following steps should be taken:

1. Provide Adequate Ventilation: For cooling purposes, the Horizon draws in ambient air

through the air intake cover on the top of the lid and exhausts this air in the rear of the base.

The centrifuge should be placed on a hard smooth surface for good air circulation.

2. Always Spin Balanced Loads: This centrifuge is equipped with imbalance detection.

However, it is still possible to run loads that are minimally imbalanced, particularly at an

imbalance setting of LOW SENSITIVITY. For maximum centrifuge life, set the imbalance

detection to HI SENSITIVITY and always run balanced loads. Refer to pages 8 and 9 on for

additional information on balancing the load.

3. Keep the Tube Holders Clean: NOTE: Always follow the safety guidelines of your

laboratory to properly clean up and/or dispose of materials in the event that a substance

known to be potentially toxic, radioactive or contaminated with a pathogenetic

microorganism is spilt in or on the centrifuge. Small glass fragments left in the tube carrier /

holder after a tube breakage may adhere to the next test tube inserted in that carrier /

holder. When this tube is handled, these fragments may puncture protective gloves and

lacerate the operator’s ngers or hand. Remaining fragments may provide stress points

on subsequent tubes and result in additional breakage. If a tube breakage occurs,

carefully remove the tube holder. Properly dispose of the sample and tube fragments and

thoroughly clean both the inside and outside of the tube carrier / holder. Insert a new tube

cushion (if necessary) and replace the tube carrier / holder in the rotor.

4. Motor and Electrical Maintenance: This centrifuge uses a brushless-DC motor. There

are no brushes to replace and it should not need routine servicing for the life of the

centrifuge. The electrical components are selected for high reliability and should not need

service.

5. Keep the Centrifuge Clean: The cabinet, rotor top and accessories shall be thoroughly

cleaned using either isopropyl alcohol, soap and water, or a mild bleach solution. The use

of Fully/Partially Halogenated Hydrocarbons, Ketones, Esters and all other chemicals not

prescribed by the manufacturer may cause damage to the rotor and tube carriers / holders

and shall not be used. Before using any cleaning or decontamination methods except those

recommended by the manufacturer, users should check with the manufacturer that the proposed

method will not damage the equipment

If it is necessary to remove the rotor for additional cleaning it is required that a qualied

technician remove the rotor assembly.

Apply cleaning solutions with a towel or cloth. Do not submerge the centrifuge in water or

other cleaning solutions as this will cause damage and void your warranty!

If hazardous material is spilt on or inside the centrifuge, the centrifuge must be decontaminated.

6. Tube Holder Replacement: It is recommended that the tube holders be replaced after 24

months or 25,000 cycles, whichever comes rst.

page 13

Page 14

Rotor Removal and Installation:

To remove the rotor:

1. Unlock the centrifuge by pushing the ‘OPEN / EMERGENCY STOP’ button and unlatch and

open the lid.

CAUTION:

1) Unplug the centrifuge from the electrical outlet at this time to eliminate the possibility of electrical

shock or other injury.

2) Rotors may be removed for cleaning. However, rotors are not to be replaced in the eld. The

factory installed rotor is the only rotor intended to be used in the centrifuge.

2. Remove the test tube holders.

3. Remove the screw in the center of the rotor using the supplied 5/32” Allen wrench by turning

the screw counterclockwise. Be sure to save the screw and washer in a safe place.

4. The rotor is sitting on a cone-shaped adapter. Pull the rotor up and off of this adapter.

5. Remove the rotor from the rotor chamber.

NOTE: If you are removing the performance plus rotor, you must: 1) Move the rotor towards

the front of the centrifuge; 2) Angle the back edge of the rotor; 3) Slide it through the

opening. See illustration below.

Proper position for removing or installing the performance-plus rotor

To install the rotor:

1. Place the rotor back onto the cone-shaped adapter. You may need to turn the rotor slightly to

line it up properly.

NOTE: If you are installing the performance plus rotor, angle the rotor as needed to get it back

into the rotor chamber.

2. The rotor should slide onto the rotor cone freely.

3. Once a proper t has been achieved, thread the screw and washer back into the center of the

rotor. Use the Allen wrench to tighten the screw.

4. Replace the tube holders and verify that they are seated properly.

5. It is recommended that the initial setup procedures be performed to ensure that the rotor has

been installed correctly and that no damage has been done to the centrifuge during either the

rotor installation or possible rotor chamber cleaning.

page 14

Page 15

Troubleshooting:

1. Problem: The rotor does not spin freely.

Solutions: • Make sure that nothing has fallen into the rotor chamber.

• If there is nothing obstructing the rotor, the motor may be damaged.

Contact your authorized dealer or The Drucker Company for further

assistance.

2. Problem: There is excessive noise when the machine is running.

Solutions: • Check to see that the load is balanced.

• Make sure that nothing has fallen into the rotor chamber.

• Make sure that the screw in the center of the rotor is snug.

• The motor may be damaged. Contact your authorized dealer or

The Drucker Company for further assistance.

3. Problem: The centrifuge does not run or an error message is displayed

Solutions: • Make sure that the centrifuge is getting power. Does the control panel come

on? Check the electrical outlet that the unit is plugged into. Check the

circuit breaker on the base near the rear of the centrifuge.

• If the unit is getting power, make sure that the lid latch is closed properly.

The latch is closed properly when the yellow ‘LATCHED’ indicator light is

illuminated.

• If the centrifuge stops soon after start-up and ‘ERROR’ is displayed on the

speed display, refer to the following table for fault information:

ERROR / SPEED

The centrifuge cannot reach full speed due to a problem with the rotor, an

inadequate power supply, or other electrical problems. Press the OPEN/

STOP button to cancel the error and then check the rotor and the line

voltage. Contact your authorized dealer or The Drucker Company.

ERROR / BALANC

The centrifuge has detected an imbalance. Press the OPEN/STOP button to

cancel the error and balance the load. If the load is balanced, make sure

that the centrifuge is installed on a secure, level location.

4. Problem: The lid knob cannot be turned / the lid cannot be unlocked.

Solutions: • Make sure the centrifuge has power and that the rotor is stopped. Press the

‘OPEN/STOP’ button. The red ‘UNLOCKED’ indicator light should illuminate

and the unlocked mechanism should disengage, allowing entry into the lid.

• If the lid is still locked, make sure that the red ‘UNLOCKED’ indicator is

illuminated and turn the lid knob rst completely clockwise and then

counterclockwise.

• If the red ‘UNLOCKED’ indicator will not illuminate or the locking

mechanism will not disengage, the electronics or locking mechanism may

be damaged. Have a technician service the centrifuge or contact The

Drucker Company for further assistance.

For additional assistance, contact technical support

Monday-Friday, 8:30AM - 5:00PM, EST

200 Shadylane Drive • Philipsburg, PA 16866

Phone: 814-342-6205 or 814-692-7661 • Fax: 814-692-7662

www.druckercompany.com

page 15

Page 16

The Horizon 842VES complies with all requirements of CE EN 61000-3-2, -3-3, EN

Safety:

Horizon Lid Safety Switch: The Horizon lid is secured to the top of the cabinet by a latching

knob and pawl system. When the knob is rotated clockwise, the pawl grips the underside of the

cabinet opening and prevents the lid from opening. A mechanical stop positions the pawl and

prevents it from rotating completely. When rotated to the stop position, the pawl makes contact

with a micro–switch mounted underneath the cabinet top. The lid safety switch prevents the

centrifuge from operating while the lid is open. The yellow ‘LATCHED’ indicator light on the front

of the machine will illuminate when the lid has been latched properly.

Horizon Lid Safety Interlock System: In addition to the Lid Safety Switch, the Horizon has a

true “0 RPM” lid locking system. The lid safety interlock system keeps the lid locked at all times,

(even during power failure), and requires that the rotor be at rest in order to unlock the lid. The

centrifuge will not allow entry into the rotor chamber unless the centrifuge has power and the

rotor is stopped. To open the lid, make sure that the centrifuge is plugged in and, with the rotor

stopped, press the ‘OPEN / EMERGENCY STOP’ button.

Note: After the centrifuge has started spinning, it may be possible to rotate the lid knob enough

to cause the pawl to lose contact with the lid safety switch. If this happens, the centrifuge

motor may lose power, but the lid will still remain locked. If the knob is accidentally moved and

this situation should occur, rotate the knob fully clockwise to its stop position and the centrifuge

will resume operation.

61000-4-2, -4-3, -4-4, -4-5, -4-6, -4-11, EN 61010-1, -2-020 and UL standard 3101–2–20,

Can/CSA C22.2 No. 1010.1 , Can/CSA C22.2 No. 1010.2.20

Circuit Breaker: The Horizon is protected with a 4 Amp circuit breaker located at the rear of the

machine mounted to the base. Any electrical short circuit will cause the breaker to cut power to

the machine.

Emergency Rotor Chamber Entry:

In the event of power failure, it may be impossible to unlock

the lid by conventional means. In this case, entry into the

rotor chamber may be made by removing the latch label and

using a pen to manually disengage the locking mechanism

(see photo). Pull the mechanism towards the control panel

and then unlatch and open the lid. If the unit is damaged,

contact your authorized dealer or The Drucker Company.

Calibration and Earth Ground Testing:

It is recommended that the top speed, ground continuity and line leakage be tested every two

years for continued safe operation. Contact The Drucker Company for further information or

testing availability.

page 16

Page 17

Contact your authorized dealer or The Drucker Company

to order replacement parts or accessories.

Replacement Parts:

Part No. Description

7724177 Rubber Foot

7751068 Lid Tray Micro-Switch

7723002 Lid Tray Solenoid

7735011 Motor, ½ H.P. Brushless DC

7717041 PC Control Board

3056001 Step Down Transformer

3056003 Step Down Transformer,

220V to 12V

7751043 Circuit Breaker

7724033 Front Panel Label

7760003 Line cord

7714101 Pawl, latch, lid

7714103 Knob, latch, lid

7712263 Lid

7724071 Hinge, friction

7732018 Gasket, cabinet opening

7732019 Gasket, rotor chamber

Tube

Holder Cap

75mm

Tube Holder

p/n 7713056

p/n

7713011

75 mm

Tube Holder

p/n 7713043

12-Place (75mm only)

Fixed-Angle STAT

Rotor

p/n 7786001

12-Place combo

([6]75mm, [6]100mm

Fixed-Angle STAT Rotor

p/n 7786003

6-Place

Horizontal Rotor

p/n 7786021

6-Place

Fixed-Angle Rotor

p/n 7786047

6-Place

Performance

Plus

Horizontal

Rotor

p/n 7786017

1.5 to 2mL

tube Adapter

p/n 7713065

125 mm

Tube Holder

p/n 7713044

100 mm

Tube Holder

p/n 7713040

13 x 75mm

insert, p/n

7713064

Phone: 814-342-6205 or 814-692-7661 • Fax: 814-692-7662 • www.druckercompany.com

13 x 100 mm

insert, p/n

7713066

.5 to 1 ml

tube Adapter

p/n 7713068

Made in the USA by

200 Shadylane Drive • Philipsburg, PA 16866

Loading...

Loading...