Page 1

Providing Quality Centrifuges since 1932

Operator’s Manual

Model 614B • Laboratory Centrifuge

P/N 03-0-0002-0040

Rev. A

Page 2

Table of Contents

Rev. A

P/N 03-0-0002-0040

Model Description pg. 2

Supplied Equipment pg. 2

Features pg. 3

Specications pg. 3

Setup Location and Procedure pg. 4

Operation pg. 5

Rotor Removal and Installation pg. 5

Tube Holder Congurations pg. 6

Care and Preventative Maintenance pg. 7,8

Safety pg. 8

Calibration and Ground Testing pg. 8

Troubleshooting pg. 8

Replacement Parts pg. 9

Available Accessories pg. 9

Warranty pg. 10

WARNING: For the safety of both the

operator and service personnel, care should

be taken when using this centrifuge if

handling substances that are known to be

toxic, radioactive or contaminated with

pathogenic microorganisms. When Risk

Group II materials are used, (as identied in

the World Health Organization “Laboratory

Bio–Safety Manual”), a Bio–Seal should be

employed. The Bio–Seal accessory for the

model 614 tube holders is the non–aerosol

shield cap, p/n 7713011. In the event that

materials of a higher risk group are being

used, more than one level of protection must

be provided. The use of ammable or explosive materials as well as those materials

which have a vigorous chemical reaction is

prohibited. For your safety and the durability

of your machine, never transport or store

centrifuge with tube holders inside machine.

Model Description:

The Model 614B is a continuous duty centrifuge designed for the small lab or

doctor’s ofce for the purposes of separating laboratory uids. The unit is controlled

by a mechanical timer settable from 1 to 30 minutes. Samples can be safely viewed

through the transparent lid. In the event that the lid is opened during a run, the

power to the motor is disconnected.

For warranty information, turn to page 10.

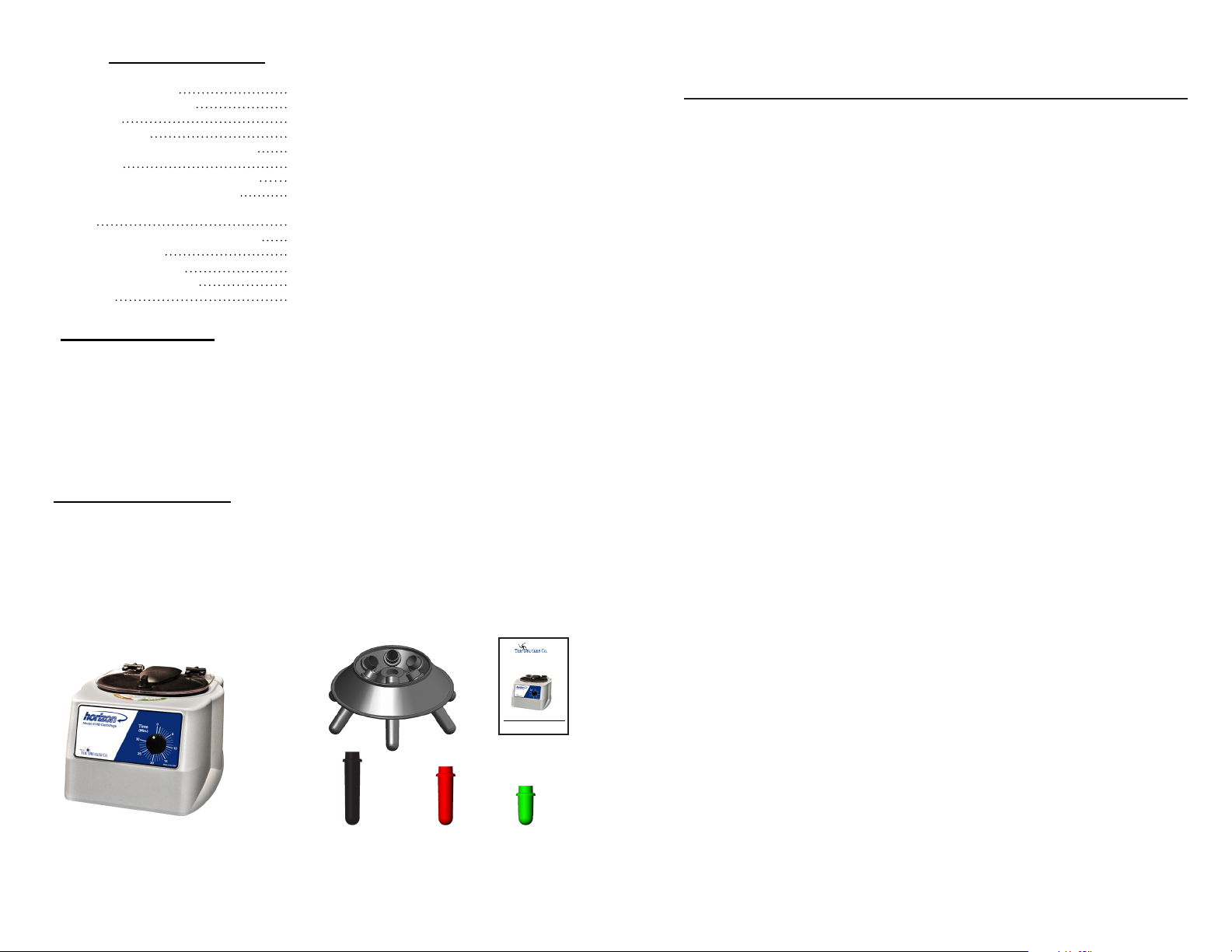

Supplied Equipment*:

The following items come standard with each Model 614B centrifuge:

NOTES:

1. One (1) six-place xed-angle rotor

p/n 7786047

2. Operator’s manual p/n 03-0-0002-0040

3. Six (6) 125 mm tube holders

4. Six (6) 100 mm tube holders

5. Six (6) 75 mm tube holders

p/n 7713032

p/n 7713031

p/n 7713033

1.

x 6

3.

* The rotor and rotor accessories are rated for a rotation frequency of 3,500 RPM.

Page 2

x 6

4.

Operator’s Manual

Model 614B • Laboratory Centrifuge

2.

5.

x 6

Page 11

Page 3

WARRANTY:

The Drucker Company warranties that this centrifuge is free

from defects in workmanship and parts for 2 years.

Features:

• Fixed-angle rotor for spinning 75 mm, 100 mm and 125 mm test tubes in

specially designed tube holders

• Cool–Flow air ow design that prevents overheating of samples

• Heavy gauge steel construction for safety and durability

• Lid safety switch that prevents the centrifuge from operating unless the

lid is closed and latched

• Removable rotor for easy cleaning

• Brushless A/C motor

• Clear lid for safe observation of samples and optical calibration of speed

Specications:

General Specications for the Model 614B Centrifuge

Nominal Speed (125 mm holders): 3,150 (± 100) RPM

Nominal RCF (125 mm holders): 1,200 (± 80) xg

Nominal Speed (100 mm holders): 3,250 (± 100) RPM

Nominal RCF (100 mm holders): 1,080 (± 80) xg

Nominal Speed (75 mm holders): 3,300 (± 100) RPM

Nominal RCF (75 mm holders): 950 (± 80) xg

Maximum capacity: 90 mL (6 x 15 mL)*

Overall Dimensions (H x W x D): 8.75 in. x 11.75 in. x 14 in.

Centrifuge Motor: 1/30 HP, AC

Nominal Acceleration Time: 45 seconds

Protection Breaker: 4 Amp. re–settable

Timer: mechanical, 1 to 30 minutes

accuracy ± 10%

Current Requirement: 1.0 Amps

Voltage Requirement: 115 (±10) Volts

Frequency: 60 Hz

Weight: 13.75 lbs.

Made in the USA by

200 Shadylane Drive • Philipsburg, PA 16866

Phone: 814-342-6205 or 814-692-7661 • Fax: 814-692-7662 • www.druckercompany.com

Page 10

Before using any cleaning or decontamination methods except those recommended

by the manufacturer, users should check with the manufacturer that the proposed

method will not damage the equipment. See page 7, (bottom), for the recommended

cleaning solutions.

Any use other than those specied by the Manufacturer is explicitly prohibited.

* Maximum sample density is 1.15 grams / mL,

(water density = 1.0 grams / mL)

Page 3

Page 4

Setup Location:

1. Unpack the centrifuge and verify that all of the supplied equipment is present.

2. Choose a setup location which meets the following criteria:

a) A bench top clearance height of 20” is required in order to open the lid.

b) The clearance envelope is the space around the centrifuge which is

required for safety. Choose a setup location which will allow for a

clearance envelope of at least 24” x 24”, (with the centrifuge at the center).

No person or hazardous material shall be permitted in the clearance

envelope during operation. The operator time within the envelope shall

be limited to the time necessary for loading, unloading and centrifuge

operation only.

c) Proper ventilation is necessary to prevent the overheating of samples as

well as premature failure of the centrifuge. Choose an area which will

allow unencumbered air ow.

d) The centrifuge is designed to secure to the operating surface by four

suction feet. No adjustment is necessary for leveling the centrifuge,

however, the surface should be at and level.

e) Be sure the outlet is always within reach as the line cord is the

means of emergency disconnection!

Initial Setup Procedure:

If any problems are found during the initial setup procedure, refer

to the troubleshooting section on page 8. For further assistance,

contact The Drucker Company at 814-342-6205 or 814-692-7661.

1. Plug the centrifuge in to an approved electrical outlet. For electrical safety,

the unit must always be properly grounded.

2. Turn the latch counter–clockwise and open the lid.

3. Spin the rotor by hand; check for free and level rotation.

4. Close the lid. Rotate the lid knob clockwise to its complete stop position.

5. Turn the centrifuge on by turning the timer to 10 minutes.

6. Listen to the centrifuge. A smooth whirring sound should be heard.

Replacement Parts:

Part No. Description

7724037 Foot, rubber

7751068 Switch, lid safety

7786047 Rotor, six–place xed-angle

7735050 Motor, 1/30 H.P.

7722027 Timer, mechanical

7751043 Circuit Breaker

03-0-0003-0061 Front Panel Label

7760002 Power cord

7714101 Pawl, latch, lid

7714103 Knob, latch, lid

7712260 Lid

7724071 Hinge, friction

7732018 Seal, lid gasket

7732019 Seal, rotor chamber gasket

7713033 Tube holder, green, for 75mm tubes

7713031 Tube holder, red, for 100mm tubes

7713032 Tube holder, black, for 125mm tubes

Available Accessories:

1” Tube cushion

p/n 1525

Shield

caps

p/n

7713011

After the centrifuge has passed this procedure it is ready for operation.

BALANCED LOADS

Your centrifuge must contain a balanced load in order to work properly.

Use the following rules when loading the rotor. Spinning balanced

loads will extend the life of the machine and produce better results.

1. Opposing tube holders must be identical and must contain the same

cushion, or none at all.

2. Opposing tube holders must be empty or loaded with equally

weighted samples.

3. If an odd number of samples is to be spun, ll a tube with water to

match the weight of the unpaired sample and place it across from

this sample.

Page 4

Page 9

Page 5

(Continued)

6. Tube Holder Replacement: It is recommended that the tube holders be

replaced after 24 months of use.

Operation:

7. Remove Accessories Before Moving: All tube holders, samples, and caps

must be removed from the rotor chamber before transporting or storing

the centrifuge to prevent damage and injury.

Safety:

Lid Safety Switch: The lid is secured to the top of the cabinet by a latching knob

and pawl system. When the knob is rotated clockwise, the pawl grips the underside

of the cabinet opening and prevents the lid from opening. A mechanical stop

positions the pawl and prevents it from rotating completely. When rotated to the

stop position, the pawl makes contact with a micro–switch mounted underneath the

cabinet top. The lid safety switch prevents the centrifuge from operating while the

lid is open.

Circuit Breaker: The Model 614B is protected with a 4 Amp circuit breaker located

at the rear of the machine mounted to the base. Any electrical short circuit will

cause the breaker to cut power to the machine.

The Model 614B complies with all requirements of UL standard

61010A-1, 61010A-2-20; Can/CSA C22.2 No’s 1010.1; 1010.2.20.

Calibration and Earth Ground Testing:

It is recommended that the top speed, ground continuity and line leakage be tested

every two years for continued safe operation. Contact The Drucker Company for

further information or testing availability.

NOTE:

The latch must be turned completely

Troubleshooting:

1. Problem:

Solutions: – Make sure nothing has fallen into the rotor chamber.

2. Problem: Excessive noise when the machine is running.

Solutions: – Check to see that the load is balanced.

3. Problem: The centrifuge does not run.

Solutions: – Check the electrical outlet.

The rotor does not spin freely.

– If there is nothing obstructing the rotor, contact The Drucker

Company for further assistance.

– Make sure that nothing has fallen into the rotor chamber.

– Make sure that the nut in the center of the rotor is tight.

– Have a technician test the motor and replace it if necessary.

– Make sure the lid latch is turned completely clockwise to its stop

position.

– Check the circuit breaker switch at the bottom left of the machine.

If the switch is white, the breaker has tripped. Contact The

Drucker Company for further assistance.

clockwise to its stop position in order

for the centrifuge to operate.

NOTE: Follow the initial setup procedure on page 4 before initial operation.

1. Plug the centrifuge into an approved 115 Volt A.C., 60 Hz. outlet.

2. Turn the latch counter-clockwise and open the lid.

3. Insert cushions (if needed) into the tube holders for the tube size you are

using. Refer to ‘Tube Holder Congurations’ (page 6) for assistance.

4. Place the test tube samples into the tube holders. Be sure to follow the

rules for balanced loads.

5. Close the lid and turn the lid knob clockwise to its complete stop position.

6. Turn on the machine by turning the timer to the desired run time.

7. The centrifuge should begin to spin.

8. Once the timer reaches zero (0), power will be cut to the motor and the

rotor will coast to a stop. Do not open the lid until the rotor has come to a

complete stop.

9. Turn the lid knob counter–clockwise and open the lid.

10. Remove the samples.

11. The centrifuge is immediately ready for operation.

Rotor Removal and Installation:

To remove the rotor:

CAUTION: Unplug the centrifuge from the electrical outlet at this time to

eliminate the possibility of electrical shock or other injury.

1. Open the lid.

2. Remove the test tube holders.

3. Remove the knob or nut in the center of the rotor by turning it

counter-clockwise. A nut driver may be required.

4. The rotor is sitting on a cone-shaped adapter. Pull the rotor up and off

of this adapter.

To install the rotor:

1. Place the rotor back onto the cone-shaped adapter. You may need to

turn the rotor slightly to line it up properly.

2. The rotor should slide onto the rotor cone freely.

3. Once a proper t has been achieved, replace the rotor knob or nut and

turn it until it is hand-tight.

4. Replace the tube holders and verify that they are seated properly.

5. It is recommended that the initial setup procedures be performed to

ensure that the rotor has been installed correctly and that no damage

has been done to the centrifuge during either the rotor installation or

possible rotor chamber cleaning. See page 4 for this procedure.

Page 8

Page 5

Page 6

Tube Holder Congurations:

The xed-angle rotor that came with your Model 614B is capable of spinning test tubes

up to 17 mm x 125 mm. Use the following chart and drawing to determine which tube

holder and cushion combination should be used with your application.

Care and Preventative Maintenance:

With proper care and maintenance your centrifuge will provide years of

laboratory service.

For proper care, the following steps should be taken:

DIRECTIONS:

1. Compare the tube to be spun with the four boxes shown below.

2. Find the box that most closely matches the tube’s length. NOTE: The

tube length with its stopper or cap must be shorter then the chosen

box or the tube will not t properly in the tube holder.

3. Match the letter from the chosen box with one of the congurations shown.

For Example: A tube is found to be as long as box B. Accordingly, we can

A.

use a 125 mm tube holder with a 1525 cushion or a 100 mm tube holder

with no cushion, (conguration B).

B.

A.

125 mm

Tube

Holder

125 mm

cushion*

Tube

Holder

with

1525

B.

or

100 mm

Tube

Holder

C.

D.

cushion*

* This part is available as an accessory. Contact The Drucker Company for assistance.

Page 6

100 mm

Tube

Holder

with

1525

C.

75 mm

Tube

Holder

D.

75 mm Tube Holder*

with

1525 cushion

1. Provide Adequate Ventilation: For cooling purposes, the centrifuge draws

in ambient air through the air intake cover on the top of the lid and exhausts

this air in the rear of the base. The centrifuge should be placed on a hard

smooth surface for good air circulation.

2. Always Spin Balanced Loads: Make certain that you are always spinning

a balanced load. The Model 614B has a unique counter balanced motor

mounting design which, along with its rubber suction feet, produces

excellent vibration dampening. However, out–of–balance loads may break

glass test tubes and may produce unsatisfactory separation results.

Proper load balancing will improve sample separation and extend the life of

the centrifuge. Refer to page 4 on balanced loads for additional information

on balancing the load.

3. Keep the Tube Holders Clean: NOTE: Always follow the safety guidelines

of your laboratory to properly clean up and/or dispose of materials in the event

that a substance known to be potentially toxic, radioactive or contaminated

with a pathogenic microorganism is spilt in or on the centrifuge. Small

glass fragments left in the tube holder after a tube breakage may adhere to

the next test tube inserted in that holder. When this tube is handled, these

fragments may puncture protective gloves and lacerate the operator’s

ngers or hand. Remaining fragments may provide stress points on

subsequent tubes and result in additional breakage. If a tube breakage

occurs, carefully remove the tube holder. Properly dispose of the sample

and tube fragments and thoroughly clean both the inside and outside of the

tube holder. Insert a new tube cushion (if necessary) and replace the tube

holder in the rotor.

4. Motor and Electrical Maintenance: The Model 614B uses a brushless

A/C motor. It should not need servicig for the life of the centrifuge. The electrical

components are selected for high reliability and should not need service.

5. Keep the Rotor Chamber Clean: Every six months, or whenever there is a

tube breakage, (refer to the note in #3), it may be necessary to remove the

rotor and clean the rotor chamber. Follow the instructions on page 5 to

remove and re–install the rotor.

CAUTION: Before cleaning, always unplug the line cord from the electrical

outlet to eliminate the risk of electric shock.

The rotor chamber, rotor and accessories should be thoroughly cleaned

using either isopropyl alcohol, soap and water, or bleach. The use of Fully/

Partially Halogenated Hydrocarbons, Ketones, Esters and all other

chemicals not prescribed by the manufacturer may cause damage to the

rotor and tube holders and should not be used. Apply cleaning solutions

with a towel or cloth.

Do not submerge the centrifuge in water or other cleaning solutions

as this will cause damage and void your warranty!

Page 7

(Cont.)

Loading...

Loading...