Page 1

INSTALLATIEVOORSCHRIFT EN GEBRUIKERSHANDLEIDING

INSTRUCTIONS FOR INSTALLATION AND OPERATIONS

INSTRUCTIONS D’INSTALLATION ET MODE D’EMPLOI

INSTALLATIONSVORSCHRIFT UND GEBRAUCHSANWEISUNG

ROMANO

Bewaar dit document zorgvuldig

Please retain this document carefully

Conservez soigneusement cette notice

Bewahren Sie dieses Dokument sorgfältig auf

957.582.01

DRU VERWARMING B.V.

HOLLAND

Page 2

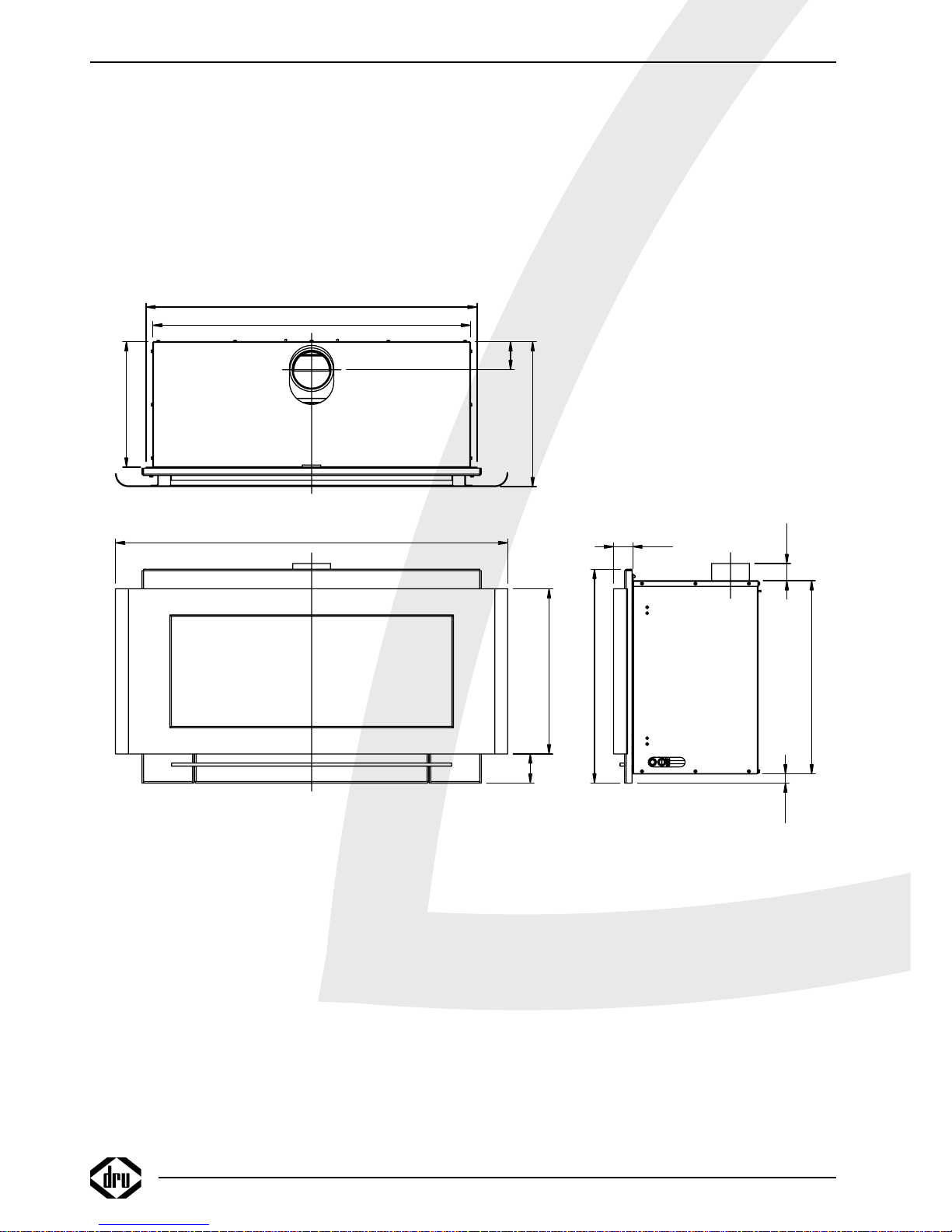

38c-1097

393

7676

862

898

340340

1064

448

79

580

52

47

524

25

Romano

Page 3

Belangrijk

•

Zorg dat er minimaal 3 mtr afvoerpijp (verticaal) met een diameter van 100 mm

aangesloten wordt op het toestel.

•

Het is niet toegestaan het toestel in de schouw te voorzien van een isolatie deken o.i.d.

•

Voordat men het toestel in gebruik neemt dient u altijd de ruit schoon te maken, dit om

inbranden van evt. verontreinigingen tegen te gaan.

Important

•

Ensure that at least 3 m. (vertical) outlet pipe, 100 mm diameter, is connected to the

appliance.

•

It is not allowed to wrap a built in appliance in any kind of isolation material.

•

Before you start using your fire, it is wise to clean the glass front.This to prevent burning in

of possible dirt into the glass.

Important

•

Assurez-vous de raccorder à l'appareil un conduit d'évacuation d'au moins 3 mètres de

haut et 100 mm de diamètre.

•

L'appareil, lors de son installation dans la cheminée, ne peut en aucun cas être recouvert

d'un matériel isolant!!!

•

Avant de mettre l'appareil en fonctionnement, il faut nettoyer soigneusement la vitre afin

d'éviter que des salissures puissent être carbonisées sur celle-ci.

Wichtig

•

Sorgen Sie dafür, daß minimal 3 Meter Abfuhrrohr (vertikal) mit einem Durchmesser von

100 mm an das Gerät angeschlossen wird.

•

Es ist nicht erlaubt ein eingebautes Gerät in Isolationsmaterial zu wickeln.

•

Bevor Sie das Gerät zum ersten Mal benützen sollten Sie das Glas reinigen. Dies um

einbrennen von eventueller Schmutz im Glas zu vermeiden.

Romano

Page 4

Romano

English

CONTENTS

13

CONTENTS

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Instructions for installation . . . . . . . . . . . . . . . . . . . .14

Gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Conditions of installation . . . . . . . . . . . . . . . . . . . . .14

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Fitting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mantel iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connecting to a chimney flue . . . . . . . . . . . . . . . . .16

Connecting to the gas supply . . . . . . . . . . . . . . . . . .16

Adjusting for G25 natural gas . . . . . . . . . . . . . . . . . .16

Positioning the logs or white carrara stones . . . . . .17

Mounting the frame and front . . . . . . . . . . . . . . . . . .19

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connecting the Receiver . . . . . . . . . . . . . . . . . . . . . .20

Replacing the batteries in the receiver . . . . . . . . . . .20

Inserting or replacing the batteries in the

remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Oxypilot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . .21

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Pilot light setting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . .21

Conversion instructions . . . . . . . . . . . . . . . . . . . . . .21

Removing the burner unit and the interior . . . . . . .21

Changing the elements . . . . . . . . . . . . . . . . . . . . . . .22

Replacing the base set and burner unit . . . . . . . . . .23

Adjusting the burner pressure . . . . . . . . . . . . . . . . .23

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Gas Safety Regulations (for installation & use) 1998

. .23

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . .23

Discoloration of walls and ceiling . . . . . . . . . . . . . . .23

Lighting the heater for the first time . . . . . . . . . . . .24

Extra protection . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Conditions of warranty

• This appliance has been manufactured and tested by DRU verwarming BV of The Netherlands with utmost care.

• Subject to the conditions set out on this card DRU guarantees the proper operation of this vented room heater to the original purchaser for a period of

one year after date of purchase.

• Subject to the conditions set out on this card, the cast iron combustion chamber of your DRU vented room heater carries a full guarantee to the original

purchaser for a period of ten years after date of purchase.

• The guarantee does not cover the normal wear and tear, damage due to incorrect treatment, changes of the equipment or unauthorised installations and

repairs. No liability is assumed by DRU for removal or (re)installation labor costs.

• Under no circumstances shall DRU be liable for incidental,consequential, special or contingent damages or expenses arising directly or indirectly from any

defect in the product or any component or from the use thereof.The remedies set forth herein are the exclusive remedies available to the user and are in

lieu of all other remedies. Subject to specific state laws some of the above limitations or exclusions may not apply to you.

DRU Verwarming B.V.

WARRANTY CARD

Please complete this card and keep it with the invoice to verify purchase date

and to establish the warranty period*.

Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Colour: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Serial No.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type of Gas: Natural Gas L.P.G. (please check)

Customer: Dealer/Installer

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

City . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . City . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State . . . . . . . . . . . . . . . . . . . . . . . . . .ZIP . . . . . . State . . . . . . . . . . . . . . . . . . . . . . . . . .ZIP . . . . . . .

Province . . . . . . . . . . . . . . . . . . . . . . .P.C. . . . . . . Province . . . . . . . . . . . . . . . . . . . . . . .P.C. . . . . . .

Telephone ( . . . . . . . . . .) . . . . . . . . . . . . . . . . . . . .

*FOR SERVICE UNDER THIS WARRANTY CONTACT YOUR DEALER/INSTALLER.

DRU warrants the proper functioning of this vented roomheater if installed by a qualified installer and if used in

strict accordance with the manufacturers operating instructions

Page 5

Foreword

Dear Customer,

We would like to thank you for buying this DRU product.

Our products have been designed and produced to meet

the highest possible quality, performance and safety

requirements, allowing you to enjoy years of problem-free

use.

In this booklet you will find instructions for the installation

and use of your new appliance. Please read these

instructions and the manual carefully to familiarize yourself

with the appliance. If you require any further support,

please do not hesitate to contact your supplier.

Unpacking

Once the heater has been unpacked, all packaging should

be disposed of in the regular manner.

Connection

This appliance should be connected by a registered

installer.

Important

•

Ensure that at least 3 m. (vertical) outlet pipe, 100 mm

diameter, is connected to the appliance.

•

It is not allowed to wrap a built in appliance in any kind of

isolation material.

•

Before you start using your fire, it is wise to clean the glass

front.This to prevent burning in of possible dirt into the glass.

INSTRUCTIONS FOR INSTALLATION

Gas type

This appliance is suitable for G20 or G25 natural gas.The

manufacturer (DRU) has adjusted the appliance so that it

is suitable for G20 (20 mbar). Check that the local gas

type and pressure correspond with the specifications on

the gas type plate.The type plate is on the inside of the

casing.All regulations applicable for gas installation,

including any locally enforced regulations, should be

observed at all times.The appliance must be connected by

a qualified installer.

If the appliance is to work on G25, please follow the

instructions elsewhere in this booklet.

For the appliance to work on propane (G31) it will have

to be converted by a qualified installer.

A conversion set can be ordered through him.

Important

• Make sure that any curtains or other combustible

materials are at least 50 cm away from the heater.

• Beware! Touching hot parts of the heater can cause burns

and blisters!

• The appliance must be installed by a qualified fitter

• DO NOT use a dust filter under or on top of the casing.

• DO NOT hang wet clothes or towels etc. on the heater

to dry!

Conditions of installation

It is the law that all gas appliances are installed only by a

CORGI Registered Installer, in accordance with these

install appliances correctly could lead to prosecution. It is

in your own interest and that of safety to comply with

the law.

The installation must also be in accordance with all

relevant parts of the Local and National Building

Regulations where appropriate, the Building Regulations

(Scotland Consolidation) issued by the Scottish

Development Department , and all applicable requirements

of the following British Standard Code of Practice.

• B.S. 6891 Installation of Gas Pipework

• B.S. 5440 Parts 1 & 2 Installation of Flues and Ventilation

• B.S. 1251 Open fire place components

• B.S. 715 Metal flue pipes for gas appliances

• B.S. 6461 Part 1 installation of chimneys and flues

No additional ventilation is required for this appliance.

Positioning

• This appliance must be installed in accordance with the

current regulations and may only be used in a properly

ventilated room, to ensure that there is always sufficient

air supply.

• The appliance may only be installed against a wall made of

combustible material if the wall is protected with a

protective panel.

• Keep the connection between the pipe mouth and the

chimney duct as short and straight as possible. The gas

control block must be easily accessible.

• The minimum height of the chimney duct is 3 mtr.

• At least 3 metres of 100 mm ø (vertical) duct should be

connected to the appliance.

•

It is not allowed to wrap a built in appliance in any kind of

isolation material.

14

INSTRUCTIONS FOR INSTALLATION

Page 6

Fitting the appliance

The design of this fire is such that the casing can be

completely built in first, in a fireplace or chimney breast (of

incombustible and heat-resistant material) and the

appliance itself slid into place afterwards.Any existing

chimney should first be professionally cleaned before

connecting the appliance to it.The flue duct should be

fitted with an effective chimney cowl, to ensure a good

draught in the chimney no matter what the wind

conditions are.The type of chimney cowl and the position

of the opening must meet any applicable local standards, to

ensure it works properly.To build the casing into the

fireplace, a rectangular hole must be made that is:

min. 530 high and min. 875 wide

Allow for the depth of the heater itself (350 mm).

Construct the chimney accurately allowing for the size of

the flange on the casing.

• Take out the glass pane (fig.1) by removing the glass strip

at the top (1).This is fitted with 5 self-tapping screws (2).

• Slide the interior out of the casing. by unscrewing the 4

socket-head screws (3).

• Dismantle the outlet connector (4) by removing the 2 selftapping screws (5), (fig.2).

• First slide the flue pipes into the chimney and fix them to

leave sufficient room underneath to slide the casing into

the fireplace or chimney breast.

• Place the casing in the opening and feed the gas pipe

through the slot on the right.

• Feed the flue ducts through into the outlet connector.

• Reconnect the outlet connector (4) with the 2 self-tapping

screws (5).After tightening the self-tapping screws, loosen

them 1/8 turn to make it easier to slide the sides of the

outlet connector between the slots (6) in the baffle, (fig.3).

• Slide the interior back into the casing.The outlet will

automatically be centred in the slots (6) of the baffle. Fix

the interior in place with the 4 socket-head screws (3).

• Connect the gas pipe to the gas control block and check

the connections for leaks.

The appliance has been adjusted for G20

natural gas with a pre-pressure of 20 mbar.

For use with G25 natural gas, see instructions

elsewhere in this booklet: Adjusting for G25

natural gas.

English

15

INSTRUCTIONS FOR INSTALLATION

Romano

fig. 2

fig. 3

fig. 1

3

2

1

3

4

5

6

6

Page 7

Mantel iron

A good means of supporting the brickwork above the

hearth surround is an iron mantel: a steel angle section

(e.g. 60x60x4) or a lintel.This enables a stress-free

installation of the appliance. Fit the mantel iron as

illustrated in fig. 4, allowing min. 10 mm between the top

of the appliance and the bottom of the mantel iron.

Connecting to a chimney flue

• The interior diameter of the pipe opening is 100 mm.

• Ensure that at least 3 m. (vertical) outlet pipe, 100 mm

diameter, is connected to the appliance.

• Corrosion-proof material should be used to connect the

pipe and the chimney flue.

• The chimney must be cleaned before the heater is

installed and the flue duct tested in compliance with

national guidelines.

Connecting to the gas supply

The gas control block has a 3/8" internal thread for the

gas connection.

Use an approved connecting tap with coupling in the

supply pipe (for Belgium this must be B.G.V. approved).

In addition:

• Expel the air from the supply pipes before connecting the

appliance.

• Avoid pressure on the gas control block and the pipes.

• Check all connections for gas tightness.

Adjusting for G25 natural gas

Ex works the appliance is adjusted for use with G20

natural gas.The primary aeration of the burner tray has a

ø 6.5 mm opening.To run on G25 natural gas this must be

adjusted to a ø 5.0 mm opening and the burner pressure

should be adjusted accordingly.

• Remove the vermiculite tray.

• Remove the burner tray by unscrewing the 4 self-tapping

screws (7), (fig.5).

• Unscrew the adjusting screw (8) in the airflow regulator

(9), (figs. 6 and 7).

16

INSTRUCTIONS FOR INSTALLATION

38c-1102

A

A

38c-1103

SECTION A-A

A

A

38c-1103

fig. 5

fig. 6

fig. 7

38C-1008

Mantel iron

70x50x4

Packing

5

fig. 4

7

9

8

9

Page 8

Romano

• Turn the airflow regulator 180º and tighten the adjusting

screw.The primary aeration opening is now Ø 5 mm.

• Apply the new type plate.

• Replace the burner tray with the 4 self-tapping screw (7).

• Replace the vermiculite tray.

• Set the burner pressure to 19 mbar. See page 22 for

how to set the burner pressure.

These adjustments may only be made by a qualified

installer.

Positioning the logs or white carrara stones

The appliance is supplied either with a set of logs or with

white carrara stones.

Positioning the logs

• Fill the burner tray with vermiculite (10) and distribute

evenly, (fig. 8).

• Fill the vermiculite tray with chips (11) and distribute this

evenly too, (fig. 8).

• Make sure the slot between the burner tray and the

vermiculite tray stays open.

• Make sure that no vermiculite and/or chips get on or

between the (oxypilot) pilot light burner (12) as this could

prevent the pilot light from working properly (fig. 8).

• Position the logs (fig.9) as illustrated (fig.10).

Positioning the white carrara stones

• Fill the burner tray with vermiculite (10) and distribute

evenly, (fig. 8).

• Fill the burner tray and the surrounding tray with the

white carrara stones, (figs. 11 and 12). Distribute the

stones in a single layer. Stones on top of each other will

distort the flame effect.

• Make sure that there are no stones in front of the opening

of the (oxypilot) pilot light burner (12) as this could

prevent the pilot light from working properly

(figs. 11 and 12).

• N.B.: The burner tray must always be filled

with vermiculite. This is essential to warrant

the long service life of the burner tray.

You can "play" with the flames by moving the vermiculite

and chips about on the burner bed until you have created

the desired flame effect.

Do not use any materials other than those supplied.

The supplied materials are incombustible and have been

manufactured specifically for this appliance.

Once the logs or stones are in position, the

glass pane can be replaced and fixed with the glass strip

(1) and the 5 self-tapping screws (2) (fig.1).

English

INSTRUCTIONS FOR INSTALLATION

17

fig. 8

10

12

11

Page 9

INSTRUCTIONS FOR INSTALLATION

18

A

A

A A

B

C

D

E

F

F

G

G

H

H

H

F

G

A

C

A

D

A

E

F

B

H

H

G

H

A

fig. 9

fig. 10

Page 10

Mounting the frame and front

The frame and front are packed separately to the basic set.

Fit the frame to the interior with the 4 self-tapping screws

(13), ( figs. 13 and 14).

Hang the front onto the interior with the hooks (14)

(figs. 15 and 16).

Nederlands

INSTRUCTIONS FOR INSTALLATION

19

Romano

A

A

SECTION A-A

38c-1101

fig. 16

14

fig. 12

fig. 14

fig. 11

fig. 13

fig. 15

13

14

13

12

12

Page 11

Remote control

Remote control is supplied as a standard accessory.

The heater has a freely adjustable. Batteries, with a life

expectancy of approximately one year, feed the electrical

supply.The remote control will only work if the pilot light

is lit.

Connecting the Receiver

The remote control system comprises a receiver and a

remote control, packed together in one box.The receiver

must be connected to the appliance fitting the batteries.

This is done as follows:

• Take the receiver out of the box.

• Slide the white plug of the cable onto the receiver circuit

board (fig. 17a).

• Connect the wires to the connectors on the gas control

valve.The different sized plugs correspond with the

connectors on the gas control valve.

• Open the lid.

• Insert 4 penlight batteries (type AA). Make sure they are

the right way round.

• Replace the lid.

• Place the receiver under the appliance on the floor. Make

sure that the red LED points forwards. Place the reciever

as far away from the burner tray as possible to prevent

the reciever from getting too hot.

Replacing the batteries in the receiver

• Open the door at the front.

• Take the receiver and open the cover.

The batteries are under that cover.

• Remove the old batteries and insert the new ones, making

sure that the + and – signs on the batteries correspond

with those in the holder.

Inserting or replacing the batteries in the

remote control

• Remove the cover on the back of the remote control.

• Connect a square battery (type 6LR61) to the clip.

• Fit the battery in the holder.

• Replace the cover.

NB: Do not throw old batteries in the dustbin.

They should be treated as Chemical Waste.

Oxypilot

This appliance has been fitted with an oxypilot safety

device.The oxypilot is activated in the event of flue gasses

flowing back through the baffle. The pilot light goes out

and the gas supply to the burner is shut off.The oxypilot

will also switch the fire off if the oxygen concentration in

the room in which it is installed drops too low.

Possible causes of the safety device being activated include:

• There is little or no supply of fresh air into the home

(all draughts have been excluded and ventilation openings

sealed off).

• The outlet into the flue duct is partially or completely

blocked.

• The chimney mouth was not constructed correctly, can

cause "fall winds" in the chimney duct being a possible

result.

The appliance needs a good supply of air for optimum

combustion. If there is not enough air, because all draughts

have been excluded or all means of ventilation have been

closed or shut off, for example, and/or because a

mechanical extraction system such as a cooker hood

extracts too much air, a permanent means of ventilation

must be fitted in the room in which the heater is to be

installed. If the home has a mechanical extraction system,

the flue system to which the gas fire is connected must

have a flue fan.

Please refer to the gas installation regulations and any

relevant legislation enforced locally.

The appliance can be re-ignited once the air supply and / or

flue discharge has been restored.

INSTRUCTIONS FOR INSTALLATION

20

fig. 17a

Page 12

Romano

English

OPERATIONS INSTRUCTIONS CONVERSION INSTRUCTIONS

21

OPERATING INSTRUCTIONS

Lighting

Press button A and turn to the left to the small flame .

The flame will ignite at . Check that the pilot is alight. If

that is the case, hold button A firmly pressed for another 5

seconds.Then release button A and check that the pilot

light is still burning. Now turn button A to the large

flame , which will open the main valve of the control

block. Depending on the setting of the control button B,

high or low flames will be visible.

Remote Control

The height of the flames can be regulated by remote

control, which will turn button B (fig. 17b) on the gas

control block. Press the bottom button on the remote

control for a smaller flame; press the upper button for a

higher flame. Manually adjusting button B will have the

same effect.

A certain force is required when rotating button B,

a clicking sound is quite normal.

Pilot light setting

If the heater is not in use but you would like the pilot light

to remain alight, set button A to the small flame.The gas

supply to the main burner will then be switched off.

Switching off

Turn button A to the "0" setting.The gas supply to the

burners will then be switched off.

Important

A built-in safety lock is activated when the appliance is

switched to "OFF" (closed down setting).Therefore, wait 5

minutes before relighting the heater.Within this period, do

not try to push the lighting button, as this has been

blocked by the safety lock. Do not force the button, as this

may result in damage to the mechanism.

CONVERSION INSTRUCTIONS

The appliance will have to be converted for it to be able to

run on propane (G31).

This conversion may only be carried out by a qualified

installer, who will also be able to order the required

conversion set.

Disconnect the gas supply before converting.

Remove the burner unit and the interior

To be able to change the required elements, the complete

burner unit will have to removed and the interior slid out

of the casing.To do this:

• Remove the glass pane.

• Disconnect the gas supply pipe.

• Remove the vermiculite tray.

• Remove the burner tray.

• Remove the airflow regulator! This does not have to be

replaced.

• Remove the burner mounting plate by unscrewing the selftapping screws (15), (fig.18a).

• Slide the interior out of the casing.

fig. 17b

AB

Fig. 18a

Fig. 18b

16

15

17

18

23 4

Page 13

Changing the elements

1. Outlet connector (fig. 18b and 18c)

Break and remove the semi-circle (23) of the connection

(4).

2. Main burner jet

(fig.18a)

Using an open-ended spanner remove the jet with (16)

and fit a new one.

3. Oxypilot (fig.18a)

Disconnect the pilot light hose by unscrewing the

coupling nut (17). Disconnect the ignition wire from the

electrode. Unscrew the thermocouple from the gas

control block.

Remove the oxypilot by undoing the 2 screws (18)

and fit the new oxypilot. Reconnect the pilot light hose,

the ignition wire and the thermocouple.

4. Fine adjustment jet

(fig.19)

Once the grub screw (19) has been unscrewed, the fine

adjustment jet can be twisted out of the gas control

block. Fit the new fine adjustment jet and then the grub

screw (19) in the gas control block.

CONVERSION INSTRUCTIONS

22

fig. 21

fig. 22

fig. 20

38c-1105

20

21

22

Fig. 19Fig. 18c

19

23

Page 14

Replacing the base set and burner unit

• Apply the new type plate.

• Slide the interior back into the casing.

• Replace the burner mounting plate.

• Replace the burner tray without the airflow regulator.

• Replace the vermiculite tray.

• Position either the logs or the white carrara stones.

• Replace the glass pane.

• Fit the frame and front.

Adjusting the burner pressure (fig. 20, 21 and 22)

Reconnect the gas supply to the heater and open the

new gas pipe.

On the gas control block is point of pressure

measurement where the burner pressure can easily be

measured with a manometer. Loosen the screw at the

point of pressure measurement (20) and connect the

manometer.

Remove the cover of the gas control block by removing

the screw (21).To convert the appliance to propane or

natural gas the burner pressure must be adjusted with

the pressure regulating screw (22) as specified in the

table. Replace the cover.

Ignite the pilot light. Set the thermostat to the highest

setting and adjust the burner pressure as specified in the

table. Check the gas tightness! Turn the burner off again,

remove the manometer and tighten the screw at the

point of pressure measurement.

GENERAL NOTES

Gas Safety Regulations (for installation & use) 1998

In your own interest and that of safety, it is law that

all gas appliances are installed by competent persons

in accordance with the above regulations. Failure to

install appliances correctly could lead to

prosecution.

NB: The Council of Registered Gas Installers, whose

members are identified by the emblem shown here, are all

required to work to the recognised standards.

Cleaning and Maintenance

The appliance should be inspected once a year by a

qualified company, and cleaned and/or repaired as

necessary.The inspection and maintenance must at least

ensure that the appliance is working correctly and safely.

This can be done by your own gasinstaller or a specialised

maintenance company. It is advisable to remove any dust

from the appliance several times before and during the

heating season.After a while a deposit will form on the

inside of the glass pane.This can be removed with a damp

cloth or with a non-abrasive cleaning agent (e.g. brass

polish). Do this as soon as any deposit appears, to prevent

it from burning and becoming impossible to clean. Do not

use corrosive or abrasive substances to clean the casing.

Any damage to the coating, caused by things put on or

against the casing for example, is not covered by the

guarantee.

The chimney should be inspected regularly, to check that

all flue gasses are discharged through the chimney.

Excessive accumulation of soot in the chimney should be

avoided.The soot that does form should be removed, only

ever when cold, with a brush or vacuum cleaner.The

ventilation should also be checked regularly, to make sure

there are no obstructions.

NB: When replacing the thermocouple, the coupling nut

in the gas control block should first be tightened by hand

and then tightened a quarter-turn with an open-ended

spanner.

Discoloration of walls and ceiling

Brown discoloration is an annoying problem, which is

difficult to solve. It can be caused by dust burning as a

result of poor ventilation, for example, or by cigarette

smoke or candles.

English

GENERAL NOTES

GUARANTEE REGISTRATION CARD

In order to register your guarantee, please complete and return this card(no stamp required)

Details of equipment:

Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Serial No.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type of gas: Natural Gas L.P.G. (please tick).

Model an serial no. are to be found on data badge inside heater.

Customer: Installed by:

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Address (of installation) . . . . . . . . . . . . . . . . . . . . . . . Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Post Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel. No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tel. No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appliance installed in . . . . . . . . . . . .(Office, Church, etc.)

Is appliance replacing alternative fuel: Solid Fuel Oil Electricity (please tick).

If replacing existing balanced flue heater make of original

Date of installation

N.B.Where more than one appliance installed, please complete all cards and return in envelope using freepost address on reserve.

Completion of this card in no way affects your statutory rights

Thank you DRUGASAR LIMITED

Page 15

These problems can be avoided by ensuring that the room

the heater is in is properly ventilated.A good guideline for

ventilation is:

New buildings : 3.24 m

3

/ hour per m2floor

surface of the room.

Existing buildings : 25.20 m

3

/ hour for a room.

Use candles and oil lamps as little as possible, keeping the

wick as short as possible.While they Enhance the

atmosphere, candles and oil lamps also cause the

formation of large quantities of unhealthy soot particles in

your home. Cigarette and cigar smoke contains tar, which

upon heating will precipitate on cold or damp walls. If you

have a newly cemented chimney or have had any other

reconstructions / renovations done, you are advised to

wait at least 6 weeks before lighting your fire, to allow the

walls, floor and ceiling to dry out completely.

Lighting the heater for the first time

There can be an unpleasant smell when you light the

heater for the first time.This is caused by the varnish

evaporating and will disappear after a few hours.We

therefore advise you,on initial use, to heat the appliance at

the highest setting while ventilating the room it is installed

in well.

Extra protection

This heater meets the normal safety standards regarding

surface temperatures, but physical contact with heated

surfaces should be avoided where possible. An additional

guard is recommended to protect young children and

elderly, infirmed or handicapped people.

Before you start using your fire, it is wise to clean the glass

front.This to prevent burning in of possible dirt into the glass.

Disposal

When replacing or otherwise removing the appliance, it

should be disposed of in compliance with current

regulations.

Shut off the connecting tap with coupling before

commencing disassembly. Undo the coupling between the

connecting tap and the appliance.The whole appliance can

now be disassembled and removed.

Guarantee

Please complete the enclosed REGISTRATION CARD and

post it in an envelope (no stamp required) to the address

below within 5 days of purchase.

DRUGASAR LIMITED

FREEPOST

DEANS ROAD

SWINTON

MANCHESTER M27 1 BX

Please retain the GUARANTEE CARD (page 13) for your

own reference.The guarantee will become effective upon

receipt by DRUGASAR Limited of the fully completed

registration card.

PLEASE SEND IN AN

ENVELOPE

DRUGASAR LIMITED

FREEPOST

DEANS ROAD

SWINTON

MANCHESTER M27 1 BX

DRUGASAR, GAS HEATING FOR PEOPLE WHO DON’T HAVE MONEY TO BURN.

GENERAL NOTES

Page 16

Romano

TECHNISCHE GEGEVENS,TECHNICAL DATA, DONNÉES TECHNIQUES,TECHNISCHEN DATEN

49

Romano

Gassoort,Type of gas, Sorte de gaz, Gassorte G20

Voordruk, Pression, Pression, Gasdruck mbar 20

Branderdruk, Burner pressure, Pression de brûleur, Brennerdruck mbar 13

Nom. Belasting (Hs), Nom. Load (Hs), Puissance calorifique (Hs), Nom. Belastung (Hs) kW 6,90

Nom. Belasting (Hi), nom. Load (Hi), Puissance calorifique (Hi), Nom. Belastung (Hi) kW 6,20

Nom.Vermogen, Nom. Output, Puissance nominale, Nennleistung kW 4,30

Verbruik volstand, Gas consumption on full output, consommation de gaz plein régime, Gasverbrauch Vollstand L/h 651

Verbruik kleinstand, Gas consumption on low output, Débit de gaz débit réduit, Gasverbrauch Kleinstand L/h 267

Branderspuitstuk, burner injector, injecteur brûleur, Brennerdüse mm ø 2,10

Kleinstelspuitstuk, low setting injector, injecteur débit réduit, Kleinstelldüse mm ø 1,35

Gassoort,Type of gas, Sorte de gaz, Gassorte G25

Voordruk, Pression, Pression, Gasdruck mbar 25 20

Branderdruk, Burner pressure, Pression de brûleur, Brennerdruck mbar 19 19

Nom. Belasting (Hs), Nom. Load (Hs), Puissance calorifique (Hs), Nom. Belastung (Hs) kW 6,90 6,90

Nom. Belasting (Hi), nom. Load (Hi), Puissance calorifique (Hi), Nom. Belastung (Hi) kW 6,20 6,20

Nom.Vermogen, Nom. Output, Puissance nominale, Nennleistung kW 4,30 4,30

Verbruik volstand, Gas consumption on full output, consommation de gaz plein régime,

Gasverbrauch Vollstand L/h 747 747

Verbruik kleinstand, Gas consumption on low output, Débit de gaz débit réduit

Gasverbrauch Kleinstand L/h 271 271

Branderspuitstuk, burner injector, injecteur brûleur, Brennerdüse mm ø 2,10 ø 2,10

Kleinstelspuitstuk, low setting injector, injecteur débit réduit, Kleinstelldüse mm ø 1,35 ø 1,35

Gassoort,Type of gas, Sorte de gaz, Gassorte G31

Voordruk, Pression, Pression, Gasdruck mbar 37 NL:30 DE:50

Branderdruk, Burner pressure, Pression de brûleur, Brennerdruck mbar 28

Nom. Belasting (Hs), Nom. Load (Hs), Puissance calorifique (Hs), Nom. Belastung (Hs) kW 6,90

Nom. Belasting (Hi), nom. Load (Hi), Puissance calorifique (Hi), Nom. Belastung (Hi) kW 6,20

Nom.Vermogen, Nom. Output, Puissance nominale, Nennleistung kW 4,20

Verbruik volstand, Gas consumption on full output, consommation de gaz plein régime,

Gasverbrauch Vollstand L/h 255

Verbruik kleinstand, Gas consumption on low output, Débit de gaz débit réduit,

Gasverbrauch Kleinstand L/h 147

Branderspuitstuk, burner injector, injecteur brûleur, Brennerdüse mm ø 1,40

Kleinstelspuitstuk, low setting injector, injecteur débit réduit, Kleinstelldüse mm ø 1,20

Page 17

50

Page 18

51

Romano

Page 19

Loading...

Loading...