Dru G25, G31, G20, Milo G25, Milo G31 Installation Manual

...

English

Store this document in a safe place

Milo

Installation manual (GB / IE)

959.028.01.GB

G20/G25/G31

GB

95902801_GB Install.indd 195902801_GB Install.indd 1 12-7-10 11:212-7-10 11:2

2

MILO INSTALLATION MANUAL

English

Contents

page

Preface 3

1. Introduction 3

2. CE declaration 4

3. SAFETY 4

3.1 General 5

3.2 Regulations 5

3.3 Precautions / safety instructions during installation 5

4. Instructions 6

5. Removing the packaging 6

6. Installation 6

6.1 Regulations 6

6.2 Type of gas 6

6.3 Gas connection 6

6.4 Placing the appliance 6

6.5 Flue gas discharge / combustion air supply system 6

6.6 Placing the chimney breast 12

6.7 Connecting gas 13

6.8 Adjusting the appliance 13

6.9 Placing the wood set 14

6.10 Glass panes 15

6.11 Finishing the appliance 16

7. Wireless remote control 17

7.1 Receiver 17

8. Final check 17

8.1 Gastightness 17

8.2 Gas pressure / line-pressure 17

8.3 Ignition pilot burner and main burners 17

8.4 Flame image 18

9. Maintenance 18

9.1 Parts 19

10. Delivery 19

11. Malfunctions 19

Appendix 1 Parts included with the delivery 23

Appendix 2 Technical data 23

Appendix 3 Figures 24

Appendix 4 Figures 36

GB

95902801_GB Install.indd 295902801_GB Install.indd 2 12-7-10 11:212-7-10 11:2

3

MILO INSTALLATION MANUAL

English

Preface

DRU, a manufacturer of gas- red heating appliances, develops and produces products that comply with the highest

quality, performance and safety requirements.

This guarantees that the user will be able to enjoy using his product for many years to come.

This appliance has a CE marking, which means that it complies with the essential requirements of the European gas

appliance directive.

Two manuals are supplied with the appliance: the installation manual and the user manual.

As an installer, you must be competent in the eld of atmospheric gas- red heating.

The installation manual will give you the information you need to install the appliance in such a way that it will operate properly and safely.

This manual discusses the installation of the appliance and the regulations that apply to the installation. In addition,

you will nd technical data for the appliance and information on maintenance, any malfunctions that might occur

and their possible causes.

The gures are included at the back of this booklet (Appendix 3).

Please carefully read and use this installation manual.

The following symbols are used in the manual to indicate important information:

➠

Work to be performed

!Tip

Suggestions and recommendations

!Caution

You will need these instructions to prevent problems that might occur during installation and/or use.

Caution

You need these instructions to prevent re, personal injury or other serious damages.

Af ter delivery, you should give the user manual and this installation manual to the user.

1. Introduction

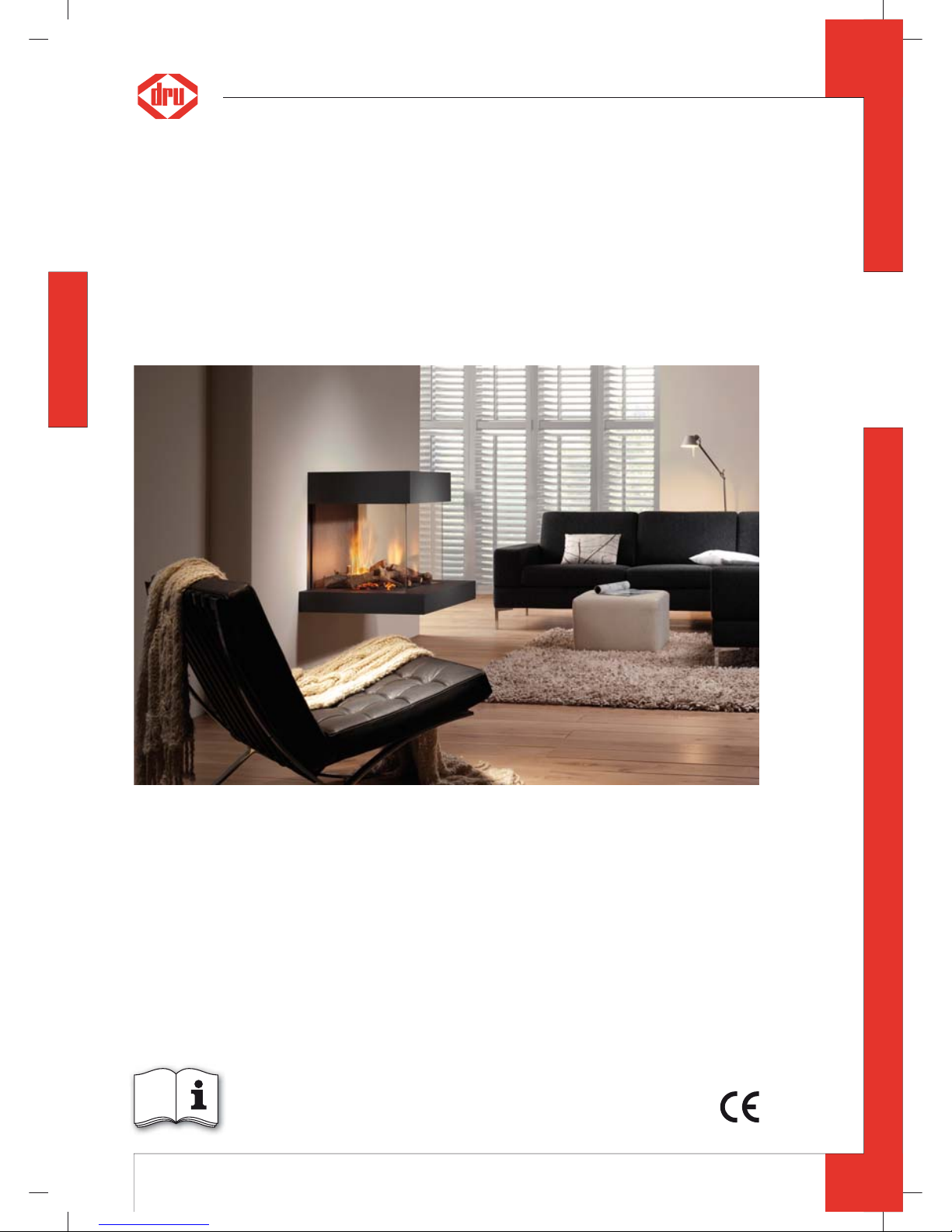

Milo is a suspended atmospheric gas- red heating appliance. It is xed to the wall by means of a supplied wall

bracket. In order to support it, the appliance is standing on 2 adjustable legs at the rear.

The safe operation of the appliance is guaranteed by the use of a second thermocouple tted to one of the main

burners.

Milo is a room-sealed appliance. A room-sealed appliance does not extract the combustion air from the living environment, but from outside. This is done by means of a combined ue gas discharge system / combustion air supply

system. In this concentric system, the outer pipe functions as the air supply and the inner pipe functions as the ue

gas discharge.

Milo has a rectangular ( at), concentric ue spigot. Both a rectangular and round concentric system can be connected to this. DRU has a number of adapters in its range for the transition from rectangular to round.

The concentric ue gas discharge / combustion air supply system can be installed through the wall or through the

roof.

Milo was designed to suspend freely. The narrow chimney breast at the rear of the appliance is only intended to hide

the ue gas discharge / combustion air supply system and the adjustable legs.

Construction in a standard chimney breast, the construction chimney breast, is allowed. In that case, a mantel iron

must be placed, in order to avoid that the appliance is burdened by the weight of the construction chimney breast.

DRU is able to supply a mantel iron. Also make sure that the gas control and receiver, which are below the appliance,

can still be reached after placing the construction chimney breast.

The chimney breast may only be made of plate material.

In order to reach a proper heat discharge, the chimney breast must be ventilated at both sides, and an air supply

must be made at the bottom. DRU has various ventilation elements in its program; the lux no elements can be

specially supplied for the narrow chimney breast.

A base (platform) will be placed around the appliance. The choice of a natural stone or lacquered steel version was

made during purchase. The construction of the appliance was based on the weight of the DRU base. If you want to

extend the base supplied by DRU, you will need an additional bearing construction.

The appliances are supplied with a wireless remote control that works on batteries.

GB

95902801_GB Install.indd 395902801_GB Install.indd 3 12-7-10 11:212-7-10 11:2

4

MILO INSTALLATION MANUAL

English

2. CE declaration

We hereby declare that the design and construction of DRU’s atmospheric gas- red heating appliance comply with

the essential requirements of the Gas Appliance Directive.

Product: atmospheric gas- red heating appliance

Type: Milo

Applicable EEC directives: 2009/142/EC

Applied harmonized standards: NEN-EN-613

NEN-EN-613/A1

Internal measures by the company guarantee that appliances produced in series comply with the essential requirements of the prevailing EEC directives and the standards derived from them.

This declaration will lose its validity if adjustments are made to the appliance, without prior written permission by

DRU.

M.J.M. Gelten

General manager

DRU verwarming B.V.

Postbus 1021, 6920 BA Duiven

Ratio 8, 6921 RW Duiven

www.dru.nl

3. SAFETY

3.1 General

Caution

- Carefully read this chapter on safety, before you start performing installation or maintenance work;

- P lease observe the general regulations and the precautions/safety instructions in this manual.

3.2 Regulations

Please install the appliance in accordance with the applicable national, local and constructional (installation) regulations.

3.3 Precautions / safety instructions during installation

Carefully observe the following precautions/safety regulations:

➠

you should only install and maintain the appliance if you are a competent installer in the eld of atmospheric gas- red

heating;

➠

do not make any changes to the appliance;

➠

use solid, non combustible and heat-resistant materials for the wall from which the appliance will be suspended;

➠

always use the adjustable legs to support the appliance;

➠

use non combustible and heat-resistant plate material for the chimney breast, including the top of the chimney breast

and the material in the chimney breast;

➠

take su cient measures to prevent temperatures of a wall behind the chimney breast becoming too high, including

the materials and/or objects behind the wall;

➠

ventilate the chimney breast at both sides by means of the ventilation holes, which will form a combined passage of at

least 200cm

2

;

➠

attach an additional air supply at the bottom of the chimney breast;

➠

in case of a narrow chimney breast, maintain a tolerance of approx. 2mm between plate material and construction

frame;

➠

comply with the minimum required internal measurements, in case of a construction chimney breast;

➠

comply with the minimum required free space of 500mm at both sides of the appliance, as well as above the appliance,

because of the heat emission of the appliance;

➠

only use the ue gas discharge / combustion air supply system supplied by DRU;

➠

mount the appliance using the wall bracket supplied;

➠

do not suspend the appliance too close to the wall; this is prevented by using the spacer brackets;

➠

do not cover the appliance and/or do not wrap it in an insulation blanket or any other material;

➠

make sure that combustible objects and/or materials have a distance from the appliance of at least 500mm

➠

only ever use the supplied wood set;

➠

place the wood set exactly as described;

➠

make sure the pilot burner and the space around it is kept free;

➠

make sure thermocouple2 and the space around it are kept free;

➠

make sure there is no dirt in gas pipes and connections;

➠

place a gas tap near the appliance;

GB

95902801_GB Install.indd 495902801_GB Install.indd 4 12-7-10 11:2412-7-10 11:24

5

MILO INSTALLATION MANUAL

English

➠

check the connections for gastightness before using the appliance;

➠

use heat resistant electrical wiring;

➠

place the electrical wiring in such a way that they are free from the appliance;

➠

replace torn or broken glass panes;

➠

avoid blocking of the pressure equalization hatch(es) on top of the appliance;

➠

check whether the pressure equalization hatch(es) t well onto the sealing surface, prior to building in the appliance;

➠

do not ignite the appliance until it is fully installed.

4. Instructions

Observe the following items during installation in order to guarantee a proper and safe operation of the appliance:

➠

place the spacer brackets in correspondence with the construction depth of the appliance. The construction depth

depends on whether a rectangular or round ue gas discharge / combustion air supply system was chosen. During

manufacturing, the spacer brackets are placed for application of a rectangular system;

➠

avoid that the ignition cable runs over the receiver;

➠

avoid that the ignition cable touches or crosses the antenna;

➠

avoid that the ignition cable runs alongside metal parts, in order to prevent weakening of the spark;

➠

avoid damaging the glass panes when removing/placing them;

➠

clean the glass panes before you use the appliance, in order to prevent dirt from burning in the glass;

➠

make sure that the wires of thermocouple 2 cannot come into contact with hot parts.

5. Removing the packaging

Note the following items when removing the packaging:

➠

Check the appliance for damages during transport.

➠

If necessary, contact DRU Service.

!Caution

Avoid damaging the front glass pane when removing it from the packaging.

After removing the packaging, you should have the following components:

- Socket spanner; you will nd it in the space between the assembly frame and the combustion chamber;

- Decorative strips; you will nd them in the abovementioned space as well;

- Front glass pane; you will nd it in the same box as the appliance – provided with protective corners;

- Box containing parts; you will nd it in the combustion chamber;

- Inner frame; consisting of a lacquered steel frame or a four part set of natural stone;

- Base; made of lacquered steel or natural stone;

- Top; intended for the top of the appliance.

➠

Remove the box containing parts from the combustion chamber.

In appendix 1 / table 5 you can see which parts you should have after removing the packaging.

➠

Contact DRU Service if you do not have all the parts after you nished removing the packaging.

➠

Dispose packaging in accordance with local regulations.

GB

95902801_GB Install.indd 595902801_GB Install.indd 5 12-7-10 11:2412-7-10 11:24

6

MILO INSTALLATION MANUAL

English

6. Installation

Read this manual carefully to ensure a proper and safe operation of the appliance.

!Caution

Install the appliance in the order described in this chapter.

6.1 Regulations

➠

Observe the applicable (installation) regulations.

➠

Observe the regulations/instructions in this manual.

6.2 Type of gas

The data plate indicates for which type of gas, gas pressure and for which country this appliance is intended. The

data plate is connected to a chain. It should remain connected to the chain.

Caution

Check whether the appliance is suitable for the type of gas and the gas pressure used at the location.

6.3 Gas connection

Place a gas tap in the gas connection, close to the appliance.

Caution

Make sure there is no dirt in gas pipes and connections.

The following requirements apply to the gas connection:

- use a gas pipe with the correct dimensions, so that no pressure loss can occur;

- the gas tap should have the CE marking;

- you sh ould always be able to reach the gas tap.

6.4 Placing the appliance

Caution

- Attach the appliance to a wall of solid, non combustible and heat-resistant material;

- Always use the adjustable legs to support the appliance;

- Take su cient measures to prevent temperatures of a wall behind the chimney breast becoming too high,

- including the materials and/or objects behind the wall;

- Comply with the minimum required free space of 500mm at both sides of the appliance, as well as above the

appliance, because of the heat emission of the appliance;

- Make sure that combustible objects and/or materials have a distance from the appliance of at least 500mm;

- Do not suspend the appliance too close to the wall; this is prevented by using the spacer brackets

- Level the appliance horizontally and vertically, using the adjustable feet and adjustment bolts;

- Do not cover the appliance and/or do not wrap it in an insulation blanket or any other material;

- Do not make any changes to the appliance.

!Caution

- Take the adjustable height of the appliance into account. It depends on the setting of the adjustable legs: minimum

250 and maximum 500mm (see g.1);

➠

Take the minimum internal depth of the appliance into account (see g.1).

!Tip

During manufacture, the spacer brackets on the appliance are mounted for the application of the rectangular ue

gas discharge / combustion air supply system.

Place the appliance as follows:

➠

Determine the location of the appliance.

➠

Determine the suspension height of the appliance; see g.1;

➠

Provide a gas connection at the location. For details, see section 6.3.

➠

Determine whether a rectangular or round ue gas discharge / combustion air supply system will be connected to the

appliance’s ue spigot; see g.1.

➠

Make a passage for the ue gas discharge/combustion air supply system with the following diameters. For details,

see section 6.5:

- Ø 160 mm for a wall terminal through non combustible material;

- Ø 250 mm for a wall terminal through combustible material;

- Ø 160 mm for a roof terminal through non combustible material;

- Ø 250 mm for a roof terminal through combustible material.

➠

Place the appliance on its destined location.

➠

When leading the rectangular ue gas discharge / combustion air supply system through a oor and/or ceiling, take

the following dimensions into account; for details see section 6.5:

GB

95902801_GB Install.indd 695902801_GB Install.indd 6 12-7-10 11:2412-7-10 11:24

7

MILO INSTALLATION MANUAL

English

- 350x140mm through non combustible material;

- 430x220mm through combustible material.

➠

Check whether the position of the spacer brackets on the appliance is suitable for the chosen rectangular (A) or

round(B) ue gas discharge / combustion air supply system; see g.2.

➠

Loosen the screws of the spacer brackets (C) and turn the brackets around when a round system is used; see g.2.

➠

Mount the appliance using the wall bracket and the key bolts supplied.

➠

Extend both adjustable legs and secure them with a self-tapping screw.

➠

Use the feet of the adjustable legs to level the appliance horizontally; see g.1, arrow1.

➠

Use the adjustment bolts to level the appliance vertically; see g.1, arrow2.

6.5 Flue gas discharge / combustion air supply system

6.5.1 General

The appliance is of the C11/C31 type.

The appliance is connected to a combined ue gas discharge/combustion air supply system, hereafter referred to as

the concentric system.

The ue spigot of the appliance, is a rectangular, concentric version. To this you can connect a rectangular (A) (310x100

/ 205x55mm) and/or round (B) (Ø100 / Ø150mm) concentric system; see g.3a.

The passage to the outside can be made with a wall terminal (see section 6.5.2) or a roof terminal (see section 6.5.3).

If necessary, you can also use an existing chimney (see section 6.5.4).

Caution

- Only use the rectangular and/or round concentric system supplied by DRU. This system has been tested together with

the appliance. DRU cannot guarantee a proper and safe operation of other systems and does not accept any liability

for this (see appendix 4);

- Always use coupling pieces with corresponding seals for the connections in the rectangular system. These are

supplied with the system; see the accompanying instructions;

- Secure the coupling pieces with the self-tapping screws supplied;

- For connecting to an existing chimney you should only use the chimney kit supplied by DRU.

The concentric system is constructed from ( ue spigot of ) the appliance.

If structural circumstances requir e that the concentric system is placed rst, the appliance can later be connected

with a telescopic pipe piece, provided a round concentric system is used. In that case, an adapter to round must rst

be placed on the ue spigot. It is not possible to supply a telescopic pipe piece for a rectangular concentric system.

6.5.2 Application with wall terminal

The wall terminal is a round conce ntric system.

6.5.2.1 Construction of concentric system with wall terminal

!Caution

- When using rectangular pipes it is only possible to end in the wall from which the appliance is suspended (there is

no bend available for the concentric system);

- When the pipes end at right angles in the appliance, you can start with rectangular pipes, but you must change

over to the round system.

The concentric system with wall terminal has to comply with the following conditions:

- First, a concentric pipe of at least 1meter should be connected vertically to the appliance;

- The total vertical pipe length may have a maximum of 4meters;

- After the vertical part, a 90º bend (round system) or a squared adapter (rectangular system) is connected;

- When using a minimum of 1meter up to a maximum of 4meters of vertical pipe length, the total horizontal pipe

length can have a maximum of 3meters (excluding wall terminal, see g.3b and g.3c).

Depending on the construction of the concentric system, the appliance must receive further settings by removing

the air inlet guide and the injector screens; see Table1 for determining the conditions and section 6.8, Adjusting the

appliance, for the method.

GB

95902801_GB Install.indd 795902801_GB Install.indd 7 12-7-10 11:2412-7-10 11:24

8

MILO INSTALLATION MANUAL

English

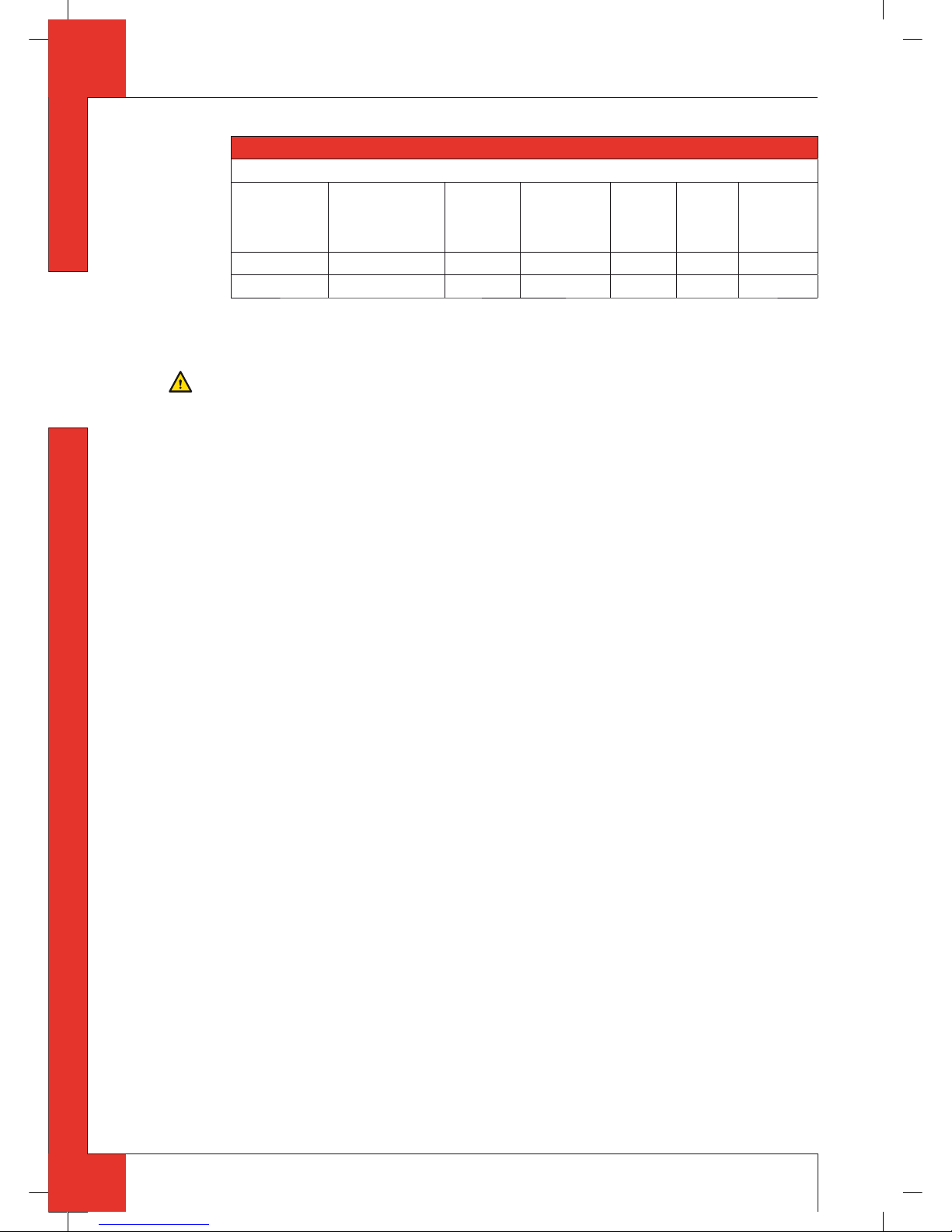

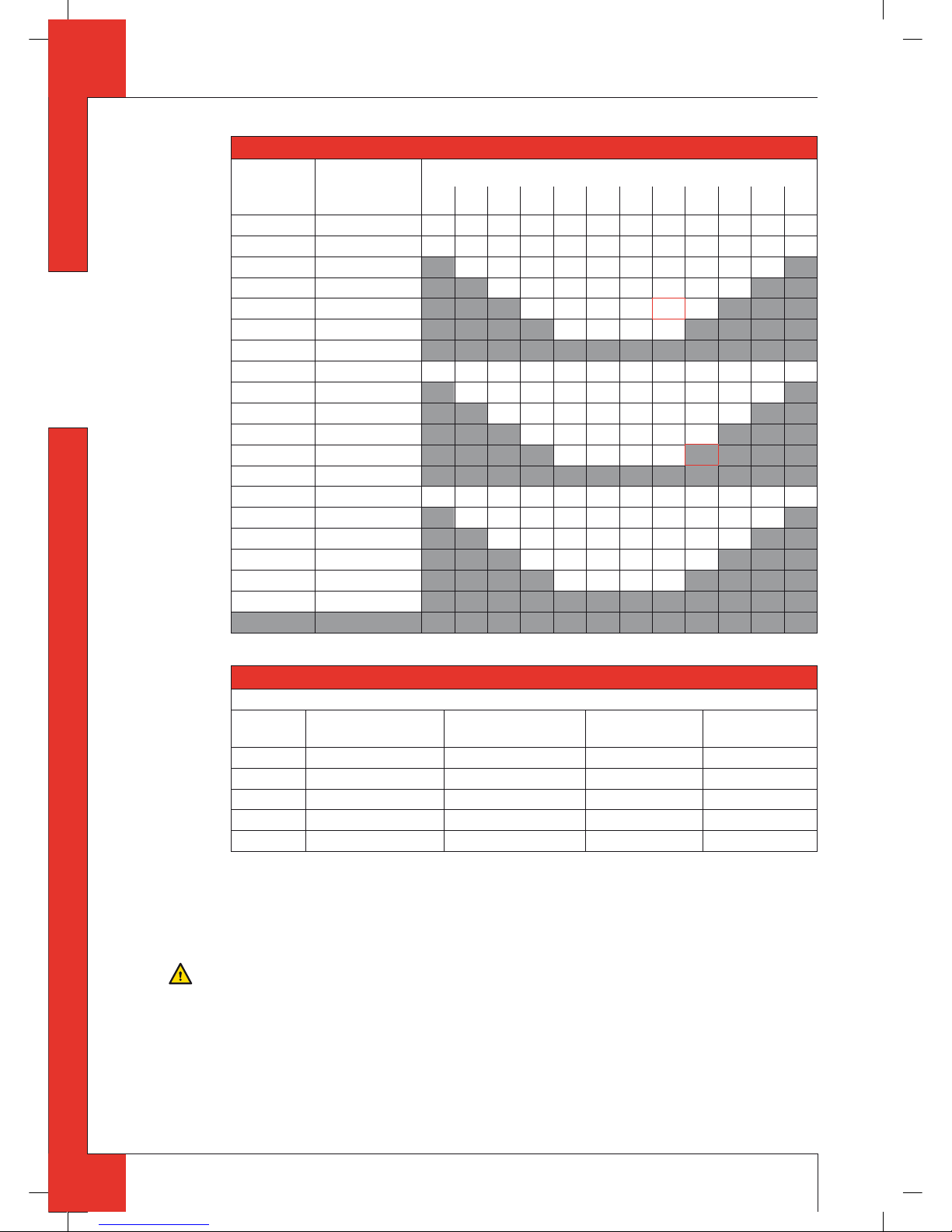

Table 1: Conditions for the adjustmen t of the appliance with a wall terminal

G20/G25/G31

Total number of

meters vertical

pipe length

Total number of

meters horizontal

pipe length (excluding

wall terminal)

See gure Air inlet guide

Injector

screens**

Ba e Distance of

restriction

in mm

1 - 4 >0 - 3 3b

NO NO NO OPEN

1 - 4 0* 3c

YES YES NO OPEN

* factory setting

** not valid for G31

6.5.2.2 Placing concentric system with wall terminal

Caution

- Maintain a distance of at least 50mm between the outside of the concentric system and the walls, when using a

round system;

- Maintain a distance of at least 23 mm between the outside of the concentric system and the walls, when using a

rectangular system; this distance is xed due to the construction of the rectangular system;

- Maintain a distance of at least 50mm between the outside of the concentric system and the ceiling;

- Use non combustible material for building the concentric in, for instance, a cove;

- Use heat-resistant insulation material when passing through combustible material;

- The rosette (mounting inner plate) of the wall terminal is too small to seal the Ø250mm opening when passing

through combustible material. That is why you should rst apply a su ciently large heat-resistant intermediate

plate to the wall. Then, the rosette is mounted on the intermediate plate.

!Caution

- When using rectangular pipes it is only possible to end in the wall from which the appliance is suspended (there is

no bend available for the concentric system);

- When the pipes end at right angles in the appliance, you can start with rectangular pipes, but you must change over

to the round system;

- Some heat-resistant insulation materials contain volatile components that will spread an unpleasant smell for a

prolonged time; these are not suitable.

Place the concentric system as follows:

➠

Build the system up from (the ue spigot of ) the appliance.

➠

Connect the concentric pipe pieces, the adapter and, if necessary, the bend.

➠

In case of the rectangular system, you must rst attach a coupling piece on each connection, as described below

(see g.3d):

!Caution

In case of rectangular pipe pieces, the internal pipe is longer at the bottom than the external pipe; the internal pipe

glides in the internal pipe of the ue spigot or the previous pipe piece;

- For reducing a rectangular pipe piece, unscrew the internal pipe from the external pipe;

- Make the internal pipe and external pipe equally long at the top end;

- Retighten the internal pipe;

- Place the coupling piece plus seal on the reduced pipe piece and x it at both front sides by means of 2 self-drilling

screws.

- Place a red seal on the ue spigot of the appliance;

- Then, place the coupling piece on the ue spigot;

- Secure the coupling peace at both front sides using 2 self-tapping screws;

- Place a red seal on the coupling piece;

- Then place a rectangular pipe piece or an adapter to round;

- Secure the rectangular pipe piece or adapter at both front sides using 2 self-tapping screws;

- At each next rectangular pipe piece or at the adapter, place the spacer brackets on the pipe at the same height as the

coupling piece;

- Secure the spacer brackets to the wall, so that the weight of the pipes does not rest on the appliance.

➠

Attach the rst round concentric pipe piece to the adapter using 4 self-drilling screws.

➠

On this connection, apply a clip binding with silicon sealing ring.

➠

In case of round pipe pieces, attach a clip binding with silicon sealing ring to each connection.

➠

Use a self-tapping screw to x the clip binding to the pipe on locations that cannot be reached after installation.

➠

In case of round pipes, apply su cient brackets, so that the weight of the pipes does not rest on the appliance.

➠

Determine the remaining length of the wall terminal;

➠

Make sure the wall terminal has the right dimensions.

GB

95902801_GB Install.indd 895902801_GB Install.indd 8 12-7-10 11:2412-7-10 11:24

9

MILO INSTALLATION MANUAL

English

!Caution

- Make sure that the right insertion length is maintained;

- Place the wall terminal with the groove/folded seam at the top;

- Make sure the horizontal concentric pipe pieces are sloping towards the wall terminal, in order to prevent rain water

from entering.

➠

Mount the rosette (mounting inner plate); if necessary, on a heat resistant intermediate plate when passing through

combustible material.

➠

Attach the wal l terminal from the outside with four screws in their respective holes.

6.5.3 Application with roof terminal

The roof termi nal is a round concentric system.

6.5.3.1 Construction of concentric system with roof terminal

The concentric system with roof terminal has to comply with the following conditions:

- The construction of the chosen system has to be allowed. (See the procedure described below);

- First, a concentric pipe of at least 1meter should be connected vertically to the appliance.

Depending on the construction of the concentric system, the appliance is set by:

- placing the ba e;

- removing the air inlet guide or placing the additional air inlet guide;

- Removing the injector screens.

In the following procedure you can see how the allowability of a concentric system can be determined and which

settings are needed.

➠

Determine the following data:

1) The number of bends required (no distinction is made between 45° and 90° bends);

2) The total number of meters of horizontal pipe length;

3) The total number of meters of vertical and/or sloping pipe length (roof terminal excluded).

With these data and Table2 you will be able to determine whether the concentric system is allowed.

In Table3 you can see which setting the appliance requires.

Follow the procedure described below:

➠

In the rst 2 columns of Table2, look for the number of bends required and the total horizontal pipe length.

➠

In the 3rd column of Table2, look for the total vertical and/or sloping pipe length.

If you end up in a box with the letter A, B, C, D or E the concentric system chosen by you is allowed.

➠

Use Table3 to determine which conditions apply for the ba e, the air inlet guide and the injector screens (for setting,

see section 6.8).

Examples

To clarify, we will give 2 examples to determine the allowability of a concentric system and the conditions for setting

the appliance.

In Table 2 the route to be followed is indicated by arrows. The result is indicated by a box with a red border.

Example 1

1) 2 bends

2) 3 meters horizontal

3) 8 meters vertical/sloping

→ Construction of this concentric system is allowed.

→ Situation C applies for the adjustment of the appliance.

Example 2

1) 3 bends

2) 4 meters horizontal

3) 9 meters vertical/sloping

→ Construction of this concentric system is not allowed.

GB

95902801_GB Install.indd 995902801_GB Install.indd 9 12-7-10 11:2412-7-10 11:24

10

MILO INSTALLATION MANUAL

English

Table 2: Determination of th e permissibility of a concentric system with a roof terminal

G20/G25/G31 Total number of

meters horizontal

pipe length

Total number of meters vertical and/or sloping pipe length

1234567

↓8 ↓9

10 11 12

no bends 0 B C C D D E E E E E E E

2 bends 0 A A B C C D D E E E E E

1 AABCCDDEEE

2AABCCDDE

→

3AABCCD

4AABC

5

3 bends 0 A A A B C C D D E E E E

1AAABCCDDEE

2AAABCCDD

3AAABCC

→

4AAAB

5

4 bends 0 A A A A B C C D D E E E

1 AAAABCCDDE

2AAAABCCD

3AAAABC

4AAAA

5

5 bends -

■

■ = situation is not allowed

Tabel 3: Voorwaarden voor afstellen van het toestel bij toepassing van een dakdoorvoer

G20/G25/G31

Situation Air inlet guide Injector screens* Ba e Distance of

restriction in mm

A N0 N0 N0 OPEN

B ADDITIONAL YES YES 30

C ADDITIONAL YES YES 24

D ADDITIONAL YES YES 19

E ADDITIONAL YES YES 15

■

■ = situation is not allowed

6.5.3.2 Placing concentric system with roof terminal

The roof terminal can end in a sloping and a at roof.

The roof terminal can be supplied with an adhesive plate for a at roof or with a universally adjustable tile for a sloping roof. In case of a sloping roof with a slope up to 24°, it is also necessary to use an adhesive plate.

Caution

- Maintain a distance of at least 50mm between the outside of the concentric system and the walls, when using a

round system;

- Maintain a distance of at least 23 mm between the outside of the concentric system and the walls, when using a

rectangular system; this distance is xed due to the construction of the rectangular system;

- Maintain a distance of at least 50mm between the outside of the concentric system and the ceiling;

- Use non combustible material for building the concentric in, for instance, a cove;

- Use heat-resistant insulation material when passing through combustible material.

!Caution

Some heat-resistant insulation materials contain volatile components that will spread an unpleasant smell for a

prolonged time; these are not suitable.

GB

95902801_GB Install.indd 1095902801_GB Install.indd 10 12-7-10 11:2412-7-10 11:24

11

MILO INSTALLATION MANUAL

English

Place the concentric system as follows:

➠

Build the system up from (the ue spigot of ) the appliance.

➠

Connect the concentric pipe pieces, the adapter and, if necessary, the bends.

➠

In case of the rectangular system, you must rst attach a coupling piece on each connection, as described below

(see g.3d):

!Caution

In case of rectangular pipe pieces, the internal pipe is longer at the bottom than the external pipe; the internal pipe

glides in the internal pipe of the ue spigot or the previous pipe piece;

- For reducing a rectangular pipe piece, unscrew the internal pipe from the external pipe;

- Make the internal pipe and external pipe equally long at the top end;

- Retighten the internal pipe;

- Place the coupling piece plus seal on the reduced pipe piece and x it at both front sides by means of 2 self-drilling

screws.

- Place a red seal on the ue spigot of the appliance;

- Then, place the coupling piece on the ue spigot;

- Secure the coupling peace at both front sides using 2 self-tapping screws;

- Place a red seal on the coupling piece;

- Then place a rectangular pipe piece or an adapter to round;

- Secure the rectangular pipe piece or adapter at both front sides using 2 self-tapping screws;

- At each next rectangular pipe piece or at the adapter, place the spacer brackets on the pipe at the same height as the

coupling piece;

- Secure the spacer brackets to the wall, so that the weight of the pipes does not rest on the appliance.

➠

Attach the rst round concentric pipe piece to the adapter using 4 self-drilling screws.

➠

On this connection, apply a clip binding with silicon sealing ring.

In case of round pipe pieces, attach a clip binding with silicon sealing ring to each connection.

Use a self-tapping screw to x the clip binding to the pipe on locations that cannot be reached after installation.

In case of round pipes, apply su cient brackets, so that the weight of the pipes does not rest on the appliance.

➠

Determine the remaining length of the roof terminal.

➠

Make sure the roof terminal has the right dimensions.

!Caution

Make sure that the right insertion length is maintained.

➠

Connect the roof terminal to the concentric pipes.

!Caution

- Make sure that the universal tile ts well with the surrounding tiles;

➠

Make sure that t he adhesive plate ts well onto the at roof.

6.5.4 Connection of existing chimney

It is possible to connect the appliance to an existing channel.

A exible SS pipe is placed in the chimney for discharging ue gases. The surrounding space is used to supply combustion air.

Caution

Protect the gas control and pipes against dirt from the chimney.

The following requirements apply when connecting to an existing chimney:

- only possible after placement of a concentric adapter to round on the rectangular ue spigot;

!Caution

- Place a concentric adapter to round, using a coupling piece with accompanying seals;

- Secure the coupling piece by means of self-tapping screws;

- Attach the rst round concentric pipe piece to the adapter using 4 self-drilling screws;

- On this connection, apply a clip binding with silicon sealing ring.

- only allowed when used in combination with the special DRU chimney kit. The installation manual is also supplied;

- the dimensions should be at least 150 x 150 mm;

- the vertical length has a maximum of 12meters;

- the horizontal length has a maximum of 3meters;

- the existing chimney has to be clean;

- the existing chimney has to be tight.

GB

95902801_GB Install.indd 1195902801_GB Install.indd 11 12-7-10 11:2412-7-10 11:24

12

MILO INSTALLATION MANUAL

English

If the appliance is installed into an existing chimney by means of a chimney kit, there may be a slight loss in heat

output.

For setting the appliance, the same conditions/instructions apply as for the concentric system described above.

6.6 Placing the chimney breast

The appliance was designed to suspend freely. The narrow chimney breast at the rear of the appliance is only intended to hide the ue gas discharge / combustion air supply system and the adjustable legs; see section 6.6.1.

Construction in a construction chimney breast is allowed. In this case, a mantel iron must be placed; DRU is able to

supply this; see section 6.6.2.

The chimney breast may only be made of plate material.

The thickness of the plate material may be 15mm minimum and 30mm maximum.

In order to reach a proper heat discharge, the chimney breast must be ventilated at both sides. At the bottom of the

chimney breast, an additional air supply must be made. DRU is able to supply di erent ventilation elements; the lux

no elements can be specially supplied for the narrow chimney breast.

Caution

- Use non combustible and heat-resistant materials for the chimney breast, including the top of the chimney breast,

the material in the chimney breast and the back wall of the chimney breast;

- The ventilation holes – which at both sides should be mounted as high as possible – should have a combined

passage of at least 200cm

2

.

- Make an air supply at the bottom of the chimney breast;

- Protect the gas control and pipes against cement and plaster.

!Caution

When placing the chimney breast, you should take the following into account: (see g.4a).

- the minimum width of the narrow chimney breast: 850mm;

- the location of the ventilation holes at both sides of the chimney breast;

- the location of the air supply at the bottom of the chimney breast;

- the measurements of the glass panes, so that they can be placed/removed after placing the chimney breast.

6.6.1 Placing the narrow chimney breast

Follow the procedure described below:

➠

Check whether the concentric system is placed correctly.

➠

Check at the rectangular system, whether the connections (coupling pieces) are installed with the accompanying seals

and self-tapping screws.

➠

In case of rectangular pipes, check the xture to the wall by means of screws, on locations that cannot be reached later.

➠

In case of round pipes, check the xture of the clip binding with self-tapping screws on places that cannot be reached

later on.

➠

Adjust the vertical adjustment strip to the thickness of the plate material; see g.1, arrow3.

➠

Attach the plate material.

Caution

Maintain a tolerance of approx. 2mm between plate material and construction frame; see g.4b.

➠

Apply the ventilation holes a t both sides of the chimney breast.

➠

Attach the air supply to the bottom of the chimney breast: min.45x550mm; see g.4a, arrow1.

➠

When using plaster nishing, the chimney breast should dry for at least 6 weeks before it is taken into operation,

in order to prevent cracks.

6.6.2 Placing the construction chimney breast

When using a construction chimney breast, a mantel iron must be placed, in order to avoid that the appliance is

burdened by the weight of the chimney breast.

!Caution

Make sure that the gas control and receiver, which are below the appliance, can still be reached.

Follow the procedure described below:

➠

Check whether the concentric system is placed correctly.

➠

Check at the rectangular system, whether the connections (coupling pieces) are installed with the accompanying seals

and self-tapping screws.

➠

In case of rectangular pipes, check the xture to the wall by means of screws, on locations that cannot be reached later.

➠

In case of round pipes, check the xture of the clip binding with self-tapping screws on places that cannot be reached

later on.

GB

95902801_GB Install.indd 1295902801_GB Install.indd 12 12-7-10 11:2412-7-10 11:24

Loading...

Loading...