Page 1

INSTALLATION MANUAL GB/IE

INSTALLATIEHANDLEIDING NL/BE

MANUEL D’INSTALLATION FR/BE/LU/CH

KAMARA

7KW / 12KW / 16KW

Please retain this document carefully

Bewaar dit document zorgvuldig

Veuillez conserver soigneusement ce document

957.625.04

DRU VERWARMING B.V.

HOLLAND

Page 2

Page 3

English

CONTENTS

Preface ..........................................................................................2

1. Introduction .......................................................................2

2. CE declaration ...................................................................2

3. SAFETY ...............................................................................3

3.1 General ...............................................................................3

3.2 Regulations .........................................................................3

3.3 Precautions/safety instructions during installation ...3

4. Removing the packaging ..................................................3

5. Installation ..........................................................................3

5.1 Regulations .........................................................................4

5.2 Type of gas .........................................................................4

5.3 Gas connection .................................................................4

5.4 Electrical connection .......................................................4

5.5 Wall-terminal and manifold ............................................4

5.6 Placing the appliance ........................................................8

5.7 Flue gas discharge/combustion air supply system.....8

5.8 Connecting gas ............................................................... 11

5.9 Converting to propane ................................................ 11

5.10 Connecting electrical equipment ............................... 11

6. Operating the appliance ...............................................12

6.1 Control panel ................................................................. 12

6.2 Switching on the appliance for heating .................... 12

6.3 Switching on the appliance for air circulation ........ 12

6.4 Switching off the appliance .......................................... 12

7. Final check .......................................................................12

7.1 Gastightness .................................................................... 12

7.2 Gas pressure / supply-pressure ................................. 13

7.3 Ignition burner ............................................................... 13

7.4 Flame picture .................................................................. 13

7.5 Flue gas discharge / combustion air supply ............. 13

8. Remove / replace the outer casing ........................... 13

9. Maintenance .................................................................... 13

9.1 Performance ................................................................... 13

9.2 Replacing parts ............................................................... 13

10. Delivery ........................................................................... 17

11. Troubleshooting guide ................................................. 18

Appendix 1 Parts included with the delivery ................19

Appendix 2 Electric wiring diagram ................................20

Appendix 3 Technical data ................................................21

Appendix 4 Parts .................................................................21

Kamara

CONTENTS

1

Page 4

Preface

DRU, a manufacturer of gas heating appliances, develops

and produces products that comply with the highest

quality, performance and safety requirements.

This guarantees that the user will be able to enjoy using

his product for many years to come.

This appliance has a CE marking, which means that it

complies with the essential requirements of the European

gas appliance directive.

As an installer, you must be competent in the field of gas

heating.

Two manuals are supplied with the appliance: the

installation manual and the user manual.

The installation manual will give you the information you

need to install the appliance in such a way that it will

operate properly and safely.

This manual discusses the installation of the appliance

and the regulations that apply to the installation. In

addition, you will find technical data for the appliance and

information on maintenance, any malfunctions that might

occur and their possible causes.

Please carefully read and use this installation

manual.

The following symbols are used in the manual to indicate

important information:

• Work to be performed

!Tip Suggestions and recommendations

!Caution You will need these instructions

to prevent problems that might

occur during installation and/or

use.

Caution You need these instructions to prevent

fire, personal injury or other serious

damages.

After delivery, you should give the user manual

AND this installation manual to the user.

1. Introduction

The Power Flue is a closed gas heating appliance with a

forced convection air flow and a forced flue gas discharge.

The appliance can be supplied in 7 kW, 12 kW and 16 kW

versions.

The appliance is always fixed against a wall of

incombustible and heat-resistant material. The passage to

the outside shall be made with the supplied wall terminal.

When using the standard flue, the terminal will be placed

in the same wall against which the appliance is placed.

It is possible to use an extended flue. This flue may have

a maximum length of 10 meters for the 7kW and 12kW

versions; for the 16kW version the extended flue can have

a maximum length of 3 meters.

The extended flue can be placed at both the left and right

side of the appliance. For this, special knock-outs have

been placed at both sides, in the casing.

The components for the extended flue will be supplied by

Drugasar upon request.

When supplied, the appliance is set for the use of natural

gas (G20). Upon request, a conversion set for propane

(G31) can be supplied.

2. CE declaration

We hereby declare that the design and construction of

DRU’s gas heating appliance comply with the essential

requirements of the applicable EC directives.

This declaration will lose its validity if adjustments are

made to the appliance, without prior written permission

by DRU.

Product: gas heating appliance with forced convection air

flow

Type: Power Flue

Applicable EEC directives:

90/396/EEC

2006/95/EC

89/336/EEC

Internal measures by the company guarantee that

appliances produced in series comply with the essential

requirements of the prevailing EEC directives and the

standards derived from them.

M.J.M. Gelten

General manager

Dru verwarming B.V.

Postbus 1021, 6920 BA Duiven

Ratio 8, 6921 RW Duiven

www.dru.nl

INSTRUCTIONS FOR INSTALLATION

2

!

Page 5

3. Safety

3.1 General

Caution - Carefully read this chapter on safety,

before you start performing installation

or maintenance work;

- Please observe the general regulations and

the precautions/safety instructions in this

manual.

3.2 Regulations

• Please install the appliance, including the electrical

installation, in accordance with the applicable national,

local and constructional (installation) regulations.

These are included in, for instance:

- Gas Safety (Installation and Use) Regulations;

- B.S. 6891;

- B.S. 5871: Part 1;

- B.S. 5440: Part 1;

- B.S. 5440: Part 2;

- Local Building Regulations;

- I.E.E Wiring Regulations;

- Health and Safety at work

3.3 Precautions / safety instructions during

installation

Carefully observe the following precautions/safety

regulations:

• you should only install and maintain the appliance if you

are a competent installer in the field of gas heating:

• do not make any changes to the appliance;

• only use the flue gas discharge / combustion air supply

material supplied by Drugasar;

• always place the appliance against a wall of incombustible

and heat-resistant material;

• use the wall brackets when mounting the appliance to the

wall. This will guarantee the minimum required distance

of 10 mm from the back wall;

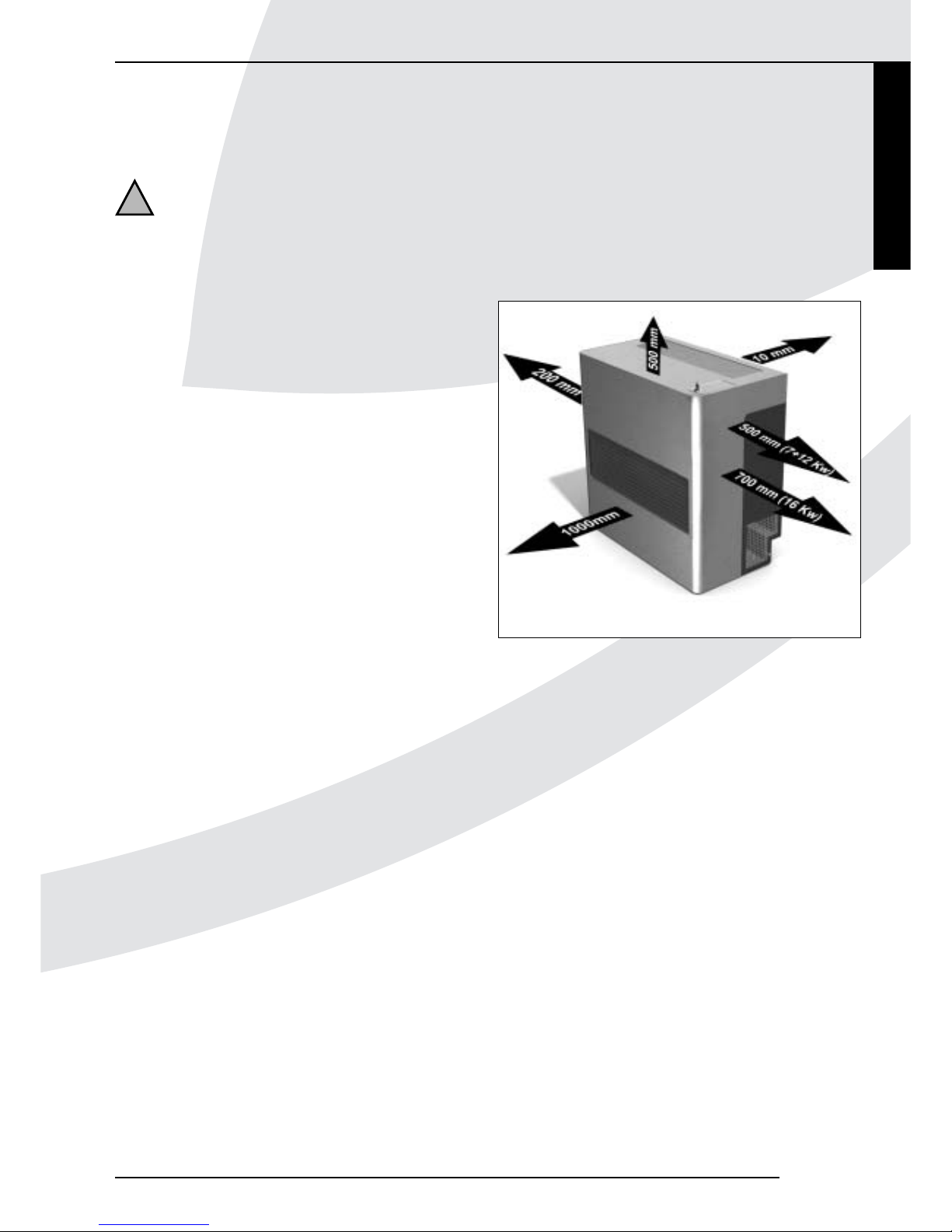

• make sure the appliance has sufficient distance from

other objects and materials (see fig. 1). The free space

surrounding the appliance is necessary for a proper

and safe operation and for accessibility in case of

maintenance;

• make sure there is a free outflow of warm convection air

at the front of the appliance;

• make sure there is a free supply of cold convection air at

both sides of the appliance; Curtains, for example, could

block the inlet as a result of the sucking action of the

convection fan.

• avoid warm convection air from recirculation through the

cold convection air inlet;

• do not cover the appliance and the discharge material

and/or do not wrap it in an insulation blanket or any

other material;

• avoid dirt in gas tubes and connections;

• check the connections for gastightness before using the

appliance;

• do not place and/or use the appliance in a moist

environment;

• place an all-pole switch near the appliance, with a contact

opening of at least 3 mm;

• connect the appliance to earth;

• place electrical connections in such a way that they are

free from the appliance;

• do not ignite the appliance until it is fully installed.

4. Removing the packaging

Note the following items when removing the packaging:

• Check the appliance for damages during transport.

• If necessary, contact Drugasar Service.

• Check whether all parts have been supplied.

In Appendix 1 you can see which parts you should have

after removing the packaging.

• Contact Drugasar Service if you do not have all the parts

after you finished removing the packaging.

• Dispose packaging in accordance with local regulations.

Kamara

INSTRUCTIONS FOR INSTALLATION

!

Fig. 1

3

English

Page 6

5. Installation

Read this manual carefully to ensure a proper and safe

operation of the appliance.

!Caution Install the appliance in the order described in

this chapter.

5.1 Regulations

• Please observe the applicable national, local and

constructional (installation) regulations for both the

appliance and the electric installation.

• Observe the regulations/instructions in this manual.

5.2 Type of gas

The type plate indicates for which type of gas, gas

pressure and for which country this appliance is intended.

The type plate can be found on the left side on the

convection box. You can see it after removing the casing.

The appliance can be converted for usage with propane.

The gas supply pressure should be at least 30 mbar.

For conversion to propane, see section 5.10.

• Check whether the appliance is suitable for the type of gas

and the gas pressure used at the location.

5.3 Gas connection

Caution Avoid dirt in the gas tube and in the

connections.

The following requirements apply to the gas connection:

- use a gas tube with the correct dimensions, so that no

pressure loss can occur;

- the gas tap, if used, should have CE marking;

- you should always be able to reach the gas tap.

5.4 electrical connection

The following requirements apply to the electrical

connection:

- you must place an all-pole switch near the appliance,

with a contact opening of at least 3 mm;

- the required electrical voltage is 230V/50Hz~;

protected with 5A.

5.5 Wall-terminal and manifold

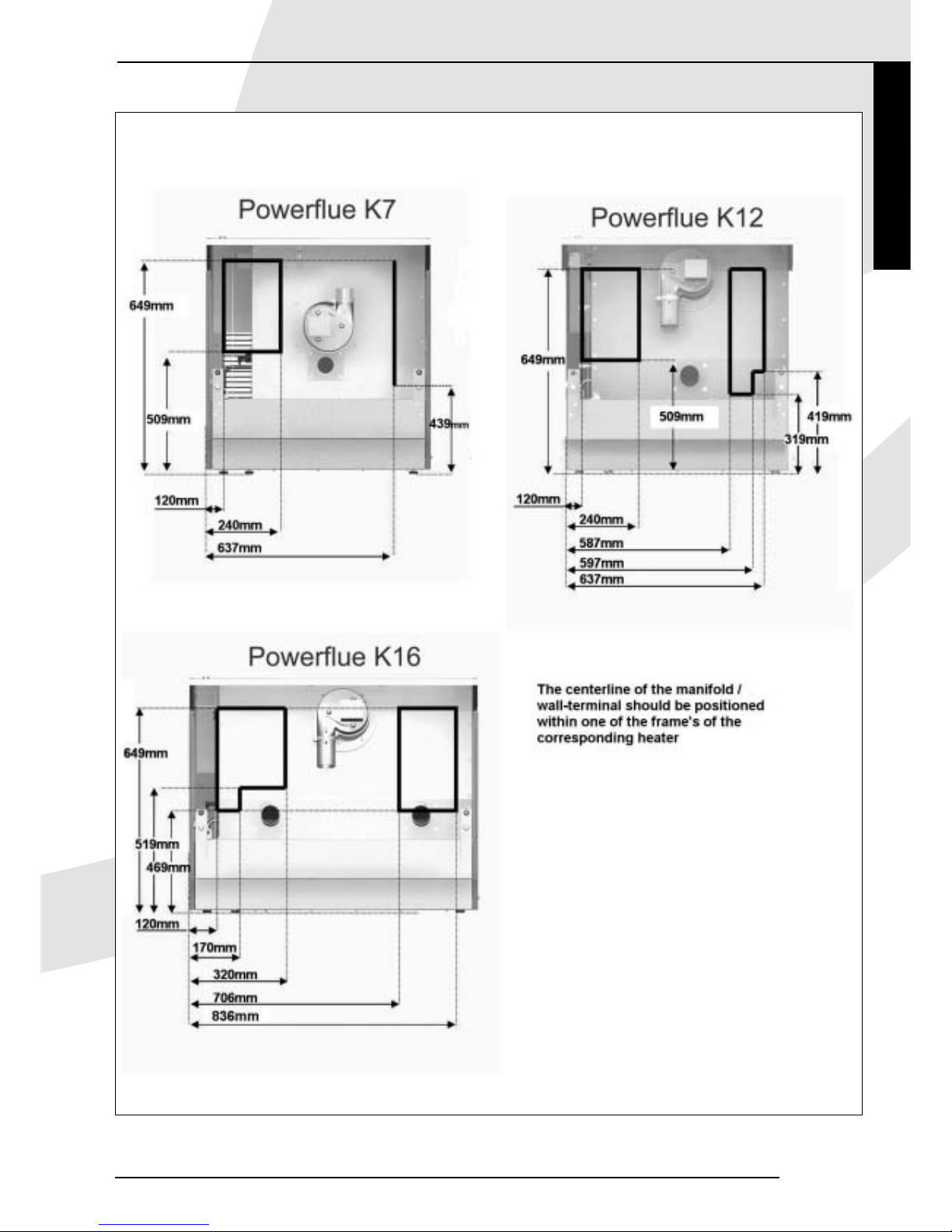

5.5.1 Position wall-terminal/manifold

Positioning of wall-terminal/manifold directly behind the

appliance. (For further information see chapter 5.7.2)

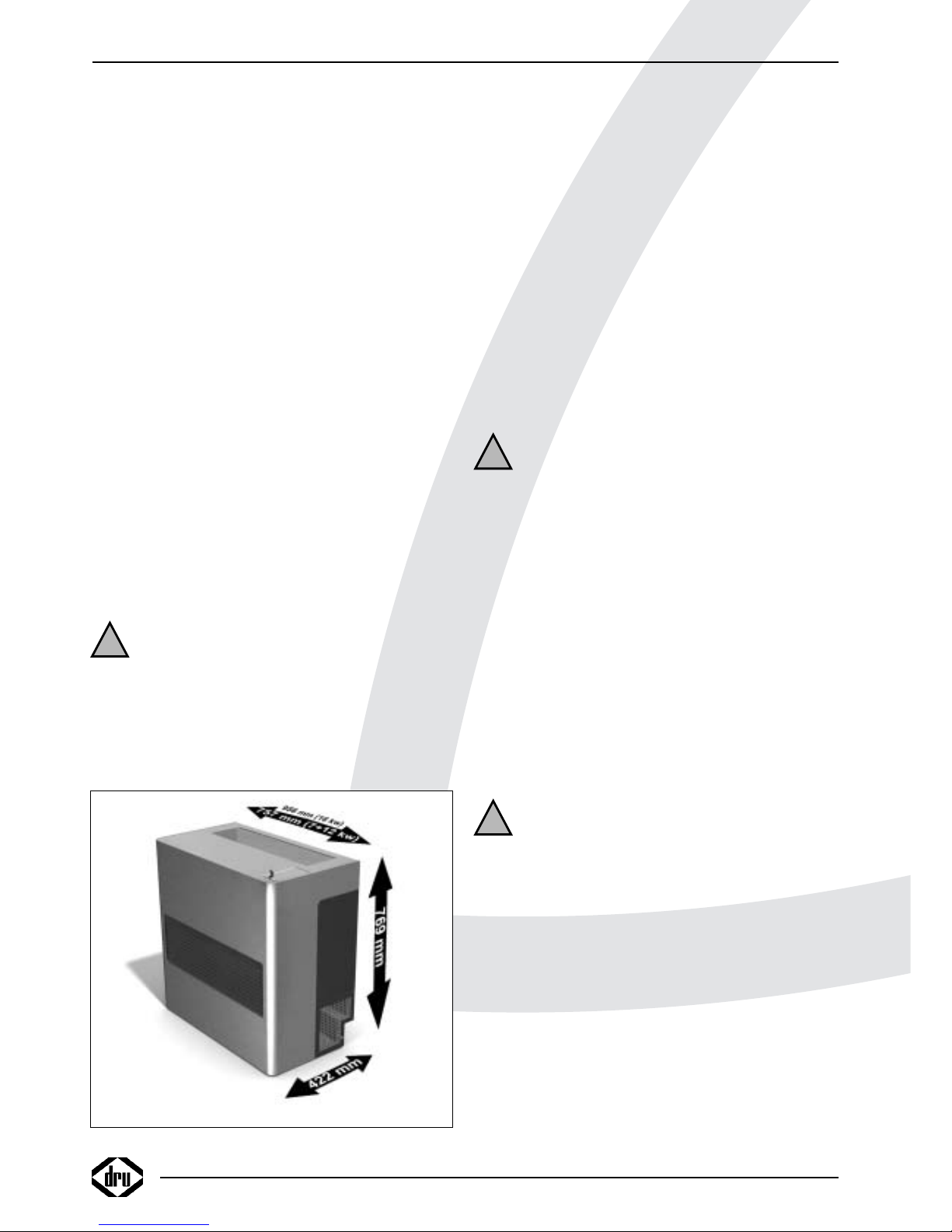

• Determine the location of the appliance; the dimensions

can be found in fig. 1 and 2.

Caution - Make sure the appliance has sufficient

distance from other objects and materials.

The free space surrounding the appliance

is necessary for a proper and safe

operation and for accessibility in case of

maintenance.

- Always place the appliance against a wall of

incombustible and heat-resistant material.

!Tip The manifold has two combustion air supply

connections, see chapter 5.5.2

!Tip Determine the position of the appliance and the

connections by using the dimensions in

fig. 3a and 3b.

For extended flue sample see fig. 8.

• Determine the location of the manifold/wall-terminal.

Caution Use Table 2 to determine the allowed

number of curves in combination with the

length of the discharge system.

!Caution - The bends in the flexible flue gas

discharge tube and the combustion air

supply hose should be as smooth as

possible, to keep the resistance as low

as possible;

- The wall-terminal is suitable for walls with

a thickness up to 400 mm; if necessary,

Drugasar can supply a wall wall-terminal

for walls with a thickness up to 900 mm;

- Take the requirements concerning the

position of the wall-terminal in the outer

wall into consideration, as indicated in

section 5.5.1.1.

- See also chapter 5.7.3, for the extended

flue option.

4

INSTRUCTIONS FOR INSTALLATION

!

Fig. 2

!

!

Page 7

INSTRUCTIONS FOR INSTALLATION

Fig. 3a

Kamara

5

English

Page 8

6

INSTRUCTIONS FOR INSTALLATION

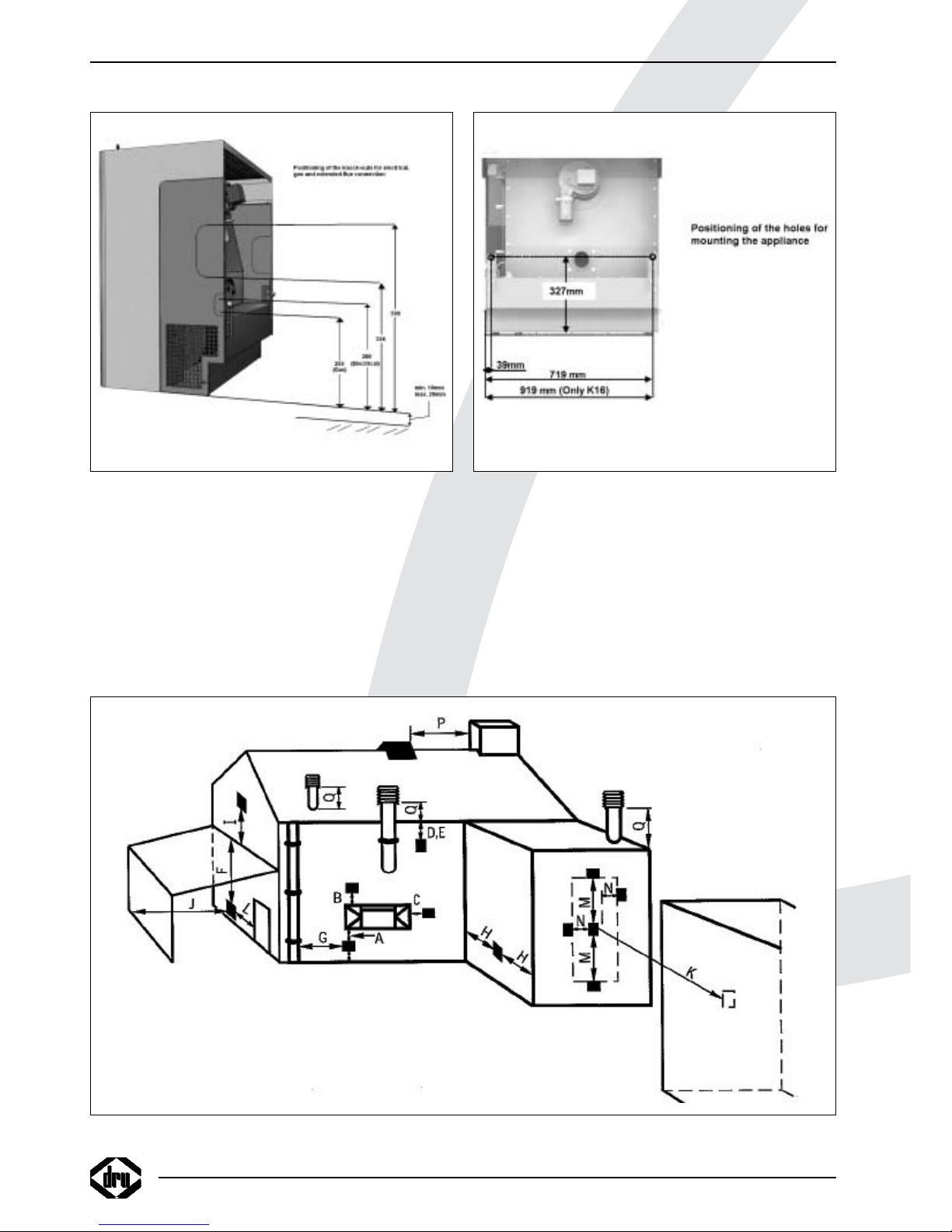

5.5.1.1 Position of wall-terminal in outside wall

The following diagram and related chart are broadly based

around BS5440:Part 1:2000. For additional comments/

applications please refer to this BSI standard directly.

Fig. 3b Fig. 3c

Page 9

INSTRUCTIONS FOR INSTALLATION

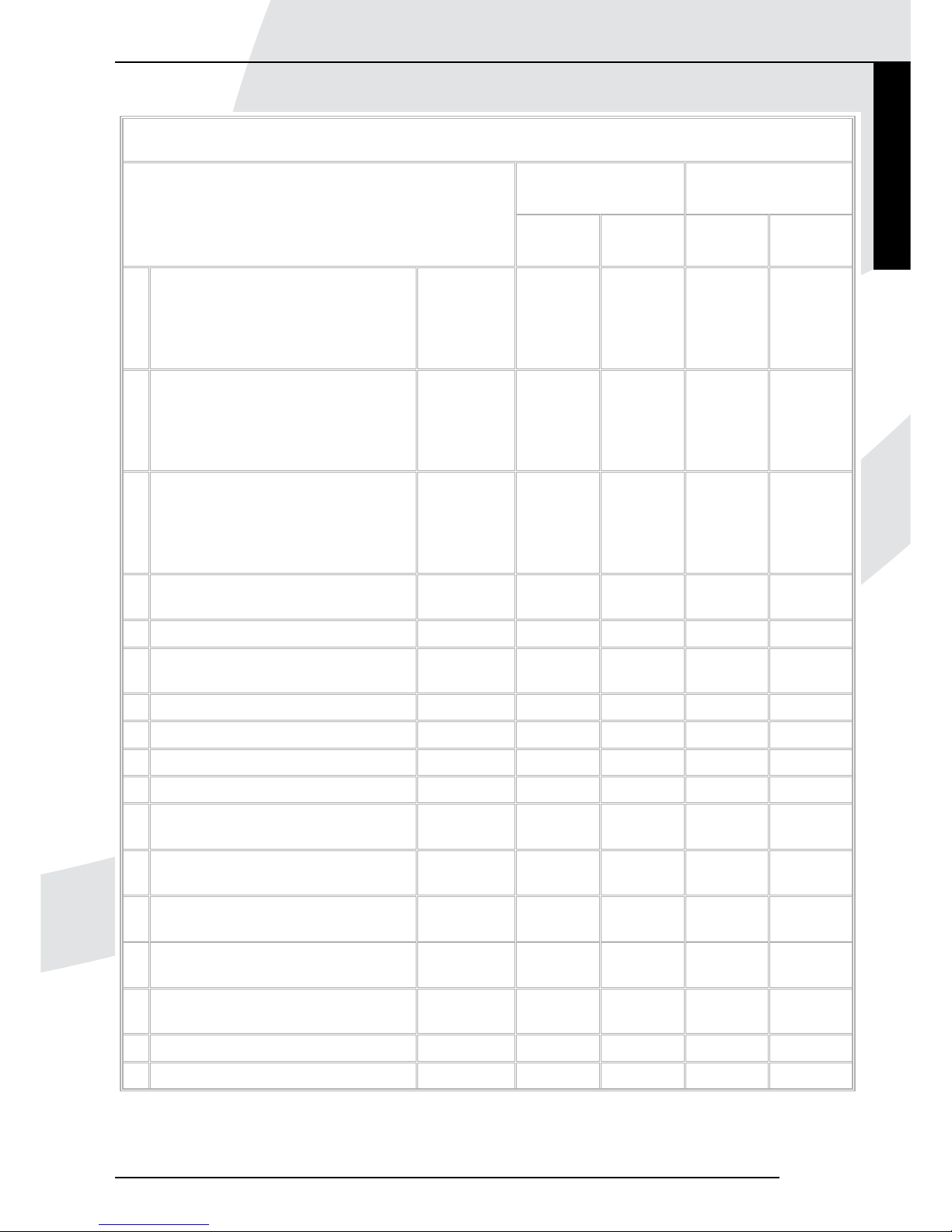

Minimum dimensions of flue wall-terminal positions

Balance flues

room sealed

Open flues

Wall-terminal position

Natural

draught

Fanned

draught

Natural

draught

Fanned

draught

A * Directly below an opening, airbrick,

window etc.

0-7kW

>7-14kW

>14-32kW

>32-70kW

300 mm

600 mm

1500 mm

2000 mm

300 mm Not allowed 300 mm

B * Above an opening, airbrick, window

etc.

0-7kW

>7-14kW

>14-32kW

>32-70kW

300 mm

300 mm

300 mm

300 mm

300 mm Not allowed 300 mm

C * Horizontally to an opening, airbrick,

window etc.

0-7kW

>7-14kW

>14-32kW

>32-70kW

300 mm

400 mm

600 mm

600 mm

300 mm Not allowed 300 mm

D Below a gutter or sanitary tube if

combustible material protected.

300 mm 75 mm Not allowed 75 mm

E Below eaves. 300 mm 200 mm Not allowed 200 mm

F Below balconies or open roofed out

buildings.

600 mm 200 mm Not allowed 200 mm

G From a vertical drain or soil tube. 300 mm 150 mm Not allowed 150 mm

H From an internal or external corner. 600 mm 300 mm Not allowed 200 mm

I Above ground or balcony level. 300 mm 300 mm Not allowed 300 mm

J From a surface facing the wall-terminal. 600 mm 600 mm N/A 600 mm

K From another wall-terminal facing the

wall-terminal.

600 mm 1200 mm N/A 1200 mm

L From an opening in the car port into a

dwelling.

1200 mm 1200 mm N/A 1200 mm

M Vertically from a wall-terminal on the

same wall.

1500 mm 1500 mm N/A 1500 mm

N Horizontally from a wall-terminal on the

same wall.

300 mm 300 mm N/A 300 mm

O From a wall on which the wall-terminal

is mounted.

N/A N/A N/A 50 mm

P From a vertical structure on the roof. N/A N/A 600 mm N/A

Q Above intersection with roof. N/A N/A 600 mm 150 mm

Notes: N/A = NOT APPLICAIABLE * In addition, the wall-terminal should not be nearer than 150mm (fan draught) or 300mm (natural draught) to an

opening in the building fabric formed for the purpose of accommodating a built-in element such as a window frame. Separation distances are linked to the

rated heat inputs as shown.

Kamara

7

English

Page 10

5.5.2 Installation of wall-terminal and manifold

Follow the procedure below when installing the wallterminal and manifold:

• Drill a hole in the wall, with a diameter of 105 mm.

• Drill 3 holes in the wall from the outside, for mounting

the wall-terminal.

!Caution - Place the wall terminal with the groove/

folded seam at the top;

• Glue the sealing/gasket of the wall-terminal to the flange.

• Temporarily mount the wall-terminal from the outside.

• Slide the manifold from the inside as far as possible onto

the concentric tubes of the wall-terminal.

• Determine the distance between manifold and wall.

• Unscrew the wall-terminal.

• Cut the wall-terminal to size.

• Mount the wall-terminal for the final time.

• Determine in which angle the manifold should be placed.

• Apply a sufficient amount of heat-resistant sealant to the

outside of the galvanized steel combustion air supply tube.

• Apply a film of heat resistant sealant to the inside of the

aluminium flue gas discharge tube.

• Place the sealing/gasket of the manifold between wall and

manifold.

!Tip For the manifold, you can choose between two

combustion air supply connections.

• Mount the manifold in the correct position.

• Drill 3 holes in the wall for mounting the manifold.

• Mount the manifold with the screws and washers supplied.

• If necessary, apply a wall-terminal guard.

• Place the wall-terminal guard centrally over the wallterminal.

5.6 Placing the appliance

Place the appliance as follows:

Caution - Do not make any changes to the

appliance;

- Do not cover the appliance and the

discharge material and/or do not wrap

it in an insulation blanket or any other

material;

- Mount the appliance to the wall using

the wall brackets; this will guarantee the

minimum required distance of 10 mm

from the back wall;

- Make sure there is a free outflow of

warm convection air at the front of the

appliance;

- Make sure there is a free supply of

cold convection air at both sides of the

appliance. Curtains, for example, could

block the inlet as a result of the sucking

action of the convection fan.

- Avoid that warm convection air can

recirculate through the cold convection

air inlet.

!Tip - Prevent construction grid/drill material from

contaminating the appliance;

- Only mount the casing, after performing the final

check in section 7.

• Provide a gas connection at the location. For details, see

section 5.3.

• Provide an electrical connection at the location. For

details, see section 5.4.

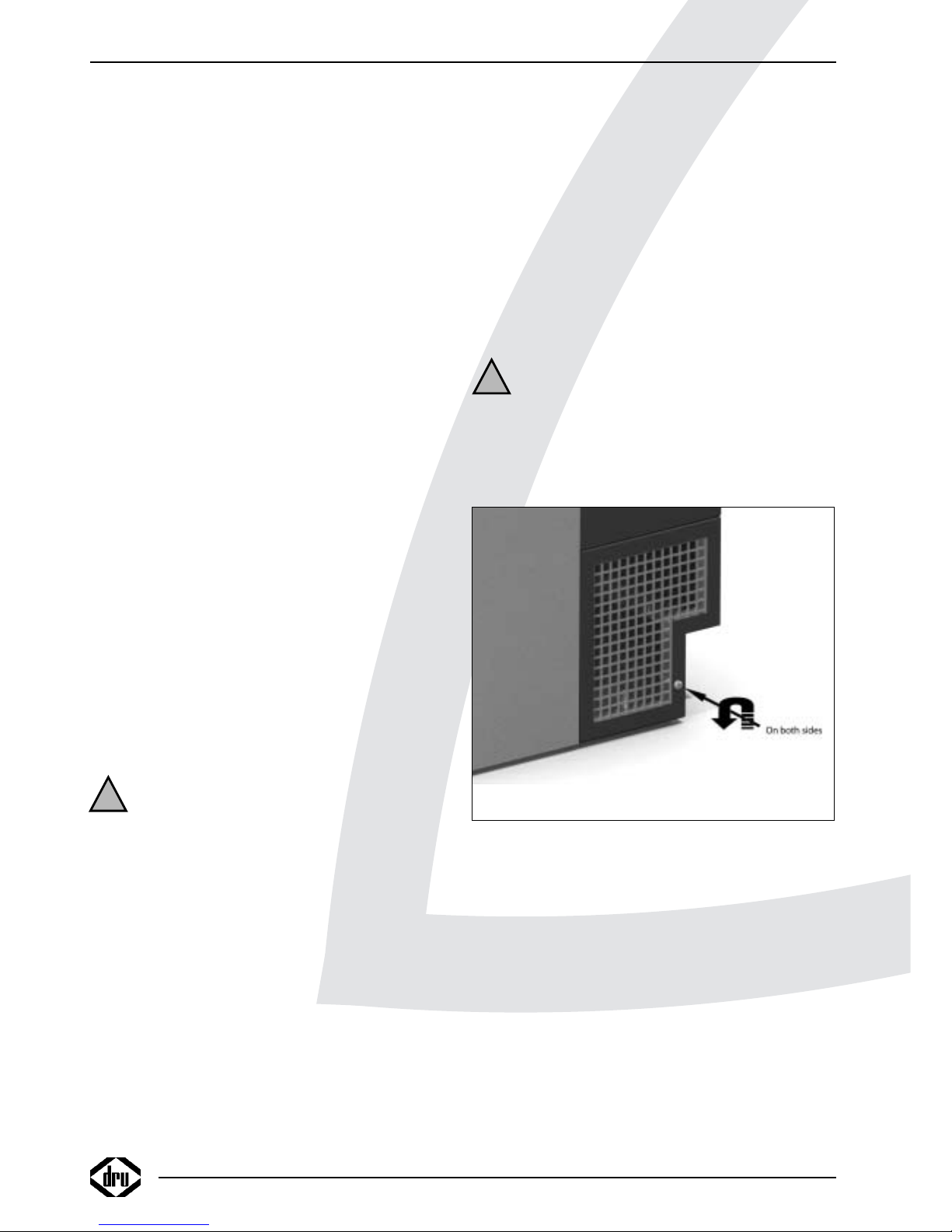

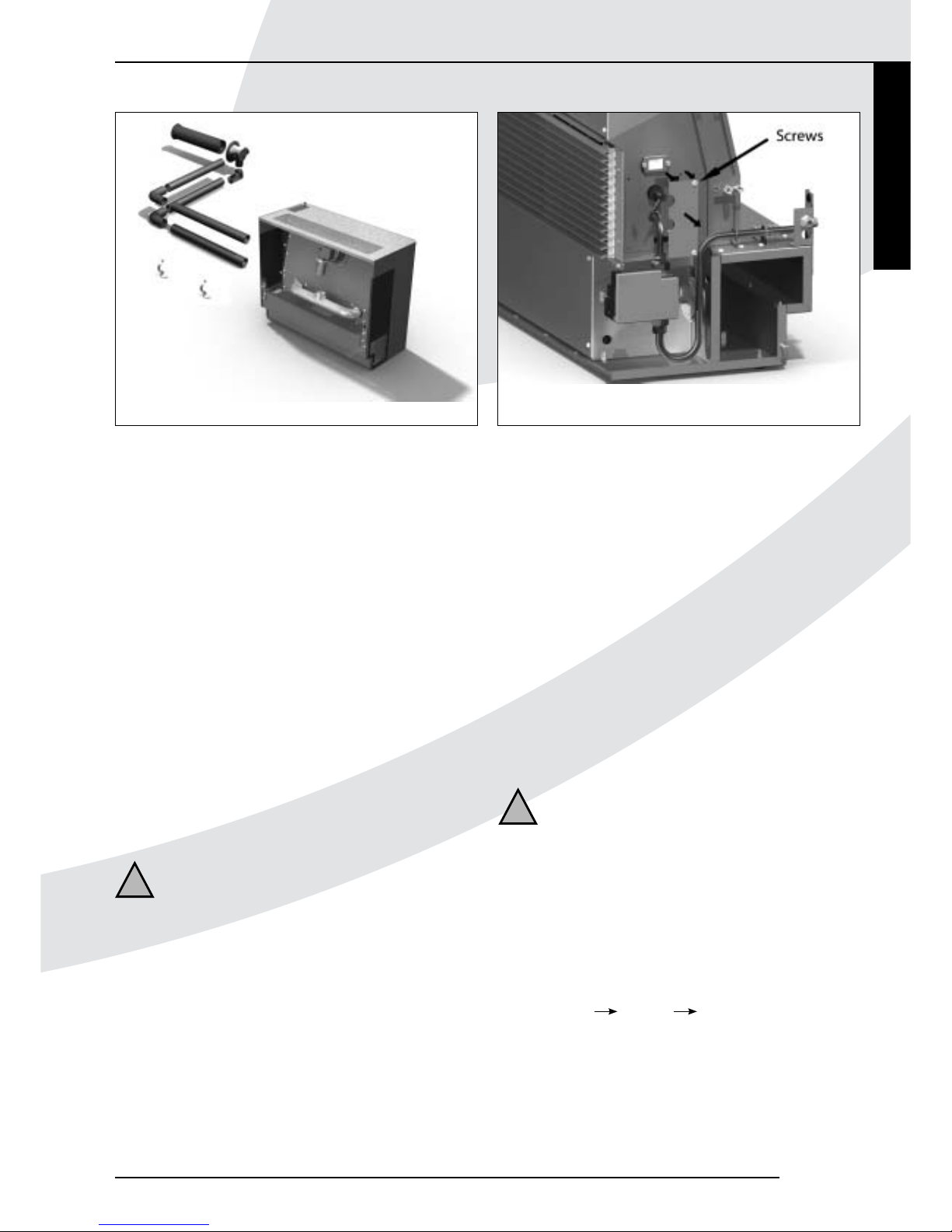

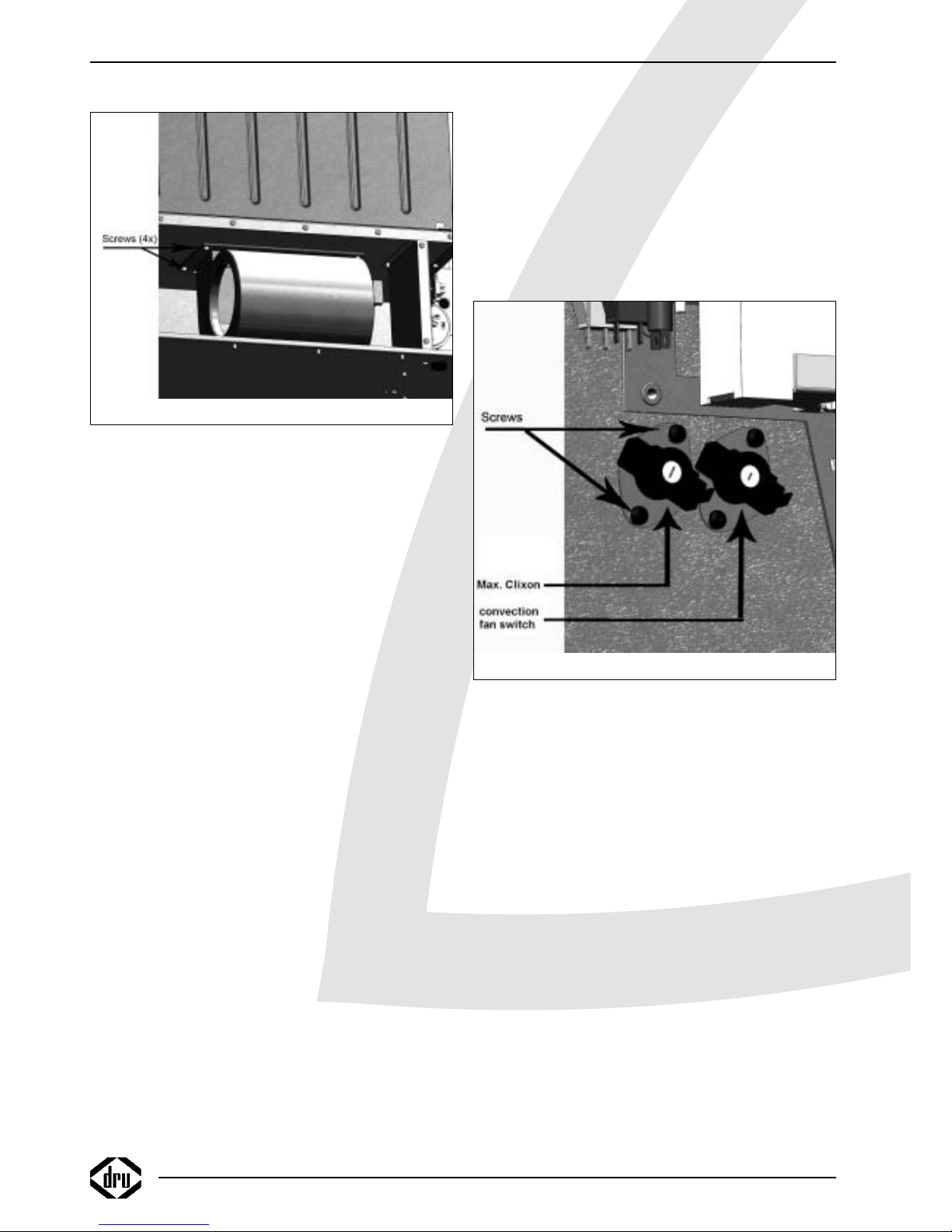

• Remove the casing:

- Unscrew the screws at both sides of the casing

(see fig. 4);

- Lift the casing appr. 1 cm and slide/lift the casing to the

front.

Caution Avoid damaging the wiring when taking off

the mantel.

• Place the appliance on its destined location.

• Drill holes for mounting the appliance.

• Attach the appliance to the wall, using the supplied plugs,

washers and screws.

5.7 Flue gas discharge / combustion air supply

system

5.7.1 Construction

For the 7kW and 12kW Power Flue, the maximum length

of the discharge tubes (vertical and horizontal) is 10

meters when using a maximum of 2 bends of 90º; when

3 bends of 90º will be used, the total maximum length of

the discharge system is 6 meters, and when 4 bends of 90º

will be used, the maximum length is 2 meters.

For the 16 kW Power Flue, the maximum length of the

discharge tubes (vertical and horizontal) is 3 meters, with

a maximum of 1 bend of 90°.

Depending on the construction, the appliance is set by

means of a restriction.

INSTRUCTIONS FOR INSTALLATION

8

!

!

Fig. 4

Page 11

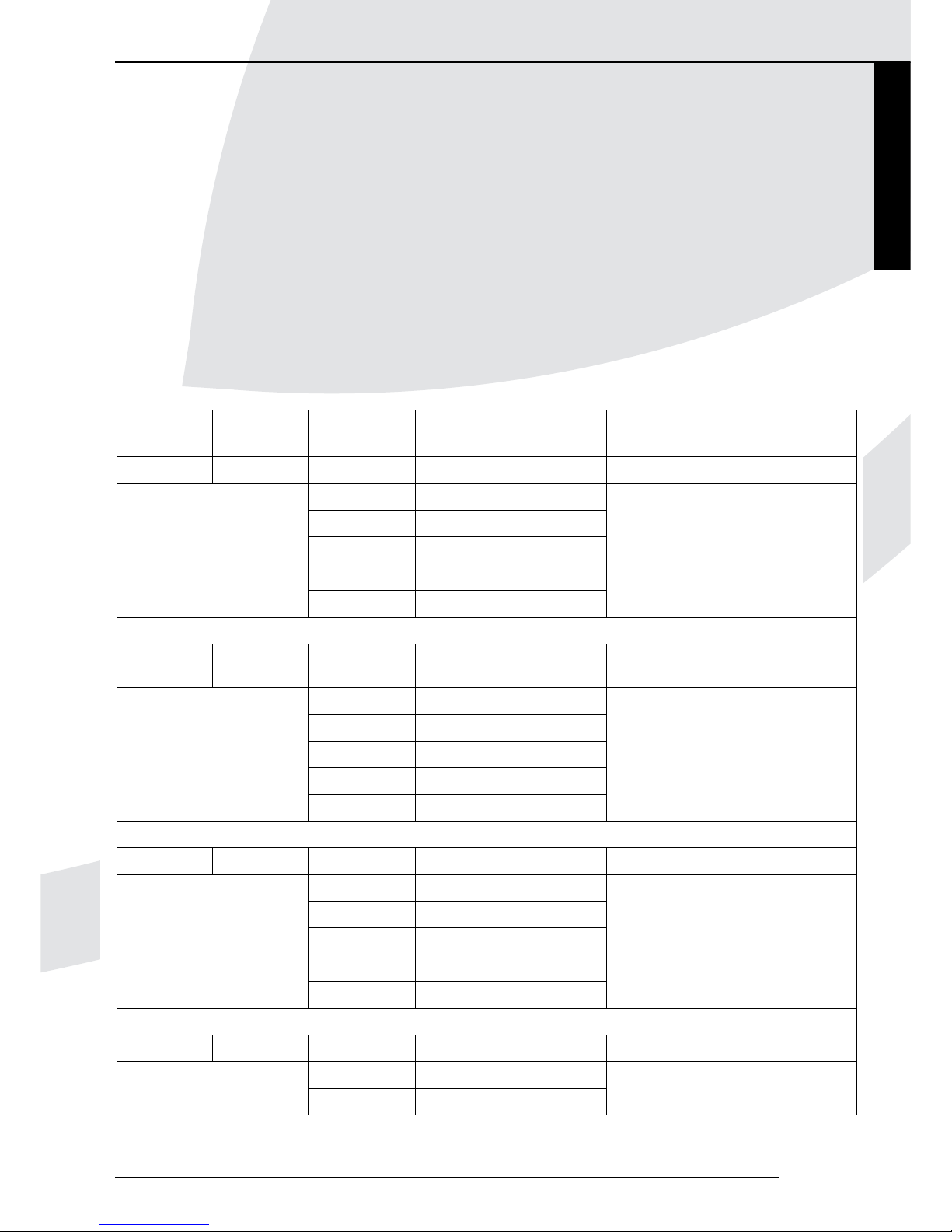

For the 7kW version, the restrictor (supplied) is mounted

on the combustion fan. Please note the restrictor is part

of the venturi on the combustion fan.

For the 7kW Power Flue, the restriction is 22.5 mm when

using natural gas and propane.

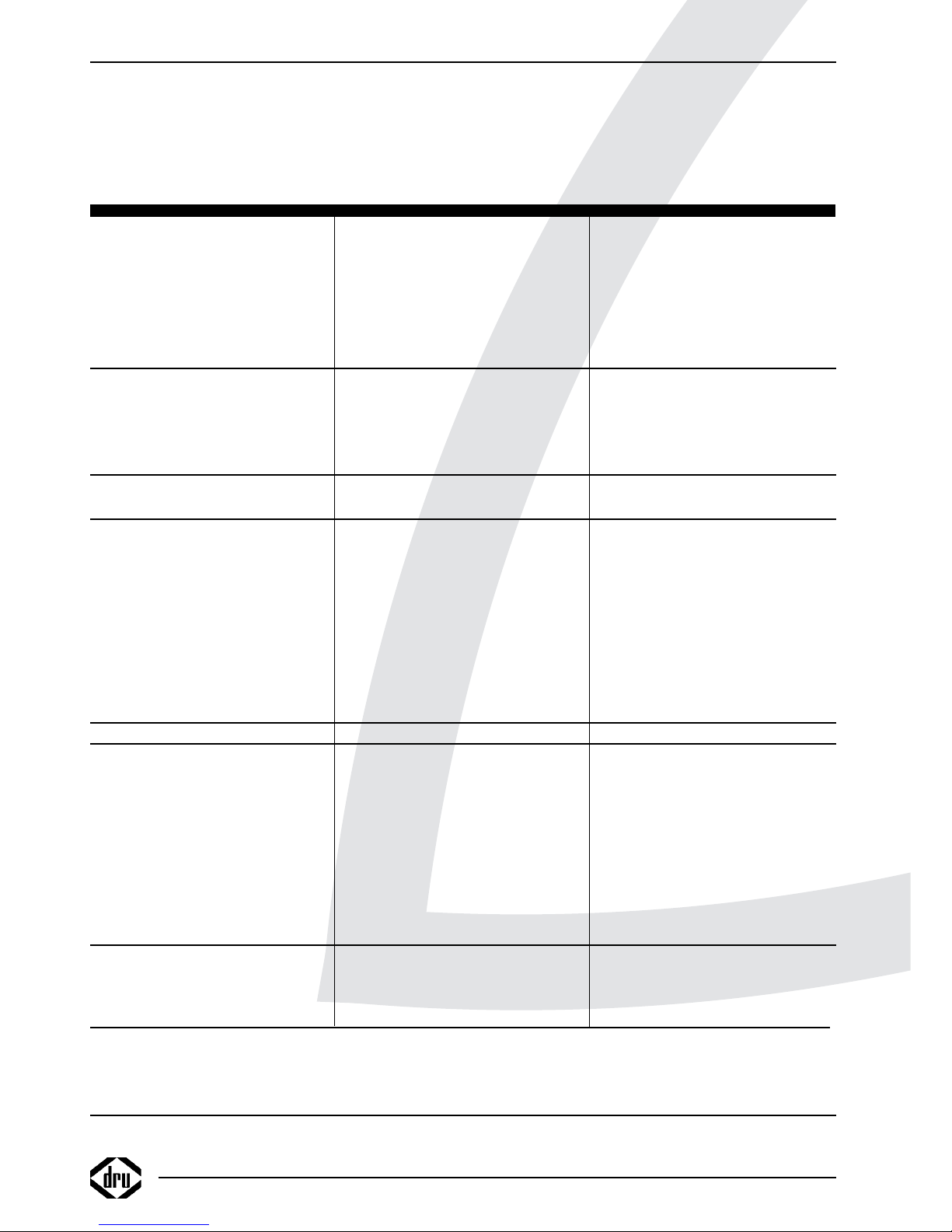

In Table 2 below, you can see the settings of the

restriction in relation to the construction of the discharge

system and the type of gas that is used

At the 12kW and 16kW versions, the restriction – if

necessary – will be placed in the flue gas discharge

connection of the manifold, with a heat-resistant sealant

(see fig. 7).

At the 12kW Power Flue, a restriction is only required if

the appliance is connected directly to the wall-terminal.

When using natural gas, the restriction will be 36 mm, and

when using propane 45 mm.

For the 16kW Power Flue, a 45 mm restriction is also

only required in case of a direct connection to the wallterminal. This value applies to the usage of both natural

gas and propane.

INSTRUCTIONS FOR INSTALLATION

Type Type of gas Number of

90º bends

tube length

(meter)

Restriction

(mm)

Remarks

7kW G20/G31 0 0 22,5

Direct connection to wall-terminal

0 1-10 22,5

1 1-10 22,5

Restriction is a fixed part

2 1-10 22,5

of venturi tube

3 1-6 22,5

4 1-2 22,5

12kW G20 0 0 36

Direct connection to wall wallterminal

0 1-10 none

1 1-10 none

2 1-10 none

3 1-6 none

4 1-2 none

G31 0 0 45

Direct connection to wall-terminal

0 1-10 none

1 1-10 none

2 1-10 none

3 1-6 none

4 1-2 none

16kW G20/G31 0 0 45

Direct connection to wall-terminal

0 1-3 none

1 1-3 none

Table 2: Relations between restriction, discharge system construction and type of gas

Kamara

9

English

Page 12

5.7.2 Placing standard flue kit

Caution Only use the standard flue kit supplied by

Drugasar.

!Caution - The cutting sides of the flexible

combustion gas discharge tube are sharp;

- The bends in the flexible flue gas discharge

tube and the combustion air supply hose

should be as smooth as possible, to keep

the resistance as low as possible;

- The 16kW Power Flue has 2 combustion

air supply connections on the appliance.

They should both be connected and be

combined by means of a T-joint (see fig.

5).

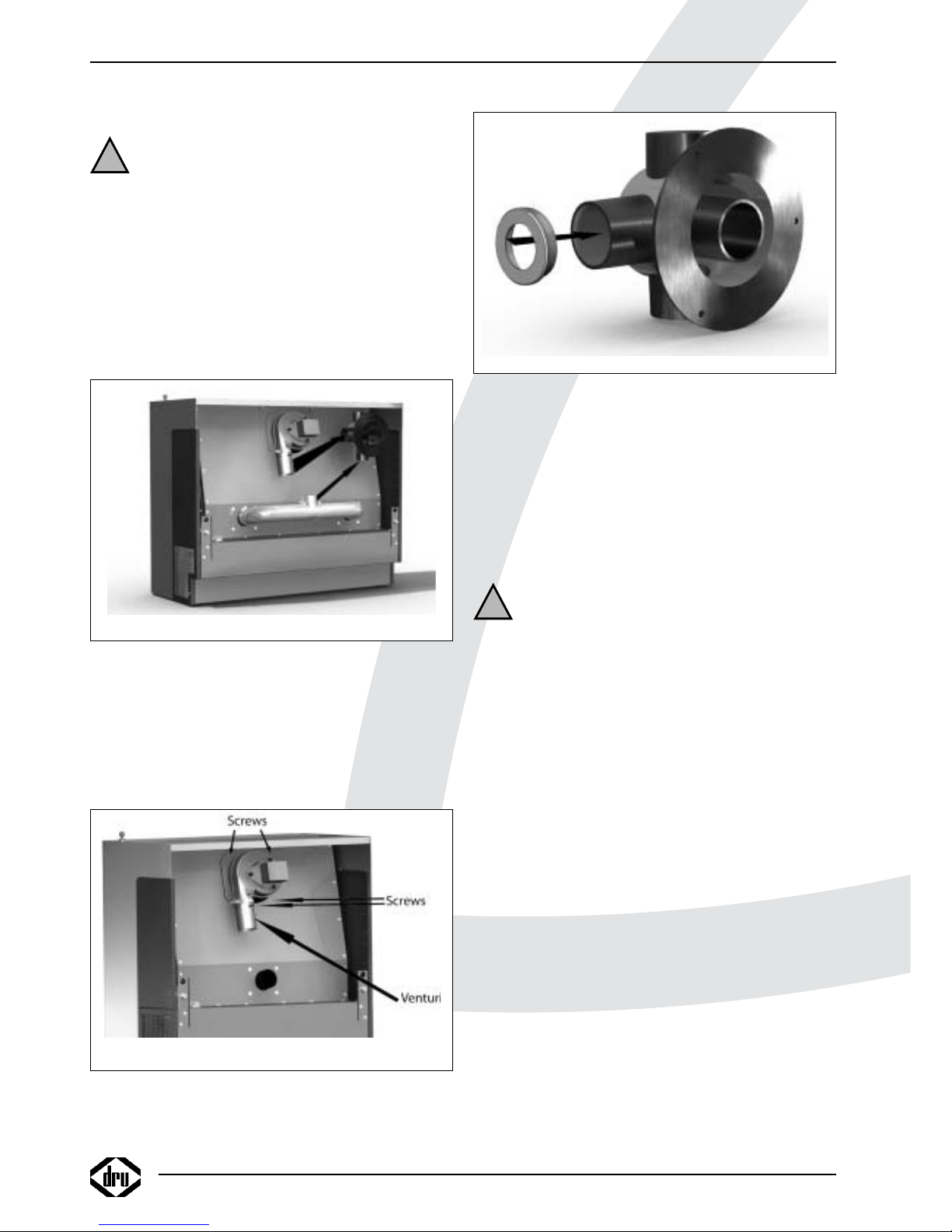

Follow the steps below for mounting the standard flue kit:

• Make sure the flexible combustion gas discharge tube has

the right dimensions

• On one side of the flexible combustion gas discharge tube,

apply the heat-resistant sealant in the grooves on the

inside.

• Add the hoseclamps

• Slide the flexible discharge tube onto the venturi tube that

is connected to the combustion fan (see fig. 6).

• If necessary, attach the restriction in the flue gas discharge

connection of the manifold with the supplied heat resistant

sealant; see Table 2; see fig. 7.

• Connect the flexible flue tube to the manifold in the same

way as described above.

• Fasten the hoseclamps.

• Make sure the flexible combustion air supply hose has the

right dimensions.

• Connect this hose to the appliance and the manifold by

using the supplied standard hose clamps.

• Seal the unused combustion air supply connection on the

manifold using the supplied silicon plug.

5.7.3 Placing the extended flue

Caution - Mount the flue tubes sloping towards the

appliance.

- Place a condensate drain with U-trap in

the rigid part of the discharge system, if

the total length exceeds 3 meters;

- Install the condensate drain within a

distance from the appliance of 3 meters,

but preferably as close as possible to the

appliance.

!Caution - Connect rigid tube pieces/bends to the

manifold. You may only use the flexible

discharge tube/air supply hose on the

appliance;

- Prevent construction grid/drill material

from contaminating the appliance.

!Tip The extended flue can optionally be

connected to the left or right side of the

appliance.

Proceed as follows, when installing the extended flue

(see fig. 8):

• Mount the required brackets for the rigid aluminium flue

gas discharge tube and the rigid aluminium combustion air

supply tube.

• See also fig. 3b for possible position of the tubes.

• Mount the tubes and any bends of rigid aluminium.

• Connect the flexible discharge tube/air supply hose as

described above for the standard flue kit, section 5.7.2

INSTRUCTIONS FOR INSTALLATION

10

!

Fig. 5

Fig. 6

Fig. 7

!

Page 13

5.8 Connecting gas

Use the following procedure when connecting the gas; for

this, also see section 5.3, Gas connection:

!Tip The gas connection can optionally be connected

to the left or right side of the appliance.

• If necessary, blow through the gas tube.

• Connect the gas tube with gas tap to the 15mm tube on

the appliance.

!Caution Do not twist the gas tap when connecting the

gas tube.

• Bleed the gas tube.

5.9 Converting to propane

If necessary, the appliance can be converted to use of

propane.

For this, the injector has to be replaced and the burner

pressure has to be adjusted.

Follow the procedure described below:

Caution - Close the gas tap;

- Switch off the all-pole switch;

- Remove the main fuse.

• Remove the ignition cap.

• Remove the sealing surrounding the electrode pen.

• Unscrew the 4 screws of the cover plates around the gas

tube and ignition pen (see fig. 9).

• Remove the cover plates.

• Unscrew the brass union of the gas tube under the

electrode pen.

• Unscrew the brass union of the gas tube on the gas

control valve.

!Caution Make sure the thread reducing bushes on the

gas control valve do not rotate as well.

• Remove the gas tube from the appliance.

• Remove the injector holder.

• Replace the injector by the propane injector.

• Reassemble everything in opposite order.

• Adjust the burner pressure for propane, using the test

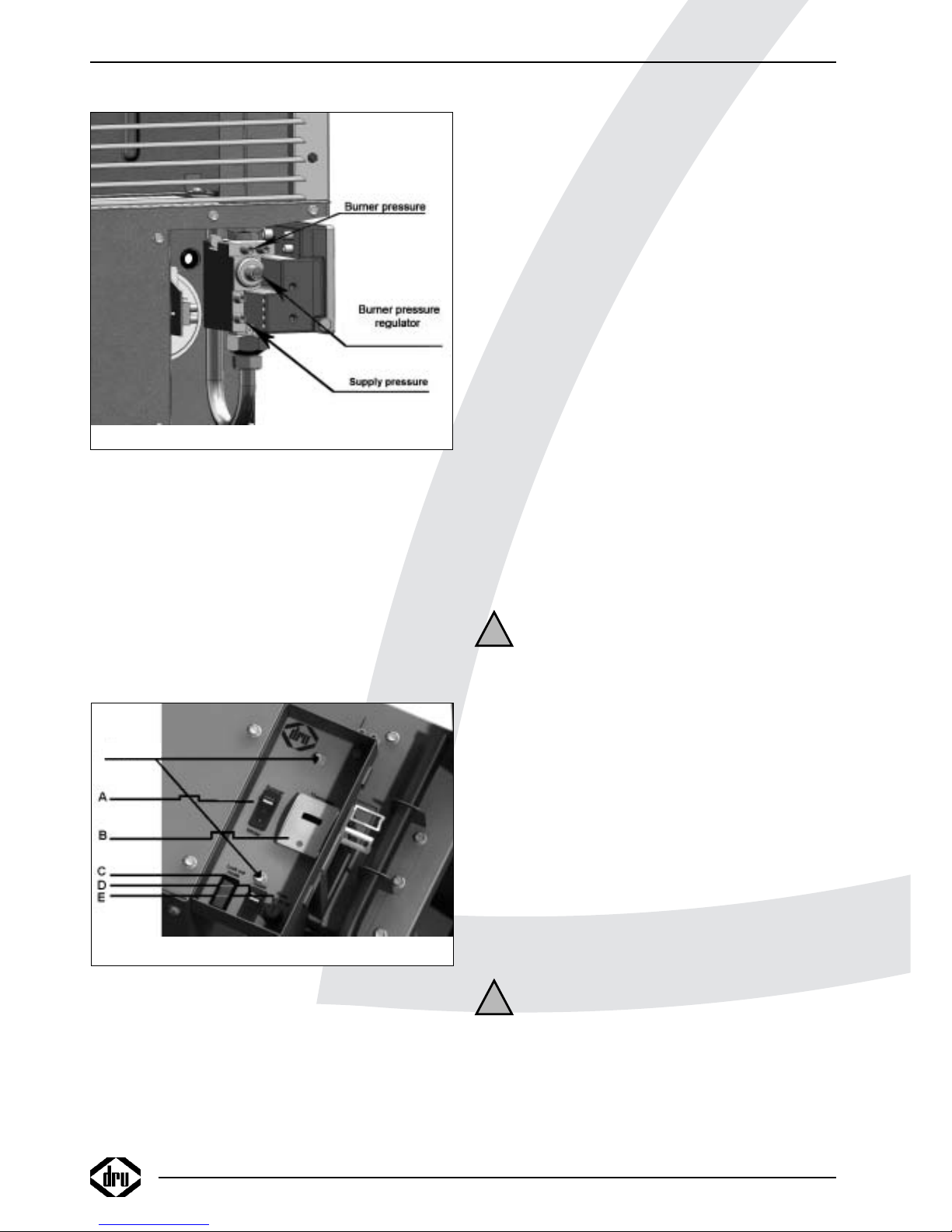

point and the adjusting screw; see fig. 10. Appendix 3

contains the required gas pressure for the various versions

of the appliance.

!Caution When checking/adjusting the burner pressure,

the appliance should be in operation for at least

10 min.

!Tip The adjusting screw is located behind the cover

screw.

5.10 Connecting electrical equipment

Caution The appliance must be earthed.

!Tip The electrical connection can optionally

be made at the left or right side of the

appliance.

Standard, the appliance is designed for use of an external

clock and/or thermostat through a 5 wire cable; for this,

see the electrical diagram in appendix 2.

When the external clock and/or thermostat is not used,

the relay can be bridged by connecting the contacts.

Or connect 1 N and 2 L

• Connect the electric wiring in accordance to the diagram.

INSTRUCTIONS FOR INSTALLATION

Fig. 8

!

Fig. 9

!

Kamara

11

English

Page 14

6. Operating the appliance

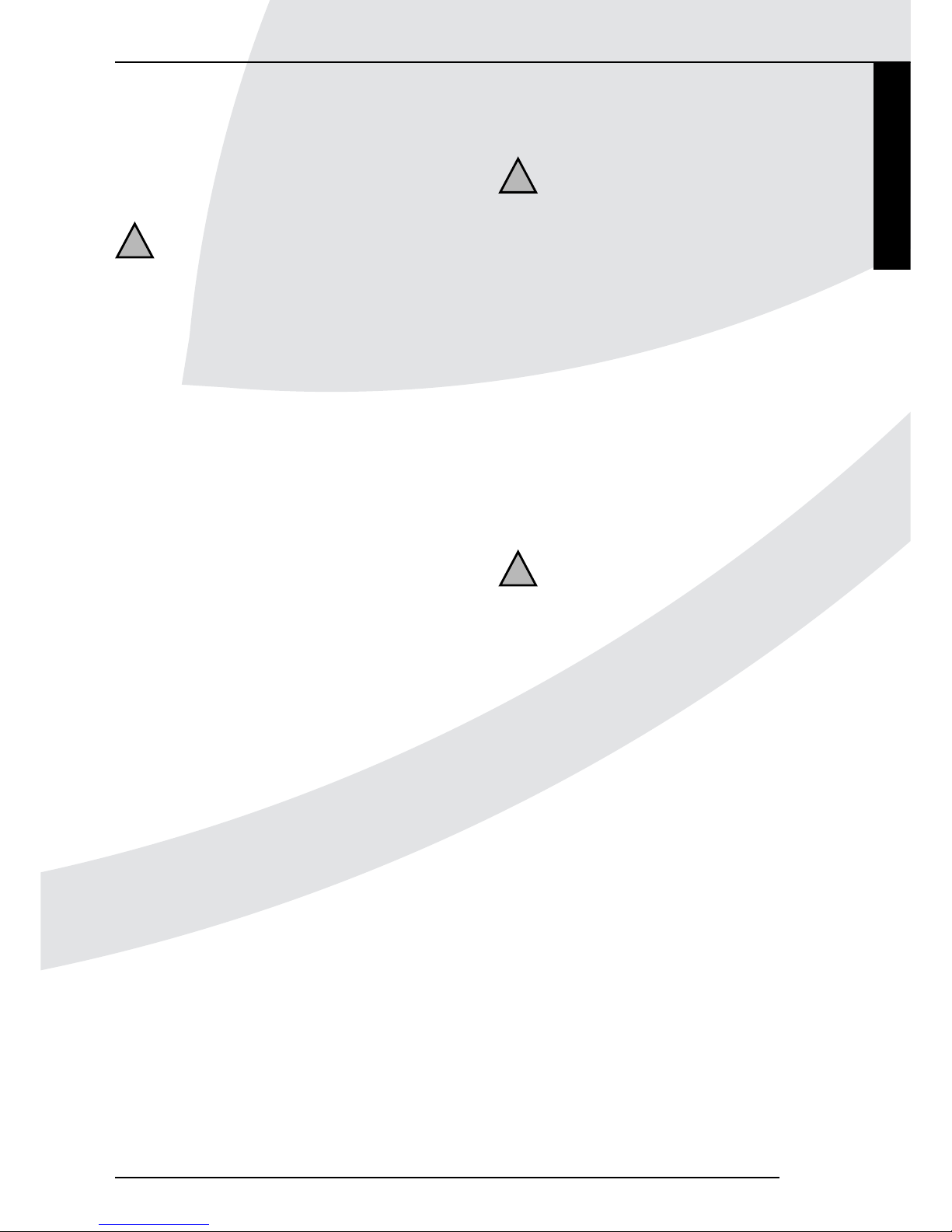

6.1 Control panel

The control panel is located under the cover at the top of

the appliance.

The cover is provided with a lock.

On the panel you will find (see fig. 11)

a) summer/winter switch;

b) thermostat;

c) lock-out mode;

d) reset button;

e) fuse.

sub a)

“0” position

In the position “0”, the appliance is switched off

winter position

In the winter position, you have 2 options:

1) The appliance is controlled by an external clock and/or

thermostat;

2) The appliance is only controlled by the internal

thermostat.

summer position

In the summer position the appliance will operate

independently from an external clock and/or thermostat.

In this position, only convection air (= surrounding air) is

circulated.

Sub b)

The (internal) thermostat can be set between 5 ºC

and 35 ºC.

The green led of the thermostat will light if the appliance

is switched on and the thermostat is “not requesting”.

The red led will light if the appliance is switched on and

the thermostat is “requesting”.

Sub c)

In case of a malfunction, the red lamp of the lock-out

mode will light.

Sub d)

In case of a malfunction, the appliance can be reset by

using the reset button.

6.2 Switching on the appliance for heating

• Set the external clock and/or thermostat, if present.

• Set the thermostat to the required temperature.

• Set the switch to the winter position.

Caution About approximately 30 seconds after

igniting the burner, the convection fan

should switch on.

The louvre openings will release warm air.

6.3 Switching on the appliance for air

circulation

• Set the switch to the summer position.

The appliance will continuously circulate convection air

(= surrounding air).

6.4 Switching off the appliance

• Set the switch to the “0” position.

7. Final check

To check that the appliance is operating correctly and

safely, you must proceed as follows before the appliance is

used.

7.1 Gastightness

Caution All connections must be gastight.

!Caution The supply pressure to the gas control

valve cannot exceed 50 mbar.

• Check the connections for gastightness.

• Make the connections gastight, if necessary.

INSTRUCTIONS FOR INSTALLATION

12

!

!

Fig. 11

SCREWS

(behind cover screw)

Fig. 10

test point

test point

Page 15

7.2 Gas pressure / supply-pressure

The burner pressure is set at the factory for the use of

natural gas; see type plate. It is not necessary to check the

burner pressure after installation.

The supply-pressure in house installations should be

checked, as they can vary.

Caution - After conversion to propane, the

burner pressure must be checked and if

necessary adjusted.

- After maintenance work the burner

pressure must be checked, irrespective

of whether you are using natural gas or

propane, and adjusted if necessary.

Proceed as follows; see fig. 10:

• Check the supply-pressure.

• Contact the gas company if the supply-pressure is not

correct.

• If necessary, check the burner pressure; see Appendix 3

for the required burner pressure.

!Caution When checking/adjusting the burner

pressure, the appliance should be in

operation for at least 10 min.

• Adjust the burner pressure, if necessary.

!Tip The adjusting screw is located behind the

cover screw.

7.3 Ignition burner

For igniting the burner, see section 6.2.

!Caution After 5 ignition attempts, the appliance

will enter the lock-out mode.

• Ignite the burner

• Check if the convection fan is working.

• See in Table 3, Diagnosis of malfunctions, if the convection

fan does not work and/or the burner does not ignite.

7.4 Flame picture

• Check the flame picture.

If the flame picture is unacceptable, do the following:

• Check whether the flue gas discharge and/or air supply are

blocked.

• If necessary, remedy the blockage.

7.5 Flue gas discharge / combustion air supply

• Check the flue gas discharge and the combustion air

supply for gastightness.

• Check whether the flue gas discharge and/or combustion

air supply are lying free from, for example, electrical

wiring, the convection housing.

• If a failure occurs, correct it.

8. Remove / replace the outer casing

The casing is removed as follows:

Caution Avoid damaging the wiring when taking off

the casing.

• Take out the screws at both sides of the casing

(see fig. 4);

• Lift the casing appr. 1 cm and slide/lift the casing to the

front.

Replace in reverse order of the removal procedure.

!Tip If the casing is placed for the first time,

the knock-outs concerned must be

removed first.

!Caution Make sure that the locating bracket fall

into the intended notches.

9. Maintenance

Once a year the appliance should be checked, cleaned and,

if necessary, repaired by a competent installer in the field

of gas heating.

Check that the appliance is operating correctly and safely.

!Caution - Close the gas tap;

- Switch off the all-pole switch;

- Remove the main fuse

during maintenance

work;

- Check the gastightness after repair.

9.1 Maintenance instructions

Perform maintenance work as described below:

• Remove the casing, see section 8.

• Clean the filters as follows:

- Suck/blow the filter clean.

If the filter is not sufficiently clean, you must

- Unscrew the 4 screws;

- Remove the filter;

- Flush the filter with water and clean it with a soft brush.

• Perform the procedure above for both filters.

• Check the fans for contamination and clean, if necessary.

• Check if the fans are operating correctly and replace them

if necessary; see section 9.2.

• Inspect the flue gas discharge / combustion air supply

system and, if necessary, replace the flexible flue gas

discharge tube.

• If necessary, clean the burner and the injector. For

removing the burner, see section 9.2.1.

• Perform a check as described in chapter 7.

9.2 Replacing parts

Below you will see how the various parts can be replaced.

• Remove the casing, for this see section 8.

INSTRUCTIONS FOR INSTALLATION

!

!

!

Kamara

13

English

Page 16

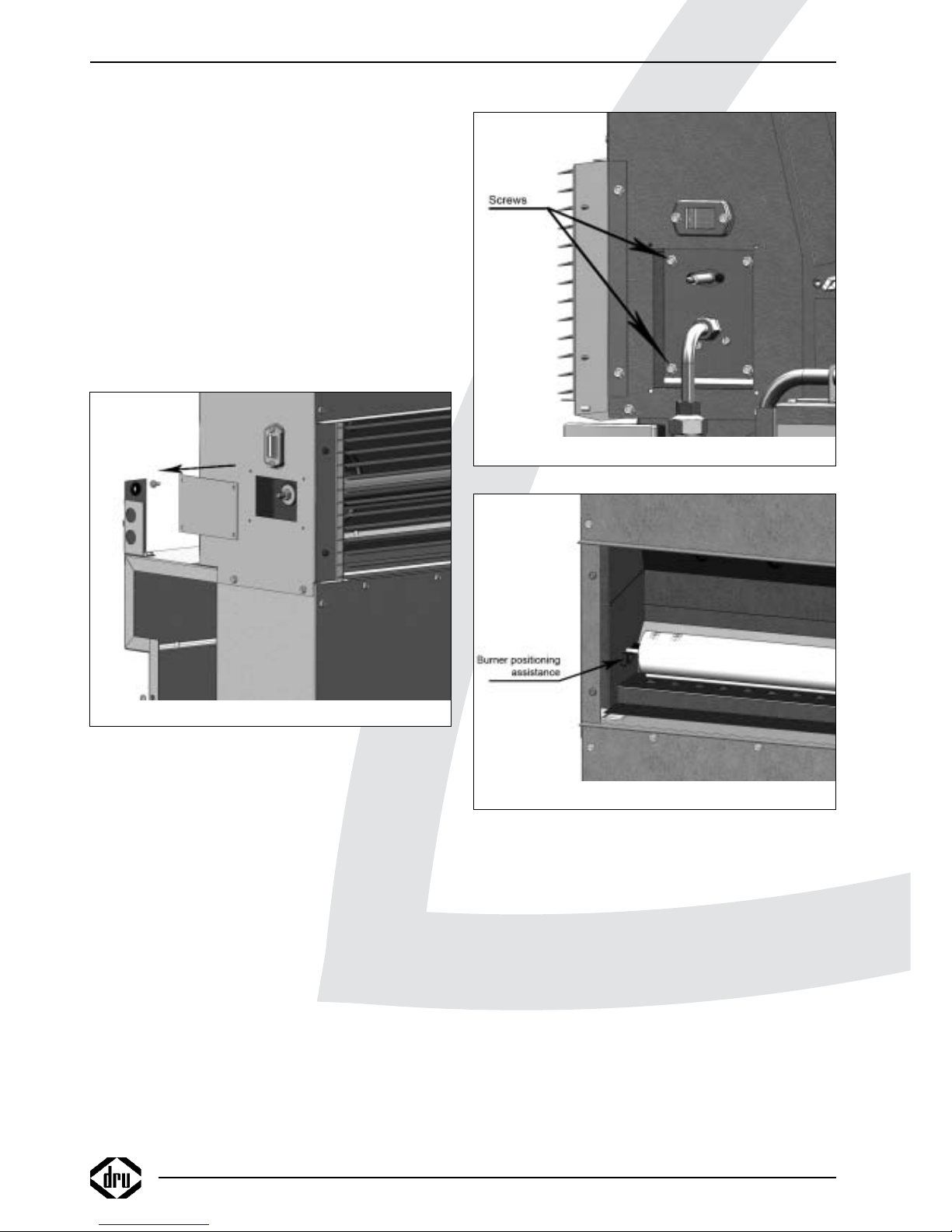

9.2.1 Burner

!Caution Only for Power Flue 7kW

- Remove the cover plate to the left on the

convection housing; see fig. 12;

- Unscrew the nut;

- Remove the washer and the sealing ring.

For all appliances, continue as described below:

• Remove the ignition cap.

• Remove the sealing surrounding the electrode pen.

• Take out the 4 screws of the cover plates around the gas

tube and the ignition pen (see fig. 9).

• Remove the cover plates.

• Unscrew the brass union of the gas tube under the

ignition pen.

• Unscrew the brass union of the gas tube on the gas

control valve.

!Caution Make sure the thread reducing bushes on the

gas control valve do not rotate as well.

• Remove the gas tube from the appliance.

• Take out the 4 screws of the burner; see fig 13.

• Carefully remove the burner tube from the combustion

chamber.

• Place the new burner in reverse order.

!Caution Only for Power Flue 12kW and 16 kW:

- Place the pin at the end of the burner tube

on the V; see fig. 14;

- Position the burner tube in such a way, that

the pin drops in the hole.

• Check supply pressure.

• Check the burner pressure and, if necessary, adjust it as

described in section 7.2

9.2.2 Electrode pen

• Remove the ignition cap.

• Remove the sealing surrounding the electrode pen

• Take out the 4 screws of the cover plates around the gas

tube and the electrode pen (see fig. 9).

• Remove the cover plates.

• Take out the 2 screws of the mounting plate.

• Remove the electrode pen.

• Place the new electrode pen in reverse order

9.2.3 Automatic ignition sequence

• Take out the 2 screws of the cover on the automatic

ignition sequence (see fig. 15)

(the upper screw is used to fix the automatic burner to

the gas control valve; the lower screw fixes the cover)

• Remove the cover.

• Pull the 2 connectors out of the automatic ignition

sequence (see fig. 16).

INSTRUCTIONS FOR INSTALLATION

Fig. 12

Fig. 13

Fig. 14

14

Page 17

• Pull out the ignition cable.

• Remove the automatic ignition sequence by pulling it to

the front side of the appliance.

• Place the new automatic ignition sequence in reverse

order.

!Caution - Place the automatic ignition sequence in such

a way, that the connector is connected again;

- Prevent wiring from getting stuck under the

cover.

9.2.4 Gas control valve

• Remove the automatic ignition sequence, as described

above in section 9.2.3.

• Remove the ignition cap.

• Remove the sealing surrounding the electrode pen

• Take out the 4 screws of the cover plates around the gas

tube and the electrode pen (see fig. 9).

• Remove the cover plates.

• Unscrew the brass union of the gas tube under the

electrode pen.

• Unscrew the brass union of the gas tube on the gas

control valve.

• Disconnect the earth wire.

• Remove the gas control valve.

• Disconnect the thread reducing bushes (top and bottom

side) from the gas control valve.

• Connect the thread reducing bushes to the new gas

control valve.

!Caution Use new sealing rings when mounting the

thread reducing bushes.

• Place the gas control valve in opposite order.

• Adjust the burner pressure as described in section 7.2

• Perform a final check as described in chapter 7

9.2.5 Convection fan

• On the appliance, disconnect the electric wiring of the

convection fan (see fig. 17).

• Take out the screws from the lower cover plate at the

front of the appliance.

• Remove this plate.

• Remove the electric cable from the cable clips.

• Take out the 4 socket cap screws that are used to mount

the fan (see fig. 18).

• Remove the fan.

• Place the new fan in reverse order

Kamara

INSTRUCTIONS FOR INSTALLATION

15

Fig. 15

Fig. 16

Fig. 17

English

Page 18

9.2.6 Combustion fan

• Take out the clamp of the flexible flue gas discharge tube.

• Remove the flexible flue gas discharge tube.

• Take out the clamp that is used to mount the venturi tube

on the fan.

• Remove the venturi tube.

• Disconnect the air hose from the fan (positive measuring

point).

• Disconnect the electric wiring from the fan.

• Take out the 4 screws of the assembly plate (see fig. 6).

• Remove the fan assembly.

• Take out the 3 screws connecting the fan to the assembly

plate.

• Remove the fan

• Place the new fan in reverse order.

!Caution - Using new gaskets;

- Fix the venturi tube using heat-resistant

sealant and the clamp;

- Also fix the flexible discharge tube using the

sealant and the clamp;

- Make sure that the wiring is lying free from

the convection box and the fan house.

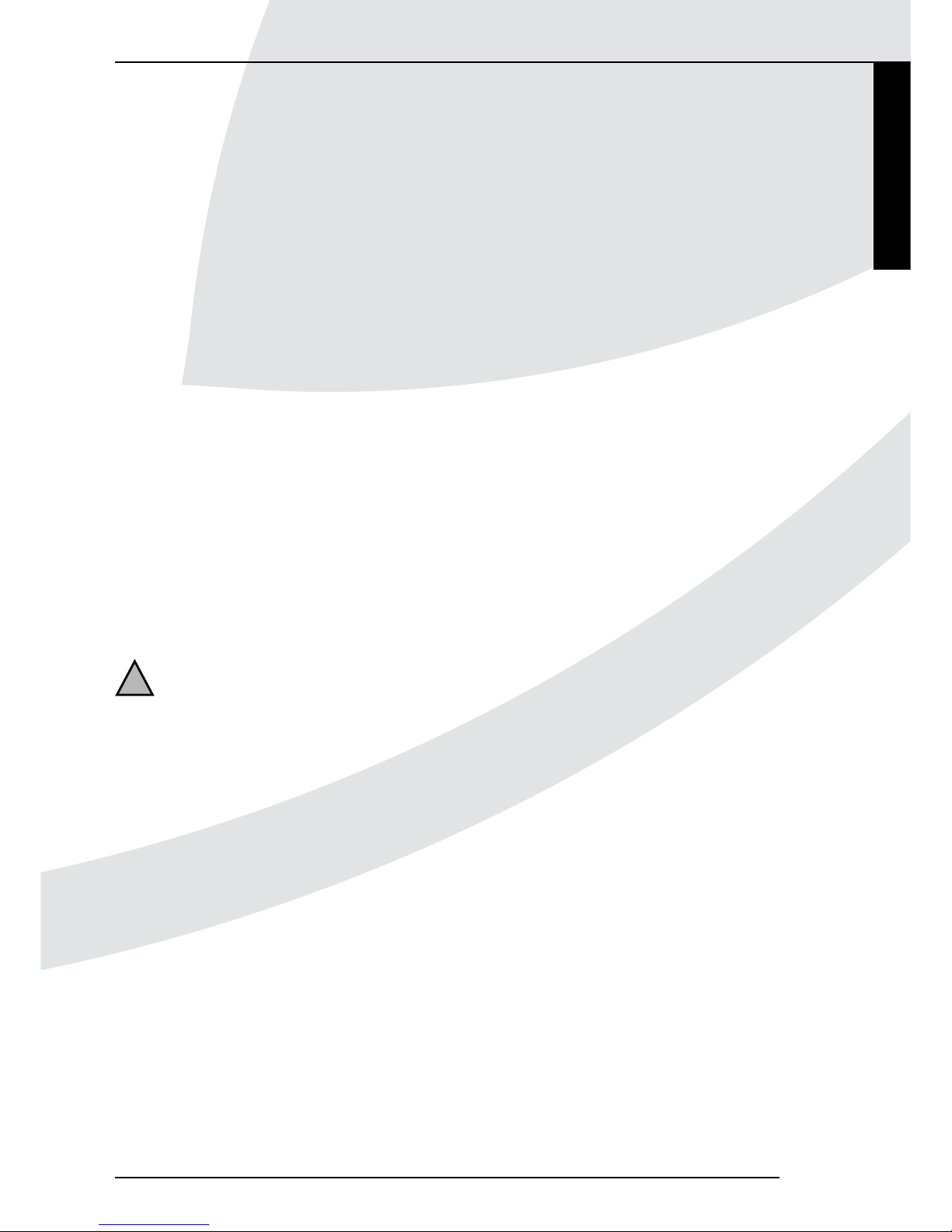

9.2.7 Temperature limit switch

(maximum thermostat)

• Disconnect the fast-on connections of the electrical

connection.

• Take out the 2 screws of the mounting plate (see fig. 19 of

Power Flue 12/16kW).

!Tip Only for Power Flue 7kW:

- Take out the 2 screws on the control panel

(see fig. 11);

- Slightly lift the panel;

- Take out the upper screw of the mounting

plate.

• Remove the switch.

• Place the new switch in reverse order.

!Caution For the Power Flue 16kW, 2 distance bushes

and a gasket are used.

9.2.8 Convection fan switch

• Disconnect the fast-on connections of the electrical

connection.

• Take out the 2 screws on the mounting plate (see fig. 19);

!Tip Only for Power Flue 7kW:

- Take out the 2 screws on the control panel

(see fig. 11);

- Slightly lift the panel;

- Take out the upper screw of the mounting

plate.

• Remove the switch.

• Place the new switch in reverse order.

9.2.9 Thermostat

• Take out the 2 screws on the control panel (see fig. 11).

• Slightly lift the control panel.

• Remove the thermostat.

• Disconnect the wiring.

• Place the new thermostat in reverse order.

INSTRUCTIONS FOR INSTALLATION

16

Fig. 18

Fig. 19

Page 19

Kamara

INSTRUCTIONS FOR INSTALLATION

17

9.2.10 NTC temperature sensor

The temperature sensor is located in the convection air

inlet, at the filter on the right side of the appliance.

• Take out the 2 screws on the control panel.

• Lift the control panel and slide it slightly to the side.

• Disconnect the wires of the temperature sensor on the

thermostat.

• Remove the temperature sensor.

• Place the new temperature sensor in reverse order.

9.2.11 Air pressure switch

• Take out the screws.

!Tip You can reach the screws through the

convection air inlet on the right side

• Disconnect the hoses.

• Disconnect the wiring.

!Caution - Remember how the hoses are connected;

- Remember how the wiring is connected;

- The setpoint of the air pressure switch

depends on the type of appliance.

• Remove the air pressure switch.

• Place the new air pressure switch in reverse order.

10. Delivery

You must explain the user how to operate the appliance.

You should instruct the user on using the appliance for

the first time, its operation and annual maintenance.

Caution - Tell the user to close the gas tap

immediately and switch off the all-pole

switch in case of malfunctions/bad

performance and contact the installer in

order to prevent dangerous situations;

- Indicate the location of the gas tap;

- Indicate the location of the all-pole switch.

• Instruct the user on how the appliance works.

• Remind the user that the appliance requires annual

maintenance.

• Give the user manual and installation manual to the user

(the installation manual should be kept near the appliance).

!

English

Page 20

18

TROUBLESHOOTING GUIDE

1. Set clock properly

2. Set thermostat correctly

3. Set the switch in the correct position

4. Switch on the all-pole switch

5. - First find the cause of the defective fuse

and remedy it

- Then replace the main fuse

6. - First find the cause of the defective fuse

and remedy it

- Then replace the appliance fuse

1. Clean filters

2. Check burner pressure;

If necessary, correct burner pressure

3. Check convection air circuit:

If necessary, unblock it.

4. Clean fan

5. Replace fan

1. Check gas supply

If necessary, repair gas supply

1. Replace the ignition cable

2. Replace the electrode pen

3. Check connections air pressure switch:

- Connect properly

- If necessary, replace the air pressure

switch

4. Replace fan

5. Unblock

6. Check the electric connections:

improve connections where necessary

Note: the automatic burner is phase

sensitive

7. Gap between electrode and burner should

be between 5 and 6 mm

7. Replace automatic burner

1. Set summer / winter switch to summer

position.

If convection fan switches on:

- Check and, if necessary, replace the

wiring

- If necessary, replace switch

2. Set summer / winter switch to summer

position

Convection fan also does not work in

summer position:

- Check and, if necessary, replace the

wiring

- If necessary, replace the fan

1. Check if life and neurtal are in the correct

possition, if necessary change

2. Check flue and terminal, if necessary

remove blockage

A. Appliance does not react/work

B. Temperature limit switch

(clixon 120 ºC) interferes

C. No gas

D. No ignition (spark)

E. Convection fan does not switch on

F. Burner ignite, but goes out in a few

seconds

1. Clock not set properly

2. Thermostat set incorrectly

3. Summer / winter switch in incorrect

position

4. All-pole switch switched off

5. Main fuse defective

6. Appliance fuse defective (on control

panel)

1. Very contaminated filters

2. Appliance overloaded

3. Convection air circuit blocked

4. Convection fan very dirty

5. Convection fan defective

1. Gas supply interrupted/stopped.

1. Ignition cable damaged

2. Electrode pen corroded

3. Air pressure switch does not function

4. Combustion gas fan very dirty

5. Flue gas discharge / combustion air supply

system blocked

6. Electric connections incorrect

7. Gap electrode / burner to small or to big

7. Automatic burner defective

1. Convection fan switch defective

2. Convection fan defective

1. Reversed plolarity

2. Partial or complete flue blockage

OBSERVED PROBLEM: POSSIBLE CAUSE: REMEDY:

11. MALFUNCTIONS

In the following table you will find an overview of malfunctions that might occur, the possible causes and the remedies.

Table 3 diagnosis of malfunctions

Page 21

19

Kamara

APPENDIX 1

Appendix 1 Parts included with the delivery

In the following table you can find the parts that are supplied with the appliance.

PART K7 K12 K16 ORDERNR.

Installation manual 1x 1x 1x 95762501

User manual 1x 1x 1x 95762401

Sealant 1x 1x 1x 907918

Standard hose clamp 50-70mm 2x 2x 2x 806656

Hose clamp (64-67mm) 2x 2x 2x 806763

Screws 8x 8x 8x 519456

Plugs 8x 8x 8x 929964

Washers 2x 2x 2x 525015

Exhaust hose I=600 St. Steel 1x 1x 1x 24124

Air inlet hose L=600mm Alu 1x 1x 1x 24126

Cable gland 1x 1x 1x 806695

Wall-terminal 1x 1x 1x 24115

Manifold 1x 1x 1x 806643

Restriction only k12 n.a 1x n.a. 806646

Restriction only k16 n.a. n.a. 1x 806647

Set of 2 lock keys 1x 1x 1x 806511

Silicon plug 1x 1x 1x 806818

English

Page 22

20

APPENDIX 2 ELECTRIC WIRING DIAGRAM

Appendix 2 Electric wiring diagram

white

red

black

5 6 7 8

24.1

23.1

25.1

25

A111 10 9 8 7 6 5 3 2 1

14 13

Page 23

Kamara

APPENDIX 3 TECHNICAL DATA APPENDIX 4 PARTS

21

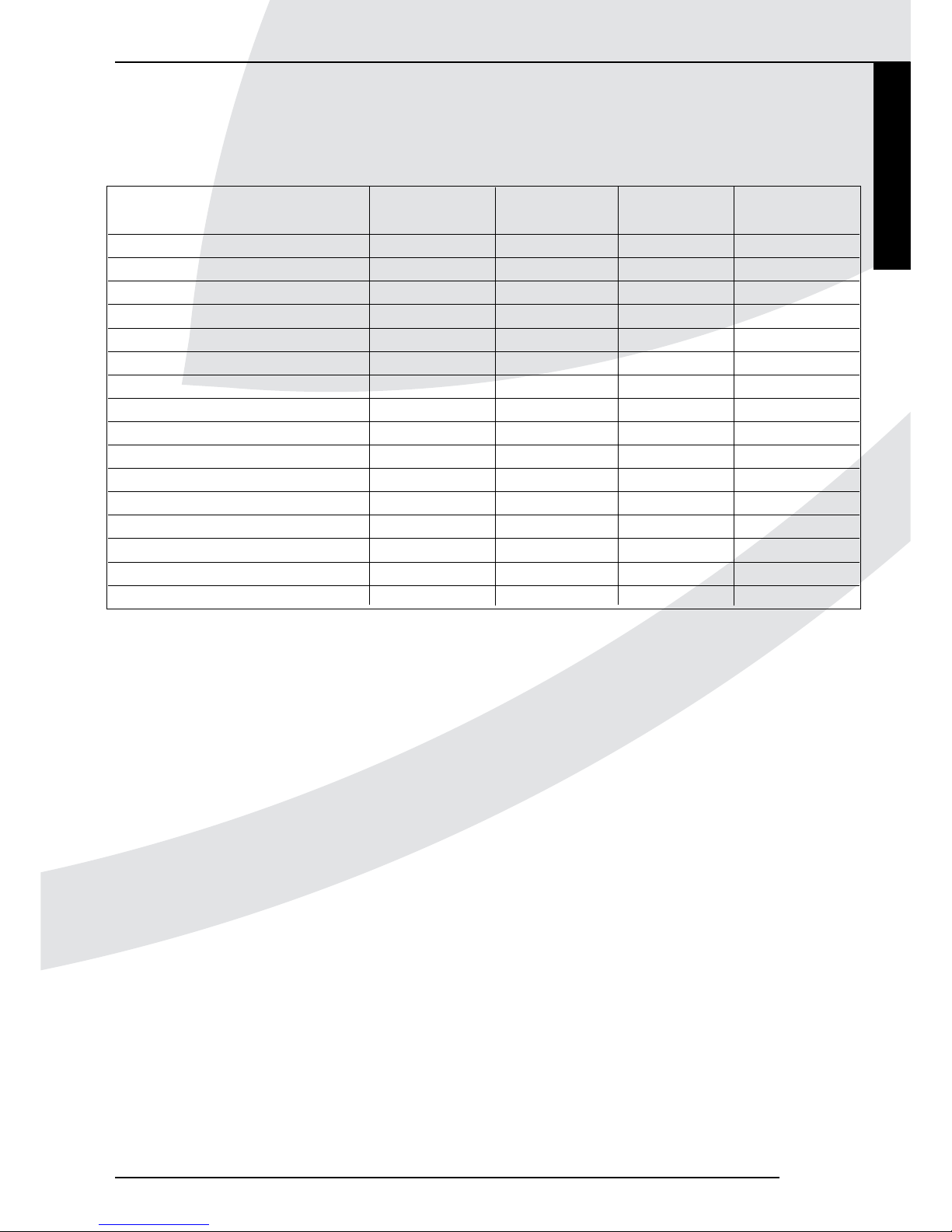

Appendix 3 Technical data

In the following table you can find the technical data.

Type 7kW 12kW 16kW

Type of gas G20 G31 G20 G31 G20 G31

Burner pressure mbar 13.4 26 17.9 28.9 18.7 29

Nom. load (Hs) kW 8.4 8.3 14.3 13.9 19.6 18.8

Nom. load (Hi) kW 7.6 7.6 12.9 12.8 17.6 17.4

Nom. output kW 7 7 12 11.8 16 15.7

Consumption L/h 785 305 1360 517 1875 704

Burner injector mm 2.25 1.55 2.7 1.9 3.15 2.25

Efficiency class 1 1 1 1 1 1

Appendix 4 Parts

Parts can be ordered through www.drugasar.co.uk

POWER FLUE

K7 230 - 240 Vac 50 Hz Rated power 140 W IP 20

K12 230 - 240 Vac 50 Hz Rated power 140 W IP 20

K16 230 - 240 Vac 50 Hz Rated power 155 W IP 20

English

Page 24

Page 25

INHOUD

Woord vooraf .......................................................................... 24

1. Inleiding ............................................................................ 24

2. CE-verklaring .................................................................. 24

3. VEILIGHEID .................................................................... 25

3.1 Algemeen ......................................................................... 25

3.2 Voorschriften.................................................................. 25

3.3 Voorzorgsmaatregelen / veiligheidsinstructies bij

installatie ......................................................................... 25

4. Uitpakken ........................................................................ 25

5. Installatie .......................................................................... 26

5.1 Voorschriften.................................................................. 26

5.2 Gassoort .......................................................................... 26

5.3 Gasaansluiting ................................................................. 26

5.4 Elektrische aansluiting ................................................. 26

5.5 Geveldoorvoer en verdeelstuk .................................. 26

5.6 Plaatsen van het toestel ............................................... 30

5.7 Verbrandingsgasafvoer- /

verbrandingsluchttoevoersysteem ........................... 30

5.8 Gas aansluiten ................................................................ 33

5.9 Ombouwen naar propaan ........................................... 33

5.10 Elektrische apparatuur aansluiten ..............................33

6. Bedienen van het toestel ............................................ 34

6.1 Bedieningspaneel ............................................................ 34

6.2 Toestel inschakelen voor verwarming ..................... 34

6.3 Toestel inschakelen voor luchtcirculatie ................. 34

6.4 Uitschakelen toestel ..................................................... 34

7. Eindcontrole ................................................................... 34

7.1 Gasdichtheid ................................................................... 34

7.2 Gasdruk / toevoerdruk ................................................ 34

7.3 Ontsteken van de brander .......................................... 35

7.4 Vlambeeld ........................................................................ 35

7.5 Verbrandingsgasafvoer/verbrandingsluchttoevoer . 35

8. Buitenbehuizing verwijderen / vervangen ................ 35

9. Onderhoud ..................................................................... 35

9.1 Aanwijzingen voor onderhoud ................................... 35

9.2 Onderdelen vervangen ................................................. 35

10. Oplevering ....................................................................... 39

11. Storingen ......................................................................... 40

Bijlage 1 Meegeleverde onderdelen ..................................41

Bijlage 2 Schema elektrische bedrading ..........................42

Bijlage 3 Technische gegevens ............................................43

Bijlage 4 Onderdelen ...........................................................43

Nederlands

Kamara

INHOUD

23

Page 26

Woord vooraf

Als fabrikant van gasverwarmingstoestellen ontwikkelt en

produceert DRU producten volgens de hoogst mogelijke

kwaliteits-, prestatie- en veiligheidseisen. De gebruiker kan

hierdoor rekenen op jarenlang gebruiksplezier.

Dit toestel heeft een CE merk; het voldoet daarmee aan

de essentiële eisen van de Europese Gastoestellenrichtlijn.

Als installateur dient u vakbekwaam te zijn op het gebied

van gasverwarming.

Bij het toestel worden twee handleidingen geleverd: de

installatiehandleiding en de gebruikershandleiding. De

installatiehandleiding geeft u de informatie die u nodig hebt

om het toestel zo te installeren dat het goed en veilig

functioneert.

Deze handleiding schenkt aandacht aan de installatie

van het toestel en de daarbij geldende voorschriften.

Daarnaast treft u technische gegevens van het toestel aan

en informatie over onderhoud, eventueel optredende

storingen en de mogelijke oorzaak hiervan.

U dient deze installatiehandleiding zorgvuldig te

lezen en te gebruiken.

In de handleidingen worden de volgende markeringen

gebruikt om belangrijke informatie aan te geven:

• Uit te voeren acties

!Tip Suggesties en adviezen

Let op Deze instructies zijn noodzakelijk ter

voorkoming van mogelijke problemen bij

installatie en/of gebruik.

Let op Deze instructies zijn noodzakelijk ter

voorkoming van brand, persoonlijk

letsel of andere ernstige schade.

Na oplevering dient u de gebruikershandleiding én

deze installatiehandleiding te overhandigen aan de

gebruiker.

1. Inleiding

De Power Flue is een gesloten gasverwarmingstoestel

met een geforceerde convectieluchtstroom en met

een geforceerde afvoer van de verbrandingsgassen.

Het toestel wordt geleverd in een uitvoering van 7

kW, 12 kW en 16 kW.Het apparaat wordt altijd tegen

een wand van onbrandbaar en hittebestendig materiaal

geplaatst. De doorlaat naar buiten vindt plaats middels de

geleverde geveldoorvoer. Bij toepassing van de standaardverbrandingsgasafvoer wordt de geveldoorvoer in dezelfde

wand aangebracht waartegen het toestel is geplaatst.

Het is mogelijk een verlengde verbrandingsgasafvoer te

gebruiken. Deze mag maximaal 10 meter lang zijn voor de

7kW en de 12kW uitvoering; voor de 16kW versie mag

de verlengde verbrandingsgasafvoer maximaal 3 meter lang

zijn.De verlengde verbrandingsgasafvoer kan zowel aan de

linker- als aan de rechterzijkant van het toestel worden

geplaatst. In de behuizing zijn hiervoor aan weerszijden

speciale knock-outs aangebracht. De onderdelen voor

de verlengde verbrandingsgasafvoer worden op verzoek

door Drugasar geleverd.Het toestel is bij levering afgesteld

voor gebruik van aardgas (G20). Op verzoek kan er een

ombouwset worden geleverd voor propaan (G31).

2. CE-verklaring

CE-verklaring Hierbij verklaren wij dat het door DRU

uitgebrachte gasverwarmingstoestel door zijn ontwerp

en bouwwijze voldoet aan de essentiële eisen van de van

toepassing zijnde EG-richtlijnen.

Deze verklaring verliest haar geldigheid als zonder

schriftelijke toestemming van DRU wijzigingen aan het

toestel worden aangebracht.

Product: gasverwarmingstoestel met geforceerde

convectieluchtstroom

Type: Power Flue

Van toepassing zijnde Europese richtlijnen:

90/396/EEC

2006/95/EC

89/336/EEC

Door bedrijfsinterne maatregelen is gewaarborgd dat

seriematig geproduceerde toestellen aan de essentiële

eisen van de van kracht zijnde EG-richtlijnen en de daarvan

afgeleide normen voldoen.

M.J.M. Gelten

Algemeen directeur

Dru verwarming B.V.

Postbus 1021, 6920 BA Duiven

Ratio 8, 6921 RW Duiven

www.dru.nl

INSTALLATIEHANDLEIDING

24

!

Page 27

3. Veiligheid

3.1 Algemeen

Let op - Lees dit hoofdstuk over veiligheid

zorgvuldig door,voordat u begint met

installatie- of onderhoudswerkzaamheden;

- Neem de algemene voorschriften

en voorzorgsmaatregelen /

veiligheidsinstructies in deze handleiding in

acht;

• plaats en/of gebruik het toestel niet in een vochtige

omgeving;• plaats bij het toestel een hoofdschakelaar met

een contactopening voor elke pool van ten minste 3 mm;

• sluit het toestel op aarde aan;

• zorg dat er geen elektriciteitskabels tegen het toestel

hangen;

• ontsteek het toestel niet voordat het volledig is

geïnstalleerd.

3.2 Voorschriften

• Installeer het toestel en de elektrische aansluitingen

volgens de geldende nationale, lokale en bouwkundige

(installatie)voorschriften. Deze zijn onder meer

opgenomen in:

- Gasveiligheid (Installatie en Gebruik) Voorschriften;

- B.S. 6891;

- B.S. 5871: Deel 1;

- B.S. 5440: Deel 1;

- B.S. 5440: Deel 2;

- Plaatselijke Bouwvoorschriften;

- I.E.E Bedradingsvoorschriften;

- Arbowet

3.3 Voorzorgsmaatregelen /

veiligheidsinstructies bij installatie

Volg de onderstaande voorzorgsmaatregelen /

veiligheidsvoorschriften zorgvuldig op:

• installeer en onderhoud het toestel alleen als u een

vakbekwame installateur op het gebied van gasverwarming

bent;

• breng geen wijzigingen aan het toestel aan;

• gebruik uitsluitend het door Drugasar geleverde materiaal

voor verbrandingsgasafvoer / verbrandingsluchttoevoer;

• plaats het toestel altijd tegen een wand van onbrandbaar

en hittebestendig materiaal;

• gebruik de muurbeugels bij het bevestigen van het toestel

aan de wand. Deze waarborgen de minimaal vereiste

afstand van 10 mm vanaf de achterwand;

• zorg ervoor dat het toestel voldoende afstand heeft tot

andere objecten en materialen (zie afb. 1). De vrije ruimte

rond het toestel is nodig voor de goede en veilige werking

en ook voor de toegankelijkheid bij onderhoud;

• zorg voor vrije uitstroom van warme convectielucht aan

de voorzijde van het toestel;

• zorg ervoor dat er aan beide zijden van het toestel een

vrije toevoer is van koude convectielucht. Gordijnen

zouden b.v. door de aanzuigende werking van de

convectieventilator de inlaat kunnen blokkeren;

• voorkom dat warme convectielucht recirculeert via de

inlaat voor koude convectielucht;

• dek het toestel en het afvoermateriaal niet af en/of pak

deze niet in met een isolatiedeken of enig ander materiaal;

• zorg dat alle gasleidingen en aansluitingen van binnen

schoon zijn;

• controleer alle aansluitingen op gasdichtheid voordat u het

toestel gaat gebruiken;

• plaats en/of gebruik het toestel niet in een vochtige

omgeving;

• plaats bij het toestel een hoofdschakelaar met een

contactopening voor elke pool van ten minste 3 mm;

• sluit het toestel op aarde aan;

• zorg dat er geen elektriciteitskabels tegen het toestel

hangen;

• ontsteek het toestel niet voordat het volledig is

geïnstalleerd.

4. Uitpakken

Schenk aandacht aan de onderstaande punten bij het

uitpakken van het toestel:

• Controleer het toestel op transportschade.

• Neem, indien nodig, contact op met Drugasar Service.

• Controleer of alle onderdelen meegeleverd zijn. In Bijlage

1 ziet u over welke onderdelen u moet beschikken nadat

u de verpakking hebt verwijderd.

• Neem contact op met Drugasar Service als u na het

uitpakken niet over alle onderdelen beschikt.

• Voer de verpakking af via de reguliere weg.

Kamara

INSTALLATIEHANDLEIDING

25

!

Fig. 1

Nederlands

Page 28

5. Installatie

Lees de handleiding zorgvuldig door om een goede en

veilige werking van het toestel te garanderen.

!Let op Installeer het toestel in de volgorde zoals in dit

hoofdstuk is beschreven.

5.1 Voorschriften

• Neem altijd de geldende nationale, lokale en bouwkundige

(installatie)voorschriften in acht, zowel voor het toestel als

voor de elektrische installatie.

• Houdt u zich aan de voorschriften/instructies zoals

vermeld in deze handleiding.

5.2 Gassoort

Gassoort Het typeplaatje geeft aan voor welk type gas,

welke gasdruk en voor welk land dit toestel bestemd

is. Het typeplaatje vindt u aan de linkerkant, op de

convectiekast. Het is zichtbaar na verwijdering van de

behuizing.

Het toestel kan worden omgebouwd naar propaan. De

gasdruk dient minimaal 30 mbar te bedragen. Zie voor

ombouw naar propaan, zie hoofdstuk 5.10.

• Controleer of het toestel geschikt is voor de gassoort en

gasdruk ter plaatse.

5.3 Gasaansluiting

Let op Avoid dirt in the gas tube and in the

connections.

Voor de gasaansluiting gelden de volgende eisen:

- dimensioneer de gasleiding zodanig dat geen drukverlies

kan optreden;

- de gaskraan, indien gebruikt, moet een CE-markering

hebben;

- de gaskraan moet altijd bereikbaar zijn.

5.4 Elektrische aansluiting

Voor de elektrische aansluiting gelden de volgende eisen:

- plaats bij het toestel een hoofdschakelaar met een

contactopening voor elke pool van ten minste 3 mm;

- de vereiste elektrische spanning bedraagt 230V/50Hz~;

gezekerd met 5A.

5.5 Geveldoorvoer en verdeelstuk

5.5.1 Positie geveldoorvoer/verdeelstuk

Plaatsing van geveldoorvoer/verdeelstuk direct achter het

toestel. (Voor meer informatie, zie hoofdstuk 5.7.2)

• Bepaal de plaats van het toestel; de afmetingen zijn

aangegeven in afb. 1 en 2.

Let op - Zorg ervoor dat het toestel voldoende

afstand heeft van andere objecten en

materialen. De vrije ruimte rond het

toestel is nodig voor de goede en veilige

werking en ook voor de toegankelijkheid

bij onderhoud.

- Plaats het toestel tegen een wand van

onbrandbaar en hittebestendig materiaal.

!Tip Het verdeelstuk heeft twee

verbrandingsluchttoevoeraansluitingen, zie

hoofdstuk 5.5.2!

!Tip Bepaal de positie van het toestel en de

aansluitingen door gebruik te maken van de

afmetingen in afb. 3a en 3b. Voor een voorbeeld

van een verlengde verbrandingsgasafvoer, zie afb. 8

• Bepaal de locatie van verdeelstuk/geveldoorvoer.

Let op Gebruik Tabel 2 om het aantal toegestane

bochten vast te stellen in combinatie met de

lengte van het afvoersysteem.

Let op - Laat de bochten in de flexibele

verbrandingsgasafvoerleiding en de

verbrandingsluchttoevoerslang zo vloeiend

mogelijk verlopen om de weerstand zo

gering mogelijk te houden;

- De geveldoorvoer is geschikt voor muren

met een dikte tot en met 400 mm;

Drugasar kan zo nodig een geveldoorvoer

voor muren met een dikte tot en met 900

mm leveren;

- Houd rekening met de eisen m.b.t. de

positie van de geveldoorvoer in de

buitengevel, zoals aangegeven in hoofdstuk

5.5.1.1.

- Zie ook hoofdstuk 5.7.3, voor de optie

met verlengde verbrandingsgasafvoer.

INSTALLATIEHANDLEIDING

26

!

Fig. 2

!

!

Page 29

Kamara

INSTALLATIEHANDLEIDING

27

De middenlijn van het verdeelstuk/de

geveldoorvoer moet worden geplaatst

binnen een van de frames van de

corresponderende verwarmer.

Nederlands

Page 30

5.5.1.1 Positie geveldoorvoer in buitengevel.

Het onderstaande schema en de bijbehorende grafiek

zijn ruwweg gebaseerd op BS5440:Deel 1:2000. Voor

aanvullende opmerkingen/toepassingen moet u deze BSInorm zelf raadplegen.

INSTALLATIEHANDLEIDING

28

Fig. 3b Fig. 3c

Page 31

Kamara

INSTALLATIEHANDLEIDING

29

Minimale afmetingen posities geveldoorvoer voor verbrandingsgasafvoer

Gesloten systeem met

afgesloten ruimte

Open systeem

Positie geveldoorvoer

Natuurlijke

trek

Geforceerde

trek

Natuurlijke trek

Geforceerde trek

A * Direct onder een opening, luchtsteen,

raam etc.

0-7kW >714kW >1432kW >3270kW

300 mm 600

mm 1500

mm 2000

mm

300 mm Niet

toegestaan

300 mm

B * Boven een opening, luchtsteen, raam etc. 0-7kW >7-

14kW >1432kW

>32-70kW

300 mm 300

mm 300 mm

300 mm

300 mm Niet

toegestaan

300 mm

C * Horizontaal t.o.v. een opening, luchtsteen,

raam etc.

0-7kW >714kW >1432kW

>32-70kW

300 mm 400

mm 600 mm

600 mm

300 mm Niet

toegestaan

300 mm

D Onder een goot of sanitaire leiding als

brandbaar materiaal is afgeschermd.

300 mm 75 mm Niet

toegestaan

75 mm

E Onder dakranden.

300 mm 200 mm Niet

toegestaan

200 mm

F

Onder balkons of vrijstaande gebouwen

zonder

afgewerkt plafond.

600 mm 200 mm Niet

toegestaan

200 mm

G Vanaf een verticale afvoer of grondleiding.

300 mm 150 mm Niet

toegestaan

150 mm

H Vanaf een interne of externe hoek.

600 mm 300 mm Niet

toegestaan

200 mm

I Boven grond of balkonniveau.

300 mm 300 mm Niet

toegestaan

300 mm

J Vanaf een oppervlak tegenover

geveldoorvoer.

600 mm 600 mm n.v.t.

600 mm

K Vanaf een andere geveldoorvoer tegenover

de geveldoorvoer.

600 mm 1200 mm n.v.t.

1200 mm

L Vanaf een opening in de carport naar een

woning.

1200 mm 1200 mm n.v.t.

1200 mm

M Verticaal vanaf een geveldoorvoer aan

dezelfde gevel.

1500 mm 1500 mm n.v.t.

1500 mm

N Horizontaal vanaf een geveldoorvoer aan

dezelfde gevel.

300 mm 300 mm n.v.t.

300 mm

O Vanaf een gevel waaraan de geveldoorvoer

is gemonteerd.

n.v.t.

n.v.t.

n.v.t.

50 mm

P Vanaf een verticale constructie op het dak.

n.v.t.

n.v.t.

600 mm n.v.t.

Q Boven kruising met dak.

n.v.t.

n.v.t.

600 mm 150 mm

N.B.: n.v.t. = niet van toepassing * Bovendien, mag de geveldoorvoer niet dichter dan 150mm (geforceerde trek) of 300mm (natuurlijke trek) bij een

opening in de gebouwconstructie worden aangebracht die bedoeld is voor een inbouwelement, zoals een raamkozijn. De vrije afstanden zijn gerelateerd

aan de vermelde nominale warmtevermogens.

Nederlands

Page 32

5.5.2 Installatie van geveldoorvoer en

verdeelstuk

Ga bij het installeren van geveldoorvoer en verdeelstuk als

volgt te werk:

• Boor een gat in de muur, met een diameter van 105 mm.

• Boor aan de buitenzijde van de muur 3 gaten, voor

bevestiging van de geveldoorvoer.

!Let op - Plaats de geveldoorvoer met de ril/felsnaad

aan de bovenkant;

• Plak de afdichting/pakking van de geveldoorvoer aan de

flens.

• Bevestig de geveldoorvoer tijdelijk vanaf de buitenkant.

• Schuif het verdeelstuk vanaf de binnenzijde zo ver mogelijk

op de concentrische pijpen van de geveldoorvoer.

• Bepaal de afstand tussen verdeelstuk en muur.

• Schroef de geveldoorvoer weer los.

• Zaag de geveldoorvoer op maat.

• Monteer de geveldoorvoer definitief.

• Bepaal onder welke hoek het verdeelstuk moet worden

geplaatst.

• Breng een ruime hoeveelheid van het hittebestendige

dichtingsproduct aan op de buitenkant van de

verbrandingsluchttoevoerleiding van gegalvaniseerd staal.

• Breng een laagje hittebestendig dichtingsproduct aan op de

binnenkant van de aluminium verbrandingsgasafvoerleiding.

• Plaats de afdichting/pakking van het verdeelstuk tussen

muur en verdeelstuk.

!Tip U kunt bij het verdeelstuk uit twee aansluitingen

voor de verbrandingsluchttoevoer kiezen.

• Breng het verdeelstuk aan in de juiste positie.

• Boor 3 gaten in de muur voor bevestiging van het

verdeelstuk.

• Bevestig het verdeelstuk met de meegeleverde schroeven

en sluitringen.

• Breng zo nodig een doorvoerbescherming aan.

• Plaats de doorvoerbescherming centraal over de

geveldoorvoer.

5.6 Plaatsen van het toestel

Het plaatsen van het toestel gebeurt als volgt:

Let op - Breng geen wijzigingen aan het toestel aan;

- Dek het toestel en de afvoeren niet af en/

of pak deze niet in met een isolatiedeken

of enig ander materiaal;

- Bevestig het toestel aan de wand met

behulp van de muurbeugels;

- dit waarborgt de minimaal vereiste afstand

van 10 mm vanaf de achterwand;

- Zorg voor vrije uitstroom van warme

convectielucht aan de voorzijde van het

toestel;

- Zorg voor vrije toevoer van koude

convectielucht aan beide zijden van

het toestel. Gordijnen zouden b.v.

door de aanzuigende werking van de

convectieventilator de inlaat kunnen

blokkeren;

- Voorkom dat warme convectielucht

recirculeert via de inlaat voor koude

convectielucht.

!Tip - Voorkom dat bouwgruis/boorstof het toestel

vervuilt;

- Monteer de behuizing pas nadat de laatste controle

in hoofdstuk 7 is verricht.

• Zorg voor een gasaansluiting op de locatie. Raadpleeg

voor meer details hoofdstuk 5.3.

• Zorg voor een elektriciteitsaansluiting op de locatie.

Raadpleeg voor meer details hoofdstuk 5.4.

• Verwijder de behuizing:

- Draai de schroeven aan weerszijden van de behuizing los

(zie Afb. 4);

- Til de behuizing ca. 1 cm omhoog en schuif/til de behuizing

naar voren.

Let op Beschadig de bedrading niet bij het

verwijderen van de behuizing.

• Zet het toestel op de bestemde plek.

• Boor gaten voor de bevestiging van het toestel.

• Bevestig het toestel aan de muur, met de geleverde

pluggen, afdichtringen en schroeven.

5.7 Verbrandingsgasafvoer- /

verbrandingsluchttoevoersysteem

5.7.1 Constructie

Voor de Power Flue van 7kW en 12kW is de maximale

lengte van de afvoerpijpen (verticaal en horizontaal)

10 meter bij gebruik van maximaal 2 bochten van 90º;

wanneer er 3 bochten van 90º worden toegepast, bedraagt

de totale lengte van het afvoersysteem maximaal 6 meter

INSTALLATIEHANDLEIDING

30

!

!

Fig. 4

Page 33

en bij toepassing van 4 bochten van 90º is de lengte

maximaal 2 meter.

Voor de Power Flue van 16kW is de maximale lengte van

de afvoerpijpen (verticaal en horizontaal) 3 meter, met

maximaal 1 bocht van 90º.

Afhankelijk van de uitvoering moet het toestel worden

afgesteld met behulp van een restrictie.

Bij de 7kW uitvoering is de (geleverde) restrictie

op de verbrandingsventilator bevestigd. Denk erom

dat de restrictie onderdeel is van de venturi op de

verbrandingsventilator.

Voor de Power Flue 7kW bedraagt de restrictie 22,5 mm

bij toepassing van aardgas en propaan.

In Tabel 2 hieronder, ziet u de vereiste instellingen

van de restrictie afhankelijk van de opbouw van het

afvoersysteem en het type gas dat wordt gebruikt.Bij de

12kW en 16kW versie wordt de restrictie zo nodig in

de verbrandingsgasafvoerverbinding van het verdeelstuk

aangebracht, met hittebestendig dichtingsproduct.

(zie afb. 7).

Bij de Power Flue 12kW is alleen een restrictie nodig als

het toestel direct op de geveldoorvoer wordt aangesloten.

Bij toepassing van aardgas is de restrictie 36 mm en bij

propaan 45 mm.

Bij de Power Flue 16kW, is een restrictie van 45 mm

alleen nodig in het geval van een directe verbinding met de

geveldoorvoer. Deze waarde geldt voor het gebruik van

zowel aardgas als propaan.

Kamara

INSTALLATIEHANDLEIDING

31

,y g

Type

Gassoort

Aantal bochten

van 90°

Buislengte

(meter)

Restrictie

(mm)

Opmerkingen

7kW G20/G31 0 0 22,5 Directe aansluiting op geveldoorvoer

0 1-10 22,5

1 1-10 22,5

2 1-10 22,5

3 1-6 22,5

4 1-2 22,5

Restrictie is vast onderdeel van

venturibuis

12kW G20 0 0 36 Directe aansluiting op geveldoorvoer

0 1-10 geen

1 1-10 geen

2 1-10 geen

3 1-6 geen

4 1-2 geen

G31 0 0 45 Directe aansluiting op geveldoorvoer

0 1-10 geen

1 1-10 geen

2 1-10 geen

3 1-6 geen

4 1-2 geen

16kW G20/G3I 0 0 45 Directe aansluiting op geveldoorvoer

0 1-3 geen

1 1-3 geen

Table 2: Relatie tussen restrictie, afvoersysteemconstructie en gassoort

Nederlands

Page 34

5.7.2 Plaatsen standaard

verbrandingsgasafvoerset

Let op Gebruik uitsluitend de door Drugasar

geleverde standaard verbrandingsgas-

afvoerset.

!Let op - De snijranden van de flexibele

verbrandingsgasafvoerleiding zijn scherp;

- Laat de bochten in de flexibele

verbrandingsgasafvoerleiding en de

verbrandingsluchttoevoerslang zo vloeiend

mogelijk verlopen om de weerstand zo

gering mogelijk te houden;

- De Power Flue 16kW heeft 2

verbrandingsluchttoevoeraansluitingen op

het toestel. Deze dienen beide te worden

aangesloten en via een T-stuk te worden

gecombineerd (zie Afb. 5).

Volg de onderstaande stappen bij het aanbrengen van de

standaard verbrandingsgasafvoerset:

• Maak de flexibele verbrandingsgasafvoerleiding op maat

• Breng aan één kant van de flexibele

verbrandingsgasafvoerleiding het hittebestendige

dichtingsproduct aan in de rillen aan de binnenzijde.

• Breng de slangklemmen aan

• Schuif de flexibele afvoerleiding op de venturi-buis die op

de verbrandingsventilator is bevestigd (zie Afb. 6).

• Volg voor het aansluiten van de flexibele

verbrandingsleiding op het verdeelstuk dezelfde werkwijze.

• Maak de slangklemmen vast.

• Maak de flexibele verbrandingsluchttoevoerslang op maat.

• Sluit deze slang aan op het toestel en op het verdeelstuk

met behulp van de meegeleverde slangklemmen.

• Dicht de ongebruikte verbrandingsluchttoevoeraansluiting

op het verdeelstuk af met behulp van de geleverde

siliconenplug.

5.7.3 Verlengde verbrandingsgasafvoer

plaatsen

Let op - Monteer de verbrandingsgasbuizen zodanig

dat zij naar het toestel toe aflopen.

- Plaats een condensaatafvoer met

zwanenhals in het starre gedeelte van het

afvoersysteem als de totale lengte meer

dan 3 meter bedraagt;

- Installeer de condensaatafvoer binnen 3

meter van het toestel, maar bij voorkeur

zo dicht mogelijk bij het toestel.

!Let op - Sluit starre leidingstukken/bochten aan

op het verdeelstuk. U mag de flexibele

afvoerleiding / luchttoevoerslang alleen op

het toestel gebruiken;

- Voorkom dat bouwgruis/boorstof het

toestel vervuilt.

!Tip De verlengde verbrandingsgasafvoer kan

zowel links als rechts van het toestel

worden geplaatst.

Ga als volgt te werk bij het installeren van de verlengde

verbrandingsgasafvoer (zie Afb. 8):

• Monteer de benodigde beugels voor de starre aluminium

verbrandingsgasafvoerleiding én de starre aluminium

verbrandingsluchttoevoerleiding.

• Zie ook Afb. 3b voor de mogelijke posities van de

leidingen.

• Monteer de leidingen en alle bochten van star aluminium.

• Sluit de flexibele afvoerleiding/luchttoevoerslang

aan zoals hierboven is beschreven bij de standaard

verbrandingsgasafvoerset, sie hoofdstuk 5.7.2

INSTALLATIEHANDLEIDING

32

!

Fig. 5

Fig. 6

Fig. 7

!

Page 35

5.8 Gas aansluiten

Ga voor het aansluiten van het gas als volgt te werk; zie

hiervoor ook hoofdstuk 5.3, Gasaansluiting:

!Tip De gasaansluiting kan zowel aan de linker- als

aan de rechterzijkant van het toestel worden

aangesloten.

• Blaas, indien nodig, de gasleiding door.

• Sluit de gasleiding met gaskraan aan op de leiding van

15mm op het toestel.

!Let op Verdraai de gaskraan niet bij het aansluiten van

de gasleiding.

• Ontlucht de gasleiding.

5.9 Ombouwen naar propaan

Zo nodig kan het toestel worden omgebouwd voor

gebruik van propaan.

Hiertoe dient het spuitstuk te worden vervangen en moet

de branderdruk worden aangepast.

Ga hierbij als volgt te werk:

Let op - Sluit de gaskraan;

- Schakel de hoofdschakelaar uit;

- Verwijder de hoofdzekering.

• Verwijder de ontstekingsdop.

• Verwijder de afdichting rond de elektrodepen.

• Draai de 4 schroeven los van de afdekplaatjes die om de

gasleiding en ontstekingspen zitten (zie Afb. 9).

• Verwijder de afdekplaatjes.

• Draai de messing koppeling van de gasleiding onder de

elektrodepen los.