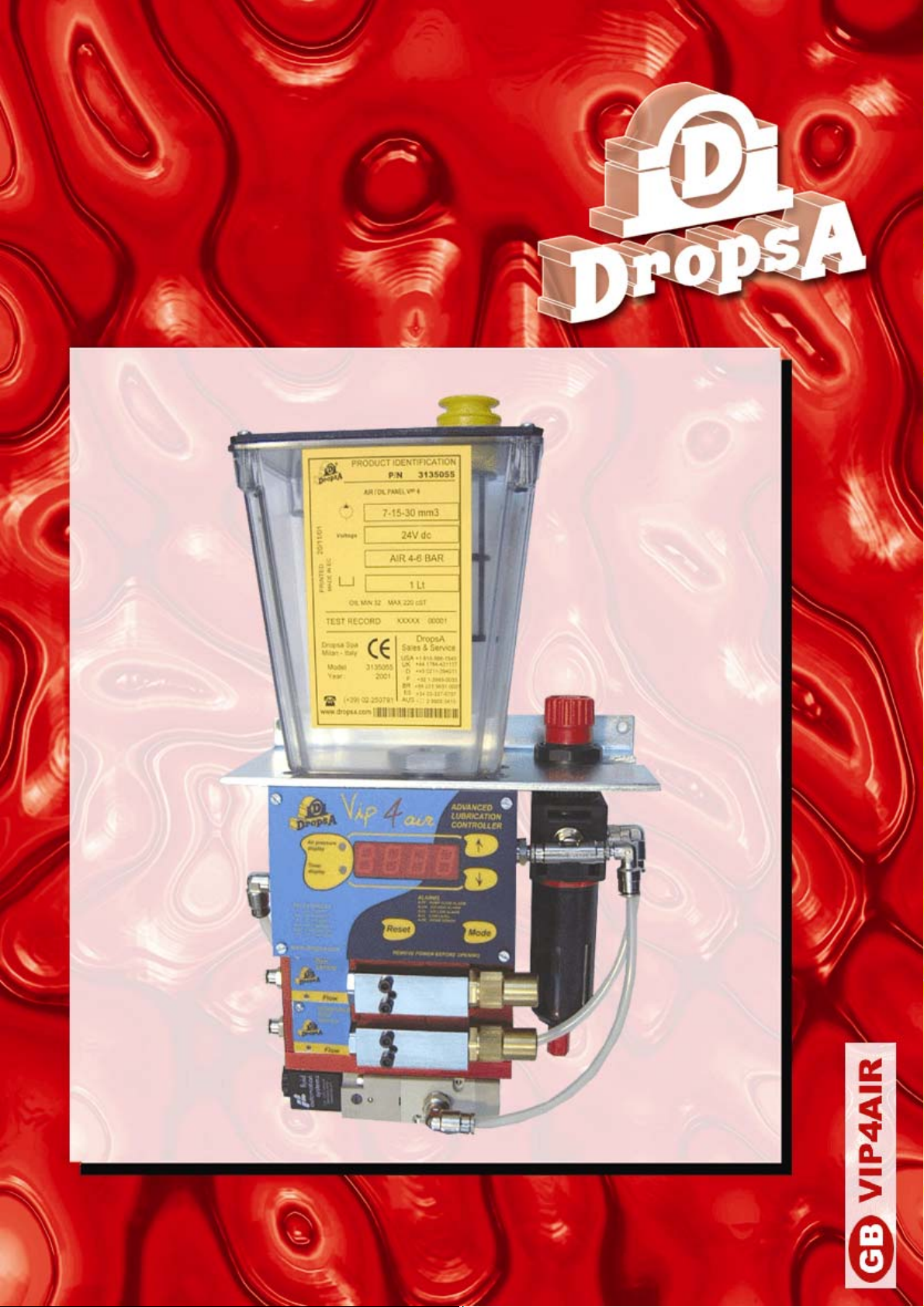

DROPSA VIP4Air Series, VIP4Air 110 V AC, VIP4Air 24 V DC User And Maintenance Manual

VIP4Air

Minimal Air/Oil

Lubrication System

Automatic Lubrication Systems

The VIP4Air is the most complete and compact

A

A

Minimal Air/Oil Lubrication System available today.

ir/Oil Minimal lubrication is a relatively new technology that has

been used successfully to substitute costly Oil Re-circulation and

non environmentally-sound Mist Systems.

It has provided excellent results both in terms of performance and

total system cost.

It is ideal for use on Bearings, High Speed Bearings, Gears and

also in certain circumstances on Guides. It is particularly suited to

Spindle Lubrication.

In the past, excessive oil has been used often only to ensure that

the ‘system is working’. This oil generates heat and has to be

collected away from the lubrication point.

Dropsa has taken the ‘minimal lubrication’ concept one step further

with the VIP4Air that can achieve ultra-low volume oil discharge

and at the same time provide electronic monitoring (using a custom

designed differential flow sensor integrated into the unit). This

allows true minimal lubrication by applying micro-amounts of

lubricants at more frequent intervals whilst giving positive feedback

that oil is correctly being injected and mixed into the air stream.

The VIP4Air System contains all components necessary to

achieve and monitor optimum minimal Air/Oil Lubrication.

PRODUCT FEATURES :

• 1 – 8 Lubrication Points each with independent monitoring

• 0.005 – 0.030 cm3 (0.0003 – 0.0018 cu.in) of oil per discharge

(standard settings 7-15-30 mm

3

)(0.0004 – 0.0009 – 0.018 cu.in).

• Tamperproof adjustment ‘rings’ avoids end-user modifications.

• Integrated Differential Flow sensor gives positive feedback of

Air/Oil lubrication.

• Fully Electronic Controls = quick Set-up and interfacing to host.

• Integrated Mixing Air Pressure Transducer provides accurate

and quick setting of Air Pressure on the electronic display, as

well as providing alarms for blocked or broken lubrication lines

via high/low air pressure monitoring.

• Automated Priming Sequence for quick and easy installation.

• Integrated & Compact – Connections are internal to the unit

Air/Oil Minimal Lubrication :

Continuous Air Flow: Cyclic micro-oil Injection:

Provides Cooling

Provides Transport Medium

Prevents Contamination and

ingress of water or dirt.

Reduces friction

Minimal quantities avoid

‘churning’ and heat generation.

No Excess Oil

Frequent lubrication intervals

help thermal stability of system.

Dropsa is a leading international manufacturer of Automatic

Lubrication Systems and can assist with a wide range of technical

and application advice, systems and components. Contact one of

our offices or distributors for more information.

N°

Pumps

VIP4Air 24 V DC VIP4Air 110 V AC

1 3135064 3135065

2 3135055 3135056

3 3135067 3135068

4 3135070 3135071

5 3135073 3135074

6 3135076 3135077

7 3135079 3135080

8 3135082 3135083

ttention: connector not included, to be ordered

separately; connector, p/n 1639115 + cable 2 mt

Technical Characteristics

VIP4Air Lubrication System

Voltage

Power

Air Pressure Inlet

Output Signal

Operating

Temperature

Humidity

Protection

Lubricants

Oil Viscosity

Reservoir capacity

Elements Y X Z Depth

24 V DC

110 V AC

10 W

5 ÷ 8 bar

(73.5 ÷ 117.6 psi)

Remote Alarm

relay: max 250 V

1 A NO / NC

-5 ÷ +55 °C

(23 ÷ 131°F)

90% max

IP-44

Mineral Oils

32 ÷ 220 cSt

(150 ÷ 1018 SUS)

1 lt

1 331

2 359

3 387

4 415

5 443

200 125

270

6 471

7 499

8 527

Web site:

http://www.dropsa.com

E-mail:

sales@dropsa.com

WK 32/03

C2033PE

ITALIA

Dropsa SpA

t.(+39) 02-250791

f.(+39) 02-25079767

ESPAÑA

Polydrop, S.A.

t.(+34) 93-260-22-50

f.(+34) 93-260-22-51

U.S.A.

Dropsa Corporation

t.(+1) 586-566-1540f.(+1) 586-566-1541

U.K.

Dropsa (UK) Ltd

t.(+44) 01784-431177

f.(+44) 01784-438598

BRAZIL

Dropsa

t.(+55) 011-563-10007

f.(+55) 011-563-19408

GERMANY

Dropsa Gmbh

t.(+49) 0211-394-011

f.(+49) 0211-394-013

AUSTRALIA

Dropsa Australia Ltd.

t.(+61) 02-9938-6644

f.(+61) 02-9938-6611

FRANCE

Dropsa Ame

t.(+33) 01-3993-0033

f.(+33) 01-3986-2636

VIP4Tools

LUBRICATION SYSTEM

User and

Maintenance Manual

Warranty Information

TABLE OF CONTENTS

1. INTRODUCTION

2. IDENTIFICATION

3. GENERAL DESCRIPTION

4. DESCRIPTION OF COMPONENTS

5. TECHNICALSPECIFICATION

6. HANDLING AND TRANSPORT

7. PRECAUTION IN USE

8. CONTRAINDICATIONS

9. INSTALLATION

10. INSTRUCTIONS FOR USE

11. MAINTENANCE

12. DISPOSAL

13. REPLACEMENT PART LIST

14. DIMENSIONS VIP 1 LITER

15. DIMENSIONS VIP 3 LITER

16. GARANTEE

17. DECLARATION OF CONFORMITY

18. DISTRIBUTORS

http://www.dropsa.com

Manufacturer

Product VIP4Tools

Year 2001

Certification

DropsA SpA

Manual drawn up in accordance with CE

Directive 98/37 Att. I, paragraph 1.7.4

C2040IE - WK 51/02

1. INTRODUCTION

This user’s and maintenance manual refers to VIP4Tools air/oil lubrication system.

This manual should be conserved in such a way that it remains undamaged over time and is readily

available to personnel needing to consult it.

Further copies of this manual, updates or clarifications can be obtained by directly contacting the

Technical Sales Office at Dropsa.

The manufacturer reserves the right to update the product and/or the user’s and maintenance manual

without the obligation to revise previous versions. It is however, possible to contact the Technical

Sales Office for the latest revision in use, or to consult our web site at http://www.dropsa.com.

The use of the equipment referred to in this manual must be entrusted to qualified personnel with a

basic knowledge of mechanics, hydraulics and electrical systems.

It is the responsibility of the installer to use tubing suitable for the system; the use of inadequate

tubing can cause problems with the pump, injury to persons and create pollution.

Loosening of connections can cause serious safety problems; carry out a check before and after

installation and, if necessary retighten them.

Never exceed the maximum working pressure values permitted for the panel and the components

connected to it.

Before any maintenance or cleaning operation disconnect the power supply, close off the air supply

and discharge the pressure from inside the equipment and the tubing connected to it.

Do not subject the panel, the connections, the tubing or parts under pressure to violent impacts;

damaged tubing or connections are dangerous and should be immediately replaced.

After long periods of inactivity check air tightness of all parts subjected to pressure.

Personnel must use personal protection equipment, clothing and tools adequate for the location and

the use of the panel both during its operation and during maintenance operations.

The panel, and any accessories mounted on it, should be carefully checked immediately on receipt

and in the event of any discrepancy or complaint the Dropsa SpA Sales department should be

contacted without delay.

Dropsa SpA declines to accept any responsibility for injuries to persons or damage to property in the

event of the non-observance of the information presented in this manual.

Any modification to component parts of the system or the different destination of use of this system or

its parts without prior written authorization from Dropsa SpA will absolve the latter from any

responsibility for injury to persons and/or damage to property and will release them from all

obligations arising from the guarantee

2. IDENTIFICATION OF THE MACHINE

A yellow plate showing the product code and the basic characteristics is mounted on the front of the

oil tank.

3. GENERAL DESCRIPTION

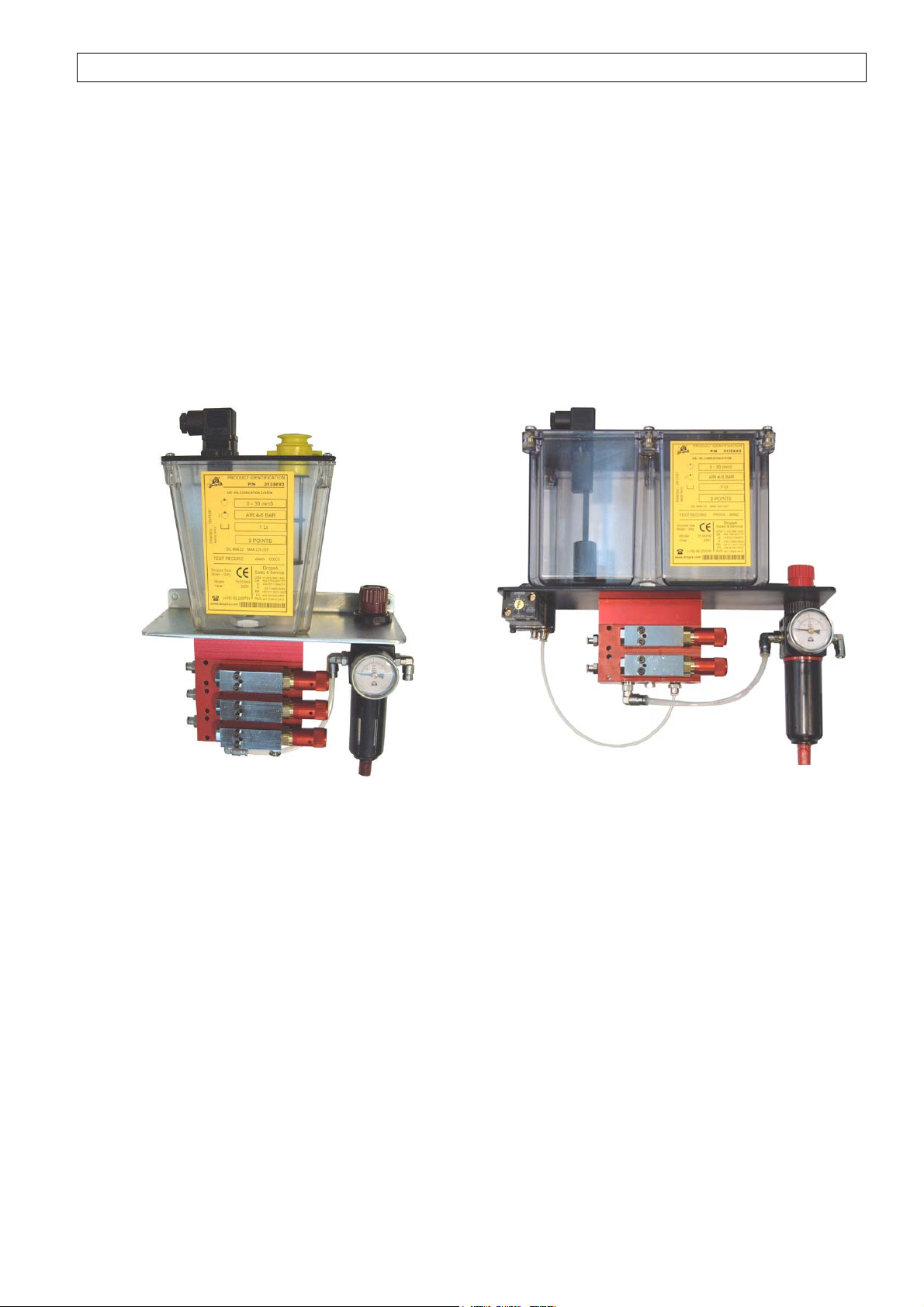

The VIP4Tools panel is to be utilized for ‘on mandrel’ applications, without controls on the machine,

for the lubrication of tooling and chains.

Designed for high performance at a low cost, it is distinguished by its compactness.

The system comprises a pneumatically controlled mini-pump and the mixer base. The mini-pump can

be manually regulated to cover a wide range of needs (0-30 mm³). The modular design of the system

makes it extremely versatile; up to a maximum of 8

timed by adding the pneumatic impulse generator kit P/N 3132572 or by controlling it from the

machine PLC.

mixer bases can be installed. The system can be

2

4. DESCRIPTION OF COMPONENTS

Central VIP4Tools Unit

The central unit of the lubrication system is composed of the following items:

• a Tank, made of transparent plastic material, compatible with lubricants on the market.

• a System for the regulation of the mixer air

• a modular Subframe

• a Samba type Minimum level indicator,

• an adjustable Mini-pump

1 Liter tank

3 Liter tank

ES:(version complete with timer kit)

3

Loading...

Loading...