DROPSA MiQueL EXT, MiQueL EXT PRO - i, MiQueL EXT BASE, MiQueL EXT BASE - i, MiQueL EXT PRO User Operating And Maintenance Manual

http://www.dropsa.com

MiQueL EXT

Air/oil modular minimal system

With external pump

User Operating and

Maintenance Manual

Original text translation

Warranty Information

CONTENT

1. INTRODUCTION

2. GENERAL DESCRIPTION

3. IDENTIFICATION OF THE MACHINE

4. TECHNICAL FEATURES

5. MACHINE COMPONENTS

6. UNPACKING AND INSTALLATION

7. INSTRUCTIONS FOR USE

8. PROBLEMS AND SOLUTIONS

9. MAINTENANCE PROCEDURES

10. DISPOSAL

11. ORDER INFORMATION

12. DIMENSIONS

13. HANDLING AND TRANSPORT

14. PRECAUTIONS FOR USE

15. OPERATIONAL HAZARDS

16. WARRANTY

17. DECLARATION OF COMPLIANCE

18. DISTRIBUTORS

The manual has been prepared in compliance with Directive C2168IE – WK 01/12

EC 06/42

2

1. INTRODUCTION

Serbatoio pressurizzato

(Optional)

1

2

3

4 5 5

6

7

This user and maintenance manual relates to the MiQueL EXT.

Using this pump means that oils and greases can be distributed within lubrication systems even at high pressures of up to 400

bar (5880 psi).

The latest version may be obtained from the Technical-Commercial Office, or by consulting our web site

http://www.dropsa.com.

The pump subject of this manual must be used by qualified personnel with basic hydraulic and electrical knowledge.

This user and maintenance manual contains important information about protecting the health and safety of the personnel who

intend to use this apparatus. You must read and look after it carefully, making sure that it is available at all times for the

operators who intend to consult it.

2. GENERAL DESCRIPTION

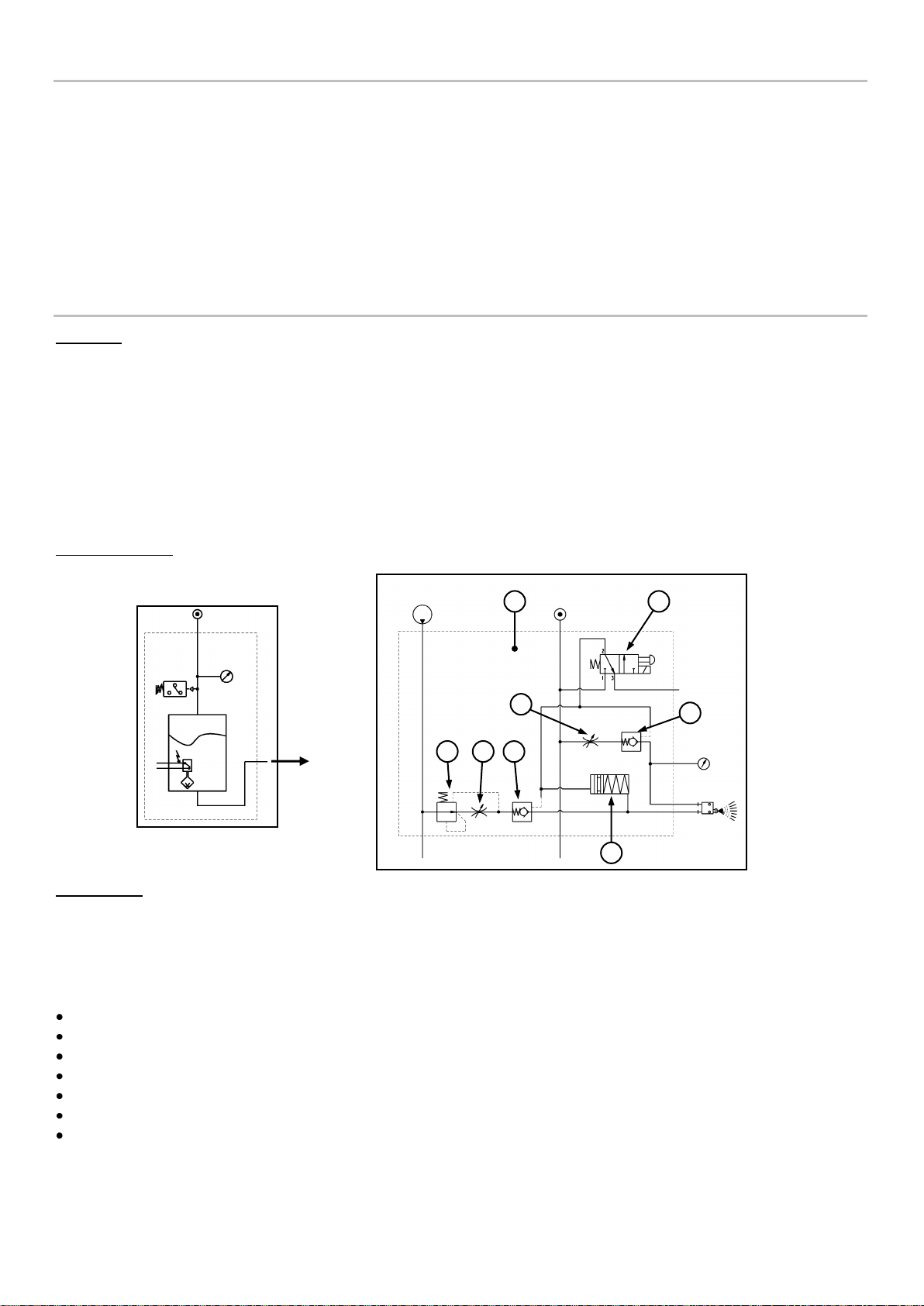

Operation

The system consists of a pressurised lubricant tank, one or more mixture regulation modules, pipes and spray nozzles (see

hydraulic diagram below).

The lubricant is sent to mixing valve through an external pump or a pressurised reservoir.

Each module has oil and air check valves that are controlled manually by the operator. The outward oil and air flow can

be managed independently between the different modules using a mini solenoid valve (“-i”version only) that activates the

control valves on the module. The module has a compensation valve (“PRO” version only) is able to keep the flow rate

constant as the inlet tank pressure and outlet counter-pressure varies.

The lubrication pipes can be traditional or coaxial. In the latter case, the lubricant and nebulisation air are transported

separately to the nozzle. The piston keeps the oil from dripping from the nozzle when the lubrication operation is complete.

Hydraulic diagram

Spray nozzles

When traditional pipes are used, the air and oil are already mixed when they arrive at the nozzle.

If coaxial pipes are used, the nozzle mixes the air and oil at the point to be lubricated. The lubricant is atomised in minuscule

particles by the air flow that passes in front of the oil outlet hole.

The geometry of the nozzle is designed based on the type of spray to be obtained (conic, blade-shaped, etc.).

Advantages

Easy to install on the machine

Reduction in tool wear

Improved surface finish on the part

No lubricant residuals left on the part when the work is complete

The nozzles do not drip after being turned off

Large spray range (up to 300 mm)

Greater safety and environmental hygiene at the workplace

3

Application

TECHNICAL SPECIFICATIONS

Pumping system

External pump

Maximum number of modules

8

Maximum Oil inlet pressure

2,5:1 in relation with air inlet pressure

Air inlet pressure

4bar ÷ 7bar [87psi ÷ 101,5psi]

Maximum air consumption at the outlet

~50Nl/min (per module)

Air inlet pipe

Ø6mm

Oil inlet pipe

Ø6mm

Air outlet pipe

Ø6mm

Oil outlet pipe

Ø3mm

Oil flow rate per element (with compensation valve)

0 ÷ 2cc/min (oil 10cSt ÷ 32 cSt)

0 ÷ 0,5cc/min (oil 32cSt ÷ 100 cSt)

Lubricant

10cSt ÷ 100cSt

Pressure switch calibration

6bar [87psi]

Element solenoid valve power supply

24Vdc

Operating temperature

+5°C ÷ +50°C

Storage temperature

-10°C ÷ +80°C

Max relative humidity without operating condensate

90%

Sound level pressure

< 70 db (A)

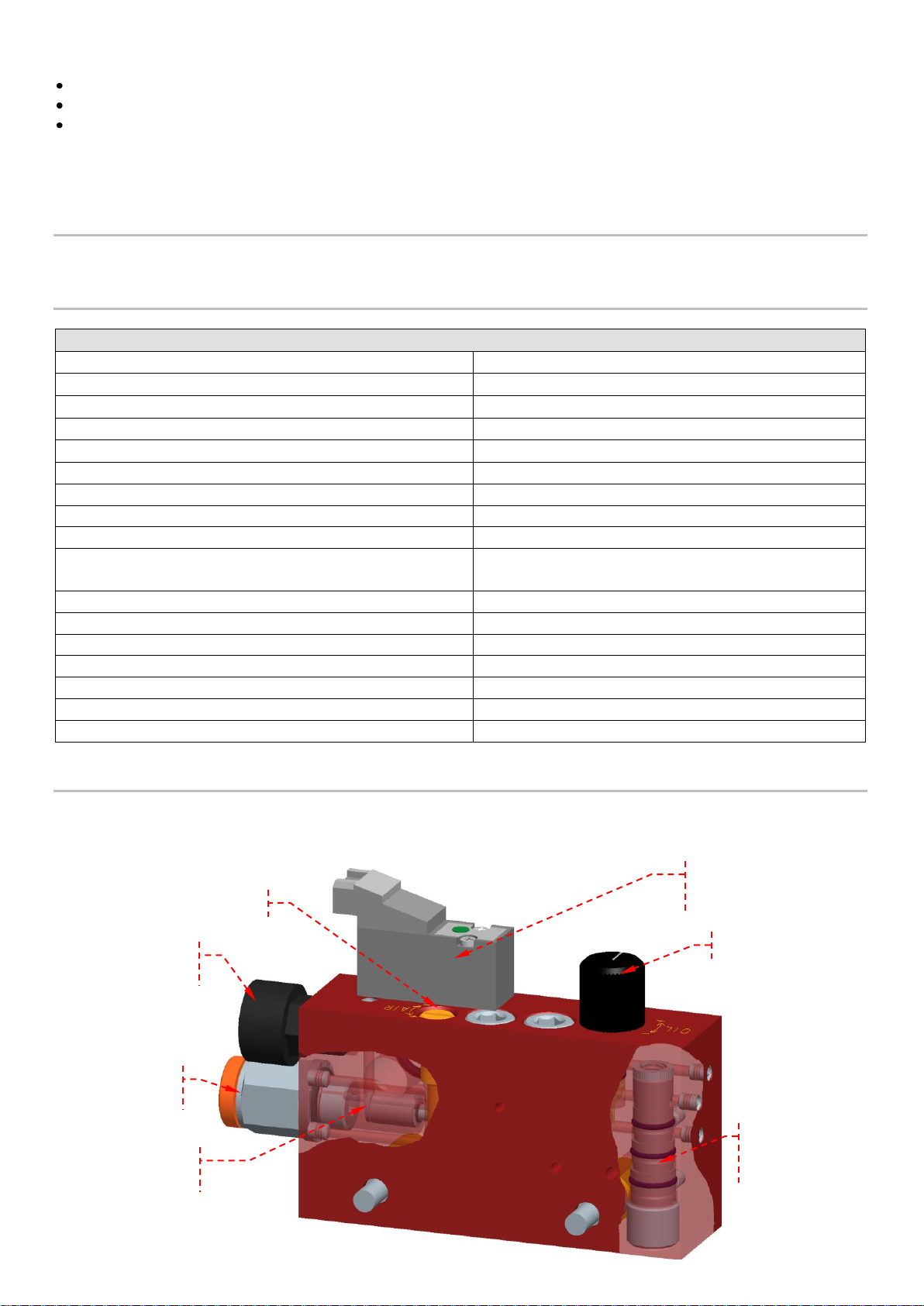

Solenoid valve

(“-i ” version only)

Pressure gauge

(optional)

Push-in pipe Ø6 air

outlet

Air regulation

Oil regulation

Compensation valve

(“PRO” version only)

Push-in pipe Ø3 oil

outlet

Machine tools

Machines for cutting and bending plate

Steelworks

The units are supplied without accessories. The installer is responsible for providing the accessories needed for safe and

correct operation (condensate separator, filters, pressure gauges, by-pass, etc…).

3. MACHINE IDENTIFICATION

There is a plate on the side of the unit that displays the product code, the power supply voltages and the basic characteristics.

4. TECHNICAL SPECIFICATIONS

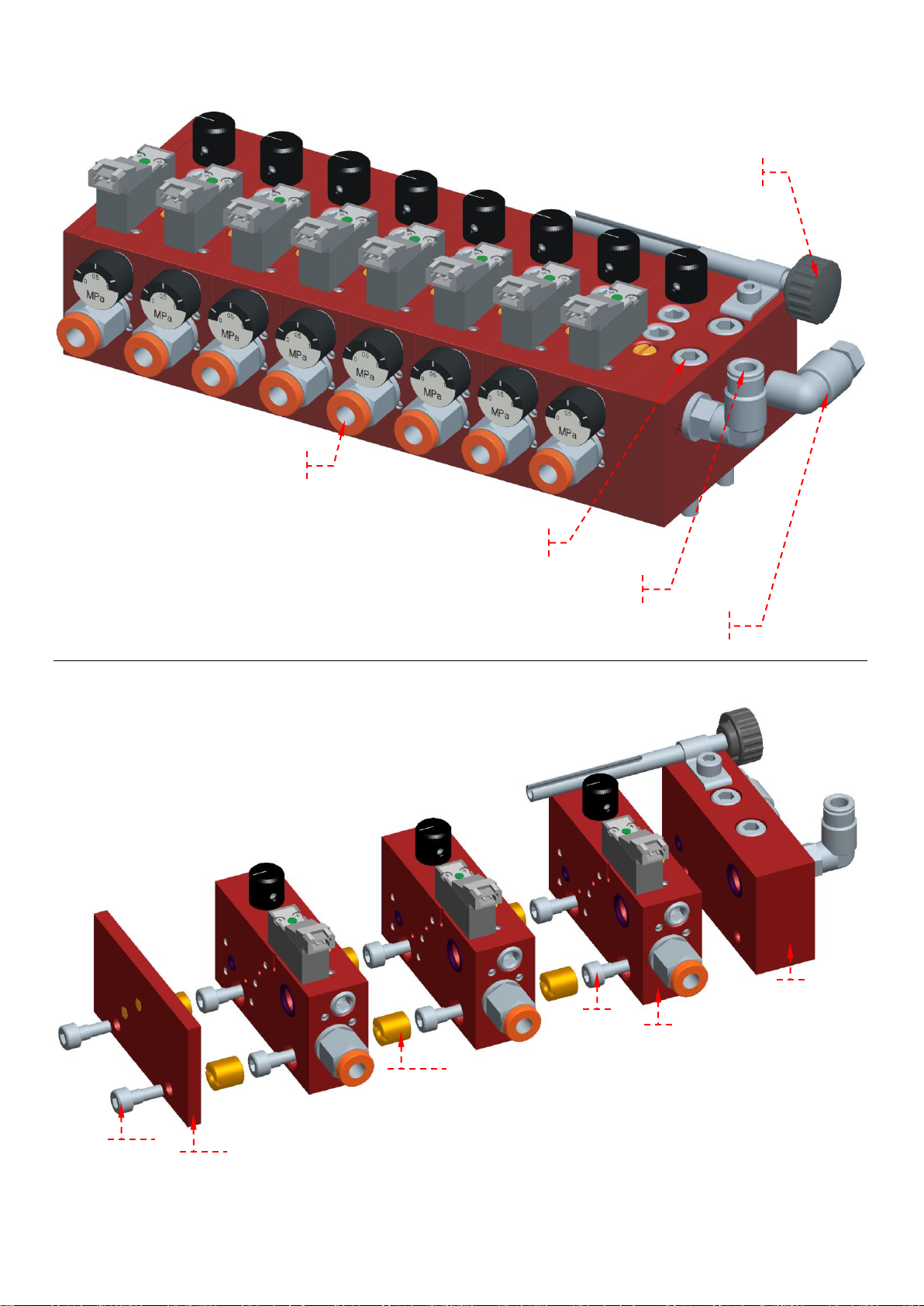

5. MACHINE COMPONENTS

MODULAR ELEMENT

4

Assembly system / increasing modular elements

Final closure

screws

Modular element

Screw assembly modules

Fixing intermidia set screw

Starting element

End cover

Modular element outlets

Air inlet

Mounting screws

Ø3 pipe removal tool

Oil inlet

MiQueL PRO-i EXT Module

5

Pressurized reservoir for MiQueL EXT (optional)

ATTENTION: Always install a regulator filter with condensate recovery on the air inlet. Any unfiltered deposits

or sediments could irreparably damage the product.

TECHNICAL SPECIFICATIONS

Reservoir capacity

1lt – 3lt

Air inlet pressure

4bar ÷ 7bar [87psi ÷ 101,5psi]

Air inlet pipe

Ø6mm

Oil outlet pipe

Ø6mm

Pressure switch calibration

6bar [87psi]

Maximum pressure switch load

Voltage free contact maximum voltage 250V

Maximum power 100W

Maximum electric level load

0,2A @ 30V

1lt Reservoir

3lt Reservoir

Pressure switch

Pressure gauge

Loading cap

Visible level

Air inlet

Oil Outlet

Mounting

brackets

Reservoir

Minimum electric

level

6

6. UNPACKING AND INSTALLATION

6.1 UNPACKING

Once the suitable location for installation has been identified, open the package and remove the unit.

Check that it was not damaged during transport or storage.

The packaging material does not require special disposal precautions as it is not in any way dangerous or polluting.

6.2 INSTALLATION

Allow a sufficient amount of space for installation, leaving a minimum perimeter space of 100 mm (3,93 in.).

Install the unit at “shoulder height” to prevent abnormal positions or the possibility of impacts.

Use the brackets with the holes (see chap. 12) to fix the unit properly. It is also possible to disassemble the brackets from their

current position and reassemble them in the prepared threaded holes for side or corner installation.

It is prohibited to use the unit if submersed in fluids or in a particularly aggressive or explosive/inflammable environment if not

previously prepared for that purpose by the supplier.

Use safety gloves or glasses as specified in the safety sheet for the lubricant.

Do not use aggressive lubricants with NBR gaskets. In the case of doubt, contact the Dropsa SpA technical office to receive a

detailed card about the recommended oils.

Do not ignore the hazards to health and comply with the health regulations.

6.3 PNEUMATIC CONNECTIONS

Before making the connection, check that the valve for the main air, the manual sliding valve and the check valves (air and oil)

are closed. Make sure that the inlet pressure does not exceed 7bar.

Use fittings and pipes that are suitable for the operating pressures, push-in connection for Ø10mm pipe.

6.4 ELECTRIC CONNECTIONS

AIR

AIR

OIL

2

1 4 3

AIR

OIL

Connect the unit to the pump or to the pressurized reservoir using suitable piping for the working pressure that must not be

greater than 2.5 times the air pressure (es.: air 6bar [87psi] – oil 15bar [217,5psi] max.).

6.5 AIR/OIL HYDRAULIC CONNECTIONS TO THE LUBRICATION NOZZLE

Using coaxial pipes, connect the Ø3mm pipe to the oil outlet push-in on the module, slide the Ø6mm tube outside the

Ø3mm tube until connect it to the air outlet push-in .

Then connect the same coaxial pipes to the lubrication nozzle push-in as shown below:

1. Insert the Ø6 air pipe in the push-in on the nozzle connection.

2. Remove the nozzle head from the articulated pipe, through which the Ø3 oil tube should pass, making it protrude approx.

20/25mm.

3. Insert the Ø3 oil pipe in the push-in on the nozzle head.

4. Replace the nozzle head on the articulated pipe.

To make it easier to remove the pipes exiting the module, use the supplied device: unscrew the Ø6 push-in, insert the device in

the Ø3 pipe, push the device on the collar of the Ø3 push-in, push and pull the Ø3 pipe.

7

7. INSTRUCTIONS FOR USE

DIAGNOSTICS TABLE

ANOMALY

CAUSE

SOLUTION

Lubrication does not take place

activating the solenoid valve.

Solenoid valve broken.

Replace the solenoid valve.

The air supply pressure is below 4 bar

[58psi].

Increase the supply pressure up to a

minimum of 4 bar.

The lubricant exits irregularly and with

large air bubbles visible in the Ø3 oil

pipe.

The Ø3 oil pipe is not perfectly engaged

into push-in of module.

Top up the tank with new lubricant.

Insert the pipe, making sure to insert it to

the end.

ATTENTION: Make sure that the pneumatic power supply is disconnected before carrying out any maintenance

work.

ATTENTION: The unit may only be opened and repaired by authorised Dropsa personnel.

Operations to perform before start-up.

Check the integrity of the unit.

Check the power supply pressure.

Check that the electric connection was carried out correctly.

Check that the unit is at the operating temperature.

7.1 USE

Open the manual cursor valve;

Press the start button on the machine to which the unit is connected or start it;

Check that the solenoid valves on the elements are correctly activated;

At the first start-up, it may be necessary to fill the oil pipes, wait until the lubricant exits;

Check that the lubrication is suitable (if there are doubts about correct operation, the Dropsa SpA technical office can be

contacted to request the inspection procedure).

7.2 REGULATION

The modular elements are normally supplied with the oil regulation and the air regulation completely closed. To regulate the

air/oil mixture for the individual elements, proceed as follows:

Turn the oil regulation knob clockwise to increase the flow rate or anticlockwise to decrease the flow rate.

Use a screwdriver to turn the air regulation pin clockwise to increase the flow rate or anticlockwise to decrease the flow rate,

until the desired spray is obtained.

8. PROBLEMS AND SOLUTIONS

A diagnostics table is provided below that indicates the main anomalies, the probable causes and the possible solutions.

If you were not able to solve the problem after consulting the diagnostics table, do not try to find the fault by disassembling

machine parts but contact the Dropsa technical office and report the discovered anomalies, with a detailed description.

9. MAINTENANCE PROCEDURES

The units were designed and built in order to minimise maintenance requirements.

To simplify maintenance, it is recommended to install them in an easy to reach position.

(See paragraph 6.2).

Periodically check the pipe joints to detect any leaks.

Always keep the modules clean to be able to quickly detect any leaks.

The machine does not require any special equipment for any control and/or maintenance activity. It is recommended to use

tools and personal protective devices suitable for use in ref. to leg. Decree 81/2008, and that are in good condition according to

current regulations to prevent damage to people or machine parts.

8

10. DISPOSAL

VERSION

DESCRIPTION

CODE

MiQueL PRO

Air/Oil modular minimal system with compensation valve

without a solenoid valve for independent control N(1-8) modules

313558N

N=1÷8 (Modules)

MiQueL PRO - i

Air/Oil modular minimal system with compensation valve

with a solenoid valve for independent control N(1-8) modules

313559N

N=1÷8 (Modules)

MiQueL BASE

Air/Oil modular minimal system without compensation valve

without a solenoid valve for independent control N(1-8) modules

313560N

N=1÷8 (Modules)

MiQueL BASE - i

Air/Oil modular minimal system without compensation valve

with a solenoid valve for independent control N(1-8) modules

313561N

N=1÷8 (Modules)

ACCESSORIES AND SPARE PARTS

CODE

DESCRIPTION

CODICE

DESCRIPTION

1525430

MiQueL PRO- i - Modular element

5717301

Ø6 AIR outlet pipe

1525440

MiQueL PRO - Modular element

3226664

Oil MK 150 20 lt.

1525450

MiQueL BASE- i - Modular element

3226665

Oil MK 100 25 lt.

1525460

MiQueL BASE - Modular element

3226666

Oil MK High Performance 29 lt.

3133561

Pressurized Reservoir for MiQueL EXT – 1lt

3225465

Oil MK Stainless 20 lt

3133560

Pressurized Reservoir for MiQueL EXT – 3lt

3133455

Coaxial nozzle - Narrow Cone Pattern

0020694

Pressure gauge for module AIR outlet (-i

3133558

65° Coaxial nozzle – flat cone

1525446

Module solenoid valve connector (-i)with 600mm cable

3133564

FULL cone monotube nozzle

1525476

Module solenoid valve connector (-i)with M8 connector

3133565

65° monotube nozzle flat cone

1525442

Module solenoid valve (-i)

1525050

Monotube nozzle for 50mm BLADE

5717232

Outlet oil Ø3 tube

1525051

Monotube nozzle for 70mm BLADE

During machine maintenance, or if it is demolished, do not dispose of the polluting parts in an improper manner. Refer to the

local regulations for their correct disposal. When demolishing the machine, the identification plate and all other documents

must be destroyed.

11. ORDER INFORMATION

11.1 ACCESSORIES AND SPARE PARTS

For more information about accessories and spare parts, contact our technical sales office.

9

12. DIMENSIONS

MiQueL - EXT

Reservoir for MiQueL EXT (optional)

Dimensions in mm [inch].

10

13. HANDLING AND TRANSPORT

Note: Personnel must use protective devices, garments and tools in compliance with current standards with

regard to the location and the use of the unit both during work as well as during maintenance operations.

Lift the equipment according to the direction shown on the cardboard package.

The machine components can be stored at temperatures between -30 and + 80 °C; however, to prevent

damage, it must only be started up after the machine has reached a temperature of +5 °C.

ATTENTION!

Never try to stop or deviate any leaks with your hands or other body parts.

Before shipping, the units are carefully packed inside cardboard boxes. When transporting and storing the equipment, pay

attention to the direction indicated on the boxes themselves.

Upon receipt, check that the package has not been damaged and store the equipment in a dry location.

14. PRECAUTIONS FOR USE

The warnings about the risks involved in using a unit for lubricants must be read.

The operator must understand its operation and clearly understand the hazards connected to pumping pressurised oils.

Therefore we recommend the following:

Check the chemical compatibility of the material with which the unit is built with the fluid to be pumped (see chap. 4). An

incorrect selection could cause, in addition to damaging the units and pipes, serious risks for people (spillage of irritating

products that are harmful to health) and for the environment.

Never exceed the maximum operating pressure permitted for the unit and the components connected to it. In the case of

doubt, refer to the data specified on the machine plate.

Only use original spare parts.

If components must be replaced with others, make sure they are suitable for operating at the unit's maximum operating

pressure.

Electric current

Do not carry out any work on the machine before disconnecting it from the electrical power supply and making sure that no one

can reconnect it during the operation. All the installed equipment (electric and electronic), tanks and basic structures must be

connected to the ground line.

Inflammability

The lubricant used in the lubrication circuits is normally not an inflammable liquid. It is however necessary to adopt all the

possible measures to prevent that it comes into contact with very hot parts or open flames.

Pressure

Before each operation, make sure there in every branch of the lubrication circuit that there is no residual pressure that could

cause oil to spray when disassembling fittings or components.

After long periods of inactivity, check the seal of all the parts subject to pressure.

Do not subject the fittings, pipes and pressurised parts to violent impacts.

Damaged flexible pipes or fittings are DANGEROUS and must be replaced.

Only original spare parts should be used.

Noise

Under normal operating conditions, noise emission does not exceed 70 dB “A” at a distance of 1 metre (39.3 inches) from the

unit.

For further information about the technical specifications and the safety measures to adopt, refer to the product safety sheet

(Directive 93/112/EEC) relative to the type of lubricant selected and supplied by the manufacturer.

11

15. GUIDELINES FOR USE

FLUIDS THAT ARE NOT PERMITTED

FLUIDS

RISKS

Lubricants with abrasive additives.

Wear of internal components.

Lubricants with silicone additives.

Seizure.

Petrol – solvents – inflammable liquids.

Fire – explosion – damage to the gaskets.

Corrosive products.

Corrosion - damage to people.

Water.

Unit oxidation.

Food substances.

They would be contaminated.

Compliance with the essential safety requirements and the provisions specified in the machine directive was checked by filling

out prepared check lists that are contained in the technical file.

Two types of lists were used:

Risk assessment (UNI EN ISO 14121-1).

Compliance with the essential safety requirements Machine Directive –EC 06/42).

The risks that were not completely eliminated, but considered acceptable, are specified below:

During maintenance, sprays of oil at low pressure are possible (for this purpose, suitable PPE must be worn during

maintenance activities).

Unsuitable postures: The correct dimensions and installation methods are described in this manual.

Use of unsuitable lubricant: The specifications of the lubricant are indicated both on the unit as well as in this User and

maintenance manual (in the case of doubt, contact the Dropsa S.p.A technical office).

12

16. WARRANTY INFORMATION

All products manufactured and marketed by Dropsa are warranted to be free of defects in material or workmanship for a period

of at least 12 months from date of delivery. Extended warranty coverage applies as follows:

Complete system installation by Dropsa: 24 Months

All other components: 12 months from date of installation; if installed 6 months or more after ship date, warranty shall be

maximum of 18 months from ship date.

If a fault develops, notify us giving a complete description of the alleged:

malfunction

part number(s)

test record number where available (format xxxxxx-xxxxxx)

date of delivery

date of installation

operating conditions of subject product(s)

We will subsequently review this information and, at our option, supply you with either servicing data or shipping instruction

and returned materials authorization (RMA) which will have instructions on how to prepare the product for return.

Upon prepaid receipt of subject product to an authorized Dropsa Sales & Service location, we will then either repair or replace

such product(s), at out option, and if determined to be a warranted defect, we will perform such necessary product repairs or

replace such product(s) at our expense.

Dropsa S.p.A. reserves to right to charge an administration fee if the product(s) returned are found to be not defective.

This limited warranty does not cover any products, damages or injuries resulting from misuse, neglect, normal expected wear,

chemically caused corrosion, improper installation or operation contrary to factory recommendation. Nor does it cover

equipment that has been modified, tampered with or altered without authorization.

Consumables and perishable products are excluded from this or any other warranty.

No other extended liabilities are states or implied and this warranty in no event covers incidental or consequential damages,

injuries or costs resulting from any such defective product(s).

The use of Dropsa product(s) implies the acceptance of our warranty conditions. Modifications to our standard warranty must

be in made in writing and approved by Dropsa S.p.A.

13

Dropsa Spa

Via Benedetto Croce, 1

20090 Vimodrone (MI)

Italy

Tel.:

Fax Sales:

E-mail:

Web site:

(+39) 02. 250.79.1

(+39) 02. 250.79.767

sales@dropsa.it

http://www.dropsa.com

DICHIARAZIONE DI CONFORMITÁ/DECLARATION OF COMPLIANCE WITH STANDARDS/

DECLARATION DE CONFORMITE/ KONFORMITÄTSERKLÄRUNG DES STANDARDS /DECLARACIÓN DE

CONFORMIDAD/ DECLARAÇÃO DE CONFORMIDADE

La società Dropsa S.p.A., con sede legale in Milano, Via Besana,5/ Dropsa S.p.A., registered office in Milan, Via

Besana,5 / Dropsa S.p.A. au Siège Social à Milan, Via Besana,5/ Dropsa S.p.A., Sitz in Milano, Via Besana 5/ La

sociedad Dropsa S.p.a., con sede legal en Milán, Via Besana,5/ A Dropsa S.p.A, com sede em Milão, via Besana, nº 5

DICHIARA /CERTIFIES / CERTIFIE/ ZERTIFIZIERT, DASS/ DECLARA/ CERTIFICA:

che il prodotto denominato/that the product called/ le produit appelè/ das Produkt mit dem Namen/ el producto que se

llama/ o produto chamado:

Descrizione/ Description/ Description/ Beschreibung/

Descripción/ Descrição:

Lubrificatore Modulare Aria/Olio

Air/Oil Modular Lubricator

Nome Commerciale/ Product Name/ Dénomination/

Handelsname/ Denominación/ Denominação:

MiQueL EXT

Versioni/ Versions/ Versions/ Versionen/ Versiones/

Versões:

EXT -PRO/ EXT -PRO I / EXT-BASE/ EXT-

BASE I

Codici/ Codes/ Códigos/:

3135581÷3135618

è conforme alle condizioni previste dalle Direttive CEE /has been constructed in conformity with the Directives Of

The Council Of The European Community on the standardization of the legislations of member states/ a été

construite en conformité avec les Directives Du Conseil Des Communautes Europeennes/ Entsprechend den

Richtlinien des Rates Der Europäischen Union, für die Standarisierung der Legislative der Mitgliederstaaten,

konstruiert wurde/ cumple con las condiciones establecidas por las directivas comunitarias/ foi construído em

conformidade com as diretivas do Conselho das Comunidades Europeias:

2006/95 CE Bassa tensione / Low Voltage Directive / Directive Basse Tension/ Niedrigspannungsrichtlinien/ Directiva de

baja tensión/ Directiva de Baixa Tensão;

2004/108 CE Compatibilità elettromagnetica/ Electromagnetic Compatibility/ Compatibilité electromagnétique/

Elektromagnetische Verträglichkeit/ Compatibilidad electromagnetica / Compatibilidade Eletromagnética

17. DECLARATION OF CONFORMITY

Technical Director:

Maurizio Greco

.....................................

Legal representative

Milena Gavazzi

.....................................

Vimodrone (MI), Gennaio 2012

La persona autorizzata a costituire il Fascicolo Tecnico c/presso Dropsa S.P.A.

The person authorized to compile the Technical File care of Dropsa S.P.A.

14

18. DISTRIBUTORS

Dropsa S.p.A.

Via B. Croce,1

20090 Vimodrone (MI) Italy.

Tel: (+39) 02 - 250.79.1

Fax: (+39) 02 - 250.79.767

E-mail: sales@dropsa.it (Export)

E-mail: vendite@dropsa.it (National)

Dropsa Ame

23, Av.des.Morillons

Z.I. des Doucettes 91140

Garges Les Gonesse, France

Tel: (+33) 01 39 93 00 33

Fax: (+33) 01 39 86 26 36

E-mail: salesfr@dropsa.com

Dropsa (UK) Ltd

Unit 6, Egham Business Village,

Egham,Surrey,TW20 8RB

Tel: (+44) 01784 - 431177

Fax: (+44) 01784 - 438598

E-mail: salesuk@dropsa.com

Dropsa do Brazil Ind. E Com. Ltda

Rua Sobralia 175,

Sao Paulo, Brazil

Tel: (+55) 011-5631-0007

Fax: (+55) 011-5631-9408

E-mail: salesbr@dropsa.com

Dropsa USA Inc.

6645 Burroughs Ave

48314-2132 Srerling Hts,Mi Us -USA

Tel: (+1) 586-566-1540

Fax: (+1) 586-566-1541

E-mail: salesusa@dropsa.com

Dropsa Lubrication Systems

Nr 8 Dongxing Road,

Songjiang Industrial Zone

(Shanghai) Co., Ltd

Tel: +86 (021) 67740275

Fax: +86 (021) 67740205

E-mail: china@dropsa.com

Dropsa Gmbh

Volmerswerther Strasse 80

40221 Dusseldorf 1, Deutschland

Tel: (+49) 0211/39 4011

Fax:(+49) 0211/39 4013

E-mail: sales@dropsa.de

Dropsa Australia Pty.

C20/148 Old Pittwater Road

Brookvale, NSW 2100

Tel: +61 (02) 9938 6644

Fax: +61 (02) 99 386 611

E-mail: salesau@dropsa.com

Web site: http://www.dropsa.com - E-mail: sales@dropsa.com

Loading...

Loading...