ADVANCED LUBRICATION CONTROLLER

with Quick Remote Configuration

INSTRUCTION AND PRODUCT DATA SHEET

1. DESCRIPTION:

This high performance/low cost Advanced Lubrication

Controller has been designed to control and monitor most

small to medium size lubrication systems.

The configuration parameters are all electronically stored,

in two separate menus, eliminating the need to set DIP

switches or jumpers,

The Operator Menu - is used to adjust pause and cycle

intervals.

The Factory/System Menu - is used to configure the type

of pump and lubrication system to which the controller is

connected.

In addition the controller incorporates a scanner located

under the remote control symbol on the front panel. When

used with the Transmitter Module, the configuration can

be downloaded and stored simply by positioning the module over the symbol and pressing the transmit button

This allows for a considerable time saving for OEM’s. who

use the system on a production line, eliminating the need

to individually configure each controller.

1639076

1639077

PATENT PENDING

2. SPECIFICATION:

INPUT CONTACTS:

Power:

110V/230V, 24V, 220V Single Phase

and 380V Three Phase

Power Consumption:

20 Watts.

Operating Temperature:

-5oC. to +55oC.

Control Input:

12V Max.

N.O. Pressure Switch.

Micro/Reed Switch.

Proximity (NPN/PNP Autodetection.

Oil Level:

12V Max.

Make on Low Level.

Impulse Counter:

Max. Switching Frequency;

10Hz. at 25%

OUTPUTS:

Pump/Drive Line:

110V/230V 5A 50/60Hz. or 24V

Alarm Output:

Voltage Free Contact. Max. 250V, 1A.

ENCLOSURE:

External Dimensions:

132 x 132 x 60 mm.

Fixing Dimensions:

95 x 95 mm.

Protection Grade:

IP55.

3. INSTALLATION/OPERATION:

MENU OPERATION: (Refer to table on page 2.)

ELECTRICAL CONNECTIONS AND

CIRCUIT DETAILS:

(Refer to Fig. 1.)

Note: When using the pause timer it is possible to

suspend the timer by closing contacts 14 and 15.

DIMENSIONS:

(Refer to Fig. 2.)

4. TEST PROCEDURES:

The Controller will self-diagnose on power-on and will

display any errors on the 4-digit display.

1

C1019IE-10/97

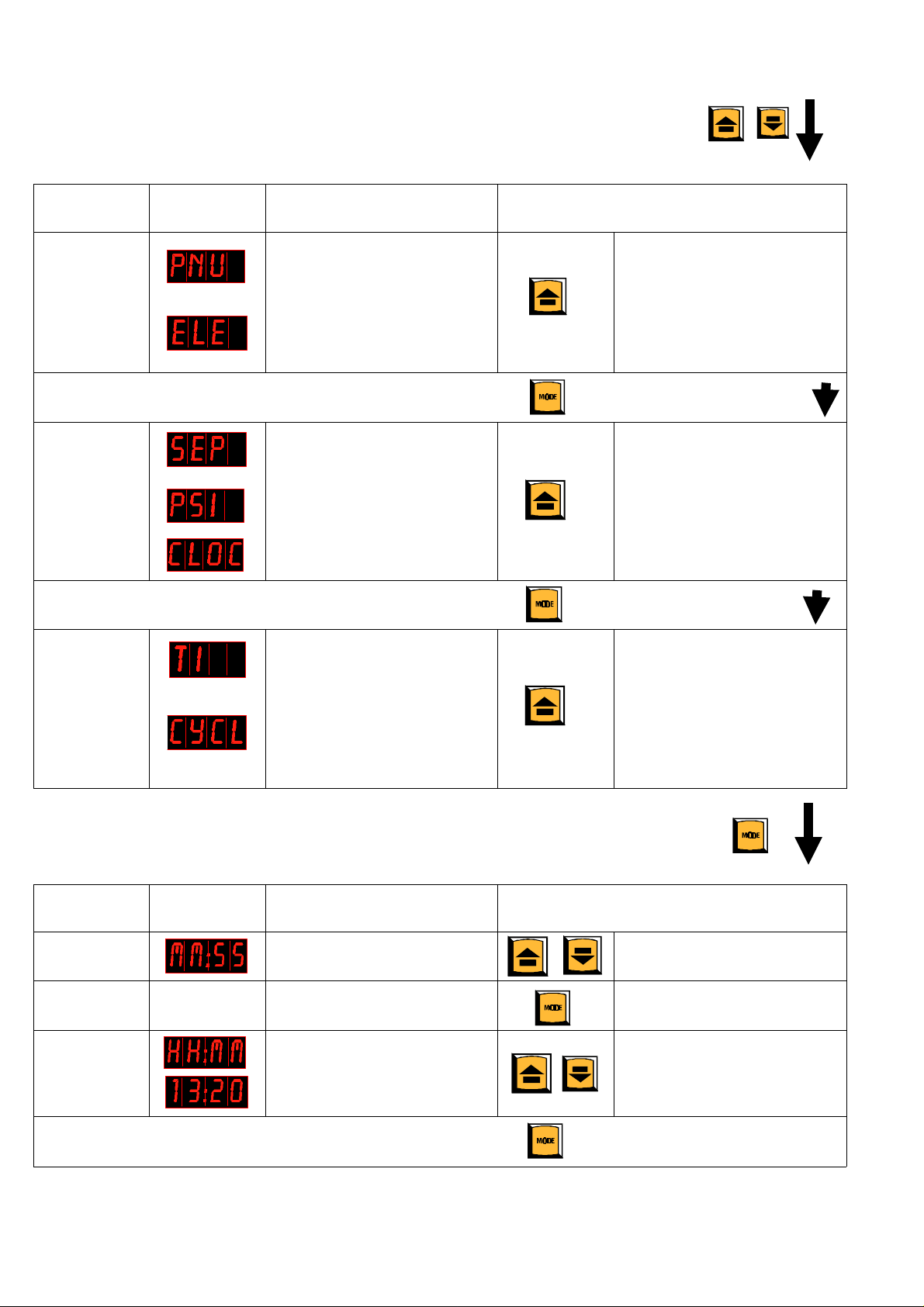

MENU OPERATION:

System Menu

The System Menu is used to configure the type of pump and

Lubrication System that is connected to the Controller

To access the System Menu press the UP and DOWN buttons together and hold for two seconds.

Parameter

Pump Type.

Press the MODE button to go to the next option.

Lubrication

System Type

Press the MODE button to go to the next option.

Pause

Interval

Selection

Screen

Display

Description Operation

The Pump receives a 4

second ON and a 4 second

OFF pulse

The Pump receives a constant

signal.

Progressive System - Monitors

switch on progressive divider.

Monitors a pressure switch on

Single Line Systems.

No monitoring, just timer.

The Pause between the Pump

ON cycle is determined by a

timer.

The Pause between Pump

cycles is determined by the

cycle switch input connected

to pulse

Press the UP button to switch

between the two options.

Press the UP button to switch

between the three options.

Press the UP button to switch

between the three options.

Operator Menu:

The Operator Menu is used to adjust the

Pump ON’ cycle and the (timer/impulse) pause interval.

To access the Operator Menu press and hold the MODE button for two seconds.

Parameters Screen

Display

Pump On

Time

Pause Timer

or

Impulse

Counter

Press the MODE button and

hold for two seconds.

2 ’VIP’ ADVANCED LUBRICATION CONTROLLER

Indicates the Minimum Pump

ON time.

Exit and go the next option. Press the MODE button and

Indicates Pause Interval.

Indicates number of impulses

between cycles.

Return to normal operating

mode

Description Operation

Use the UP and DOWN

buttons to adjust the setting.

hold for two seconds.

Use the UP and DOWN

buttons to adjust the setting.

Fig. 1. Connection Details.

Fig. 2. Fixing Details

3

Fig. 3. Panel Mounted Version.

C1019IE-10/97

trollers from the system disconnect and isolate all power

supplies.

8. OPERATING ENVIRONMENT

Controllers must not be operated in excessively corrosive

or aggressive environments. If in doubt, please contact

our Technical Office.

9. DIAGNOSTIC TABLE:

Fig. 4. Remote Transmitt Module.

5. ORDERING INFORMATION:

Part No.

1639076

1639077

1639080

1639084

1639088

1639081

1639087

Description

VIP Controller 24V Box Version.

VIP Controller 110/230V Box Version.

VIP Controller 24V Panel Mounted

Version.

VIP Controller 110/230V Panel Mounted

Version.

Remote Transmit Module.

VIP Controller 220V Single Phase in

Steel Enclosure.

VIP Controller 380V Three Phase in

Steel Enclosure.

ALARM

CODES

AO1

AO2

AO3

AO4

AO5

DESCRIPTION

OF FAULT

ACTION

No parameters set. Set parameters.

Low Level alarm. Add lubricant to the

system

The change-over

contact (in SEP

mode) has not

cycled within the

specified ’Pump

Check for loose

fittings and

blockages in

progressive system

and rectify.

ON ’ times.

PS Mode: Pressure

was already high

before the start of

Check pressure

switch and replace

if necessary.

the cycle.

PS Mode: The

system did not

achieve pressure

Check for leakage

from loose fitting

and rectify.

during the specified

cycle times.

6. SPARES

No user serviceable parts inside.

7. SAFETY REQUIREMENTS

These Controllers must be installed and operated in accordance with the requirements of this Instruction Sheet

and should not be used for any purpose than that specified

without the agreement of the suppliers.

In addition to the need to observe general safety requirements the following specific hazards apply:

Before installing or removing Advanced Lubrication Con-

ALEX/DROPSA

Vimodrone (MI)

Tel: (02) 250791

Fax: (02) 25079767

© Copyright Dropsa - all rights reserved. Reproduction of any part of this document is strictly forbidden without prior consent from Dropsa.

Dropsa reserve the right to withdraw or modify specifications without prior notice.

4 ’VIP’ ADVANCED LUBRICATION CONTROLLER

DROPSA UK LTD.

Egham, SURREY.

Tel: (01784) 431177

Fax: (01784) 438598

DROPSA GMBH

Düsseldorf, GERMANY.

Tel: (0211) 394011

Fax: (0211) 394013

DROPSA FRANCE - AME.

Garges-Les-Gonesse, CEDEX.

Tel: (01) 399.300.33

Fax: (01) 398.626.36

DROPSA CORPORATION

Houston, TEXAS.

Tel: (713) 462-1061

Fax: (713) 462-4027

Loading...

Loading...