Motor Driven Gear

User and

Maintenance Manual

Warranty Information

TABLE OF CONTENTS

1. INTRODUCTION

2. GENERAL DESCRIPTION

3. PRODUCT– MACHINE IDENTIFICATION

4. TECHNICAL SPECIFICATIONS

5. PUMP COMPONENTS

6. UNPACKING AND INSTALLING THE PUMP

7. INSTRUCTIONS FOR USE

8. TROUBLESHOOTING

9. MAINTENANCE PROCEDURE

10. DISPOSAL

11. ORDERING INFORMATION AND DIMENTIONS

12. HANDLING AND TRASPORTATION

13. OPERATING HAZARDS

14. PRECAUTIONS

15. WARRANTY INFORMATION

16. DECLARATION OF COMPLIANCE WITH STANDARDS

17. DROPSA LOCATIONS

Manual drafted in compliance with C2010IE – WK 20/11

EC Directive 06/42

http://www.dropsa.com

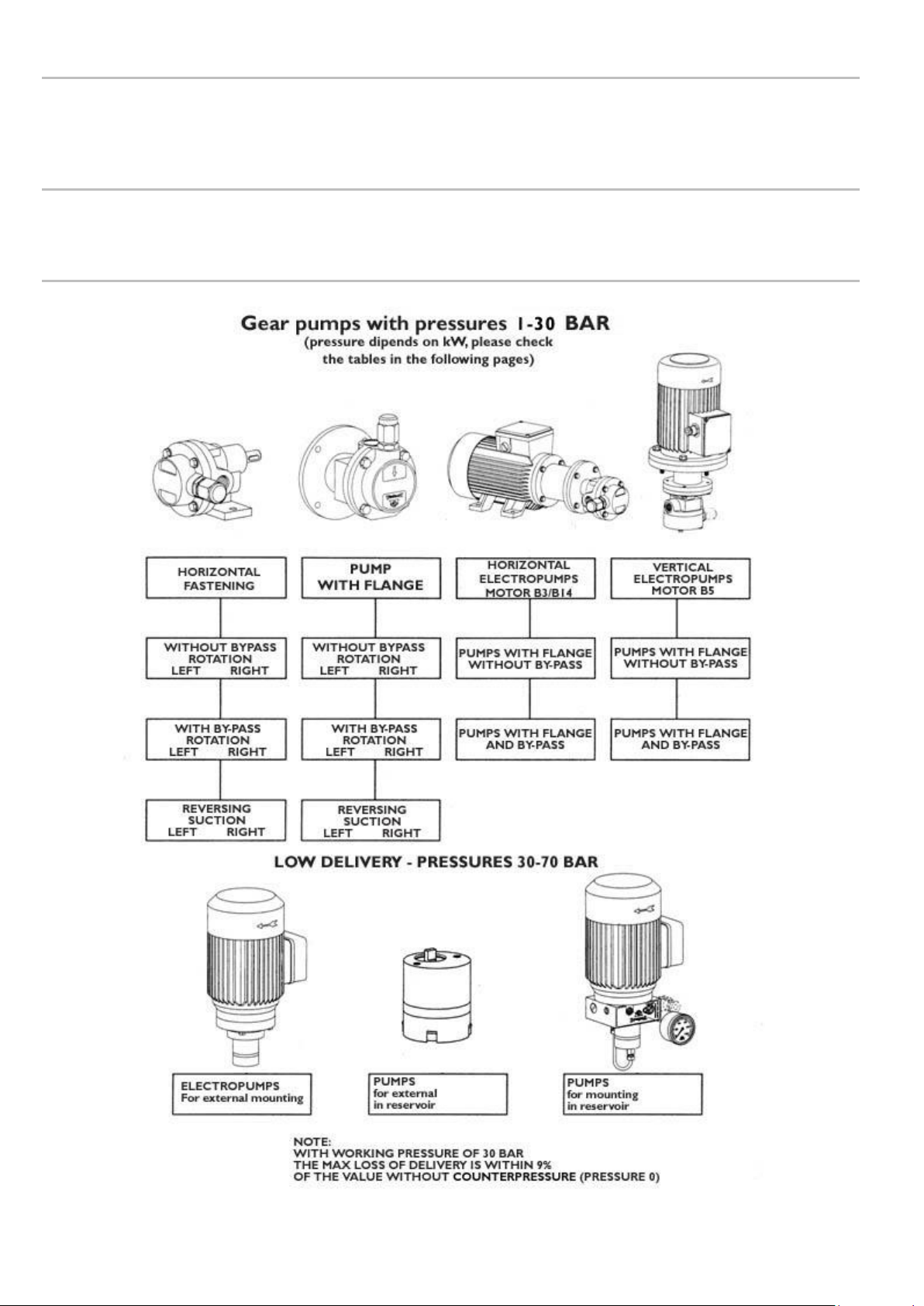

Pumps

2

1. INTRODUCTION

This user’s and maintenance manual refers to motor-driven gear pumps 37000-3400000, 3410-

It is recommended that this manual is carefully kept in good condition and is always available to persons requiring to consult it.

To request further copies, updates or clarifications with respect to this manual contact the Engineering Department at Dropsa

SpA.

The use of the pump referred to in this manual must be entrusted to qualified personnel with a knowledge of hydraulics and

electrical systems.

The manufacturer reserves the right to update the product and/or the user’s manual without the obligation to revise previous

versions. It is however, possible to contact the Engineering Department for the latest revision in use. You can find additional

copies and newer revisions of this document from our website http://www.dropsa.com. Alternatively contact one of our sales

offices.

The pump, and any accessories mounted on it, should be carefully checked immediately on receipt and in the event of any

discrepancy or complaint the Dropsa SpA Sales Department should be contacted without delay.

DROPSA S.p.A. declines to accept any responsibility for injuries to persons or damage to property in the event of the nonobservance of the information presented in this manual.

Any modification to component parts of the system or the different destination of use of this system or its parts without prior

written authorisation from DROPSA S.p.A. will absolve the latter from any responsibility for injury or damage to persons and/or

property and will release them from all obligations arising from the guarantee.

Instructions for the correct ordering of the required model, and a list of importers, is shown in Section 4.

2. GENERAL DESCRIPTION

These new pump units have been designed as the result of over thirty years experience in the field of developing and

manufacturing gear pumps.

The application possibilities are numerous; the pumps are self-lubricating and are able to operate with oils or any other fluid

with proven lubricating capacity.

These pumps can therefore be utilised in the fields of lubrication, refrigeration, hydraulics and, more generally, for the

circulation of fluids for machines, motors and linear motion applications; these units can also be employed on recirculating

systems without the need for particularly fine filtering of the circulation fluid.

One of the most striking features of these pumps is the high degree of silentness in operation, obtained with the use of gears

specially designed for this type of unit.

Also, thanks to particularly precise machining and finishing, a significant improvement has been achieved in efficiencies

compared to all previous similar models produced.

To ensure an external seal the pumps have an “O” ring located between the pump body and the relative cover in addition to a

lip seal on the main shaft.

The body of the pump is produced in hydraulic cast iron and the gears and relative shafts in chrome-nickel steel – carburized,

hardened and ground.

The body of the low flow rate pump (up to 500 cc/min) is made of sintered steel; the shafts and gears in carburized and

hardened steel with a seal on the main shaft.

WARNING

For all the motor-driven pumps we have shown the applied power to the motors in function of the maximum pressure demand

indicated in the table. For higher pressures the motor must be suitably sized; accordingly, to obtain a quotation, state the

voltage, the maximum operating pressure and if the service will be continuous or intermittent. (Max pressure = 30 bar for

continuous service); (max. pressure = 60 bar for intermittent service); (For cylinder block versions from 1-30 bar it depends form

delivery and kW). Working temperature of the fluid –20 - +100 degrees with low to medium velocity oil.

On request flameproof motors can be supplied in various voltages.

Request availability from Dropsa SpA.

3

3. PRODUCT – MACHINE IDENTIFICATION

Pump identification label is located on the front side of the grease operating pump and contains pump serial number and details

of its operating parameters.

4. TECHNICAL SPECIFICATION

See chapter 11 “ORDERING INFORMATION”

5. PUMP COMPONENTS

4

6. UNPACKING AND INSTALLING THE PUMP

6.1 UNPACKING

Once a suitable location has been found to install the unit remove the pump from the packaging. Check the pump has not been

damaged during transportation or storage. No particular disposal procedures are necessary, however packing should be

disposed of in accordance with regulations that may be in force in your area or state.

6.2 INSTALLING THE PUMP

Allow sufficient space for the installation, leaving minimum 100 mm (3.9 in.) around the unit.

In order to avoid unnatural posture for personnel install the machine in a comfortable and easy-to-reach location.

Do not install the unit in aggressive/explosive/inflammable environments or on vibrating surfaces.

WARNING: At the end of all the connecting operations, make sure that pipes and wires are safe from impacts and carefully

fixed.

7. INSTRUCTIONS FOR USE

After fixing the pump at its support, fill the tank with pure oil.

Operate the pump until the oil comes out without air bubbles.

Attach the tubing to the pump taking care of blowing compressed air inside to remove any dirt.

Reactivate the pump until oil comes out from the pipes regularly and without bubbles.

Attach piping to the lubrication points

Always pay attention to the direction of rotation.

In case of direct connection, run the engine for a few seconds checking the direction of rotation, if it is wrong to

switch two power phases.

The pump must not work with the wrong direction of rotation.

In the event of a complete unit, pump with electric motor on support, they must be carefully balanced in both

directions, to ensure that whole function silently.

5

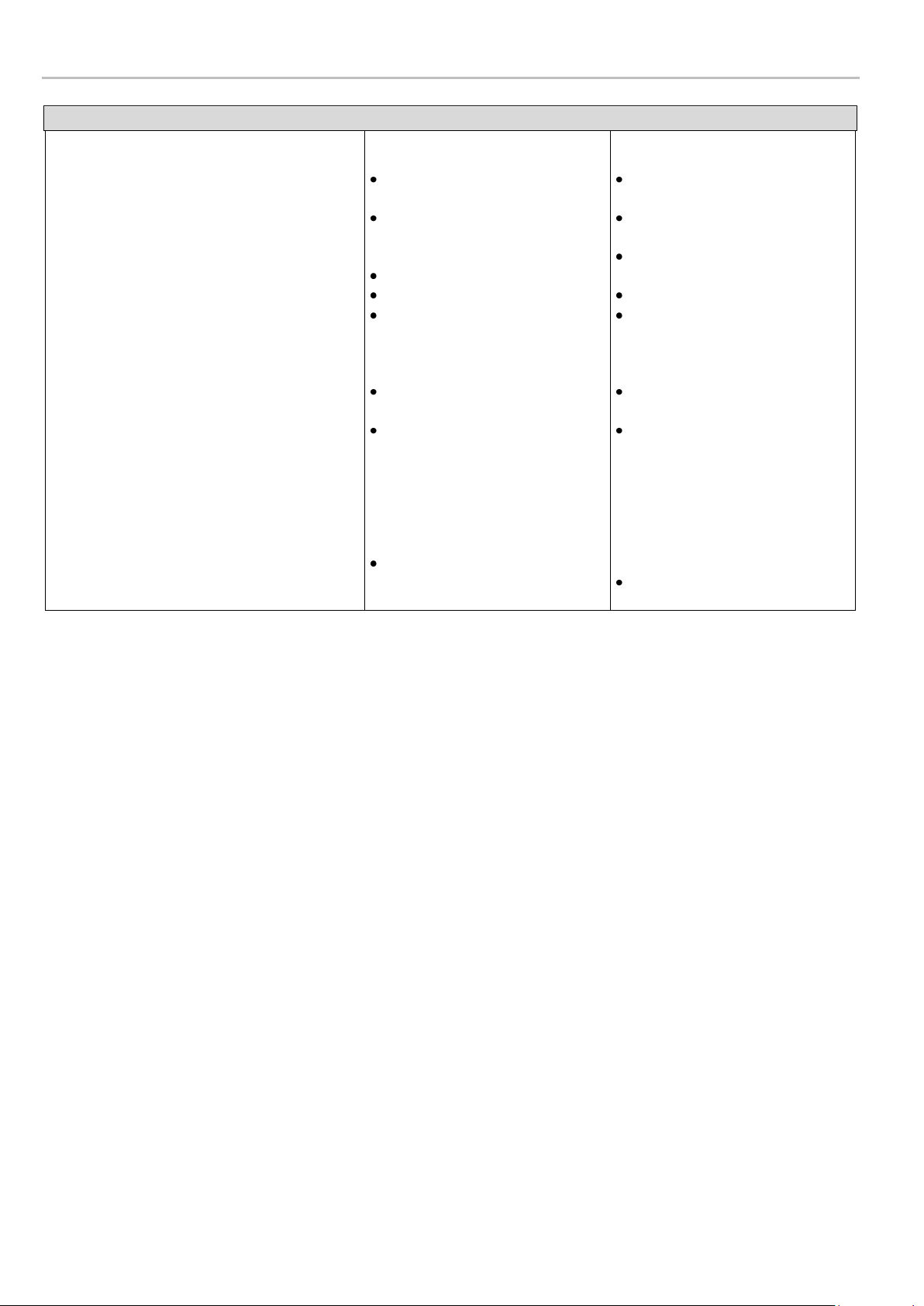

8. TROUBLESHOOTING

DIAGNOSTIC TABLE

INDICATION

The pump does not deliver oil or does not

deliver oil in the exact quantity prescribed

The pump does not deliver oil at the prescribed

pressure

PROBABLE CAUSE

Drawing in air due to the tank

being empty

The splash filter is dirty or

blocked

The connections are loose

Pump has deteriorated

Pressure regulating valve loose,

so the oil returns immediately to

the tank before flowing through

the delivery valve

Release valve damaged

Incorrect setting of the

regulating valve

Presence of dirt under the by-

pass valve

REMEDY

Refill the tank and purge air

from the system

Wash the filter and blow it

through with compressed air

Set all connections ensuring

there are no leakages

Replace the pump

Set the regulating screw until oil

exits from the delivery

Replace the valve

To the pump outlet connect a

tube approximately 30cm long

with a manometer connected to

the free end. Regulate the valve

by means of turning the screw

and reading the corresponding

pressure value on the

manometer

Disassemble the valve and clean

or replace it as necessary

6

9. MAINTENANCE PROCEDURE

Assembly Part N°

Flow rate in

litres/min

Dimension H

Pump for

external

Pump in tank

a 1500 rpm

3099127

3099129

0.35

38

3099004

3099130

0.5

40

3099131

3099133

1.2

47

The pumps require only minimal maintenance.

To facilitate maintenance it is suggested to install the pump in an easily accessible location

Periodically check piping joints to detect possible leaks.

The machine does not require any special tool for checking or maintenance tasks. However, it is recommended the

use only of appropriate and in good conditions tooling, protective devices (gloves) and clothing (in according to current

regulations) to avoid hazards to equipment or persons.

10. DISPOSAL

During maintenance or disposal of the machine care should be taken to properly dispose of environmentally sensitive items.

Refer to local regulations in force in your area.

When disposing of this unit, it is important to ensure that the identification label and all the other relative documents are also

destroyed.

11. ORDERING INFORMATION

Gear pumps for low flow rates with pressures of 30-70 bar.

Gear pumps for low flow rates can also be supplied assembled to the motors.

3 sizes are available: 0.35 – 0.5 – 1.2 litres/min. at 1500 rpm.

The direction of rotation is indifferent; simply invert the suction and delivery tubes.

The service can be either continuous or intermittent.

The following standard power supplies are provided for:

220/380 V – 50 Hz

240/440 V – 60 Hz

415V _ 50 Hz

Other voltages and frequencies are available on request.

The motors have IP55 grade protection.

In addition, it is possible to order separately a suction filter c/w dip tube (400 mesh/cm2, filtering grade 260) of an overall length

of between 100 and 455 mm depending on the needs of different installations.

These gear pumps are suitable for operating with oils of a viscosity between 32 and 1000 cSt at fluid working temperatures in

the range of –20 - +100 °C.

The maximum useful pressure in intermittent service is 70 bar; for this the design rotation speed of the pump is 1500 or 3000

rpm.

7

Assembly

Part N°

Motor power

Flow rate

litres/min

Weight

Kg

Dimensions in mm

size

kW

rpm A B C D E F G H L M N P R 3405000

56

0.09

1500

0.50

3.7

171

137

104

56

80

65

56

5.5

71

90 6 106

36

3406000

63

0.25

3000

1.00

5.5

194

153

119

56

90

75

58

5.5

--

--

--

--

--

3407000

63

0.185

1500

0.50

5.5

194

153

119

56

90

75

58

5.5

--

--

--

--

--

3402002

56

0.09

1500

0.35

3.7

171

137

104

54

80

65

56

5.5

71

90 6 106

36

Suction filter assembly

Part N° 3088053 Length 165 mm

Part N°3088054 length 80 mm

Part N°3088055 length 415 mm

Part N°3088056 length 130 mm

LL

LL

8

Electric motor for

continuous operation

DropsA

Line

By-pass

setting

Standard

setting

By-pass

Assembly

Motor power

Voltage

Flow

rate

litres/mi

n

Dimensions

Size

kW

rpm

*A

*B

*C

D

01

2-20 bar

5 bar

with

non-

return

valve

3404023

56

0.09

1500

220/380V-50 Hz

0.35

205

156

110

38

3404022

56

0.09

1500

220/380V-50 Hz

0.50

205

156

110

40

3404026

56

0.06

1500

110 V – 50 Hz

0.35

205

156

110

38

3404046

56

0.06

1500

110 V – 50 Hz

0.50

205

156

110

40

26

25-80 bar

70 bar/

3 PH

3405099

56

0.09

1500

220/380V – 50 Hz

0.35

205

156

110

38

3405101

56

0.09

1500

220/380V– 50 Hz

0.50

205

156

110

40

3405121

56

0.06

1500

110 V – 50 Hz

0.35

205

156

110

38

3415122

56

0.06

1500

110V – 50 Hz

0.50

205

156

110

40

Intermittent

33V

25-80 bar

50 bar/

3 PH

with

release

valve

3405098

56

0.12

1500

220/380V-50 Hz

0.35

187

156

110

38

3405100

56

0.12

1500

220/380V-50 Hz

0.50

187

156

110

40

3405123

56

0.06

1500

110 V – 50 Hz

0.35

205

156

110

38

3405124

56

0.06

1500

110 V – 50 Hz

0.50

205

156

110

40

This assembly consists only of the motor and the gear pump.

* NON-STANDARD DIMENSIONS

This assembly is composed of a gear pump, an electric motor, a manometer and a valve block.

Thanks to a by-pass it is possible to regulate the working pressure in accordance with the requirements of the system to which

the pump is connected.

Also included in the valve block is a non-return valve or alternatively a release valve so that it can be adapted for use with the

different DROPSA systems (line 01, line 26, 33V System) or on other systems of a similar nature.

It is also possible to order separately an intake filter with a dip tube (400 mesh/cm2 filtering grade 260) of an overall length

variable between 100 and 455 mm depending on the differing requirements of the installation).

THE MOTOR VOLTAGE MUST ALWAYS BE STATED AT THE TIME OF ORDERING.

9

Gear pumps and electro-gear pumps, (pumps with horizontal fastening)

Liters

Rotation #

Weight

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V W Z 2 37060

0,9

1/4

40

8,7

10

25 3 11,2

44,5

45,5

25

48

65 8 60

60

14,5 … … 6 …

3,5

37036

37021

10 37024

1,9

3/8

54

12,3

12

30 4 13,5

57

61

35

60

82

10

80

80

18,5 … …

9,5

…

19

37040 3,2

1/2

65

15,2

14

32 5 16

67

73

44

74

96

10

90

98

25 … …

9,5 … 32 37030

5

3/4

77,5

18,9

16

34 5 18,8

72

79

50

84

110

10,5

108

116

25 … …

11,5

…

Liters

Rotation #

Weight

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V W Z 2 37061

1

1/4

40

8,7

10

25 3 11,2

44,5 … 25

48

65 8 60

60

14,5

45,5

58 6 …

3,5

37111

37022

5,5 37063

2,1

3/8

54

12,3

12

30 4 13,5

57 … 35

60

82

10

80

80

18,5

61

78

9,5

…

10

37039

37025

Liters

Sunction

Weight

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V W Z 2

37070

0,9

1/4

40

8,7

10

25 3 11,2

44,5 … 25

48

65 8 60

60

14,5

90 … 6

49,5

3,5

37023 5,5

37071

1,9

3/8

54

12,3

12

30 4 13,5

57 … 35

60

82

10

80

80

18,5

120,5 … 9,5

69

10

37026

Max Pressure = 30 bar for continuous working – Max Pressure =60 bar for intermittent working.

Fluid working temperature = 20÷100 ºC with low and medium oil viscosity.

Note: For pumps either with clockwise rotation or bi-rotational with suction on left side, connect suction line to threaded port 1

and delivery line to threaded port 2 ;

For pumps either with counter - clockwise rotation or bi-rotational with suction on right side connect suction line to threaded

port 2 and delivery line to threaded port 1;

WITHOUT BY PASS

# Looking at the pump from shaft side

WITH BY PASS

# Looking at the pump from shaft side

REVERSIBLE

* Please ask to nearest Dropsa for availability

Dimensions and features may change without notice

10

Gear pump and electro-gear pumps (pumps with flange)

Liters

Rotation#

Weight

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V Z 2 37066

37054

0,9

1/4

70

50

60

5,7

6,5

10 2 3

11,2

32

63

8,7

60

60

15 … …

…

3,5 37001

5,5

37068

37056

1,9

3/8

100

70

84 7 8,5

12 3 4

13,5

42,5

85

12,3

80

80

19 … …

…

10

37018

37004

19 37007

3,2

1/2

120

90

100 7 9

14

3,5 5 16

53,5

102

15,2

98

90

26 … … … 26 37058

5

3/4

140

100

120 9 10

16 4 5

18

59

113

18,9

116

108

34 … …

…

32

37123

37010

*45 37013 8 1

150

110

130

11,5

11

18 4 6

20,5

65,5

138,5

22,5

140

130

38 … …

…

Liters

Rotation#

Peso

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V Z 2

37055

1

1/4

70

50

60

5,7

6,5

10 2 3

11,2

32 … 8,7

60

60

15

63

58

…

3,5 37002

5,5 37057

2,1

3/8

100

70

84 7 8,5

12 3 4

13,5

42,5 … 12,3

80

80

19

85

78

…

10

37016

37005

19

37082

37008

3,5

1/2

120

90

100 7 9

14

3,5 5 16

53,5 … 15,2

98

90

26

104

86 … 26 37059

5,5

3/4

140

100

120 9 10

16 4 5

18

59 … 18,9

116

108

34

117

102,5

…

32 37011

*45 37014

8,2 1 150

110

130

11,5

11

18 4 6

20,5

65,5 … 22,5

140

130

38

138,5

113

…

Liters

Sunction

Weight

kg

Gas

D

Dimensions (mm)

Left

Right E F G H J K L M N O P Q R S T U V Z 2 37067

0,9

1/4

70

50

60

5,7

6,5

10 2 3

11,2

32 … 8,7

60

60

15

63 … 67,5

3,5

37020

37003

5,5

37069

1,9

3/8

100

70

84 7 8,5

12 3 4

13,5

42,5 … 12,3

80

80

19

87,5 … 92

10

37006 19

37009 3,2

1/2

120

90

100 7 9

14

3,5 5 16

53,5 … 15,2

98

90

26

108,5

…

113,5

26

37083

5

3/4

140

100

120 9 10

16 4 5

18

59 … 18,9

116

108

34

120,5 … 125

32

37012

Max Pressure = 30 bar for continuous working – Max Pressure =60 bar for intermittent working.

Fluid working temperature = 20÷100 ºC with low and medium oil viscosity.

Note: For pumps either with clockwise rotation or bi-rotational with suction on left side, connect suction line to threaded port 1

and delivery line to threaded port 2 ;

For pumps either with counter - clockwise rotation or bi-rotational with suction on right side connect suction line to threaded

port 2 and delivery line to threaded port 1;

WITHOUT BY PASS

# Looking at the pump from shaft side

WITH BY PASS

# Looking at the pump from shaft side

REVERSIBLE

* Please ask to nearest Dropsa for availability

Dimensions and features may change without notice

11

Assembl.

Part N.

Liters Power

KW

Press.

max

bar

Weig

ht

Kg

gas

D

Dimensions (mm)

E G H K I L M N O P Q R T U V

3410110

2

0.185

26

8.6

1/4

115

148

306

118

--- 9 95

11

32

63

8.7

60

---

140

23

3410112

3.5

0.25

20

8.6

1/4

130

167

333

126

--- 9 110

129

32

63

8.7

60

---

160

23

3410114

5.5

0.25

13

10.4

3/8

130

167

355

148

--- 9 110

129

42

85

12.3

80

---

160

23

3410118

10

0.25 7 10.4

3/8

130

167

355

148

--- 9 110

129

42

85

12.3

80

---

160

23

3410120

10

0.55

15

12.9

3/8

165

187

392

159

---

11

130

149

42

85

12.3

80

---

200

28

3410122

19

0.55 8 15.7

1/2

165

187

437

202

---

11

140

149

53

102

15.2

90

---

200

28

3410124

19

0.75

11

17.2

1/2

165

187

437

202

---

11

140

149

53

102

15.2

90

---

200

28

3410126

26

0.75 8 19.5

3/4

165

187

451

214

---

11

150

149

59

113

18.9

108

---

200

28

3410128

26

1.1

12

25

3/4

165

210

473

214

---

11

150

172

159

113

18.9

108

---

200

28

3410130

32

0.75 6 19.5

3/4

165

187

451

214

---

11

150

149

59

113

18.9

108

---

200

28

3410132

32

1.1

10

25

3/4

165

210

473

214

---

11

150

172

59

113

18.9

108

---

200

28

Assemb.

Part N:

Lite

rs

Pow.

KW

Press..

max

bar

Weig

ht

Kg

gas

D

Dimensions (mm)

E G H K I L M N O P Q R T U V

3410111

2

0.185

26

8.7

1/4

115

148

---

118

306 9 95

111

32

63

8.7

60

58

140

23

3410113

3.5

0.25

20

8.7

1/4

130

167

---

128

333 9 110

129

32

63

8.7

60

58

160

23

3410119

10

0.25 7 10.6

3/8

130

167

---

148

355 9 110

129

42

85

12.3

80

78

160

23

3410121

10

0.55

15

13.1

3/8

165

187

---

159

392

11

130

149

42

85

12.3

80

78

200

28

3410123

19

0.55 8 16

1/2

165

187

---

204

439

11

140

149

53

104

15.2

90

86

200

28

3410125

19

0.75

11

17.5

1/2

165

187

---

204

439

11

140

149

53

104

15.2

90

86

200

28

3410127

26

0.75 8 20

3/4

165

187

---

218

455

11

150

149

59

117

18.9

108

102.5

200

28

3410129

26

1.1

12

25.5

3/4

165

210

---

218

477

11

150

172

59

117

18.9

108

102.5

200

28

3410131

32

0.75 6 20

3/4

165

187

---

218

455

11

150

149

59

117

18.9

108

102.5

200

28

3410133

32

1.1

10

25.5

3/4

165

210

---

218

477

11

150

172

59

117

18.9

108

102.5

200

28

WITHOUT BY-PASS

Vertical or horizontal application motor-driven pumps–

motor type B5 4 pole

WITH BY-PASS

12

Vertical or horizontal application motor-driven pumps–motor type B3/B14 4 pole

Assemb.

Part N.

Lite

rs

Pow.

KW

Press.

max

bar

Weig

ht

Kg

gas

D

Dimensions (mm)

E F G H K I Y L M N O P Q R S T U

V

3410011

2

0.185

26

8.6

1/4

80

127

155

306

118 - 63 7 8

111

32

63

8.7

60

100 - 120

100

3410012

3.5

0.25

20

8.6

1/4

90

140

173

333

126 - 71 7 9

129

32

63

8.7

60

112 - 136

110

3410027

5.5

0.25

13

10.4

3/8

90

150

173

355

148 - 71 7 9

129

42

85

12.3

80

112 - 136

110

3410013

5.5

0.55

29

12.9

3/8

100

166

192

392

159 - 80 9 10

149

42

85

12.3

80

125 - 155

125

3410028

10

0.25 7 10.4

3/8

90

150

173

355

148 - 71 7 9

129

42

85

12.3

80

112 - 136

110

3410014

10

0.55

15

12.9

3/8

100

166

192

392

159 - 80 9 10

149

42

85

12.3

80

125 - 155

125

3410029

19

0.55 8 15.7

1/2

100

203

192

437

204 - 80 9 10

149

53

102

15.2

98

125 - 155

125

3410015

19

0.75

11

17.2

1/2

100

203

192

437

204 - 80 9 10

149

53

102

15.2

98

125 - 155

125

3410030

26

0.75 8 19.5

3/4

100

210

192

451

218 - 80 9 10

149

59

113

18.9

116

125 - 155

125

3410016

26

1.1

12

25

3/4

100

216

216

473

218 - 90 9 11

172

59

113

18.9

116

140 - 174

128

3410031

32

0.75 6 19.5

3/4

100

210

192

451

218 - 80 9 10

149

59

113

18.9

116

125 - 155

125

3410017

32

1.1

10

25

3/4

100

216

216

473

218 - 90 9 11

172

59

113

18.9

140

140 - 174

128

3410032

45

1.1 7 28.5 1 100

222.5

216

494.5

239.5 - 90 9 11

172

65.5

138.5

22.5

140

140 - 174

128

3410018

45

2.2

15

48.5 1 140

238.5

238

570

248.5 - 100

12

12

196

65.5

138.5

22.5

140

160 - 196

170

Assemb.

Part N.

Liters Pow.

KW

Pres.

max

bar

Weig

ht

Kg

gas

D

Dimensions (mm)

E F G H K I Y L M N O P Q R S T U V 3410019

2

0.185

26

8.7

1/4

80

127

155 - 118

306

63 7 8

111

32

63

8.7

60

100

58

120

100

3410020

3.5

0.25

20

8.7

1/4

90

140

173 - 126

333

71 7 9

129

32

63

8.7

60

112

58

136

110

3410033

5.5

0.25

13

10.6

3/8

90

150

173 - 148

355

71 7 9

129

42

85

12.3

80

112

78

136

110

3410021

5.5

0.55

29

13.1

3/8

100

166

192 - 159

392

80 9 10

149

42

85

12.3

80

125

78

155

125

3410034

10

0.25 7 10.6

3/8

90

150

173 - 148

355

71 7 9

129

42

85

12.3

80

112

78

136

110

3410022

10

0.55

15

13.1

3/8

100

166

192 - 159

392

80 9 10

149

42

85

12.3

80

125

78

155

125

3410035

19

0.55 8 16

1/2

100

203

192 - 206

439

80 9 10

149

53

104

15.2

98

125

86

155

125

3410023

19

0.75

11

17.5

1/2

100

203

192 - 206

439

80 9 10

149

53

104

15.2

98

125

86

155

125

26

0.75 8 20

3/4

100

210

192 - 222

455

80 9 10

149

59

117

18.9

116

125

102.5

155

125

3410024

26

1.1

12

25.5

3/4

100

216

216 - 222

477

90 9 11

172

59

117

18.9

116

140

102.5

174

128

3410037

32

0.75 6 20

3/4

100

210

192 - 222

455

80 9 10

149

59

117

18.9

116

125

102.5

155

125

3410025

32

1.1

10

25.5

3/4

100

216

216 - 222

477

90 9 11

172

59

117

18.9

116

140

102.5

174

128

3410038

45

1.1 7 29 1 100

222.5

216 - 239.5

494.5

90 9 11

172

65.5

138.5

22.5

140

140

113

174

128

3410026

45

2.2

15

49 1 140

238.5

238 - 248.5

570

100

12

12

196

65.5

138.5

22.5

140

160

113

196

170

3410067

60

2.2

11

52 1 140

238.5

238 - 248.5

570

100

12

12

196

65.5

138.5

22.5

140

160

113

196

170

WITHOUT BY-PASSΎ

WITH BY-PASSΎ

3410036

* A, B, C - Non standart quote

13

12. DIMENSIONS

Fluids

Dangers

Lubricants containing abrasive components

Premature wear of pump

Lubricants containing silicon

Pump failure

Petrol – solvents – inflammable liquids

Fire – explosion –seal damage

Corrosive products

Pump damage - danger to persons

Water

Pump oxidization

Food Products

Contamination of the product

See tables in charter 11 “ORDERING INFORMATION”

13. HANDLING AND TRANSPORTATION

Prior to shipping, the equipment is carefully packed in a cardboard package. During transportation and storage, pay attention to

the side on the cardboard packing. On receipt, check that the packing is not damaged. Then, storage the machine in a dry

location.

14. OPERATING HAZARDS

It is necessary to carefully read about the instructions and the risks involved in the use of lubrication machines. The operator

must know the machine functioning through the User and Maintenance Manual

Inflammability

The lubricant generally used in lubrication systems is not normally inflammable. However, it is advised to avoid contact with

extremely hot substances or naked flames.

Pressure

Prior to any intervention, check the absence of residual pressure in any branch of the lubricant circuit as it may cause oil

sprays when disassembling components or fittings.

15. PRECAUTIONS

No particular operating hazards characterize Motor Driven Gear pumps, except for the following precautions:

Contact with fluid to break/open feed pipe. The operator must use appropriate protective clothing, gloves and take all

necessary safety precautions (D. Lgs. 81/08).

Awkward postures . Follow instruction in section 6.2.

Contact with oil during refilling / maintenance. The operator must use appropriate protective clothing, gloves and take

all necessary safety precautions (D. Lgs. 81/08).

Using the wrong lubricants:

14

16. WARRANTY INFORMATION

All products manufactured and marketed by Dropsa are warranted to be free of defects in material or workmanship for a period

of at least 12 months from date of delivery. Extended warranty coverage applies as follows:

Complete system installation by Dropsa: 24 Months

All other components: 12 months from date of installation; if installed 6 months or more after ship date, warranty shall be

maximum of 18 months from ship date.

If a fault develops, notify us giving a complete description of the alleged malfunction. Include the part number(s), test record

number where available (format xxxxxx-xxxxxx), date of delivery and installation and operating conditions of subject product(s).

We will subsequently review this information and, at our option, supply you with either servicing data or shipping instruction

and returned materials authorization (RMA) which will have instructions on how to prepare the product for return. Upon

prepaid receipt of subject product to an authorized Dropsa Sales & Service location, we will then either repair or replace such

product(s), at out option, and if determined to be a warranted defect, we will perform such necessary product repairs or replace

such product(s) at our expense.

Dropsa reserves to right to charge an administration fee if the product(s) returned are found to be not defective.

This limited warranty does not cover any products, damages or injuries resulting from misuse, neglect, normal expected wear,

chemically caused corrosion, improper installation or operation contrary to factory recommendation. Nor does it cover

equipment that has been modified, tampered with or altered without authorization.

Consumables and perishable products are excluded from this or any other warranty.

No other extended liabilities are states or implied and this warranty in no event covers incidental or consequential damages,

injuries or costs resulting from any such defective product(s).

The use of Dropsa product(s) implies the acceptance of our warranty conditions. Modifications to our standard warranty must be

in made in writing and approved by Dropsa.

15

17. DECLARATION OF COMPLIANCE WITH CE STANDARDS

Dropsa Spa

Via Benedetto Croce, 1

20090 Vimodrone (MI)

Italy

Tel.:

Fax Sales:

E-mail:

Web site:

(+39) 02. 250.79.1

(+39) 02. 250.79.767

sales@dropsa.it

http://www.dropsa.com

DICHIARAZIONE DI CONFORMITÁ/DECLARATION OF COMPLIANCE WITH STANDARDS/

DECLARATION DE CONFORMITE/ KONFORMITÄTSERKLÄRUNG DES STANDARDS /DECLARACIÓN DE

CONFORMIDAD/ DECLARAÇÃO DE CONFORMIDADE

La società Dropsa S.p.A., con sede legale in Milano, Via Besana,5/ Dropsa S.p.A., registered office in Milan, Via

Besana,5 / Dropsa S.p.A. au Siège Social à Milan, Via Besana,5/ Dropsa S.p.A., Sitz in Milano, Via Besana 5/ La

sociedad Dropsa S.p.a., con sede legal en Milán, Via Besana,5/ A Dropsa S.p.A, com sede em Milão, via Besana, nº 5

DICHIARA /CERTIFIES / CERTIFIE/ ZERTIFIZIERT, DASS/ DECLARA/ CERTIFICA:

che la macchina denominata/that the machine named / que la machine dénommée/ Die Maschine mit der

Bezeichnung/ que la máquina denominada/ que o equipamento denominado

ELETTROPOMPE AD INGRANAGGI TIPO 37000, 3400000, 3410...

è conforme alle condizioni previste dalle Direttive CEE /has been constructed in conformity with the Directives Of

The Council Of The European Community on the standardization of the legislations of member states/ a été

construite en conformité avec les Directives Du Conseil Des Communautes Europeennes/ Entsprechend den

Richtlinien des Rates Der Europäischen Union, für die Standarisierung der Legislative der Mitgliederstaaten,

konstruiert wurde/ cumple con las condiciones establecidas por las directivas comunitarias/ foi construído em

conformidade com as diretivas do Conselho das Comunidades Europeias:

2006/42 Direttiva macchine /Machinery Directive / 2006/42 Directive machines / Maschinenrichtlinien/

Maquinaria 2006/42/CEE /Directiva 2006/42 Máquinas;

2006/95 Bassa tensione/ Electrical Safety: Low Voltage Directive/2006/95 Sécurité électrique: Directive

Basse Tension/Elektrische Sicherheit: Niedrigspannungsrichtlinien/Seguridad eléctrica 2006/95:

Directiva de baja tensión/Segurança Elétrica 2006/95: Directiva de Baixa Tensão

Vimodrone (MI), April 2011 Technical Director:

Maurizio Greco

…………………………

Legal representative

Milena Gavazzi

…………………………

16

18. DISTRIBUTORS

Dropsa S.p.A.

Via B. Croce,1

20090 Vimodrone (MI) Italy.

Tel: (+39) 02 - 250.79.1

Fax: (+39) 02 - 250.79.767

E-mail: sales@dropsa.it (Export)

E-mail: vendite@dropsa.it (National)

Dropsa Ame

23, Av.des.Morillons

Z.I. des Doucettes 91140

Garges Les Gonesse, France

Tel: (+33) 01 39 93 00 33

Fax: (+33) 01 39 86 26 36

E-mail: salesfr@dropsa.com

Dropsa (UK) Ltd

Unit 6, Egham Business Village,

Egham,Surrey,TW20 8RB

Tel: (+44) 01784 - 431177

Fax: (+44) 01784 - 438598

E-mail: salesuk@dropsa.com

Dropsa do Brazil Ind. E Com. Ltda

Rua Sobralia 175,

Sao Paulo, Brazil

Tel: (+55) 011-5631-0007

Fax: (+55) 011-5631-9408

E-mail: salesbr@dropsa.com

Dropsa USA Inc.

6645 Burroughs Ave

48314-2132 Srerling Hts,Mi Us -USA

Tel: (+1) 586-566-1540

Fax: (+1) 586-566-1541

E-mail: salesusa@dropsa.com

Dropsa Lubrication Systems

Nr 8 Dongxing Road,

Songjiang Industrial Zone

(Shanghai) Co., Ltd

Tel: +86 (021) 67740275

Fax: +86 (021) 67740205

E-mail: china@dropsa.com

Dropsa Gmbh

Volmerswerther Strasse 80

40221 Dusseldorf 1, Deutschland

Tel: (+49) 0211/39 4011

Fax:(+49) 0211/39 4013

E-mail: sales@dropsa.de

Dropsa Australia Pty.

C20/148 Old Pittwater Road

Brookvale, NSW 2100

Tel: +61 (02) 9938 6644

Fax: +61 (02) 99 386 611

E-mail: salesau@dropsa.com

Web site: http://www.dropsa.com - E-mail: sales@dropsa.com

Loading...

Loading...