DROPSA 3106000 User And Maintenance Manual

http://www.dropsa.com

HAND OPERATED

PUMP

3106000

User and maintenance

manual

Warranty Information

CONTENTS

1. INTRODUCTION

2. GENERAL DESCRIPTION

3 PUMP IDENTIFICATION

4. TECHNICAL SPECIFICATIONS

5. PUMP COMPONENTS

6. PUMP UNPACKING AND INSTALLATION

7. INSTRUCTIONS FOR USE

8. PROBLEMS AND SOLUTIONS

9. MAINTENANCE PROCEDURES

10. DISPOSAL

11. ORDER INFORMATION

12. DIMENSIONS

13. HANDLING AND TRANSPORT

14 PRECAUTIONS FOR USE

15 GUIDELINES FOR USE

16. WARRANTY

17. DISTRIBUTORS

C2157IE – WK 39/10

2

1. INTRODUCTION

PRODUCT IDENTIFICATION

HAND OPERATED PUMP

This user and maintenance manual relates to the HAND OPERATED PUMP 3106000.

Using this pump means that oils and greases can be distributed within lubrication systems even at high pressures of up to 400

bar (5880 psi).

The latest version may be obtained from the Technical-Commercial Office, or by consulting our web site

http://www.dropsa.com.

The pump subject of this manual must be used by qualified personnel with basic hydraulic and electrical knowledge.

This user and maintenance manual contains important information about protecting the health and safety of the personnel

who intend to use this apparatus. You must read and look after it carefully, making sure that it is available at all times for the

operators who intend to consult it.

2. GENERAL DESCRIPTION

The hand operated pump 3106000 is particularly suggested due to its compact form and versatility when used with press

lubrication systems, machine tools, reducers, guides, chains, etc.…

The hand operated pump 3106000 has a built-in release valve and can be used in the following types of systems:

Progressive lubrication systems with injectors and circulation systems – System 01.

Lubrication systems that have "direct response" measuring devices – System 33V.

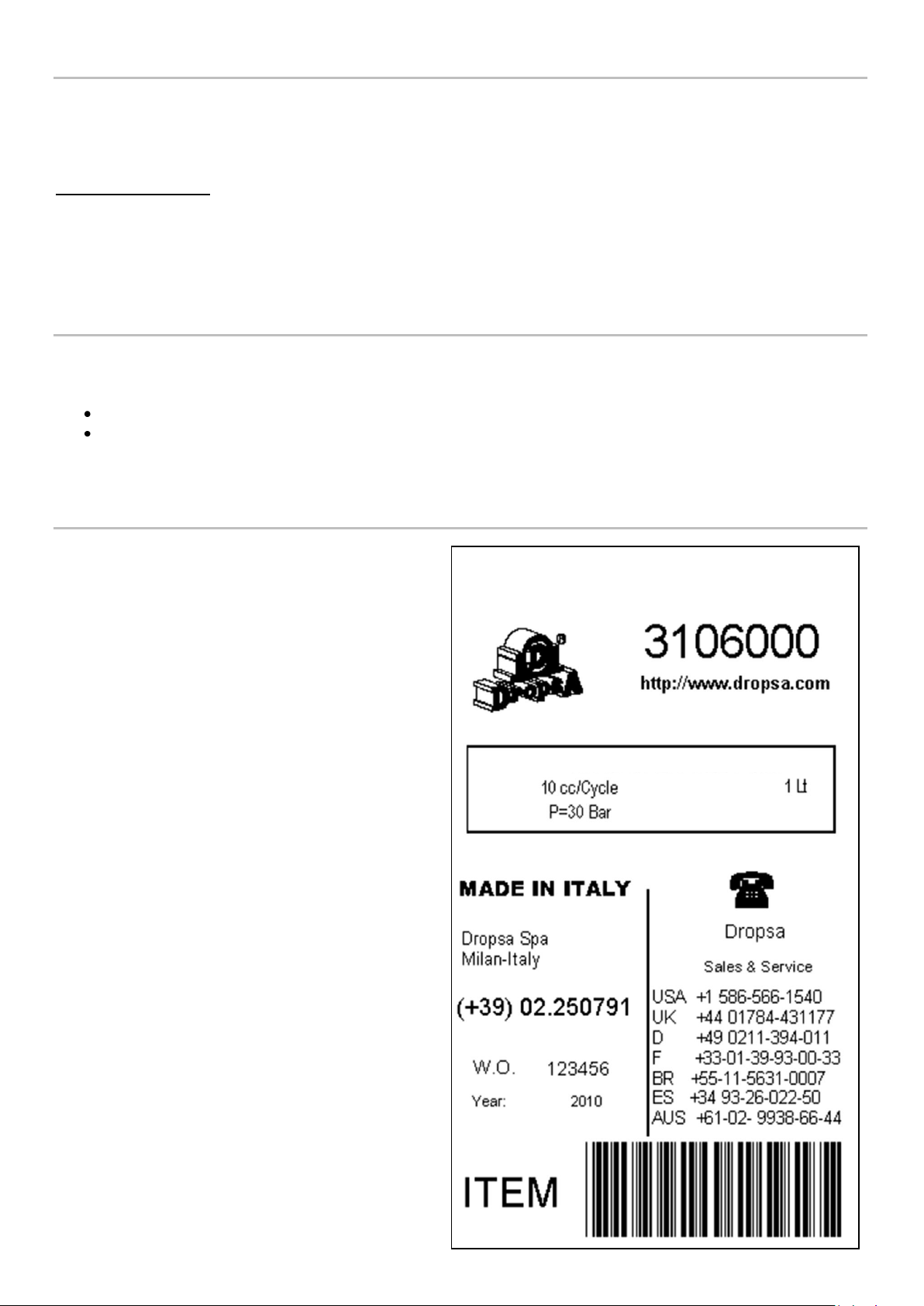

3. MACHINE IDENTIFICATION

There is a yellow label on the front of the pump tank that

displays the product code and its basic characteristics.

3

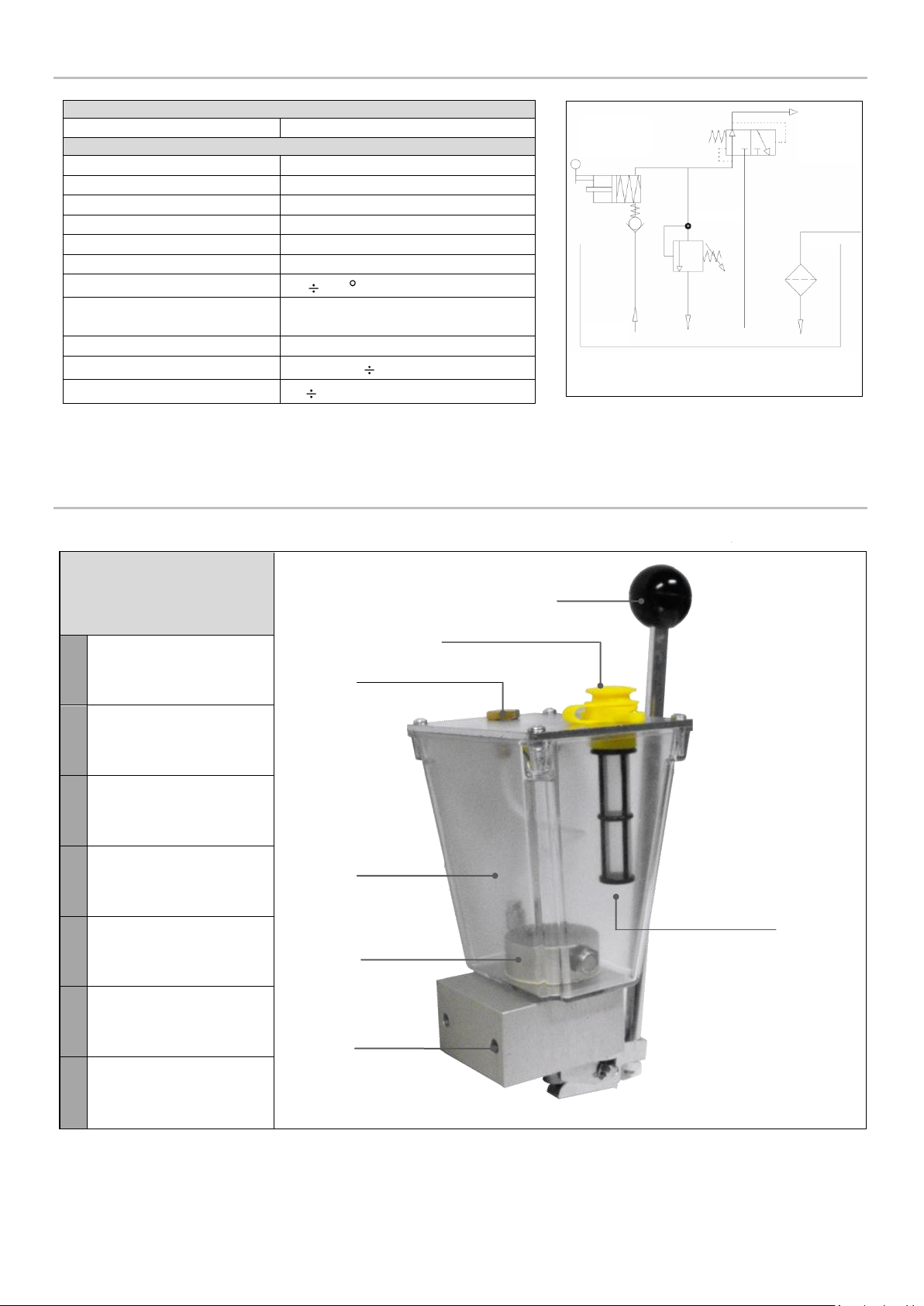

4. TECHNICAL SPECIFICATIONS

GENERAL CHARACTERISTICS

Empty weight

2.5 Kg

TECHNICAL SPECIFICATIONS

Activation

Manual

Pumping system

Piston

Maximum operating pressures

30 bar

Tank capacity

1 L

Flow rate

10 cc/shot

Outlet connection

G1/4” BSP

Temperature of use

+ 5 + 40 C

Permitted lubricants

Mineral lubricating oil min. 32 cSt/

Grease max NLGI000*

Maximum driving force

20 Kg

Bypass

Adjustable 0 30 bar

Storage temperature

-20 +65°C

PUMP COMPONENTS

1

Activation lever

2

Loading cap

3

Outlet

4

Tank 5 Distributor block

6

Fastener

7

Filter

G1/4” BSP

355 µ

0-30 bar

10 cc/shot

P. max 30 bar

1L

HYDRAULIC DIAGRAM

1

5

7

6 4 3

N.b. The specifications refer to the temperature of use of +20°C (+68 °F)

* If a different product is used, please contact Dropsa S.p.A. to ensure it is suitable for use

5. MACHINE COMPONENTS

Loading...

Loading...