OPERATING INSTRUCTIONS

PROMOVET sarl

ZAC de la Route de Beauraing, 1

08600 GIVET (France)

info @ promovet.fr

DROPER FIELD 1000

FULLY MECHANICAL INFUSION PUMP

1 / 16

Table of contents

1 Description of the Droper Field 1000 3

2 Using the Droper Field 1000 4

3 Operating issues 11

4 End of infusion 12

5 Cleaning / Disinfection 13

6 Periodic inspection 15

7 Storage 15

8 Warranty conditions 15

9 Life 16

10 Useful contacts 16

2 / 16

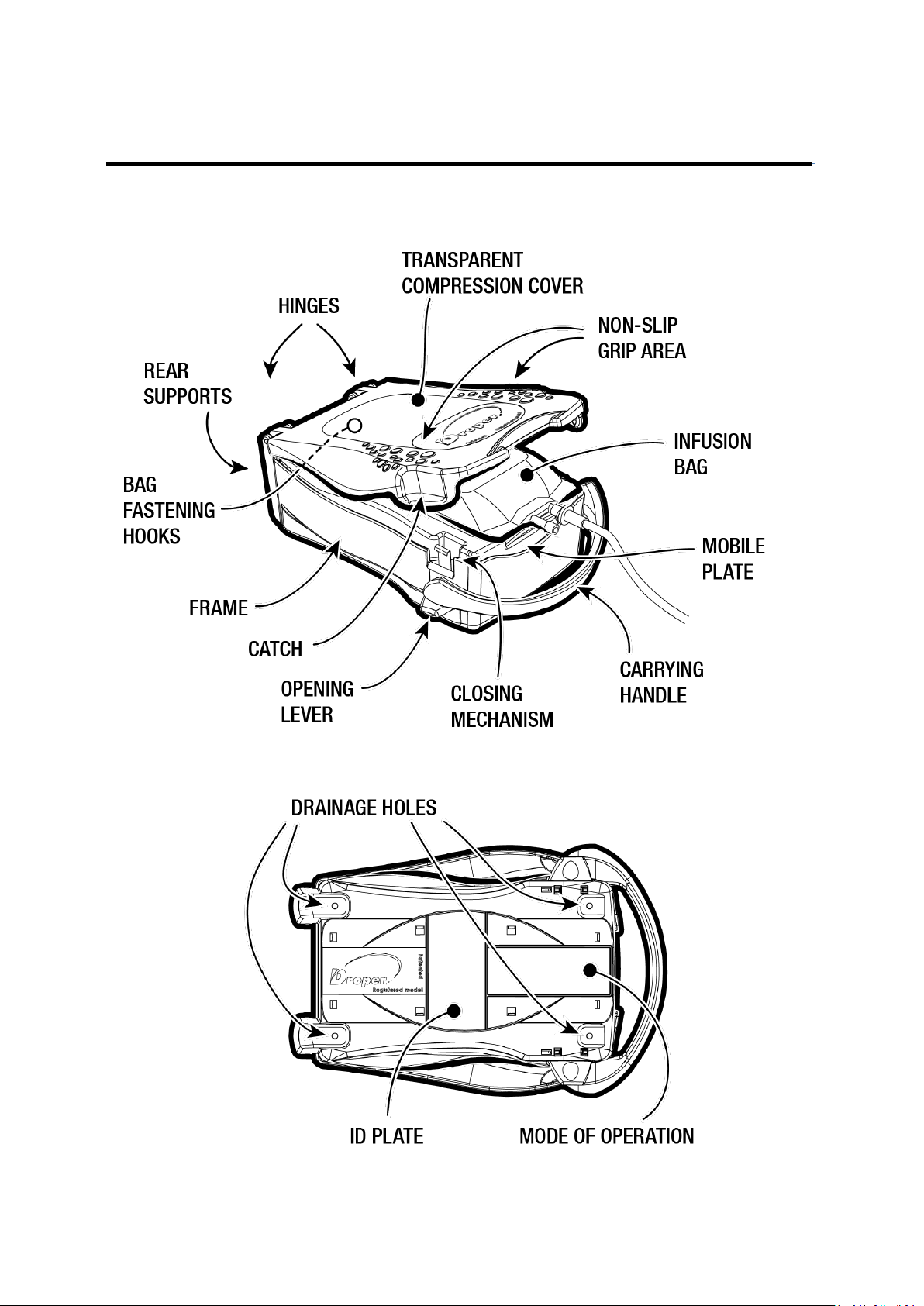

1. DESCRIPTION OF THE DROPER

3 / 16

2. USING THE DROPER FIELD 1000

The Droper Field is a medical device designed to pressurise flexible infusion bags containing all

solutions suitable for intravenous infusion for the administration, in a non-intrusive manner by

infusion, of the contained solutions to patients requiring the latter. The device is dimensioned in such

a way as to be able to receive most infusion bags up to 1,000 ml commercially available at the time of

its introduction, in order to produce a bag pressure of about 100 mbar, equivalent to an approximate

height of 1 metre between the patient and the infusion bag for administration by gravity.

The safety instructions regarding the use of such bags must be known prior to use.

Its transparent cover enables the user to see the nature of the substance

administered. Principally intended for use in emergency situations or

catastrophes where stress levels are high, the device must be used by

trained, qualified staff.

The Droper Field device is not sensitive to environmental conditions. It has

been designed using materials capable of operating at both negative and

positive temperatures.

The infusion flow rate is entirely dependent on the viscosity of the infusion

solution. In cases not using a drip chamber (see below), different types of

flow regulators are commercially available for different viscosities and for

pressures equivalent to that generated by the Droper Field 1000. The

operator must therefore take this into account when choosing the flow

regulator to be used in these cases.

Under no circumstances may rigid or semi-rigid bottles be inserted into

the device.

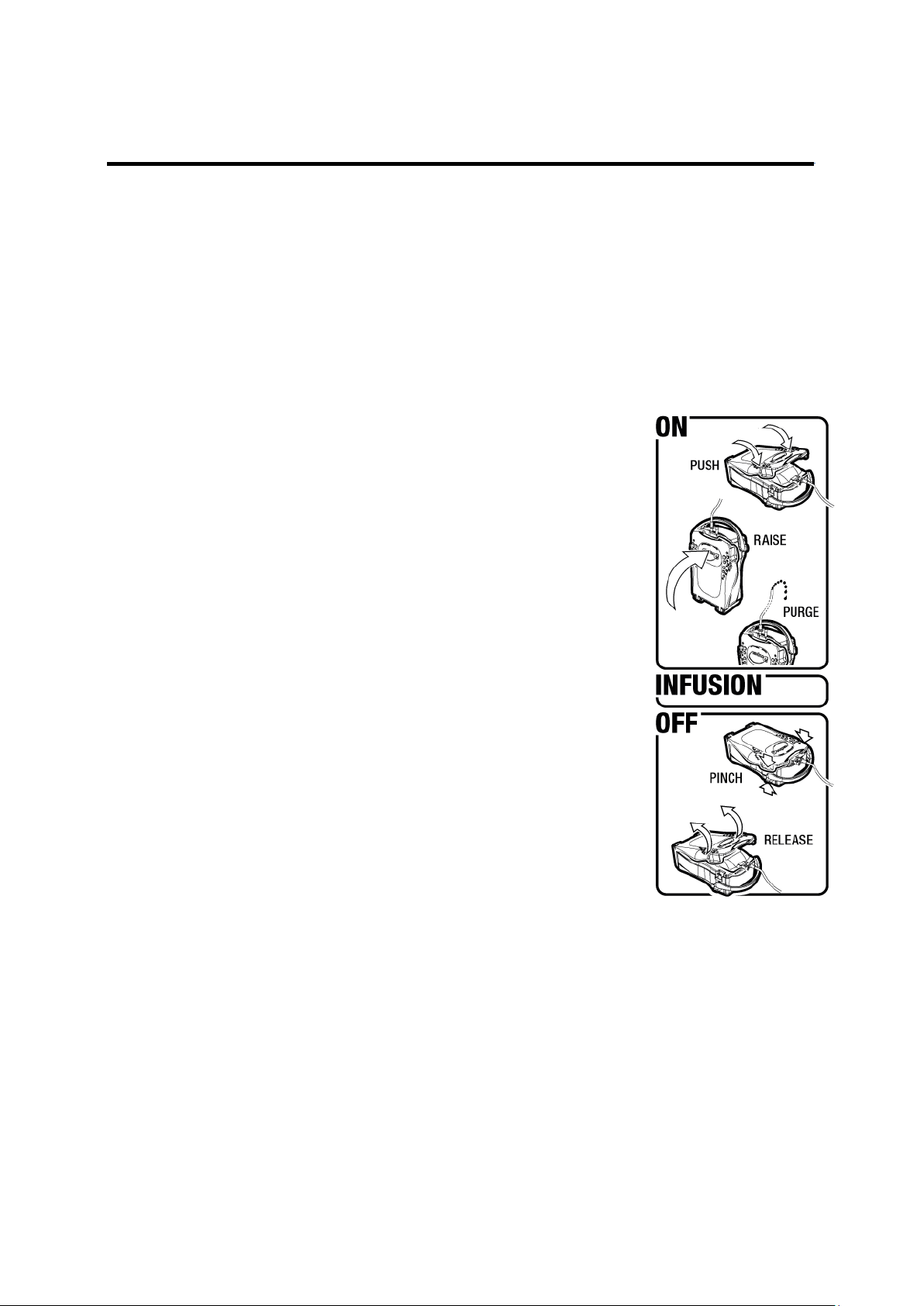

The device's method of operation is described hereinbelow in the form of

several pictograms, which can be found underneath the device and shown

opposite:

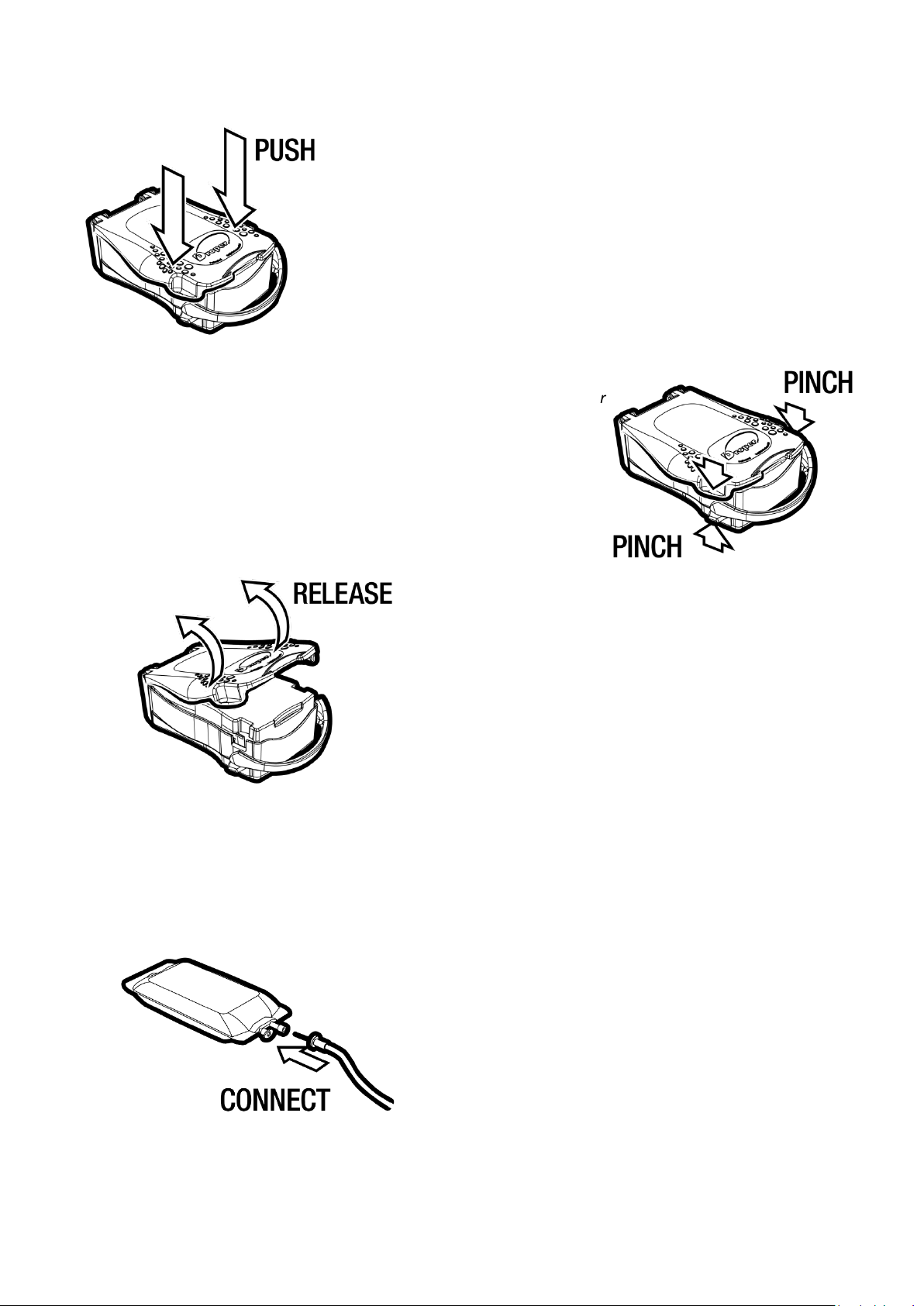

2.1 Opening the cover

The mobile plate located underneath the transparent cover has certain elastic properties when

pressure is exerted in a downwards direction. To open the Droper Field 1000, the device is placed on

a flat, stable surface directly beneath the operator. The operator grasps the Droper Field 1000 by

placing the cushion of his/her thumbs on the non-slip areas provided for this purpose on either side of

the cover.

4 / 16

With outstretched arms, the operator places his/her middle finger

of each hand underneath the disarming side lever. The device opens

in three steps:

1. The operator firstly exerts pressure in a downwards direction on

the cover using his/her body weight and with outstretched arms.

This action places pressure on the mobile plate. The resulting

small downwards movement can be observed.

2. Without releasing the pressure exerted on the cover, the operator

then exerts upwards pressure on the two disarming side levers

by pinching his/her middle fingers of each hand upwards and

inwards. This movement will result in pivoting the closing spring

clips inwards and releasing the cover.

2.2 Inserting the infusion line

3. While holding the two open levers in position, release

the pressure exerted on the cover. Then open the

cover by pushing it upwards using an index finger.

Where necessary, install an extension with a 3-way

stopcock at the start of the line to be able to check the

correct operation of the device during the infusion.

Check that the choke or flow regulator is set to the OFF

position.

Check that the air intake valve in the drip chamber is in

the closed position.

Insert the piercing pin at the bottom into the tubing port

of the infusion bag.

5 / 16

2.3 Choosing the infusion line

Different types of infusion lines may be used. Their choice and handling with regard to air drainage are

determined according to the Droper's mode of use.

1. Infusion line with drip chamber positioned in the middle of the infusion line (not with drip

chamber connected directly to the spike).

a. Residential infusion (Home care, Hospital, Field

hospital, …) with drip chamber positioned upright,

liquid output in a downwards direction (classic

example): as for gravitational infusions, the drip

chamber is filled with the perfusion fluid until a

certain height is reached, with air being

positioned at the top of the drip chamber. The

flow will be estimated by counting the number of

drops in the first minute of infusion.

b. Infusions in hostile environments with drip chambers capable of being positioned lying

down, or upright with liquid output in a upwards direction during transfer under

infusion: in this case there is a risk that air bubbles originating from the free air

enclosed in the drip chamber are infused. The operator must therefore use the reverse

purge air drainage technique expelling all air including that contained in the drip

chamber. The drip chamber will no longer be used as a reference to estimate the flow

of solution infused. This flow must be estimated or checked using a suitable flow

regulator.

6 / 16

2. Infusion line without drip chamber: the operator must therefore use the reverse purge air

drainage technique expelling all air including that contained in the infusion bag and in the

infusion line. If there is no drip chamber, the infused flow must be estimated or checked by

means of a suitable flow regulator.

2.4 Inserting the infusion bag with the infusion

line and closing the device

1. Insertion: With the cover fully open, position the

infusion bag on the plate and attach it to one of the fastening

hooks on the plate.

The purpose of these fasteners is to prevent the bag from

sliding forwards when closing the device. Two fasteners are

available according to the model of bag used. Their location is

designed to suit the main infusion bag models available on the

market.

If the fastener does not correspond to the bag model used,

the operator must maintain pressure on this bag in a backwards direction to prevent it from sliding

forwards when closing the device.

2. To close: pivot the cover forwards until it enters

into contact with the bulge at the surface of the infusion bag.

Stand directly above the device with outstretched arms and

press down on the cover, placing the cushions of each thumb

on the rough areas located on either side of the cover.

A force of approximately 36 kg is required to pressurise the

device. Prior training is thus recommended to master how to

operate the device.

WARNING: once the movement has been initiated (once the initial resistance has been broken), the

pivoting movement applied to the cover will become easier and the force exerted must be reduced.

This action places pressure on the mobile plate. The resulting significant downwards movement can

be observed. The system closes and is therefore armed as soon as the closing clicks are heard. After

releasing the pressure, the operator must check that the two fastening hooks visible through the

transparent cover are engaged.

If engagement can only be observed on one side, the plate will adopt an inclined position in relation

to the device. In this event, push back down on the cover to release the engaged hook and repeat the

closing operation. This operation pressurises the infusion bag.

7 / 16

2.5 Draining the infusion line and bag

Two reverse purge air drainage scenarios are possible:

1. Draining an infusion bag outside of the Droper by exerting upwards hand pressure on the bag held

upright and perforated with the infusion line.

a. Case where the drip chamber may be used in the

upright position (case 2.3 1-a described above): with the

clamp closed, expel all air contained in the infusion bag until

the drip chamber becomes filled with part of the liquid.

Then insert the bag into the Droper Field as described in

point 2.4 above, ensuring that the drip chamber is

positioned with the outlet pointing downwards. Close the

Droper Field, open the clamp and the Luer Lock cap located

at the end of the line and expel the residual air in the

infusion line.

b. Case where the drip chamber cannot be used upright (case 2.3 1-b described above) and

case where the line does not have a drip chamber: with both the clamp and Luer Lock cap

at the end of the line open, expel all air contained in the infusion bag until the drip chamber

is entirely filled with the infusion solution. Close the choke. Position the bag in the Droper

Field as described in point 2.4 above. Close the Droper Field, re-open the choke and drain

all residual air from the infusion line.

8 / 16

2. Draining an infusion bag installed in the Droper Field using the pressure

generated by the latter. To achieve this, position the Droper Field

upright on its two rear supports. Begin to expel the air as described

above in point 1.a and 1.b according to the type of line and whether a

drip chamber is used.

Connect the infusion line to the patient as per the operating

instructions specific to the infusion line. Check the free

tubing of the infusion line and the absence of any

folds. Adjust to the desired flow rate using the roller

clamp (case 2.3 1-a) or a suitable flow regulator

(case 2.3 1-b and 2.3 2) and begin the infusion.

Ideally, the device should be positioned level with the patient's midaxillary line

to guarantee an approximate pressure of 100 mbar.

If placed at a higher level, and according to the atmospheric pressure conditions, the pressure shall be

approximately increased (in mbar) by the distance (in cm) separating this line from the device outlet

and conversely if it is placed at a lower level. In any event, this position must be taken into account

when adjusting the flow rate.

The Droper Field 1000 is designed for use in

emergency situations and in hostile

environments and does not provide for the electronic

or electrical monitoring of the infusion. The infusion

stage may be assessed by the triangular shape drawn on the

front surface of the mobile plate and containing different

coloured lines. The rising action of the plate during the infusion will

show the first line. This line is the widest and coloured green. The next two lines are red in colour. The

appearance of the peak of the pyramid indicates that the plate has reached its end point.

9 / 16

2.6 End of infusion

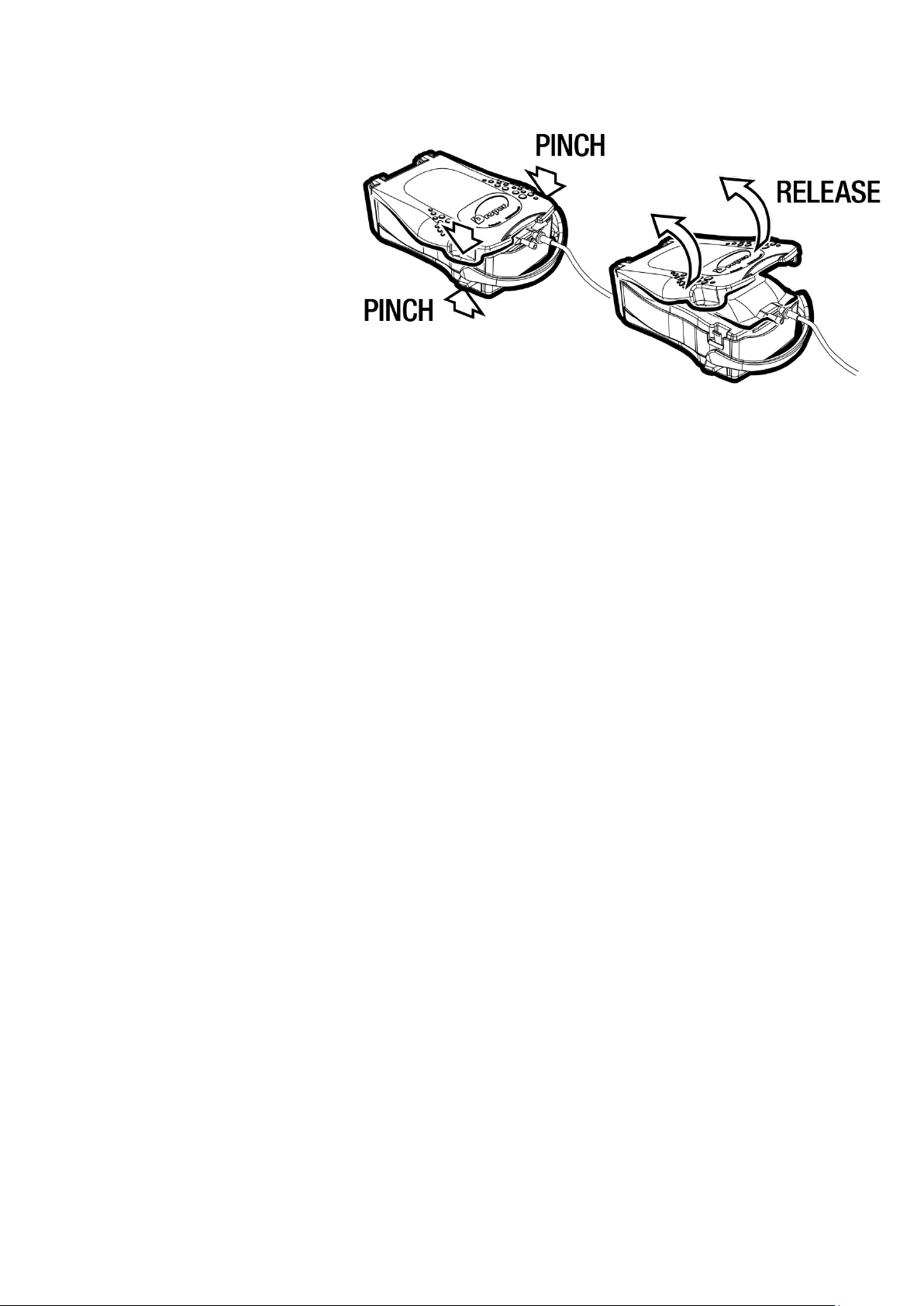

Once the infusion is complete,

open the Droper Field 1000

using the same method as

described in point 2.1 Opening

the cover, and remove the

infusion bag from the device.

2.7 Stopping the infusion

The infusion can be stopped in two ways:

1. by closing the roller clamp or flow regulator by turning them to the OFF position or by

means of any other suitable device.

2. by opening the Droper Field 1000 using the same method as described in point 2.6 End of

infusion. Opening of the cover will result in the mobile plate rising and the release of the

mechanical pressure. A low infusion pressure will however remain due to the gravity

exerted on the infusion bag in the event that the Droper Field 1000 is positioned slightly

above the patient. A low infusion suction effect may on the other hand occur in the event

that the Droper Field 1000 is positioned slightly below the patient. In this case, blood reflux

will be observed. Close the line using the roller clamp or flow regulator by turning them to

the OFF position or by means of any other suitable device.

To open the Droper Field 1000 during an infusion, a higher amount of pressure must be

exerted on the cover due to the presence of a resisting infusion bag. This resistance

increases as the amount of solution drained from the infusion bag decreases.

WARNING: once the movement has been initiated (once the resistance exerted on the anchoring

edges has been released), the pivoting movement of the cover will be fairly quick given the return

force exerted by the back pressure within the system and a strong rising movement will be observed.

2.8 Removing the infusion bag during infusion

Once the infusion has been stopped and the Droper Field 1000 opened as described above in point 2.7

Stopping the infusion, remove the infusion bag by pivoting the cover backwards to release the mobile

plate. Then disconnect the bag from the fastening hook where applicable and remove the infusion

bag/infusion line set from the device. This set may be attached to a classic infusion stand to continue

the infusion by gravity alone.

10 / 16

3. OPERATING ISSUES

3.1 Infusion stopped, insufficient or absent due to a device malfunction

If the infusion stops due to a device malfunction, characterised by a failure in bag pressurisation, this

incident may be confirmed by:

In the case where the drip chamber can be used upright (case 2.3 1-a described above): a

lack of drip flow in the drip chamber.

In the case where the drip chamber cannot be used upright (case 2.3 1-b described above)

and the case where the line does not have a drip chamber: a lack of flow of the infusion

solute under pressure when the Droper Field is at the same level as the patient and when

the external port of the 3-way stopcock is open.

In all cases, observation of the patient's blood being drawn back into the infusion tubing

when the Droper Field is at the same level as the patient (tubing being comprised at this

point by the extension)

Firstly check that the cover of the Droper Field has been closed correctly. Where necessary, open and

re-close the cover.

In the event that the cover is closed correctly, open the Droper Field 1000, unfasten the mobile plate

from its tightening clips, check the following points and implement the relevant actions:

Check that there are no objects blocking the mechanism. If this is the case, remove the

object

– Reinstall the mobile plate onto the mechanism by replacing the clips using pressure. Repressurise the system.

Check that one or several springs have not stopped working.

– Remove the infusion pocket and continue the infusion by gravity or physical pressure or

change device. Send the Droper Field 1000 to the maintenance department for repair.

Check whether the clamp, roller clamp or flow regulator is set to the OFF position

– Reposition the clamp, roller clamp or flow regulator to the desired position.

Check whether the infusion line is being clamped by excessive bending of the latter

– Remove this bend.

Check whether the infusion line is being clamped by an object crushing the line

– Remove this object.

Check whether the infusion line was clamped between the cover and the plate when

arming the Droper Field 1000

– Open the Droper Field 1000 and move the infusion line.

11 / 16

3.2 Infusion stopped, insufficient or absent due to a catheter obstruction

Check whether a catheter obstruction is causing the infusion to stop, be insufficient or absent by:

In the case where the drip chamber is used upright (case 2.3 1-a described above): the lack

of drip flow in the drip chamber.

In the case where the drip chamber is not used upright (case 2.3 1-b described above) and

the case where the line does not have a drip chamber: opening of the 3-way stopcock

positioned at the start of the infusion line extension if these elements have been installed.

With the device positioned at the same level as the patient or slightly below the level of

the latter, the net flow of the solute at the 3-way stopcock without blood reflux into the

infusion line signals the absence of permeability at the infusion site.

The catheter is obstructed or bent or has been moved from its initial position

– Reinsert another catheter.

4. END OF INFUSION

1. The end of the infusion can be checked by observing the inverted pyramid drawn on the

front surface of the mobile plate of the equipment and is reached when the final peak is

visible.

2. The absence of any flow of the infusion solute if the external port of the 3-way stopcock

is open.

3. The appearance of blood reflux in the tubing (with the device being located below the

plane on which the patient is lying).

To keep the venous port free (at the end of the infusion), a new infusion bag must be inserted.

12 / 16

5. CLEANING / DISINFECTION

The device is made from plastic and metal materials that are not subject to either biodegradation or

corrosion. The device was designed to allow for its full cleaning in the event of any leakage of bodily

fluids, liquids being administered or any other external attack.

5.1 Cleaning

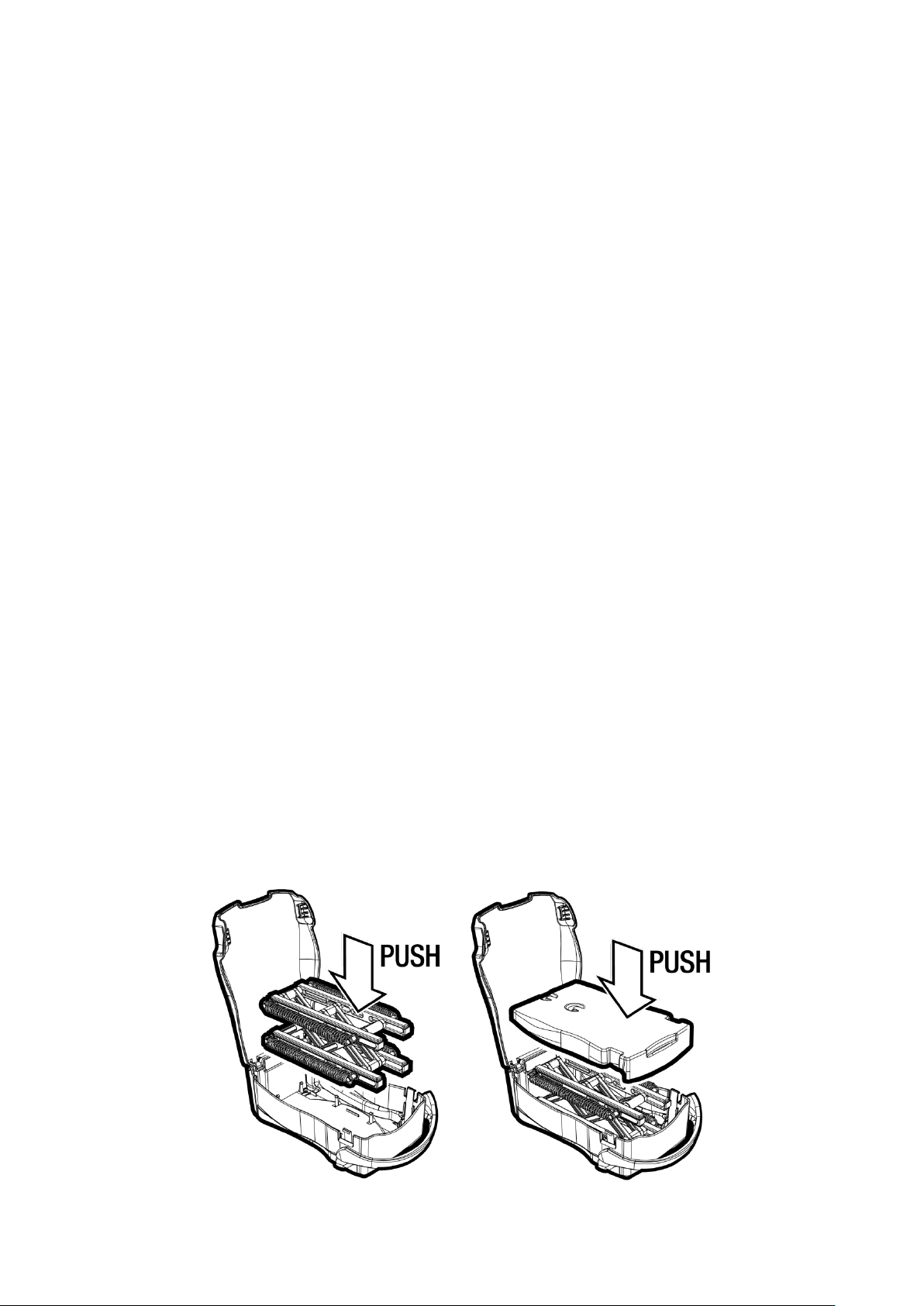

To clean the device, place the Droper Field 1000 on a flat, stable

surface. Open the Droper Field 1000 and pivot the cover

backwards as far as possible. While holding the Droper Field

1000 on the flat surface, firmly grip one of the ends of the plate

and pull it upwards. This will result in the tightening clips

releasing the plate from the mechanism (see diagram).

While holding the Droper Field 1000 on the flat surface, firmly grip

the mechanism and pull it upwards. This will result in the tightening

clips releasing the mechanism from the base of the casing (see

diagram).

Clean the plate, mechanism and casing separately.

Leave to dry.

5.2 Disinfection

After disassembly and cleaning, the different parts removed according to the procedure described

above in point 5.1 Cleaning can be disinfected by soaking, scrubbing or spraying appropriate products.

Solvent-based disinfectants are prohibited.

Particular attention must however be paid during disinfection operations to ensure no damage is

caused to the mechanism's fasteners.

Do not place in a pressure vessel and avoid abrasive scrubbing which may damage the elements.

13 / 16

Do not use cleaning products containing the following ingredients:

AMMONIUM / TRICHLOROETHYLENE

DICHLOROETHYLENE

AMMONIUM CHLORIDE

CHLORINATED or AROMATIC HYDROCARBONS

METHYLENE CHLORIDE

KETONES.

These aggressive agents may damage the plastic parts and cause the device to malfunction.

Please also beware of ALCOHOL-BASED SPRAYS (20% - 40% alcohol content), which may cause the

synthetic materials to tarnish and splinter.

Avoid using iodine solutions capable of irreversibly staining certain clear plastic parts.

The use of disinfectants applied using SPRAYS is ideal for routine disinfection operations and must take

place in compliance with the manufacturer's recommendations and at a distance of 30 cm from the

device, while ensuring that no liquid product is accumulated on the device.

For further information, please contact your company's appropriate department for the provision of

suitable cleaning and disinfection agents.

5.3 Re-installing the components

Once the parts are completely dry, re-insert the two components in the opposite manner to the

disassembly method, presenting each part opposite its tightening clips. The mechanism does not

require a specific forwards/backwards direction of installation. The plate however must be presented

with the fastening hooks facing the rear of the device. Visually check the correct installation of the

different elements.

Ensure that the mechanism is correctly installed facing its clips. Sideways installation could damage

the clips.

14 / 16

6. PERIODIC INSPECTION

The device is designed to operate for 2 years under normal operating conditions, based on a daily

usage rate of 8 infusions per day, i.e. more than 6,000 times. However, the manufacturer advises that

users perform periodic maintenance and inspections to ensure the correct operation of the device,

either by sending it to the manufacturer or distributor, or by using the method described below:

Place a 1000 ml Viaflo infusion bag of NaCl 0.9% marketed by the trademark Baxter in the Droper Field

and introduce the piercing pin of an infusion line without a catheter in the classic OFF position. Drain

the bag and line as described in 2.4 Draining the infusion line and bag. Return the Droper Field 1000

to its horizontal position. Open the infusion line into a recipient placed at the same height as the device

and measure the time required to drain the bag. This time must be between ±320 and ±340 seconds.

7. STORAGE

The device must be stored in a temperature-controlled, dry place.

Recommended relative humidity: 20% to 90%

Recommended storage temperature: - 10°C to + 60°C

8. WARRANTY CONDITIONS

The Droper Field 1000 is guaranteed against any part or manufacture defects for a period of 1 year

from its invoice date. To benefit from the parts and labour warranty from our After-Sales Service or

from an approved service, the following conditions must be complied with:

The device must have been used under the normal operating conditions described

herein.

The device must not have suffered from any deteriorations caused by its storage,

maintenance or incorrect handling.

The device must not have been modified or repaired by persons not authorised by

PROMOVET.

The serial number of the device must not have been modified or erased.

For item returns and repairs, please contact the After-Sales Service.

15 / 16

9. LIFE

v.1 - 09/2013

The Droper Field 1000 was designed to operate for a period of 2 years, calculated based on a daily

usage rate of 8 infusions per day from its commissioning date and for a period of 10 years from its date

of manufacture. The user is responsible for recording the date of first use by any means deemed

appropriate for traceability purposes.

10. USEFUL CONTACTS

Sales Department and After-Sales Services :

Promovet sarl

ZAC de la Route de Beauraing, 1

08600 GIVET (France)

Tel. : + 33 (0)3 24 42 15 71

E-mail : info@promovet.fr

Web sit e : www .dr op er. be

16 / 16

Loading...

Loading...