Page 1

™

ASSEMBLY AND MAINTENANCE GUIDE

HELPFUL HINTS

✔ Avoid working over a deep pile carpet. If you drop a small part or screw,

it may be diffi cult to fi nd.

✔ Place a mat or towel over your work area. This will prevent parts from rolling off and will protect the work surface.

✔ Avoid running the car in cold weather. The plastic and metal parts can become brittle at low temperatures. In addition, grease and

oil become thick, causing premature wear and poor performance.

MAINTENANCE

BEFORE EACH RUN

✔ IMPORTANT: Check to make sure that all

screws are tight. Check that the servo

saver screw is fully tightened to ensure

that your Dromida SC4.18 tracks straight.

✔ Always check the condition of your

radio system batteries and replace if

necessary.

✔ Check to make sure that all of the

moving parts of the Dromida SC4.18

move freely and do not bind.

✔ Turn on the radio and make sure the

servo moves easily and in the proper

direction.

✔ Check for any broken or damaged

parts. Replace them before running the

Dromida SC4.18. Running the Dromida

SC4.18 with broken or damaged parts

could damage additional parts.

✔ Check to make sure that all wires are

properly connected.

AFTER EACH RUN

✔ Clean any debris from the chassis and

moving parts.

✔ Check for any broken or damaged parts.

Replace them before the next run.

✔ Disconnect and remove the battery

from the chassis.

AFTER EVERY 10 RUNS

✔ Check to make sure that the bearings

are free of dirt and debris, and roll

smoothly.

✔ Check the shocks for oil leakage.

✔ Check the tires to make sure they are

still properly glued to the rims.

HARDWARE CHART

A

B

C

E

F

G

6x10MM BALL BEARING

8x12MM BALL BEARING

2x4MM ROUND HEAD SCREW

2x8MM ROUND HEAD SCREW

2x10MM ROUND HEAD SCREW

2x8MM FLAT HEAD SCREW

ACTUAL SIZE

H

J

K

L

M

N

(

WHEN PRINTED AT 100%

)

2x10MM FLAT HEAD SCREW

2x14MM FLAT HEAD SCREW

2.5x8MM FLAT HEAD SCREW

2.5x8MM SOCKET HEAD SCREW

2.5x14MM SOCKET HEAD CAP SCREW

3x6MM SOCKET HEAD SCREW

P

Q

R

S

T

U

V

X

2x8MM ROUND HEAD

SHOULDER SCREW

3x3MM SET SCREW

3MM LOCK NUT

2.6x5MM WASHER

3x6MM WASHER

1.5x6MM E-CLIP

BODY CLIP (SMALL

)

2x6MM SELF-TAPPING

ROUND HEAD SCREW

Page 2

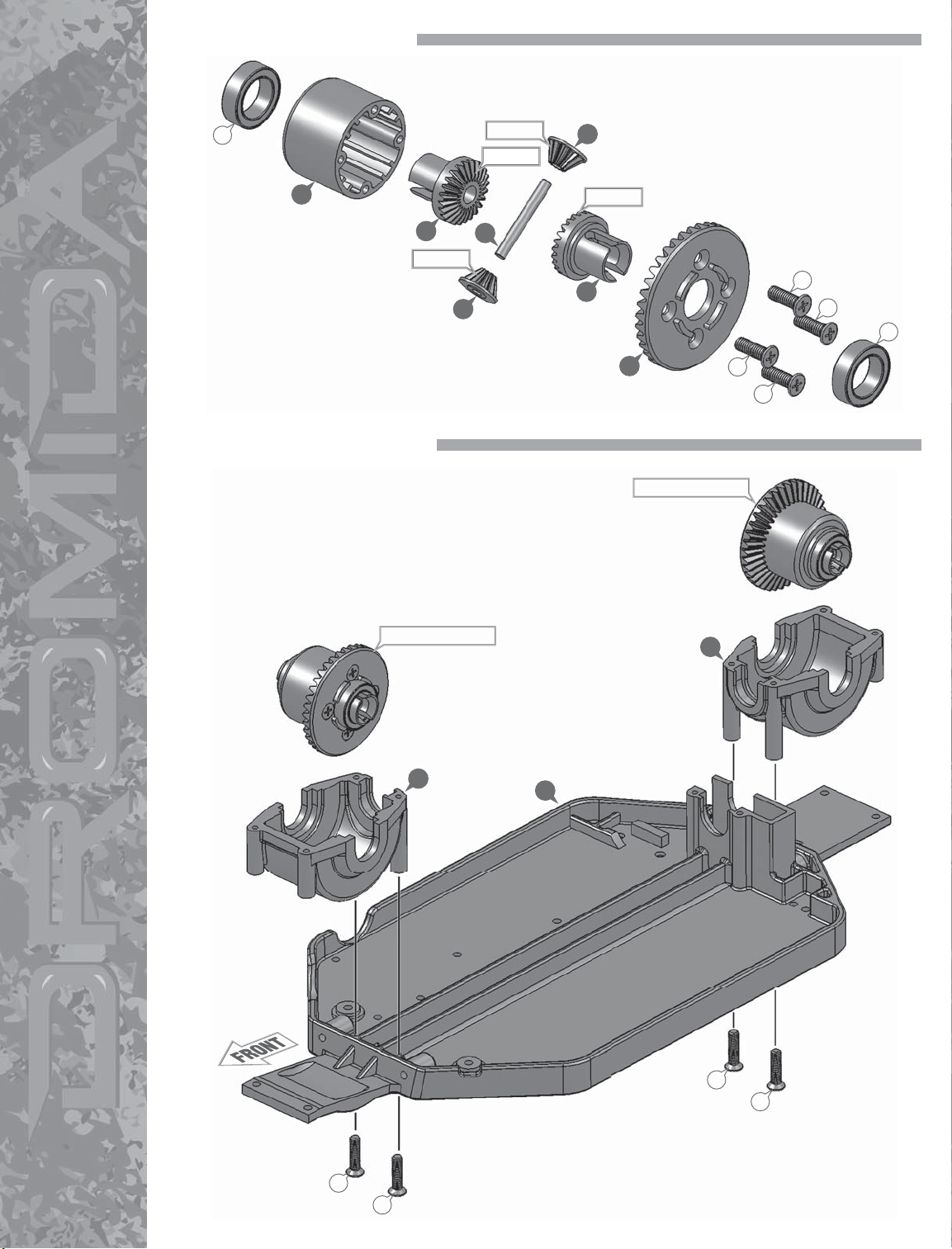

1. DIFFERENTIAL ASSEMBLY

B

31

33

GREASE

2. DIFFERENTIALS TO CHASSIS

32

GREASE

GREASE

34

32

GREASE

33

30

NOTE DIRECTION

G

G

B

G

G

NOTE DIRECTION

2

2

1

H

H

H

H

Page 3

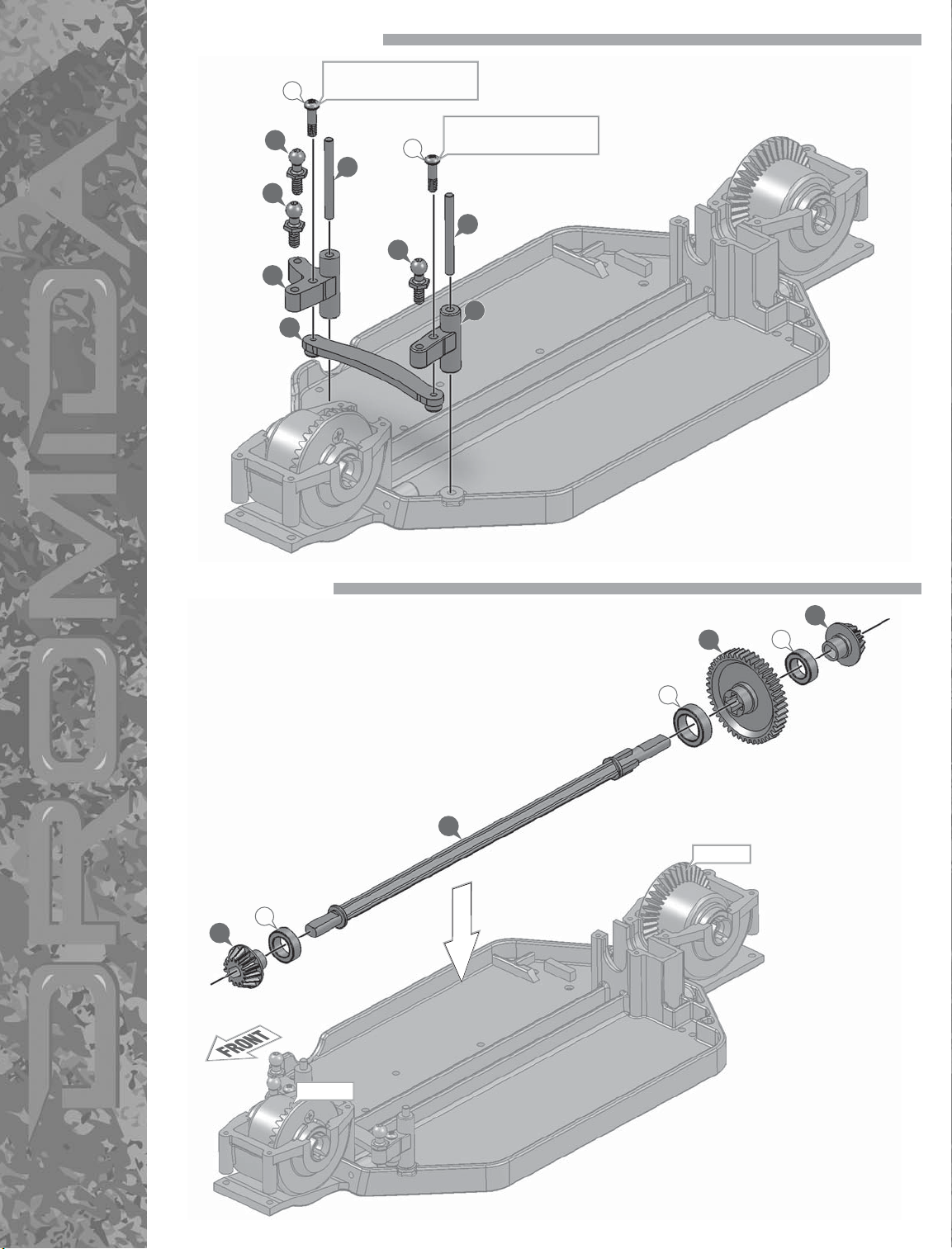

3. STEERING ASSEMBLY

DO NOT OVERTIGHTEN

(

WILL CAUSE BINDING

P

)

40

40

44

46

4. CENTER SHAFT

18

40

DO NOT OVERTIGHTEN

(

WILL CAUSE BINDING

P

18

45

)

28

27

A

28

B

29

GREASE

A

GREASE

Page 4

5. SHOCK TOWERS

8

7

E

8

E

E

40

40

3

8

8

7

E

E

E

40

40

3

NOTE DIFFERENCE

12

11

V

71

NOTE DIFFERENCE

V

G

6. MOTOR MOUNT

G

E

E

E

E

26

N

4

E

E

T

Q

T

39

N

25

24

THREADLOCK

K

THREADLOCK

K

Page 5

7. FRONT SUSPENSION

11.2

MM

ACTUAL SIZE

H

43

41

42

41

DO NOT OVERTIGHTEN

35

36

L

40

40

37

38

9

17

40

H

18

C

13

11

L

B

15

B

DO NOT OVERTIGHTEN BEARINGS FULLY SEATED

8. REAR SUSPENSION

9

J

10.75MM

41

35

17

40

J

C

36

18

42

37

41

38

B

13

BEARINGS FULLY SEATED

ACTUAL SIZE

40

B

Page 6

9. RADIO BOX

5

47

48

6

47

X

40

50

7.5MM

ACTUAL SIZE

X

CENTER SERVO FIRST

51

49

52

S

F

SCREW MUST BE SNUG

G

G

G

10. SHOCK ASSEMBLY

63

U

U

58

54

62

62

59

61

SHOCK OIL

SHOCK OIL

SHOCK OIL

56

60

66

69

64

68

65

SHOCK OIL

1. Completely fill the

shock body with

shock oil.

2. Slowly move the

shaft up and down

to remove bubbles.

3. Slowly tighten the shock cap

onto the shock body to allow

any remaining air to escape.

Page 7

11. REAR SHOCK INSTALLATION

53

S

M

12. FRONT SHOCK INSTALLATION

53

S

M

Page 8

13. REAR BUMPER

DO NOT OVERTIGHTEN

E

C

23

E

E

E

E

21

E

DO NOT OVERTIGHTEN

22

C

23

14. FRONT BUMPER

19

E

E

E

20

E

E

E

Page 9

15. WHEELS

73

72

70

R

70

R

Page 10

TUNING GUIDE

When tuning the Dromida SC4.18 make sure that you have equal lengths from one side to the other on the shocks

and upper rods. Also, make sure to have the shock pre-load adjusters at the same setting from left to right. They

do not have to be the same front to rear.

PINIONS

The Dromida SC4.18 comes stock with the 12 tooth pinion. To obtain higher top speeds you can install a larger

pinion gear onto the motor. This will, however, decrease your acceleration and run time. TIP: Smaller pinion equals

more torque, less top speed. Larger pinion equals more top speed, less torque.

SHOCK OIL

The Dromida SC4.18 comes stock with 30 weight oil in the shocks. The handling can be tuned by changing the

shock oil to either heavier (bigger number) or lighter (smaller number). By putting heavier oil in the shocks, the

car will have less chassis roll and become more responsive. Putting lighter oil in the shocks will cause the car to

be less responsive and have more chassis roll. For smooth, high traction surfaces, a thicker oil would be best. For

low traction or bumpy surfaces, a lighter oil would be best.

CAMBER

Camber refers to the angle at which the tire and wheel ride

in relation to the ground when viewed from the front or rear.

Negative camber is when the wheels lean inward and positive

camber is when the wheels lean outward. Usually adding

a small amount of negative camber (0° to -2°) will increase

traction. However, adding too much camber will decrease

traction. The objective is to keep as much of the tire as possible

in contact with the running surface. Never put in positive

camber. Make sure that both sides are equal.

SHOCK SPRINGS

For low traction or bumpy surfaces, a softer spring should be used. For high traction or smooth surfaces, a fi rmer

spring should be used.

FRONT SHOCK ADJUSTMENT

Moving the tops of the shocks out (A) will increase steering

reaction but decrease front traction. Moving the tops of the

shocks in (B) will result in slower steering reaction but will be

smoother over bumps and have more front traction.

REAR SHOCK ADJUSTMENT

Moving the tops of the shocks out (A) will increase steering

reaction and decrease rear traction. Moving the tops of the

shocks in (B) will result in slower steering reaction but will be

smoother over bumps and have more rear traction.

2˚ NEGATIVE CAMBER

ADJUST LENGTH TO

CHANGE THE CAMBER

AA

BB

A

We try very hard to have accurate and up-to-date information in this document. Any errors are unintentional.

DIDC0041 v1.0 © 2013 DROMIDA, A HOBBICO COMPANY

dromida.com

Loading...

Loading...