Page 1

Installation and Operation Manual

Edison (

250, rue de Copenhague, St-Augustin-de-Desmaures

DP00065)

Safety tested according to ULC S627, UL1482

by an accredited laboratory.

Stove Builder International Inc.

After-sale service: 418-908-8002

E-mail: tech@sbi-international.com

and ASTM E1509

www.drolet.ca

(Quebec) Canada G3A 2H3

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS

PELLET FUEL-BURNING ROOM HEATER. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR

EVEN DEATH.

INSTALLATION BY A PROFESSIONAL IS STRONGLY RECOMMENDED

This manual is available for free download on the manufacturer’s web site. It is a

copyrighted document. Re-sale is strictly prohibited. The manufacturer may update this

manual from time to time and cannot be responsible for problems, injuries, or damages

arising out of the use of information contained in any manual obtained from

unauthorized sources

Read and keep this manual for future reference

45787A

Printed in Canada 08-09-2015

.

Page 2

Edison Installation and Operation Manual

THANK YOU FOR CHOOSING THIS DROLET PELLET STOVE

As one of North America’s largest and most respected pellet stove, wood stove and

fireplace manufacturers, Stove Builder International takes pride in the quality and

performance of all its products. We want to help you get maximum satisfaction as you use

this product.

In the pages that follow you will find general advice on pellet heating, detailed instructions

for safe and effective installation, and guidance on how to get the best performance from

this stove as you build and maintain your pellet heating system.

We highly recommend that our pellet burning hearth products be installed and serviced by

professionals who are certified in the United States by NFI (National Fireplace Institute®) or

in Canada by WETT (Wood Energy Technology Transfer) or in Quebec by APC

(Association des Professionnels du Chauffage).

Congratulations on making a wise purchase.

REGISTER YOUR WARRANTY ONLINE

To receive full warranty coverage, you will need to show evidence of

the date you purchased your stove. Keep your sales invoice. We also

recommend that you register your warranty online at:

http://www.drolet.ca/en/service-support/warranty-registration

Registering your warranty online will help us to quickly track the

information we need about your stove.

2

Page 3

Edison Installation and Operation Manual

Table of contents

1 Introduction .............................................................................................................................................. 6

1.1 About Pellet Heating .............................................................................................................................. 6

1.1.1 Top 10 Reasons for Buying a DC Pellet Stove ............................................................................. 6

1.2 Edison Specifications............................................................................................................................. 7

1.3 Overall Exterior Dimensions .................................................................................................................. 8

PART A – INSTALLATION ................................................................................................................................ 9

2 Installation Safety Information ............................................................................................................... 9

2.1 Installation Warnings, Cautions and Recommendations ....................................................................... 9

2.2 Regulations Covering Pellet Stove Installation .................................................................................... 11

2.3 Before Operating Your Stove .............................................................................................................. 11

2.4 Connection of the Auxiliary Battery System (Optional) ....................................................................... 14

3 Clearances to Combustible Material .................................................................................................... 14

3.1 Certification Label Location ................................................................................................................. 15

3.2 Minimum Clearances to Combustibles ................................................................................................ 15

3.3 Back Wall Installation........................................................................................................................... 16

3.3.1 With LCD Touch Screen Wall Mount Support: ........................................................................... 16

3.3.2 With Optional LCD Touch Screen Sliding System: ..................................................................... 16

3.4 Corner Installation ................................................................................................................................ 16

3.4.1 With LCD Touch Screen Wall Mount Support: ........................................................................... 16

3.4.2 With Optional LCD Touch Screen Sliding System: ..................................................................... 16

3.5 Ceiling Clearances ............................................................................................................................... 16

3.6 Floor Protection ................................................................................................................................... 17

4 Venting System ...................................................................................................................................... 17

4.1 General ................................................................................................................................................ 17

4.2 Recommendations ............................................................................................................................... 17

4.3 Equivalent Vent Length (EVL) ............................................................................................................. 18

4.4 Termination Location ........................................................................................................................... 19

4.4.1 Permitted Termination Location .................................................................................................. 20

4.5 Installation Configurations ................................................................................................................... 21

4.5.1 Installation Warnings, Cautions and Recommendations Reminder ........................................... 21

4.5.2 Through Wall Installation (Main Floor or Basement) .................................................................. 22

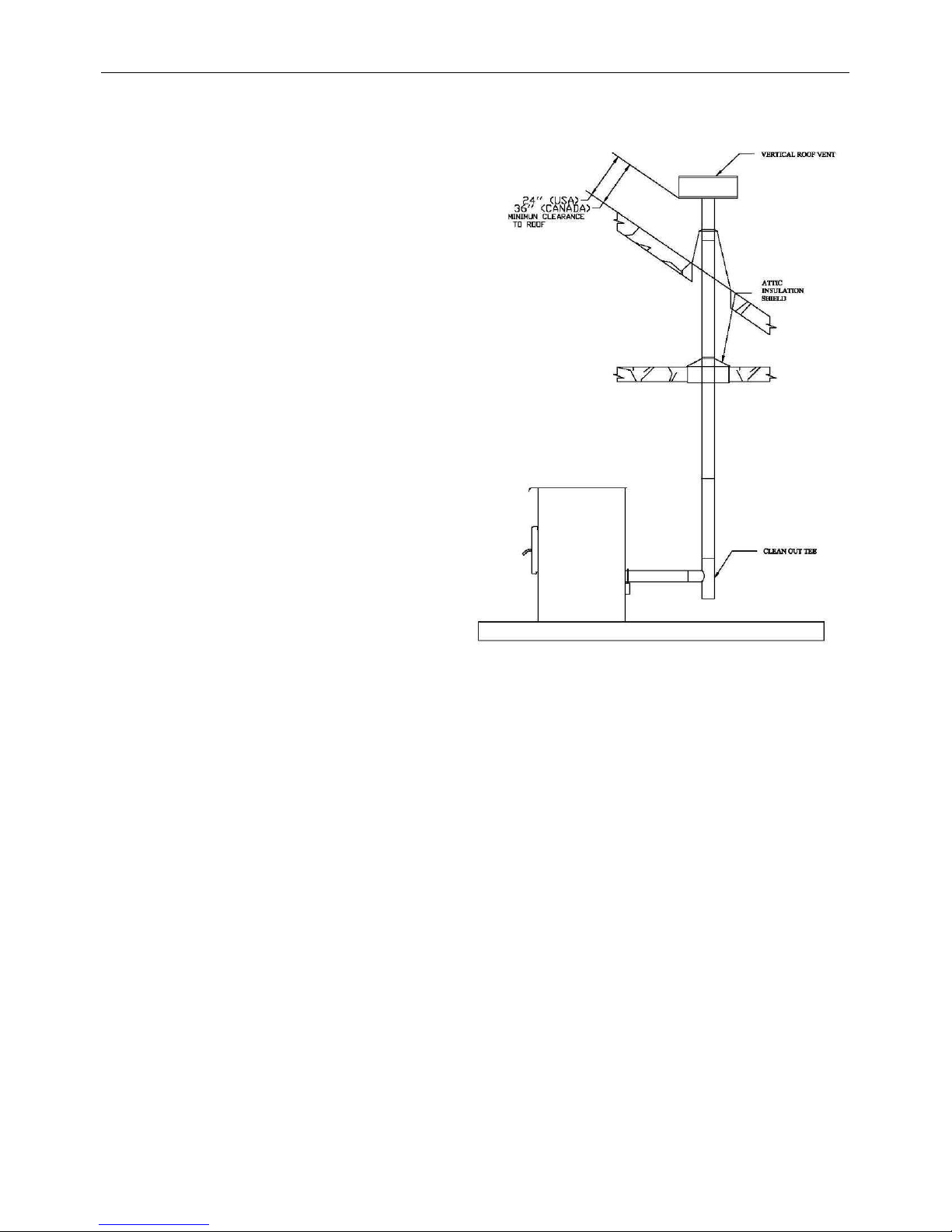

4.5.3 Through Roof Installation ............................................................................................................ 23

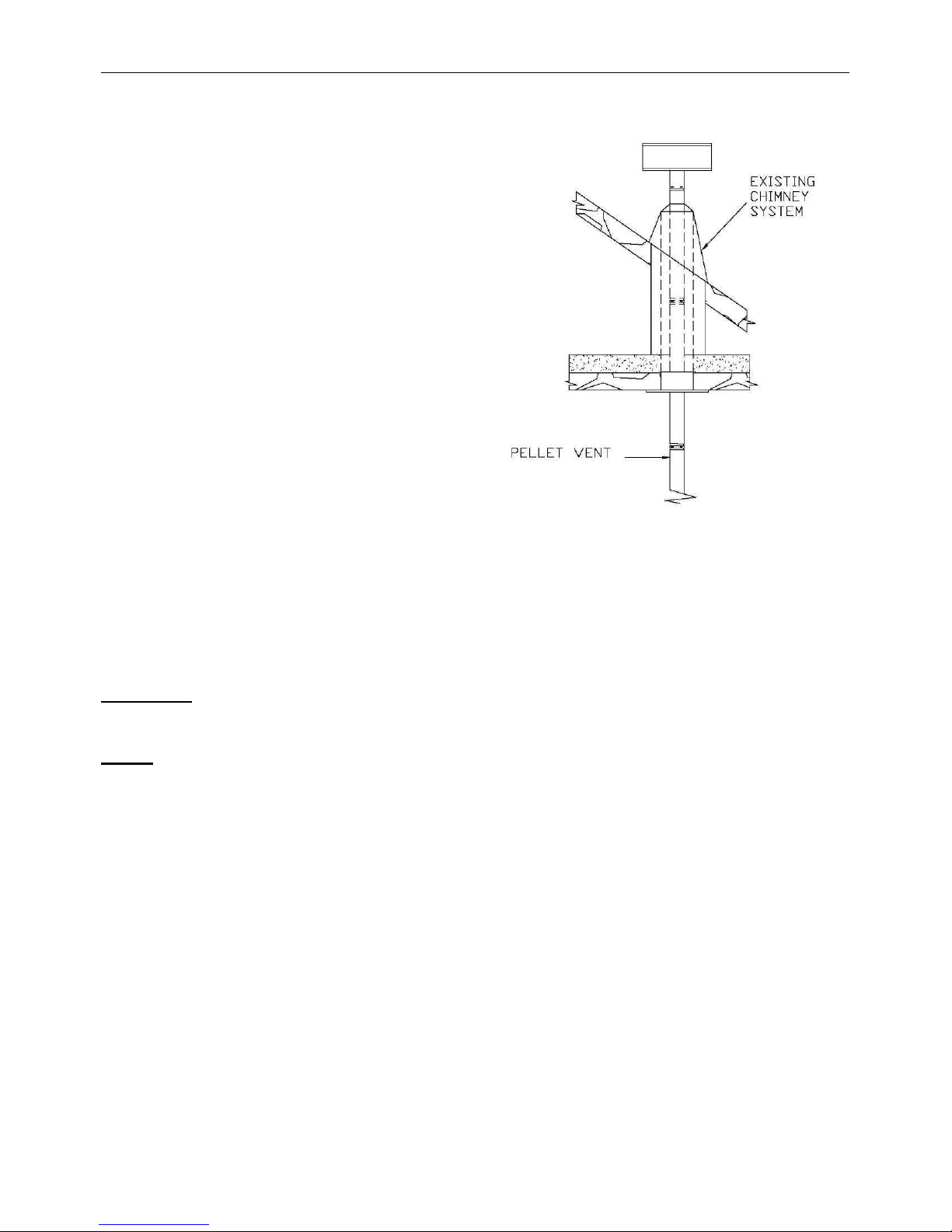

4.5.4 Through a Factory Built Chimney ............................................................................................... 24

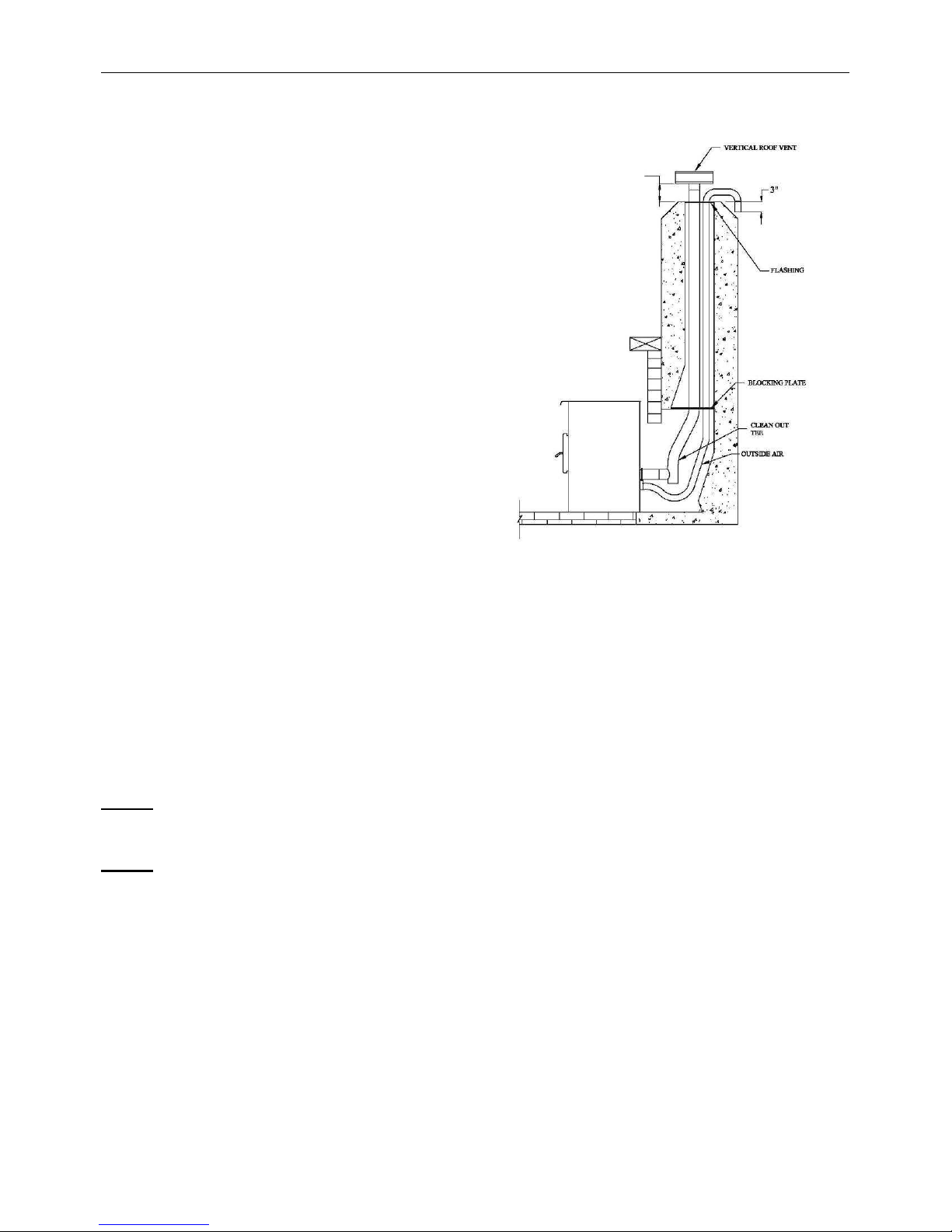

4.5.5 Through an Existing Masonry Fireplace ..................................................................................... 25

4.5.6 Through an Existing Masonry Chimney ...................................................................................... 26

PART B - OPERATION .................................................................................................................................... 27

5 General Information ............................................................................................................................... 27

5.1 Operation Warnings, Cautions and Recommendations ...................................................................... 27

5.1.1 Operation Warnings, Cautions and Recommendations on Auxiliary Battery System ................ 29

5.1.2 Zone Heating and How to Make It Work for You ........................................................................ 30

5.2 Combustible ......................................................................................................................................... 30

5.2.1 Proper Fuel ................................................................................................................................. 30

5.2.2 Where to Store Bags of Pellets ................................................................................................... 31

6 Stove controls ........................................................................................................................................ 31

6.1 General Information ............................................................................................................................. 31

6.1.1 LCD Touch Screen Controls, Operation and Configuration ....................................................... 31

6.1.2 Configuration and Operation Diagram ........................................................................................ 33

6.1.3 Selecting the Language and Temperature Unit (°F or °C).......................................................... 33

6.1.4 Viewing Statistics ........................................................................................................................ 33

6.1.5 Auxiliary Battery System Level ................................................................................................... 34

6.1.6 Adjusting the Combustion Level (Heat Output) .......................................................................... 34

6.1.7 Combustion Settings and Pilot Settings depending on Fuel Quality .......................................... 35

6.1.8 Convection Fans Speed Adjustment .......................................................................................... 36

6.1.9 Selecting MANUAL or AUTO THERMOSTAT ............................................................................ 36

3

Page 4

Edison Installation and Operation Manual

6.1.10 Selecting the Pilot Cycle ............................................................................................................. 37

6.1.11 Filling or Purging Auger Housing ................................................................................................ 37

6.1.12 Demo Mode................................................................................................................................. 38

7 Stove operation ...................................................................................................................................... 39

7.1 First Startup ......................................................................................................................................... 39

7.2 Everyday Startup ................................................................................................................................. 39

7.3 Running Out of Pellets ......................................................................................................................... 39

7.4 Refueling .............................................................................................................................................. 39

7.5 Shutting Down Procedure .................................................................................................................... 40

7.6 Signs of an Overheating Stove ............................................................................................................ 40

8 Maintenance ........................................................................................................................................... 41

8.1 Stove Maintenance .............................................................................................................................. 41

8.1.1 Recommended Maintenance Schedule ...................................................................................... 41

8.1.2 Cleaning the Baffle, the Heat Exchanger and the Combustion Chamber .................................. 42

8.1.3 Exhaust Channel and Exhaust Blower Maintenance .................................................................. 45

8.1.4 Cleaning the Burn Pot ................................................................................................................. 47

8.1.5 Ash Removal ............................................................................................................................... 49

8.1.6 Glass Care .................................................................................................................................. 50

8.1.7 Replacement of Broken Door Glass ........................................................................................... 50

8.1.8 Door Gasket Maintenance .......................................................................................................... 50

8.1.9 Door Adjustment ......................................................................................................................... 51

8.2 Venting System Maintenance .............................................................................................................. 51

8.2.1 Dealing With a Chimney Fire ...................................................................................................... 51

8.2.2 Soot and Fly Ash ......................................................................................................................... 52

9 Troubleshooting ..................................................................................................................................... 53

9.1 Validating Status .................................................................................................................................. 53

9.2 Testing Components............................................................................................................................ 55

9.3 Main Error messages, Possible Causes and Solutions ....................................................................... 55

9.3.1 Blocked Flue ............................................................................................................................... 56

9.3.2 No Fuel ........................................................................................................................................ 57

9.3.3 Failed Ignition .............................................................................................................................. 59

9.3.4 Defective Igniter Fuse ................................................................................................................. 60

9.3.5 Auger Fuse.................................................................................................................................. 60

9.3.6 Unit Overheat .............................................................................................................................. 61

9.3.7 Hopper Lid Open ......................................................................................................................... 63

9.3.8 Power Loss ................................................................................................................................. 63

9.3.9 Low battery (With Auxiliary Batteries Only) ................................................................................ 64

9.3.10 Cancel stop timeout .................................................................................................................... 64

9.3.11 Stove hot while off ....................................................................................................................... 64

9.3.12 Back draft .................................................................................................................................... 65

9.3.13 Smoke Smell ............................................................................................................................... 66

9.3.14 Combustion Air Starvation .......................................................................................................... 66

9.3.15 The LCD Touch Screen Does Not Lightup. ................................................................................ 67

9.4 software update ................................................................................................................................... 67

9.4.1 How to update the DC Mother Board .......................................................................................... 68

9.4.2 How to update the LCD Touch Screen ....................................................................................... 69

9.4.3 Screen Calibration ...................................................................................................................... 69

10 Wiring Diagram....................................................................................................................................... 70

11 Access to Fuses ..................................................................................................................................... 71

12 Components Location ........................................................................................................................... 73

13 Blower Replacement .............................................................................................................................. 74

14 L-250 and F-160 Thermal Switch Replacement ................................................................................... 80

15 Replacement Parts ................................................................................................................................. 82

4

Page 5

Edison Installation and Operation Manual

Appendix A: Horizontal and Vertical Vent Chart ......................................................................................... 93

Appendix B: LCD Touch Screen Supports .................................................................................................. 95

Appendix C: Battery Holder kit (AC01452) and Optional 24V (2X 12V) battery kit (AC01454) ................ 98

Appendix D: Installing an Optional Thermostat ........................................................................................ 102

Appendix E: Mobile Home Installation ....................................................................................................... 105

Appendix F: Combustion Air Supply .......................................................................................................... 107

DROLET LIMITED LIFETIME WARRANTY .................................................................................................. 110

5

Page 6

Edison Installation and Operation Manual

1 Introduction

1.1 About Pellet Heating

Pellet stoves offer a dramatic improvement in the convenience of heating with solid fuel.

Wood pellets are handled in bags and are therefore easily and cleanly stored. A single

loading of a pellet stove can provide long hours of warmth. Pellet stoves also provide a

special comfort associated with wood burning. The combination of fans delivering warm air

currents and the direct comfort of radiant heat provides special satisfaction on a cold

winter day. The heat provided is even and constant, due to the auto fuel feed responding

to owner settings. Pellet stoves also offer strong environmental benefits; pellets not only

reduce dependence on finite supplies of fossil fuels like oil and gas, but they also put to

good use materials that would otherwise unnecessarily and expensively add to our waste

disposal problems.

In addition, pellet stoves burn very cleanly and offer the lowest emissions of unwanted

pollutants of all solid fuel burning appliances.

1.1.1 Top 10 Reasons for Buying a DC Pellet Stove

1) Works during power breakdown due to an optional battery system (see Appendix C:

Battery Holder kit (AC01452) and Optional 24V (2X 12V) battery kit (AC01454)).

2) Fuel is relatively cheap, easy to handle and store.

3) Installation is relatively inexpensive and flexible.

4) Can be thermostatically controlled.

5) Can run for long hours without the need to refuel.

6) Heat output is steady because fuel feed is regulated.

7) Provides powerful convection heat.

8) Has the lowest emissions of all solid fuels.

9) Reduces our dependence on fossil fuels.

10) Wood pellets are made of 100% residual matter (saw dust) and are a renewable fuel.

This creates added-value from waste that would otherwise end up in a landfill.

6

Page 7

Edison Installation and Operation Manual

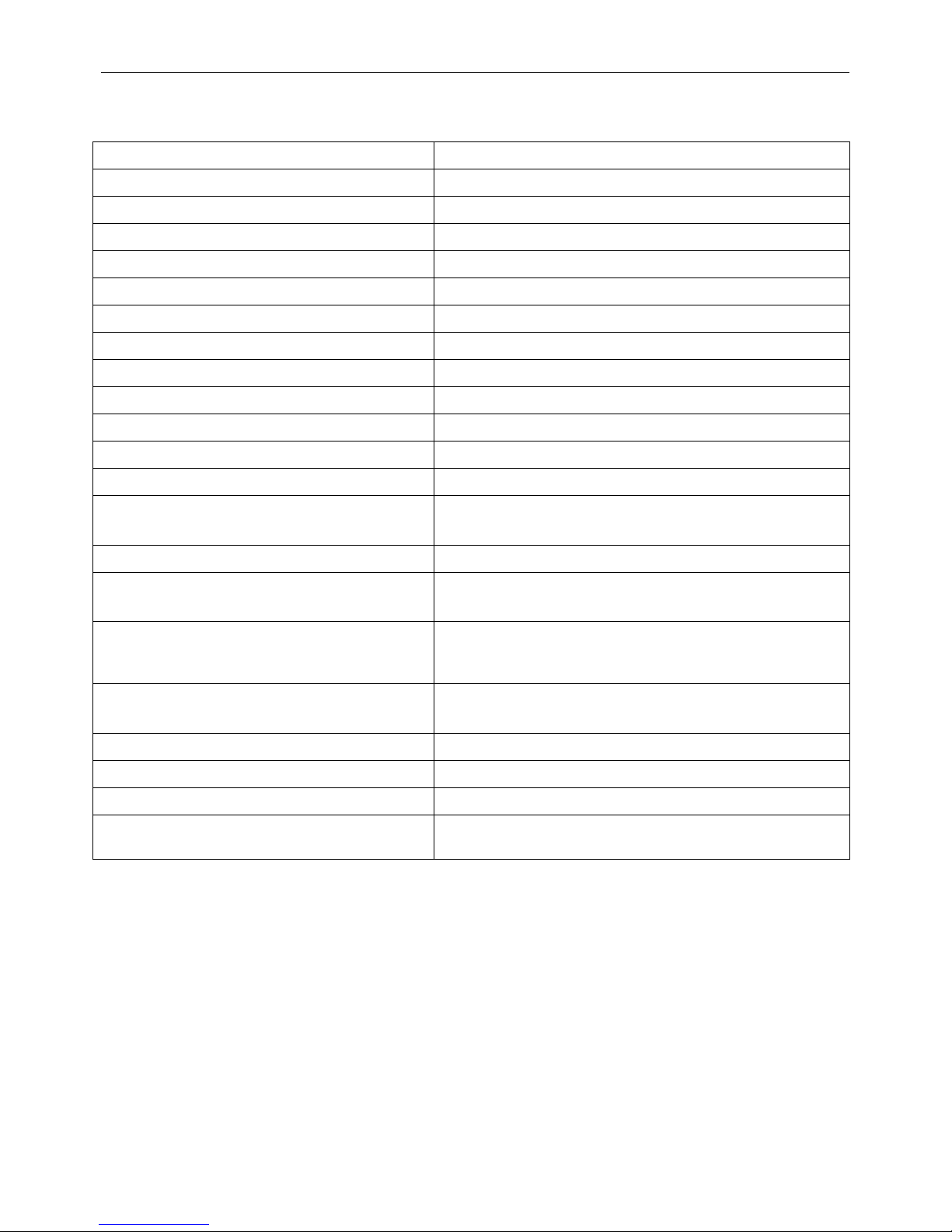

1.2 Edison Specifications

Fuel Type Wood pellets

Test Standards (safety) ULC S627, ASTM E1509 and UL 1482

Heating capacity range1 500 to 1800 sq. ft. (45 to 167 m2)

Input range (BTU/h) 2 From 10,000 BTU to 45,000 BTU (3 kW to 13kW)

Hopper capacity2 60 lb (27 Kg)

Average particulate emission rate 2.5 g/h

Average overall efficiency3 62.8 % (HHV) 4 67.7 % (LHV) 4

Overall heat output rate3 6,619 BTU/h to 25,478 BTU/h (1.9 kW to 7.5 kW)

Average carbon monoxyde 111.8 g/h

Maximum Burn Time1 50 h

Burn rate2 1.2 lb to 5.3 lb per hour (0.5 kg/h – 2.4 kg/h)

Shipping Weight 414 lb (188 kg)

Appliance Weight 384 lb (174 kg)

Vent system size

3 po (see Section 4.3: Equivalent Vent Length

(EVL))

Baffle material Stainless Steel

Energy consumption

1.6A for ignition cycle

0.3A Min./0.6A Max. for continuous operation

Voltage and frequency : 88 - 264VAC and 47 - 63Hz

Electrical requirements

AC Current: 3.6A/115VAC - 1.8A/230VAC

Battery back-up (optional): 24v DC and20 Ah (min.)

Control board fuses

Main: ATC Auto Fuse 7.5A 32VDC

Battery Backup: ATC Auto Fuse 7.5A 32VDC

Power cord inlet socket 3A / 250V (5 X 20) fuse

Main Board Battery : CR2032

Mobile home approved‡

Approved for alcove application

1

Burn time and heating capacity may vary subject to location in home, chimney draft, chimney

diameter, locality, heat loss factors, climate, selected fuel level, fuel types and other variables.

2

This can vary depending on pellet density, length, and diameter.

3

As calculated per CSA B415.1-10

4

Higher Heating Value of the fuel (HHV) and Lower Heating Value of the fuel (LHV).

Yes

Yes (see Section 3.2: Minimum Clearances to

Combustibles)

‡

Mobile home (Canada) or manufactured home (USA): The US department of Housing and

Urban Development describes “manufactured homes” better known as “mobile homes” as

followed; buildings built on fixed wheels and those transported on temporary wheels/axles and

set on a permanent foundation. In Canada, a mobile home is a dwelling for which the

manufacture and assembly of each component is completed or substantially completed prior to

being moved to a site for installation on a foundation and connection to service facilities and

which conforms to the CAN/CSA-Z240-MH standard.

7

Page 8

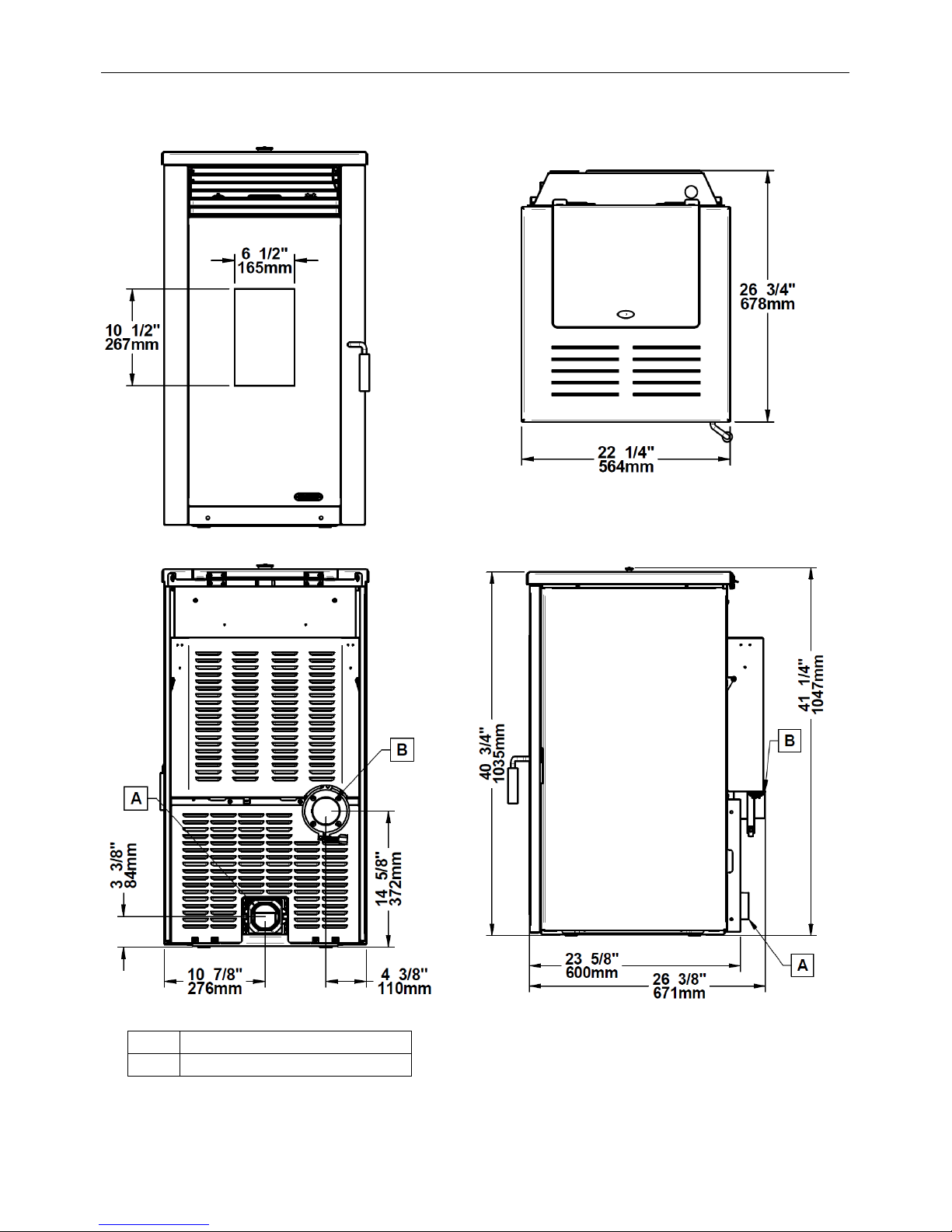

Edison Installation and Operation Manual

A

B

1.3 Overall Exterior Dimensions

FRESH AIR INLET

EXHAUST

8

Page 9

Edison Installation and Operation Manual

PART A – INSTALLATION

2 Installation Safety Information

2.1 Installation Warnings, Cautions and Recommendations

• PROFESSIONNAL INSTALLATION IS HIGHLY RECOMMENDED.

• YOU MAY NEED TO OBTAIN A BUILDING PERMIT FOR THE INSTALLATION OF

THIS STOVE AND ITS VENTING SYSTEM. CONSULT YOUR MUNICIPAL

BUILDING DEPARTMENT OR FIRE DEPARTMENT BEFORE INSTALLATION TO

DETERMINE THE NEED TO OBTAIN ONE. WE RECOMMEND THAT YOU ALSO

INFORM YOUR HOME INSURANCE COMPANY TO FIND OUT IF THE

INSTALLATION WILL AFFECT YOUR POLICY.

• THIS STOVE MUST BE CONNECTED TO A STANDARD GROUNDED ELECTRICAL

OUTLET FROM 88 TO 264V AC AND FROM 47 TO 63 HZ. DO NOT USE AN

ADAPTER PLUG OR SEVER THE GROUNDING PLUG. DO NOT ROUTE THE

ELECTRICAL CORD UNDERNEATH, IN FRONT OR OVER THE STOVE.

• THIS STOVE CAN BE PLUGGED TO A 24 TO 30V BATTERY SYSTEM (MINIMUM

20Ah) AND ABSOLUTLY NEEDS TO USE THE ANDERSON SB50® CONNECTOR.

IF YOU INSTALL THE BATTERY BEHIND THE STOVE USING THE OPTIONAL

BATTERY HOLDER KIT (AC01452), THE BATTERIES MUST BE SEALED.

• IF THIS STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT.

TO REDUCE THE RISK OF FIRE, FOLLOW THE INSTALLATION INSTRUCTIONS.

• BURNING ANY SOLID FUELS GENERATES CARBON MONOXIDE IN LOW

CONCENTRATION. THIS GAS IS EVACUATED BY THE VENTING SYSTEM. IN

HIGHER CONCENTRATIONS, CARBON MONOXIDE IS TOXIC AND MAY CAUSE

DEATH. TO PREVENT THIS, ENSURE THAT YOUR VENTING SYSTEM IS

AIRTIGHT.

• THIS STOVE IS MOBILE HOME APPROVED AND REQUIRES INSTALLATION OF

A FRESH AIR KIT, SOLD SEPARATELY. THE STOVE MUST BE ATTACHED TO

THE STRUCTURE OF THE MOBILE HOME AND THE STRUCTURAL INTEGRITY

OF THE MOBILE HOME FLOOR, WALL, AND CEILING/ROOF MUST BE

MAINTAINED. DO NOT INSTALL IN A SLEEPING ROOM.

• THIS STOVE IS NOT RECOMMENDED TO BE INSTALLED IN A BEDROOM OF

CONVENTIONAL HOUSES.

• THIS STOVE HAS BEEN DEVELOPED AND BUILT FOR RESIDENTIAL

SUPPLEMENTARY HEAT SOURCE. COMMERCIAL AND INDUSTRIAL USE IS

PROHIBITED AND WILL VOID THE WARRANTY.

9

Page 10

Edison Installation and Operation Manual

• THE INFORMATION GIVEN ON THE CERTIFICATION LABEL AFFIXED TO THE

STOVE ALWAYS OVERRIDES THE INFORMATION PUBLISHED IN ANY OTHER

MEDIA (OWNER’S MANUAL, CATALOGUES, FLYERS, MAGAZINES AND/OR WEB

SITES).

• CONNECT THIS STOVE ONLY TO A LISTED PELLET VENT FOR USE WITH SOLID

FUEL OR TO A LINED CHIMNEY CONFORMING TO NATIONAL AND LOCAL

BUILDING CODES.

• DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF

THIS UNIT.

• DO NOT CONNECT THIS STOVE TO ANY OTHER EXISTING VENTING SYSTEM

SERVING ANOTHER APPLIANCE.

• DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION

DUCTWORK.

• THE VENTING SYSTEM MUST BE COMPLETELY AIRTIGHT AND PROPERLY

INSTALLED. ALL VENT CONNECTOR JOINTS MUST BE SEALED AND

FASTENED IN ACCORDANCE WITH THE PELLET VENT MANUFACTURER'S

INSTRUCTIONS TO ENSURE CONSISTENT PERFORMANCE AND AVOID SMOKE

AND ASH SPILLAGE.

• THE VENTING SYSTEM SHOULD BE CHECKED, AT LEAST TWICE A YEAR FOR

ANY BUILDUP OF SOOT OR CREOSOTE.

• NEVER BLOCK ANY LOUVERS OF THE STOVE.

• IF REQUIRED, A FRESH AIR KIT CAN BE INSTALLED TO SUPPLY COMBUSTION

AIR TO THE ROOM OR SPACE (SEE APPENDIX F: COMBUSTION AIR SUPPLY).

• MIXING OF APPLIANCE COMPONENTS FROM DIFFERENT SOURCES OR

MODIFYING COMPONENTS IS PROHIBITED AND WILL VOID THE WARRANTY.

• ANY MODIFICATION OF THE STOVE THAT HAS NOT BEEN APPROVED IN

WRITING BY THE TESTING AUTHORITY IS PROHIBITED AND VIOLATES CSA

B365 (CANADA), AND ANSI NFPA 211 (USA).

• NO MODIFICATION SHOULD BE MADE TO THE AUXILIARY BATTERY SYSTEM.

• STOVE BUILDER INTERNATIONAL INC. (SBI) GRANTS NO WARRANTY, IMPLIED

OR STATED, FOR THE POOR INSTALLATION OR LACK OF MAINTENANCE OF

YOUR STOVE AND ASSUMES NO RESPONSIBILITY OF ANY CONSEQUENTIAL

DAMAGES.

10

Page 11

Edison Installation and Operation Manual

2.2 Regulations Covering Pellet Stove Installation

When installed and operated as described in these instructions, this pellet stove is suitable

for use as a freestanding heater in residential installations.

In Canada, the CSA B365 Installation Code for Solid Fuel Burning Appliances and

Equipment and the CSA C22.1 Canadian National Electrical Code are to be followed in the

absence of local code requirements. In the USA, the ANSI NFPA 211 Standard for

Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances and the ANSI NFPA 70

National Electrical Code are to be followed in the absence of local code requirements.

This stove must be connected to a pellet vent system complying with the requirements for

Pellet Vent in the standards UL 103, UL 641, ULC S629M, CAN/ULC S609 and ULC/ORD

C441 or to a code-approved masonry chimney with a stainless steel flue liner.

2.3 Before Operating Your Stove

Some minor installation and adjustment are required prior to use:

• If your unit has the optional LCD touch screen sliding support, it can be installed on the

left at the back of the stove; (see Appendix B: LCD Touch Screen Supports).

• If you do not use the optional LCD touch screen sliding support, you can install the

LCD touch screen wall mount support provided in the owner’s manual kit on the side or

at the back of the stove; (see Appendix B: LCD Touch Screen Supports).

• See that handle and door are well adjusted (see section 8.1.9: Door Adjustment).

• The stove must be leveled using threaded legs.

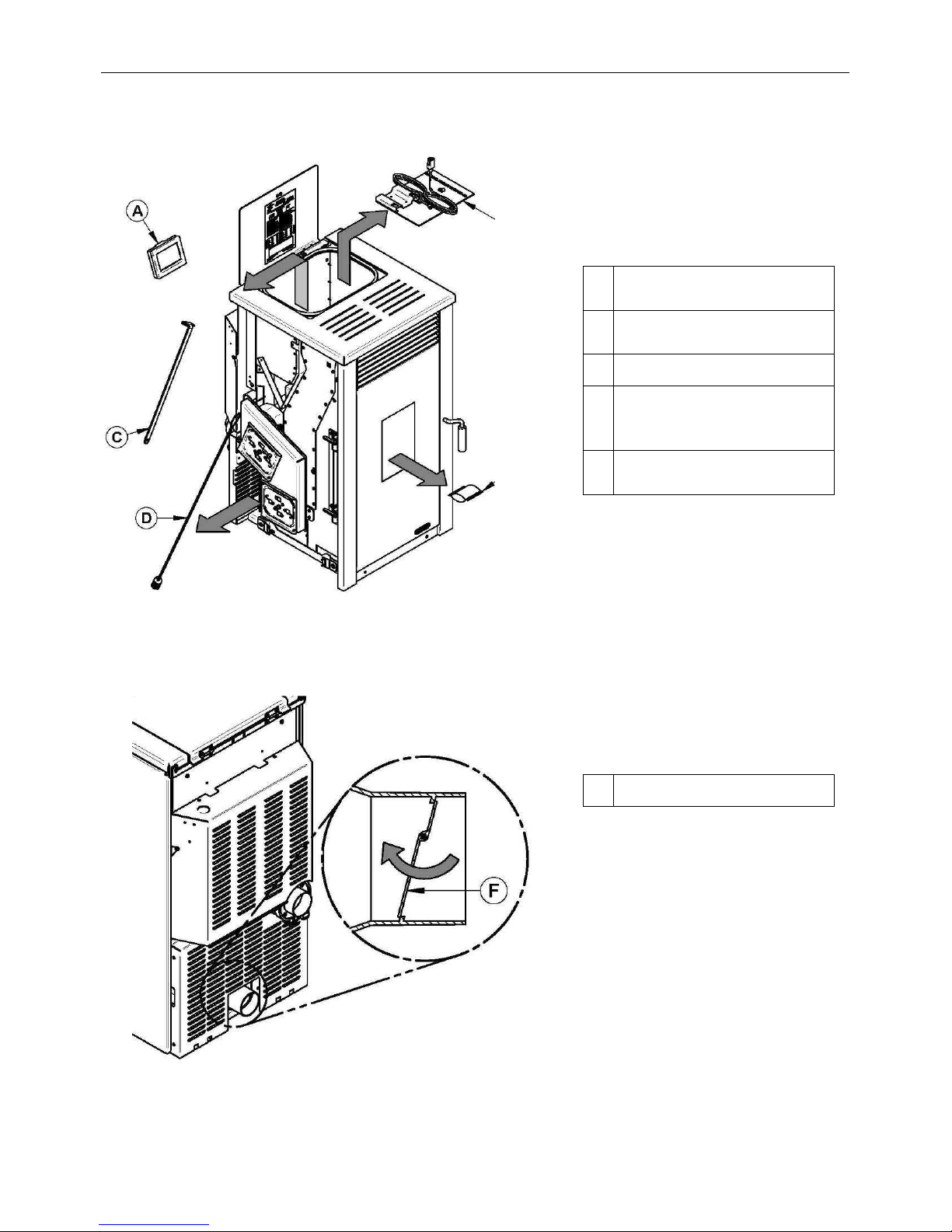

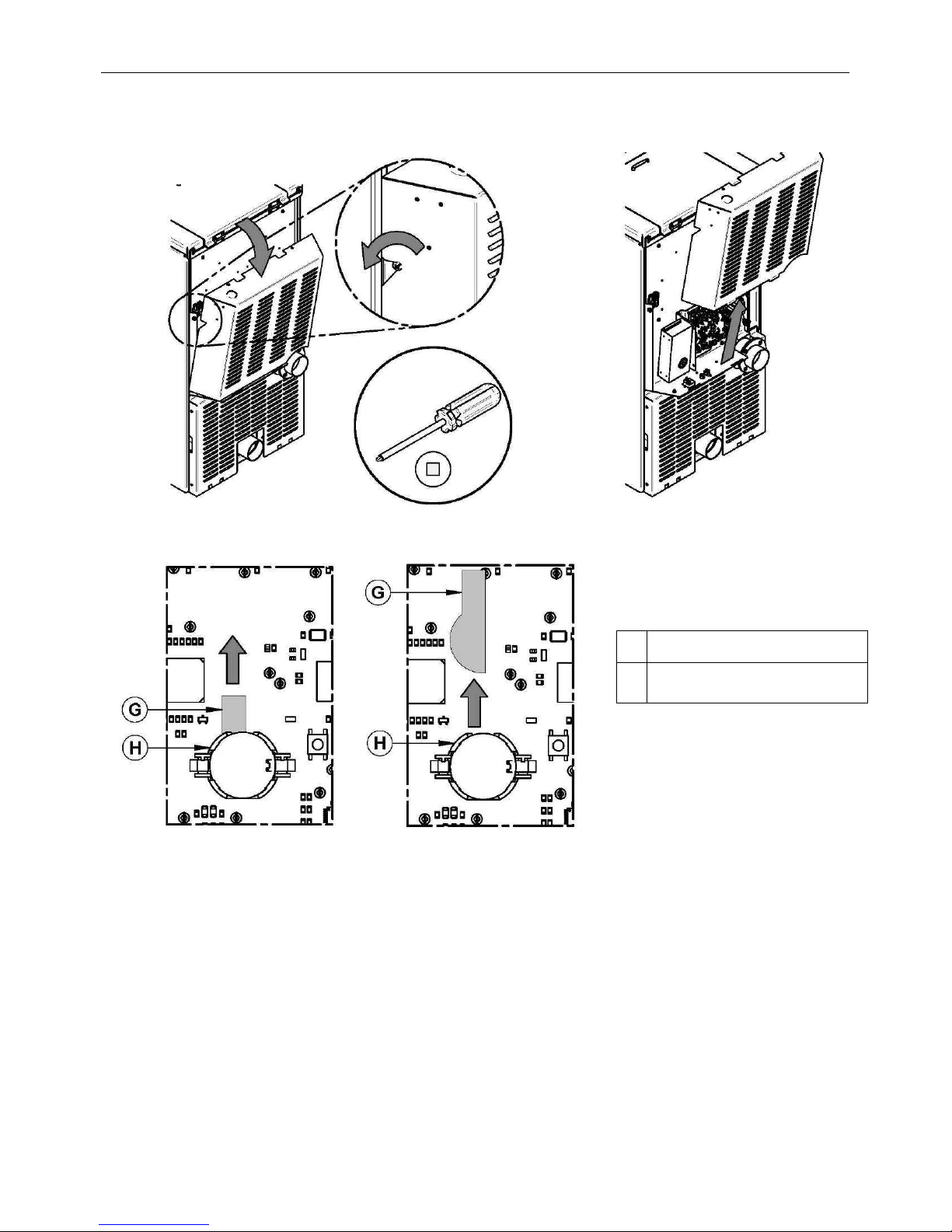

• Make sure to remove all tools or accessories (A-E) that have been inserted in the stove

for transportation purposes (see following illustration).

• Make sure the fresh air intake back draft shutter (F) works freely.

• Remove the insulating film (G) from the Main Board Battery (H).

• If your stove is equipped with the auxiliary battery system, connect it to the stove (see

Appendix C: Battery Holder kit (AC01452) and Optional 24V (2X 12V) battery kit

(AC01454))

NOTE: For first start-up, see Section 7: Stove operation.

11

Page 12

Edison Installation and Operation Manual

STEP 1

LCD TOUCH SCREEN

A

OWNER’S MANUAL

B

SCREEN

KIT

STEP 2

C

SCRAPER

SWEEPING BRUSH

D

(the tie wrap must be

cut)

DESICCANT (drying

E

F

BACK DRAFT SHUTTER

agent)

12

Page 13

Edison Installation and Operation Manual

STEP 3

STEP 4

G

H

INSULATING FILM

BUTTON BATTERY

(CR2032)

13

Page 14

Edison Installation and Operation Manual

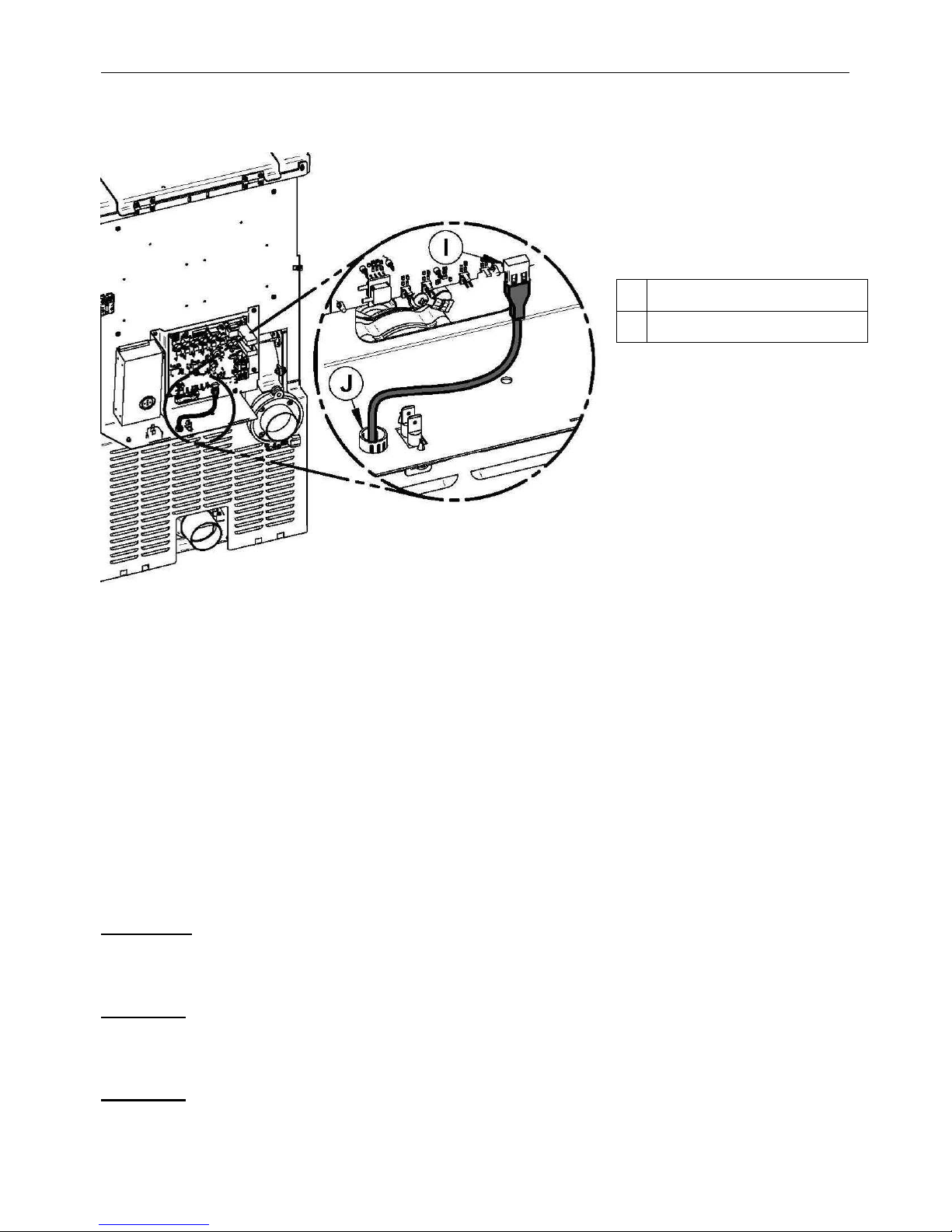

STEP 5

I

J

USB CONNECTOR

USB CABLE GROMMET

2.4 Connection of the Auxiliary Battery System (Optional)

If your stove is equipped with the auxiliary battery system, see Appendix C: Battery

Holder kit (AC01452) and Optional 24V (2X 12V) battery kit (AC01454) to connect it to

the stove.

3 Clearances to Combustible Material

The clearances shown in this section have been determined by tests according to

procedures set out in safety standards ULC S627 (Canada), ASTM E1509 (U.S.A) and

UL1482 (U.S.A). When the pellet stove is installed so that its surfaces are at, or beyond,

the minimum clearances specified, combustible surfaces will not overheat under normal

and even abnormal operating conditions.

WARNING: NO PART OF THE STOVE MAY BE LOCATED CLOSER TO

COMBUSTIBLES THAN THE MINIMUM CLEARANCES SPECIFIED ON THE

CERTIFICATION LABEL.

CAUTION: NO PART OF THE PELLET VENT SYSTEM MAY BE LOCATED CLOSER

TO COMBUSTIBLES THAN THE MINIMUM CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

CAUTION: DO NOT USE MAKESHIFT MATERIALS OR MAKE ANY COMPROMISES

WHEN INSTALLING THIS STOVE.

14

Page 15

Edison Installation and Operation Manual

3.1 Certification Label Location

Since the information given on the certification label affixed to the stove always overrides

the information published in any other media (owner’s manual, catalogues, flyers,

magazines and/or web sites), it is important to refer to it in order to have a safe and

compliant installation. In addition, you will find important information about your stove

(model, serial number, etc.). You will find the certification label on the inner side of the

hopper lid of the stove.

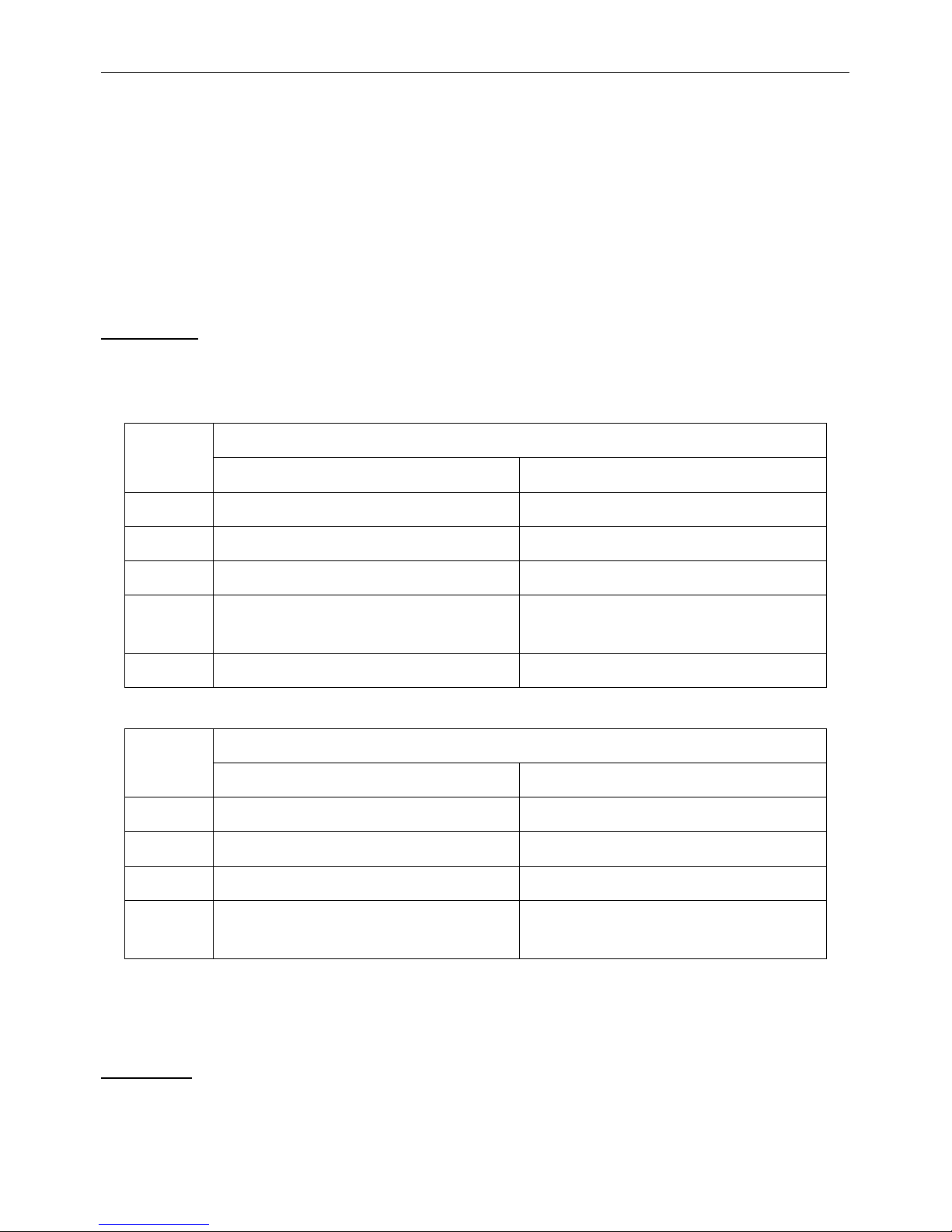

3.2 Minimum Clearances to Combustibles

WARNING: MINIMUM CLEARANCES IN THE TABLE BELLOW DO NOT TAKE INTO

ACCOUND THE MINIMUM SPACE NEEDED TO ALLOW THE LCD TOUCH SCREEN

SLIDING SUPPORT TO MOVE FREELY AND FULLY EXTENDED (SEE SECTION 3.3:

BACK WALL INSTALLATION AND SECTION 3.4: CORNER INSTALLATION).

LETTE

R

MINIMUN CLEARANCES TO COMBUSTIBLES

CANADA USA.

A* 1″ (25 mm) 1″ (25 mm)

B 4″ (102 mm) 4″ (102 mm)

C 1″ (25 mm) 1″ (25 mm)

D

Refer to vent manufacturer’s

clearances

Refer to vent manufacturer’s

clearances

I 54″ (1 372 mm) 54″ (1 372 mm)

LETTR

E

RECOMMENDED CLEARANCES FOR MAINTENANCE

CANADA USA

A* 12″ (305 mm) 12″ (305 mm)

B 24″ (610 mm) 24″ (610 mm)

C 12″ (305 mm) 12″ (305 mm)

D

Refer to vent manufacturer’s

* From the rear panel

Note: These clearances are also valid for an alcove installation.

WARNING: IF THE STOVE IS INSTALLED IN AN ALCOVE, TO PERFORM

MAINTENANCE, YOU SHOULD EXPECT TO MOVE THE APPLIANCE TO GET TO THE

MAINTENANCE ACCESS DOORS AND COMPONENTS.

clearances

Refer to vent manufacturer’s

clearances

15

Page 16

Edison Installation and Operation Manual

3.3 Back Wall Installation

3.3.1 With LCD Touch Screen Wall Mount Support:

If you wish to install the stove with minimum clearances

(see table in Section 3.2 Minimum Clearances to

Combustibles), it is possible to locate the LCD touch

screen on a wall with the wall mount support provided. If

not, you can install the LCD touch screen within the

maximum length of the USB wire provided (see

Appendix B: LCD Touch Screen Supports).

3.3.2 With Optional LCD Touch Screen Sliding

System:

In order to allow the optional LCD touch screen sliding

system to move freely and fully extend, you should allow

a minimum of 7.5" (190 mm) clearance from the side

wall (B) and 2″ (52 mm) clearance at the back of the

stove, from the real panel (A). You may also install the

LCD touch screen sliding system on the left side of the

stove (see Appendix B: LCD Touch Screen

Supports).

3.4 Corner Installation

3.4.1 With LCD Touch Screen Wall Mount Support:

If you wish to install the stove with minimum clearances

(see table in Section 3.2 Minimum Clearances to

Combustibles), it is possible to locate the LCD touch

screen on a wall with the wall support provided. If not,

you can install the LCD touch screen within the

maximum length of the USB wire provided.

3.4.2 With Optional LCD Touch Screen Sliding

System:

In order to allow the LCD touch screen sliding system to

move freely and fully extend, you should allow a 10"

(254 mm) minimum clearance from the adjacent wall

(C). You could also want to install the LCD touch screen

sliding system on the left side of the stove (see

Appendix B: LCD Touch Screen Supports).

3.5 Ceiling Clearances

For ceiling clearances refer to the table in Section 3.2

Minimum Clearances to Combustibles.

16

Page 17

Edison Installation and Operation Manual

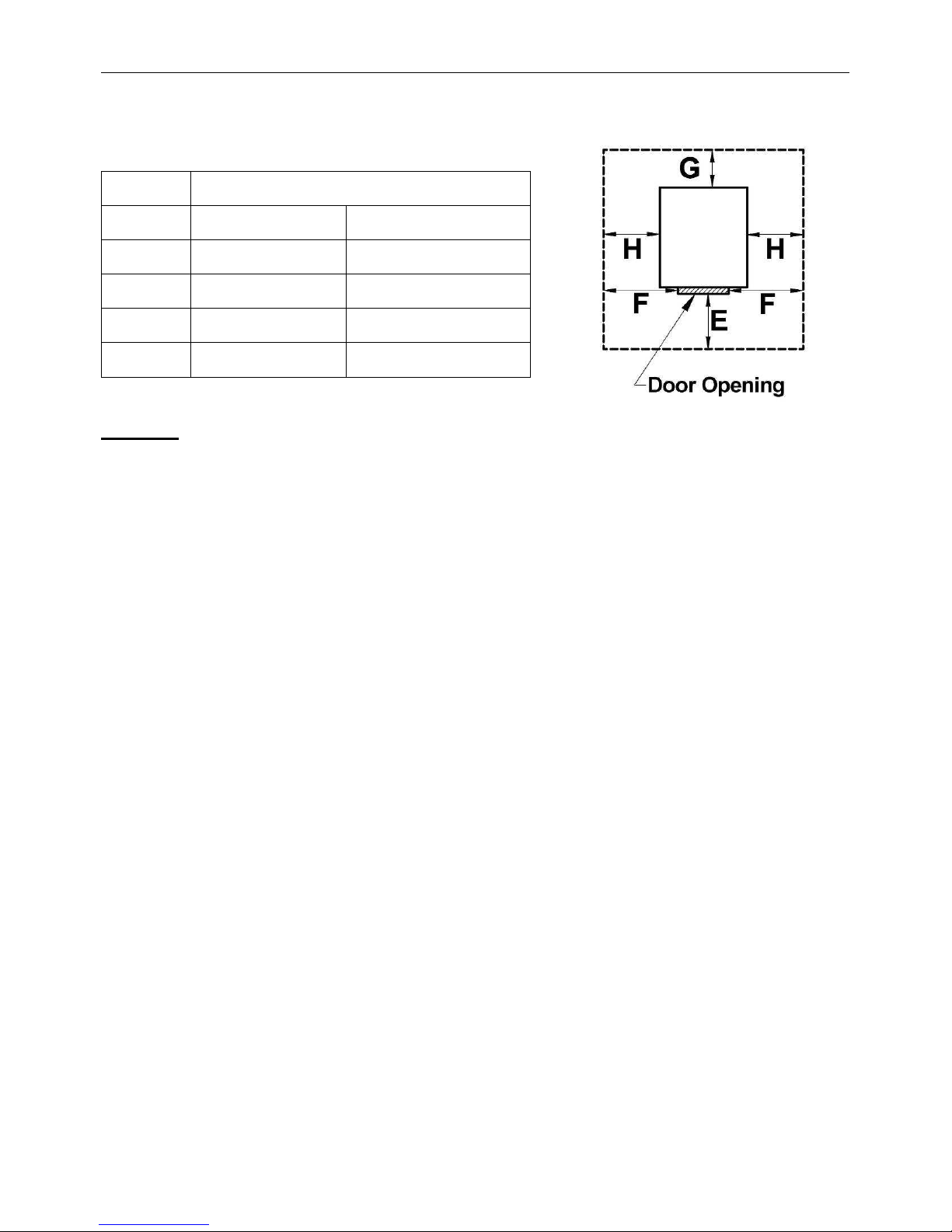

3.6 Floor Protection

For floor protection clearances refer to the following table.

FLOOR PROTECTION

LETTER

CANADA USA

E 18″ (460 mm) 6″ (155 mm)

F N/A (USA only) 6″ (155 mm)

G 8″ (205 mm) N/A (Canada only)

H 8″ (205 mm) N/A (Canada only)

CAUTION: THE STOVE MUST BE PLACED ON A CONTINUOUS (GROUTED JOINTS)

NONCOMBUSTIBLE MATERIAL SUCH AS CERAMIC TILE*, CEMENT BOARD, BRICK,

MILLBOARD OR EQUIVALENT, OR ANY OTHER APPROVED OR LISTED MATERIAL SUITED

FOR FLOOR PROTECTION.

*Any type of tile will require a continuous non combustible sheet beneath to prevent the

possibility of embers falling through to the combustible floor if cracks or separation should

occur in the finished surface, this would include floor protection for built-in raised hearths.

Check local codes for approved alternatives.

4 Venting System

4.1 General

Even though the chimney draft is mechanical, a suitable venting system will ensure a

natural draft which will prevent smoke spillage in your home if a power outage occurs.

Moreover, a suitable venting system configuration will help getting the best efficiency out

of your stove when installed in accordance with the required EVL (see Section 4.3

Equivalent Vent Length (EVL)).

Even the best stove will not function safely and efficiently as intended if it is not connected

to a suitable venting system.

4.2 Recommendations

In Canada, we recommend that you use a listed pellet vent that meets the CAN/ULC S609

or ULC/ORD C441 Standard. A pellet vent listed to ULC S629M is also suitable for

installation with this stove.

For the United States, we recommend that you use a listed pellet vent that meets the UL

641 Standard. A pellet vent listed to UL 103 is also suitable for installation with this stove.

This stove can be vented in an existing factory-built or masonry chimney with the addition

of a stainless steel liner, provided the chimney is more than 4” in diameter. The liner

should be listed and should meet the ULC S635 or CAN/ULC S640 standard in Canada

and the UL 1777 standard in the USA. Refer to the instructions provided by the vent

manufacturer, especially when passing through a wall, ceiling or roof.

17

Page 18

Edison Installation and Operation Manual

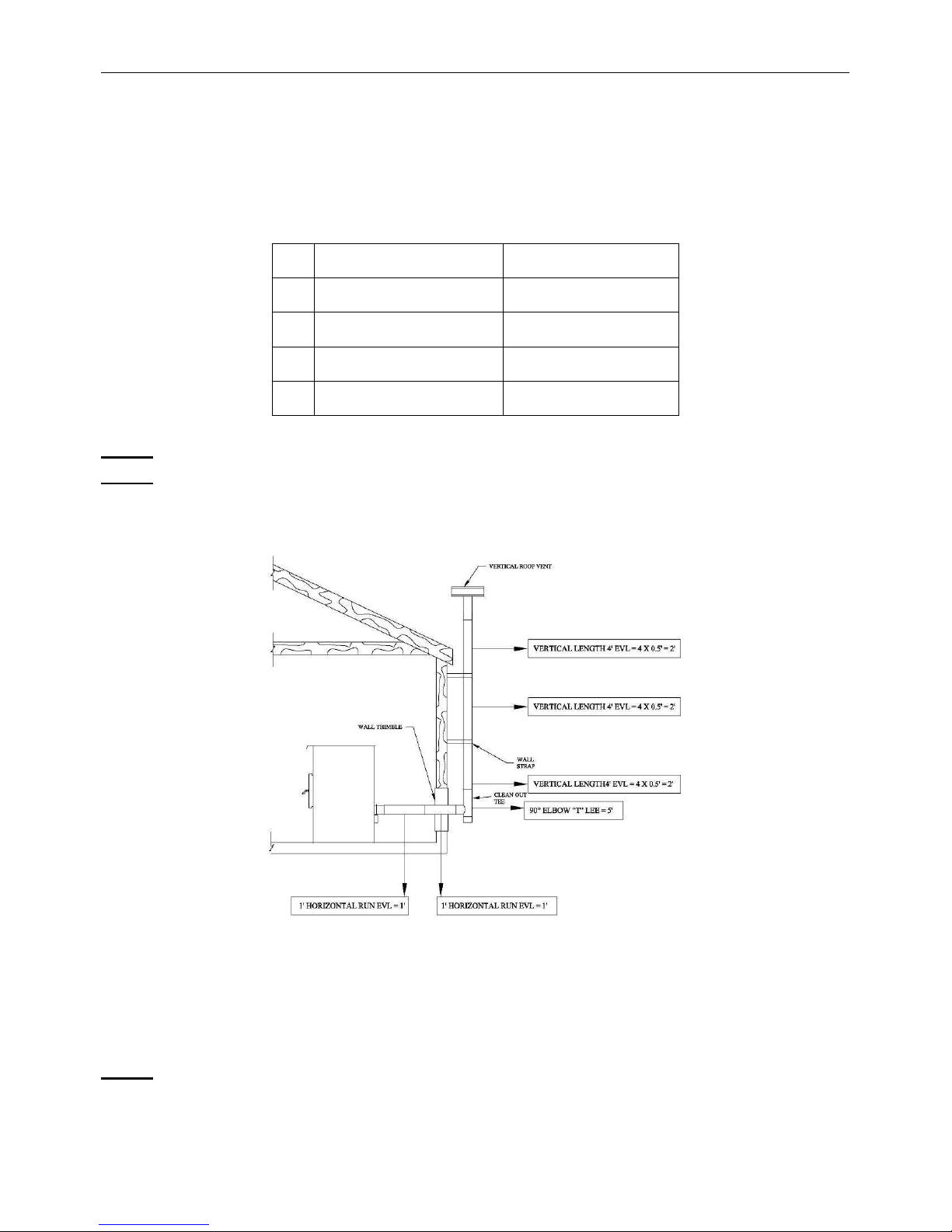

4.3 Equivalent Vent Length (EVL)

Recommended venting system inner pipe diameter is 3”. Use a 4” pipe if you have more

than 15 feet of Equivalent Vent Length (EVL).

To calculate the EVL of your installation, use the following conversions:

Qty

Type of pipe EVL equivalent(ft)

1 90° elbow or “T” 5

1 45° elbow 3

1 ft Horizontal pipe run 1

1 ft

Vertical pipe run 0.5

NOTE: Horizontal runs shall not exceed 9 feet.

NOTE: Never exceed 30 feet of EVL.

Here is an example to help you calculate Equivalent Vent Length. On the following figure

the EVL can be calculated like this:

• 2 horizontal run of 1’ = (2 X 1’) X 1’ = 2’ of EVL

• 1 elbow 90° or "Tee" = 5’ of EVL

• 3 vertical length of 4’ = (3 X 4’) X 0.5’ = 6’ of EVL

• Total EVL = (2’ + 5’ + 6’) = 13’.

NOTE: Do not include the exterior wall termination in the EVL calculation (45° elbow

and termination).

18

Page 19

Edison Installation and Operation Manual

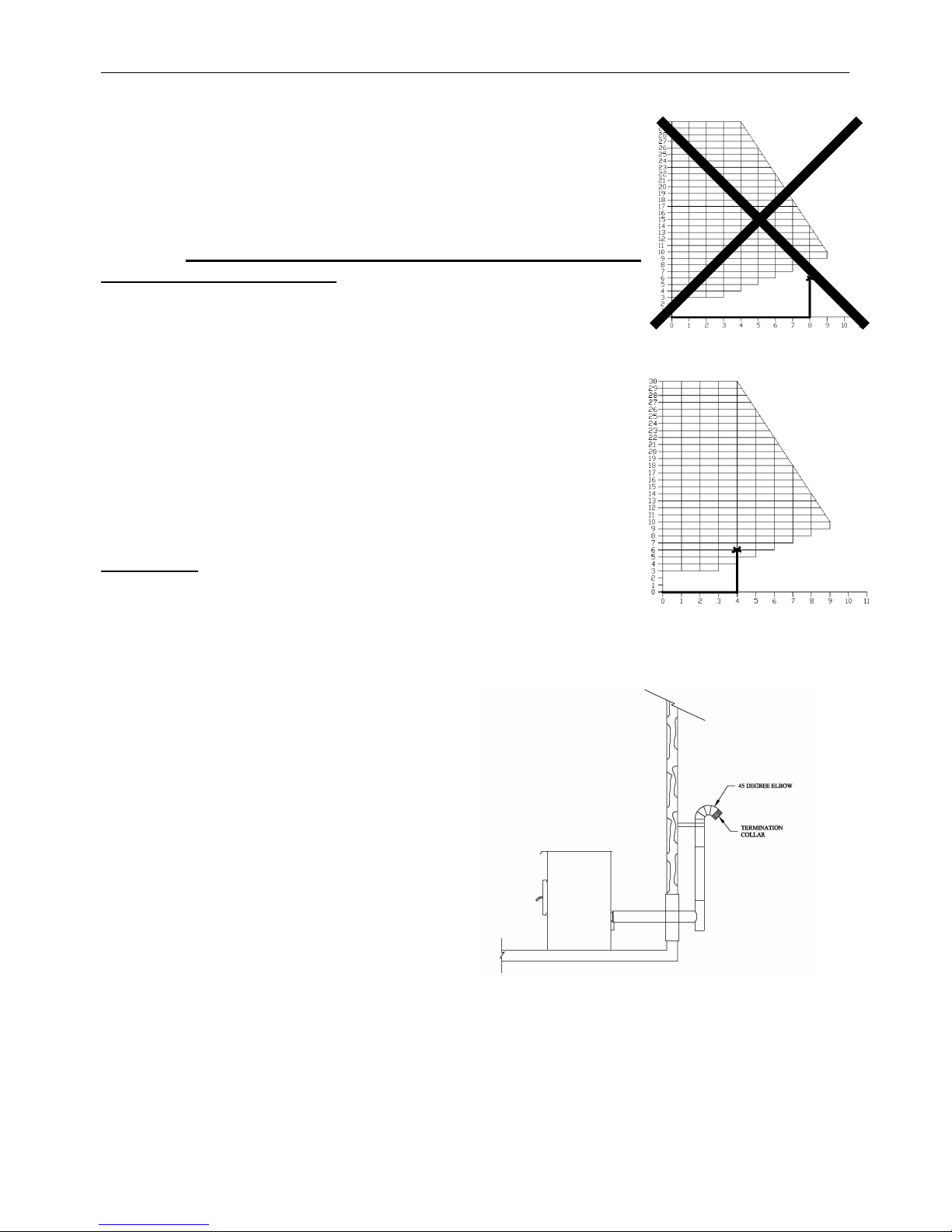

For example, let’s imagine an installation consisting of a

horizontal vent coming out at the back of the stove on a total

distance of 8 feet. This horizontal run is followed by a tee and a

6-foot vertical rise. This type of installation is not acceptable. As

you can see, the vent termination is clearly outside the allowed

configuration zone on the chart because the venting system

proposed does not have at least one foot of vertical rise for

each foot of horizontal run.

Instead, if the installation consisted of a horizontal vent coming

out at the back of the stove on a total distance of 4 feet,

followed by a tee and a 6-foot vertical rise, it would be

acceptable. The installation end should be within the allowable

configuration zone on the chart since it would have at least one

foot of vertical rise for each foot of horizontal run. Furthermore,

the total vertical rise would be at least 3-foot high.

O.K.

WARNING: To reduce the risk of smoke spillage there

should always be at least one foot of vertical rise for each

foot of horizontal run. In all cases, at least 3 feet of vertical

rise is needed.

4.4 Termination Location

Termination should not be located so that

hot exhaust gases can be a hazard. They

can reach temperatures of 500°F (260°C)

and cause serious burns.

CAUTION: TERMINATION COLLAR

(SPARK ARRESTER) IS MANDATORY.

19

Page 20

Edison Installation and Operation Manual

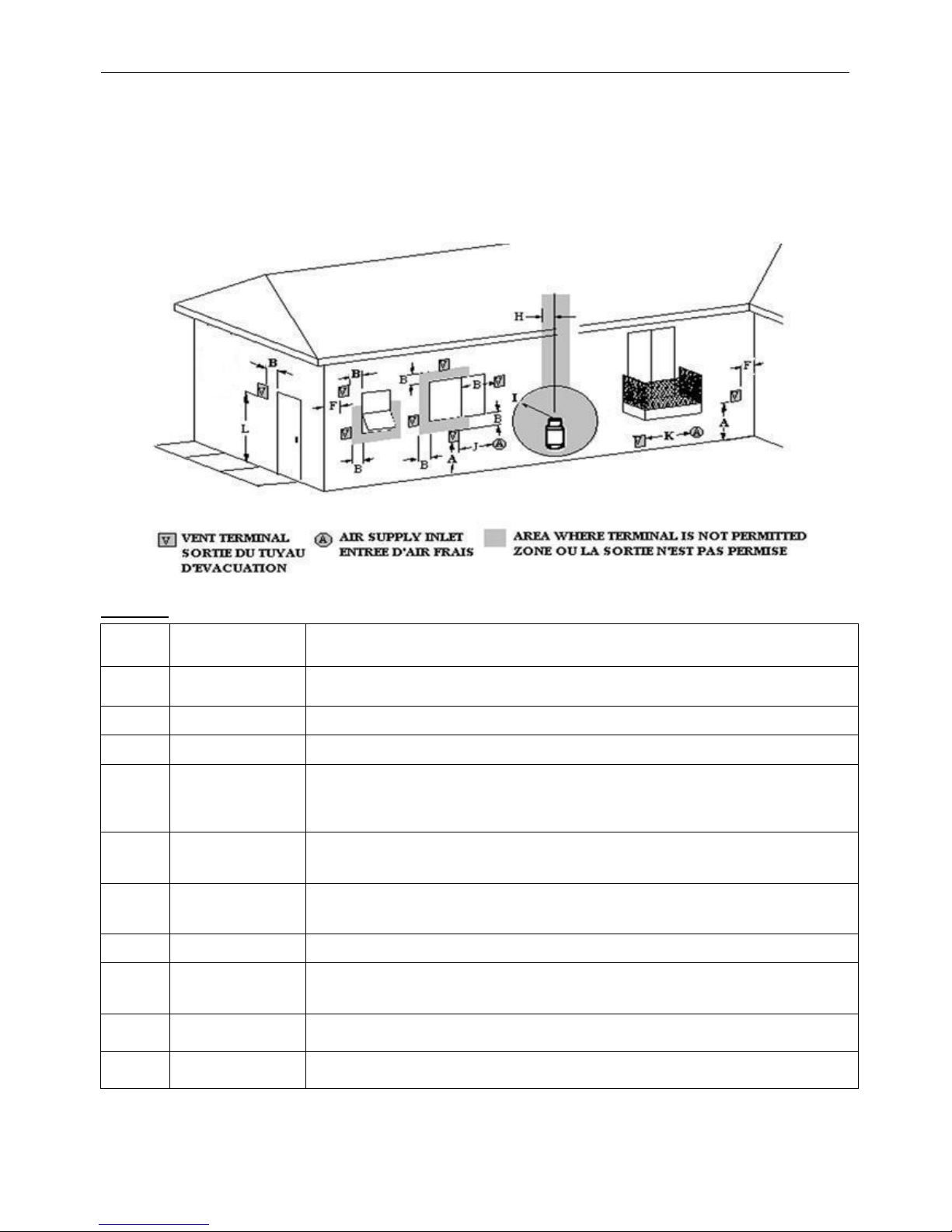

4.4.1 Permitted Termination Location

Refer to NFPA 211 (USA) or CSA B365 (Canada) for rules for the distance of exit terminal

from windows and openings. The exit terminal of a mechanical draft system, other than a

direct vent appliance (see Section 4.4.1.1: Direct Vent System (2-in-1 Exhaust and

fresh air intake)) shall be located in accordance with the following.

Canada:

Letter

A

B*

F

H

I

J

K

L

Min.

clearances

12’’ (30 cm)

39’’ (100 cm) Clearance to window or door that may be opened

39’’ (100 cm) Clearance to corner or adjacent wall

39’’ (100 cm)

72’’ (183 cm)

39’’ (100 cm) Clearance to the combustion air inlet to any other appliance

72’’ (183 cm) Clearance to a mechanical air supply inlet

84’’ (213 cm)

Clearances above grade level or any adjacent surface that might

support snow, ice, or debris

Not to be installed above a meter/regulator assembly within 39" (100

cm) horizontally from the vertical center-line of the regulator and for 15’

vertically

Clearance to gas service regulator vent outlet or within 39’’ (100 cm) of

an oil tank vent or an oil tank fill inlet

Clearance above paved side-walk or a paved driveway located on

public property

Description

39’’ (100 cm) Clearance to property boundary

A vent shall not terminate underneath a veranda, porch, or deck

20

Page 21

Edison Installation and Operation Manual

United States:

• Not Less than 36’’ (91 cm) above any forced air inlet located within 10 feet (305 cm);

• Not Less than 48’’ (122 cm) below and horizontally from, or one foot (30 cm) above,

any door, window or gravity air inlet into any building (See Section 4.4.1.1: Direct

Vent System (2-in-1 Exhaust and fresh air intake);

• Not Less than 24’’ (61 cm) from an adjacent building and not less than 84’’ (213 cm)

above grade when located adjacent to a public walkway.

• Cannot be located less than 12 inches (300mm) above grade.

• Cannot be located above a gas meter/regulator within 3 feet (900mm) horizontally of

the vertical center line of the regulator.

• Not within 6 feet (1.8 meters) of a gas service regulator vent outlet.

• Other restrictions may apply. See NFPA 211 for further information.

4.4.1.1 Direct Vent System (2-in-1 Exhaust and fresh air intake)

When the stove is installed with a direct vent system, the exit terminal shall be located at

least 9" (23 cm) away from a window or door.

The bottom of the exhaust terminal and air intake must be located at least 1” (30 cm)

above the ground.

4.5 Installation Configurations

4.5.1 Installation Warnings, Cautions and Recommendations Reminder

• PROFESSIONNAL INSTALLATION IS HIGHLY RECOMMENDED

• THIS STOVE USES A PRESSURIZED VENTING SYSTEM. ALL VENT CONNECTOR

JOINTS MUST BE SEALED AND FASTENED. YOU MAY USE RTV SILICONE

(ROOM TEMPERATURE VULCANISATION), METALLIC TAPE, AND A MINIMUM

OF THREE SELF-TAPING SCREWS AT ALL JOINT CONNECTIONS TO ENSURE A

TIGHT SEAL. CONSULT THE PELLET VENT MANUFACTURER’S INSTRUCTION

TO ENSURE PROPER INSTALLATION, CONSISTENT PERFORMANCE, AND TO

AVOID SMOKE AND ASH SPILLAGE.

• THE CHIMNEY CONNECTOR SHALL NOT PASS THROUGH AN ATTIC OR ROOF

SPACE, CLOSET OR SIMILAR CONCEALED SPACE OR FLOORS OR CEILING.

• INSTALL VENTING SYSTEM AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

• THE USE OF A SPARK ARRESTER AT THE END OF THE TERMINATION IS

MANDATORY. IT IS IMPORTANT THAT THE SPARK ARRESTER BE CLEAR OF

ANY DEBRIS AT ALL TIME.

21

Page 22

Edison Installation and Operation Manual

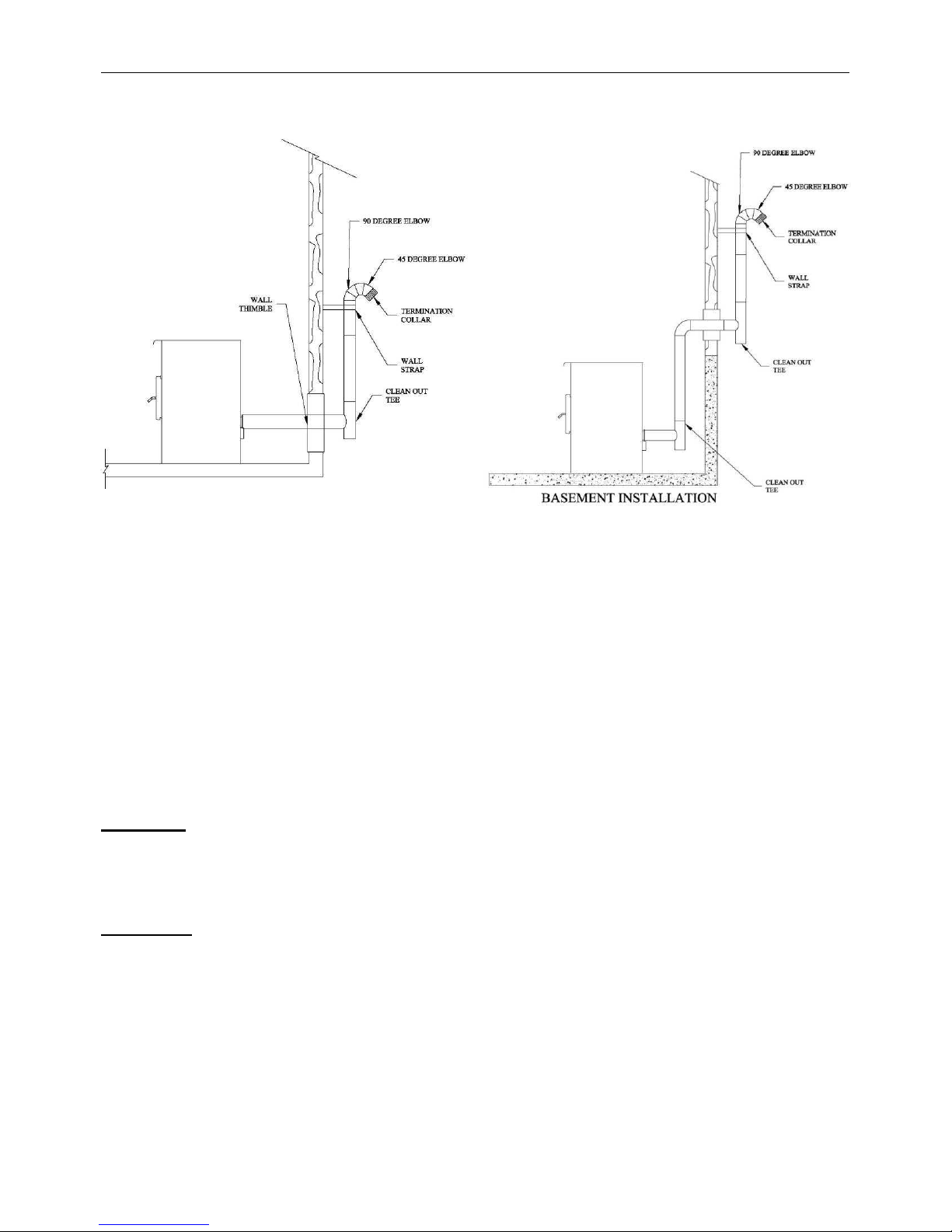

4.5.2 Through Wall Installation (Main Floor or Basement)

1. Position stove following clearances given in Section 3: Clearances to Combustible

Material and following vent manufacturer’s instructions. Then locate the position of the

exhaust pipe in the wall.

2. Install wall thimble as per vent manufacturer’s instructions.

3. Attach enough piping length to go through the wall thimble and extend at least 6 inches

beyond the exterior wall.

4. Attach cap and seal outside wall thimbles with high temperature waterproof silicone

sealant.

CAUTION: TO REDUCE THE RISK OF SMOKE SPILLAGE THERE SHOULD ALWAYS

BE AT LEAST 12” (30 CM) OF VERTICAL RISE FOR EACH FOOT OF HORIZONTAL

RUN. IN ALL CASES, AT LEAST 36” (91 CM) OF VERTICAL RISE IS NEEDED

BEFORE THE TERMINATION.

WARNING: TERMINATION SHOULD NOT BE LOCATED SO THAT HOT EXHAUST

GASES CAN BE A HAZARD. EXHAUST GASES CAN REACH TEMPERATURES OF

500°F (260°C) AND CAUSE SERIOUS BURNS. SEE SECTION 4.4.1 PERMITTED

TERMINATION LOCATION.

22

Page 23

Edison Installation and Operation Manual

4.5.3 Through Roof Installation

1.

Position stove following clearances given

in

Section 3.2: Minimum Clearances

to Combustibles and following vent

manufacturer’s instructions.

2. Install a cleanout tee to the stove

exhaust. If necessary, use a horizontal

additional length between the exhaust

and the tee. If you wish to center the

vertical part of the vent with the stove,

a 45° elbow and a tee can be used to

route the pipe from the exhaust

towards the back center of the stove.

3. Drop the plumb bob over the center of

the tee outlet and mark location on the

ceiling. Install the ceiling support and

the vent pipe by following the vent

manufacturer’s instructions.

4. Always follow vent manufacturer’s

clearances instructions from

combustible materials. When passing

through additional floors or ceilings,

always install a fire stop spacer.

5. After lining up for hole in roof, cut either

a round or square hole in roof. Install

upper edge and sides of flashing under

roofing materials. Nail it to the roof

along upper edge. Do not nail lower

edge. Seal nail heads with flexible

waterproof sealant.

6. Apply high temperature waterproof

silicone sealant where the storm collar

meets the vent. Slide storm collar

down until it sits on the flashing.

7.

Seal and install

required, seal and install a storm collar.

vertical roof vent. If

23

Page 24

Edison Installation and Operation Manual

4.5.4 Through a Factory Built Chimney

To make an installation through a factory

built chimney, run a 4" stainless steel liner

inside the factory built chimney.

1. Position stove following clearances

given in Section: 3.2 Minimum

Clearances to Combustibles and

following vent manufacturer’s

instructions.

2. Install a cleanout tee to the stove

exhaust. If necessary, use a horizontal

additional length between the exhaust

and the tee. If you wish to center the

vertical part of the vent with the stove, a

45° elbow and a tee can be used to

route the pipe from the exhaust towards

the back center of the stove.

3. Connect the pellet vent to the stainless

steel liner according to the vent

manufacturer’s instructions.

4. Seal and install vertical roof vent. If

required, seal and install a storm collar.

WARNING: IN THE U.S., THE USE OF A STAINLESS STEEL LINER IS MANDATORY.

IN CANADA, IT IS NOT MANDATORY BUT IS STRONGLY RECOMMENDED.

NOTE: VENTING DIRECTLY IN AN OVERSIZED CHIMNEY AND OMITTING THE USE

OF A STAINLESS STEEL LINER CAN AFFECT CHIMNEY DRAFT AND DECREASE

STOVE PERFORMANCES.

24

Page 25

Edison Installation and Operation Manual

4.5.5 Through an Existing Masonry Fireplace

1. Position stove, following clearances

shown in Section 3.2: Minimum

12”-18”

Clearances to Combustibles and

following vent manufacturer’s

instructions.

2. Build and Install a blocking plate inside

the chimney to seal the fireplace

damper. Stainless steel plate and

screws are recommended. Cut a hole

for the exhaust pipe. If needed, cut a

second hole for the air intake pipe (see

Appendix F: Combustion Air Supply).

3. Attach a section of pipe and clean out

tee to the exhaust, making sure the

clean out tee is centered in the chimney

flue area.

4. Install a vented flashing at the top of the

fireplace chimney. Stainless steel plate

and screws are recommended. Cut a

hole for the vent pipe. If needed, cut a

second hole for the air intake pipe. Seal

all joints with high temperature

waterproof silicone sealant to prevent

water leakage.

5. Seal and install vertical roof vent. If

required, seal and install a storm collar.

NOTE: THE STRUCTURAL CONDITION OF THE MASONRY CHIMNEY MUST FIRST

BE INSPECTED BY A QUALIFIED CHIMNEY SWEEP OR INSTALLER.

NOTE: YOU WILL NEED A PIPE LENGTH EQUAL TO THE CHIMNEY HEIGHT FROM

THE HEARTH. IF OUTSIDE COMBUSTION AIR IS TO BE USED, YOU WILL NEED A

PIPE LENGTH SUPERIOR FROM 12 TO 18 INCHES (30 TO 46 CM) OF THE CHIMNEY

HEIGHT TO ENSURE A PROPER STOVE BEHAVIOUR.

25

Page 26

Edison Installation and Operation Manual

4.5.6 Through an Existing Masonry Chimney

1. Position stove following clearances

shown in Section 3.2: Minimum

Clearances to Combustibles and

following vent manufacturer’s

instructions.

2. Mark the center of the hole where the

vent pipe will go through the masonry

chimney.

3. It is necessary to make a hole in the

masonry with a one-inch diameter

greater than the diameter of the vent

pipe used.

4. Install a vented flashing at the top of the

masonry chimney. Stainless steel plate

and screws are recommended. Cut a

hole for the vent pipe. If needed, cut a

second hole for the air intake pipe. Seal

all joints with high temperature

waterproof silicone sealant to prevent

water leakage.

5. Install the cleanout tee at the bottom of the vertical vent system and lower it down the

chimney until the center branch of the tee is aligned with the hole in the masonry.

6. Install and seal flashing with high temperature waterproof silicone sealant.

7. Seal and install vertical roof vent. If required, seal and install a storm collar.

8. Connect the horizontal vent pipe to the cleanout tee by pushing it through the hole in

the masonry.

9. If desired, once the horizontal pipe is in place, the space between the pipe and

masonry may be filled with high-temperature grout.

10. If desired, install a trim collar and use an additional horizontal vent pipe length, if

required, to connect the stove to the chimney.

26

Page 27

Edison Installation and Operation Manual

PART B - OPERATION

5 General Information

5.1 Operation Warnings, Cautions and Recommendations

• KEEP THIS MANUAL FOR REFERENCE.

• DURING THE FIRST FEW FIRES, YOUR STOVE WILL EMIT AN ODOR AND A SMALL

AMOUNT OF FUMES AS THE HIGH TEMPERATURE PAINT CURES OR BECOMES

SEASONED TO THE METAL. MAINTAINING SMALLER FIRES WILL MINIMIZE THIS.

AVOID PLACING ITEMS ON STOVETOP DURING THIS PERIOD TO AVOID DAMAGING

THE PAINT SURFACE. MAKE SURE THE ROOM IS WELL-VENTILATED. OPEN

WINDOWS. ODORS AND FUMES RELEASED DURING THIS PROCESS ARE

UNPLEASANT BUT THEY ARE NOT TOXIC. ONCE YOU HAVE BURNED THE FIRST

40LBS OF PELLETS, IT IS RECOMMENDED TO INSPECT THE STOVE AND THE

VENTING SYSTEM TO MAKE SURE THAT THERE IS NO LEAKS.

• HOT WHILE IN OPERATION, KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS. GLOVES MAY BE NEEDED FOR STOVE

OPERATION.

• IT IS HIGHLY RECOMMENDED THAT THE USER BUYS THIS PRODUCT FROM A

RETAILER WHO CAN PROVIDE INSTALLATION AND MAINTENANCE ADVICE.

• THIS STOVE MUST SERVE AS A SUPPLEMENTARY HEAT SOURCE. AN ALTERNATIVE

HEAT SOURCE SHOULD BE AVAILABLE IN THE HOME IF NEEDED. THE

MANUFACTURER CANNOT BE HELD RESPONSIBLE FOR ADDITIONAL HEATING

COSTS ASSOCIATED WITH THE USE OF AN ALTERNATIVE HEAT SOURCE.

• USING A STOVE WITH CRACKED OR BROKEN COMPONENTS, SUCH AS GLASS OR

BAFFLE MAY PRODUCE AN UNSAFE CONDITION AND MAY DAMAGE THE STOVE.

• NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL (NAPHTHA), FUEL OIL,

MOTOR OIL, KEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR LIQUIDS OR

AEROSOLS. KEEP ALL SUCH LIQUIDS OR AEROSOLS WELL AWAY FROM THE STOVE

WHILE IT IS IN USE.

• DO NOT STORE FUEL WITHIN STOVE MINIMUM CLEARANCES TO COMBUSTIBLE.

• THIS STOVE SHOULD BE MAINTAINED AND OPERATED AT ALL TIMES IN

ACCORDANCE WITH THESE INSTRUCTIONS. NOT FOLLOWING THE INSTRUCTIONS

OF THIS MANUAL MAY CAUSE SMOKE SPILLAGE AND OTHER POTENTIAL HAZARDS.

IT IS ALWAYS RECOMMENDED TO INSTALL SMOKE DETECTORS AND FIRE

EXTINGUISHER IN A CONVENIENT LOCATION.

• THE VIEWING DOOR MUST BE CLOSED AND LATCHED AT ALL TIMES DURING

OPERATION. THE ASH DRAWER ACCESS PANEL MUST ALSO BE CLOSED DURING

OPERATION.

• NEVER TRY TO REPAIR OR REPLACE ANY PART OF THE STOVE UNLESS

INSTRUCTIONS ARE GIVEN BY THE MANUFACTURER. ALL OTHER WORK SHOULD BE

DONE BY A TRAINED TECHNICIAN.

27

Page 28

Edison Installation and Operation Manual

• DO NOT OPERATE THE STOVE IF THE FLAME BECOMES DARK AND SOOTY OR IF THE

BURN POT OVERFILLS WITH PELLETS. TURN THE STOVE OFF, INSPECT IT, AND CALL

YOUR DEALER.

• TURNING THE STOVE OFF DOES NOT DISCONNECT ALL POWER FROM THE STOVE.

ALWAYS DISCONNECT THE POWER CORD AND THE AUXILARY BATTERY SYSTEM

BEFORE PERFORMING ANY MAINTENANCE OR REPAIRS ON THE STOVE.

• ALLOW THE STOVE TO COOL BEFORE CARRYING OUT ANY MAINTENANCE OR

CLEANING. ASHES SHOULD BE PLACED IN A METAL CONTAINER WITH A TIGHT

FITTING LID. THE CLOSED METAL CONTAINER SHOULD BE PLACED ON A

NONCOMBUSTIBLE FLOOR OR ON THE GROUND, WELL AWAY FROM ALL

COMBUSTIBLE MATERIALS, PENDING FINAL DISPOSAL. IF THE ASHES ARE

DISPOSED OF BY BURIAL IN SOIL OR OTHERWISE LOCALLY DISPERSED, THEY

SHOULD BE RETAINED IN THE CLOSED CONTAINER UNTIL ALL ASHES HAVE BEEN

THOROUGHLY COOLED.

• DO NOT OPERATE THE STOVE IF YOU SMELL OR SEE SMOKE. TURN IT OFF,

MONITOR IT AND CALL YOUR DEALER IF NECESSARY. DO NOT UNPLUG IT. NEVER

OPEN THE DOOR.

• IT IS RECOMMENDED TO UNPLUG THE STOVE WHEN IT’S NOT IN USE FOR

PROLONGED AMOUNT OF TIME (I.E. DURING SUMMER). HEAT ACTIVATED SENSORS

ON THE STOVE COULD START THE FANS EVEN IF THE STOVE IS NOT IN FUNCTION.

THE CR2032 BUTTON BATTERY MUST ALSO BE REMOVED DURING THIS PERIOD

(VOIR SECTION 2.3: BEFORE OPERATING YOUR STOVE).

• THIS STOVE REQUIRES REGULAR MAINTENANCE AND CLEANING. FAILURE TO

FOLLOW THE MAINTENANCE SCHEDULE (SEE SECTION 8.1.1: RECOMMENDED

MAINTENANCE SCHEDULE) WILL REDUCE THE STOVE PERFORMANCE AND COULD

EVENTUALLY DAMAGE IT. IT ALSO MAY LEAD TO SMOKE SPILLAGE IN YOUR HOME.

• THIS STOVE IS DESIGNED AND TESTED TO BURN ONLY WOOD PELLETS. ANY OTHER

TYPE OF FUEL BURNED IN THIS HEATER WILL VOID THE WARRANTY.

• HOPPER SHOULD ONLY CONTAIN PELLETS. HOPPER SHOULD BE KEPT FREE OF

ANY FOREIGN OBJECTS AT ALL TIME TO PREVENT ANY DAMAGE TO THE STOVE.

• THE STOVE DOES NOT OPERATE WITHOUT ELECTRICITY. IF A POWER OUTAGE

DOES OCCUR AND YOU DO NOT HAVE THE AUXILARY BATTERY SYSTEM, CHECK

THE STOVE FOR SMOKE SPILLAGE. OPENING A WINDOW WILL PREVENT NEGATIVE

PRESSURE AND SMOKE SPILLAGE IN THE ROOM. IT IS IMPORTANT NOT TO OPEN

THE HOPPER LID OR THE STOVE DOOR.

• DO NOT UNPLUG THE STOVE IF YOU SUSPECT IT IS MALFUNCTIONING. TURN IT OFF,

MONITOR IT AND CALL YOUR DEALER IF NECESSARY.

• THIS STOVE IS DESIGNED TO PROVIDE THE OPTIMUM PROPORTIONS OF FUEL AND

AIR TO THE FIRE IN ORDER TO BURN FREE OF SMOKE AND SOOT. ANY BLOCKAGE

OF THE AIR SUPPLY TO OR FROM THE STOVE WILL SERIOUSLY DECREASE ITS

PERFORMANCE AND WILL BE EVIDENT BY A SMOKING EXHAUST, A SOOT BUILDUP

ON THE WINDOW AND ON OUTSIDE WALLS. FOR BEST OPERATION, THE ASH

CONTENT OF THE PELLET FUEL SHOULD BE LESS THAN 1% AND THE CALORIFIC

VALUE APPROXIMATELY 8,500 BTU/LB. OTHERS FUELS WITH A HIGH ASH CONTENT

WILL REQUIRE A HIGHER LEVEL OF MAINTENANCE AND CLEANING.

28

Page 29

Edison Installation and Operation Manual

• THE STOVE WILL NOT OPERATE USING NATURAL DRAFT OR WITHOUT A POWER

SOURCE TO ACTIVATE THE BLOWER SYSTEMS AND FUEL FEED SYSTEM.

• STOVE BUILDER INTERNATIONAL INC. GRANTS NO WARRANTY, IMPLIED OR STATED,

FOR IMPROPER INSTALLATION OR LACK OF MAINTENANCE OF YOUR STOVE, AND

ASSUMES NO RESPONSIBILITY OF ANY CONSEQUENTIAL DAMAGES.

• IF YOU NOTICE A SMOLDERING FIRE (BURNPOT FULL BUT NO VISIBLE FLAME) AND A

HEAVY SMOKE BUILDUP IN FIREBOX, IMMEDIATELY TURN OFF THE STOVE, BUT DO

NOT UNPLUG IT. DO NOT OPEN THE DOOR OR THE HOPPER LID. MAKE SURE THAT

THE FRESH AIR INTAKE SHUTTER WORKS FREELY. WAIT UNTIL SMOKE INSIDE THE

FIREBOX CLEARS AND BLOWERS SHUT DOWN. DO AS INSTRUCTED IN “EVERYDAY

STARTUP” THEN ATTEMPT TO RESTART THE STOVE. IF THE PROBLEM PERSISTS,

CONTACT YOUR DEALER. NOTE THAT SMOKE BUILD-UP DURING IGNITION MAY

OCCUR. SMOKE CAN ACCUMULATE IN THE FIREBOX FOR A FEW SECONDS JUST

BEFORE THE IGNITOR IS HOT ENOUGH TO FIRE-UP THE PELLETS IN THE BURN POT.

THIS IS NORMAL. AS SOON AS THERE IS FIRE IN THE BURN POT, SMOKE WILL

DISAPPEAR.

• MAINTAIN PROPER VENTILATION. IT IS IMPORTANT THAT ADEQUATE OXYGEN IS

BEING SUPPLIED TO THE FIRE FOR PROPER COMBUSTION. DURING THE WINTER

SEASON, MAKE SURE THAT THE FRESH AIR INTAKE IS FREE OF ANY ICE, SNOW,

ETC., AS THIS WILL STARVE THE FIRE OF AIR AND PREVENT THE PROPER

OPERATION OF THE STOVE. MAKE SURE THE FRESH AIR INTAKE BACKDRAFT

SHUTTER WORKS FREELY.

• OPERATING YOUR STOVE AT THE MAXIMUM SETTING DURING A LONG PERIOD OF

TIME MAY REDUCE THE STOVE AND ITS COMPONENTS LIFE EXPECTANCY.

5.1.1 Operation Warnings, Cautions and Recommendations on Auxiliary Battery System

• FOLLOW THE MANUFACTURER'S INSTRUCTIONS FOR TESTING, JUMPING,

INSTALLING, DISCHARGING, CHARGING, EQUALIZING AND MAINTAINING BATTERIES.

• ALWAYS USE BATTERIES OF IDENTICAL MAKE, MODEL AND WITH THE SAME

MANUFACTURING DATE.

• MAKE SURE THE BATTERY CABLE IS NOT UNDERSIZED FOR THE BATTERY SYSTEM.

• MAKE SURE THE BATTERY CABLES ARE CONNECTED TO THE TERMINALS

CORRECTLY. IF UNSURE, PROFESSIONAL ASSISTANCE IS RECOMMENDED.

• NEVER MOVE THE BATTERIES FROM THEIR ORIGINAL POSITION.

• DO NOT SHORT-CIRCUIT THE BATTERIES.

• DO NOT CHARGE WITHIN A SEALED HOUSING.

• WHEN USING AN AUXILIARY BATTERY SYSTEM OTHER THAN THE OF THE STOVE’S

MANUFACTURER, ALWAYS USE THE CONNECTOR OF THE UNIT PROVIDED BY THE

MANUFACTURER AND MAKE SURE THAT THE BATTERIES ARE LOCATED BEYOND

THE MINIMUM CLEARANCES TO COMBUSTIBLES.

• EXERCISE CAUTION WHEN WORKING WITH METALLIC TOOLS OR CONDUCTORS, TO

PREVENT SHORT CIRCUITS AND SPARKS.

29

Page 30

Edison Installation and Operation Manual

5.1.2 Zone Heating and How to Make It Work for You

Your new pellet stove is a space heater, which means it is intended to heat the area it is

installed in, as well as spaces that connect to that area, although to a lower temperature.

This is called zone heating and it is an increasingly popular way to heat homes or spaces

within homes.

Zone heating can be used to supplement another heating system by heating a particular

space within a home, such as a basement family room or an addition that lacks another

heat source.

Although the stove may be able to heat the main living areas of your house to an adequate

temperature, this stove must serve as a supplementary heat source. You should have a

conventional oil, gas or electric additional heating system to provide heating in the home.

The manufacturer cannot be responsible for additional heating costs associated with the

use of an alternative heat source in case of stove failure or power outage.

Your success with zone heating will depend on several factors: Proper stove size, stove

location, heating area, house layout, insulation and your climate zone.

5.2 Combustible

5.2.1 Proper Fuel

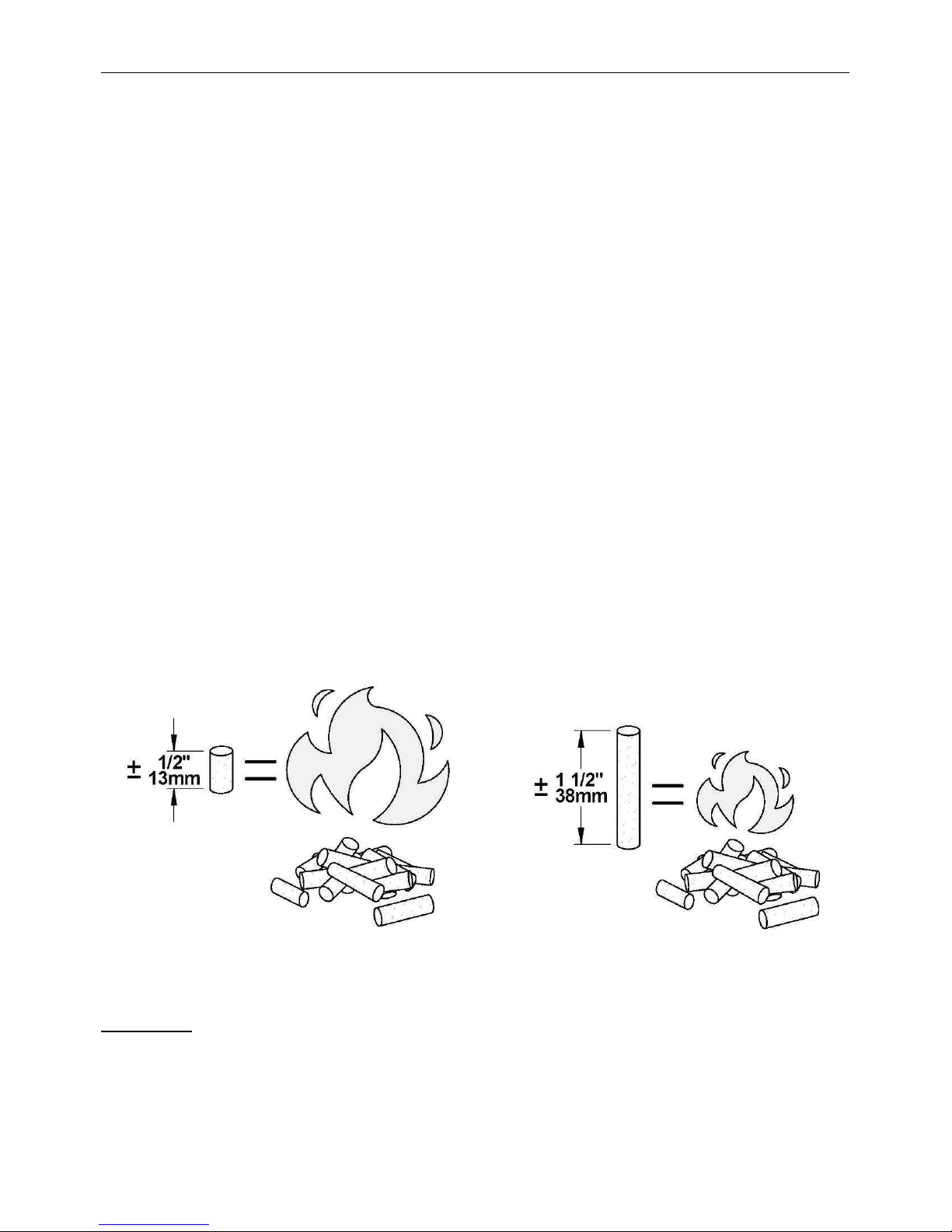

Each type of pellet has its properties and will burn differently. The amount of ashes

produced can also vary greatly. Conventional pellets are those ¼” or 5/16” in diameter and

not over 1” long. Longer or thicker pellets will prevent proper pellet feed.

For example, if the pellets are very short, they will have more ease to accumulate and pile

into the feed screws. Thus, the volume of pellets will be denser, which will lead to an

increase in BTU. By contrast, longer pellets will pile less so the BTU will be reduced.

The bottom-feed system of this stove is designed and tested specifically for use with wood

pellets.

WARNING: BURNING OTHER TYPES OF PELLETS IS PROHIBITED. IT VIOLATES

THE BUILDING CODES FOR WHICH THE STOVE HAS BEEN APPROVED AND WILL

VOID THE WARRANTY

30

Page 31

Edison Installation and Operation Manual

5.2.2 Where to Store Bags of Pellets

We recommend that you store your bags of pellets in a dry and well ventilated area if

possible. Using dry pellets will increase the performance of your stove. You may want to

have a bag or two in the same room as your stove for refueling but make sure to respect

the minimum clearances to combustible materials and the space required for refilling and

ash removal.

6 Stove controls

6.1 General Information

The stove uses an LCD touch screen (A), the latest technology in control devices. The

blowers and feed system are controlled from this screen.

It is possible to install the support on the back of the stove or on a wall. In addition, it is

possible to install the LCD touch screen on a sliding support (optional) to the back of the

stove. See Appendix B: LCD Touch Screen Supports.

6.1.1 LCD Touch Screen Controls, Operation and Configuration

The LCD touch screen control is an electronic visual display as well as a touch screen that

will light-up as you touch any location on the display area. The main status page will then

display different icons layout depending if the stove is on or not

There is four important components of the LCD touch screen which are the On/Off button

(A), the temperature sensor (B), the micro USB connector (C) (for communication with the

stove) and the USB connector (D) (to update software).

.

31

Page 32

Edison Installation and Operation Manual

Main status page when the stove is OFF

Description of each main status page icon:

Operating mode

(thermostat or

manual)

Settings

button

On/Off

button

Thermostatic

Burn rate

adjustment

Convection

blower speed

adjustment

Main status page when the stove is ON

mode

Feed screw

parameters

Feed screw

options

32

Page 33

Edison Installation and Operation Manual

VX.XX(

VX.XX

X:XX:X

XX°F

XX°

X:XX:X

Feed screw

button when

On

6.1.2 Configuration and Operation Diagram

Access to

program

Button to

stop the feed

screw

Demo mode

of the unit

Allows to slightly adjust

the combustion and

pilot parameters

6.1.3 Selecting the Language and Temperature Unit (°F or °C)

From the main status page, choose the settings icon . Select "SETUP". You can

choose between three languages, English, French or Spanish and between “°F or °C”.

Select “°F or °C” icon to display temperatures in the desired unit.

6.1.4 Viewing Statistics

From the main status page, choose the settings icon . Select “TROUBLESHOOT” and

then using the arrows, go to page 2. Statistics will be available between page 1 to 3.These

statistics can be very useful to a service technician or SBI technical support.

33

Page 34

Edison Installation and Operation Manual

6.1.5 Auxiliary Battery System Level

The batteries’ voltage at full load is 25.2V and the minimum voltage to avoid damaging the

batteries is 22.5V. When the minimum battery voltage is reached, the stove will

automatically stop. The batteries must be recharged or the stove must be connected to a

power source.

Red

Yellow

Green

Green

Red

Yellow

Green

Green Indicates that the stove is on and the batteries are full loads.

Indicates that the stove runs on the auxiliary battery system and the

batteries are 25% load (until 22.5V).

Indicates that the stove runs on the auxiliary battery system and the

batteries are 50% load (until 23.6V).

Indicates that the stove runs on the auxiliary battery system and the

batteries are at 75% load (until 24.5V).

Indicates that the stove runs on the auxiliary battery system and the

batteries are full loads (until 25.2V).

Indicates that the stove is powered, the batteries are 25% charged and

that they are charging.

Indicates that the stove is powered, the batteries are 50% charged and

that they are charging.

Indicates that the stove is powered, the batteries are 75% charged and

that they are charging.

6.1.6 Adjusting the Combustion Level (Heat Output)

Press on the

pellet burn rate

adjustment button

Press + or to adjust

the burn rate

The stove’s input range goes from 10,000 BTU/h to 45,000 BTU/h. To change combustion

level, select the flame icon on the main status page to display the “+” and “-”

combustion level settings.

Note: Input range may vary according to the type of pellets being used.

Even though your stove can burn a large variety of wood pellets, we strongly recommend

the use of high quality pellets to obtain maximum performance out of your stove (see

Section 5.2.1: Proper Fuel). When using lower quality combustible, a restrictive venting

system or using the stove in high altitude, you may need to adjust the “PILOT

ADJUSTMENT SETTING” and the “COMBUSTION ADJUSTMENT SETTING”. These two

(2) settings are available from the “SETUP” page.

34

Page 35

Edison Installation and Operation Manual

Note: To obtain optimal results make sure the venting system, heat exchanger and

exhaust channels are cleaned before performing any setting changes.

6.1.7 Combustion Settings and Pilot Settings depending on Fuel Quality

6.1.7.1 PILOT ADJUSTMENT (Pilot Settings Adjustment)

The “PILOT ADJUSTEMENT” will allow you to modify default settings by ± 2 for auger

motor 1 and ± 10 for combustion and exhaust fan, but will only apply during pilot cycle:

To restore default setting, select “DEFAULT”.

6.1.7.2 COMBUSTION ADJUSTMENT (Fuel Quality Adjustment)

The “COMBUSTION ADJUSTMENT” will allow you to modify default settings by ± 2 for

auger motor 1 and ± 10 for combustion and exhaust fan.

To restore default setting, select “DEFAULT”.

Here are some situations where you may want to adjust these components:

Average speed of auger motor #1:

You may want to increase the auger motor #1 speed if fire goes out when combustion

level is at its minimum setting. When burning poor quality pellets you may also need to

reduce the auger motor speed to avoid unburned pellets to fall into the ash drawer at any

combustion level.

35

Page 36

Edison Installation and Operation Manual

Speed of combustion fan:

You may want to reduce combustion fan speed if fire goes out when combustion level is at

minimum setting. You may also want to increase combustion fan speed to avoid unburned

pellets to fall into the ash drawer at any combustion level.

Speed of exhaust fan:

You may want to reduce exhaust fan speed if natural draft is excessive and/or if the flame

is low and almost at the same height at any combustion level. You may also want to

increase the exhaust fan speed if vent configuration is too restrictive or flame height tends

to be high at any combustion level.

6.1.8 Convection Fans Speed Adjustment

You can adjust the stove’s convection fans speed for each combustion level selected.

Thus, an adjustment range is offered to reduce or increase air distribution in the room.

Press the blower

button to adjust

the blowing speed

Press + or to increase

or decrease

blower speed

If overheating is detected, the convection fans speed will automatically go to the maximum

setting and an envelope icon will appear on the Main Status Page . Press on the

envelope icon to view the warning message. Meanwhile, the convection fans will operate

at its highest setting until the stove reaches a safe temperature. Once the stove reaches

that temperature, it will return to the previously selected convection fan selection.

6.1.9 Selecting MANUAL or AUTO THERMOSTAT

To change operating mode, press on the selected mode and then select the desired mode

from the scrolling menu.

Operating mode

(Thermostat or manual)

Press on the desired mode

Indicates that the stove is in manual mode. It will therefore run

continuously on the selected setting until it is manually modified,

turned OFF or if the stove runs out of pellets.

36

Page 37

Edison Installation and Operation Manual

Indicates that the stove is in thermostat mode. The red waves

indicate that the thermostat is calling for heat. It will heat at the

selected combustion level until the thermostat has reached room

temperature setting.

The waves will disappear once the thermostat has reached room

temperature setting. At this time the combustion level will switch

into the selected pilot mode until its cycle is completed. When

thermostat calls for heat, the icon will change for the one with

waves and combustion level will use the last setting.

6.1.10 Selecting the Pilot Cycle

To change the pilot cycle press the word “PILOT” from the Main Status Page. You can

choose from one of the four different pilot cycles: "ON", "30 MIN", “60 MIN”, or

"OFF".Default setting is "OFF" since this is the most fuel efficient configuration.

Press on PILOT

button to set

pilot time settings

Note: Pilot feed rate is lower than the minimum combustion level feed rate.

6.1.10.1 Pilot OFF

When the “PILOT OFF” cycle is selected, the stove will shut down when the temperature

set on the thermostat is reached. Every time the thermostat will call for heat, the stove will

go through the complete ignition cycle.

6.1.10.2 30 Minutes or 60 Minutes

The pilot cycle begins when temperature set on the thermostat is reached. It will last 30 or

60 minutes depending of the selected pilot cycle. If the thermostat does not call for heat

before the end of the selected pilot cycle delay, the stove will shut down and will need to

go through the complete ignition cycle when the thermostat calls for heat again.

6.1.10.3 Pilot ON

The pilot cycle begins when temperature set on the thermostat is reached. When the

“PILOT ON” cycle is selected, the stove will remain on pilot mode until the thermostat calls

for heat.

6.1.11 Filling or Purging Auger Housing

Note: This function is disabled when the stove is running.

37

Page 38

Edison Installation and Operation Manual

To fill or purge the auger housing press the auger icon and select either “FEED AND

START” or “PURGE SCREW” in the displayed page.

Feed

screw

button

Feed screw

button when on

Feed screw

parameters

Button to stop

the feed screw

6.1.11.1 Feed and Start

Use this option when you start the stove for the first time of the season or after the hopper

ran out of pellets. The auger will turn then the stove will automatically start an ignition

cycle.

6.1.11.2 Purge Screw

Use this option to empty the auger at the end of the season. When selected, the auger will

turn for two minutes

6.1.12 Demo Mode

6.1.12.1 Demo Mode Operation

The demo mode has been developed primarily to enable sales people to show the stove's

functionalities in showrooms without starting it. Thus, when the "DEMO" mode is activated,

the stove will not turn on but all the components will operate as if the stove was on. To

disable the "DEMO" mode, you must press the word "DEMO MODE" followed by "OFF".

38

Page 39

Edison Installation and Operation Manual

7 Stove operation

7.1 First Startup

Before starting your stove, make sure that the burn pot, the baffles and the maintenance

access panels are properly installed. Make sure that the stove has been emptied of all

tools and accessories (see Section 2.3: Before Operating Your Stove). Also make sure

that the venting system is properly sealed, that all doors and hopper lid are closed. Make

sure that the hopper is full of pellets. Press the auger icon on the Main Status Page

and select “FEED AND START” in the displayed page.

WARNING: NEVER PRESS THE “FEED AND START” BUTTON IF YOU HAVE NOT

RUN OUT OF PELLETS OR IF IT IS NOT YOUR FIRST START-UP.

If fire doesn’t start within 20 to 25 minutes, a warning message

will appear. Refer to troubleshooting section for more details.

WARNING: NEVER USE A GRATE OR OTHER MEANS OF SUPPORTING THE FUEL.

ONLY USE THE APPROVED STOVE BURN POT.

7.2 Everyday Startup

Before starting the stove, make sure there is enough pellets in the hopper and that the

recommended maintenance schedule has been followed (see Section 8.1.1:

Recommended maintenance schedule) then press the “ON/OFF” icon on the main

status page.

7.3 Running Out of Pellets

If your stove runs out of pellets, the fire will slowly go out; the convection fan will run until

the heat sensor on the exhaust fan reads 115 °F. The cooling cycle will take a few minutes

before all other motors stops. When this temperature is reached, a warning message “NO

FUEL” will be displayed on the LCD touch screen.

To restart the stove, wait until all components stop running (usually 15 minutes after the

warning message has been displayed). Press the “RESET” button, refill the hopper, and

press the auger icon on the Main Status Page followed by “FEED AND START”

button in the displayed page.

7.4 Refueling

While the stove is running, you have up to 3 minutes to refill the hopper with pellets. Note

that opening the hopper lid will stop the auger from feeding pellets to the stove. If the

hopper lid is left open more than 3 minutes, the stove will stop and a warning message

39

Page 40

Edison Installation and Operation Manual

‘’HOPPER LID OPEN’’ will appear on the LCD touch screen. To restart the stove, close

the lid, press the “RESET” button, and then press the “ON/OFF” icon on the Main

Status Page.

NOTE: Keep hopper lid closed at all times except when refueling. Do not overfill the

hopper.

7.5 Shutting Down Procedure

To turn your stove off, press the “ON/OFF” icon on the Main Status Page. The

cooling cycle will take a few minutes. The exhaust blower and the burn pot auger will

continue working for a few minutes while the stove is cooling down. Note it is possible to

increase the exhaust blower’s stopping time (see Section 9.3.13: Smoke smell).

IMPORTANT: DO NOT DISCONNECT THE POWER CORD TO TURN OFF THE STOVE.

7.6 Signs of an Overheating Stove

Under normal conditions, the flame should have a bright yellow color and be very active,

but stable. If you see the flame getting lazy, very high and orange, it may be a sign that

there is something wrong. Usually, overheating issues are caused by too much restriction

in the venting system, a blocked heat exchanger, a lack of combustion air or a lack of

maintenance.

If this happens, your stove will become very hot. If the stove becomes too hot, “UNIT

OVERHEAT” message will appear on the LCD touch screen. Before starting the stove

again make sure the recommended maintenance has been done properly. Press the