DRIVEN UCT4060 User Manual

UCT4060 Chain Cutting & Press-Fit Tool Instructions

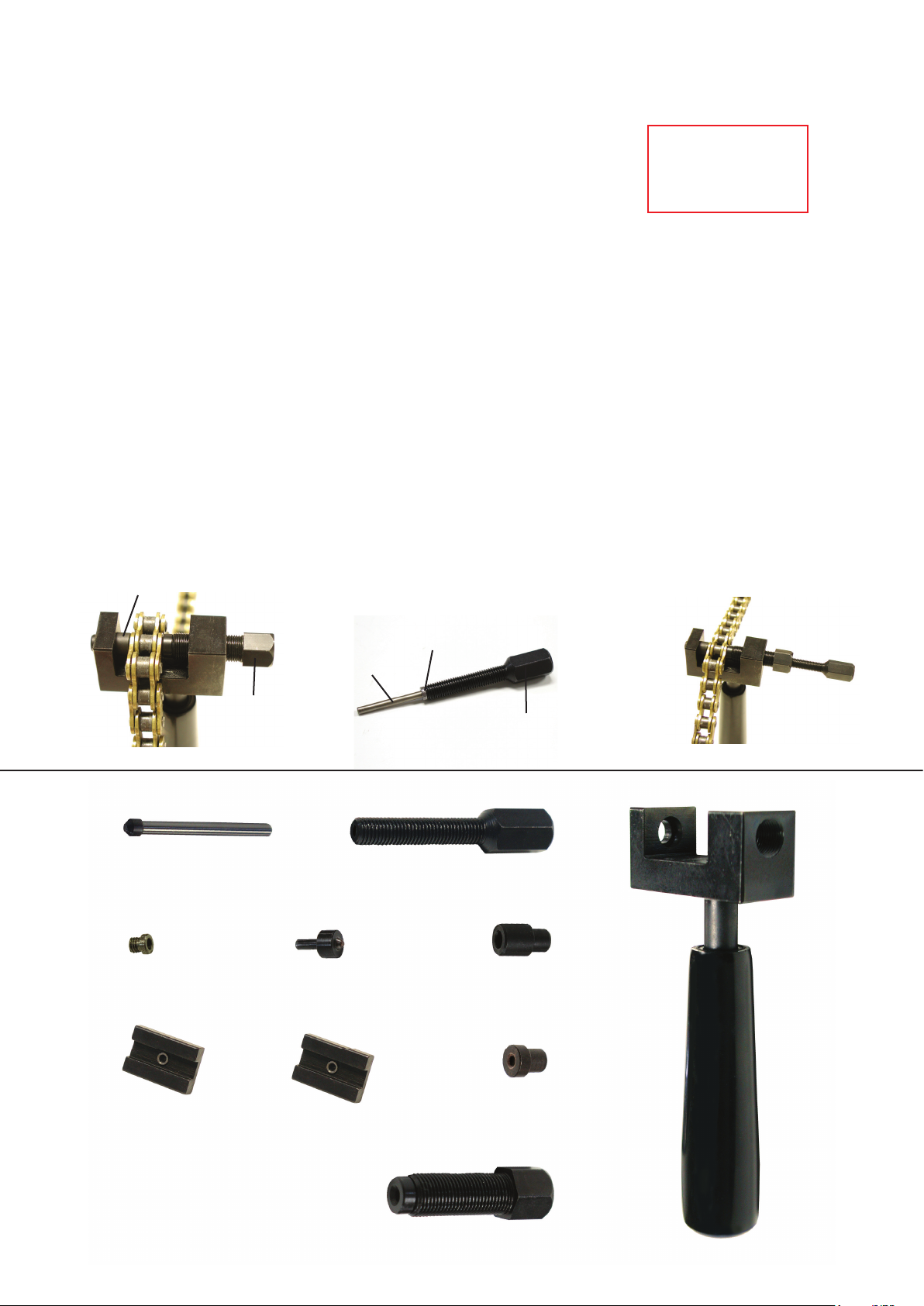

To break a chain:

1. Thread the large pressure bolt PB4060 into the tool body TB4060.

2. Insert the chain cutting tail piece TP4050 into the opposite side of the tool body.

3. Position the chain to be cut between the hole in the end of the large pressure bolt and the hole in the tail piece

(Figure 1A).

4. Using a 17mm wrench, snug up the large pressure bolt so that the chain pin is held firmly in place.

5. Slide the cutting pin holder CP4050H onto the cutting pin CP4050.

6. Thread the cutting pin holder into the small pressure bolt PB4050 (Figure 1B).

7. Thread the small pressure bolt into the large pressure bolt (Figure 1C).

8. Using a 14mm wrench, turn the small pressure bolt until the chain pin is pushed completely through the side plates.

CAUTION: The first few turns will be very hard as the quad stake riveted edges on the chain pin are pushed through

the side plate. If it seems exceptionally hard, check the alignment of the chain pin with the hole in the end of the

large pressure bolt.

NOTE: If you are cutting a new chain to length, be sure to remove the chain pin that will leave you with an inner

side plate as the end of the chain. A connecting link can only be installed onto inner side plates.

CP4050

Cutting Pin

PB4050

Small Pressure Bolt

CP4050H

Cutting Pin Holder

FP5060

Rivet Flare Pin

TP4050

Tail Piece for Chain Cutting

PH4060C

Clip Link Plate Holder

PH5060R

Rivet Link Plate Holder

PB4060

Large Pressure Bolt

TP4060

Tail Piece for Press Fitting

BH4060

Black Handle

TB4060

Tool Body

TOOL COMPONENTS

TP4050

WARNING! DO NOT USE TOOL TO CUT 630 AND 632 TYPE CHAIN!

1A 1B

1C

PB4060

PB4050

CP4050

CP4050H

DO NOT CUT

MASTER LINK !

Important! RK recommends using rivet type connecting links whenever possible for the most

secure connection.

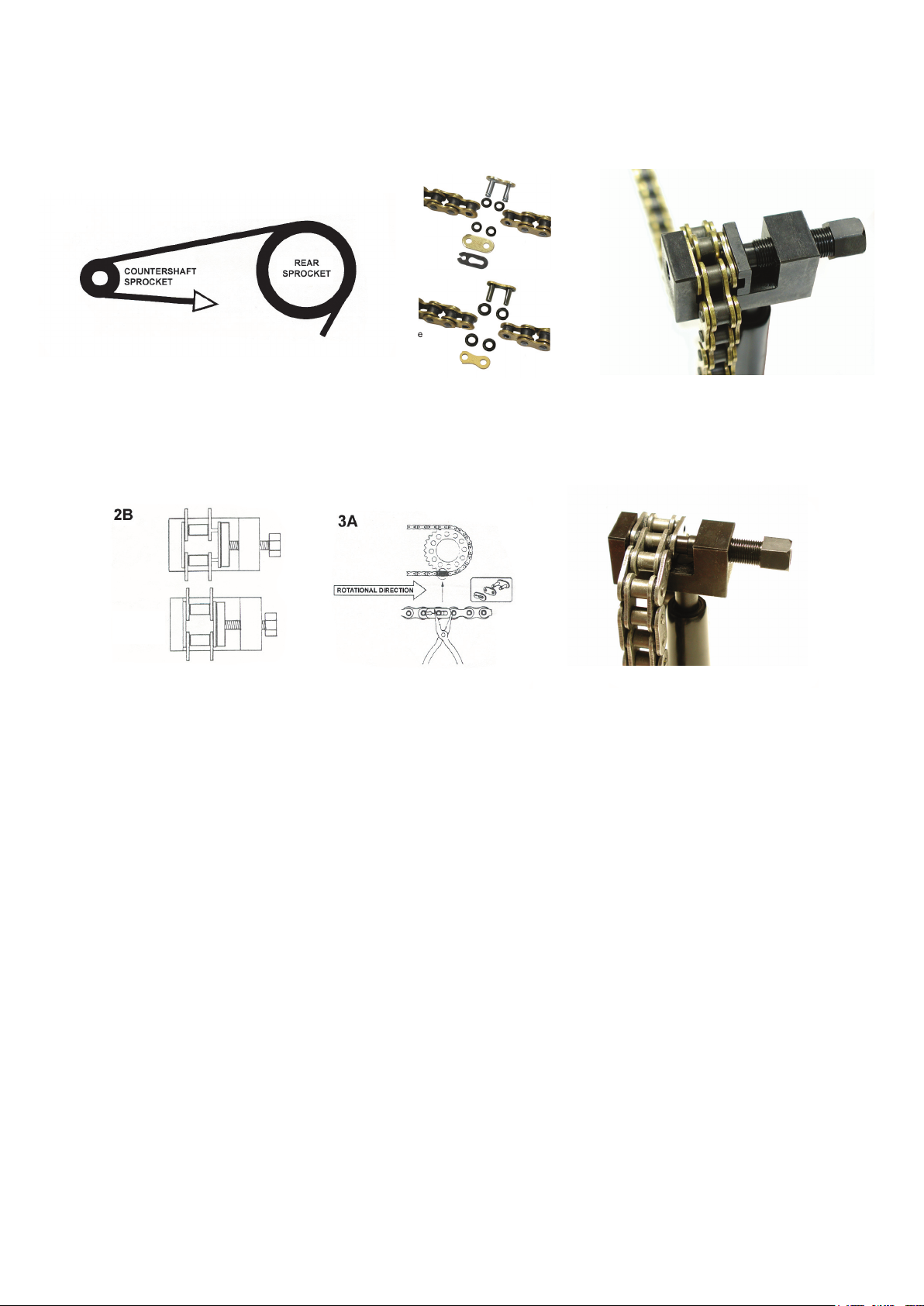

Installation/Press-fitting of Sideplate:

1. Review the drawings for reference. Route chain over and around counter shaft sprocket (Figure 1A).

2. If applicable, put 1 O-ring over each connecting link pin. Slide the pins through the two ends of the chain from the back to connect the chain

near the bottom of the rear sprocket (Figure 1B).

3. If applicable, put the other two O-rings over each pin and spread the excess grease over all the O-rings.

4. Insert the correct plate holder for the chain (see Plate Holder Selection below) into the large pressure bolt hole and position the connecting

link side plate in the plate holder (Figure 2A).

5. Place the tool/plate holder/sideplate assembly under the connecting link and align the pins with the side plate holes (Figure 2B).

6. Turn the pressure bolt by hand making sure to keep the pins and side plate holes aligned until snug (Figure 2B).

7. Use a 17mm socket and ratchet wrench to tighten the bolt. The side plate should press-fit firmly but without difficulty.

8. Tighten bolt to correct depth allowed by plate holder channel (do not over-torque). Loosen bolt and remove tool.

Installing The Clip

1. Using thin-nose pliers, snap clip into pin grooves with closed end of clip facing rotational direction of chain (Figure 3A).

2. Warning!!! Make sure the clip is properly tension-seated in the groove of the pins. If the clip is loose, walk the side plate up the

pins with pliers until it is snug against the clip. NEVER REUSE A CONNECTING LINK.

1A

Clip Type

2A

Rivet Type

Ready to press

Plate completely

pressed

3B

RK Pin Hole Riveting:

First, follow procedures 1-8 above.

1. Remove plate holder and insert flare pin FP5060 into the large pressure bolt of the tool and insert tail piece TP4060 into hole in tool wall

opposite the pressure bolt.

2. Place the tool under the connecting link. Align the flare pin with the hole in the end of the pin. Make sure the other end of the link pin is seated

in the tail piece (Figure 3B). Tighten the bolt by hand so that the flare pin is snug against the link pin hole.

3. Use a 17mm socket and ratchet wrench to tighten the bolt until the pin hole is flared out sufficiently to keep the side plate from coming off.

Repeat this procedure for the second pin.

4. Warning!!! Tighten the bolt only until firm resistance is felt, then loosen the bolt and inspect the pin for complete, even flaring. Do

not over-tighten the bolt – you may bend or damage the link pins or bind the link entirely. A pronounced, even flare will securely

connect the chain links together.

Plate Holder Selection:

PH4060C – To press-fit Clip sideplates for 520/525/530/532/630/632 O-ring.

PH5060R – To press-fit Rivet sideplates for 520/525/530/532/630/632 O-ring.

1B

Loading...

Loading...