Drivecon XT Series Service Manual

Service Manual

Pro2V070

XT SERIES

Service Manual

820 Lakeside Drive – Gurnee, IL 60031

Phone: 1-800- 374-8266

Fax: (847) 855-9650

www.drivecon.com

XT Series rev 5.5B Pro2V070

?

Page 1

Service Manual

Pro2V070

CAUTION

1. Before starting, read the instructions carefully.

2. Verify all of the connections are in accordance to the drawings.

3. Verify the motor supply is connected correctly; faulty connection will

destroy the inverter.

4. Check the device cover is properly installed.

5. High voltages are present in this device. Switch the power off and after

the display turns off, wait 5 minutes before opening the cover.

6. Insulation resistance test with a megger requires special precautions.

7. Do not make any measurements inside the device when it is connected

to the main supply.

8. Do not touch the components on the circuit boards. Static voltage

discharge may cause damage or destroy the IC-circuits.

9. Check all ventilation holes are clear and uncovered.

10. Check that hot air coming from the brake resistors does not cause any

danger.

11. Do not make any inspections unless the supply has been disconnected

by the main switch.

12. It is forbidden to use radiophones or portable phones near this device

with the doors open.

13. All the doors and covers must be closed during crane operation.

?

This manual is valid for XT Series revisions 5.5. The release number of this document is XT

SERIESCSM55BEN. The parameter numbers are based on the software version Pro2V070.

?

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

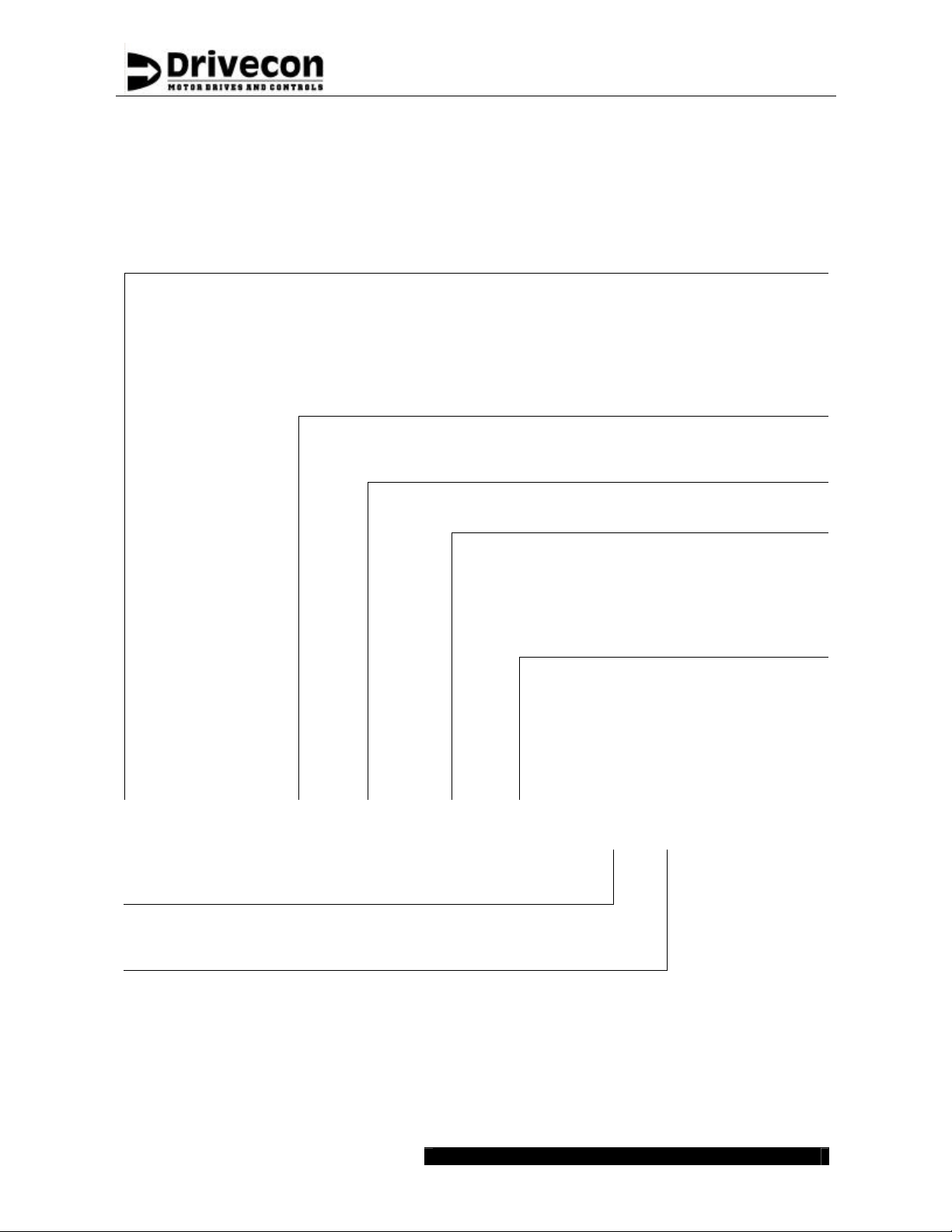

CONTENTS

1 GENERAL................................ ................................ .......................................................4

1.1 Technical data ................................ ................................ .......................................4

1.2 Type mark coding................................ ................................ ..................................5

1.3 Basic description ................................................................ ................................ ...6

1.4 Main components ................................................................ ................................ ..7

1.5 Functional description................................................................ ............................ 8

1.6 Control methods ................................ ................................ ................................ .... 9

1.7 Mechanical brake control ................................ ................................ .....................12

1.8 Motor control modes ................................ ................................ ............................13

1.9 EMC ................................................................ ................................ ...................14

1.9.1 Fulfilled EMC-standards ................................ ................................ ............14

2 INSTALLATION ................................ ................................ .............................................16

2.1 Cooling................................ ................................................................ ...............16

2.2 Power cabling ................................ ................................ ......................................16

2.3 Control wiring................................................................ ................................ ......19

2.4 EMC compatible grounding ................................ ................................ ...................19

3 START -UP PROCEDURE................................................................ ...............................20

3.1 Visual checks ................................ ................................ ......................................20

3.2 Checks before the first test run................................ ................................ .............20

3.3 Test run without load ................................................................ ...........................21

3.4 Test run with load................................ ................................ ................................21

3.5 After the test run ................................................................ ................................ .21

4 PARAMETER ADJUSTMENTS ................................ ................................ ........................22

4.1 Control keypad operation ................................................................ .....................22

4.1.1 Navigation on the control keypad ...............................................................23

4.1.2 Value line editing................................ ................................ ......................23

4.1.3 Passwords................................................................ ................................24

4.1.4 Special button functions ................................................................ ............24

4.1.5 Monitoring................................ ................................ ................................25

4.2 Input selections ................................................................................................ ...26

4.3 Speed supervision settings................................................................ ...................27

4.3.1 Functional test run for SSU................................ ................................ ........29

4.4 Open Loop motor parameter adjustments ..............................................................30

4.4.1 Open Loop speed control for hoisting ................................ .........................30

4.4.2 Open Loop rated motor parameters for traveling .........................................30

4.4.3 Open Loop autotuning for traveling, frequency control.................................32

4.4.4 Open Loop manual tuning for travelling ......................................................32

4.4.5 Open Loop manual tuning for traveling, frequency control ............................34

4.4.6 Open Loop manual tuning for traveling, current control ................................34

4.5 Closed Loop motor parameter adjustments................................ ............................36

4.5.1 Closed Loop rated motor parameters..........................................................36

4.5.2 Closed Loop autotuning, speed control ................................ .......................37

4.5.3 Closed Loop manual tuning for hoisting, speed control ................................ 41

5 PARAMETER DESCRIPTIONS ................................ ................................ .......................44

Page 2

Service Manual

Pro2V070

6 COMPONENTS ................................................................ ................................ .............58

6.1 Inverter ................................................................................................ ...............58

6.1.1 Power supply unit (PSU) ................................ ................................ ............60

6.1.2 Control unit (CSU) ................................................................ ....................60

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

6.1.3 Basic I/O board (Slot A) ................................................................ ............61

6.1.4 Relay / Thermistor board (Slot B)...............................................................62

6.1.5 SSU Speed Supervision board (Slot C) .......................................................62

6.1.6 I/O Extension board (Slot D)................................................................ ......63

6.1.7 Relay Extension board (Slot E) ................................ ................................ ..63

6.1.8 Profibus board (Slot E)................................................................ ..............65

6.2 Reference potentiometer......................................................................................67

6.3 Speed sensors ................................ ................................ .....................................69

6.3.1 Encoder (if applicable) ................................................................ ..............69

6.3.2 Sensor bearing (if applicable) ....................................................................71

6.3.3 Proximity switch (if applicable) ................................................................ ..72

6.3.4 Buffer amplifier KAE234 (if applicable) .......................................................73

6.4 Brake controllers ................................ ................................ ................................ .75

6.4.1 REC12-690+DC ................................ ................................ ........................75

6.4.2 ESD141................................ ................................ ................................ ....75

7 TROUBLESHOOTING................................................................ ................................ ....76

7.1 Field repair actions................................................................ ..............................76

7.2 Inverter fault codes ................................ ................................ ..............................77

7.2.1 Fault time data record ................................................................ ...............83

7.2.2 Fault Counter ................................ ................................ ...........................84

7.3 Inverter Alarm codes................................ ................................ ............................85

8 SERVICE ................................ ................................ ......................................................86

8.1 DC-bus electrolytic capacitors ................................................................ ..............86

8.1.1 Re-forming after a long storage period .......................................................86

9 GENERAL DRAWINGS ................................ ................................ ................................ ..87

Page 3

Service Manual

Pro2V070

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 4

Service Manual

Pro2V070

1 GENERAL

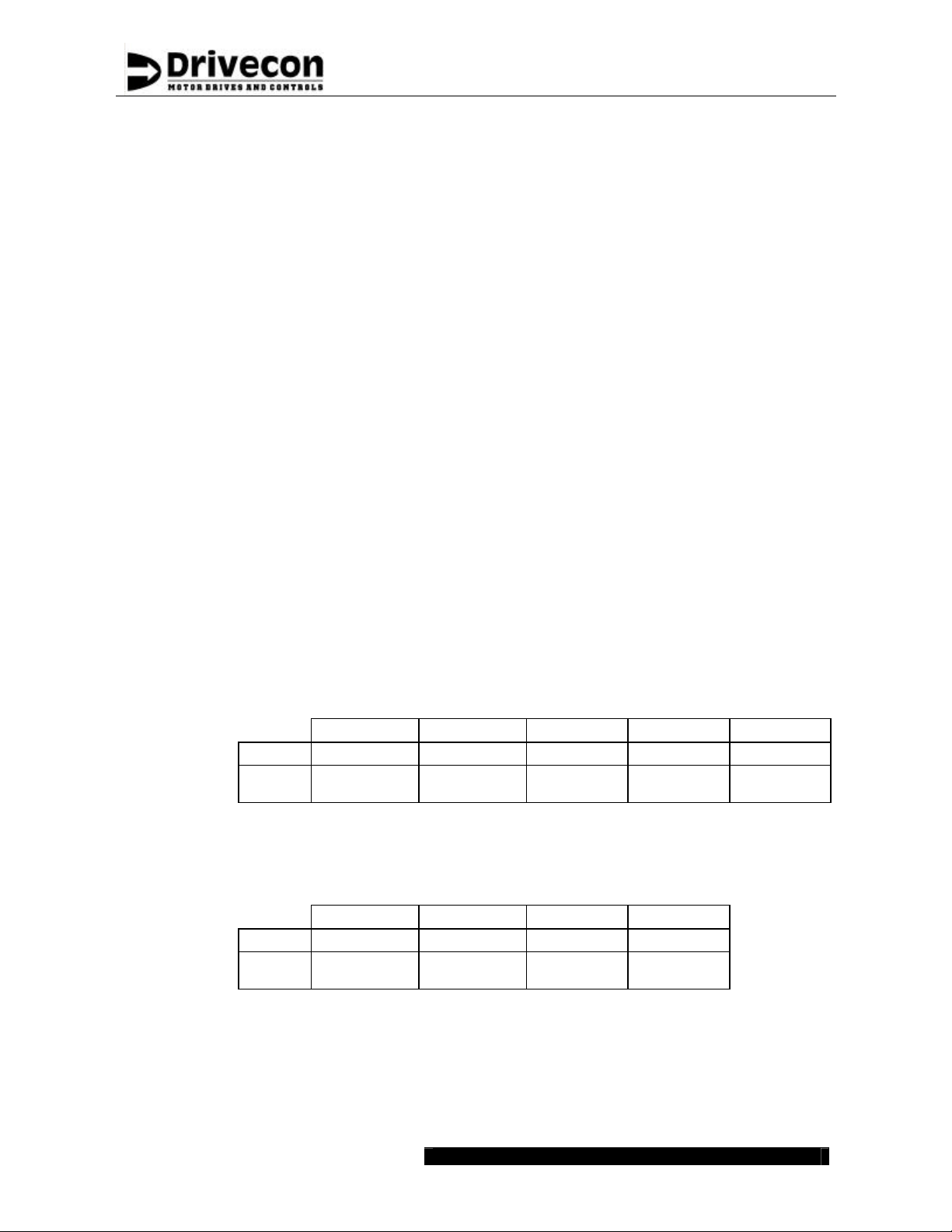

1.1 Technical data

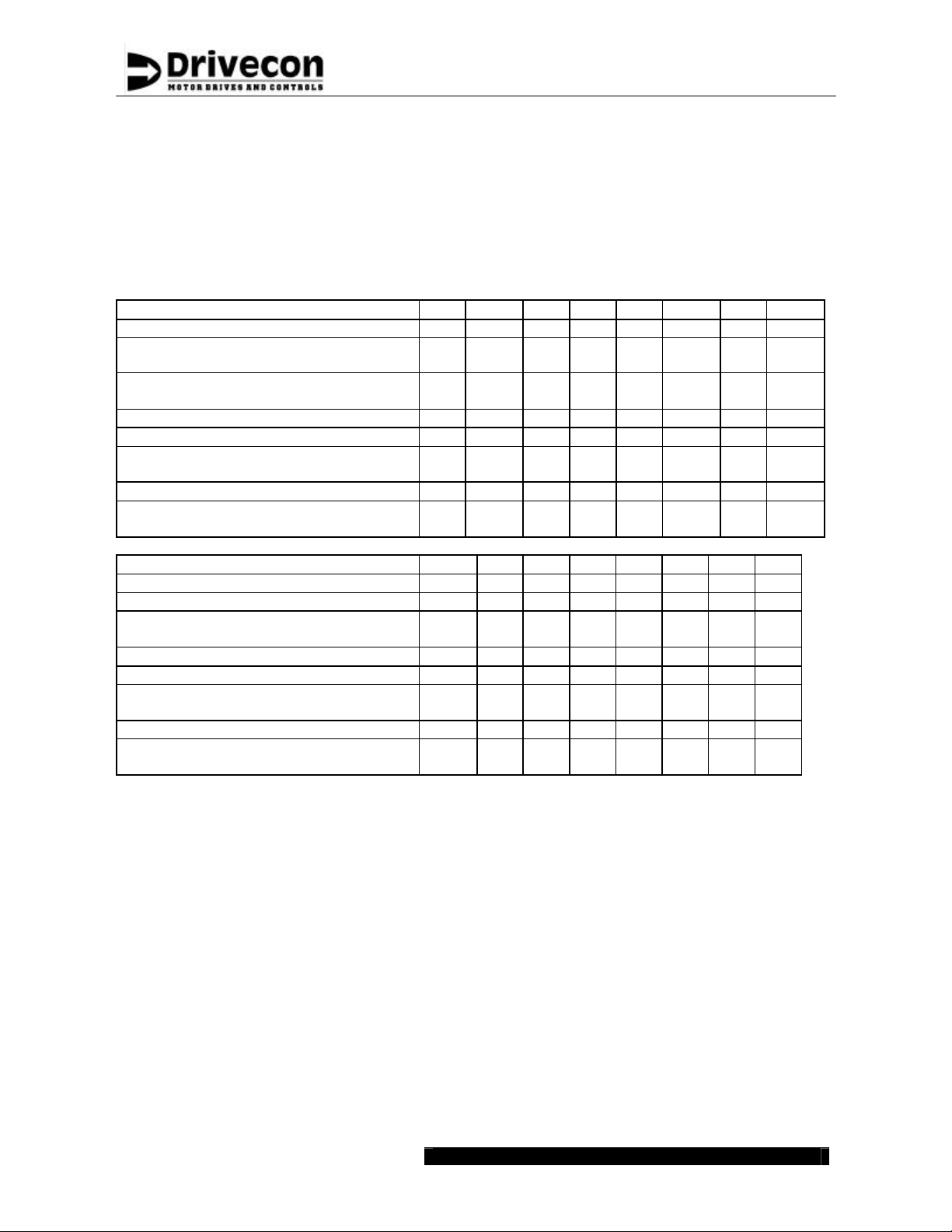

Power class 4004 4005 4009 4012 4016 4022 4031 4038 4045 4061 4072 4087 4105 4140F 4168 4210

Horsepower (Hp) at 460V 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150

Output current In (A) 4.3 5.6 9 12 16 23 31 38 46 61 72 87 105 140 170 205

Max. current 1min (A) 6.5 8.4 13.5 18 24 35 47 57 69 92 108 131 158 210 255 308

Max. current ,Is,2 sec (A) 8.6 10.8 18 24 32 46 62 76 92 122 144 174 210 280 336 410

Overloadability 1.5 x In, 1min/10min

Max. output voltage Equal to supply voltage

Supply

Supply voltage 380-500VAC

Allowable voltage fluctuation +/- 10%

Nominal supply frequency 50/60Hz +/- 5%

Signal input levels

Digital controls S1, S2, DIA3, DIA4, DIA5, DID1, DID2, DID3, DID4, DID5: 42 … 240VAC; 15mA

Analog references

Encoder feedback EA+/- and EB+/-; 0/24V; 3k? load; floating differential inputs

Control features

Control method Open loop or closed loop vector control

Frequency control range 0 ... 250Hz

Frequency command Potentiometer, motor potentiometer, 2 -4-step controller or 0 ... 10V analog signal

Limit switch functions Slowdown and stop limit inputs for both directions

Speed control range Open loop vector control

sN ... 100% (sN= motor nominal slip)

Closed loop vector control

0 ... 100%

Speed accuracy Open loop vector control

Closed loop vector control

0.01% of nominal speed

Extended speed range 100 ... 200%

Braking torque 150%

Protections

Stall prevention During acceleration and constant speed

Motor overload protection Thermistor based temperature measurement

Overload protection Fault is detected if the current momentarily exceeds 280% of rated current

Undervoltage / blown fuse Fault is detected if DC voltage drops below 333V

Overvoltage protection Fault is detected if DC voltage exceeds 911V

Momentary power loss Immediate fault stop

Inverter overtemperature Temperature sensor on the heat sink

Mechanical brake Circuit breaker

Braking transistor Electronic supervision for the braking chopper and for the braking resistor

Brake slip protection Programmable relay output

Ground fault Provided by electronic circuitry

Overspeed / stall,

Speed difference supervision Independent measurement using pulse wheel or encoder

Ambient conditions

Ambient temperature

Storage temperature

Humidity <95%RH (no condensation)

Altitude Maximum 1000m at In. Above 1000m: In reduces 1% per each 100m.

Above 3000m: consult factory.

Vibration Operation: maximum displacement amplitude 3mm at 2-9Hz.

Maximum acceleration amplitude 0.5g (5m/s²) at 9-200Hz

Conforms to LV and EMC directives.

1% of nominal speed at speed range 10 ... 100%

1/3 of motor nominal slip at speed below 10%

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

AIN1: 0 … +10V and AIN2: -10 … +10V; 200k? load? accuracy 0.5%

-10?C ... +55?C (14?F ... 131?F) for ED?60%

-40?C ... +60?C (-31?F ... 140?F) dry. Power on >1h in a year.

Page 5

Service Manual

Pro2V070

Type mark coding

XT SERIES can be summarized as "crane motor control systems, which controls the speed by

changing the frequency of supply voltage of a squirrel cage motor". A stepless speed adjustment

can be achieved by this method.

Type marking is shown below.

000 XTx

Device name

000- Base Drive (430,440)

000-Pre-engineered Panel (488,489,490,491,492,493,494,496,497,498,499)

x- d (Base drive vector), e (base drive vector with SSU board), s (open loop

vector panel), v (closed loop vector panel)

XT Series

Supply voltage

4

4 380 - 500VAC, 50/60Hz

6 525 - 690VAC, 50/60Hz

009

Rated Amps

009=9A, 168=168A

TC

Panel Motion and Duty Class

XX=Base Drive only

TC=Traverse class C

TD=Traverse class D

HC=Hoist class C

HD=Hoist class D…etc

0 Option Control PCB’s

0 Standard (A,B,D)

1 Standard with SSU (A,B,C,D)

2 Profibus (A,B,D,E)

3 Profibus with SSU (A,B,C,D,E)

8 Relay (A,B,D,E)

9 Relay with SSU (A,B,C,D,E)

000 XTx 4 009 TC 0 55 0

Software Revision code

The latest revision may differ

Special

0 None

L Varnished boards

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

0

55

Page 6

Service Manual

Pro2V070

1.2 Basic description

XT SERIES have many advantages and offer many new features, when compared to other

inverter-based systems, which might be used in crane applications.

Inverter

Crane user interface

Brake control

Electrical braking

Control methods

Limit switch

functions

Speed supervisio n

Protections

The inverter in XT SERIES is a crane inverter. The specific crane

features for the inverter hardware and the special software are

achieved by combining the experience and know-how of crane

applications with the latest technology. The inverter uses vector

calculation for several different motor control modes.

All XT SERIES have exactly the same interface with pre-designed

locations for all typical crane functions. The main part of this interface

is carried out by a terminal strip, which has separated sections for

signals with main, control and electronics voltage levels.

XT SERIES include the brake contactor for disk brakes. XT SERIES

also includes it’s own DC-rectifier.

XT SERIES include a braking transistor, which is dimensioned for every

crane application. For resistor braking XT SERIES are equipped with

external resistor.

XT SERIES can be controlled by the electronic potentiometer control

with 2-step pushbuttons, the potentiometer control with analog joysticktype control, the automation control with PLC and radio controls and by

the multistep control with 2-4-step controllers. All these control methods

are available with every XT SERIES.

XT SERIES have built-in slowdown and stop limit switch functions for

both running directions.

XT SERIES include a speed supervision unit SSU, which is separate

from the inverter and not dependent on software. This safety circuitry is

used to monitor the speed of the motor. In case of speed difference,

overspeed or stall, the speed supervision unit stops the motion

immediately. It can also be equipped with SSU.

XT SERIES include a motor thermal protection, which is based on

motor temperature measurement by thermistors placed in the motor

windings. A great number of other protections included in every XT

SERIES are shown in the technical data.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

1.3 Main components

The main components are:

Page 7

Service Manual

Pro2V070

A1 Inverter 002-132F

F7 Input supply circuit breaker 007-132F

K7 Brake contactor 002-132F

F71 Circuit breaker for the brake contactor 055-132F

XT SERIES

The most important external components are:

R1 External braking resistor unit

M1 Motor

Y1 Mechanical brake

B5 Speed sensor (P-models)

B6 Encoder (N-models)

Thermal sensor for motor protection

Overload protection device (e.g. Premium)

Control devices (switches, pushbuttons, potentiometers etc.)

Limit switches

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

1.4 Functional description

See circuit diagrams for following descriptions of operation.

Operation when

power is switched on

Normal operation

Other features

Limit switches S11, S12, S21 and S22 are assumed to be closed, as

??

well as the emergency stop button ES.

The control voltage is supplied to A1 control inputs (external

??

42V…230V control voltage). The main voltage is connected to

inverter power supply and inverter turns on. If the control voltage is

connected to RDY -signal and the fault circuit is OK, inverter is ready

to operate in about 1-2 seconds.

?? If either one of the direction signals S1 or S2 is on, the display

shows F6 and running can begin only after the direction signals have

been off for a while.

–

For the description of the speed reference setting see chapter 1.6

"Control methods".

–

Running starts when switch S1 (S2) closes. Closing the contact

ROB2 on A1 energizes K7, which opens the brake. XT SERIES

accelerate according to the acceleration ramp setting to the selected

speed.

–

When the switch S1 (S2) opens, XT SERIES stop according to the

deceleration ramp setting and then the brake closes.

–

R1 dissipate the regenerated energy during deceleration and

lowering periods. The power supply to R1 is controlled by A1. If the

braking resistor fan(s) are included in external resistor unit, they

start to operate when power is supplied to the braking resistors. The

cooling continues about 4-5 minutes after electrical braking to

ensure that the temperature of the resistors drops below 150? C

(302?F).

–

Slowdown limit switches S11 and S21 provide position dependent

frequency limiting.

–

Any reason, which opens the contact RDY, stops the operation of

inverter A1.

–

In case of overload, motor overheating etc. the hoisting can be

disabled by cutting the direction signal.

–

Thermistor relay function, which can be used when needed.

–

When the stop limit switch S12 or S22 opens, K7 de-energizes and

the mechanical brake stops the motion.

–

Independent speed supervision unit, SSU.

–

The speed measurement and supervision can be done either with

encoder, bearing encoder or proximity switch. The measured signals

are square wave pulses. The frequency of the pulses is proportional

to the speed of the motor and if the frequency is too high, ove rspeed

is detected. If there are no pulses a stall situation is detected. If the

actual speed differs too much from the supply frequency of the

motor, the speed difference supervision stops the motion.

–

Proximity switch buffer amplifier amplifies the sensor pulses and

filters out disturbances. The amplifier is located close to the sensor.

–

The extended speed range ESR can be used, if the signal FWE (field

weakening enabled) is on. Then it is possible to run up to twice the

nominal speed depending on the a pplication.

Page 8

Service Manual

Pro2V070

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 9

Service Manual

Pro2V070

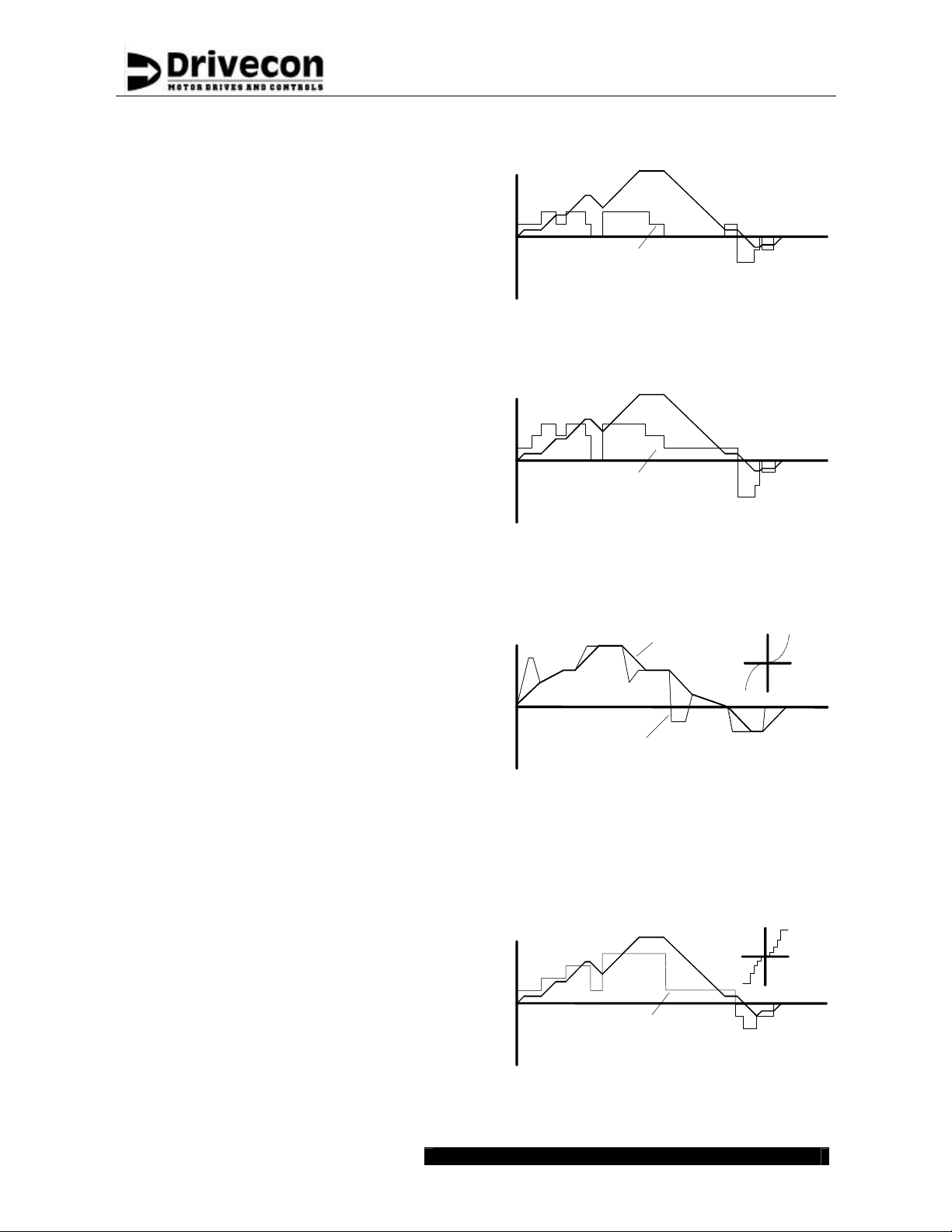

1.5 Control methods

There are four different control methods (command modes) available. All of them are available

without any changes in the hardware or software. Any single XT SERIES can be controlled either

by a pushbutton controller in EP -mode, by a joystick type controller with a potentiometer located in

the cabin in PO -mode or by a process computer in AU -mode. The only external device needed is a

switch to select the desired control method.

Command mode

selection

PO- and AU -modes

DIA3

DIA4

EP-mode

DIA3

DIA4

EP Electronic motor potentiometer function.

?? Stepless control using a 2-step pushbutton controller.

?? EP3 stepless control using a 3-step controller.

PO Potentiometer control using a joystick type controller.

?? Requires a single 15V power supply (included in XT SERIES).

?? Any ad ditional amplifier is not needed.

AU Automation control

For any control device with an output in the range of 0-10V.

??

?? E.g. radio-controls, process computers.

MS Multistep control (2-4 steps as standard).

Requires programmable digital inputs for speed reference steps

??

(included in XT SERIES).

The command mode (EP, PO or AU) is selected by the switches CMS

and AP. Normally the selection can be done only when the motion is

stopped (not when running), but in special applications changing the

mode is allowed during run by changing parameter values.

PO - and AU-modes select either of the analog inputs for speed

reference. Both analog inputs can be adjusted similar from 0V to 10V

(radio or PLC-reference) or from 10V to 6.7V (potentiometer). As

default, Ain1 is used in PO-mode and Ain2 is used in AU -mode.

Ain1 / PO Ain1 / PO Ain2 / AU Ain2 / AU Ain1 / PO

AP not used AP not used

CMS not

used

EP-mode selects the AP-button for speed reference. EP step 1 is

command for minimum speed or hold speed. EP step 2 is the

acceleration command.

EP step 1 EP step 2 EP step 1 EP step 2

AP = 0 AP = 1 AP = 0 AP = 1

CMS not

used

CMS = 0 CMS = 1 CMS = 1 CMS = 1

CMS not

used

AP not used AP = 0 AP = 1

CMS = 0 CMS = 0

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Synchronization

If required, two or more XT SERIES can be run in precise

synchronization. A separate synchronization controller is needed for

this. The same speed reference (in EP- or PO-mode) is connected to

every XT SERIES and the correction signal for synchronization is

connected to all XT SERIES to input AIN2+. The speed reference signal

of each XT SERIES can also be modified separately by a PLC.

Synchronization is activated by parameter selection.

Page 10

Service Manual

Pro2V070

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Description of the control methods

EP-control requires two 2-step pushbuttons, one

for each direction. The operation is as follows:

?? the rest position means standstill (0-position)

?? during run the rest position means deceleration

step one (switch S1 or S2) means hold speed

??

when starting, step one means acceleration up to

??

the minimum speed

step two (switch AP) means acceleration (up to

??

the maximum speed if desired)

?? at the maximum speed step two means hold

speed, because the maximum speed cannot be

exceeded

EP3-control requires a 3-step controller. The

operation is as follows:

?? the rest position means standstill (0-position)

?? step one (switch S1 or S2) is the minimum speed

command

?? step two (EP hold command) means hold speed

?? step three (switch AP) means acceleration (up to

the maximum speed if desired)

?? when releasing the controller, step one means

deceleration down to the minimum speed

PO-control requires a controller with

potentiometer. The operation is as follows:

when the controller is at the rest position, the

??

potentiometer is at the middle position causing

zero speed

run commands are controlled separately by

??

closing the direction switches (S1 and S2)

?? when the operator turns the controller to any

direction, the speed increases

?? the same turning angle of the controller causes a

smaller change in speed, the closer the speed is

to the minimum speed

AU -control requires an analog reference from radio

or PLC. The operation is as follows:

?? the speed linearly follows the input signal. 0V

means zero speed and the higher the voltage,

the higher the speed

?? run commands are controlled separately by

closing the direction switches (S1 and S2)

MS-control requires a 2-4-step controller. The

operation is as follows:

each step has its own frequency

??

the frequencies are freely selectable

??

?? when controller is set to a certain step, the speed

changes to equal value

Page 11

up / fwd

down / rev

up / fwd

down / rev

up / fwd

down / rev

up / fwd

Service Manual

Pro2V070

Pushbutton position

speed

pushbutton

position

EP-mode

speed

pushbutton

position

EP3-mode

speed

potentiometer reference (controller position)

or auxiliary reference

PO - and AU -modes

controller

position

rest = deceleration

step 1 = hold speed

step 2 = acceleration

Pushbutton position

rest = stop

step 1 = minimum speed

step 2 = hold speed

step 3 = acceleration

speed

controller

position

speed

speed

controller

position

time

time

time

time

down / rev

MS -mode

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 12

Service Manual

Pro2V070

1.6 Mechanical brake control

The brake is controlled so that during starting, the motor first generates torque and after that the

brake is opened. The same applies for stopping; while the brake is being closed, the motor still

generates torque. During a direction change, the brake is kept open all the time. XT SERIES

decelerate the motor to a stop according to the set deceleration time when the run command is

switched off, so the brake is used only as a holding brake. This way brake wear is minimized. Only

if a failure occurs or the emergency stop button is pushed, the brake closes immediately stopping

the motor and the load.

The motors of CXT -hoists an d SM-trolleys have an electromechanical disk brake. The disk brake is

opened and kept open during run by DC-voltage. When there is no voltage present the brake is

closed and also kept closed by spring force.

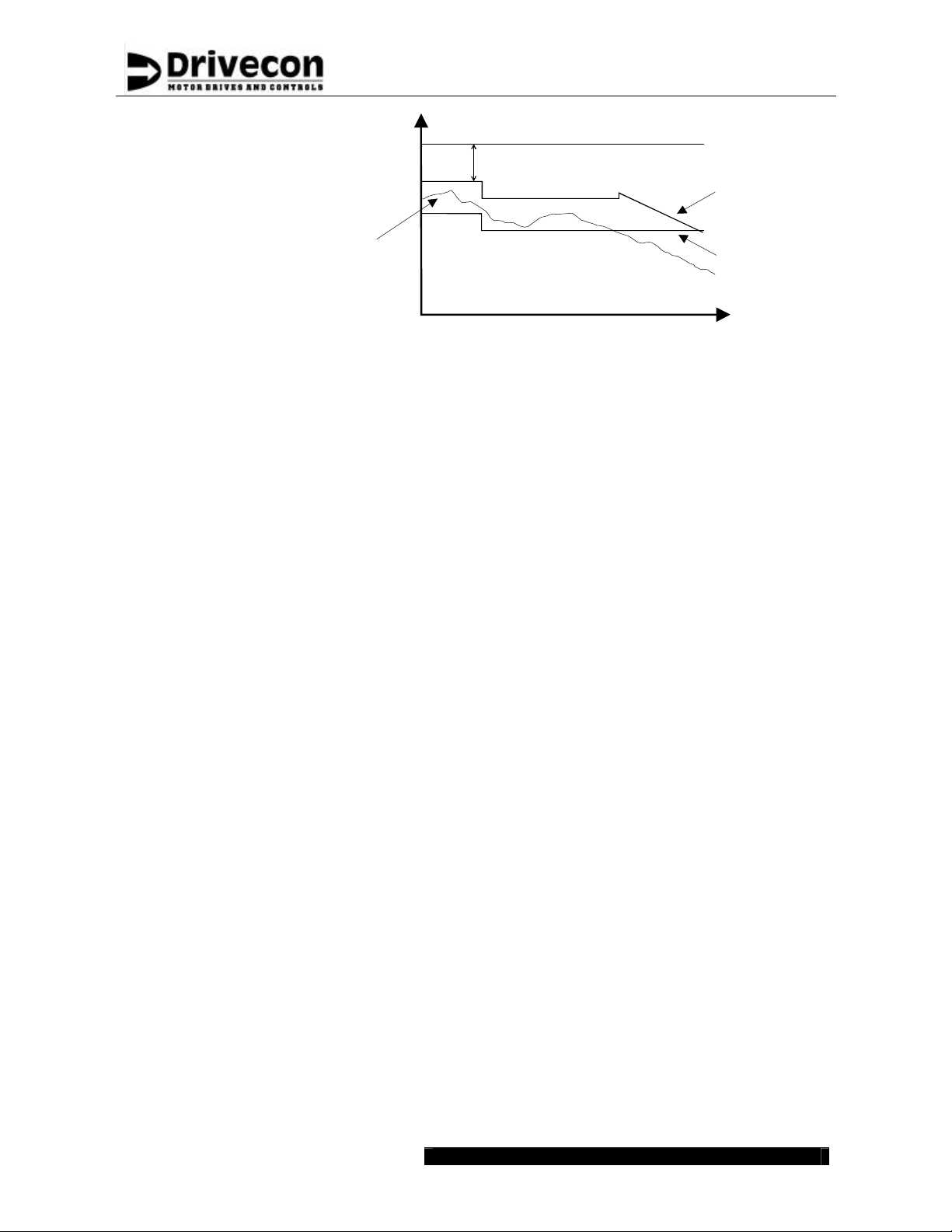

2-phase AC

3-phase AC

XT SERIES models may include an AC-supply from two phases for the

brake control. XT SERIES controls this line and it is protected by an

adjustable circuit breaker. An external rectifier may be included to

rectify the AC -voltage to DC-voltage for DC brake coils.

XT SERIES models may include a 3-phase AC-supply for the brake

control. XT SERIES control this line and it is protected by an adjustable

circuit breaker.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 13

Service Manual

Pro2V070

1.7 Motor control modes

Open loop

XT SERIES have a built-in motor model, which calculates - one thousand times in a second - the

values of the real motor. The input data needed for the calculation is the instantaneous value of

the motor voltage from the ASIC and the measured motor current. Motor magnetic flux and shaft

torque are calculated in the motor model based on the nameplate data of the motor.

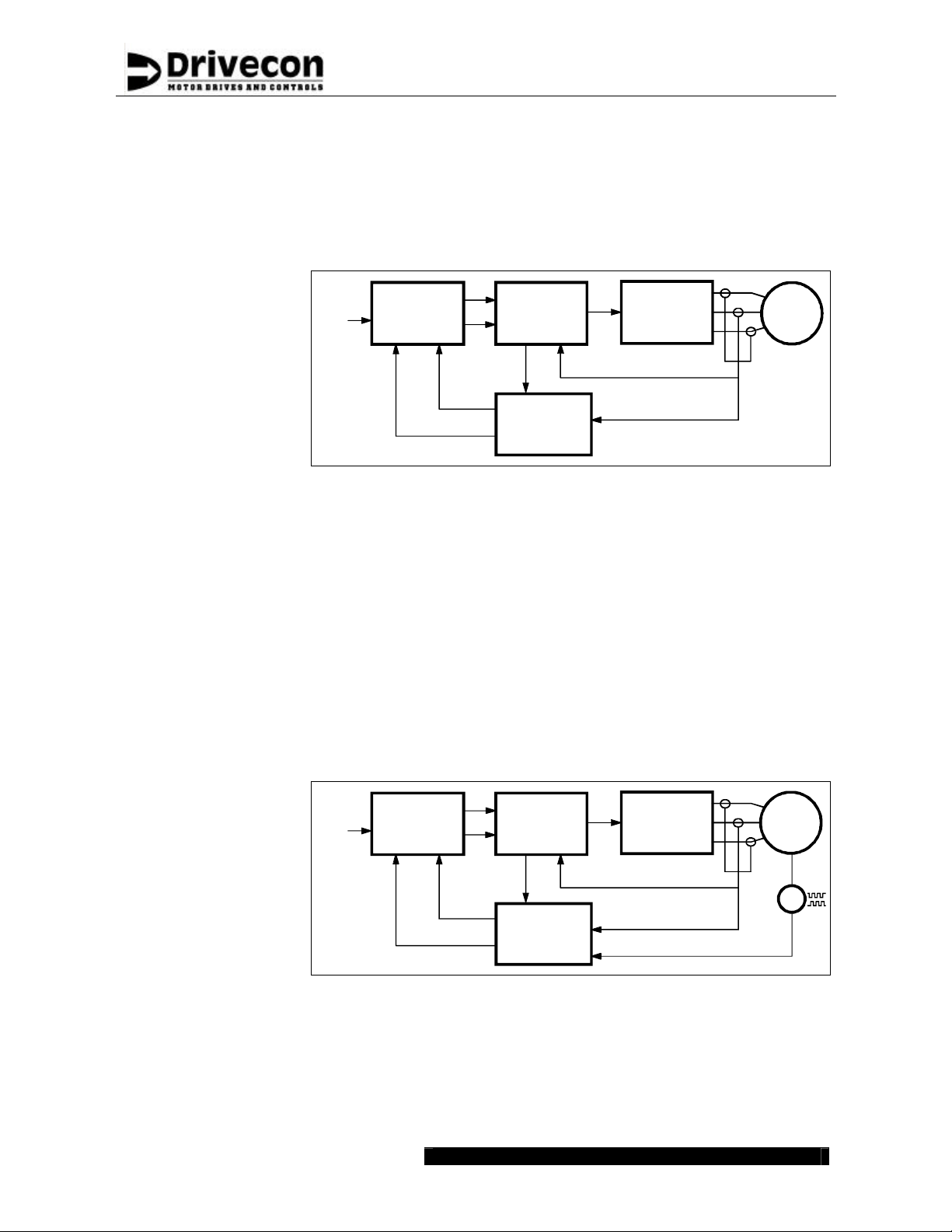

Open loop

Vector control

Speed

ref

Speed

Control

ref

InverterAsic

M

~

3

Torque

Vector

calculation

Frequency control

Open loop (mode 0)

Current control

Open Loop (mode 1)

Flux

In frequency control mode of Open Loop, the motor frequency follows the

frequency reference signal. The actual rotating speed depends on load and is

equal to the slip below or above the output frequency. Even with frequency

control, the vector calculation is used to keep the magnetization at a correct

level.

In current control mode of Open Loop, the motor follows the frequency

reference signal. The motor is current controlled in small frequencies

(typically <10Hz) and in higher frequencies the motor is voltage controlled.

The current control ensures that in small frequencies the speed of the motor is

almost independent of the load.

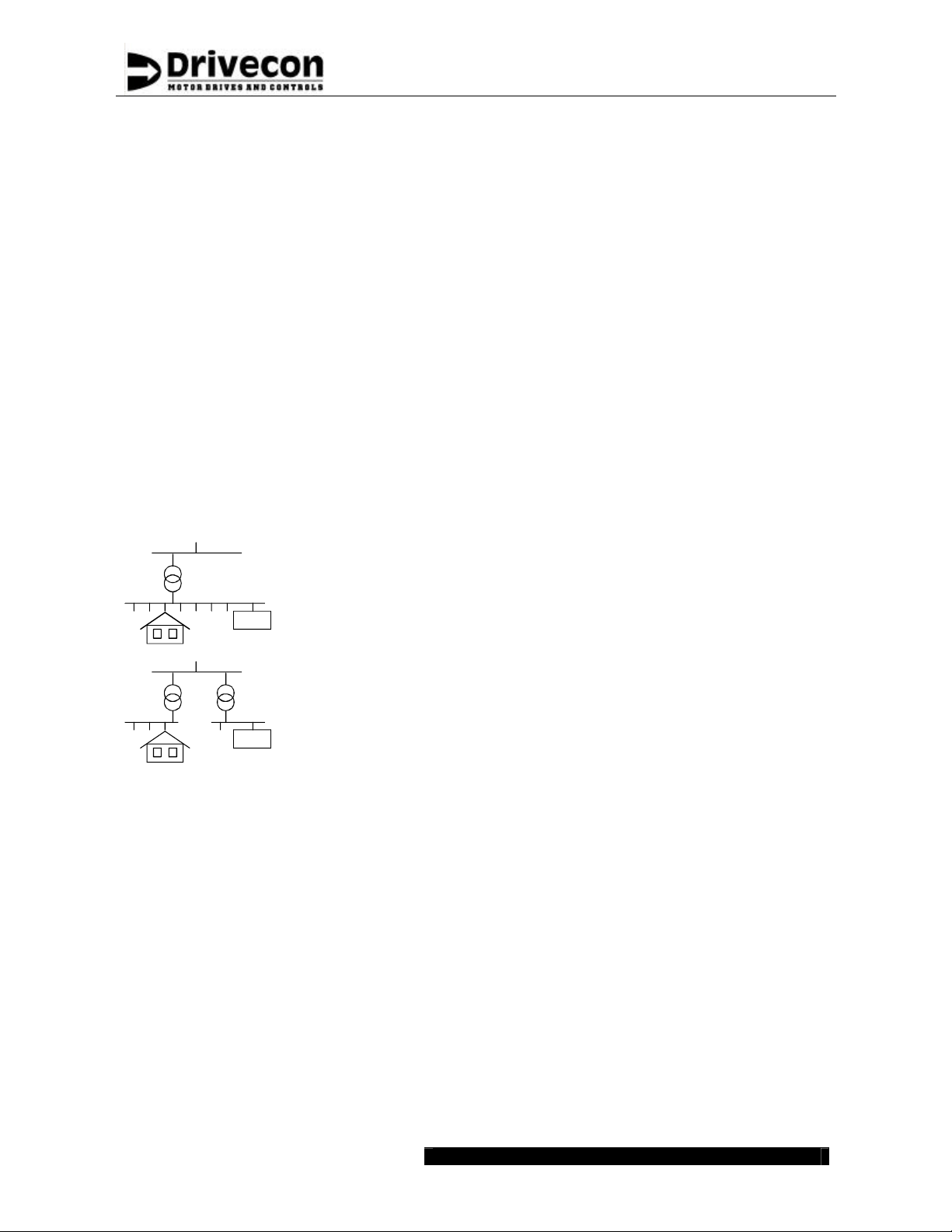

Closed loop

The closed loop vector control also includes a motor model, which has even a simpler

configuration than the open loop vector control. This is because an additional input data, as the

signal from the incremental encoder is available. This measurement of the function of the actual

motor is used as feedback to the motor model calculation and allows possibilities for additional

checking of the motor control.

Closed loop vector

control

Speed

ref

Speed

Control

ref

Current

InverterAsic

M

~

3

Torque

Flux

Speed control

Closed loop (mode 3)

Torque control

Closed loop (mode 4)

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

In the speed control mode of Closed Loop, the motor speed follows the speed

reference signal. XT SERIES adjust the motor frequency and with this function

compensates the load-dependent slip. The slip compensation keeps the actual

shaft speed constant and independent of loading conditions. With the closed

loop speed control it is even possible to reach zero speed with full torque.

In torque control mode, the shaft torque is kept equal to the reference signal.

The motor speed depends very much on loading conditions - for example, an

unloaded motor would run at full speed all the time. For safety reasons, the

speed is limited between adjustable minimum and maximum speeds.

Vector

calculation

Current

Speed

G

Page 14

Service Manual

Pro2V070

1.8 EMC

The shortening "EMC" stands for the Electro Magnetic Compatibility. According to the EMC

directive "the apparatus shall be so constructed that:

a) The electromagnetic disturbance it generates does not exceed a level allowing other

apparatus to operate as intended

b) The apparatus has an adequate level of intrinsic im munity of electromagnetic disturbance to

enable it to operate as intended."

Technical

construction file

Declaration of

conformity

CE -mark

Environments

PDS

PDS

The technical construction file describes how the frequency converters

have been constructed to comply with the directive and standard

requirements.

With the declaration of conformity the manufacturer informs that device

is manufactured to fulfill required EMC standards.

The CE marking is a declaration by a manufacturer or importer located

in the European Economic Area that a product complies with the safety

and health requirements of the directive in question. The manufacturer

demonstrates for the authorities that the product complies with the

safety requirements within the EU.

Immunity and emission requirements are divided in two levels in the

product standard according to the environments.

First environment means environment that includes domestic premises

and also establishments directly connected to a low-voltage power

supply network.

XT SERIES are not intended to be used on a low-voltage public

network, which supplies domestic premises. Radio frequency

interference is expected if used on such a network.

Second environment means environment that includes all

establishments other than those directly connected a low-voltage power

supply network.

Power drive system (PDS) means a system consisting of power and

control equipment, including XT SERIES.

1.8.1 Fulfilled EMC-standards

Immunity

Emissions

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

XT SERIES fulfill the immunity requirements defined in the EN 61800 -3

Amendment 11 (2000) for the second environment.

XT SERIES fulfill the emission requirements of the EN 61800-3 A11

2000 for the second environment.

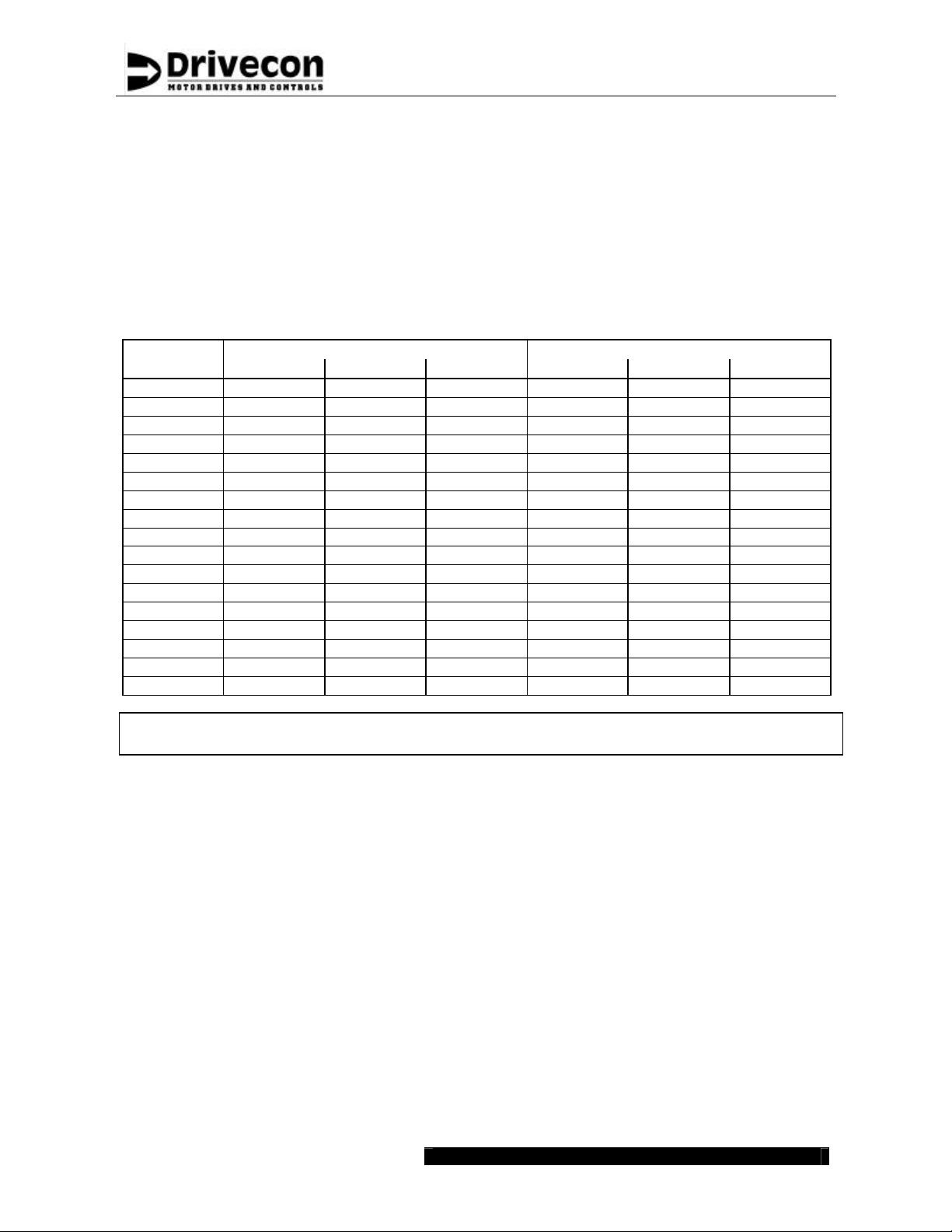

Interference

level

Page 15

Safety margin

Service Manual

Pro2V070

Immunity level of

second environment

Emission limit of

second environment

Typical emission

of D2H/D2C

Emission limit of

first environment

Frequency

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 16

Service Manual

Pro2V070

2 INSTALLATION

2.1 Cooling

The needs of cooling arrangements for the XT SERIES vary by application. The actual thermal

loading of the enclosure has to be estimated based on the loading conditions and duty cycles. The

power losses of XT SERIES are listed in the below table for each power rating. In most cases, XT

SERIES models up to 132F do not require any special cooling arrangements as the main part of

the losses is fed outside the cubicle in standard installations. Cooling for models, which are

installed in totally closed cubicles, is required to be checked case by case.

Through panel mounted Totally enclosed cubicle

Model ED40 ED60 ED100 ED40 ED60 ED100

002F 21 24 29 67 92 141

003F 20 22 25 53 70 104

004F 21 23 28 64 87 132

005F 24 28 36 96 134 211

007F 25 30 39 116 160 248

011F 31 39 54 176 250 398

015F 30 37 51 177 246 383

018F 38 49 71 256 364 581

022F 41 54 79 289 413 662

030F 34 43 60 230 318 493

037F 43 57 83 322 456 724

045F 53 71 107 415 596 957

055F 54 72 108 570 749 1108

075F 73 101 156 763 1039 1591

090F 89 125 197 927 1284 1999

110F 73 101 157 1013 1291 1845

132F 89 125 196 1170 1526 2237

Note! The power losses given above do not include the power fed to the braking

resistors.

2.2 Power cabling

Shielded

motor cable

Double

collectors

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

In crane application, XT SERIES fulfills EN61800-3/A11 (IEC 1800-3) second

environment radiated emission requirements without shielded motor cable.

However shielded motor cable is recommended to use in fixed installations,

especially in buildings.

In the second environment, shielded motor cable is recommended to use in fixed

installations, especially in buildings. However motor cables in crane and festoon

power supplies are normally not shielded due to the practical reasons.

Shielded motor cable is essential to use if installation is requested to fulfill the

first environment emission requirements.

If the power is supplied to the crane via conductor rails, double collectors are

needed. This ensures a reliable contact with the rail in all circumstances. Short

interruptions and sparks between the conductor rail and the collector may cause

nuisance tripping, other undesired operations and in worst case even permanent

damage to components.

Page 17

Service Manual

Pro2V070

Cable

selection

Cabling for XT SERIES can be done using normal crane cables. All the cables

must be dimensioned according to local regulations. Ambient temperature, cabling

method (size of bunches etc.) and allowable current for the cable in use must be

taken into consideration. If there are no other regulations, following values can be

used (three phase 400V supply).

The table below is based on rated continuous current and ambient temperature

+40? C (104?F). A higher ambient temperature may require increased cable sizes.

If the actual load current is below XT SERIES continuous current, then the fuses

and the supply cable may be dimensioned according to the load current.

Power class 002 004 005 007 011 015 018 022

Continuous current I

Fuse/MSP A

Max motor cable

length

A 5.6 9 12 16 23 31 38 46

CONT

6.2

11.25 15 20

5

27.

5

38.75

47.

5

m 50 50 50 50 50 50 50 50

56.25

Ft 160 160 160 160 160 160 160 160

Motor cable

Braking resistor cable

o

104

104

AWG 14 14 14 14 14 10 8 8

F

o

F

AWG

14 14 14 14 14 14 10 8

Power class 030 037 045 055 075 090 110 132

Continuous current I

A 61 72 87 105 140 170 205 245

CONT

Fuse A 80 90 110 125 175 225 250 300

Max motor cable

length

m 50 50 75 75 75 75 100 100

Ft 160 160 240 240 240 240 325 325

Motor cable

Braking resistor cable

104

F

104

F

o

AWG

o

AWG

6 5 4 3 1/0 2/0 3/0 3/0

6 4 3 2 1/0 1/0 2/0 3/0

Cable

protection

To protect the supply cables against short circuit there must be fuses or motor

circuit breakers (MCCBs) installed at the mains end of the supply cable.

Dimensioning of the fuses or MCCBs depends on the cable used and on the type

of primary fuses or MCCBs. If there are no other regulations, the values given in

this section can be used to dimension fuses (three phase 400V supply).

The overload protection of XT SERIES protects both the supply and the motor

cables. The fuses of the supply provide the short circuit protection.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

?

?

Cable

length

Note! All control cables must be placed as far from the motor and braking resistor

The maximum motor cable lengths in the preceding table are based on 150% of

inverter rated current (=current during acceleration) and a 2.5 % voltage drop in

the cable. For longer cables, the required conductor cross sectional area A (mm2)

is given by formula

A

? ?

where

p

U

cables as possible.

24315.

l I

p U

is the cable length (m)

l

is the motor current (A) at shaft power

I

F

is the allowed voltage drop in %

is the nominal motor voltage

Page 18

.

?

F

Service Manual

Pro2V070

P

F

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 19

Service Manual

Pro2V070

2.3 Control wiring

Shielded signal cable

Reference signals

Sensor bearing

Encoder

Note! All shielded cables must be placed as far from the motor cables as possible

(>20cm). Shielding must be continuous. The "pigtail" (= the end to be connected)

of the shield should not be connected to minimize disturbances.

It's recommended to use twisted pair and braided shielded signal

cables. Foil type shield is not sufficient enough in crane applications

because of poor mechanical durability. Cable insulation material effects

the cable capacitance. Recommended cable capacitance between

signal-signal and signal -ground is equal or less than 100pF/m (31pF/ft).

It is not recommended to use shielded flat cable, because its

capacitance is extremely high and this may cause high frequency

interference.

Shielded round cables must be used for analog reference signals. The

shield is to be grounded only at XT SERIES (not at the other end of the

cable).

The cable for the sensor bearings must be shielded round cable and

grounded at both ends.

The encoder connections may be split into two cables, then the signal

conductors (4pcs) should go together in one cable and the supply and

common (+24V/0V) together in another cable. The encoder cable(s)

must be shielded round cable(s) and grounded at both ends.

2.4 EMC compatible grounding

Construction

connections

Cable connections

Shielded control

cables

All metal construction parts of the cubicle must be electrically

connected to each other using largest possible surface area. Paint to

paint connection must not be used.

Control cables and power cables should be separated and routed

separately for eliminating noise coupling. The distance between braking

resistor cables and the other cables should be kept as long as possible.

The distance between the resistor cables should be kept as low as

possible to prevent the antenna behavior. Cable lengths should be kept

as short as possible to minimize coupling capacitances and

inductances.

Shielded control cables should be grounded in both ends. The shield

must be connected to the ground using the largest possible surface

area. Extra intermediary terminators cutting the shield are not allowed;

the shield should maintain its integrity as much as possible. Spare

conductors should be grounded in the both ends.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 20

Service Manual

Pro2V070

3 START-UP PROCEDURE

If any problems or malfunctions occur during the start-up, refer to Chapter “Troubleshooting”, to

find out the reason. All problems must be solved before continuing.

Warning! High voltages inside the device. Wait for at least five minutes after the supply

voltage has been switched off before doing any service actions. The display in

the operating condition (lights on) indicates a dangerous voltage on the DC-bus.

When display turns off, the DC -bus voltage is approximately 100V. Note also that

?? Do not connect any voltage to the output terminals (U, V, W). Otherwise, the inverter will be

dam aged.

?? The overload protection protects both the supply and the motor cables. The fuses of the supply

provide short circuit protection.

3.1 Visual checks

–

Record all checks and results.

–

Check condition of the cubicles.

–

Check that XT SERIES serial number is the same as in the delivery documents.

Check the switch settings on SSU (see chapter "SSU").

??

??

?? Check the cabling to the motor, brake, thermistors and speed sensor.

?? Check the motor type.

?? Check the wire terminations in the motor connection box

?? Check connections for motor, thermistors, heaters, brake wear and speed sensor circuits.

?? Disconnect motor (U, V, W) and brake cables to prevent damage of the inverter. Measure the

isolation resistance of the brake coil and the motor windings (each phase to ground).

?? Re-connect motor and brake cables.

?? Check braking resistor(s).

there is always a dangerous voltage in the braking resistor when the DC-bus is

charged.

If necessary, open the control box cover and adjust the SSU settings.

3.2 Checks before the first test run

Warning! High voltages inside the device.

?? Check the power supply voltage (nominal voltage +/- 10%).

–

Make sure that run commands are off ( pushbuttons / controller (master switch) at zero position).

?? Turn on the power from the main switch and the control voltage switch.

–

Within about 1 second the keypad should display "AC on", and then in about 1 second the

display changes to the multimonitor screen displaying “output voltage, current and frequency”

and the green READY status indicator turns on.

–

In a fault situation, the red FAULT status indicator blinks and the display shows a fault code

instead of frequency.

Check that the green RUN status indicator is off.

??

Check that the external connections and programming of digital inputs are according to the

??

application.

The parameters are properly set after factory tests and no adjustments are needed except for

??

the parameters that depend on the application and the motor. Write down in the parameter list

all the values that have been changed.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 21

Service Manual

Pro2V070

3.3 Test run without load

?? See also chapter 4.4 Open Loop motor parameter adjustments and chapter 4.5 Closed Loop

motor parameter adjustments

?? Make sure that movement will not cause any danger to the environment or to the crane itself.

Avoid running close to the limit areas.

?? Check the limit switches manually if possible.

?? Check the run commands on the keypad display and correct the motor rotating direction. The

arrow rotates clockwise if S1 (fwd/up) is applied, and counter-clockwise if S2 (rev/down) is

applied.

Check the function of the speed sensor, see chapter “Speed sensors”

??

?? Check the function of the speed supervision circuit. See "Functional test run for SSU".

?? Run forward (upwards) at minimum speed for 5 to 10 seconds. Accelerate to full speed. Run 5

to 10 seconds. Stop. Repeat the same in the reverse (down) direction. Check the frequency

display to make sure that the frequency changes through the whole operational frequency range

from the minimum to the nominal speed.

Check the motor operation (acceleration, deceleration and braking): accelerate to full speed

??

forward (up), change to full speed reverse (down) and full speed forward (up) again and stop.

?? Check the limit switch functions: run forward (up) slowly and check the slowdown and the stop

limit switch operations. Re-check using full speed. Repeat the same check for the reverse

(down) direction.

?? If the optional ESR is used, check the maximum frequency.

3.4 Test run with load

?? See also chapter 4.4 Open Loop motor parameter adjustments and chapter 4.5 Closed Loop

motor parameter adjustments

?? Note, three loads are required:

?? Nominal load (100%) for normal operation.

?? Limited load for ESR (optional).

?? An adequate extra load for dynamic overload testing and to test the ESR load limit.

?? See the maintenance instruction HU1.03.0004 “Erection, Installation and Testing of EOT

cranes” for the details of the load tests.

–

Make sure that movement will not cause any danger to the environment or to the crane itself.

?? If the optional extended speed range (ESR) is used, check that the load limit is correctly set and

hoisting with bigger loads is prevented.

–

Run in both directions at minimum and maximum speeds.

?? If the fan tube resistor unit is included, check that the fan(s) starts to blow when running down

with nominal load and continues to blow for about 4-5 minutes after stopping.

3.5 After the test run

–

Record all the parameter value changes in the parameter list.

–

Make sure all remarks and setting values are recorded.

–

Copy all parameters up to keypad memory by parameter S6.3.2.

–

Save user parameters in Control Unit by parameter B4.1.2.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 22

4 PARAMETER ADJUSTMENTS

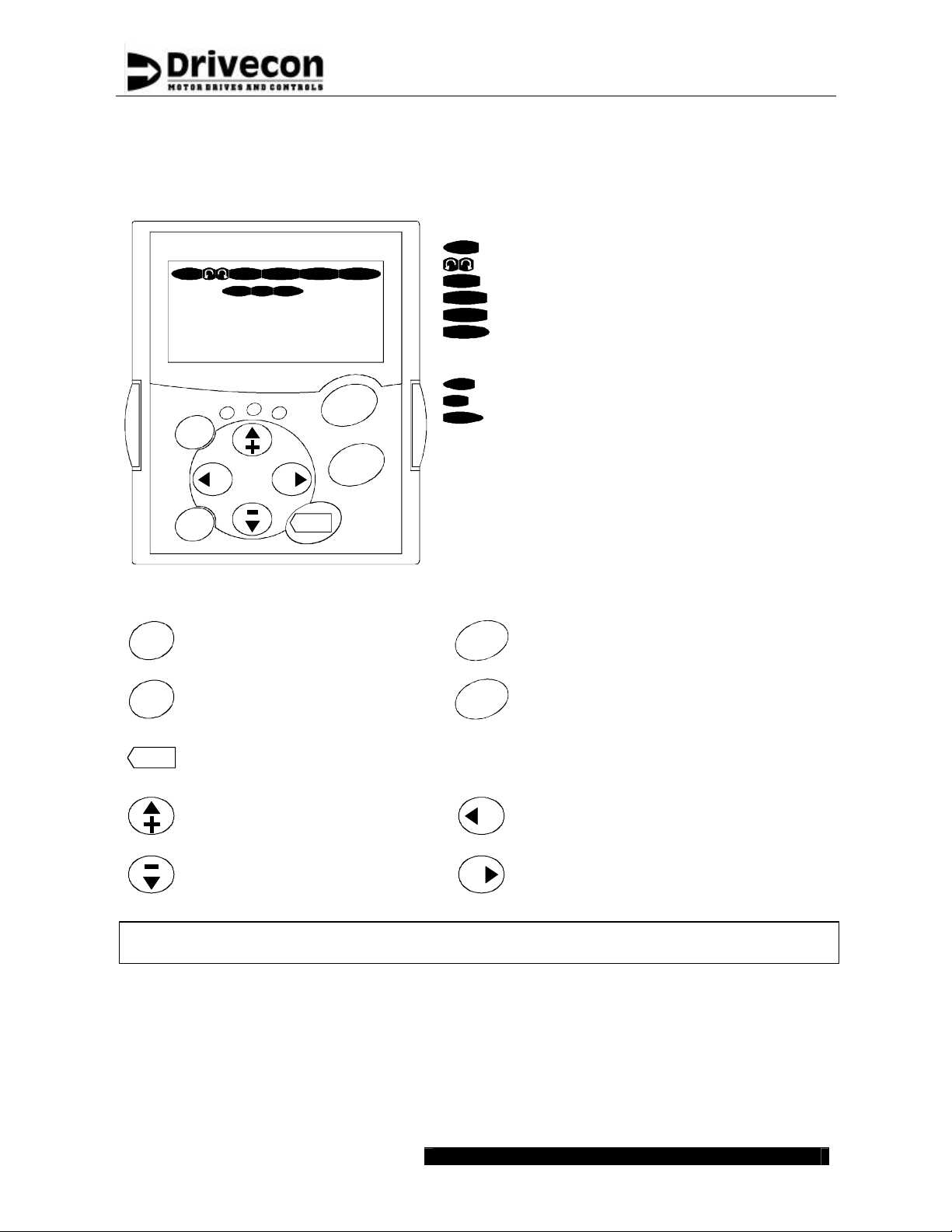

4.1 Control keypad operation

Drive status indications:

READY FAULTSTOPRUN

KeypadI/O term

P3.4.1.1.

Bus/Comm

Motor Nom Volt

400 V

run

ready

reset

select

Button descriptions :

fault

ALARM

enter

START

STOP

RUN

STOP

READY

ALARM

FAULT

Control place indications:

I/O term

Keypad

Bus/Comm

Text lines:

Line 1 Location indication (parameter number)

Line 2 Description line (parameter name)

Line 3 Value line (parameter value)

Status LEDs:

ready green Illuminates the AC -supply is on

run green Illuminates during run

fault red Illuminates due to fault tri p

Motor is running

Motor rotation direction

Inverter is not running

AC power is on

Warning is on

Fault is on

Terminals are the selected control place

Control keypad is the selected control place

Control through Profibus is selected

Service Manual

Pro2V070

reset

select

enter

Reset active faults

START

Switch between two latest

displays

Confirmation of selections

STOP

Browse up the menus

Increase values

Browse down the menus

Decrease values

Starts the motor if the keypad is the

active control location

Stops the motor if the keypad is the

active control location

Move to previous menu level

Move cursor left

Exit edit mode

Move to next menu level

Move cursor right

Enter edit mode

Warning! Running via keypad can cause a hazardous situation. Keypad cont rol must not be

used.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 23

Service Manual

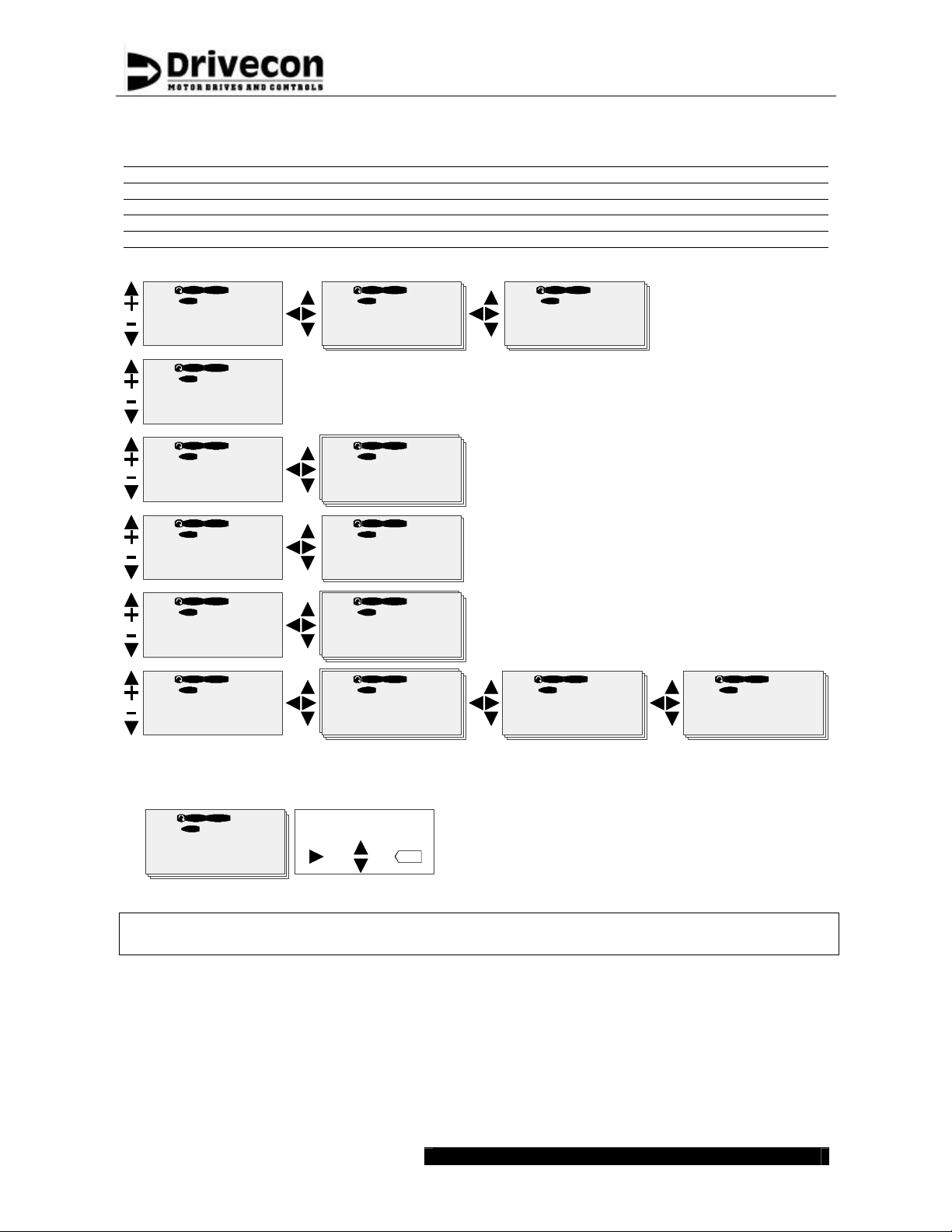

4.1.1 Navigation on the control keypad

Letter front of the code number describes variable type

B = Button G = Group N = Multimonitor T = Trip Counter

C = Counter H = Fault History P = Parameter V = Value

D = Data I = Info R = Reference

E = Expander M = Menu Group S = System

M8.

Fault History

H1?Hxx

READY

STOP

I/O term

M7.

?

H8.1.

57 Thermistor

F T1?T16

READYSTOP

I/O term I/O term I/O term

READYSTOP

T8.1.1.

READYSTOP

Operation days

?

0

Active Faults

F0

Pro2V070

M6.

System Menu

S1?S8

READY

STOP

I/O term I/O term

G5.

?

Panel Control

B1?R2

READYSTOP

I/O term I/O term

G4.

?

Monitoring

G1?G23

READYSTOP

I/O term I/O term I/O term I/O term

G3.

?

Parameters

G1?G9

?

S6.2.

Application

Crane

B5.1.

Panel Control

Off

V4.22.

Output Frequency

0.00 Hz

G3.4.

Motor Parameters

G1?G7

READYSTOP

I/O term I/O term

STOP

READYSTOP

READY

READYSTOP

READYSTOP

?

G3.4.1.

READYSTOP

Motor Set 1

P1?G23

?

P3.4.1.1.

READYSTOP

Motor Nom Volt

400 V

4.1.2 Value line editing

P3.4.1.1.

Motor Nom Volt

400 V

Warning! Changing parameter settings during running may cause a hazardous situation.

READYSTOP

I/O term

Mode

change

Edit

value

Accept

value

enter

Parameter settings must not be changed during running.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

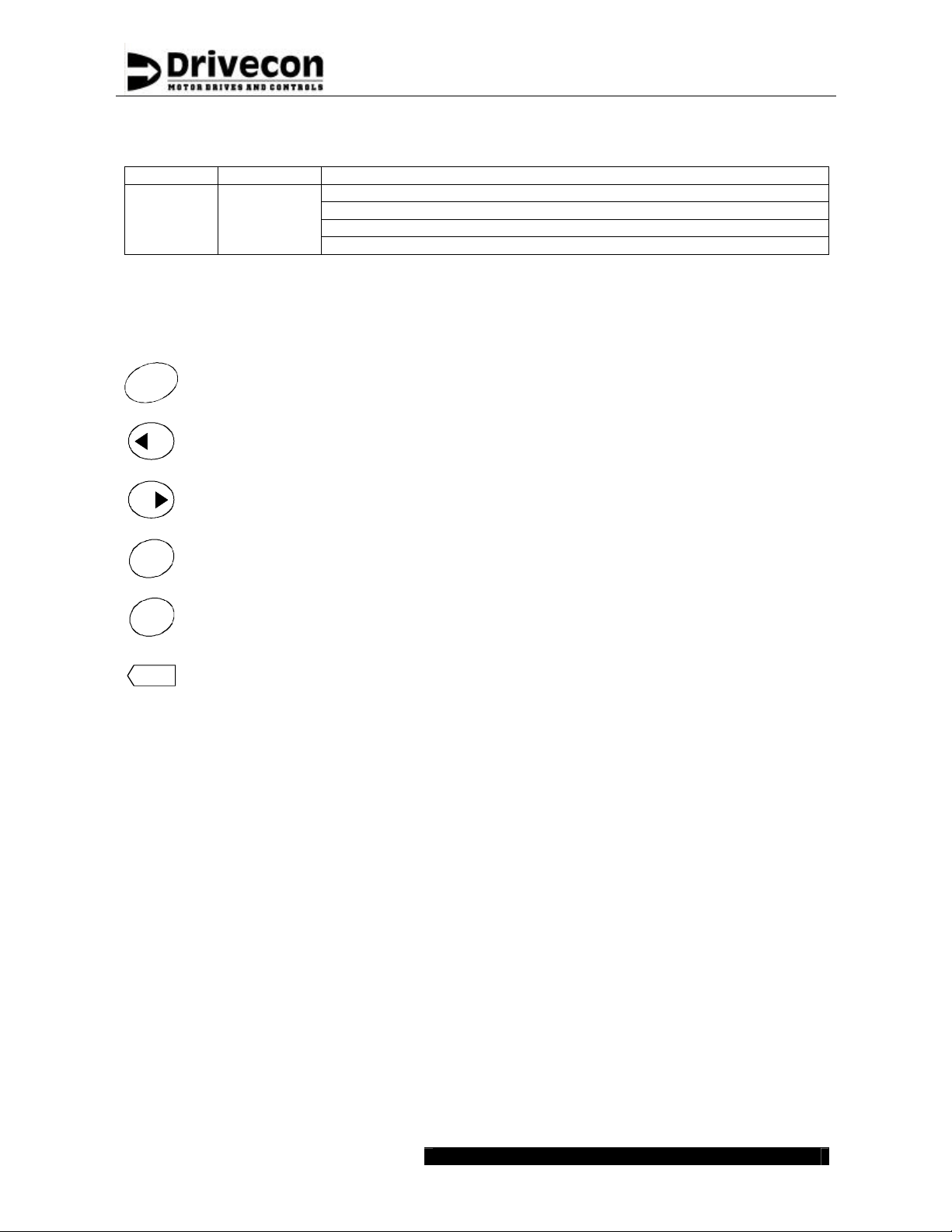

4.1.3 Passwords

Parameter Name Description

P3.1. 1 Password

Following passwords release the parameter locks.

Level 1 Locked 0

Level 2 Start-up 26

Level 3 Engineering 768

4.1.4 Special button functions

Button Time delay Description

Page 24

Service Manual

Pro2V070

START

select

reset

enter

> 2 seconds Password level changes to Level 3 Engineering.

> 2 seconds Displays the software version.

> 2 seconds Display changes straight to adequate autotuning parameter.

> 2 seconds Changes display straight to V4.22 Output Frequency.

> 3 seconds Resets whole H8 Fault History when display in any level of H8 menu.

> 1 second Resets whole H8 Fault History when display in sublevel of H8 menu.

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

G4.1

Parameter Backup

G4.7

Digital Input

G4.7.1

DI Status

G4.1.4

Factory default

G4.2

Analog I/O

G4.3

Relay Output

G4.7.2

DI Function

G4.4

Operate Counters

G4.5

Fault Counter

G4.8

SSU

G4.9

Service

G4.6

Bus Control

G4.9.10

Max Current

G4.10

Sway control

G4.23

Multimonitor

Page 25

Service Manual

Pro2V070

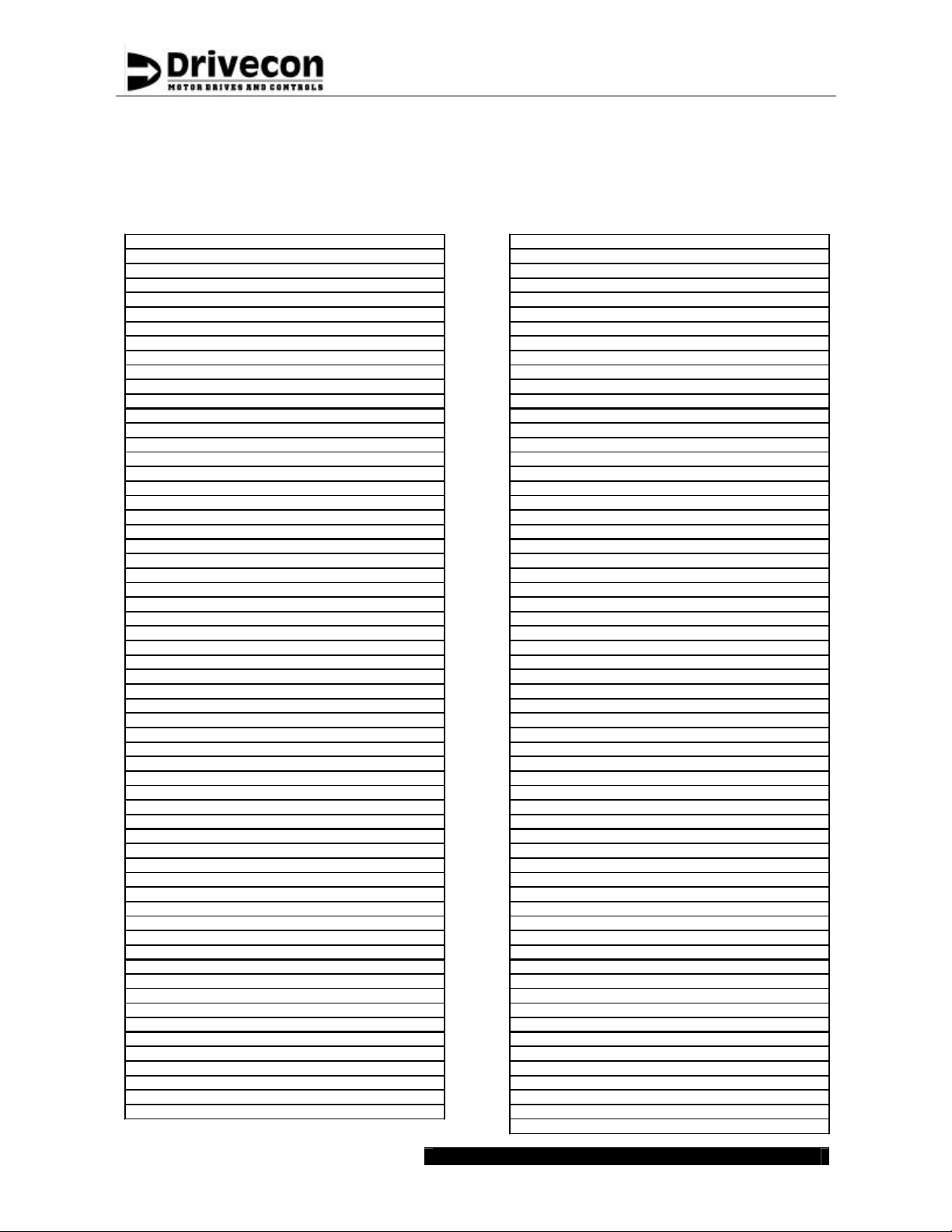

4.1.5 Monitoring

Below are listed the parameters of Group G4 Monitoring. For example, operation of analog and

digital inputs can be verified with monitoring parameters. After power off and on the display returns

as default to V4.22 Output Frequency.

B4.1.1 Load Default Par

B4.1.2 Save User Par

B4.1.3 Load User Par

B4.1.4 Save Default Par

V4.2.1 Ain1 Value V V4.7.1.6 OK

V4.2.2 Ain2 Value V V4.7.1.7 DID1

V4.2.3 Aout1 Value mA V4.7.1.8 DID2

V4.2.4 Aout2 Value V V4.7.1.9 DID3

V4.3.1 ROB1 State V4.7.1.11 DID5

V4.3.2 ROB2 State K7

V4.3.3 ROC1 State V4.7.2.1 DIA3 Function

V4.3.4 ROD1 State V4.7.2.2 DIA4 Function

V4.3.5 ROE1 State V4.7.2.3 DIA5 Function

V4.3.6 ROE2 State V4.7.2.4 DID1 Function

V4.3.7 ROE3 State V4.7.2.5 DID2 Function

V4.4.1 Motor MWh MWh V4.7.2.7 DID4 Function

V4.4.2 Generator MWh MWh V4.7.2.8 DID5 Function

V4.4.3 Start Counter x 1k V4.7.3 Basic Board

V4.4.4 MotorRuntime (h) h V4.7.4 Extension Board

V4.7.1.1 S1

V4.7.1.2 S2

V4.7.1.3 DIA3

V4.7.1.4 DIA4

V4.7.1.5 DIA5

V4.7.1.10 DID4

V4.7.2.6 DID3 Function

R4.5.1 Fault Counter V4.8.1 Overspd Lim 1 %

V4.5.2 Total Faults V4.8.2 Overspd Lim 2 %

V4.5.3 Selected Faults

V4.9.1 Phase U Curr A

V4.6.1 S1 V4.9.2 Phase V Curr A

V4.6.2 S2 V4.9.3 Phase W Curr A

V4.6.3 Motor Set 2 V4.9.4 Encoder Speed Hz

V4.6.4 Second Speed Lim V4.9.5 HeatSinkTempMax °C

V4.6.5 Field Weakening V4.9.6 HeatSinkTempMin °C

V4.6.6 Alt Control Mode V4.9.7 IGBT Temp Max °C

V4.6.7 Brake Feedback V4.9.8 IGBT Temperature °C

V4.6.8 Ramp 2 V4.9.9 SlipAdjustChange %

V4.6.9 Torque Limit

V4.6.10 AP V4.9.10.1 Max Current

V4.6.11 Slow Limit S11 V4.9.10.2 Max Current Freq

V4.6.12 Slow Limit S21 V4.9.10.3 Max Current Torq

V4.6.13 End Limit S12

V4.6.14 End Limit S22 V4.10.1 Swing Time s

V4.6.15 Brake Pedal V4.10.2 Pendulum Length m

V4.6.16 S-Curve Inhibit V4.10.3 StoppingDistance m

V4.6.17 Tare V4.10.4 Sway Ctrl Status

V4.6.18 Inching V4.10.5 License Status

V4.6.19 SlackCableByPass V4.10.6 DemoLicenseTime

V4.6.20 Brake Pedal 2 V4.11 Freq Ref Hz

V4.6.21 Synchronizing V4.12 Speed Req Hz

V4.6.22 Speed Reference Hz V4.13 Distance Counter m

V4.6.23 Torque Reference % V4.14 DC-link Voltage V

V4.6.24 Speed Correction Hz V4.15 Heat Sink Temp °C

V4.6.25 Ramp Reference V4.16 MotorTemperature %

V4.6.26 Torque Limit Ref % V4.17 Motor Power %

V4.6.27 Speed Limit Ref V4.18 Motor Voltage V

V4.6.28 Load Feedback V4.19 Motor Torque %

V4.6.29 Sway Ctrl Height V4.20 Motor Current A

V4.6.30 Calibration Pos V4.21 Motor Speed rpm

V4.6.31 Profibus Status V4.22 Output Frequency Hz

V4.6.32 Bus Cycle Time ms

N4.23.1 Multimonitor

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Page 26

Service Manual

Pro2V070

4.2 Input selections

Digital inputs are programmed based on function. Each function can be set to one of the 8

programmable digital inputs. The programmable digital inputs are DIA3, DIA4, DIA5, DID1, DID2,

DID3, DID4 or DID5.

There are also 3 other inputs, which functions cannot be changed by parameters. These nonprogrammable inputs are OK-input and the direction signals S1 and S2.

In basic applications one function is set to certain input. For special applications it is also possible

to set many functions to same input.

Example: Torque limit and Ramp2 should be activated with DIA5. Select the value 3=DIA5 in both

parameters P3.2.1.7 and P3.2.1.8.

Note! Impossible function combinations may be selected.

In following table are listed the possible inputs for each function.

Parameter Name / Function DIA3 DIA4 DIA5 DID1 DID2 DID3 DID4 DID5

P3.2.1.1 Motor Set 2 X X X X X X X X

P3.2.1.2 SSL X X X X X X X X

P3.2.1.3 ESR X X X X X X X X

P3.2.1.4 Micro Speed Sel X X X X X X X X

P3.2.1.5 Alt Control Sel X X X X X X X X

P3.2.1.6 Profibus Control - - X - - - - P3.2.1.7 Ramp2 X X X X X X X X

P3.2.1.8 Trq Limit X X X X X X X X

P3.2.1.9 AP X - - - - - - P3.2.1.10 CMS - X - - - - - P3.2.1.11 EP-Hold X X X X X X X X

P3.2.1.12 Multistep2 X X - - - - - P3.2.1.13 Multistep3 - X X - - - - P3.2.1.14 Multistep4 - - X X - - - P3.2.1.15 Multistep5 - - - X X - - P3.2.1.16 PO/MS

P3.2.1.17 S11 - - X - X - - P3.2.1.18 S21 - - - X - X - P3.2.1.19 S11 & S21 X X X X X X X X

P3.2.1.20 S12 - - - - X - X P3.2.1.21 S22 - - - - - X - X

P3.2.1.22 MF1 Input X X X X X X X X

P3.2.1.24 MF2 Input X X X X X X X X

X X X X X X X X

Drivecon Inc. reserves the right to alter or amend the above information without notice 21.12.2004 • XT SERIESCSM55BEN

Loading...

Loading...