DriSteem XTR Series Installation, Operation And Maintenance Manual

READ AND SAVE THESE INSTRUCTIONS

XTR MODULATING SERIES

Electrode Steam Humidifier

Installation, Operation,

and Maintenance Manual

Warnings and cautions

WARNINGS AND CAUTIONS

WARNING

Indicates a hazardous situation that could result in death or

serious personal injury if instructions are not followed.

mc_051508_1145

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualifi ed

HVAC and electrical contractors. Installation must be code approved. Improper installation can cause property damage,

severe personal injury, or death as a result of electric shock, burns, or fi re.

DriSteem

Europe: +3211823595

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal injury,

or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth can

cause illness.

mc_032612_1153

®

Technical Support: North America: 800-328-4447

CAUTION

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

Hot surfaces and hot water

This steam humidifi cation system has extremely hot surfaces. Water in steam cylinders, steam tubing, and dispersion

assemblies can be as hot as 212 °F (100 °C). Discharged steam is not visible. Contact with hot surfaces, discharged hot

water, or air into which steam has been discharged can cause severe personal injury. To avoid severe burns, follow the

cool-down procedure in this manual before performing service or maintenance procedures on any part of the system.

mc_032612_1154

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any part of

the humidifi cation system. Failure to disconnect electrical power could result in fi re, electrical shock, and other hazardous

conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fi re. Do not remove cabinet covers until electrical power is disconnected.

Follow the shutdown procedure on Page 38 before performing service or maintenance procedures on any part of the

system.

mc_032612_1155

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Warnings and cautions

WARNING

Electrical shock hazard

If the humidifi er starts up responding to a call for humidity during maintenance, severe personal injury or death from

electrical shock could occur. To prevent such start-up, follow the shutdown procedure on Page 38.

mc_032612_1156

CAUTION

Follow steam piping recommendations

Controlling condensate fl ow and collection in an electrode steam humidifi er system is critical to maximum performance. Failure to

follow the steam piping recommendations in this manual can cause system pressure fl uctuations and increase cylinder pressure,

steam velocity, and condensate noise.

Hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage some drain plumbing materials not rated for hot drain

water. To prevent such damage, make sure drain water tempering is selected, and supply water is not heated. Do not shut off

supply water to the cylinder before it is drained.

Excessive supply water pressure

Supply water pressure greater than 80 psi (550 kPa) can cause the humidifi er to overfl ow.

mc_123010_1520-XT

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Table of contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Dimensional drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Voltages, weights, and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Dispersion options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selecting a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control and dispersion devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing covers and steam cylinder . . . . . . . . . . . . . . . . . . . . . . . . 8

Wall mounting humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing steam cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Piping: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supply water and drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Field piping overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XTR steam blower and XTR fan pack . . . . . . . . . . . . . . . . . . . . . . . 11

Field wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sensor placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dispersion: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Interconnecting piping requirements . . . . . . . . . . . . . . . . . . . . . . . . 21

XTR dispersion tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

XTR steam blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

XTR fan pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Download DriSteem literature

ii

DriSteem product manuals can be downloaded,

printed, and ordered from our website:

www.dristeem.com

DriSteem Technical Support

800-328-4447

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Steam cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Drain valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacement parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Dispersion devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

XTR humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

OVERVIEW

Product overview

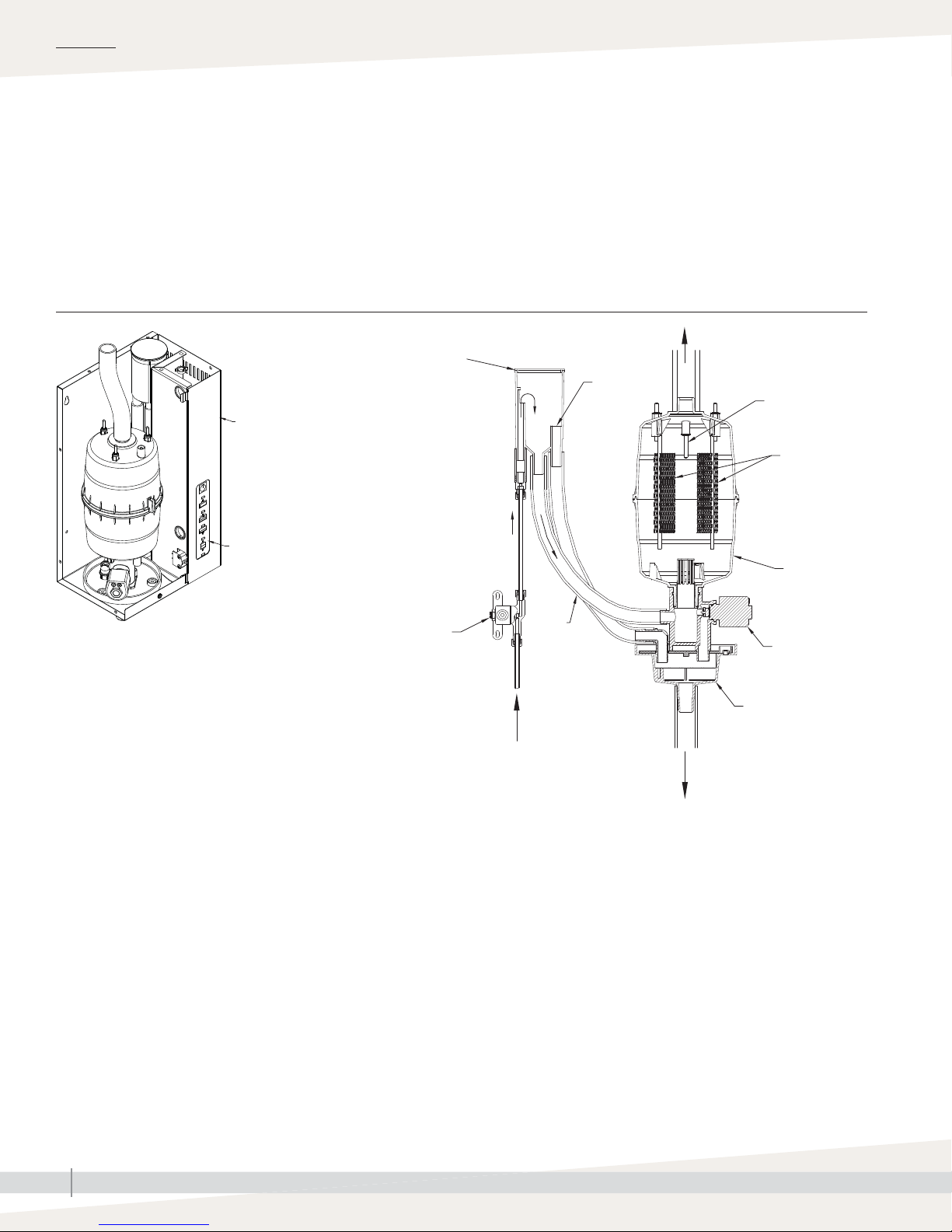

HUMIDIFIER

DriSteem XTR electrode steam humidifi ers use heat caused by electrical

resistance in their fi ll water to boil the fi ll water into humidifi cation steam.

Steam output and water conductivity are managed via automatic draining and

fi lling. See Figure 2-1.

FIGURE 2-1: XTR HUMIDIFIER COMPONENTS

Fill cup

Steam outlet

OM-7717

Painted cabinet and

removable covers

Control panel

Fill valve

Supply water

Fill

line

Overfl ow

High water sensor

Electrodes

Steam cylinder

Drain valve

Drain cup

90-1522a

Drain

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Product overview

OVERVIEW

SUPPLY WATER

There are benefi ts and trade-offs to consider when the application allows a

choice between hard and softened water:

Hard water: The benefi t of hard water is less frequent draining and fi lling

than with soft water, which results in better energy and water effi ciency

and more consistent steam output. However, cylinder replacement could

be more frequent with hard water, because hard water scale coats the

electrodes. The harder the water, the more frequent the need for a new

cylinder.

Softened water: The benefi t of softened water is longer cylinder life

(depending on water chemistry) than with hard water, because softened

water does not coat the electrodes as much as hard water. However,

softened water ions stay in solution to much higher concentrations than hard

water ions. This requires more frequent draining and fi lling, which results in

less energy and water effi ciency and less consistent steam output.

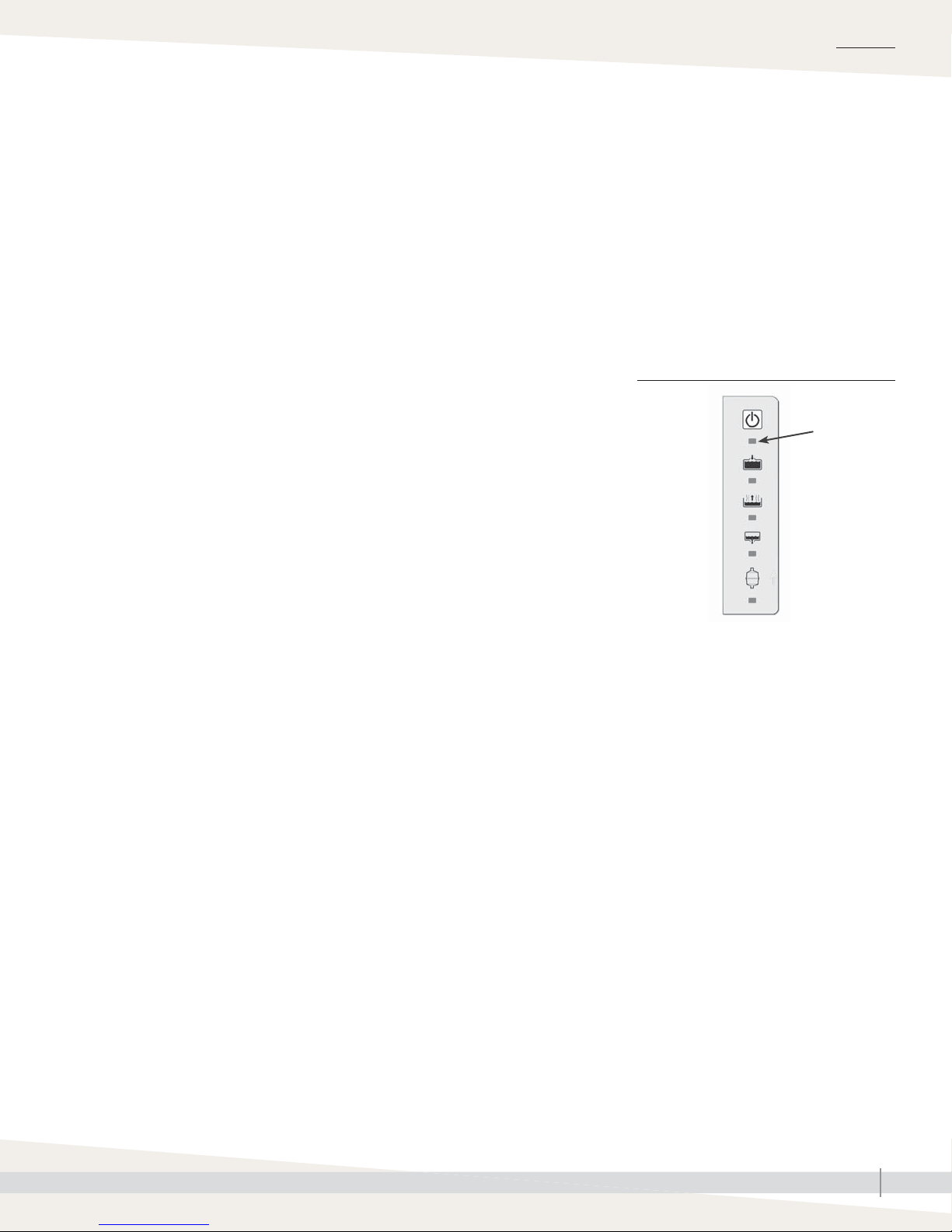

CONTROL PANEL

The XTR humidifi er controller provides push-button operation and indicator

lights for operating status and troubleshooting information. See “Operation”

beginning on Page 32 for details.

Important:

• Recommended supply water conductivity

for DriSteem electrode humidifiers is 125

to 1250 μS/cm (roughly comparable to

water hardness of 3 to 36 grains per

gallon).

• Demineralized, deionized, and reverseosmosis water cannot be used. These

water types are not conductive enough

for electrode humidifiers.

FIGURE 3-1:

XTR HUMIDIFIER CONTROL PANEL

On-off button

Fill

Steam

Drain

Service

Indicator lights

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

SPECIFICATIONS

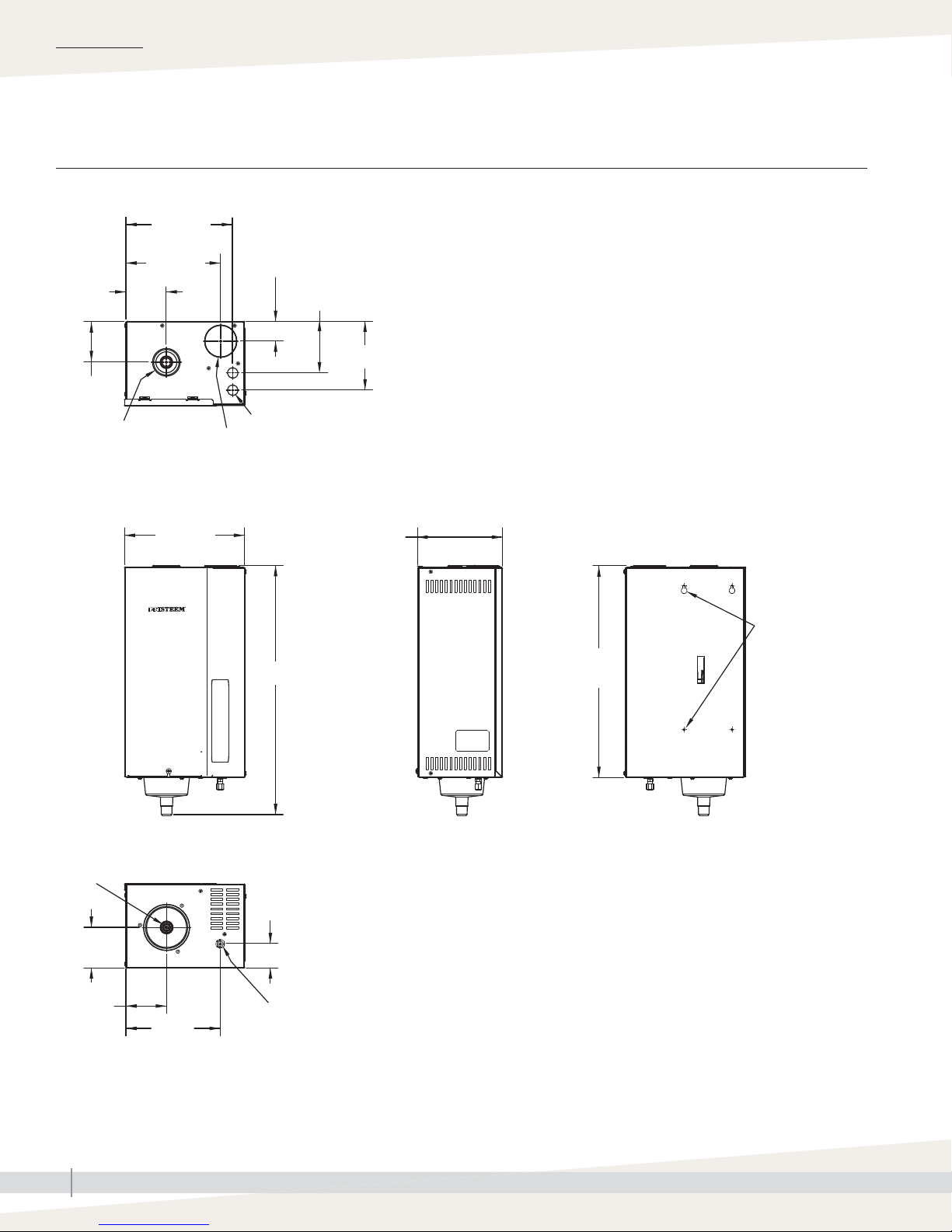

Dimensional drawing

FIGURE 4-1: XTR HUMIDIFIER DIMENSIONS

Top

8-7/8"

(225 mm)

3-3/8"

(86 mm)

3-3/8"

(86 mm)

Steam outlet

7-7/8"

(200 mm)

Fill cup

1-5/8" (41 mm)

4-1/4" (108 mm)

Electrical knockouts

5-3/4"(146 mm)

Drain

3-3/8"

(86 mm)

Front Side Back

10-1/8"

(257 mm)

20-7/8" (530 mm)

7-1/8"

(181 mm)

17-1/2"

(445 mm)

Bottom

2" (51 mm)

Mounting holes

(see mounting

dimensions in

Figure 8-1)

3-3/8"

(86 mm)

90-1701X

mc_050712_1400

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

7-7/8"

(200 mm)

Supply water

connection

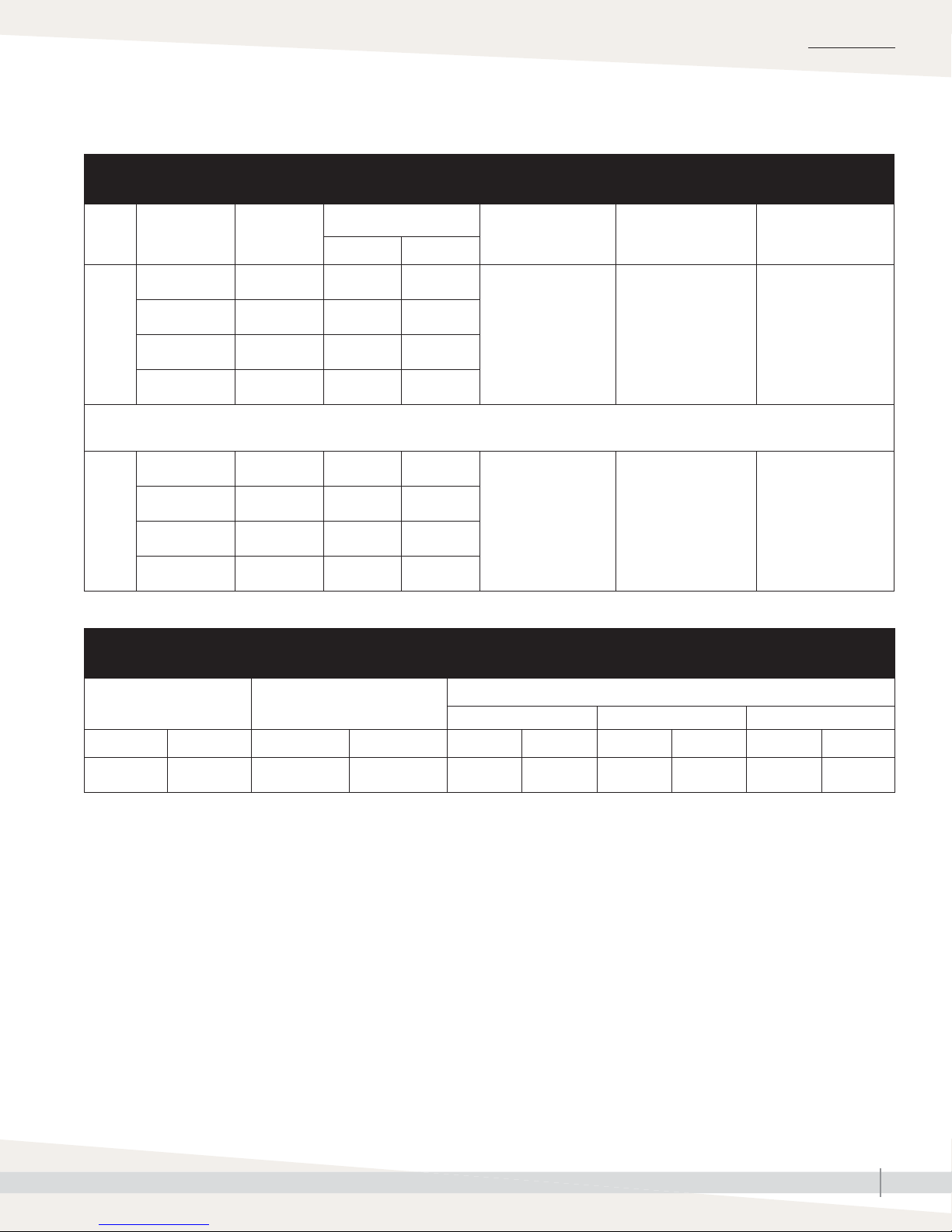

Voltages, weights, and dimensions

Table 5-1:

XTR humidifier capacities and electrical specifications

SPECIFICATIONS

Mode Voltage Input power

120V, 60 Hz 1.92 kW 5.6 2.5

208V, 60 Hz 3.33 kW 9.9 4.5

16 A

230V, 50 Hz 3.68 kW 10.8 4.9

240V, 60 Hz 3.84 kW 11.3 5.1

The XTR humidifi er can be confi gured to operate in a current limited mode if lower maximum operating capacity is desired.

See page 15 for setting this option.

120V, 60 Hz 1.38 kW 4.0 1.8

11.5 A

mc_050712_1408

208V, 60 Hz 2.39 kW 7.1 3.2

230V, 50 Hz 2.65 kW 7.8 3.5

240V, 60 Hz 2.76 kW 8.1 3.6

Nominal steam capacity

Nominal current draw Maximum line current Fuse

lbs/hr kg/h

16 A 19.2 A 25 A

11.5 A 13.8 A 25 A

Table 5-2:

XTR humidifier weights and dimensions

Shipping weight Maximum operating weight

Width Height Depth

lbs kg lbs kg inches mm inches mm inches mm

27.0 12.2 23.0 10.4 10-1/8 257 20-7/8 530 7-1/8 181

mc_050712_1409

Dimensions

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

INSTALLATION

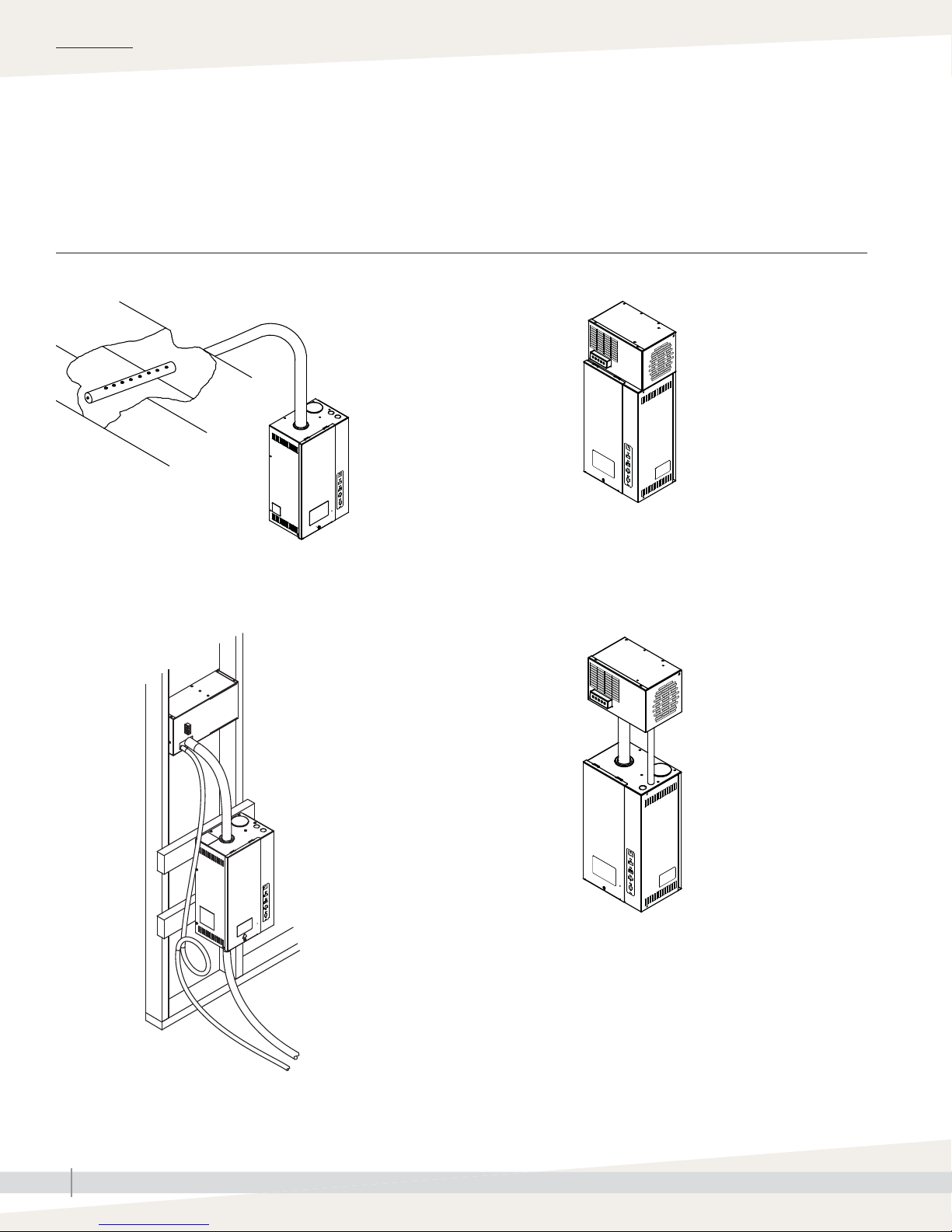

Dispersion options

The dispersion options in Figure 6-1 are available for XTR humidifi ers. For

installation details, see “Dispersion” beginning on Page 7.

FIGURE 6-1: XTR HUMIDIFIER DISPERSION OPTIONS

XTR dispersion tube in a duct

OM-7718

XTR steam blower mounted on top of humidifi er

OM-7720

XTR fan pack Remote-mounted XTR steam blower

90-1796

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

OM-7719

Selecting a location

INSTALLATION

HUMIDIFIER

When selecting a location for the humidifi er, consider the following:

• Proximity to duct

Install the humidifi er near the duct. The maximum recommended length for

steam hose connecting an XTR humidifi er to a dispersion tube is 6' (1.8 m).

See “Dispersion” beginning on Page 20.

• Elevation of installed dispersion assembly

The recommended installation location for the dispersion device is at an

elevation higher than the humidifi er. However, if the dispersion device must

be installed at an elevation lower than the humidifi er, install a drip tee and

drain, as shown in Figure 19-3.

• Temperature and relative humidity (RH):

Install humidifi er only in locations that meet the following temperature and

RH requirements:

- Maximum ambient temperature: 104 °F (40 °C)

- Minimum ambient temperature: 41 °F (5 °C)

- Maximum ambient humidity: 80% RH (non-condensing)

• Recommended clearances (see Figure 7-1)

Control and dispersion devices

See “Sensor placement” on Page 18.

See “Dispersion” beginning on Page 20.

• Electrical connections

See “Field wiring” beginning on Page 12.

• Supply water and drain piping connections

See “Piping” on Page 9.

• Exterior wall insulation

Install the humidifi er on an exterior wall only if the wall is properly

insulated.

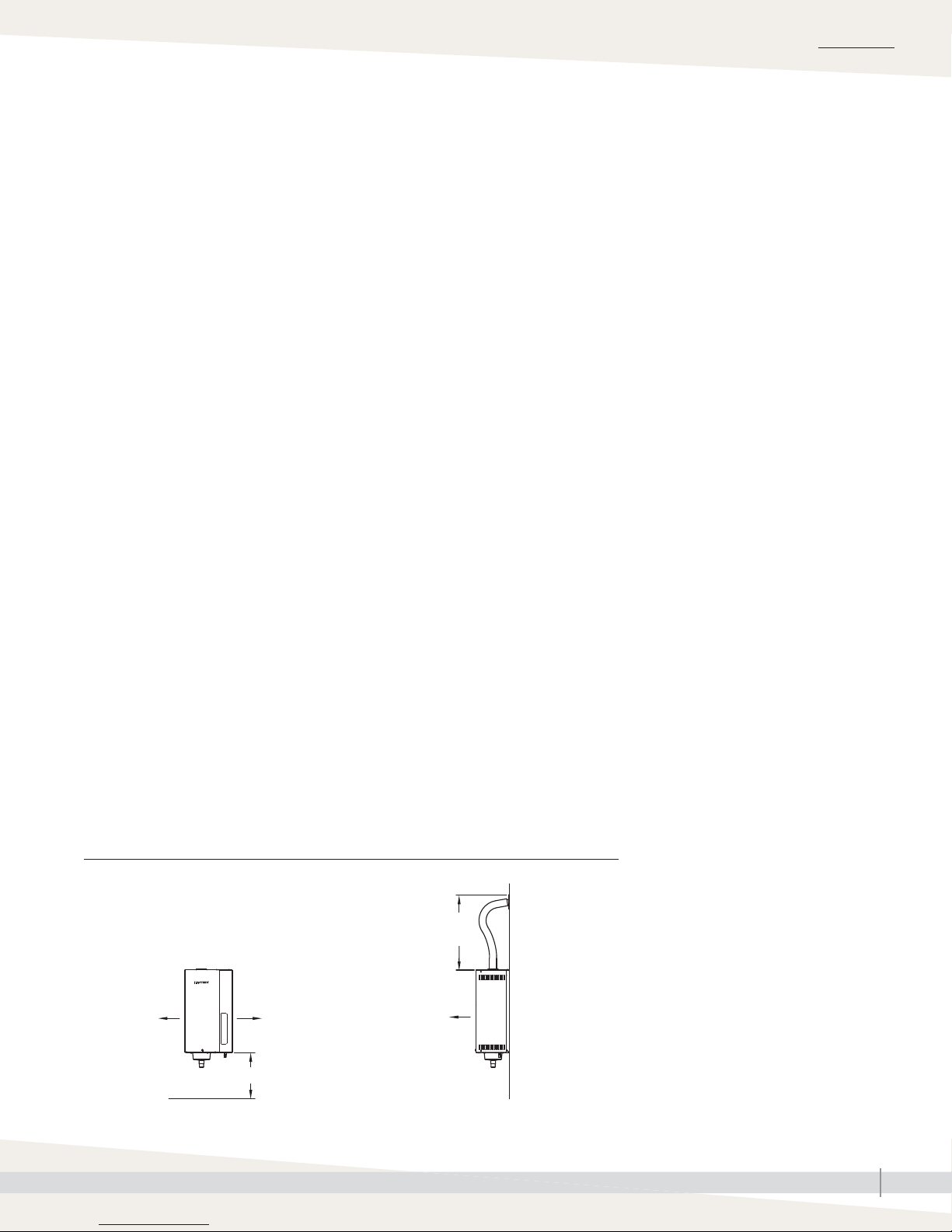

FIGURE 7-1: XTR HUMIDIFIER RECOMMENDED MINIMUM CLEARANCES

Side

4" (102 mm)

Front

16" (406

mm) for

electrical

clearance

16" (406 mm)

for steam hose

30" (762 mm)

for service

access

16" (406 mm) for drain

90-1702X

mc_050712_1405

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

7

INSTALLATION

Mounting

REMOVING COVERS AND STEAM CYLINDER

1. Unpack humidifier from shipping carton, and remove front cover by

removing screw and lifting cover up and away from humidifier.

2. If any wires are connected to top cylinder, pull straight up on plugs to

disconnect them from pins.

3. Remove cylinder and any packaging from inside of humidifier cabinet.

4. Remove two screws on right side of humidifier and remove side cover to

expose electrical compartment.

WALL MOUNTING HUMIDIFIER

The XTR humidifi er weighs 23 lbs (10.5 kg) with a full cylinder. Make sure the

mounting system will support its weight. Secure humidifi er to sturdy wall or to

sheet metal duct. If mounting to stud frame wall:

1. Install two spanner boards spanning two studs. Position top spanner board

so it will align with top of cabinet, and center bottom spanner board on

bottom mounting holes. See mounting holes in Figure 8-1.

WARNING

Mounting hazard

Mount humidifi er per the instructions

in this manual and to a structurally

stable surface. Improper mounting of

the humidifi er can cause it to fall or tip,

resulting in severe personal injury or

death.

mc_060110_1540

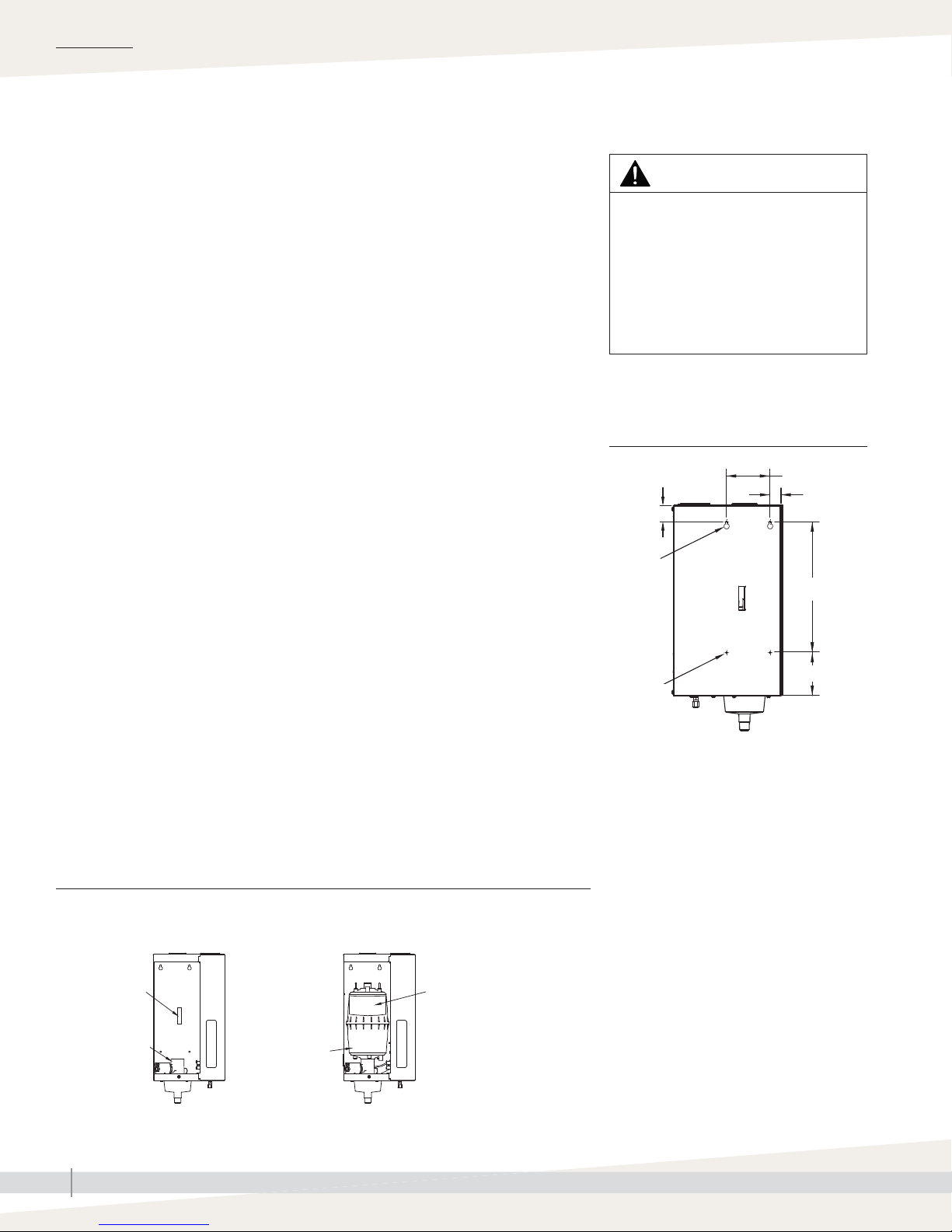

FIGURE 8-1: XTR HUMIDIFIER

MOUNTING HOLES

1-1/2" (38 mm)

4" (102 mm)

1" (25 mm)

2. Predrill holes in spanner boards, and secure humidifier to spanner boards

with screws provided.

Note: Use appropriate mounting methods and mounting hardware for other

mounting surfaces.

INSTALLING STEAM CYLINDER

1. Verify that O-ring is in place in slot of drain body. See Figure 8-2.

2. Use water to lubricate drain outlet on bottom of cylinder and O-ring in

drain valve body. Do not use oil, grease or any lubricant.

3. Insert cylinder drain outlet into drain valve body, and rotate cylinder so

Warning label is visible.

4. Attach the two electrode wires (they are interchangeable) and high water

sensor wire to pins on top of cylinder. Make sure plugs fit snugly and are

fully engaged on pins.

FIGURE 8-2: XTR STEAM CYLINDER INSTALLATION

Front view of cabinet

without cylinder

Front view of cabinet

with cylinder installed

Mounting

keyholes

Mounting

holes

90-1701-dims

mc_050712_1404

12" (305 mm)

4" (102 mm)

Cylinder guide

Drain valve body

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

Cylinder

Warning label

OM-7721

INSTALLATION

Piping:

SUPPLY WATER QUALITY

Supply water and drain

XTR humidifi ers use tap water to generate humidifi cation steam. Recommended

supply water conductivity for DriSteem electrode humidifi ers is 125 to 1250

μS/cm (roughly comparable to water hardness of 3 to 36 grains per gallon).

Do not use demineralized water. Do not use heated supply water, because

unheated supply water is required for drain water tempering.

SUPPLY WATER PIPING

Use only copper for supply water piping—do not use rubber or plastic. The fi ll

valve connection size is a 1/4" (DN8) compression fi tting.

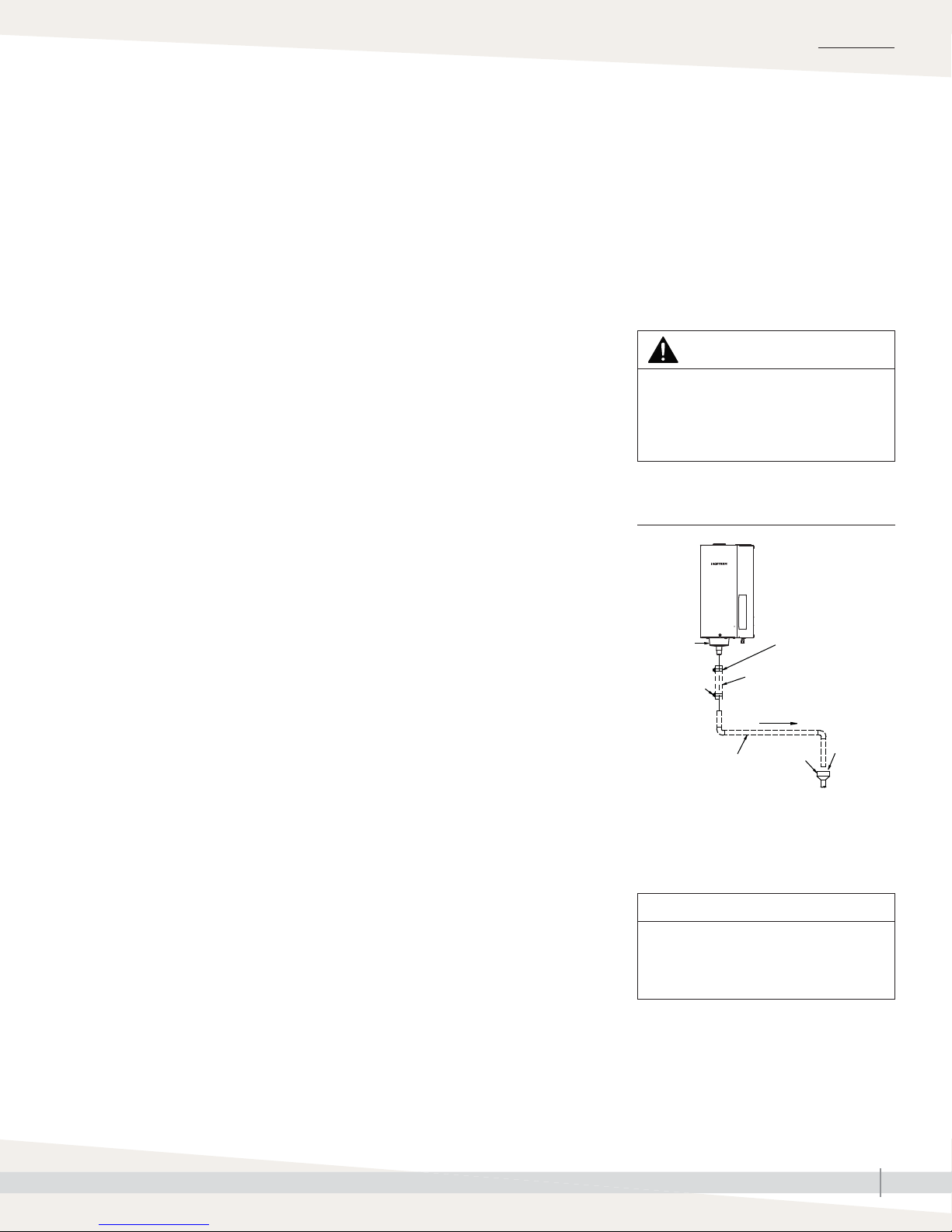

HUMIDIFIER DRAIN PIPING

Drain piping must be code-approved copper or steel rated for 212 °F (100 °C)

minimum. The fi nal connection size is 3/4" (DN20) copper for the steam

cylinder drain. Do not reduce this connection size. See Figure 9-1.

If drainage by gravity is not possible, use a condensate pump rated for 212 °F

(100 °C) water.

ACTIVATING AUTOMATIC DRAIN WATER TEMPERING

The XTR humidifi er is shipped with drain water tempering set to OFF. To

activate automatic drain water tempering, locate the DIP switch #4 on the

control board, and place it in the ON position as shown in Figure 15-1.

Note: Control board location is shown in Figure 42-1.

Important:

Thoroughly fl ush the supply water piping

to remove pipe residue and stagnant water

before connecting piping to the humidifi er.

Pipe residue and stagnant water in the water

supply piping can cause foaming, preventing

the humidifi er from reaching the required steam

capacity.

WARNING

Hot drain pipes

Drain piping surface may be hot.

Touching or contact with hot pipe may

cause severe personal injury.

FIGURE 9-1: DRAIN PIPING DETAIL

Drain cup

Hose clamp

(fi eld supplied)

Hose clamp

(fi eld supplied)

Black rubber hose

Pitch 1/8"/ft (1%) toward drain

OM-7499X

3/4" (DN20) copper

Note: Dashed lines indicate provided by

installer.

mc_050812_1111

Open

drain

1"

(25 mm)

air gap

CAUTION

To prevent drain steam from

condensing on the cabinet, do not

install the drain under the humidifi er.

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

INSTALLATION

Piping:

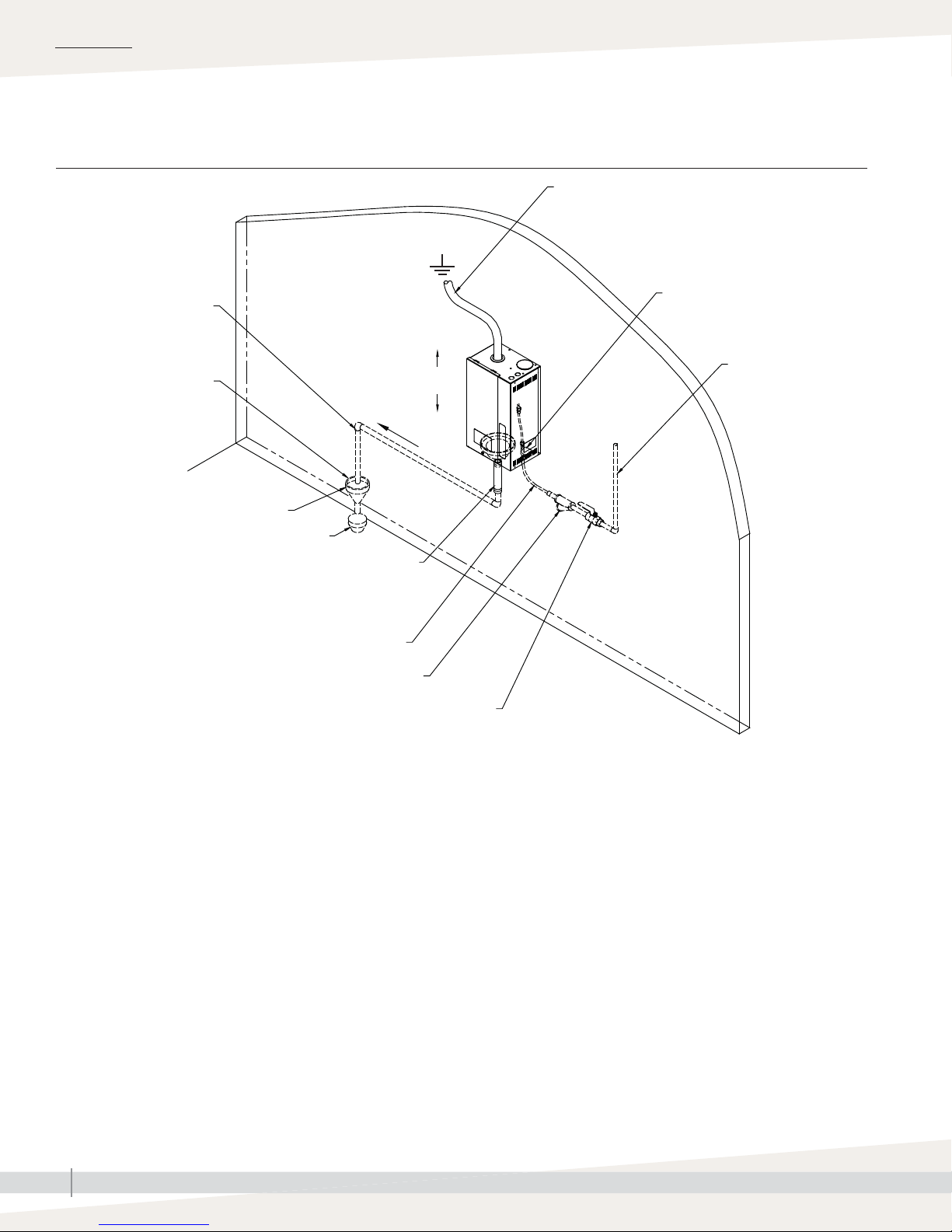

FIGURE 10-1: XTR HUMIDIFIER FIELD PIPING OVERVIEW

3/4" (DN20) metallic drain

piping. If piping run is over

10' (3 m) increase pipe to

1¼" (DN32).

1" (25 mm) air gap required

Open drain required. Locate air gap only in

spaces with adequate temperature and air

movement to absorb fl ash steam, or condensing

could occur on nearby surfaces. Refer to

governing codes for drain pipe size and

maximum discharge water temperature.

Field piping overview

Spill funnel; plumb to fl oor drain

Pitch 1/8”/ft (1%) toward drain

Install plumb

Hose and

clamps

Steam hose; may also use tubing. See Table 20-1 for

maximum lengths. Tubing must be grounded.

Fill valve (with screen)

Continuous copper

water supply line; water

pressure must be 25 to

80 psi (175 to 550 kPa)

1/4" (DN8) O.D. copper line

Inlet strainer, by installer

Note: Dashed lines indicate provided by installer.

mc_050812_1110

Supply valve, by installer

OM-7722

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

INSTALLATION

Piping:

FIGURE 11-1: PIPING CONNECTIONS TO XTR STEAM BLOWER

XTR steam blower and XTR fan pack

XTR steam blower mounted remotely XTR steam blower mounted directly on top of XTR humidifi er

Hose clamp (supplied with

Hose clamp (supplied with

humidifi er)

Steam hose, 6' (1.8 m) long

(supplied with humidifi er)

Hose clamp (supplied with

humidifi er)

OM-7723

mc_050912_1130

steam blower)

Steam hose (supplied with

steam blower)

Hose clamp (supplied with

humidifi er)

OM-7724

FIGURE 11-2: PIPING CONNECTIONS TO XTR FAN PACK

Fan pack

Steam hose

(provided with humidifi er)

XTR humidifi er

Condensate drain

hose, 3/8" ID

(provided with fan

pack)

To drain

Note: Dashed lines indicate provided by installer.

mc_050912_1131

Grille

(front of fan pack)

Wall

90-1551

XTR humidifi er drain

Back view of fan packSide view of wall

90-1560

Condensate drain

hose connection

Steam hose connection

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

INSTALLATION

Field wiring

All wiring must be code approved and in accordance with the unit wiring

diagram. Power supply wiring must be rated for 220 °F (105 °C). See Figure

12-1 for the humidifi er wiring diagram location.

When selecting a location for installing the humidifi er:

• Avoid areas close to sources of electromagnetic emissions such as power

distribution transformers.

• Do not loop power wiring.

• Do not use aluminum wire.

CONDUIT KNOCKOUTS

Conduit knockouts are provided on top and bottom of the cabinet. Control

wiring knockouts are toward the top front; power wiring knockouts are on the

top rear.

WARNING

Electric shock hazard

Only qualifi ed electrical personnel

should perform fi eld wiring installation

procedures. Improper wiring or contact

with energized circuits may cause

property damage, severe personal

injury, or death as a result of electric

shock and/or fi re.

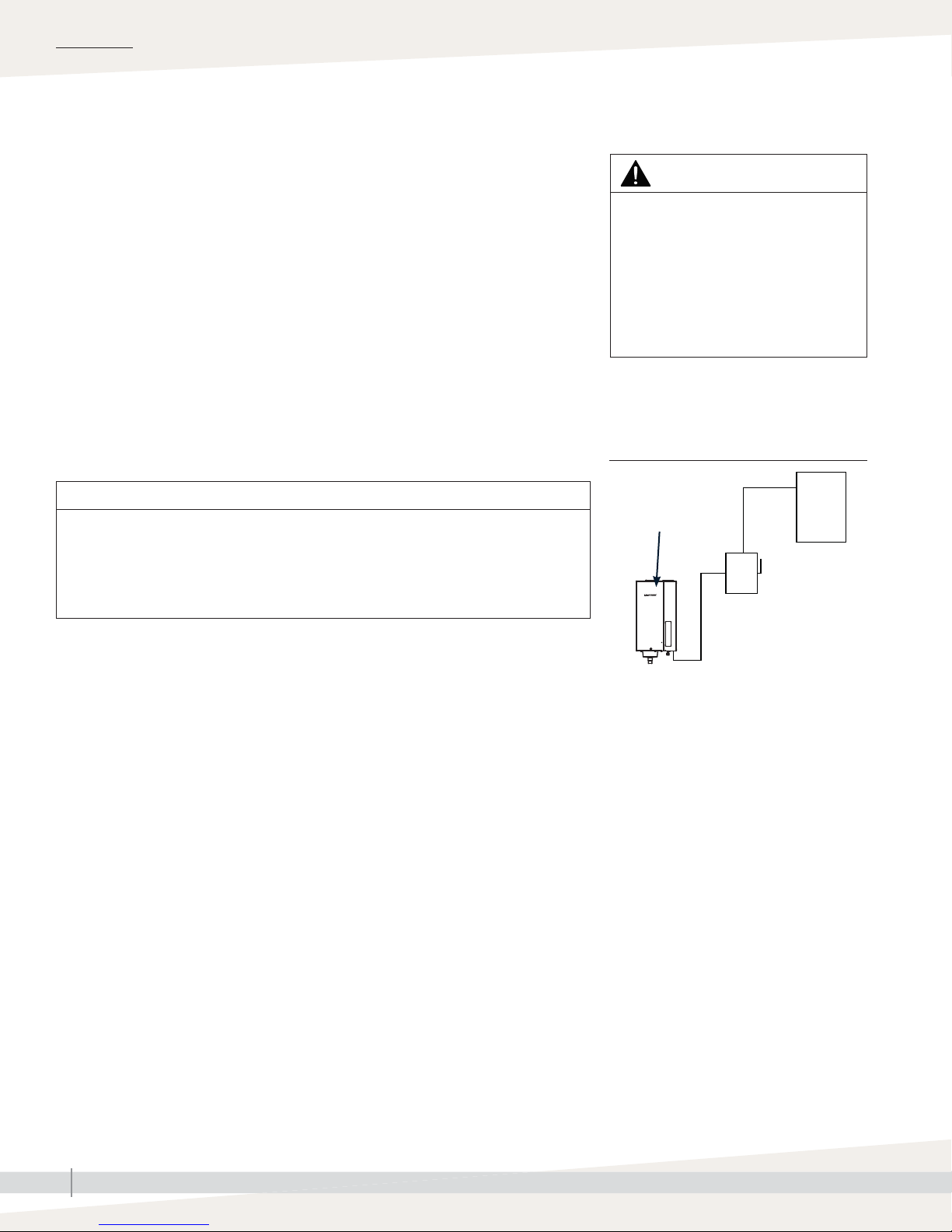

FIGURE 12-1:

FIELD WIRING REQUIREMENTS

CAUTION

Adding conduit connections not recommended

Adding alternate conduit connections is not recommended. If you must make

additional holes in the humidifi er cabinet, protect all internal components from

debris, and vacuum out the cabinet when fi nished. Failure to follow these precautions

can damage sensitive electronic components and void the DriSteem warranty.

FIELD WIRING CONNECTION INSTRUCTIONS

• Connect to line power.

XTR humidifi er is shipped confi gured for 230V or 240V. To confi gure for

120V or 208V, refer to wiring diagram on humidifi er subpanel and inside

of humidifi er side cover.

See Table 5-1 and the data plate on outside of cabinet for nominal current

draw, maximum line current, and recommended fusing.

• Connect to control signal wiring from a humidistat. See note below.

• Connect to duct airfl ow proving switch and duct high limit humidistat wiring

(recommended optional devices). See note below.

Note: See recommended control wiring in Figure 14-1.

Wiring diagram

inside of front cover

Power supply

Fused disconnect

OM-7692X

XTR humidifi er

Notes:

• Control wiring and power wiring must be

run in dedicated or separate earthed metal

conduit, cable trays, or trunking.

• Separate line-voltage wiring from low-voltage

control circuit wiring when routing electrical

wiring inside humidifi er cabinet.

• Do not use chassis or safety grounds as

current-carrying commons. Never use a

safety ground as a conductor or neutral to

return circuit current.

• For circuit protection requirements, see

recommended fusing in Table 5-1.

XTR INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

Loading...

Loading...