DriSteem Vapormist, Vapormist DI Installation, Operation And Maintenance Manual

READ AND SAVE THESE INSTRUCTIONS

®

VAPORMIST and

VAPORMIST DI

ELECTRIC STEAM HUMIDIFIERS

Installation, Operation

and

Maintenance Manual

For toll-free technical support

call 1-800-328-4447

TABLE OF CONTENTS

To the purchaser and installer

Thank you for purchasing our VAPORMIST® humidifier. We have designed and built this equipment to give you

complete satisfaction and trouble-free service for many years. Familiarizing yourself with this manual will help

ensure proper operation of the equipment for years to come.

This manual covers the installation and maintenance procedures for both the VAPORMIST and VAPORMIST DI

humidifiers.

DRI-STEEM Humidifier Company

General information

Product overview ................................................................. 3

Dimensions .......................................................................... 4

Electrical specifications, capacities and weights ................. 5

Installation

Locating and mounting the humidifier .................................. 6

Piping ................................................................................... 6

Wiring .................................................................................. 9

Dispersion

Using space distribution units (SDU-E and SDU-I) ..... 10

Using Single Tubes ..................................................... 13

Using a RAPID-SORB® dispersion panel .................... 15

Drip tee installation ..................................................... 16

Interconnecting piping tables ...................................... 17

Operation

Start-up procedures ........................................................... 18

Control ............................................................................... 19

Maintenance

Maintenance procedures ................................................... 20

Troubleshooting guide ....................................................... 23

Replacement parts ............................................................ 25

Notes ................................................................................. 31

Warranty ........................................................................... 32

2

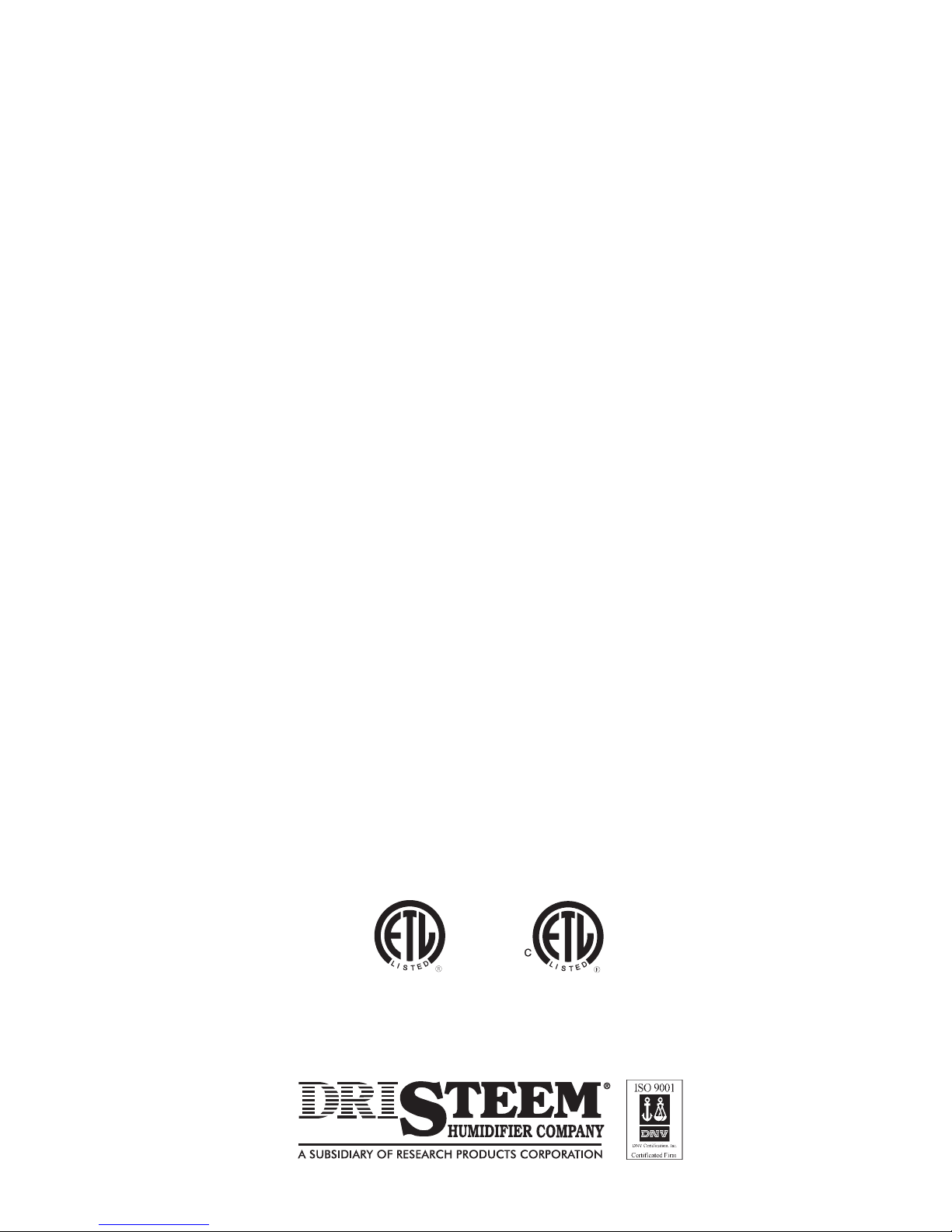

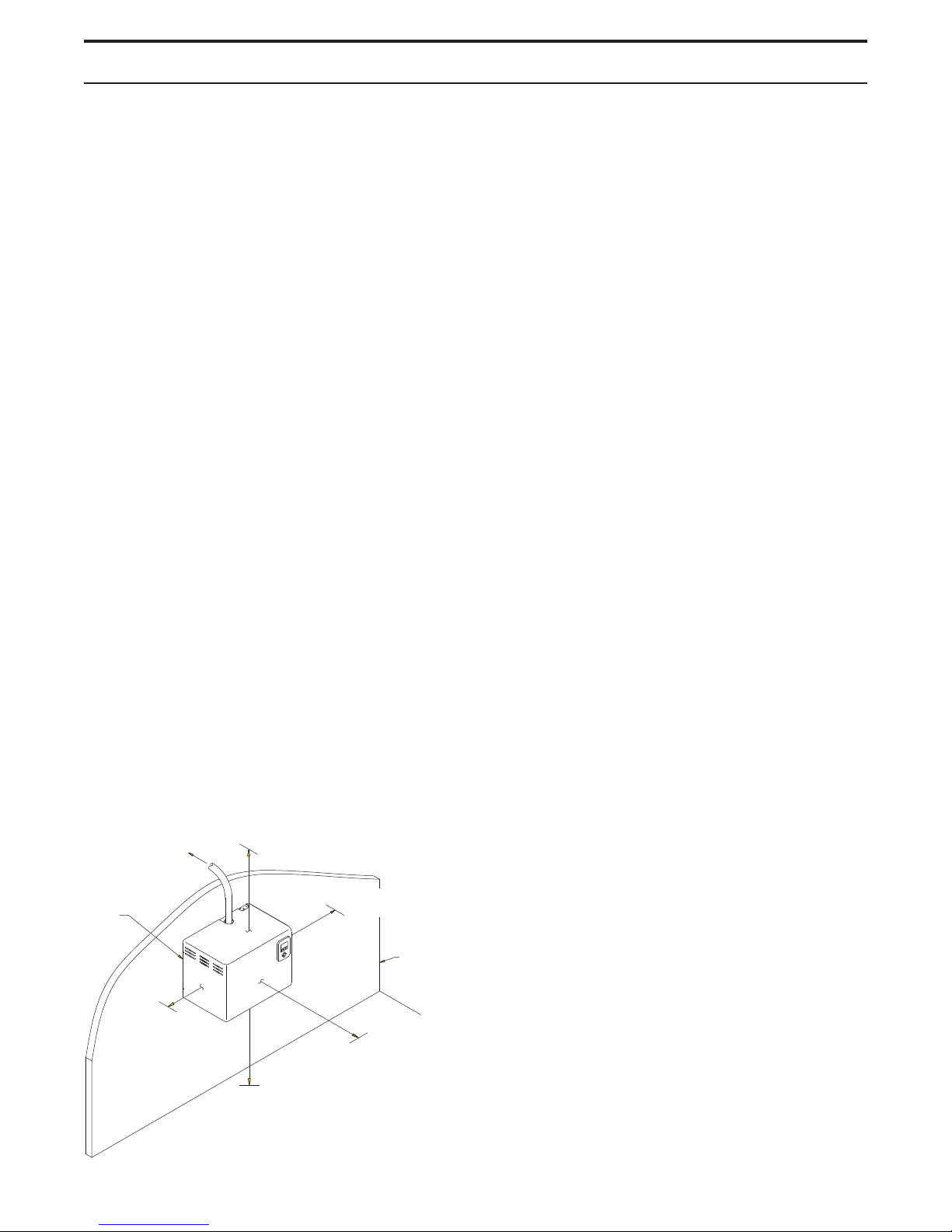

VAPORMIST® HUMIDIFIER OVERVIEW

Standard water models (VAPORMIST)

The standard water VAPORMIST unit requires

water conductivity of at least 100 µS/cm

(2 grains/gallon) to operate. It will not

operate with water treated

by reverse osmosis or

deionization processes

(see DI water model

below).

1½" (DN40) or 2" (DN50) flexible

vapor hose, pipe or tubing connects

to dispersion tube(s) or to an SDU

Water fill ¼" NPT (female)

Keyholes for

wall mounting

Water fill access hole

¾" NPT (DN20)

coupling, skimmer port

and overflow drain

Electrical conduit

knockouts

Removable

evaporating

chamber

Duct

Electrical area

INCOLOY alloy-sheathed

immersion heaters

Condensate

return line

Slide assembly under evaporating chamber

provides easy removal for cleaning

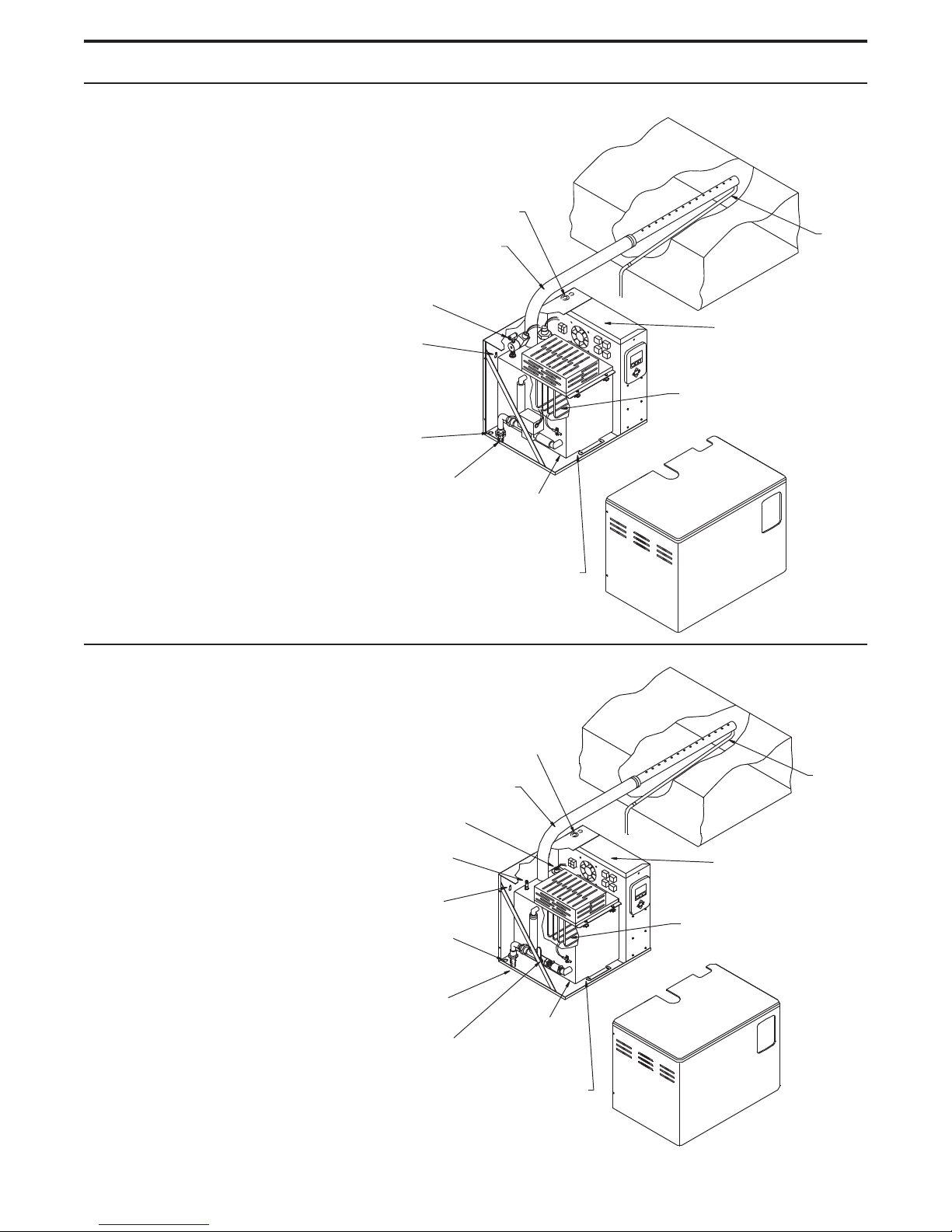

Deionized water models (VAPORMIST DI)

The VAPORMIST DI, shown here, is specifically

designed for use with deionized or reverse osmosis

water.

1½" (DN40) or 2" (DN50) flexible

vapor hose, pipe or tubing connects

to dispersion tube(s) or to an SDU

Float cutoff switch

Water fill ¼" NPT (female)

Keyholes for

wall mounting

Water fill access hole

¾" NPT (DN20) coupling,

skimmer port and overflow drain

Electrical

conduit

knockouts

OM-82-4

Duct

Electrical area

INCOLOY alloy-sheathed

immersion heaters

Condensate

return line

Removable

Ball valve

Slide assembly under

evaporating chamber provides

easy removal for cleaning

evaporating

chamber

OM-82-5

3

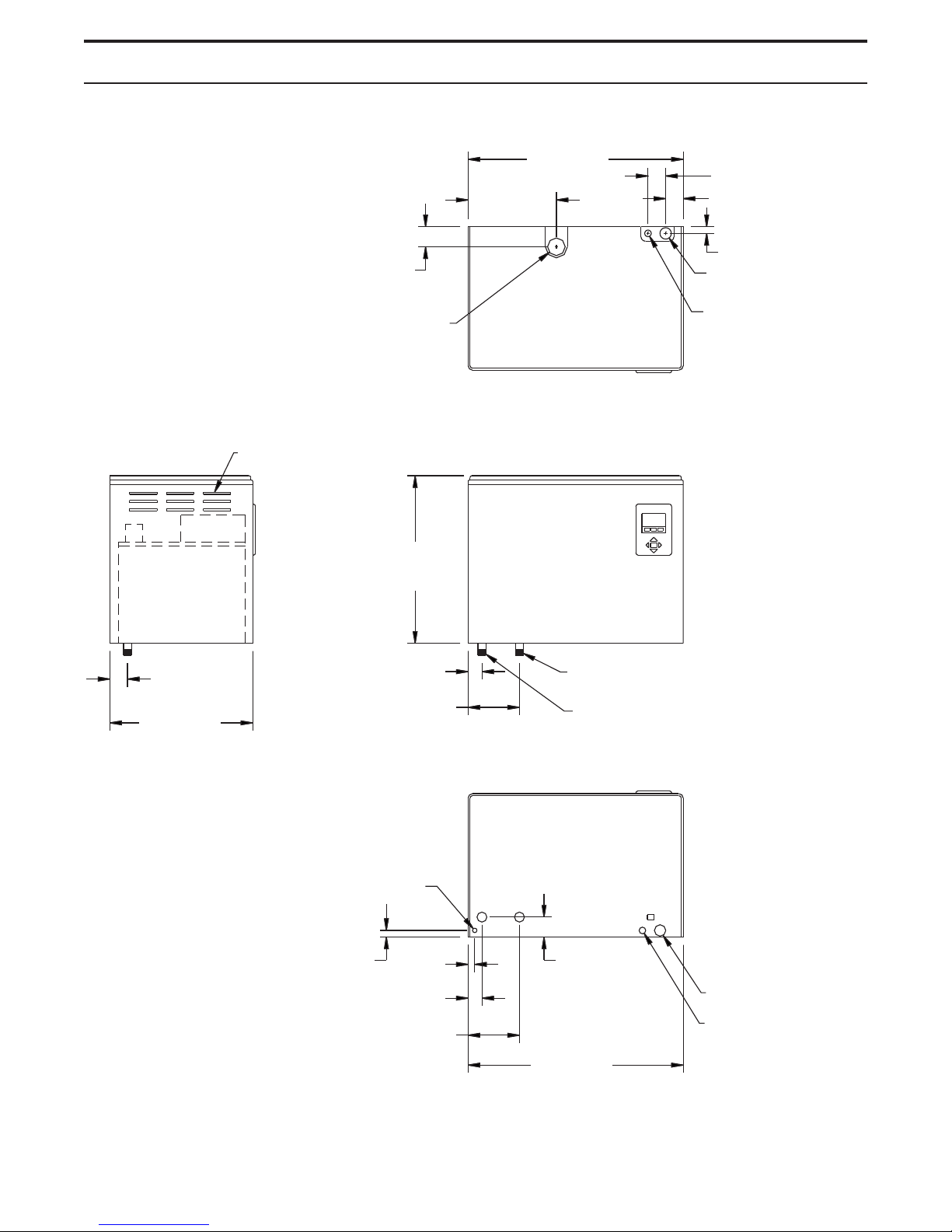

VAPORMIST® DIMENSIONS

Left side view

Venting

Top view

2.25" (57 mm)

Steam outlet

Front view

18.6"

(472 mm)

10.9"

(276 mm)

24.2"

(614 mm)

2" (50 mm)

2" (50 mm)

1" (25 mm)

Power wiring

knockout

Control or SDU

wiring knockout

2.25" (57 mm)

16.1"

(409 mm)

1.50" (38 mm)

5.75" (146 mm)

Bottom view

0.50" (13 mm) hole in

base for water fill line

0.75" (19 mm)

1.50" (38 mm)

5.75" (146 mm)

0.63"

(16 mm)

¾" NPT (DN20) frame drain

¾" NPT (DN20) tank drain

2.25" (57 mm)

Power wire

knockout

Control wiring

knockout

24.2"

(614 mm)

4

DC-1167

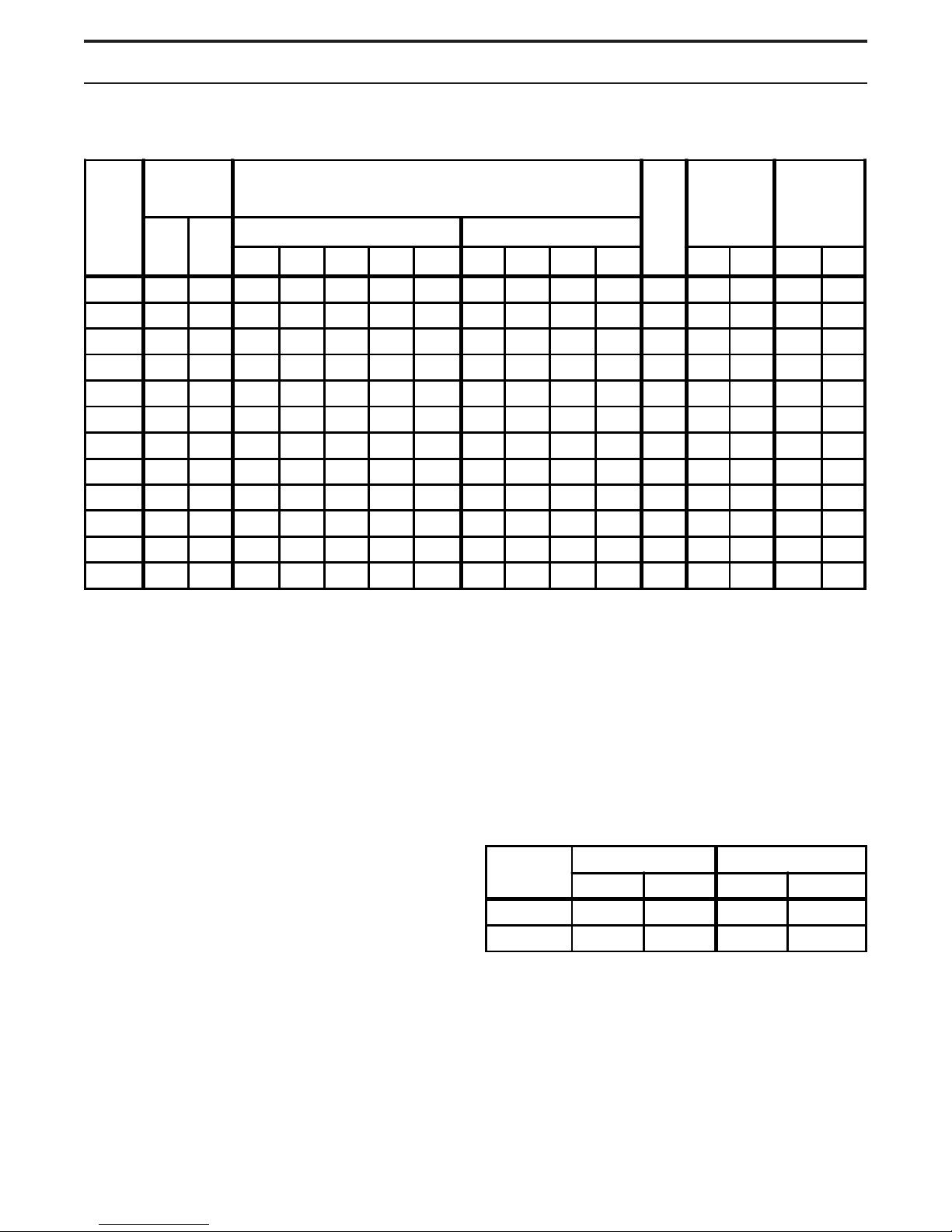

VAPORMIST specifications

VAPORMIST® SPECIFICATIONS

VM

model

number

2 6 2.7 16.7 9.6 8.3 4.2 3.3 -- -- -- -- 2 80 36 95 43

4 12 5.4 33.3 19.2 16.7 8.3 6.7 16.7** 14.4** 7.2** 5.8** 4 80 36 95 43

6 18 8.2 -- 28.8 25.0 12.5 10.0 25.0** 21.7** 10.8** 8.7** 6 88 40 122 55

8 24 10.9 -- 38.5 33.3 16.7 13.3 33.3** 28.9** 14.4** 11.5** 8 88 40 122 55

10 30 13.6 -- -- 41.7 20.8 16.7 29.1** 25.3** 12.6** 10.1** 10 93 42 139 63

12 36 16.3 -- -- -- 25.0 20.0 33.3 28.9 14.4 11.5 12 93 42 139 63

14 42 19.1 -- -- -- 29.2 23.3 38.9 33.7 16.8 13.5 14 93 42 139 63

16 48 21.8 -- -- -- 33.3 26.7 44.4 38.5 19.2 15.4 16 93 42 139 63

21 63 28.6 -- -- -- 43.8 35.0 -- -- 25.3 20.2 21 95 43 152 69

25 75 34.0 -- -- -- -- 41.7 -- -- 30.1 24.1 25 95 43 152 69

30 90 40.9 -- -- -- -- -- -- -- 36.1 28.9 30 101 46 156 71

34 102 46.3 -- -- -- -- -- -- -- 40.9 32.7 34 101 46 156 71

Steam

capacity

lbs/hr kg/h Single-phase Three-phase

120V 208V* 240V* 480

Table notes:

* On 208V/240V/single-phase/three-wire and on

208V/three-phase/four-wire supplies, the neutral

line provides a separate 120V circuit for the SDU

fan unit.

** For wire sizing, the highest leg draw is shown due

to current imbalance.

† Add the following to VAPORMIST weights if using

an SDU option:

Current draw (amps) kW Shipping

†

600V †208V* 240V †480V †600V

†

weight ‡

lbs kg lbs kg

Notes about SDUs (Space Distribution Units):

• The SDU-I is available for models VM-2 through VM-8,

and all VM-10 models except those using 240V, threephase power with SSR control.

• The SDU-E is available for all VAPORMIST models

except those models using 240V/480V/600V/threephase power with the SSR control option and

drawing more than 21.7 amps.

• SDUs ship separately from the VAPORMIST.

– SDU-I: 12 lbs (5.5 kg)

– SDU-E: 9 lbs (4 kg)

Note: These weights are for additional control

components housed within the VAPORMIST

cabinet. See the SDU weights table at right for SDU

weights (shipped separately).

‡ Add the following if using the SSR option:

– For single-phase or three-phase models drawing

SDU weights

SDU

model

SDU-I 68 31 58 26

SDU-E 61 28 51 23

Shipping weight Operating weight

lbs kg lbs kg

less than 21.7 amps, add 2 lbs (1 kg)

– For three-phase models drawing more than

21.7 amps, add 4 lbs (2 kg)

All VAPORMISTs operate at 50/60 Hz.

Operating

weight ‡

5

VAPORMIST® MOUNTING AND PIPING

Locating and mounting the humidifier

The VAPORMIST humidifier is designed to attach to

the wall with lag bolts, and it should be installed in a

space located near an air duct system, unless using a

Space Distribution Unit (SDU) for dispersion.

Consider the following when selecting the location of

the humidifier:

• Convenient access to duct

• Electrical and plumbing connections

• Required clearances

• External water seal requirements

Electrical power supply, water makeup piping and drain

piping must also be considered. Electrical power

supply connections are made at the lower or upper

right rear corner of the unit. Water makeup and drain

piping connections are made at the lower left rear

corner.

When mounting on a stud wall (studs 16" [406 mm] on

center), locate studs and position lag bolts in place so

that each of the bolts will center on a stud. Mark hole

locations and predrill ¼" (6 mm) diameter pilot holes

using mounting template on the VAPORMIST box.

Secure frame to wall with lag bolts provided.

VAPORMIST piping

Water makeup piping may be of any code-approved

material (copper, steel, or plastic). The final connection

size is ¼" NPT (DN8). In cases where water hammer

may be a possibility, a shock arrestor should be

considered. Water pressure must be between 25 psi

and 80 psi (175 kPa and 550 kPa).

Drain piping may be of any code-approved material

(copper, steel, or plastic rated for 212 °F [100 °C]

minimum). If drainage by gravity is not possible, use a

small pump (DRI-STEEM Part No. 400280).

The final connection size is ¾" NPT (DN20) for tank

and frame drains. This connection size should not be

reduced. (See the drawings on the following pages for

proper drain piping configurations.) The tank drain

should be piped separately from the frame drain, as

shown, to prevent backflow of drain water into the

humidifier cabinet.

Install a union in the water supply line as shown in

the drawings on the next two pages to allow tank

removal.

For hollow block or poured concrete wall mounting,

position template in place and mark the holes. Drill

appropriate pilot holes for two 3/8" (10 mm) toggle

bolts or two 3/8" (10 mm) machine bolt lead anchors.

Secure frame in place.

Clearance recommendations

For recommended service and maintenance purposes,

maintain the following clearances:

Top (when SDU is not

mounted directly above the

To dispersion

unit

Secured to

supporting

wall

Left side:

12" (305 mm)

VAPORMIST): 18" (460 mm)

Right side electrical

controls: 36" (915 mm)

Supporting

wall

Front: 36" (915 mm)

Floor: 24" (610 mm)

6

DC-1201

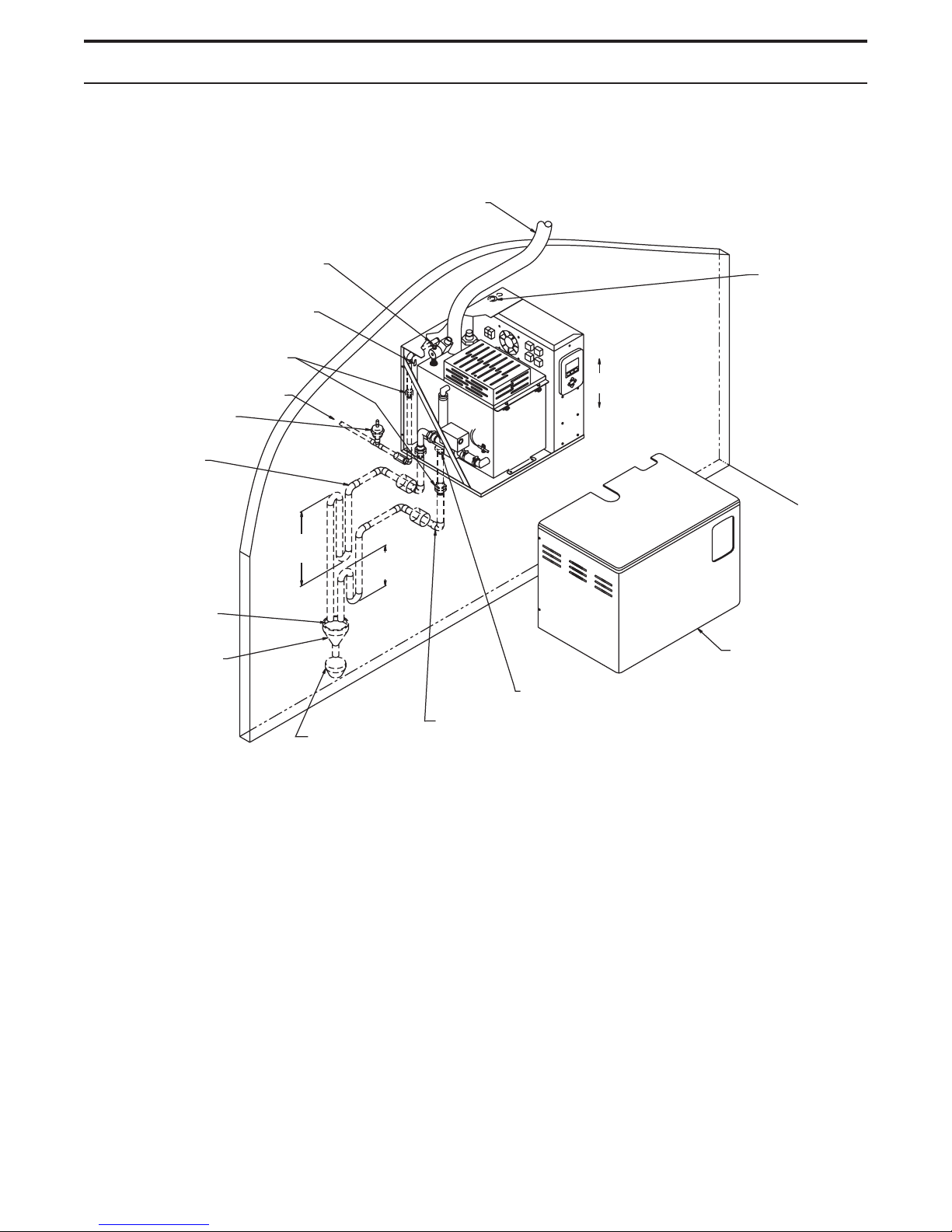

VAPORMIST® PIPING

VAPORMIST (standard water) field piping overview

Steam vapor hose

¼" NPT (DN8) connection to water

supply line; water pressure must be

between 25 psi and 80 psi (175 kPa

and 550 kPa); water conductivity

minimum 2 grains/gallon (100 µS/cm)

Two keyholes for wall

mounting, 16" (406 mm)

on center

Unions by installer

Water supply line

Shock arrester

recommended to

reduce water hammer

¾" NPT (DN20) tank

drain, skimmer and

P-trap piping, rated

for 212 °F (100 °C).

If piping run is over

10' (3 m) increase

pipe to 1¼" (DN32)

after P-trap.

12"

(300 mm)

(maximum run 10' [3 m]).

May also use pipe or

tubing.

2" (50 mm)

Install plumb

Electrical conduit

knockouts provided

top and bottom:

• Combination, for

½" and ¾"conduit

connectors (knockout diameters

22.3 mm and

28.6 mm)

• Combination, for

¾" and 1" conduit

connectors (knockout diameters

28.6 mm and

34.9 mm)

1" (25 mm) air gap

Spill funnel.

Plumb to

floor drain

Open floor drain.

Refer to local codes

for drain pipe size

and maximum

temperature

requirements.

Frame drain

¾" NPT (DN20)

frame drain and

P-trap piping, rated

for 212 °F (100 °C)

Cover

Notes:

• Offset humidifier from spill funnel or floor drain to prevent flash steam from rising into the cabinet.

• Dashed lines indicate provided by installer.

• The water supply inlet is more than 1" (25 mm) above the skim/overflow port, eliminating the possibility

of backflow or siphoning from the tank. No additional backflow prevention is required, however, local

codes prevail.

• Install a union in the water supply line as shown to allow tank removal.

DC-1136

7

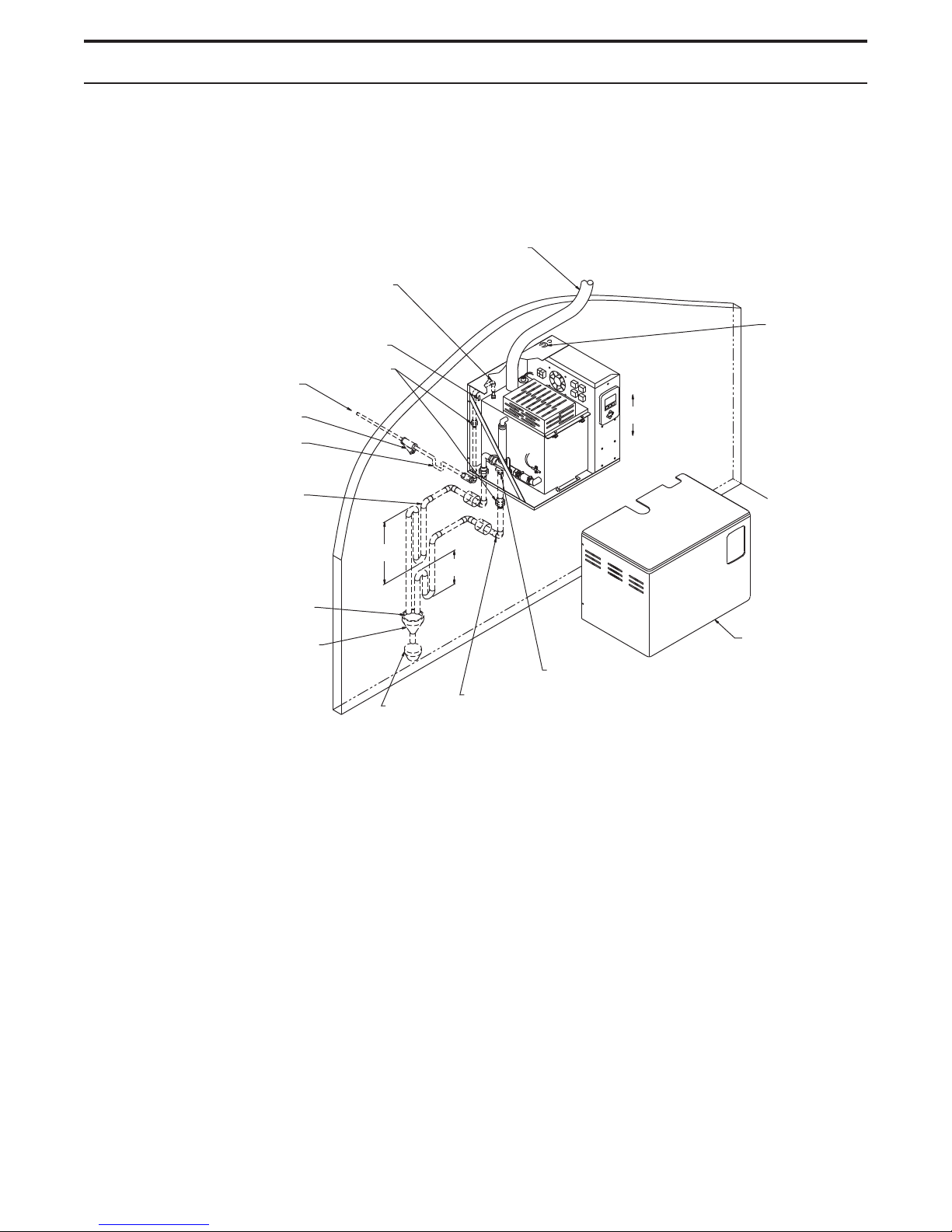

VAPORMIST® PIPING

VAPORMIST DI (deionized/reverse osmosis water) field piping overview

¼" NPT (DN8) connection to water

supply line; water pressure must be

between 25 psi and 80 psi (175 kPa

and 550 kPa); water chloride content

must be less than 3 ppm; first

3' (1 m) of supply line must be

rated for 212 °F (100 °C)

Two keyholes for

wall mounting, 16"

(406 mm) on center

Water supply line

Strainer,

by installer

If water piping to humidifier is non-metallic,

we recommend a 2" (50 mm) water seal in

the supply line to isolate steam during

DI/RO water system maintenance

¾" NPT (DN20) tank drain and P-trap

piping, rated for 212 °F (100 °C);

if piping run is over 10' (3 m)

increase pipe to 1¼" (DN32)

after P-trap

1" (25 mm) air gap

Spill funnel.

Plumb to

floor drain

Unions by

installer

12"

(300 mm)

Open floor

drain. Refer

to local codes for drain

pipe size and maximum

temperature requirements.

Steam vapor hose

(maximum run 10'

[3 m]). May also use

pipe or tubing

2" (50 mm)

¾" NPT (DN20)

frame drain and

P-trap piping, rated for

212 °F (100 °C)

Frame drain

Install plumb

Electrical conduit

knockouts provided

top and bottom:

• Combination, for

½" and ¾"conduit

connectors (knockout diameters

22.3 mm and

28.6 mm)

• Combination, for

¾" and 1" conduit

connectors (knockout diameters

28.6 mm and

34.9 mm)

Cover

DC-1139

Notes:

• Offset humidifier from spill funnel or floor drain to prevent flash steam from rising into the cabinet.

• Dashed lines indicate provided by installer.

• The water supply inlet is more than 1" (25 mm) above the overflow port, eliminating the possibility of backflow

or siphoning from the tank. No additional backflow prevention is required, however, local codes prevail.

• Install a union in the water supply line as shown to allow tank removal.

8

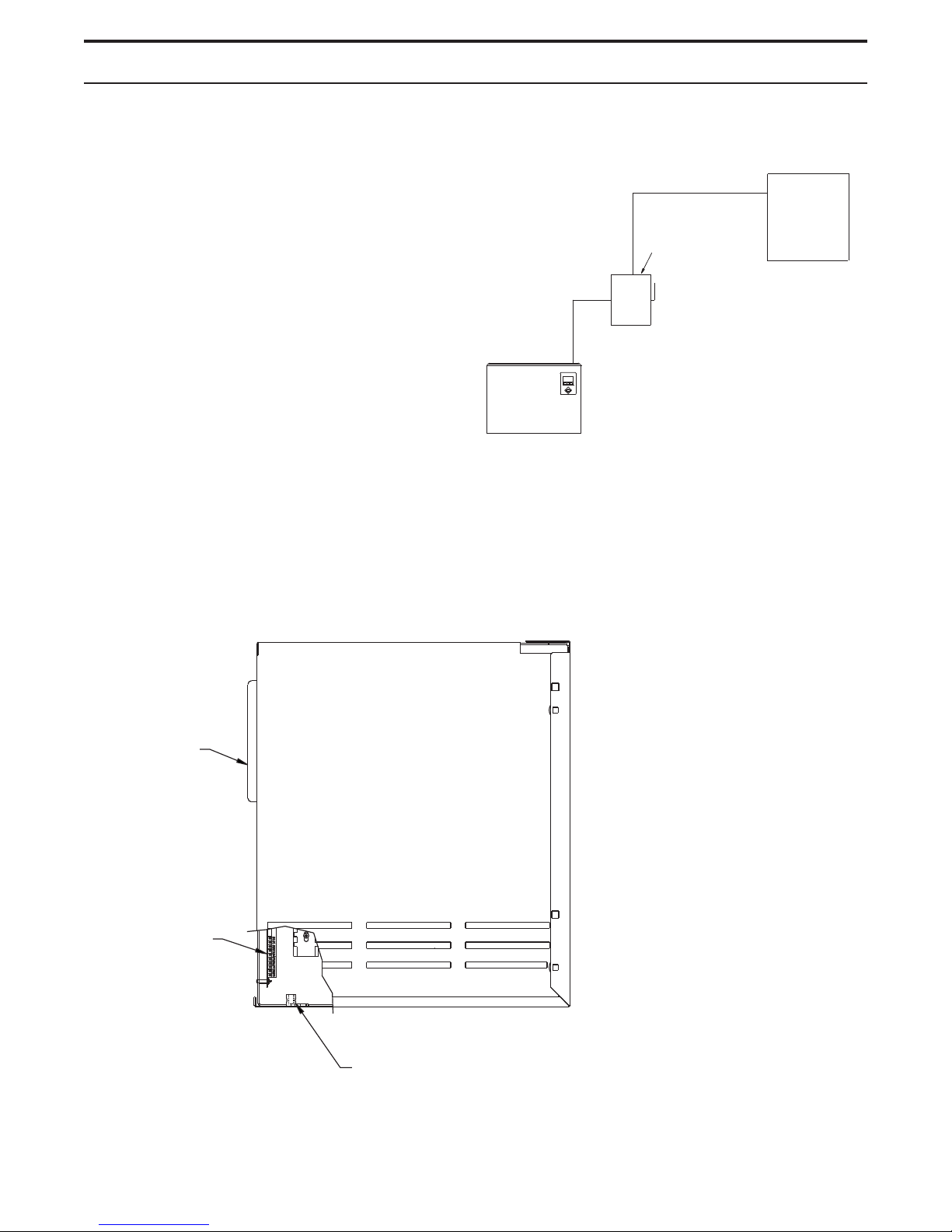

VAPORMIST®WIRING

VAPORMIST wiring

All wiring must be in accordance with all governing

codes, and with the VAPORMIST or VAPORMIST DI

wiring diagram. The diagrams are located inside the

removable subpanel cover on the right side of the

humidifier cabinet. Power supply wiring must be rated

for 105 °C.

When selecting a location for installing the

VAPORMIST, avoid areas close to sources of

electromagnetic emissions such as power distribution

transformers.

The use of semiconductor fusing sized per the National

Electric Code is recommended with the SSR option.

Grounding requirements

The earth must be made by solid metal to metal

connections. The ground must be a good radio

frequency earth. Ground wire should be same size as

power wiring.

Shielded/screened cable drain wire connection to lug

Field wiring requirements

Power supply

Fused disconnect

(provided by

installer)

(provided by

installer)

OM-1007

Note: Control wiring and power wiring must be run in

dedicated or separate earthed metal conduit, cable

trays or trunking.

VAPOR-LOGIC

keypad on front of

cabinet

Microprocessor

board

3

Right side view of VAPORMIST

OM-1505

Shield/screen ground lug

Note: For maximum EMC effectiveness, all humidity, temperature, and airflow controls should be wired using

multicolored shielded/screened plenum-rated cable with a drain wire for the shield/screen. The drain wire should

be connected to the shield/screen ground terminal with its length kept to less than 2".

9

VAPORMIST® DISPERSION

SDU-I:

Provides instant, internal absorption

The Space Distribution Unit Internal Absorption

(SDU-I) disperses humidity with no visible vapor trail

or wetness, making the VAPORMIST® with an SDU-I

ideal for use in finished spaces. When room RH is 45%

or less, the SDU-I fan mixes room air and steam to

ensure complete absorption before discharge as

humidified air. The SDU-I is available for models VM-2

through VM-8, and all VM-10 models except those

using 240 V, three-phase power with SSR control.

SDU-E:

For higher capacity units

The Space Distribution Unit External Absorption

(SDU-E) is designed for higher capacity dispersion.

The SDU-E is available for all VAPORMIST models

except those models using 240V/480V/600V/threephase power with the SSR control option and drawing

more than 21.7 amps.

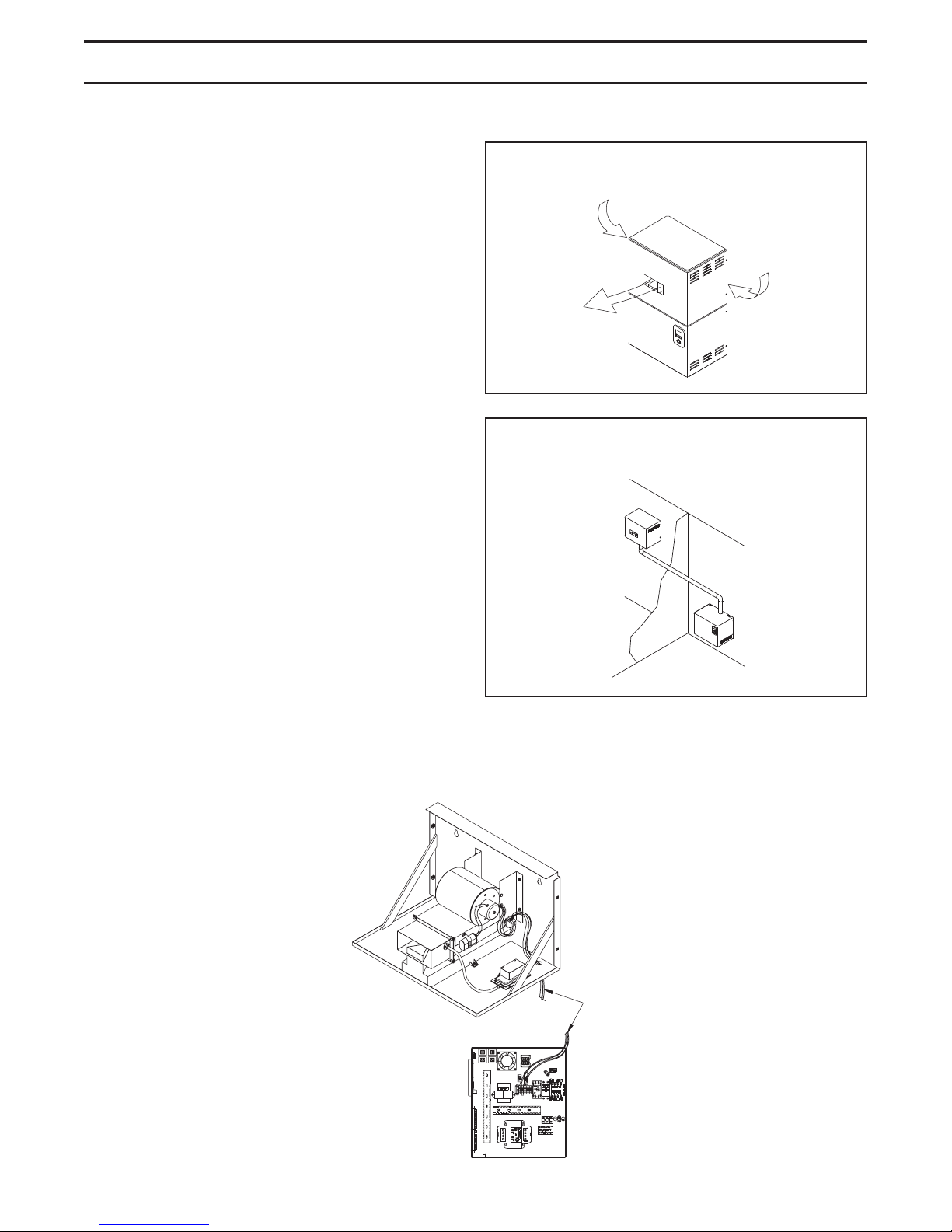

Mounting the SDU-I and SDU-E

Both SDUs may be mounted on a wall directly above

the VAPORMIST cabinet or mounted on a wall remote

from the VAPORMIST. Use the mounting template on

the box for correct placement. Two lag bolts are

provided with each fan unit.

The SDU can be mounted directly

above the VAPORMIST.

Air

intake

vents

Steam

outlet

OM-55-1

The SDU can be mounted remotely

from the VAPORMIST.

Note: See the following pages for more information

about SDU-I and SDU-E.

SDU field wiring

OM-56-1

SDU-E

Field wiring for

fan and airflow

proving switch

VAPORMIST

Electrical panel

right side view

10

OM-921

Loading...

Loading...