DriSteem Ultra-sorb LV, Ultra-sorb LH Installation, Operation And Maintenance Manual

Ultra-sorb

Steam Dispersion Tube

Humidifier Panel

®

Installation, Operation,

and Maintenance Manual

For applications using steam from

a boiler or from any DRI-STEEM

steam generating humidifier.

Table of contents

Overview

Unpacking High-eciency tubes ...........................3

Field assembly of Model LH ...............................4

Field assembly of Model LV ...............................7

Installation

Selecting the location ...................................... 10

Determine humidier placement ............................11

Installation in a cold air stream .............................12

Mounting in a horizontal duct ..............................13

Mounting in a vertical duct ................................14

Installation inside an air handling unit .......................15

Supply and drain connections and dimensions ................16

Piping ................................................... 17

Mounting ...............................................19

Retrofitting an existing Ultra-sorb ..........................20

Performance data .........................................22

Maintenance

Maintenance .............................................23

Troubleshooting guide .....................................24

Replacement parts ........................................26

Warranty .........................................Back cover

Page 2 • DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual

Unpacking High-efficiency tubes

NOTE: If you have an Ultra-sorb without High-efficiency

dispersion tubes (non-insulated tubes), please skip to the next

page.

Unpacking

• Remove the dispersion assembly from the shipping container; be

careful not to bump or scrape the PVDF insulating material on

the dispersion tubes.

• Some dispersion panels are shipped unassembled by customer

request or by shipping necessity. Do not lay High-efficiency tubes

across or under anything that could compress or damage the

insulating material. Compressed insulating material has a reduced

R-value.

• Avoid bumping or snagging the PVDF insulating material.

Although PVDF is robust, rough handling can cause tears, which

could negatively impact performance.

•

Before start-up, remove the clear poly film by tearing it along the

perforation.

Do not use a knife or sharp object to remove the poly

film.

CAUTION!

The High-efficiency tubes are sleeved in clear poly

film for protection during processing, shipping,

and installation.

To prevent dirty insulating material, leave the clear

poly film on until installation is complete.

Equally important, remove and discard the clear

poly film before start-up by tearing it along the

perforations.

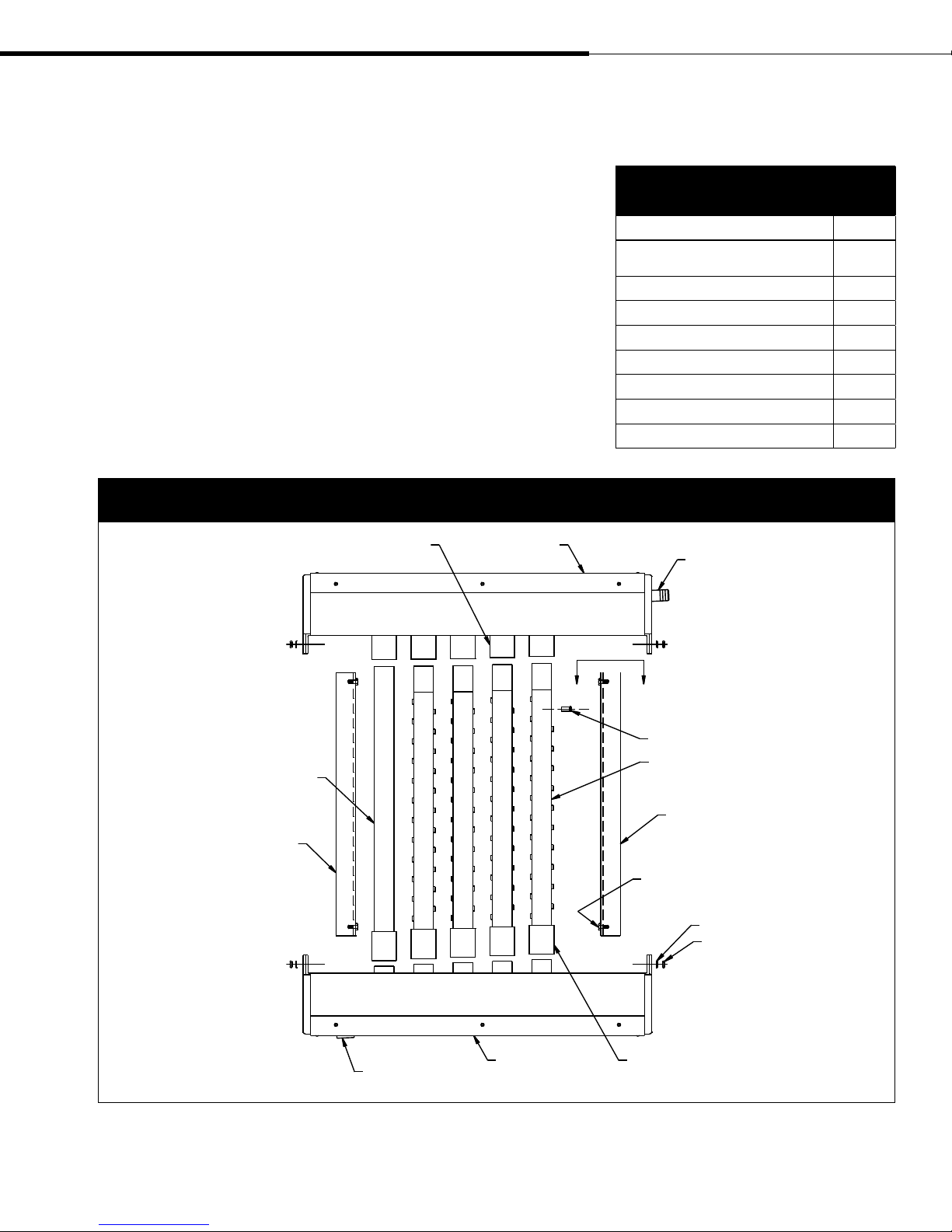

Figure 3-1:

Ultra-sorb with the High-efficiency

Tube option

High-efficiency Tube option

Ultra-sorb dispersion assemblies with the

High-efficiency Tube option are designed to

produce significantly less dispersion-generated

condensate and airstream heat gain, which

reduces wasted energy by up to 85%. These

improvements are accomplished by reducing

the thermal conductivity of the tubes with

1/8" of polyvinylidene fluoride (PVDF)

insulating material on the outside of the tubes.

These assemblies require careful unpacking,

installation, and handling. If your dispersion

assembly has the High-efficiency Tube option,

be sure to read this section carefully.

DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual • Page 3

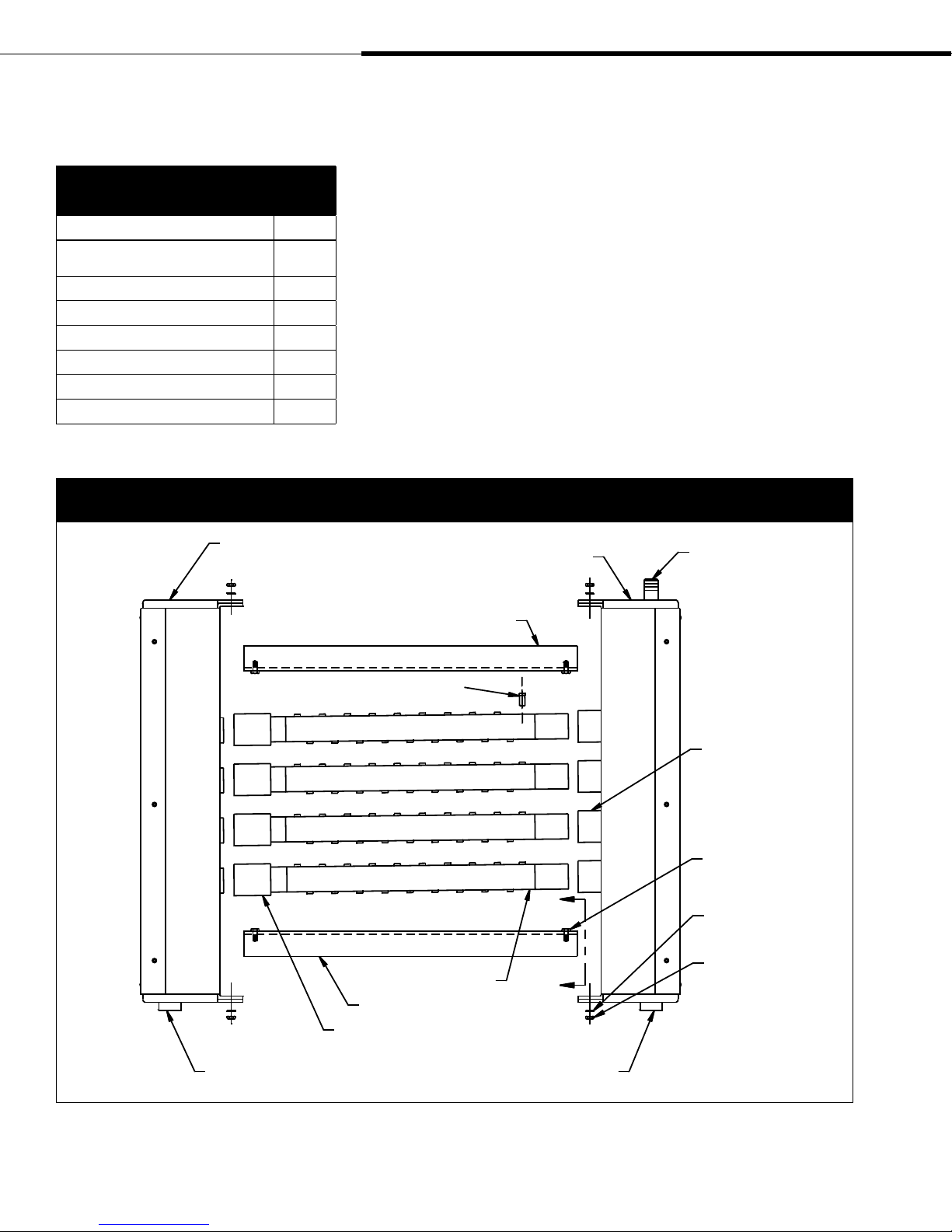

Field assembly of Model LH

Table 4-1:

Ultra-sorb Model LH components

Description Qty.

Supply header assembly with shouldered

slip couplings

Condensate header assembly 1

Mounting flange 2

Dispersion tubes with slip couplings varies

¼ - 20 x ¾" bolt 8

¼ - 20 nut 8

¼ lock washer 8

1

Figure 4-1:

Ultra-sorb Model LH

Condensate header assembly

Please read instructions while assembling

STEP 1 - Unpack

Unpack the Ultra-sorb components and verify that you have all

items on the packing list.

Note that both the supply header assembly and the condensate

header assembly have a ¾" half coupling drain connection on one

end. This will be the lower end of the installed dispersion assembly.

The supply header assembly has a steam inlet (nipple or tubing) on

the end opposite the drain connection.

Arrange the components on a large, flat working surface,

positioning them as indicated in Figure 4-1 (condensate header to

the left, supply header to the right).

Supply header assembly

Mounting flange

Steam inlet

¾" pipe thread coupling

(DN 20) drain connection

Tubelet

Dispersion tube

Mounting flange

Slip coupling without shoulder

¾" pipe thread coupling

(DN 20) drain connection

Slip coupling

with shoulder

¼" - 20 nut (8)

Washer (8)

¼" - 20 nut (8)

OM-238-1

Page 4 • DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual

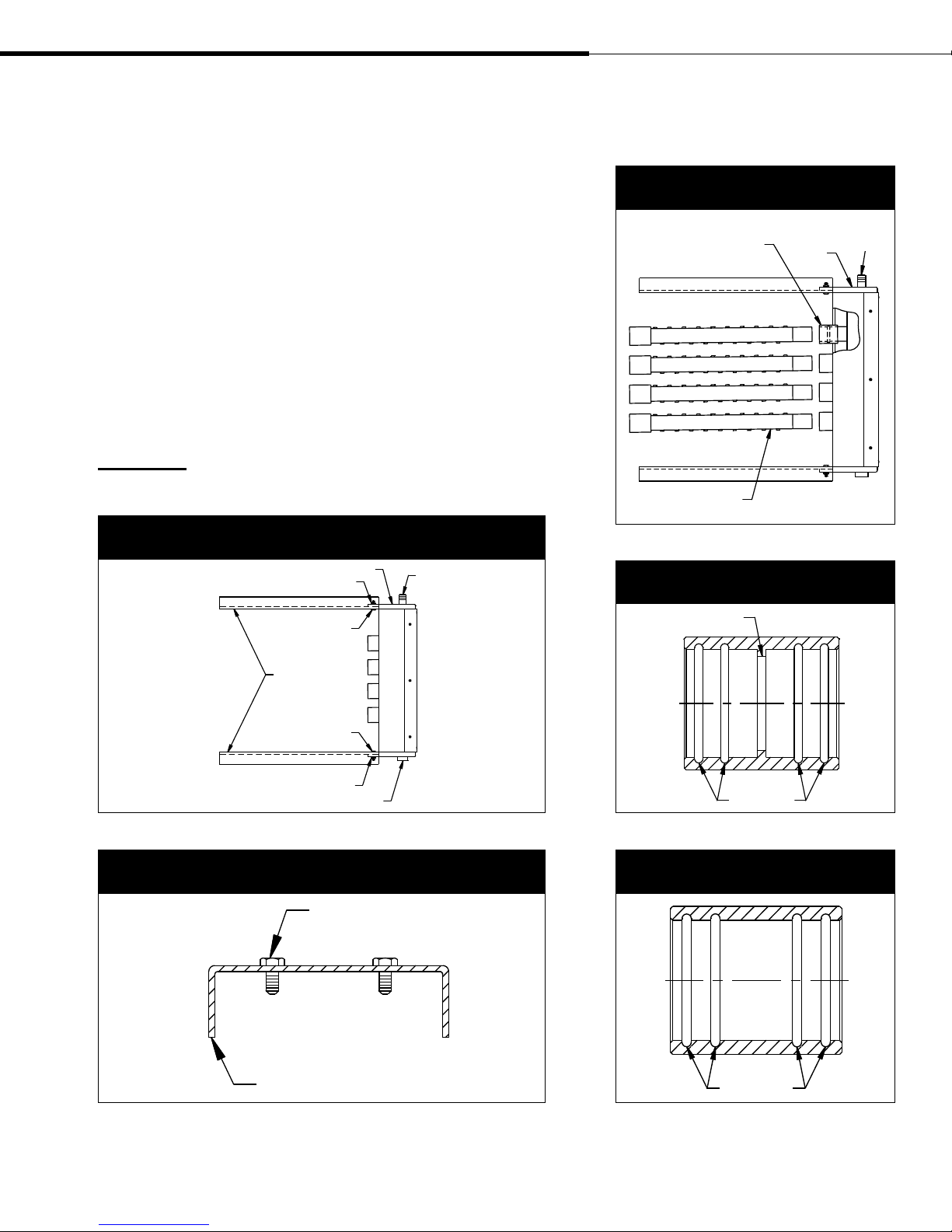

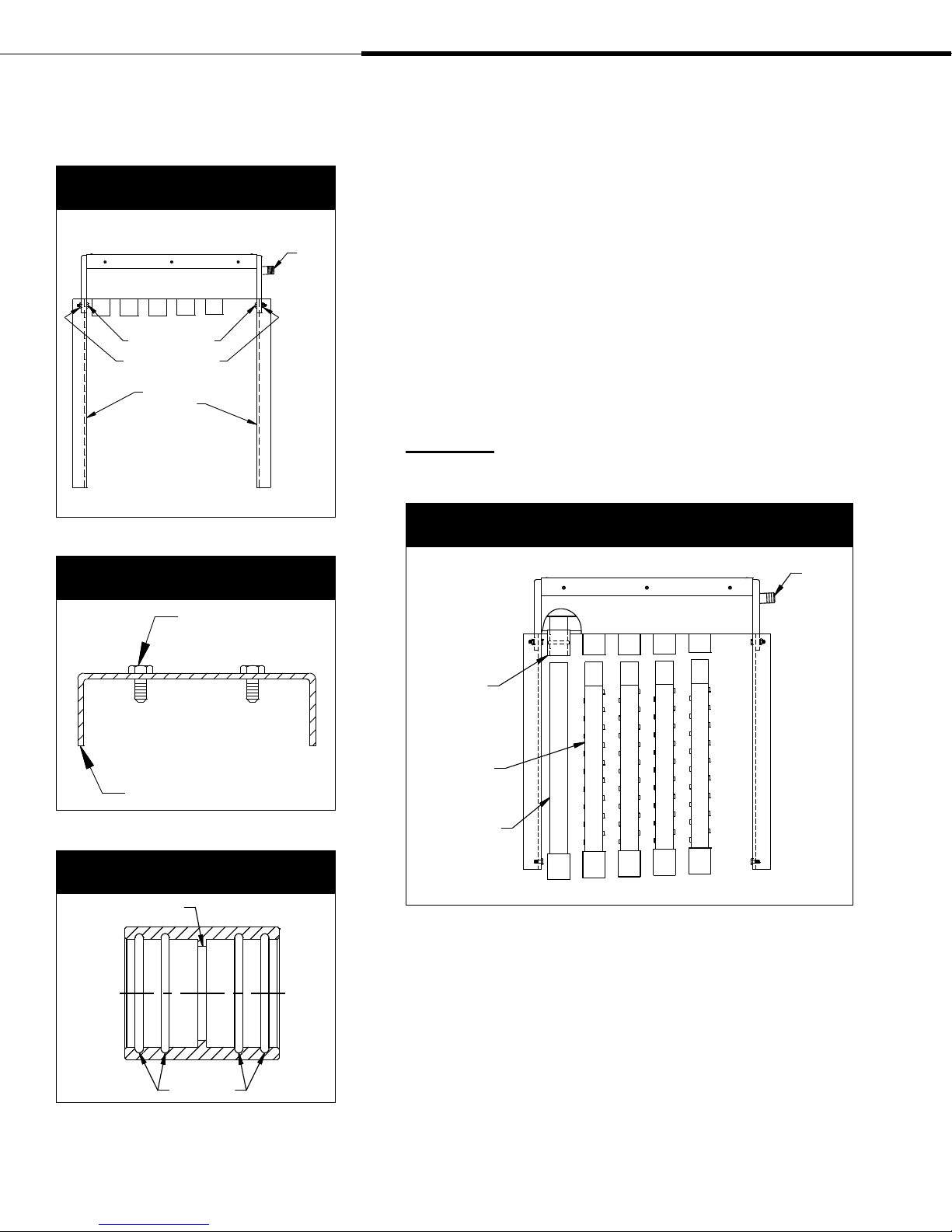

Field assembly of Model LH

STEP 2 - Bolt the mounting flanges to the supply header

assembly

Refer to Figure 5-1 and 5-2.

Attach the two mounting flanges to the supply header assembly as

indicated using ¼" - 20 bolts with the nuts finger tight.

STEP 3 - Insert the dispersion tubes

Refer to Figure 5-3. Insert the plain ends (no slip couplings)

of the dispersion tubes into the slip couplings already mounted

on the supply header assembly. The slip couplings are factory

lubricated; if well aligned during insertion, no further lubrication

should be needed. Push and twist the tube in until it bottoms out

on the internal shoulder of the slip coupling (see Figure 5-4).

CAUTION! Use care to avoid cutting the internal O-rings of the

slip couplings.

Figure 5-1:

Supply header assembly

Supply header assembly

Washer and nut

¼" - 20 bolt

Steam inlet

Figure 5-3:

Dispersion tubes

Slip coupling with shoulder

Dispersion tube

Supply header

assembly

Figure 5-4:

Slip coupling with shoulder

Shoulder

Steam

inlet

OM-238-3

Mounting flange

¼" - 20 bolt

Washer and nut

Drain connection

Figure 5-2:

Detail view of mounting flange

Mounting flange

¼" - 20 bolts

OM-238-2

OM-239

O-rings

Figure 5-5:

Slip coupling without shoulder

O-rings

OM-238-6

OM-238-7

DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual • Page 5

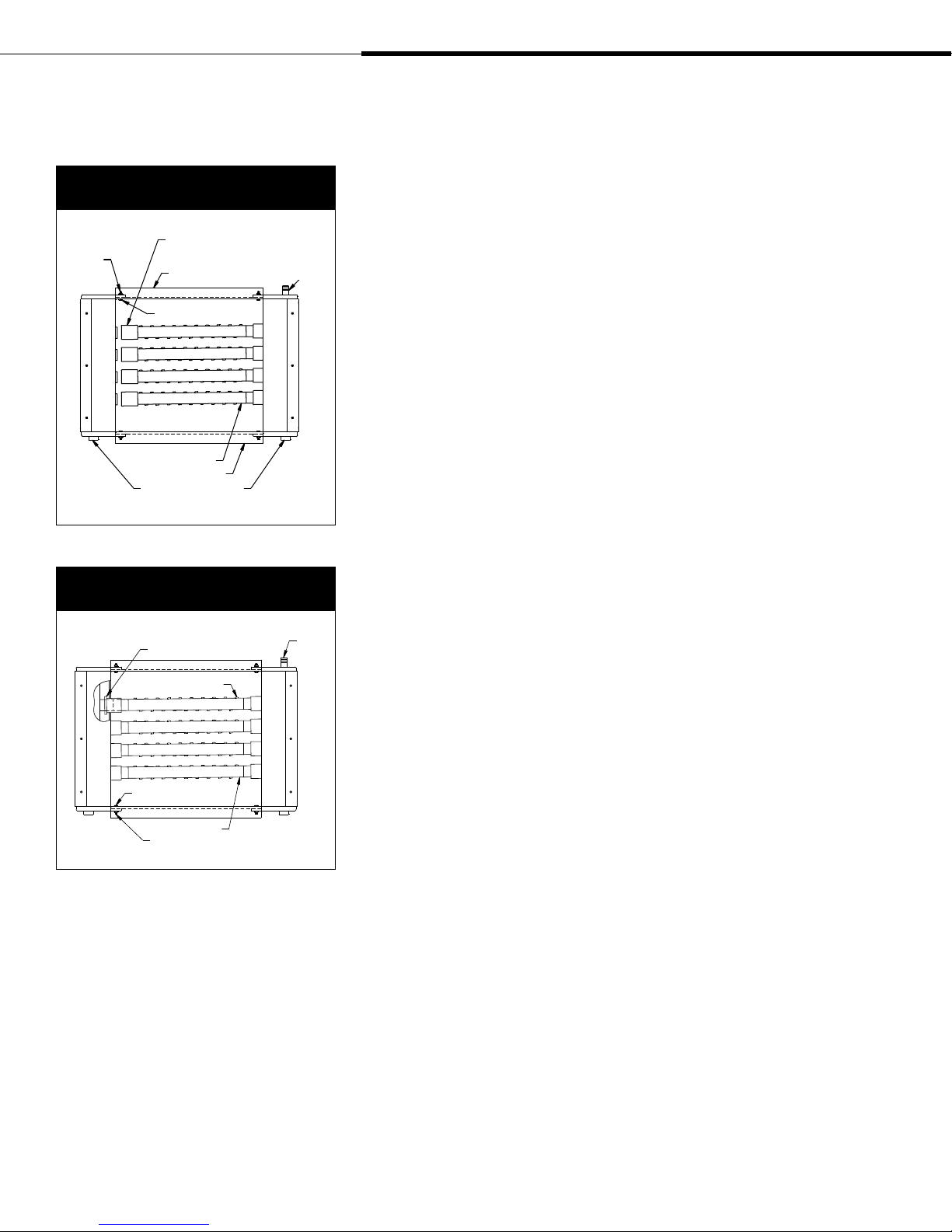

Field assembly of Model LH

Figure 6-1:

Condensate header assembly

Align coupling (without shoulder)

Washer

and nut

Condensate header assembly

flush with end of dispersion tube

Mounting flange

¼" - 20 bolt

Dispersion tube

Mounting flange

Drain connection

Figure 6-2:

Slip coupling placement

Stop disc

Steam

inlet

Supply header assembly

OM-238-4

Steam

inlet

STEP 4 - Bolt the mounting flanges to the condensate header

assembly

Refer to Figure 6-1. Push the slip couplings onto the dispersion

tubes flush with the tube ends. Make sure the drain connection is

properly oriented. Attach the mounting flanges using

¼" - 20 bolts,

and leave the nuts finger tight.

STEP 5 - Slide the slip couplings onto the condensate header assembly and orient the tubelets

SUGGESTION: Gripping the drain connection with vise grip pliers

and applying a back and forth rolling motion to the header will

assist in sliding the slip couplings into place.

Refer to Figure 6-2. It may be necessary to push and twist the

slip couplings onto the condensate header. Again care must be

taken to avoid cutting the internal O-rings. Slide the slip couplings

on until they bottom out against the stop disc on the condensate

header. The steam tubelets must be aimed so that they discharge the

steam perpendicular to the airstream. Rotate the dispersion tubes as

needed.

After tightening the ¼" - 20 bolts at all 4 corners, the Ultra-sorb

panel is ready for installation. See page 10.

Tubelet

Condensate header assembly

¼" - 20 bolt (8)

Dispersion tube

Nut and washer (8)

Supply header assembly

OM-238-5

Page 6 • DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual

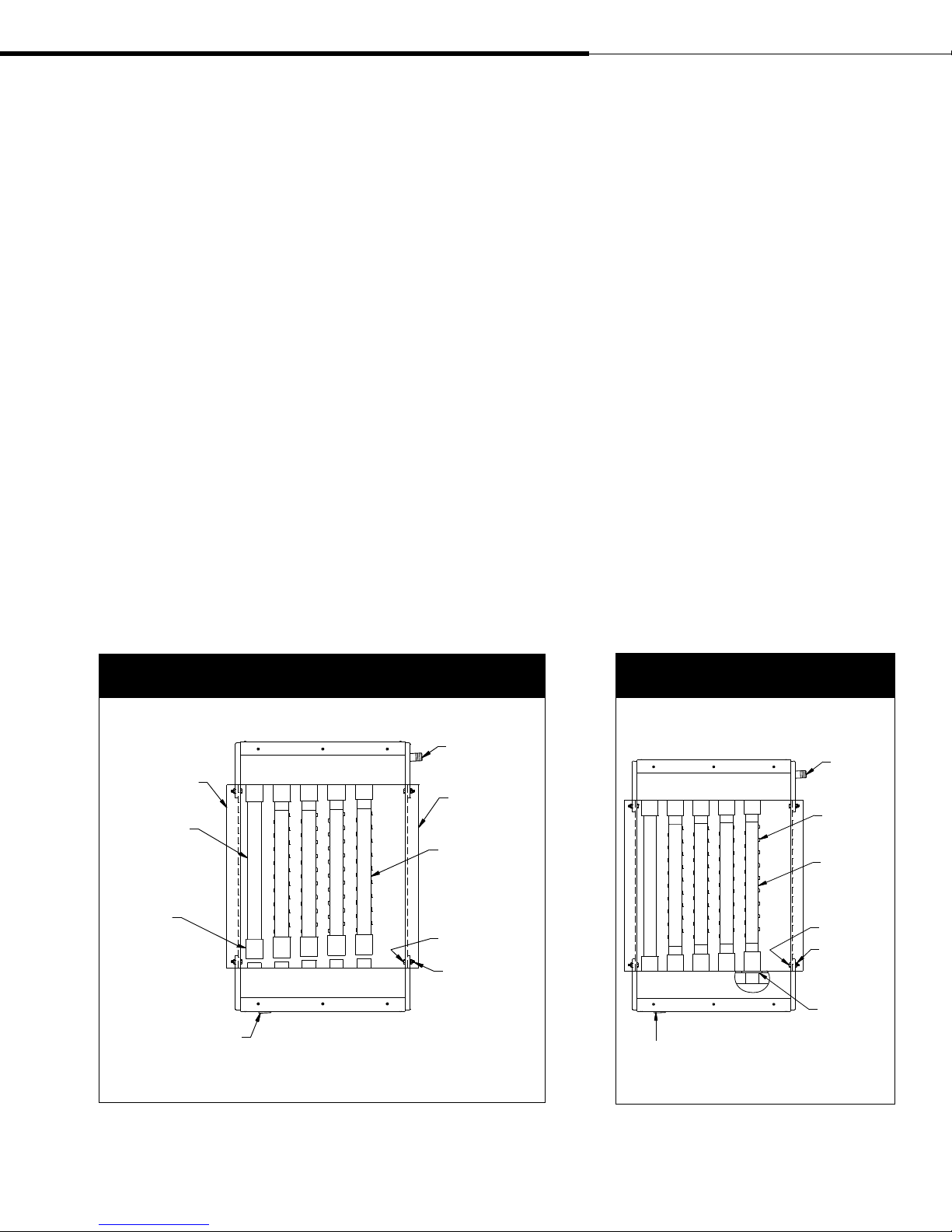

Field assembly of Model LV

Please read instructions while assembling

STEP 1 - Unpack

Unpack the Ultra-sorb components and verify that you have all

items on the packing list.

Lay the components on a flat surface, and position the header

assemblies as shown in Figure 7-1. Orient the condensate header

assembly so the ¾" half coupling drain connection is to your left,

and orient the supply header assembly so the steam inlet (nipple or

tubing) is to your right.

Figure 7-1:

Ultra-sorb Model LV

Slip coupling

with shoulder

Supply header

assembly

Table 7-1:

Ultra-sorb Model LV components

Description Qty.

Supply header assembly with shouldered

slip couplings

Condensate header assembly 1

Mounting flange 2

Dispersion tubes with slip couplings varies

Condensate drain tube 1

¼ - 20 x ¾" bolt 8

¼ - 20 nut 8

¼ lock washer 8

Steam inlet

1

Condensate drain

Mounting flange

¾" pipe thread coupling

(DN 20) drain connection

A

Condensate header

assembly

A

Tubelet

Dispersion tube

Mounting flange

¼" - 20 bolt (8)

Washer (8)

¼" - 20 nut (8)

Slip coupling without shoulder

OM-260-1

DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual • Page 7

Field assembly of Model LV

Figure 8-1:

Supply header assembly

Supply header assembly

¼" - 20 bolt

Washer and nut

Mounting

flange

Figure 8-2:

Detail view of mounting flange

¼" - 20 bolts

Steam

inlet

OM-260-2

STEP 2 - Bolt the mounting flanges to the supply header

assembly

Refer to Figure 8-1 and 8-2. Attach the two mounting flanges

as indicated using ¼" - 20 bolts with the nuts only finger tightened.

STEP 3 - Insert the dispersion tubes

Refer to Figure 8-4. Insert the plain ends (no slip couplings) of

the dispersion tubes into the slip coupling already mounted on the

supply header assembly. The slip couplings are factory lubricated;

if well aligned during insertion, no further lubrication should be

needed. Push and twist the tube in until it bottoms out on the inter

nal shoulder of the slip coupling. See Figure 8-3.

CAUTION! Use care to avoid cutting the internal O-rings of the

slip couplings.

Figure 8-4:

Dispersion tubes

Supply header assembly

Steam

inlet

-

Mounting flange

Figure 8-3:

Detail view of slip coupling

Shoulder

O-rings

Slip coupling

with shoulder

Dispersion

tube

OM-239

Condensate

drain tube

OM-260-3

OM-238-6

Page 8 • DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual

Field assembly of Model LV

STEP 4 - Bolt the mounting flanges to the condensate header

assembly

Refer to Figure 9-1. Push the slip couplings onto the dispersion

tubes flush with the tube ends. Make sure the drain connection is

properly oriented. Attach the mounting flanges using

and leave the nuts finger tight.

STEP 5 - Slide the slip couplings onto the condensate header assembly and orient the tubelets

SUGGESTION: Gripping the drain connection with vise grip pliers

and applying a back and forth rolling motion to the header will

assist in sliding the slip couplings into place.

Refer to Figure 9-2. It may be necessary to push and twist the

slip couplings onto the condensate header. Again care must be

taken to avoid cutting the internal O-rings. Slide the slip couplings

on until they bottom out against the stop disc on the condensate

header. The tubelets must be aimed so that they discharge the

steam perpendicular to the airstream. Rotate the dispersion tubes as

needed.

¼" - 20 bolts,

After tightening the ¼" - 20 bolts at all 4 corners the Ultra-sorb

panel is ready for installation. See page 10.

Figure 9-1:

Condensate header assembly

Supply header assembly

Mounting flange

Condensate drain

Slip coupling

(without shoulder)

flush with end

of dispersion tube

Condensate header assembly Condensate header assembly

Drain connection

Steam inlet

Mounting flange

Dispersion tube

¼" - 20 bolt

Washer and nut

Figure 9-2:

Condensate header assembly

Supply header assembly

Drain connection

Steam

inlet

Tubelet

Dispersion

tube

¼" - 20 bolt (8)

Washer

and nut

Stop disc

DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual • Page 9

OM-260-4 OM-260-5

Loading...

Loading...